Introduction: Navigating the Global Market for auto starter parts

In the fast-evolving landscape of the global automotive industry, sourcing high-quality auto starter parts presents a critical challenge for international B2B buyers. Whether you’re operating in Africa, South America, the Middle East, or Europe, navigating the complexities of supplier selection, product authenticity, and cost-efficiency can be daunting. This comprehensive guide addresses these challenges head-on, offering insights into various types of starter parts, their applications across different vehicle categories, and effective strategies for vetting suppliers.

From premium new starters to reliable remanufactured options, the guide covers a wide array of products tailored to meet diverse market needs, including automotive, commercial, marine, and industrial sectors. Additionally, we delve into essential considerations such as warranty policies, shipping logistics, and return processes, ensuring that buyers are equipped with the necessary knowledge to make informed purchasing decisions.

By empowering international buyers with actionable insights and a thorough understanding of the auto starter parts market, this guide serves as a valuable resource for optimizing procurement strategies. With the right information at their fingertips, businesses can enhance operational efficiency, reduce downtime, and ultimately improve customer satisfaction across their service offerings.

Table Of Contents

- Top 3 Auto Starter Parts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for auto starter parts

- Understanding auto starter parts Types and Variations

- Key Industrial Applications of auto starter parts

- 3 Common User Pain Points for ‘auto starter parts’ & Their Solutions

- Strategic Material Selection Guide for auto starter parts

- In-depth Look: Manufacturing Processes and Quality Assurance for auto starter parts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto starter parts’

- Comprehensive Cost and Pricing Analysis for auto starter parts Sourcing

- Alternatives Analysis: Comparing auto starter parts With Other Solutions

- Essential Technical Properties and Trade Terminology for auto starter parts

- Navigating Market Dynamics and Sourcing Trends in the auto starter parts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of auto starter parts

- Strategic Sourcing Conclusion and Outlook for auto starter parts

- Important Disclaimer & Terms of Use

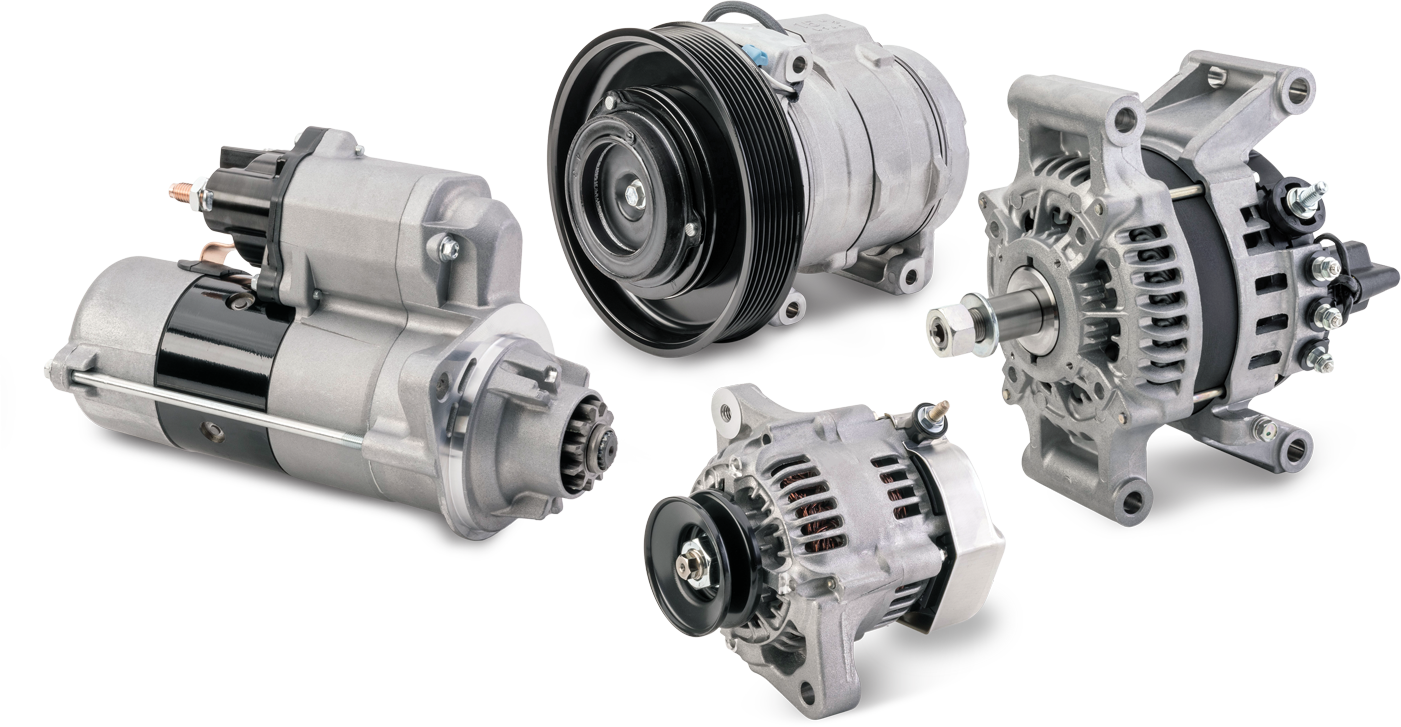

Understanding auto starter parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| New Starters | Brand new components, often with modern technology | OEM replacements, fleet maintenance | Pros: Reliable performance, warranty protection. Cons: Higher upfront cost compared to remanufactured options. |

