Introduction: Navigating the Global Market for how to replace car starter

In the fast-paced world of automotive maintenance, sourcing the right components, such as a car starter, can pose significant challenges for international B2B buyers. A reliable starter is essential for ensuring optimal vehicle performance, and understanding how to effectively replace it is critical for minimizing downtime and maintaining operational efficiency. This comprehensive guide delves into the various types of starters, their applications across different vehicle models, and the importance of selecting quality suppliers.

By covering essential aspects such as the tools required for replacement, step-by-step installation instructions, and tips for supplier vetting, this resource equips buyers with the knowledge to make informed purchasing decisions. Additionally, we’ll explore cost factors, including parts pricing and labor considerations, to help businesses budget accurately.

International buyers from regions like Africa, South America, the Middle East, and Europe, including Brazil and Germany, will find actionable insights tailored to their specific market dynamics. This guide not only demystifies the process of replacing a car starter but also empowers businesses to source high-quality components effectively, ensuring their fleets remain reliable and efficient. By investing in this knowledge, B2B buyers can navigate the complexities of the automotive parts market with confidence and precision.

Table Of Contents

- Top 4 How To Replace Car Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to replace car starter

- Understanding how to replace car starter Types and Variations

- Key Industrial Applications of how to replace car starter

- 3 Common User Pain Points for ‘how to replace car starter’ & Their Solutions

- Strategic Material Selection Guide for how to replace car starter

- In-depth Look: Manufacturing Processes and Quality Assurance for how to replace car starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to replace car starter’

- Comprehensive Cost and Pricing Analysis for how to replace car starter Sourcing

- Alternatives Analysis: Comparing how to replace car starter With Other Solutions

- Essential Technical Properties and Trade Terminology for how to replace car starter

- Navigating Market Dynamics and Sourcing Trends in the how to replace car starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to replace car starter

- Strategic Sourcing Conclusion and Outlook for how to replace car starter

- Important Disclaimer & Terms of Use

Understanding how to replace car starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Starter Replacement | Traditional starter replacement with basic tools | Automotive repair shops, DIY mechanics | Pros: Cost-effective, straightforward process. Cons: Requires basic mechanical skills. |

| High-Performance Starter | Upgraded components for enhanced power and durability | Performance automotive shops, racing teams | Pros: Improved reliability, better cranking power. Cons: Higher cost, may require specialized installation. |

| Remote Starter Installation | Incorporates remote start technology | Dealerships, aftermarket accessory retailers | Pros: Convenience for end-users, added vehicle value. Cons: Complex installation, potential electrical issues. |

| Hybrid Electric Starter Replacement | Specialized for hybrid vehicles | Electric vehicle manufacturers, hybrid repair shops | Pros: Tailored for hybrid systems, energy-efficient. Cons: Limited availability, higher price point. |

| Heavy-Duty Starter Replacement | Designed for larger vehicles and commercial use | Trucking companies, construction vehicle maintenance | Pros: Robust performance, designed for high-demand applications. Cons: Heavier, may require specific tools for installation. |

What Are the Key Characteristics of Standard Starter Replacement?

Standard starter replacement is the most common approach used in automotive repair. It typically involves removing the old starter and installing a new one using basic hand tools. This method is suitable for most passenger vehicles and is widely practiced in repair shops and by DIY mechanics. B2B buyers should consider the availability of the right tools and the skill level of their technicians, as this replacement method requires a foundational understanding of automotive systems.

How Do High-Performance Starters Differ From Standard Options?

High-performance starters are engineered for enhanced durability and greater power output, making them ideal for high-performance vehicles and racing applications. They often feature upgraded materials and designs to withstand extreme conditions. Businesses in the automotive performance sector should consider these starters for customers looking to improve their vehicle’s efficiency and reliability. However, the higher price point and potential need for specialized installation may be a consideration for buyers.

What Are the Benefits of Remote Starter Installation?

Remote starter installations allow users to start their vehicles from a distance, providing convenience, especially in extreme weather conditions. This installation is often sought by dealerships and aftermarket accessory retailers looking to enhance vehicle offerings. B2B buyers should evaluate the complexity of installation and potential electrical issues that may arise, as these systems often involve intricate wiring and components.

How Is Hybrid Electric Starter Replacement Specialized?

Hybrid electric starter replacements are tailored specifically for hybrid vehicles, accommodating their unique electrical systems. This specialization is crucial for electric vehicle manufacturers and hybrid repair shops that require components designed for energy efficiency and reliability. B2B buyers must consider the limited availability of these starters and the higher price point associated with specialized parts.

What Makes Heavy-Duty Starters Essential for Commercial Use?

