Introduction: Navigating the Global Market for auto alternator test

In the competitive landscape of automotive parts, understanding how to effectively test auto alternators is crucial for B2B buyers aiming to maintain operational efficiency. A malfunctioning alternator can lead to significant downtime, impacting productivity and customer satisfaction. This guide delves into the intricacies of sourcing reliable auto alternator testing methods and equipment, addressing the challenges faced by businesses in regions such as Africa, South America, the Middle East, and Europe, including Brazil and Saudi Arabia.

Throughout this comprehensive resource, we will explore various types of alternator testing techniques, their applications, and the importance of selecting the right suppliers. We will also provide insights into the cost implications associated with different testing equipment and services, enabling businesses to make informed purchasing decisions.

This guide empowers international B2B buyers by equipping them with the knowledge needed to assess alternator performance effectively, ensuring that they can make strategic choices that enhance their service offerings. By understanding the nuances of auto alternator testing, businesses can not only prevent costly breakdowns but also foster stronger relationships with their clients through reliable automotive solutions.

Table Of Contents

- Top 2 Auto Alternator Test Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for auto alternator test

- Understanding auto alternator test Types and Variations

- Key Industrial Applications of auto alternator test

- 3 Common User Pain Points for ‘auto alternator test’ & Their Solutions

- Strategic Material Selection Guide for auto alternator test

- In-depth Look: Manufacturing Processes and Quality Assurance for auto alternator test

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto alternator test’

- Comprehensive Cost and Pricing Analysis for auto alternator test Sourcing

- Alternatives Analysis: Comparing auto alternator test With Other Solutions

- Essential Technical Properties and Trade Terminology for auto alternator test

- Navigating Market Dynamics and Sourcing Trends in the auto alternator test Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of auto alternator test

- Strategic Sourcing Conclusion and Outlook for auto alternator test

- Important Disclaimer & Terms of Use

Understanding auto alternator test Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Voltage Drop Test | Measures voltage drop across the alternator under load | Automotive repair shops, fleet maintenance | Pros: Quick and effective; Cons: Requires load testing equipment. |

| Load Test | Assesses alternator performance under simulated load | Heavy-duty vehicle servicing, OEM testing | Pros: Accurate assessment; Cons: More complex setup required. |

| Bench Test | Conducted outside of the vehicle for detailed analysis | Alternator remanufacturers, parts suppliers | Pros: Comprehensive results; Cons: Equipment intensive. |

| Visual Inspection | Involves checking physical components for wear | Parts distributors, automotive training | Pros: Low-cost, easy to perform; Cons: Limited diagnostic capability. |

| Oscilloscope Test | Analyzes electrical output waveforms | Advanced diagnostics, high-tech workshops | Pros: Detailed insights into performance; Cons: Requires specialized knowledge and equipment. |

What is the Voltage Drop Test and Its Importance for B2B Buyers?

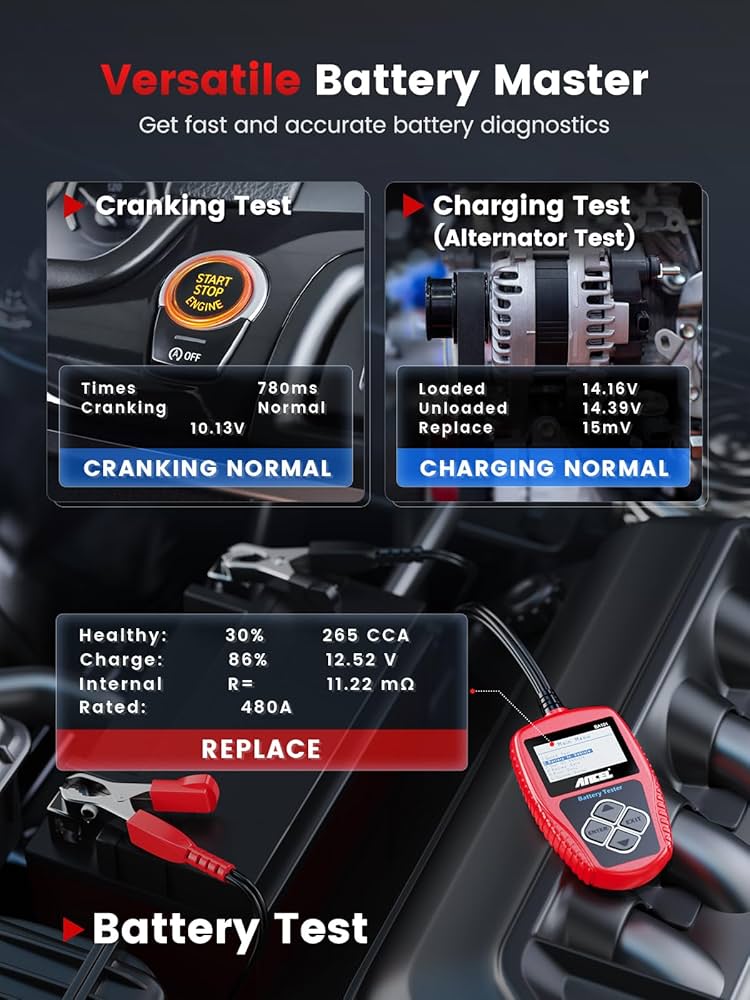

The voltage drop test is a fundamental method to evaluate an alternator’s efficiency by measuring the voltage drop across its terminals while under load. This test is particularly beneficial for automotive repair shops and fleet maintenance services, as it allows for quick diagnostics and immediate feedback on alternator health. Buyers should consider the investment in load testing equipment, as it enhances the accuracy of assessments, ensuring that alternators are functioning optimally before replacement or repair.