| Remanufactured Starters | Refurbished to meet OEM specifications, tested for quality | Cost-effective replacements, small garages | Pros: Affordable, eco-friendly. Cons: May not have the same longevity as new starters. |

| Starter Rebuild Kits | Kits with all necessary parts for rebuilding starters | DIY mechanics, workshops | Pros: Customizable, cost-saving for repairs. Cons: Requires technical skills to assemble. |

| Heavy-Duty Starters | Designed for commercial vehicles, increased power output | Heavy-duty trucks, agricultural machinery | Pros: Enhanced durability, higher torque. Cons: Bulkier, potentially more expensive. |

| Marine Starters | Engineered for marine environments, resistant to corrosion | Boats, ships, and marine equipment | Pros: Specialized for harsh conditions. Cons: Limited compatibility with non-marine applications. |

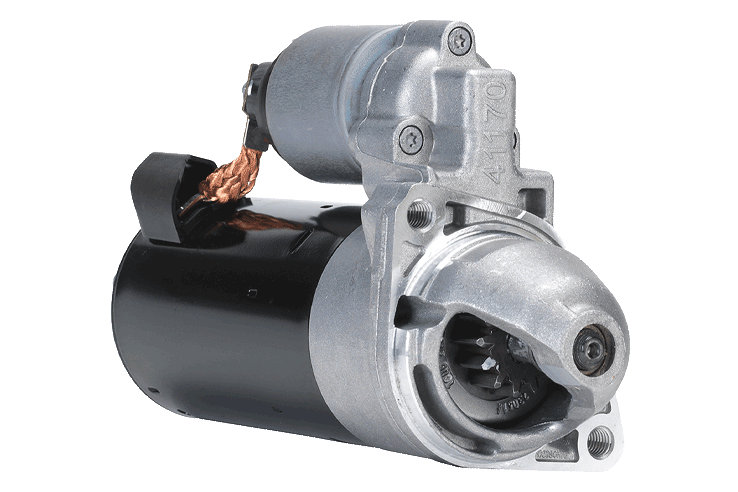

What Are the Characteristics of New Starters?

New starters are manufactured from scratch using the latest technology and materials, ensuring optimal performance and reliability. They are ideal for businesses seeking OEM (Original Equipment Manufacturer) replacements, particularly in fleet maintenance operations where vehicle uptime is critical. Buyers should consider the warranty and service support available, as these can vary by supplier. The initial investment is higher, but the long-term reliability can justify the cost for many businesses.

How Do Remanufactured Starters Compare?

Remanufactured starters are refurbished components that meet or exceed OEM specifications. They undergo rigorous testing to ensure quality and performance, making them a popular choice for small garages and cost-conscious buyers. B2B buyers should weigh the cost savings against potential longevity issues; while they are generally reliable, they may not last as long as new starters. This option is particularly appealing for businesses looking to balance performance with budget constraints.

Illustrative image related to auto starter parts

What Should Buyers Know About Starter Rebuild Kits?

Starter rebuild kits provide all the necessary components to restore a starter to its original functionality. These kits are especially beneficial for DIY mechanics and workshops that prefer hands-on repairs. When purchasing, B2B buyers should assess the complexity of the rebuild process and the technical skills required. While these kits can save money and allow for customization, they may not be suitable for all buyers, especially those lacking mechanical experience.

What Are the Advantages of Heavy-Duty Starters?

Heavy-duty starters are specifically designed for high-demand applications, such as commercial trucks and agricultural machinery. They offer increased torque and durability, making them essential for vehicles that operate under extreme conditions. For B2B buyers, the investment in heavy-duty starters can lead to reduced downtime and lower maintenance costs in the long run. However, these starters can be bulkier and more expensive, necessitating careful consideration of the specific application requirements.

How Are Marine Starters Engineered for Special Conditions?

Marine starters are uniquely designed to withstand the harsh conditions of marine environments, including exposure to saltwater and humidity. They feature corrosion-resistant materials and enhanced sealing to ensure longevity and reliability on boats and ships. B2B buyers in the marine industry should prioritize compatibility with specific engine types and consider the potential for higher costs associated with specialized components. While these starters excel in marine applications, their use outside this context may be limited.

Illustrative image related to auto starter parts

Key Industrial Applications of auto starter parts

| Industry/Sector | Specific Application of auto starter parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Assembly of vehicles and engines | Ensures reliable vehicle performance | Compatibility with various vehicle models and OEM standards |

| Commercial Transportation | Fleet maintenance and repair | Reduces downtime and maintenance costs | Availability of bulk orders and quick shipping options |

| Agriculture | Starting agricultural machinery | Enhances operational efficiency | Durability in harsh environments and compatibility with diverse machinery |

| Marine Industry | Starting marine engines | Ensures reliable operation in marine conditions | Resistance to corrosion and saltwater exposure |

| Heavy Equipment | Starting construction and mining equipment | Increases productivity and minimizes delays | Heavy-duty specifications and compliance with safety standards |

How Are Auto Starter Parts Used in Automotive Manufacturing?

In the automotive manufacturing sector, auto starter parts are integral during the assembly of vehicles and engines. They ensure that the vehicle starts reliably, which is critical for both consumer satisfaction and safety. Manufacturers must source starter parts that meet OEM specifications to guarantee compatibility across various models. For international buyers, particularly in regions like Africa and South America, understanding local vehicle models and sourcing parts that fit these specifications is essential to streamline production and minimize assembly errors.