Heavy-duty starters are designed for larger vehicles and commercial applications, such as trucks and construction machinery. They are built to handle high-demand usage, making them essential for businesses in the trucking and construction industries. While they offer robust performance, buyers should be aware of their weight and potential need for specialized tools during installation, which can impact labor costs.

Key Industrial Applications of how to replace car starter

| Industry/Sector | Specific Application of how to replace car starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Offering starter replacement services | Enhances customer satisfaction and retention | Availability of quality starter parts and tools |

| Fleet Management | Regular maintenance of fleet vehicles | Reduces downtime and repair costs | Sourcing bulk starter components at competitive prices |

| Automotive Parts Retailers | Selling starter replacement kits and tools | Expands product offerings and increases sales | Ensuring a diverse range of starter types for various vehicles |

| Vehicle Rental Companies | Maintaining rental vehicle performance | Ensures reliability and customer trust | Access to reliable suppliers for quick part replacements |

| Export and Import Businesses | Trading starter motors across regions | Taps into diverse markets and increases revenue | Compliance with international shipping regulations and standards |

How Can Automotive Repair Shops Benefit from Starter Replacement Services?

Automotive repair shops can significantly enhance their service offerings by including starter replacement. Given the central role of the starter in vehicle functionality, timely replacement can prevent further mechanical failures and improve customer satisfaction. For international B2B buyers, sourcing high-quality starters and the necessary tools is crucial. They need to consider the warranty and reliability of parts to ensure long-term customer loyalty and minimize the risk of returns.

Illustrative image related to how to replace car starter

Why is Starter Replacement Important for Fleet Management?

In fleet management, regular maintenance, including starter replacement, is vital for operational efficiency. A malfunctioning starter can lead to unexpected vehicle downtime, which directly affects productivity and profitability. B2B buyers in this sector should prioritize sourcing bulk starter components to leverage cost advantages. They must also ensure that these parts meet the specific requirements of the diverse fleet vehicles they manage to maintain performance standards.

How Can Automotive Parts Retailers Increase Sales with Starter Replacement Kits?

Automotive parts retailers can expand their product offerings by selling starter replacement kits and tools. This diversification can attract both DIY enthusiasts and professional mechanics, ultimately increasing sales. For B2B buyers, it is essential to source a wide range of starter types compatible with various vehicle models. Retailers should also consider the demand for starter components in their target markets, especially in regions with diverse automotive needs like Africa and South America.

What Role Does Starter Replacement Play in Vehicle Rental Companies?

For vehicle rental companies, maintaining the performance and reliability of their fleet is paramount. Regular starter replacement ensures that vehicles remain operational and minimizes the chances of breakdowns, thus enhancing customer trust. International B2B buyers in this sector must establish relationships with reliable suppliers to ensure quick access to starter parts, which is critical for minimizing rental downtime and maintaining a competitive edge.

How Can Export and Import Businesses Capitalize on Starter Motors?

Export and import businesses can tap into the global market by trading starter motors across regions. This not only increases revenue but also allows them to cater to diverse automotive markets with varying needs. B2B buyers in this sector should navigate compliance with international shipping regulations and standards to ensure smooth transactions. Establishing strong supplier relationships can also help in sourcing high-demand starter motors efficiently.

3 Common User Pain Points for ‘how to replace car starter’ & Their Solutions

Scenario 1: Sourcing the Right Starter Motor for Diverse Vehicle Models

The Problem: B2B buyers, especially those in regions with a varied vehicle population like Africa and South America, often face the challenge of sourcing starter motors that fit multiple makes and models. This difficulty is compounded by the lack of reliable parts suppliers, leading to extended downtimes and increased operational costs. Buyers may struggle to find parts that meet quality standards while also being compatible with different vehicle types, which can result in significant delays in repairs and customer dissatisfaction.

The Solution: To effectively address this issue, B2B buyers should partner with reputable distributors that specialize in a wide range of automotive parts. Implementing a robust inventory management system can help track which starter motors are in demand and which vehicle models they fit. Additionally, utilizing online platforms that aggregate parts specifications can aid in quickly identifying the right starter motor based on the vehicle’s make, model, and year. Providing staff with training on vehicle identification and parts compatibility can further streamline the sourcing process. By establishing relationships with multiple suppliers, businesses can ensure they have access to a diverse inventory, thus minimizing downtime and enhancing service delivery.