How Does the Load Test Benefit Automotive Businesses?

A load test simulates the operational conditions of an alternator, assessing its performance under various electrical loads. This method is crucial for heavy-duty vehicle servicing and original equipment manufacturer (OEM) testing, where reliability is paramount. For B2B buyers, the key consideration is the complexity of the setup, which may require specialized staff and equipment. However, the accuracy of the results justifies the investment, especially in environments where alternator performance directly impacts operational efficiency.

What are the Advantages of Conducting a Bench Test?

The bench test is a thorough examination performed outside the vehicle, allowing for a detailed analysis of an alternator’s capabilities. This method is widely used by alternator remanufacturers and parts suppliers, providing comprehensive insights into performance metrics. B2B buyers should weigh the benefits of acquiring the necessary equipment against the potential for increased service quality. While bench testing is resource-intensive, it ensures that only the highest-quality alternators are supplied to customers.

Why is Visual Inspection Still Relevant for Automotive Parts Distributors?

Visual inspection remains a valuable tool in the diagnostic arsenal, enabling quick checks of physical components for signs of wear or damage. This method is particularly useful for parts distributors and automotive training institutions, where low-cost solutions are prioritized. Although visual inspections have limited diagnostic capabilities compared to more advanced tests, they are an essential first step in identifying potential issues, making them a worthwhile consideration for B2B buyers.

How Can Oscilloscope Testing Enhance Diagnostic Precision?

Oscilloscope testing involves analyzing the electrical output waveforms of an alternator, providing in-depth insights into its performance characteristics. This advanced diagnostic technique is ideal for high-tech workshops and businesses focusing on precision and reliability. B2B buyers interested in this method should consider the required specialized knowledge and equipment investment. While oscilloscope testing can be complex, the detailed performance analysis it offers can significantly enhance service quality and customer satisfaction.

Key Industrial Applications of auto alternator test

| Industry/Sector | Specific Application of auto alternator test | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Routine maintenance checks for vehicle alternators | Prevents unexpected breakdowns, ensuring customer satisfaction | Quality testing equipment, skilled technicians, and reliable parts suppliers |

| Fleet Management | Regular alternator testing for commercial vehicles | Reduces downtime and maintenance costs, improving operational efficiency | Bulk purchasing of testing tools, training for staff, and reliable service agreements |

| Transportation Services | Testing alternators in buses and trucks | Ensures safety and reliability, minimizing service interruptions | Compliance with local regulations, availability of parts, and service support |

| Renewable Energy | Assessing alternators in hybrid and electric vehicles | Optimizes energy efficiency and vehicle performance | Advanced testing technology, compatibility with various vehicle models, and supplier reliability |

| Heavy Machinery | Alternator tests in construction and mining equipment | Enhances equipment uptime and reliability, reducing operational delays | Durable testing equipment, local support services, and availability of spare parts |

How is Auto Alternator Testing Applied in Automotive Repair?

In the automotive repair sector, regular alternator testing is crucial for maintaining vehicle performance. Mechanics use specialized equipment to identify issues before they escalate, ensuring that customers avoid unexpected breakdowns. For international buyers, especially in regions like Africa and South America, sourcing high-quality testing tools and skilled technicians is essential. This proactive approach not only enhances customer satisfaction but also builds loyalty, as reliable service leads to repeat business.

What Role Does Alternator Testing Play in Fleet Management?

For fleet management, conducting routine alternator tests on commercial vehicles is vital. By identifying potential failures early, businesses can reduce downtime and associated maintenance costs. This is particularly important in regions with challenging driving conditions, such as the Middle East, where vehicle reliability is paramount. B2B buyers should focus on bulk purchasing agreements for testing equipment and consider training staff to ensure consistent maintenance standards across their fleet.

How Does Testing Benefit Transportation Services?

Transportation services, including buses and trucks, rely heavily on functional alternators for safety and reliability. Regular testing helps prevent service interruptions that can lead to customer dissatisfaction. In Europe, where regulatory compliance is strict, ensuring that all vehicles are properly maintained is not just a best practice but a legal requirement. Buyers in this sector should prioritize sourcing durable testing equipment and ensure they have access to local service support to address any issues swiftly.

Why is Alternator Testing Important in Renewable Energy Vehicles?

In the renewable energy sector, particularly with hybrid and electric vehicles, alternator testing is essential for optimizing energy efficiency. These vehicles often incorporate advanced electrical systems that require reliable alternators to function effectively. Buyers from Europe and the Middle East should seek suppliers that provide advanced testing technology and ensure compatibility with various vehicle models. This helps maintain vehicle performance and supports sustainability initiatives by maximizing energy usage.

How Does Alternator Testing Enhance Heavy Machinery Operations?