What Role Do Auto Starter Parts Play in Commercial Transportation?

In commercial transportation, auto starter parts are vital for fleet maintenance and repair. Reliable starters minimize vehicle downtime, which is crucial for logistics and transportation companies that rely on timely deliveries. Buyers in this sector should consider suppliers that offer bulk purchasing options and rapid shipping to ensure they can quickly replace faulty parts. Additionally, warranty options can provide peace of mind, ensuring that investments in starter parts are protected over time.

How Are Auto Starter Parts Utilized in Agriculture?

In agriculture, auto starter parts are used to start various types of machinery, including tractors and harvesters. The efficiency of agricultural operations depends heavily on the reliability of this equipment. Buyers need to prioritize sourcing starter parts that can withstand the rigors of outdoor use, including exposure to dirt and moisture. Additionally, parts should be compatible with a wide range of agricultural machinery to avoid delays in operations, especially during peak seasons.

Illustrative image related to auto starter parts

What Importance Do Auto Starter Parts Have in the Marine Industry?

In the marine industry, auto starter parts are crucial for the reliable starting of marine engines. Given the unique challenges posed by marine environments, such as saltwater corrosion, sourcing high-quality, corrosion-resistant starter parts is essential. International B2B buyers must ensure that the parts are designed to withstand harsh marine conditions, thereby reducing the risk of engine failure at critical moments. Selecting suppliers with expertise in marine applications can enhance operational reliability.

How Are Auto Starter Parts Essential for Heavy Equipment?

Heavy equipment used in construction and mining relies on auto starter parts for efficient operation. These parts are critical for starting large machinery, and any failure can lead to significant downtime, impacting project timelines and costs. Buyers should focus on sourcing heavy-duty starter parts that meet rigorous safety and performance standards. Additionally, understanding the specific requirements of different equipment types will help in selecting the right components, ensuring that operations run smoothly and efficiently.

3 Common User Pain Points for ‘auto starter parts’ & Their Solutions

Scenario 1: Sourcing Quality Auto Starter Parts in a Competitive Market

The Problem:

B2B buyers often struggle with sourcing high-quality auto starter parts, especially in regions where counterfeit products are prevalent. This can lead to significant operational issues, such as delays in repairs, increased downtime, and financial losses. Buyers may find it challenging to identify reputable suppliers who provide genuine parts that meet OEM specifications, making the selection process both critical and daunting.

The Solution:

To ensure quality and reliability, B2B buyers should prioritize suppliers with established reputations and transparent sourcing practices. Conduct thorough research by checking industry certifications, customer testimonials, and warranty offerings. Engage directly with suppliers to inquire about their quality assurance processes and ask for detailed product specifications. Additionally, consider establishing long-term partnerships with suppliers who specialize in auto starter parts for your specific vehicle types. This approach not only guarantees access to premium quality parts but also fosters better communication and support throughout the purchasing process.

Scenario 2: Navigating Compatibility Issues with Auto Starter Parts

The Problem:

One of the most common pain points for buyers is the compatibility of auto starter parts with various vehicle models. Misalignment in specifications can lead to improper installations, increased labor costs, and customer dissatisfaction. Buyers may be overwhelmed by the multitude of options available, making it difficult to determine which parts will fit their specific needs.

The Solution:

Buyers should utilize detailed product catalogs and online databases that offer comprehensive fitment information. Many suppliers provide tools to filter parts based on vehicle make, model, and year, ensuring a precise match. Additionally, investing in training for staff about product specifications and compatibility can help mitigate errors. When in doubt, do not hesitate to reach out to supplier technical support teams. They can assist in verifying compatibility and providing insights into any necessary modifications needed for installation.

Scenario 3: Managing Inventory and Reducing Costs for Auto Starter Parts

The Problem:

Managing inventory levels of auto starter parts can be a logistical nightmare for B2B buyers, especially when dealing with a wide range of products and fluctuating demand. Over-purchasing can tie up valuable capital, while under-purchasing can lead to stockouts and lost sales opportunities. This balancing act is critical, especially in regions where lead times for restocking can be lengthy.

The Solution:

Implementing a just-in-time inventory system can be an effective strategy to manage stock levels and reduce costs. This approach involves closely monitoring sales trends and utilizing data analytics to forecast demand accurately. Collaborating with suppliers to establish flexible order quantities and delivery schedules can also help maintain optimal inventory levels. Additionally, consider using inventory management software that integrates with your sales systems to automate tracking and ordering processes, ensuring you only stock what is necessary without sacrificing service quality.

Strategic Material Selection Guide for auto starter parts

What Are the Key Materials Used in Auto Starter Parts?

When selecting materials for auto starter parts, several factors must be considered, including performance, durability, cost, and regional compliance standards. The following analysis covers four common materials used in the manufacturing of auto starter components: steel, aluminum, copper, and plastic. Each material has unique properties that influence its suitability for specific applications.

How Does Steel Perform in Auto Starter Parts?

Steel is widely used in auto starter parts due to its exceptional strength and durability. It can withstand high temperatures and pressures, making it suitable for components like housings and gears. Steel’s corrosion resistance can be enhanced through coatings or galvanization, which is particularly important in regions with harsh environmental conditions.

Pros: Steel is cost-effective and readily available, making it a popular choice for manufacturers. Its strength ensures long-lasting performance, reducing the need for frequent replacements.

Cons: The weight of steel can be a disadvantage in applications where weight reduction is critical. Additionally, if not properly treated, steel can be susceptible to rust, especially in humid climates.