Scenario 2: Navigating Complex Installation Procedures

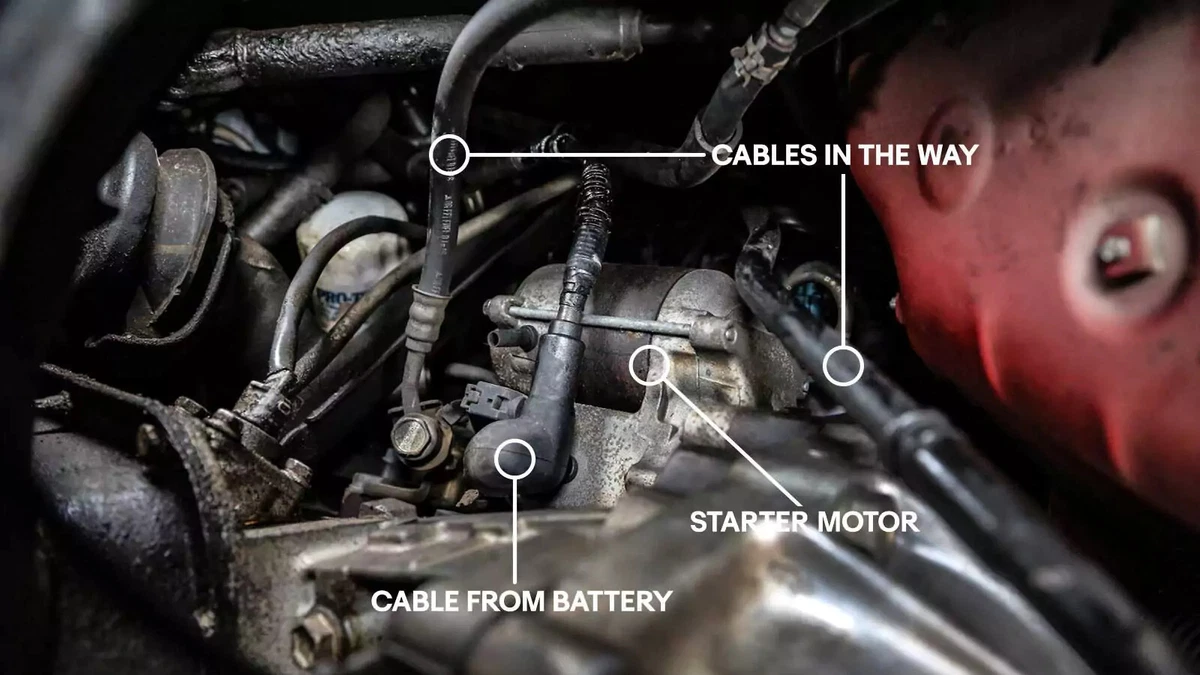

The Problem: Many B2B buyers, particularly those managing fleets or automotive repair shops, encounter difficulties with the complex installation procedures for starter motors. Vehicles today have varying designs and configurations, which can complicate the replacement process. This complexity often leads to longer repair times, increased labor costs, and the risk of improper installation that could damage the new starter or other components.

The Solution: To mitigate these challenges, it is essential for buyers to invest in comprehensive training programs for their technicians focused on starter motor installation. This training should include hands-on workshops, access to service manuals, and online resources that outline step-by-step installation processes specific to various vehicle models. Additionally, having access to diagnostic tools can help technicians identify issues quickly, ensuring that the installation is done efficiently. Encouraging a culture of continuous learning and improvement among staff can lead to better installation practices, thereby reducing labor costs and enhancing overall service quality.

Scenario 3: Ensuring Quality and Reliability of Replacement Parts

The Problem: The market is flooded with aftermarket starter motors, and B2B buyers often struggle to ensure the quality and reliability of these parts. Low-quality replacements can lead to frequent failures, increasing the total cost of ownership and eroding customer trust. This concern is especially prevalent in regions where counterfeit parts are common, posing a significant risk to businesses that rely on vehicle performance and safety.

The Solution: To combat this issue, B2B buyers should develop a stringent vetting process for their suppliers, ensuring that they only source starter motors from manufacturers with a proven track record of quality. Implementing a quality assurance program that includes regular audits and feedback from technicians can help maintain high standards. Additionally, buyers should consider establishing partnerships with reputable brands that offer warranties and guarantees on their products. Educating customers about the importance of using high-quality parts can also help them make informed purchasing decisions, ultimately leading to improved satisfaction and loyalty. By prioritizing quality over cost, businesses can significantly reduce the likelihood of returns and enhance their reputation in the marketplace.

Illustrative image related to how to replace car starter

Strategic Material Selection Guide for how to replace car starter

What Are the Key Materials for Replacing a Car Starter?

When considering the replacement of a car starter, the selection of materials is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials used in starter motors and their components, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Steel in Starter Motors?

Steel is one of the most widely used materials in automotive applications, including starter motors. Its key properties include high tensile strength and durability, which are essential for withstanding the mechanical stresses during engine cranking. Steel also offers moderate resistance to corrosion, especially when treated with protective coatings.