For heavy machinery used in construction and mining, conducting alternator tests is critical to enhance equipment uptime and reliability. These machines often operate in harsh environments where electrical failures can lead to significant operational delays. B2B buyers in this industry should focus on sourcing durable testing equipment capable of withstanding tough conditions, as well as establishing relationships with local service providers for timely support and spare parts availability.

3 Common User Pain Points for ‘auto alternator test’ & Their Solutions

Scenario 1: Difficulty in Diagnosing Alternator Issues

The Problem:

B2B buyers in the automotive repair industry often face the challenge of accurately diagnosing alternator issues in their clients’ vehicles. Many symptoms, such as dimming lights or difficulty starting the engine, could point to multiple electrical problems, not just a faulty alternator. This uncertainty can lead to unnecessary parts replacements, increased labor costs, and dissatisfied customers, ultimately impacting the business’s bottom line.

The Solution:

To effectively diagnose alternator issues, invest in high-quality diagnostic tools, such as digital multimeters and specialized alternator testers. These devices can provide precise voltage readings and help determine if the alternator is functioning correctly. Train your technicians on the step-by-step process of testing the alternator while considering the vehicle’s battery and electrical system as a whole. Regular training sessions and workshops can enhance your team’s troubleshooting skills, ensuring they can accurately identify issues and recommend appropriate solutions. Additionally, maintaining a database of common alternator problems for different vehicle makes and models can streamline diagnosis and repair processes.

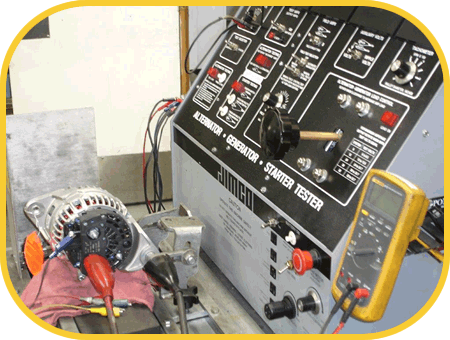

Illustrative image related to auto alternator test

Scenario 2: Inconsistent Testing Procedures Leading to Errors

The Problem:

Inconsistent testing procedures among technicians can lead to erroneous conclusions about an alternator’s health. When different team members use varying methods or tools to test the same vehicle, it can cause discrepancies in the reported performance of the alternator. This inconsistency not only results in potential misdiagnoses but also damages the trust between repair shops and their clients.

The Solution:

Establish a standardized protocol for alternator testing in your workshop. Create a detailed checklist that outlines each step of the testing process, including safety precautions, necessary tools, and expected voltage readings. Provide clear documentation and training to ensure all technicians are on the same page. This uniformity will reduce errors and improve the reliability of testing results. Furthermore, consider implementing a quality control system where test results are double-checked by a senior technician before proceeding with repairs. This practice not only enhances accuracy but also fosters a culture of accountability within the team.

Scenario 3: Limited Access to Quality Testing Equipment

The Problem:

In many regions, particularly in developing markets across Africa and South America, access to high-quality automotive testing equipment can be severely limited. Local repair shops often struggle with outdated tools or insufficient inventory, making it difficult to conduct thorough alternator tests. This limitation can lead to prolonged vehicle downtimes, frustrated customers, and ultimately a loss of business.

The Solution:

To address this issue, consider forming partnerships with reputable suppliers that can provide access to modern testing equipment at competitive prices. Establishing a relationship with a reliable distributor can lead to better pricing, bulk purchasing options, and even equipment leasing opportunities. Additionally, explore options for training programs that can help your team learn how to maximize the use of the tools they have. Investing in portable diagnostic equipment can also be beneficial, as it allows technicians to perform tests in various locations, increasing service efficiency. By ensuring your shop is equipped with reliable tools and knowledge, you can significantly enhance your service offerings and customer satisfaction levels.

Illustrative image related to auto alternator test

Strategic Material Selection Guide for auto alternator test

What Materials Are Commonly Used in Auto Alternator Testing?

In the context of auto alternator testing, selecting the right materials can significantly influence the effectiveness and reliability of the testing process. Here, we analyze three common materials used in this domain: copper, aluminum, and rubber.

How Does Copper Perform in Auto Alternator Testing?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for wiring and components in alternator testing setups. Its key properties include a high melting point (around 1,984°F or 1,085°C) and good corrosion resistance, particularly when coated.

Pros: Copper’s superior conductivity ensures minimal energy loss, enhancing the accuracy of voltage readings during tests. Additionally, it is durable and can withstand the thermal stresses associated with alternator operation.

Cons: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum. Furthermore, it is heavier, which may complicate installation in mobile testing units.

Impact on Application: Copper’s compatibility with various electrical systems is crucial, as it can handle the high currents generated during alternator testing without overheating.

Illustrative image related to auto alternator test

Considerations for International Buyers: Buyers from regions like Africa and South America should consider copper’s compliance with international standards such as ASTM B170 and JIS H 3100. The availability and cost may vary significantly based on local market conditions.

What Role Does Aluminum Play in Auto Alternator Testing?

Aluminum is another common material used in alternator testing, particularly for structural components and casings. It boasts a lower density than copper, making it lightweight and easier to handle.