Impact on Application: Steel is compatible with various automotive fluids and can withstand the mechanical stresses encountered during operation.

Illustrative image related to auto starter parts

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or ISO. The availability of high-quality steel may vary, so sourcing from reputable suppliers is crucial.

What Role Does Aluminum Play in Auto Starter Parts?

Aluminum is increasingly favored for its lightweight properties and excellent corrosion resistance. In auto starter applications, aluminum is often used for housings and brackets, where reducing weight can enhance overall vehicle efficiency.

Pros: The lightweight nature of aluminum contributes to better fuel efficiency in vehicles. Additionally, aluminum’s natural resistance to corrosion makes it suitable for various environmental conditions.

Cons: Aluminum is generally more expensive than steel and can be less durable under extreme mechanical stress. It may also require specialized manufacturing techniques, increasing production complexity.

Impact on Application: Aluminum is compatible with automotive fluids and provides good thermal conductivity, which can help in managing heat dissipation.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of aluminum grades and their compliance with standards like DIN. The cost implications of sourcing aluminum must also be evaluated.

Why Is Copper Essential for Auto Starter Parts?

Copper is primarily used in electrical components of auto starters, such as windings and connectors, due to its excellent electrical conductivity. This property is critical for efficient energy transfer during the starting process.

Pros: Copper’s high conductivity ensures minimal energy loss, leading to better performance and efficiency of starter systems. It is also resistant to corrosion, especially when coated.

Cons: Copper is more expensive than both steel and aluminum, which can impact overall production costs. Additionally, its weight can be a concern in applications where lightweight materials are preferred.

Impact on Application: Copper is ideal for electrical connections and components due to its compatibility with electrical systems and resistance to thermal expansion.

Considerations for International Buyers: Compliance with electrical standards is vital, particularly in regions with stringent regulations. Buyers should also consider the fluctuating market prices of copper.

How Does Plastic Fit into the Auto Starter Parts Landscape?

Plastic materials, particularly high-performance polymers, are used in non-structural components of auto starters, such as insulators and covers. Their lightweight and insulating properties make them suitable for specific applications.

Pros: Plastics are lightweight and can reduce the overall weight of the starter assembly. They also provide excellent insulation, preventing electrical shorts.

Cons: Plastics may not withstand high temperatures as effectively as metals, which can limit their use in certain components. They can also be less durable under mechanical stress.

Impact on Application: Plastics are compatible with various automotive fluids, but their temperature limitations must be considered in high-heat environments.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with international standards for automotive applications, such as those set by JIS in Japan or ASTM in the U.S.

Illustrative image related to auto starter parts

Summary Table of Material Selection for Auto Starter Parts

| Material | Typical Use Case for auto starter parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Housings, gears | High strength and durability | Heavier, rust potential | Low |

| Aluminum | Housings, brackets | Lightweight, corrosion-resistant | More expensive, less durable | Med |

| Copper | Electrical windings, connectors | Excellent conductivity | High cost, heavier | High |

| Plastic | Insulators, covers | Lightweight, good insulation | Limited temperature resistance | Med |

This material selection guide provides valuable insights for B2B buyers in the automotive sector, enabling them to make informed decisions based on performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for auto starter parts

What Are the Key Stages in the Manufacturing Process of Auto Starter Parts?

The manufacturing process of auto starter parts involves several critical stages that ensure the final product meets performance and durability standards. Understanding these stages can help B2B buyers make informed decisions when sourcing these components.

-

Material Preparation

The first step involves selecting high-quality raw materials. Common materials for auto starters include steel, aluminum, and copper. These materials are assessed for their mechanical properties, corrosion resistance, and conductivity. Suppliers often employ advanced techniques like laser cutting and precision machining to prepare these materials for further processing. -

Forming

During the forming stage, the prepared materials undergo various techniques such as stamping, die casting, or forging. Stamping is commonly used for creating the starter housing and components, while die casting is preferred for complex shapes. These processes require specialized molds and tooling, which must be meticulously designed to ensure dimensional accuracy. -

Assembly

The assembly phase is critical, as it involves bringing together the various components such as the motor, solenoid, and gear assembly. This stage often utilizes automated assembly lines for efficiency, but skilled labor is also essential for tasks that require precision. Each assembly line is designed to minimize errors and ensure that components fit together seamlessly. -

Finishing

The finishing stage includes surface treatments like plating, painting, or coating to enhance corrosion resistance and aesthetic appeal. Additionally, components may undergo balancing and alignment procedures to ensure optimal performance. Quality checks during this stage ensure that any imperfections are addressed before the product moves to the next phase.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is paramount in the production of auto starter parts, ensuring that each component meets international standards and customer expectations.

-

International Standards and Certifications

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with regional certifications like CE for the European market or API standards for industrial applications is also critical. These certifications indicate that the manufacturer has met stringent quality and safety requirements. -

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter production.

– In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC ensures that each stage adheres to quality standards. This may involve regular inspections and testing of components.

– Final Quality Control (FQC): The final inspection occurs before products are shipped. This stage includes performance testing, dimensional checks, and verification of compliance with specifications. -

Common Testing Methods

Various testing methods are employed to ensure the reliability of auto starter parts. These may include:

– Electrical Testing: Measures the performance of electrical components under load conditions.

– Torque Testing: Evaluates the efficiency and functionality of the starter motor.