Pros: Steel is generally cost-effective and widely available, making it an attractive option for manufacturers. Its strength ensures reliable performance, while its machining properties allow for complex designs.

Cons: While it has decent corrosion resistance, untreated steel can rust over time, especially in humid environments. Additionally, steel components can be heavier than alternatives, which may affect overall vehicle weight.

Illustrative image related to how to replace car starter

Impact on Application: Steel is suitable for components that require high strength and durability, such as the starter housing and mounting brackets. However, care must be taken to ensure proper corrosion protection, particularly in regions with high moisture levels.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local corrosion resistance standards. In Europe, adherence to DIN standards is essential for quality assurance.

How Does Aluminum Compare for Starter Components?

Aluminum is another popular choice for starter motors due to its lightweight and excellent corrosion resistance. It is often used for housings and other components where weight savings are critical.

Pros: The lightweight nature of aluminum can enhance fuel efficiency by reducing overall vehicle weight. Its natural corrosion resistance makes it suitable for various environmental conditions.

Cons: Aluminum is generally more expensive than steel and may require specialized manufacturing techniques, which can increase production costs. It also has lower tensile strength compared to steel, making it less suitable for high-stress applications.

Impact on Application: Aluminum is ideal for components that benefit from reduced weight, such as the starter motor casing. However, it may not be the best choice for high-load components due to its lower strength.

Considerations for International Buyers: Buyers must consider local manufacturing capabilities and costs, as aluminum fabrication can be more complex. Compliance with international standards such as ASTM for aluminum alloys is also essential.

What Role Does Copper Play in Electrical Connections?

Copper is a critical material for electrical connections within starter motors due to its excellent conductivity. It is commonly used for wiring and terminals.

Pros: Copper offers superior electrical conductivity, ensuring efficient power transfer from the battery to the starter motor. Its malleability allows for easy shaping and installation.

Cons: Copper is prone to corrosion, especially in harsh environments, which can lead to electrical failures. Additionally, it is more expensive than alternatives like aluminum.

Illustrative image related to how to replace car starter

Impact on Application: Copper is essential for reliable electrical connections, but protective coatings or treatments may be necessary to prevent corrosion in humid or saline environments.

Considerations for International Buyers: Buyers should ensure compliance with electrical standards relevant to their regions, such as IEC or NEMA standards. In regions with high humidity, additional corrosion protection measures may be necessary.

How Does Plastic Contribute to Starter Motor Components?

Plastic materials, particularly high-performance polymers, are increasingly used in starter motors for insulation and housing components.

Pros: Plastics are lightweight and resistant to corrosion, making them suitable for various applications. They can also be molded into complex shapes, providing design flexibility.

Cons: Plastics generally have lower mechanical strength compared to metals and may not withstand high temperatures. They can also degrade over time when exposed to certain chemicals or UV light.

Illustrative image related to how to replace car starter

Impact on Application: Plastic is suitable for non-load-bearing components, such as insulation for electrical connections. However, care must be taken to select high-temperature and chemical-resistant varieties.

Considerations for International Buyers: Buyers should verify that the plastics used comply with local automotive standards, such as those set by ISO. In regions with extreme temperatures, selecting appropriate materials is vital.

Summary of Material Selection for Replacing a Car Starter

| Material | Typical Use Case for how to replace car starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Starter housing, mounting brackets | High strength and durability | Susceptible to rust without treatment | Low |

| Aluminum | Starter motor casing | Lightweight and corrosion-resistant | Higher cost and lower strength | Med |

| Copper | Electrical connections | Excellent conductivity | Prone to corrosion | High |

| Plastic | Insulation and non-load-bearing components | Lightweight and design flexibility | Lower mechanical strength | Low |

This analysis provides valuable insights for B2B buyers looking to source materials for starter motor replacements, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how to replace car starter

What Are the Key Stages in the Manufacturing Process of Car Starters?

Manufacturing car starters involves a series of well-coordinated stages that ensure the production of high-quality, reliable components. Here’s a breakdown of the main stages:

1. Material Preparation

The manufacturing process begins with the careful selection of raw materials, which typically include high-grade steel for the casing, copper for the windings, and various plastics for insulation and housing. These materials are sourced from reputable suppliers who adhere to international standards. Upon arrival at the manufacturing facility, materials undergo inspection to ensure they meet specified quality benchmarks. This step is crucial for minimizing defects in the final product.