Pros: Aluminum is cost-effective and offers good corrosion resistance, especially when anodized. Its lightweight nature aids in the portability of testing equipment.

Cons: While aluminum has decent conductivity, it is not as efficient as copper, which may lead to less accurate voltage readings. Additionally, it can be more susceptible to wear and tear under high-stress conditions.

Impact on Application: Aluminum’s lower conductivity may limit its use in high-performance applications but is suitable for basic testing setups.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is essential for ensuring quality. Buyers in the Middle East and Europe may prefer aluminum for its cost-effectiveness, particularly in large-scale operations.

Why Is Rubber Important in Auto Alternator Testing?

Rubber is primarily used for insulation and protective components in testing setups. Its properties include excellent electrical insulation capabilities and resistance to various environmental factors.

Pros: Rubber’s flexibility and durability make it ideal for protecting sensitive components from physical damage. It also provides excellent insulation, preventing short circuits during testing.

Cons: Rubber can degrade over time when exposed to extreme temperatures or chemicals, which may necessitate more frequent replacements.

Impact on Application: Rubber’s insulation properties are critical for ensuring safety during electrical testing, particularly in environments with fluctuating temperatures.

Considerations for International Buyers: Buyers should ensure that the rubber used complies with standards such as ASTM D2000 to guarantee performance. In regions like Brazil and Saudi Arabia, sourcing high-quality rubber can be crucial due to varying climate conditions.

Summary Table of Material Selection for Auto Alternator Testing

| Material | Typical Use Case for auto alternator test | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and electrical connections | Excellent conductivity and durability | High cost and weight | High |

| Aluminum | Structural components and casings | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Rubber | Insulation and protective components | Superior electrical insulation and flexibility | Can degrade under extreme conditions | Low |

In conclusion, selecting the appropriate materials for auto alternator testing is crucial for ensuring accurate results and reliable performance. By understanding the properties, advantages, and limitations of copper, aluminum, and rubber, international B2B buyers can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for auto alternator test

What Are the Main Stages in the Manufacturing Process of Auto Alternators?

The manufacturing process of auto alternators consists of several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets the rigorous performance standards required by the automotive industry.

Material Preparation: How Are Components Sourced and Prepared?

The first stage involves sourcing high-quality materials such as copper, aluminum, and steel, which are essential for the alternator’s performance. Suppliers are typically vetted based on their ability to provide materials that meet specific standards, including conductivity for copper windings and corrosion resistance for housing.

Illustrative image related to auto alternator test

Once materials are sourced, they undergo initial processing, which includes cutting, shaping, and treating to enhance durability. For instance, aluminum components may be anodized to improve corrosion resistance, while copper wires are insulated to prevent short circuits.

Forming: What Techniques Are Used to Shape Alternator Parts?

Forming involves various techniques such as die-casting and stamping to create the alternator’s core components. Die-casting is often used for aluminum housings, allowing for complex shapes with excellent surface finish. Stamping is employed for producing rotor and stator laminations, which are essential for minimizing energy losses.

Advanced technologies, such as CNC machining, may also be utilized to achieve precise dimensions and tolerances. This precision is crucial, as even minor deviations can lead to inefficiencies or failures in the alternator’s operation.

Assembly: How Are Components Integrated for Optimal Performance?

The assembly stage is where all components are brought together. This typically involves multiple sub-assemblies, including the rotor, stator, voltage regulator, and rectifier. Automated assembly lines are commonly used, allowing for high-speed integration while maintaining quality standards.

During assembly, each component is subjected to inspections to ensure proper fit and function. For example, rotor and stator alignment is critical for efficient operation; misalignment can lead to excessive wear or failure.

Finishing: What Processes Ensure a Quality End Product?

Finishing processes include painting, coating, and final inspections. Coatings are applied to protect against corrosion and wear, particularly in harsh environments. A final quality check ensures that all specifications are met before the alternators are packaged for shipment.

How is Quality Assurance Implemented in the Manufacturing of Auto Alternators?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each alternator meets international standards and customer specifications.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that a manufacturer consistently meets customer and regulatory requirements.

Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for automotive components can provide further assurance of quality and safety.

Illustrative image related to auto alternator test

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages, including visual inspections and measurements, helps identify any deviations early in the process.

- Final Quality Control (FQC): A thorough inspection of the finished product before packaging. This includes testing electrical performance and physical integrity, often using automated testing equipment.

What Common Testing Methods Are Utilized for Quality Assurance?

Common testing methods include:

- Electrical Testing: This verifies that the alternator meets voltage and current specifications under various loads, ensuring reliable performance.

- Thermal Imaging: Used to identify hot spots that may indicate potential failures.

- Vibration Testing: Assesses the durability of the alternator under operational conditions, simulating the stresses it will encounter in a vehicle.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers have several options for verifying the quality control practices of their suppliers:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits can provide insights into a manufacturer’s QA processes. Buyers should:

- Request Documentation: Ask for quality manuals, process flow charts, and inspection records to understand the supplier’s quality management system.

- On-Site Audits: If feasible, visiting the manufacturing facility can provide firsthand knowledge of the processes, equipment, and adherence to quality standards.