– Vibration Testing: Assesses the durability and stability of components under operational conditions.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure that their suppliers maintain rigorous quality control standards. Here are actionable insights for verifying supplier QC:

-

Supplier Audits

Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and compliance with international standards. This firsthand observation can reveal insights into the supplier’s operational capabilities and quality commitment. -

Requesting Quality Reports

Buyers should request comprehensive quality reports, including results from IQC, IPQC, and FQC stages. These reports should detail any issues identified during production and the corrective actions taken, providing transparency into the supplier’s commitment to quality. -

Third-party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality systems. These independent inspections can validate the supplier’s claims regarding their manufacturing processes and adherence to standards.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers in regions like Africa, South America, the Middle East, and Europe face unique challenges when sourcing auto starter parts. Understanding these nuances can help mitigate risks:

-

Cultural and Regulatory Differences

Each region may have specific regulatory requirements and cultural practices that influence manufacturing processes and quality assurance. Buyers should familiarize themselves with local regulations to ensure compliance and avoid potential delays. -

Language Barriers

Communication can be challenging due to language differences. Buyers should consider working with suppliers who can provide documentation and support in a language they understand, ensuring clear communication regarding quality expectations. -

Logistics and Supply Chain Considerations

Transporting auto starter parts across international borders can introduce risks related to damage and delays. Buyers should verify that suppliers have robust logistics strategies and quality assurance measures in place during shipping to protect the integrity of their products.

Conclusion

Understanding the manufacturing processes and quality assurance measures for auto starter parts is crucial for B2B buyers. By familiarizing themselves with key stages of production, international standards, and quality control strategies, buyers can make informed sourcing decisions. Proactive engagement with suppliers through audits, quality reports, and third-party inspections can further ensure the reliability and performance of the components they procure.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto starter parts’

Introduction

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring auto starter parts. It outlines essential steps to ensure that you select high-quality components and reliable suppliers, ultimately leading to smoother operations and enhanced customer satisfaction.

Illustrative image related to auto starter parts

1. Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Specify the types of starter parts needed, such as new or remanufactured starters, and any particular specifications like voltage ratings, rotation direction, and kW ratings. This clarity will help you communicate effectively with suppliers and ensure you receive the correct products.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers of auto starter parts. Look for companies with a proven track record in the industry, focusing on their experience, customer reviews, and product offerings. Utilize online platforms, trade shows, and industry publications to gather information on suppliers that meet your criteria.

3. Evaluate Supplier Certifications

✅ Verify Supplier Certifications

It is vital to check whether potential suppliers hold relevant certifications such as ISO 9001, which indicates a commitment to quality management. Certifications assure you that the supplier adheres to industry standards and regulations, reducing the risk of receiving subpar products. Additionally, inquire about their warranty policies to protect your investment.

4. Assess Product Quality and Variety

Ensure that the supplier offers a wide range of auto starter parts to meet your specific needs. Request samples or product specifications to evaluate the quality of the components. Look for features such as premium materials, durability, and compatibility with various vehicle models to ensure that you are sourcing reliable parts.

Illustrative image related to auto starter parts

5. Request Pricing and Payment Terms

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, minimum order quantities, and payment terms. Compare these offers to identify the best value while considering total costs, including shipping and duties, especially for international purchases. Transparent pricing structures will aid in budgeting and financial planning.

6. Inquire About Shipping and Delivery Options

✅ Understand Shipping and Logistics

Discuss shipping methods, lead times, and logistics with your potential suppliers. Fast and reliable shipping options are crucial, especially if you operate in regions with limited access to parts. Ensure that the supplier can provide tracking information and has a solid plan for handling any potential delays.

7. Establish Communication Channels

Finally, set up clear communication channels with your selected suppliers. This includes regular updates on order status and responsiveness to inquiries or concerns. A good relationship with your supplier can lead to better service, quicker resolution of issues, and potential discounts on future orders.

By following this comprehensive checklist, B2B buyers can streamline the sourcing process for auto starter parts, ensuring they receive quality components from reliable suppliers while optimizing their procurement strategy.

Comprehensive Cost and Pricing Analysis for auto starter parts Sourcing

What Are the Key Cost Components for Auto Starter Parts?

When sourcing auto starter parts, understanding the cost structure is crucial for international B2B buyers. The main cost components include:

-

Materials: The quality and type of materials used in production significantly impact costs. High-grade metals and plastics that meet industry standards can raise the base price. Sourcing from suppliers who offer premium materials may yield better performance and longevity, justifying higher initial costs.

-

Labor: Labor costs vary by region and manufacturing processes. Automated production lines may reduce labor costs but require higher upfront investments. Conversely, manual labor-intensive methods may be cheaper but less efficient.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Buyers should consider suppliers with optimized operations that can reduce overhead, potentially lowering overall prices.

-

Tooling: Custom tooling can be a significant expense, especially for specialized parts. Buyers should inquire about tooling costs and whether these can be amortized over larger orders to achieve better pricing.

-

Quality Control (QC): Investing in robust QC processes ensures that parts meet specifications and reduces the risk of defects. While this can increase initial costs, it often leads to lower returns and warranty claims, enhancing long-term savings.

-

Logistics: Shipping costs can vary significantly based on distance, shipping method, and Incoterms. Understanding these can help buyers optimize their total expenses.

-

Margin: Supplier margins can vary widely based on their business model and market position. Buyers should assess the value provided against the margin to ensure they receive competitive pricing.

How Do Price Influencers Affect Auto Starter Parts Pricing?