2. Forming

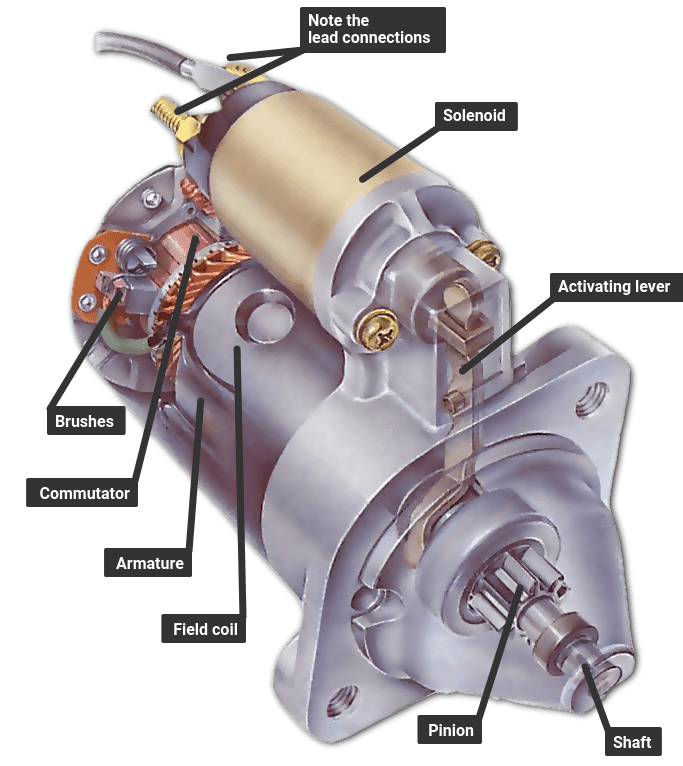

In this stage, raw materials are transformed into usable components. Techniques such as stamping, casting, and machining are employed to create parts like the housing, armature, and pinion gear. For instance, stamping is often used for the metal casing, while precision machining is crucial for components that require exact dimensions, such as the shaft and gear assembly. This stage may also involve heat treatment to enhance the durability of metal parts.

3. Assembly

After forming, components are assembled into a complete starter motor. This process is often semi-automated, combining robotic assembly with manual labor to ensure precision. Workers are trained to follow strict assembly protocols, including torque specifications and alignment checks, to guarantee that each starter meets performance standards. This stage typically includes the installation of the solenoid, which is vital for engaging the starter.

4. Finishing

The final stage involves surface treatments and coatings to protect the starter from corrosion and wear. This might include painting, plating, or applying protective seals. Finishing processes are essential not only for aesthetic purposes but also for enhancing the longevity of the starter under various environmental conditions. Quality assurance checks are performed at this stage to ensure that the finished product meets all design specifications.

Illustrative image related to how to replace car starter

What Quality Assurance Measures Are Essential for Car Starter Production?

Quality assurance (QA) is integral to manufacturing car starters, ensuring they are safe, reliable, and efficient. Here are key aspects of QA:

International Standards and Certifications

Compliance with international standards such as ISO 9001 is essential for manufacturers targeting the global market. ISO 9001 outlines criteria for a quality management system, emphasizing consistent quality, customer satisfaction, and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application of the starter.

What Are the Key Quality Checkpoints in the Manufacturing Process?

Manufacturers implement several checkpoints throughout the production process to maintain quality:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. The focus is on verifying that materials meet predefined quality criteria.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify defects early. Techniques such as statistical process control (SPC) are often employed to track process performance.

-

Final Quality Control (FQC): Once assembly is complete, each starter undergoes rigorous testing. This includes electrical tests, mechanical performance assessments, and environmental simulations to ensure reliability under various conditions.

What Common Testing Methods Are Used in Starter Motor Quality Assurance?

Effective testing methods are vital for verifying the functionality and durability of car starters:

-

Electrical Testing: This involves checking the starter’s voltage, current draw, and resistance to ensure it operates efficiently. Testing for short circuits and grounding issues is also critical.

-

Durability Testing: Starters are subjected to simulated wear-and-tear tests to evaluate their performance over time. This may include cyclic testing to replicate the stresses experienced during normal vehicle operation.

-

Environmental Testing: To ensure starters perform under different climatic conditions, manufacturers may subject them to temperature extremes, humidity, and corrosion tests.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are several actionable strategies:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance measures. Buyers should look for evidence of compliance with international standards and certifications. An audit checklist should include aspects like material sourcing, production methods, and adherence to QA protocols.

Illustrative image related to how to replace car starter

Reviewing Quality Reports

Suppliers should provide detailed quality reports that outline their quality control processes, testing results, and any corrective actions taken in response to defects. These reports can serve as a valuable resource for evaluating supplier reliability.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can enhance trust in the quality of products. These independent entities can conduct thorough inspections and testing before shipment, ensuring that the products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances that can differ by region:

-

Regulatory Compliance: Different regions may have unique regulatory requirements. For instance, European buyers need to ensure products comply with CE marking regulations, while buyers in the Middle East might require adherence to local standards.