- Third-Party Inspections: Engaging independent third-party firms to evaluate the supplier’s QC practices can offer an unbiased assessment of their capabilities.

How Do Quality Certification Nuances Affect International Trade?

For international B2B transactions, understanding the nuances of quality certifications is vital. Different regions may have varying compliance requirements, which can affect product acceptance and marketability. For instance, products sold in the EU must adhere to CE marking requirements, while those in the U.S. may need to comply with specific automotive safety standards.

B2B buyers should ensure that their suppliers are not only compliant with local regulations but also with international standards that facilitate smoother cross-border transactions.

Conclusion: The Importance of Robust Manufacturing and Quality Control Processes

In summary, the manufacturing process of auto alternators involves meticulous attention to detail at every stage, from material preparation to finishing. Quality assurance practices, guided by international standards, play a crucial role in ensuring the reliability and performance of alternators. By understanding these processes, B2B buyers can make informed decisions and select suppliers that meet their quality requirements, ultimately leading to more successful partnerships in the automotive industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto alternator test’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure equipment or services related to auto alternator testing. Understanding how to evaluate and select the right products and suppliers is crucial to ensuring the reliability and efficiency of vehicle electrical systems. This checklist will help streamline your procurement process and mitigate risks associated with faulty equipment.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the alternator testing equipment or services you need. This includes voltage ranges, test capabilities (e.g., stress testing), and compatibility with different vehicle models. Having precise specifications ensures you engage with suppliers that can meet your unique operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in auto alternator testing equipment or services. Look for companies with a strong reputation in the industry and a history of serving clients in your region, such as Africa, South America, the Middle East, or Europe. Utilize platforms like industry forums, trade shows, and directories to gather a list of potential partners.

Step 3: Evaluate Supplier Credentials

Before making a decision, verify the credentials of potential suppliers. Check for certifications, quality management systems (e.g., ISO certifications), and industry affiliations. This step is vital to ensuring that the supplier adheres to international quality standards and practices, which can significantly impact the reliability of the equipment.

Step 4: Request Product Demonstrations

Whenever possible, ask suppliers for demonstrations of their auto alternator testing equipment. This allows you to evaluate the functionality, ease of use, and accuracy of the equipment. A hands-on demonstration can also provide insights into the supplier’s customer support and training services, which are essential for effective operation.

Step 5: Review Warranty and Support Services

Examine the warranty terms and after-sales support offered by suppliers. A robust warranty indicates the supplier’s confidence in their product quality, while comprehensive support services can minimize downtime in case of equipment failure. Ensure that the supplier provides accessible technical support and training resources to facilitate the use of the equipment.

Step 6: Compare Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Look for transparency in pricing and consider the total cost of ownership, including maintenance and operational costs. Flexible payment options can also be beneficial for budget management, especially for international transactions.

Step 7: Check References and Customer Feedback

Finally, reach out to previous clients of the suppliers you are considering. Ask for feedback on their experience regarding product performance, customer service, and support. This step can provide valuable insights into the reliability and effectiveness of the supplier, helping you make a more informed decision.

By following this structured checklist, you can ensure a thorough evaluation of your options, leading to a successful procurement process for auto alternator testing equipment or services.

Comprehensive Cost and Pricing Analysis for auto alternator test Sourcing

What Are the Key Cost Components for Auto Alternator Testing?

When sourcing auto alternator testing services, it’s essential to understand the various cost components involved. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The materials used for testing can vary significantly based on the testing method employed. Common materials include voltage meters, digital multimeters, and other diagnostic tools. The quality of these materials can influence overall costs.

-

Labor: Skilled technicians are required to perform accurate alternator tests. Labor costs can fluctuate based on regional wage differences, the complexity of the testing procedure, and the technician’s experience level.

-

Manufacturing Overhead: This encompasses indirect costs associated with running a testing facility, such as utilities, maintenance, and administrative expenses. Efficient overhead management can impact pricing competitiveness.

-

Tooling: Specialized tools and equipment for alternator testing represent an upfront investment for service providers. The amortization of these costs over time can affect pricing structures.

-

Quality Control (QC): Implementing rigorous QC measures ensures the reliability of test results, which can add to the overall cost. However, investing in QC can enhance customer satisfaction and reduce long-term costs associated with errors.

-

Logistics: If the testing service involves transporting vehicles or parts, logistics costs become significant. Efficient logistics can minimize delays and additional charges, impacting overall pricing.

-

Margin: Service providers typically add a profit margin to cover their business risks and reinvest in their operations. This margin can vary based on market competition and service demand.

How Do Price Influencers Affect Auto Alternator Testing Costs?

Several factors can influence the pricing of auto alternator testing services, particularly for international buyers in regions like Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Larger orders often qualify for better pricing due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to reduce per-unit costs.

-

Specifications/Customization: Customized testing services may incur additional costs. Clear communication of specifications can help streamline the testing process and minimize unexpected expenses.

-

Materials: The choice of materials used in testing can impact costs significantly. High-quality, certified materials may be more expensive upfront but can lead to better long-term performance and reliability.

-

Quality/Certifications: Services that adhere to international quality standards often come at a premium. However, these certifications can reassure buyers about the reliability and safety of the testing process.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge higher rates due to their proven track record and customer service, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms applied to the transaction is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

What Buyer Tips Can Help Achieve Cost-Efficiency in Auto Alternator Testing?