Several factors influence the pricing of auto starter parts:

-

Volume/MOQ: Larger orders typically lead to lower per-unit costs. Suppliers may offer volume discounts, making it essential for buyers to understand minimum order quantities (MOQ) and negotiate accordingly.

-

Specifications/Customization: Custom parts tailored to specific applications can incur additional costs. Buyers should weigh the need for customization against the potential benefits in performance and compatibility.

-

Materials: The choice of materials directly impacts cost. Premium materials may increase upfront costs but can enhance performance and durability, leading to lower total costs over time.

-

Quality/Certifications: Parts that meet specific industry certifications (like ISO or OEM standards) may command higher prices. Buyers should consider the implications of using certified versus non-certified parts in their operations.

-

Supplier Factors: Supplier reputation, reliability, and service levels can affect pricing. Established suppliers may charge a premium but offer better service and quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect the total landed cost. Buyers should negotiate terms that minimize their risk and optimize their shipping costs.

What Are Effective Buyer Tips for Sourcing Auto Starter Parts?

To maximize value when sourcing auto starter parts, consider the following tips:

-

Negotiate Wisely: Leverage your purchasing power and market knowledge during negotiations. Highlight your potential for repeat business to encourage suppliers to offer more competitive pricing.

-

Focus on Cost-Efficiency: Look beyond the initial price. Analyze the total cost of ownership (TCO), including maintenance, warranty claims, and operational performance. Investing in higher-quality parts may reduce overall costs in the long run.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import tariffs, and local regulations that can impact pricing. This is particularly relevant for buyers from Africa, South America, the Middle East, and Europe.

-

Build Long-Term Relationships: Establishing a solid relationship with suppliers can lead to better pricing, exclusive deals, and improved service levels. Regular communication and feedback can foster mutual trust.

Disclaimer on Indicative Prices

Prices for auto starter parts can fluctuate based on market conditions, supplier pricing strategies, and other external factors. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they are getting the best possible deal.

Alternatives Analysis: Comparing auto starter parts With Other Solutions

Exploring Alternatives to Auto Starter Parts for B2B Buyers

When it comes to automotive operations, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the available alternatives to auto starter parts can significantly impact operational efficiency and cost-effectiveness. While auto starter parts are essential for vehicle ignition, several other technologies and methods can either complement or serve as alternatives. This analysis will provide insights into these alternatives, helping B2B buyers make informed decisions.

Illustrative image related to auto starter parts

| Comparison Aspect | Auto Starter Parts | Remanufactured Starters | Electric Start Systems |

|---|---|---|---|

| Performance | High reliability; designed for specific vehicles | Comparable performance; often restored to near-original specs | Excellent; offers immediate ignition without mechanical wear |

| Cost | Moderate to high; depends on brand and specifications | Lower initial cost; potential for higher long-term maintenance | Higher upfront cost; may save on maintenance over time |

| Ease of Implementation | Requires specific fitting and tools for installation | Similar installation requirements; may vary by model | Typically straightforward; often plug-and-play |

| Maintenance | Regular checks and potential replacements needed | May require occasional maintenance; generally reliable | Minimal maintenance; long lifespan if installed correctly |

| Best Use Case | Ideal for traditional combustion engines | Suitable for cost-sensitive applications needing quick replacements | Best for modern vehicles and electric systems needing efficient ignition |

What Are the Advantages and Disadvantages of Remanufactured Starters?

Remanufactured starters are a popular alternative for businesses looking to balance performance and cost. These components are restored to meet original equipment specifications and can provide reliable service at a lower price point compared to new starters. The downside is that while they are generally dependable, their longevity can be influenced by the quality of the remanufacturing process. Businesses must ensure they source these parts from reputable suppliers to avoid potential performance issues.

How Do Electric Start Systems Compare to Traditional Auto Starters?

Electric start systems represent a modern alternative to traditional auto starters. They rely on an electric motor to initiate the engine, offering a seamless ignition experience. The primary advantage is that they eliminate many mechanical failures associated with traditional starters, leading to reduced maintenance costs. However, the initial investment can be higher, and retrofitting older vehicles may present challenges. For new vehicle models, this system enhances efficiency and reliability, making it a wise investment for businesses looking to upgrade.

Making the Right Choice for Your Business Needs

Choosing between auto starter parts and their alternatives depends on various factors, including the specific operational context, budget constraints, and long-term maintenance considerations. B2B buyers should assess the performance requirements of their vehicles and the economic implications of each option. For those operating in harsh environments or with limited access to maintenance, investing in high-quality components or modern technologies may provide better value over time. Conversely, businesses with tighter budgets might find remanufactured parts to be a more viable short-term solution. Ultimately, the best choice will align with the operational demands and financial strategies of the business.

Essential Technical Properties and Trade Terminology for auto starter parts

What Are the Key Technical Properties of Auto Starter Parts?