-

Cultural Considerations: Understanding cultural attitudes towards quality can influence supplier relationships. In some regions, there may be a greater emphasis on personal relationships, while in others, contractual obligations may take precedence.

-

Communication Barriers: Language differences can pose challenges in quality assurance communication. B2B buyers should ensure that they have clear, effective lines of communication with suppliers to avoid misunderstandings related to quality expectations.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing car starters, ensuring they choose reliable suppliers that meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to replace car starter’

In the realm of automotive maintenance, replacing a car starter is a crucial procedure that can significantly impact vehicle functionality. This guide provides a comprehensive checklist for B2B buyers looking to procure the necessary components and services for a starter replacement, ensuring efficiency and reliability in their operations.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the specifications required for the starter. This includes understanding the make and model of the vehicle, as well as any specific performance criteria such as torque and power ratings. Knowing these details ensures that you source the correct starter that meets your operational needs.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify reliable suppliers that specialize in automotive parts. Look for suppliers with a proven track record in your region, as local suppliers may have better access to parts and faster shipping options. Check their online reviews and ratings to gauge customer satisfaction and reliability.

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers have the necessary certifications and quality standards in place. This is vital for maintaining the integrity of your procurement process. Look for certifications such as ISO 9001 or equivalent, which indicate a commitment to quality management systems.

Step 4: Request Sample Products

Before making a large purchase, request samples of the starter motors to assess their quality and compatibility. Evaluate the construction materials and performance specifications to ensure they align with your requirements. This step can save you from costly mistakes and ensure the longevity of your investments.

Illustrative image related to how to replace car starter

Step 5: Review Warranty and Return Policies

Examine the warranty and return policies offered by suppliers. A robust warranty can provide peace of mind, as it protects your investment in case of defects or premature failure. Additionally, understanding the return policy will help you navigate any issues that may arise post-purchase.

Step 6: Assess Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. Look beyond the initial cost; consider the total cost of ownership, including shipping, taxes, and potential customs fees. Flexible payment terms can also facilitate better cash flow management for your business.

Step 7: Establish Communication Channels

Establish clear communication channels with your chosen supplier to facilitate ongoing support and service. Ensure that they have a responsive customer service team that can assist with any inquiries or issues that may arise during the installation process. Effective communication can significantly enhance your overall procurement experience.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing components for car starter replacement, ensuring that they procure the right parts and services to keep their vehicles operational and efficient.

Comprehensive Cost and Pricing Analysis for how to replace car starter Sourcing

What are the Key Cost Components in Replacing a Car Starter?

When evaluating the costs associated with replacing a car starter, several key components must be considered. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of the starter motor itself typically ranges from $100 to $400, depending on the make, model, and quality. Higher-end models may incorporate advanced features or materials, which can increase costs.

-

Labor: Labor costs for professional installation can vary widely, generally falling between $100 to $200 per hour. The time required for installation can range from one hour to several hours, depending on the vehicle’s design and accessibility of the starter.

-

Manufacturing Overhead: This encompasses costs related to the production environment, utilities, and administrative expenses incurred during the manufacturing process. These costs are often factored into the overall pricing of the starter motor.

-

Tooling: Specialized tools may be required for installation, which can add to the total cost if the buyer does not already possess them. Tooling costs can be significant for businesses that handle multiple vehicle types.

-

Quality Control (QC): Ensuring that each starter motor meets quality standards is crucial. QC processes can add to manufacturing costs but are necessary to maintain reliability and customer satisfaction.

-

Logistics: Shipping and handling costs can vary based on the distance and method of transportation. International shipping often incurs additional fees, which can impact the overall cost for buyers in different regions.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can fluctuate based on competition, demand, and supplier reputation.

How Do Price Influencers Affect the Cost of Replacing a Car Starter?

Several factors influence the pricing of car starters, especially in international markets:

-

Volume/MOQ: Bulk purchasing can lead to significant cost savings. Suppliers often provide discounts for larger orders, which is advantageous for businesses looking to stock inventory.

-

Specifications/Customization: Custom-built starters designed for specific vehicle models may come with higher prices due to specialized manufacturing processes and materials.

-

Materials: The quality of materials used in the starter motor can greatly affect pricing. For instance, starters made from higher-grade materials will typically cost more but may offer better durability and performance.

-

Quality/Certifications: Products that meet specific quality certifications (such as ISO) may command higher prices due to their reliability and performance guarantees.