International buyers can employ several strategies to ensure cost-efficiency when sourcing auto alternator testing services:

-

Negotiation: Engaging in thorough negotiations can lead to better pricing and terms. Buyers should articulate their needs and compare multiple offers to leverage better deals.

-

Total Cost of Ownership (TCO): Consider not only the initial testing costs but also the long-term implications, such as reliability and maintenance expenses. A lower upfront cost may result in higher TCO if the service quality is subpar.

-

Pricing Nuances: Be aware of regional pricing differences. For example, costs may vary significantly between Europe and South America due to local economic conditions, labor costs, and material availability.

-

Research and Comparison: Conducting thorough research on potential suppliers and comparing their offerings can uncover hidden costs and help identify the best value for money.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming trends or changes in the market.

Disclaimer

The pricing discussed in this analysis is indicative and may vary based on specific circumstances, market conditions, and individual supplier agreements. It is advisable for buyers to conduct detailed inquiries and obtain quotes tailored to their unique needs.

Alternatives Analysis: Comparing auto alternator test With Other Solutions

Exploring Alternatives to Auto Alternator Testing

In the automotive industry, ensuring the reliability of electrical systems is crucial. While the traditional auto alternator test offers a straightforward method for diagnosing alternator performance, various alternative solutions exist that may better suit specific operational needs or contexts. Understanding these alternatives can help B2B buyers make informed decisions that align with their business requirements.

| Comparison Aspect | Auto Alternator Test | Diagnostic Software Tools | Professional Diagnostic Services |

|---|---|---|---|

| Performance | Direct measurement of voltage output | Comprehensive diagnostics with data logs | Extensive diagnostic capabilities |

| Cost | Low-cost DIY method (tools required) | Moderate cost (software and hardware) | Higher cost (service fees) |

| Ease of Implementation | Simple setup and execution | Requires initial setup and training | Requires scheduling and possible delays |

| Maintenance | Minimal maintenance required | Regular updates needed for accuracy | No maintenance; relies on service provider |

| Best Use Case | Quick checks and basic testing | In-depth analysis for complex issues | Complete assessment and repairs |

What Are the Pros and Cons of Using Diagnostic Software Tools?

Diagnostic software tools provide a sophisticated alternative to the auto alternator test. These tools can interface with a vehicle’s onboard computer to gather and analyze data from various systems, including the alternator.

Pros: They offer a comprehensive overview of vehicle health, including error codes and performance metrics, which can help pinpoint issues beyond just alternator performance. This method is particularly useful for fleets or businesses operating multiple vehicles, as it streamlines diagnostics and provides historical data for better maintenance planning.

Cons: The initial investment can be significant, as it often requires purchasing software and hardware. Additionally, the effectiveness of these tools is contingent upon proper training for staff, which can introduce a learning curve.

Illustrative image related to auto alternator test

How Do Professional Diagnostic Services Compare?

Professional diagnostic services represent another alternative, typically offered by automotive repair shops or specialized service providers. These services often include a full inspection of the vehicle’s electrical systems, including the alternator.

Pros: The main advantage is the expertise provided by trained technicians, who can offer insights based on experience. Additionally, these services often include repair options, making it a one-stop solution for diagnosing and fixing issues.

Cons: The cost can be prohibitive for small businesses or individual operators, especially if multiple vehicles require service. Moreover, the need to schedule appointments can lead to downtime, which may not be ideal for businesses relying on vehicle availability.

How Can B2B Buyers Choose the Right Solution?

When considering the right solution for testing alternators and diagnosing electrical issues, B2B buyers should evaluate their specific operational needs. If quick, on-the-go checks are paramount, the auto alternator test may suffice. For businesses with more complex fleets or those requiring detailed diagnostics, investing in diagnostic software tools could yield long-term benefits. Lastly, for those who prefer a hands-off approach, engaging professional diagnostic services may be the most practical choice, despite the higher costs. Ultimately, assessing factors such as budget, vehicle usage, and the complexity of issues faced will guide buyers to the most suitable alternative.

Essential Technical Properties and Trade Terminology for auto alternator test

What Are the Essential Technical Properties of Auto Alternators?

When considering the purchase or testing of auto alternators, several technical properties are critical for ensuring optimal performance and reliability. Understanding these properties can help B2B buyers make informed decisions that align with their operational needs.

1. Output Voltage

The output voltage of an alternator is typically between 13.5 and 14.5 volts when the engine is running. This specification is crucial as it indicates the alternator’s ability to charge the battery while powering the vehicle’s electrical systems. For international buyers, ensuring that alternators meet local voltage standards is essential to avoid compatibility issues.

Illustrative image related to auto alternator test

2. Current Rating (Amperage)

The current rating, measured in amperes (A), reflects the amount of electrical current the alternator can supply. A higher amperage rating is vital for vehicles equipped with numerous electrical components, such as advanced infotainment systems or power accessories. B2B buyers should assess their specific vehicle requirements to ensure the alternator can handle the load effectively.