When sourcing auto starter parts, understanding their technical specifications is crucial for ensuring compatibility and performance. Here are some essential properties to consider:

-

kW Rating

The kilowatt (kW) rating indicates the power output of the starter motor. Typical ratings range from 0.4 kW for smaller engines to over 7 kW for larger, high-performance engines. Selecting the appropriate kW rating is vital for ensuring the starter can handle the engine’s requirements, preventing premature failure and ensuring reliable starting performance. -

Voltage

Most auto starters operate on 12V or 24V systems, with some specialized applications using 6V. Choosing the correct voltage is essential for compatibility with the vehicle’s electrical system. Mismatched voltage can lead to inadequate performance or damage to both the starter and the vehicle’s electrical components. -

Rotation Direction

Starters can rotate clockwise or counterclockwise, depending on the engine design. This specification is crucial for installation, as using a starter with the incorrect rotation can result in improper engagement with the flywheel, leading to potential mechanical failure. -

Pinion Teeth Count

The number of teeth on the starter pinion affects its engagement with the flywheel. Common counts include 9, 10, and 11 teeth. Selecting the right pinion tooth count is critical for ensuring a smooth start and avoiding wear on both the starter and the engine’s flywheel. -

Design Type

Starters may be categorized into designs such as direct drive, gear reduction, and permanent magnet. Each design has unique advantages; for instance, gear reduction starters provide more torque at lower speeds, beneficial for larger engines. Understanding these design types helps in selecting the right starter for specific applications. -

Material Grade

The materials used in starter construction, such as aluminum for housings or high-grade steel for gears, impact durability and performance. High-quality materials can withstand heat and wear better, which is vital in high-demand environments. Buyers should prioritize parts made from reputable materials to enhance longevity and reliability.

What Are Common Trade Terms in the Auto Starter Parts Industry?

Familiarity with industry jargon can significantly enhance communication and decision-making in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM parts are produced by the vehicle manufacturer or a certified supplier. These parts are designed to meet the exact specifications of the original components. B2B buyers often prefer OEM parts for their guaranteed quality and fit, which can lead to better performance and longer service life. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for managing inventory and cash flow. For international buyers, considering MOQs can help in negotiating better pricing and terms, especially when purchasing bulk quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific parts. It typically includes details such as part numbers, quantities, and delivery requirements. Using RFQs helps buyers compare prices and terms effectively, ensuring they receive the best deal for their needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to understand their obligations and rights during the shipping process, helping to avoid disputes and additional costs. -

Lead Time

Lead time is the amount of time between placing an order and receiving the goods. For businesses, understanding lead times is critical for inventory management and planning. Longer lead times can impact production schedules, making it essential for buyers to communicate effectively with suppliers regarding expected delivery dates. -

Core Charge

A core charge is a fee levied by suppliers for the return of a used part, which can be remanufactured. This practice encourages recycling and reduces waste. Buyers should factor in core charges when budgeting for new parts, as they can significantly affect the overall cost of procurement.

These technical properties and trade terminologies are essential for B2B buyers in the auto starter parts industry, enabling informed decision-making and fostering effective supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the auto starter parts Sector

What Are the Key Market Trends Impacting the Auto Starter Parts Sector?

The global auto starter parts market is experiencing significant growth driven by the increasing demand for reliable and efficient vehicle performance across various segments, including automotive, commercial, marine, and industrial applications. As more countries enhance their infrastructure and vehicle ownership rises, particularly in Africa and South America, the demand for quality starter parts is expected to soar. Additionally, the expansion of e-commerce and advancements in B2B technology are reshaping sourcing strategies, enabling international buyers to access a broader range of products with ease. Online platforms facilitate quick comparisons of parts, allowing buyers to make informed purchasing decisions based on specifications, warranties, and customer reviews.

Emerging trends such as the rise of remanufactured parts are gaining traction, particularly among cost-sensitive markets. These products provide a sustainable alternative to new parts while maintaining performance standards. Furthermore, integration of IoT technology in vehicle parts, including starters, is expected to enhance diagnostics and predictive maintenance capabilities, allowing businesses to optimize their inventory and reduce downtime.

Illustrative image related to auto starter parts

How Is Sustainability and Ethical Sourcing Shaping the Auto Starter Parts Market?

The auto starter parts sector is increasingly acknowledging the importance of sustainability and ethical sourcing. The environmental impact of manufacturing processes, coupled with growing consumer awareness, has prompted many businesses to adopt greener practices. Buyers are now more inclined to partner with suppliers that prioritize eco-friendly materials and production methods.

Certifications such as ISO 14001 and adherence to the REACH regulation can significantly enhance a supplier’s credibility. These certifications indicate a commitment to reducing environmental impact and ensuring compliance with health and safety standards. Additionally, sourcing parts made from recycled materials or those that have undergone sustainable manufacturing processes can not only appeal to environmentally conscious buyers but also contribute to a more circular economy.

International B2B buyers, particularly from regions like Europe and the Middle East, are increasingly looking for partners who can provide transparency in their supply chains. Ethical sourcing practices not only align with global sustainability goals but also foster trust and long-term relationships between suppliers and buyers.

How Has the Auto Starter Parts Sector Evolved Over Time?

The auto starter parts sector has evolved significantly since its inception, transitioning from basic mechanical components to sophisticated electronic systems integral to modern vehicles. Initially, starters were simple devices reliant on mechanical cranking; however, advancements in technology have led to the development of high-efficiency electric starters that enhance vehicle performance and reliability.

In recent decades, the market has seen a shift towards remanufactured parts, driven by economic considerations and a growing emphasis on sustainability. This trend not only reduces waste but also offers a cost-effective solution for buyers seeking quality components. Today, the integration of smart technology into starter systems is paving the way for future innovations, allowing for better diagnostics and enhanced vehicle functionality. This evolution underscores the importance of staying informed about technological advancements and market dynamics for B2B buyers in the auto starter parts sector.

Frequently Asked Questions (FAQs) for B2B Buyers of auto starter parts

-

How do I solve issues with poor starter performance?