-

Supplier Factors: The reputation, location, and reliability of the supplier can influence pricing. Established suppliers may charge more for their products due to brand trust and product assurance.

-

Incoterms: The terms of international shipping (Incoterms) can affect the final price. Different terms dictate who is responsible for shipping costs, insurance, and risk, thereby influencing the overall cost structure.

What Are the Best Buyer Tips for Cost-Efficiency in Car Starter Replacement?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, implementing effective purchasing strategies can lead to significant cost savings:

Illustrative image related to how to replace car starter

-

Negotiation: Always negotiate prices with suppliers. Many are willing to offer discounts for bulk purchases or long-term contracts.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the upfront cost. Consider factors such as longevity, warranty, and potential maintenance costs to determine the best overall value.

-

Pricing Nuances: Be aware of regional pricing variations. Import tariffs, taxes, and shipping costs can affect the final price, so it’s crucial to understand these factors before making a purchase.

-

Supplier Relationships: Build strong relationships with reliable suppliers. This can lead to better pricing, priority service, and access to exclusive products.

-

Market Research: Conduct thorough market research to understand pricing trends and competitor offerings. This knowledge can empower buyers to make informed decisions and negotiate effectively.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and can vary based on multiple factors, including market conditions, geographical location, and specific vehicle requirements. Always consult with suppliers for precise quotations tailored to your needs.

Alternatives Analysis: Comparing how to replace car starter With Other Solutions

Exploring Alternatives to Replacing a Car Starter: A Comparative Analysis

In the automotive industry, the need for effective solutions to ensure vehicle functionality is paramount. When a car starter fails, the immediate solution is often to replace it. However, there are alternative methods and technologies that can achieve similar results, potentially offering cost savings or ease of implementation. This analysis compares the traditional method of replacing a car starter with two viable alternatives: using a starter repair kit and employing a jump-start solution.

| Comparison Aspect | How To Replace Car Starter | Starter Repair Kit | Jump-Start Solution |

|---|---|---|---|

| Performance | Restores full functionality | May restore partial functionality | Provides temporary power |

| Cost | $100 – $400 for parts + labor | $50 – $150 for the kit | Minimal cost (battery or jump starter) |

| Ease of Implementation | Requires mechanical skills and tools | Simple for DIY enthusiasts | Very easy; no tools needed |

| Maintenance | Low; depends on starter quality | Moderate; requires skill for installation | Low; involves battery maintenance |

| Best Use Case | Long-term solution for consistent performance | Economical for minor issues | Quick fix for immediate needs |

What Are the Pros and Cons of Using a Starter Repair Kit?

A starter repair kit can be an attractive option for those looking to avoid the full replacement of a starter motor. These kits typically include components necessary to fix minor issues, such as brushes, solenoids, or other small electrical parts. The primary advantage is the cost savings, as repair kits are significantly cheaper than a new starter. However, the effectiveness of a repair kit largely depends on the specific issue at hand. If the starter has severe wear or damage, a repair may not restore full functionality, leading to future problems and potentially higher costs down the line.

How Does a Jump-Start Solution Compare?

A jump-start solution is often the quickest way to get a vehicle running again. This method involves using jumper cables to connect a working battery to the dead one, providing immediate power to start the engine. The primary advantage is convenience and low cost, as it requires minimal investment beyond having access to another vehicle or a portable jump starter. However, this solution is temporary and does not address the underlying issue of a failing starter. If the starter is indeed faulty, relying solely on jump-starts can lead to repeated breakdowns, which can be inconvenient and costly in the long term.

How to Choose the Right Solution for Your Needs

When selecting the appropriate solution for replacing a car starter, B2B buyers must evaluate their specific requirements. If immediate functionality is critical and the vehicle is used for business operations, replacing the starter may be the best option for reliability. On the other hand, if the issue appears to be minor and budget constraints exist, a repair kit could suffice. For situations where downtime must be minimized and immediate access to a vehicle is essential, a jump-start solution may be the quickest fix. Ultimately, understanding the unique context of each vehicle and its operational demands will guide buyers in making the most informed decision.

Essential Technical Properties and Trade Terminology for how to replace car starter

What Are the Key Technical Properties for Replacing a Car Starter?

When considering the replacement of a car starter, several technical properties are vital to ensure compatibility and performance. Understanding these properties helps B2B buyers make informed purchasing decisions, especially when dealing with international suppliers.

1. Material Grade

The material grade of a starter motor typically includes metals like aluminum for the housing and copper for the windings. These materials are selected for their strength-to-weight ratio and conductivity. High-quality materials reduce the risk of overheating and extend the lifespan of the starter. B2B buyers should prioritize suppliers who provide detailed material specifications to ensure durability.