3. Efficiency Rating

Efficiency indicates how well the alternator converts mechanical energy into electrical energy. A higher efficiency rating means reduced fuel consumption and less strain on the engine, leading to cost savings in the long run. For businesses operating fleets, investing in high-efficiency alternators can yield significant operational benefits.

4. Material Quality

The materials used in manufacturing alternators, such as copper for windings and aluminum for housings, directly affect durability and performance. High-quality materials enhance resistance to wear and thermal stress, which is particularly important in regions with extreme temperatures. Buyers should inquire about material specifications to ensure longevity and reliability.

5. Bearing Type

The type of bearings used in an alternator can impact its performance and lifespan. Ball bearings are common for their low friction and long service life, while bushings may be used in lower-cost models. Understanding bearing types helps buyers gauge maintenance needs and potential longevity, crucial for reducing downtime in operations.

What Common Trade Terminology Should B2B Buyers Know?

Navigating the auto alternator market requires familiarity with specific trade terminology. Understanding these terms can facilitate smoother transactions and better communication with suppliers.

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the same manufacturer that produced the original components for a vehicle. B2B buyers often prefer OEM parts for their guaranteed compatibility and performance, which is critical for maintaining vehicle warranties and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell in a single order. Knowing the MOQ helps buyers plan their purchasing strategies and manage inventory effectively, especially when dealing with international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request price quotes for specific products or services. B2B buyers use RFQs to compare pricing and terms from multiple vendors, ensuring they secure the best deal for their operational needs.

Illustrative image related to auto alternator test

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Understanding these terms is vital for B2B transactions, especially for international buyers, as they define who bears the risk and costs associated with shipping.

5. Lead Time

Lead time refers to the amount of time it takes for a supplier to deliver products after an order is placed. For businesses, understanding lead time is essential for planning operations and ensuring that parts are available when needed, preventing potential disruptions.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their purchasing strategies, ensuring they select the right alternators that meet their specific needs and operational goals.

Navigating Market Dynamics and Sourcing Trends in the auto alternator test Sector

What Are the Key Market Trends Impacting the Auto Alternator Test Sector?

The auto alternator test sector is experiencing significant growth driven by several global factors. Increasing vehicle production, particularly in emerging markets like Brazil and Saudi Arabia, is one of the primary drivers. As automotive technology evolves, vehicles are equipped with more advanced electrical systems, leading to a higher demand for reliable alternator testing solutions. Additionally, the rise of electric and hybrid vehicles necessitates innovative testing methods to ensure alternators meet the specific requirements of these technologies.

Emerging technologies such as IoT (Internet of Things) are reshaping how alternator testing is conducted. B2B buyers are increasingly looking for diagnostic tools that provide real-time data and analytics, improving efficiency in testing processes. Furthermore, the trend toward automation in automotive maintenance is gaining traction. Automated testing systems can reduce labor costs and enhance accuracy, making them attractive to international buyers.

Market dynamics also reflect a growing emphasis on quality and reliability. With increased competition, suppliers must offer high-quality components and testing equipment to maintain their market position. International buyers, particularly from Africa and the Middle East, are increasingly prioritizing suppliers with proven track records in product reliability and customer service, making vendor selection crucial in the procurement process.

How Is Sustainability Influencing Sourcing Trends in the Auto Alternator Test Sector?

Sustainability is becoming a central theme in the auto alternator test sector, as environmental concerns gain prominence among B2B buyers. The automotive industry is under increasing pressure to reduce its carbon footprint, which extends to the sourcing of testing equipment and components. Buyers are now prioritizing suppliers that adopt sustainable practices, such as using eco-friendly materials and reducing waste in their manufacturing processes.

Ethical sourcing has also gained traction, with buyers keen on ensuring that their suppliers maintain fair labor practices and adhere to environmental regulations. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming essential criteria in the supplier selection process. This shift not only aligns with global sustainability goals but also enhances the brand reputation of companies committed to ethical practices.

Moreover, the trend towards circular economy principles is influencing sourcing decisions. B2B buyers are increasingly interested in suppliers that offer repairable or recyclable components, including alternators. By sourcing from manufacturers that prioritize sustainable practices, companies can contribute to a more sustainable automotive ecosystem while also meeting the demands of environmentally conscious consumers.

What Is the Historical Context of the Auto Alternator Test Sector?

The evolution of the auto alternator test sector reflects broader changes in automotive technology and consumer expectations. Initially, testing methods were rudimentary, often relying on manual checks and basic electrical measurements. As vehicles became more complex, particularly with the introduction of electronic fuel injection and advanced infotainment systems in the 1980s and 1990s, the need for more sophisticated testing solutions emerged.

The late 20th century saw the advent of diagnostic tools that could interface with vehicle onboard computers, allowing for comprehensive testing of alternators and other components. This shift not only improved the accuracy of tests but also reduced the time required for diagnostics. Today, with the integration of IoT and automation, the sector is poised for further transformation, focusing on real-time diagnostics and predictive maintenance solutions, catering to the evolving needs of B2B buyers globally.

Illustrative image related to auto alternator test

Frequently Asked Questions (FAQs) for B2B Buyers of auto alternator test

-

How do I solve issues related to alternator performance?