To address poor starter performance, first check the battery condition and connections, as these are common culprits. Ensure the starter is compatible with your vehicle’s specifications, including voltage and rotation direction. If the starter is remanufactured, verify that it has been tested for quality. Consider using starter rebuild kits that include all necessary components for restoration. If problems persist, consult with a professional technician to diagnose deeper electrical issues. -

What is the best starter part for heavy-duty vehicles?

For heavy-duty vehicles, it’s essential to select starters specifically designed for high-torque applications. Look for products from reputable manufacturers known for durability, such as Bosch or Denso. Ensure that the starter has a suitable kilowatt rating and is built with heavy-duty components like robust solenoids and bushings. Additionally, consider options with extended warranties for added assurance of quality and performance. -

How can I vet a supplier for auto starter parts?

When vetting suppliers, assess their reputation through online reviews and testimonials from other B2B buyers. Verify their certifications and compliance with international standards, such as ISO or TS16949, to ensure quality. Request samples or references from existing clients and evaluate their response times and customer service. It’s also beneficial to inquire about their inventory management practices and after-sales support to gauge reliability. -

What are the common payment terms in international B2B transactions for auto parts?

Common payment terms for international B2B transactions include Letters of Credit (LC), Telegraphic Transfers (T/T), and PayPal for smaller amounts. Some suppliers may offer open account terms after establishing a relationship, allowing for deferred payment. Always clarify payment terms before finalizing the contract to avoid misunderstandings. Consider using escrow services for high-value orders to protect both parties. -

What is the minimum order quantity (MOQ) for auto starter parts?

Minimum order quantities (MOQs) can vary significantly among suppliers, typically ranging from 50 to 500 units for auto starter parts. Factors influencing MOQ include the type of part, supplier capacity, and production costs. Discuss MOQs upfront with potential suppliers to determine feasibility. In some cases, suppliers may offer flexibility for first-time orders or smaller businesses, especially if you are willing to pay a premium. -

How do I ensure the quality of auto starter parts?

To ensure quality, source parts from established manufacturers with a track record in the industry. Look for parts that come with warranties and are tested for performance. Request certifications that confirm compliance with international quality standards. Additionally, consider third-party inspections before shipment, especially for large orders, to validate that the parts meet your specifications and expectations. -

What logistics considerations should I be aware of when importing starter parts?

When importing starter parts, consider shipping methods, lead times, and customs regulations in your country. Choose reliable freight forwarders experienced in handling auto parts to ensure timely delivery. Be aware of import duties and taxes that may apply, and prepare necessary documentation such as invoices and packing lists. Finally, establish clear communication with your supplier regarding shipping schedules and tracking information to avoid delays. -

Can I customize auto starter parts for specific applications?

Yes, many suppliers offer customization options for auto starter parts to meet specific application requirements. This may include variations in size, voltage ratings, or special features like enhanced durability for extreme conditions. When considering customization, discuss your needs with the supplier early in the process to ensure they can accommodate your specifications. Be prepared to provide detailed technical drawings or specifications to facilitate the design and manufacturing process.

Top 3 Auto Starter Parts Manufacturers & Suppliers List

1. Bosch – Starters and Alternators

Domain: boschautoparts.com

Registered: 2004 (21 years)

Introduction: Bosch offers a comprehensive range of starters and alternators designed to meet the needs of various vehicles. Their products are engineered with advanced technology for optimal performance and reliability. Bosch starters are built to provide high torque and quick starts, while their alternators are designed for efficient power generation and durability. Both product lines undergo rigorous testing…

2. MPA – Starters

Domain: motorcarparts.com

Registered: 2000 (25 years)

Introduction: MPA Starters are manufactured for durable cranking performance, providing industry-leading coverage. They are tested with in-house designed computer-controlled testers to ensure reliability and durability. Key features include: Oil-Impregnated Bronze-Sintered Bushings for reduced armature play and maximum performance; Lead Free Brushes for environmental safety and durability; Double-Sealed Bearing…

3. Advance Auto Parts – Starter Motor

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: Starter is an electric motor that rotates the engine to initiate the combustion process. Activated by turning the ignition key or pressing a button, it provides the cranking force needed to start the engine. Starters need replacement when they show signs of wear or fail to turn the engine over. Advance Auto Parts offers affordable starters for all vehicle makes and models from brands like Carquest…

Strategic Sourcing Conclusion and Outlook for auto starter parts

In navigating the competitive landscape of auto starter parts, international B2B buyers must prioritize strategic sourcing to optimize their supply chains. Key takeaways include the importance of selecting suppliers who offer a wide range of premium quality parts, including both OEM and aftermarket options, which can cater to diverse vehicle types across multiple industries, from commercial to marine applications. Buyers should also consider suppliers that provide comprehensive rebuilding services and warranty assurances, ensuring long-term reliability and performance for their fleets.

Moreover, understanding the specifications and compatibility of starter parts is crucial for seamless integration and customer satisfaction. As the market continues to evolve, focusing on suppliers who can offer rapid shipping and robust customer support will be instrumental in maintaining operational efficiency.

Looking ahead, the demand for high-quality auto starter parts is expected to grow, driven by the increasing number of vehicles on the road and the push for sustainable practices in automotive repair. B2B buyers are encouraged to engage with reliable suppliers who can meet these evolving needs and foster long-term partnerships. By embracing strategic sourcing practices today, businesses can position themselves for success in the dynamic automotive parts market of tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to auto starter parts

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.