To address alternator performance issues, first, conduct a thorough diagnostic test. Check the voltage output with a multimeter—ideally, it should range between 13.5 to 14.5 volts when the engine is running. Inspect the drive belt for tension and wear, and listen for unusual noises that might indicate bearing failure. If the alternator fails these tests, consider replacing it or seeking professional repair services. Regular maintenance checks can also help prevent unexpected failures, ensuring longevity and reliability. -

What is the best method for testing an alternator in different vehicle types?

The best method for testing an alternator varies slightly depending on the vehicle type, but generally involves using a multimeter to measure voltage output. For most vehicles, start with the engine off to check battery voltage (should be around 12.5 volts) and then with the engine running to check for a voltage increase (13.5 to 14.5 volts). It’s crucial to understand the specific requirements for various makes and models, as some may have unique systems or configurations. Always refer to the vehicle’s service manual for detailed instructions. -

What factors should I consider when sourcing alternator testing services internationally?

When sourcing alternator testing services internationally, consider factors such as the supplier’s reputation, quality of service, and technological capabilities. Ensure they use reliable and calibrated equipment for accurate testing. Look for customer reviews and case studies to gauge their expertise. Additionally, consider their location and shipping logistics to minimize delays. Compliance with international standards and certifications can also enhance trust in their processes. -

How can I vet suppliers for alternator testing services?

To vet suppliers for alternator testing services, start by checking their certifications and industry affiliations. Request references from previous clients and assess their experience with similar projects. Conduct site visits if possible, or arrange virtual tours to evaluate their facilities and equipment. It’s also wise to review their customer support and response times, as this reflects their commitment to service quality. Lastly, consider their flexibility in accommodating your specific needs, such as customization or rapid turnaround times. -

What are the typical payment terms for international transactions in alternator testing?

Typical payment terms for international transactions in alternator testing can vary significantly based on the supplier and the buyer’s relationship. Common terms include a deposit upfront (usually 30-50% of the total cost) with the balance due upon delivery or completion of services. Some suppliers may offer letters of credit or payment through secure platforms to protect both parties. It’s essential to negotiate terms that ensure clarity and security, taking into account currency fluctuations and transaction fees. -

Are there minimum order quantities (MOQ) for alternator testing equipment?

Yes, many suppliers impose minimum order quantities (MOQ) for alternator testing equipment, which can range from a few units to larger bulk orders. The MOQ often depends on the supplier’s production capabilities and inventory levels. When negotiating, consider your testing needs and future requirements to determine an acceptable MOQ. Some suppliers may offer flexibility for first-time buyers or allow for mixed orders to meet MOQ criteria, so it’s worth discussing these options during procurement discussions. -

What quality assurance measures should I expect from alternator testing services?

Quality assurance measures for alternator testing services should include adherence to international standards, routine calibration of testing equipment, and documented testing procedures. Expect comprehensive reporting on testing results, including any discrepancies or issues found. Suppliers should also have a clear process for handling disputes or retesting if necessary. Regular training of staff on the latest testing techniques and safety protocols is also vital to ensure consistent quality and reliability. -

How do logistics impact the sourcing of alternator testing services?

Logistics play a crucial role in sourcing alternator testing services, affecting timelines, costs, and service quality. Consider factors such as shipping methods, customs regulations, and potential delays in transit. A supplier’s location can influence both shipping costs and delivery times, so evaluate options that balance proximity and service quality. It’s also essential to discuss logistics with suppliers to ensure they have efficient processes in place for handling international shipments, including tracking and communication throughout the delivery process.

Top 2 Auto Alternator Test Manufacturers & Suppliers List

1. Instructables – DIY Voltage Measurement Tool

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Materials needed: Rubber hose (about three feet), Voltage meter or digital multimeter, Wheel chocks, Safety glasses.

2. Facebook – Battery Voltage Measurement

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Battery Voltage Measurement, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for auto alternator test

What Are the Key Takeaways for B2B Buyers in the Auto Alternator Market?

In summary, understanding the critical role of alternators in automotive systems is essential for international B2B buyers. A well-functioning alternator not only ensures the reliability of vehicles but also safeguards against unexpected breakdowns that can disrupt business operations. Buyers should prioritize sourcing high-quality alternators and reliable testing services to maintain vehicle efficiency and longevity.

How Does Strategic Sourcing Impact Your Business?

Strategic sourcing is vital for enhancing supply chain resilience, especially in regions like Africa, South America, the Middle East, and Europe. Establishing partnerships with reputable suppliers can lead to better pricing, improved product quality, and access to advanced testing technologies. Additionally, leveraging local expertise can provide insights into regional market dynamics, ensuring that your sourcing strategy aligns with both operational and budgetary goals.

What’s Next for B2B Buyers in the Auto Alternator Sector?

As the automotive landscape evolves, including the rise of electric vehicles and smart technologies, staying informed about innovations in alternator design and functionality will be crucial. B2B buyers are encouraged to engage with suppliers and industry experts to explore emerging trends and secure competitive advantages. Investing in quality alternators and robust testing solutions today will prepare your business for the challenges of tomorrow’s automotive market. Embrace this opportunity to enhance your sourcing strategy and ensure your fleet remains operationally efficient.

Illustrative image related to auto alternator test

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.