2. Torque Specifications

Torque specifications indicate the amount of rotational force required to secure the starter motor in place. These specs vary by vehicle make and model. Proper torque is crucial to prevent damage to the starter or the engine block. Buyers should consult vehicle manuals and ensure that the starters they purchase meet these torque requirements.

3. Power Rating

The power rating of a starter motor, usually measured in horsepower (HP), indicates its capability to turn the engine over. Most starters range from 1.5 to 3 HP, which is critical for overcoming the engine’s inertia. Selecting a starter with an appropriate power rating ensures reliable engine starts, particularly in regions with extreme temperatures.

4. Voltage Compatibility

Most automotive starters operate on a 12-volt system. However, buyers must ensure that the starter’s voltage matches the vehicle’s electrical system to prevent damage or malfunction. Understanding voltage compatibility is essential for B2B transactions, especially when sourcing components from various countries with different vehicle standards.

5. Connection Type

The type of electrical connections (e.g., terminal posts, plugs) is crucial for ensuring compatibility with existing wiring. Different vehicles may use varying connection styles, which can affect installation efficiency. B2B buyers should verify that the starter they are sourcing has the correct connection type for their specific applications.

What Are Common Trade Terms in Starter Replacement?

Familiarity with industry terminology is essential for effective communication between B2B buyers and suppliers. Here are several common terms relevant to the starter replacement market:

Illustrative image related to how to replace car starter

1. OEM (Original Equipment Manufacturer)

OEM parts are made by the same manufacturer that produced the original part for the vehicle. They ensure perfect fit and function but may come at a higher cost. Buyers often prefer OEM parts for reliability and warranty benefits.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to manage inventory and cash flow effectively. Negotiating lower MOQs can be beneficial, especially for smaller businesses or those testing new products.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It typically includes detailed specifications, quantities, and delivery timelines. Utilizing RFQs helps buyers compare prices and terms from multiple suppliers efficiently.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. B2B buyers should understand Incoterms to mitigate risks associated with international shipping and to negotiate favorable terms.

5. Aftermarket Parts

Aftermarket parts are made by companies other than the original manufacturer. They can offer cost savings and alternative options, but quality can vary significantly. B2B buyers should conduct thorough research on aftermarket suppliers to ensure they are sourcing reliable products.

Illustrative image related to how to replace car starter

Conclusion

Understanding the essential technical properties and trade terminology related to starter replacement is crucial for B2B buyers. By focusing on quality specifications and familiarizing themselves with industry terms, buyers can enhance their purchasing strategies and build stronger relationships with suppliers, ensuring successful transactions and optimal vehicle performance.

Navigating Market Dynamics and Sourcing Trends in the how to replace car starter Sector

What Are the Current Market Dynamics and Key Trends in the Car Starter Replacement Sector?

The car starter replacement market is experiencing significant growth driven by several global factors. Increased vehicle ownership in emerging economies, particularly in Africa and South America, is fueling demand for automotive parts and services. As more consumers invest in vehicles, the need for reliable starter motors becomes critical. Additionally, the rise of electric vehicles (EVs) is influencing the market, prompting suppliers to innovate and adapt their offerings to meet new technological demands. For instance, hybrid vehicles require specialized starter systems, creating opportunities for B2B suppliers to diversify their product lines.

Technological advancements are also reshaping sourcing strategies. The integration of e-commerce platforms allows international buyers to easily access a wider range of starter products and suppliers. Digital tools for inventory management and logistics tracking streamline the sourcing process, enhancing efficiency for businesses operating across multiple regions. Moreover, the trend towards just-in-time inventory practices is gaining traction, enabling businesses to minimize storage costs while responding rapidly to market fluctuations.

In regions like Europe, particularly Germany, there is a notable focus on quality and performance standards, driven by stringent automotive regulations. B2B buyers in these markets are increasingly prioritizing suppliers that demonstrate compliance with international safety and quality standards. This trend underscores the importance of establishing strong relationships with manufacturers who can provide reliable, certified components.

How Can Sustainability and Ethical Sourcing Impact the Car Starter Replacement Market?

Sustainability has become a pivotal consideration in the automotive sector, including the car starter replacement market. As environmental concerns grow, B2B buyers are increasingly focused on sourcing products that minimize ecological impact. This includes seeking starter motors manufactured using environmentally friendly processes and materials. Suppliers that invest in ‘green’ certifications, such as ISO 14001, can gain a competitive advantage by appealing to environmentally conscious buyers.

Ethical sourcing is equally crucial. Buyers are now more vigilant about the supply chain practices of their suppliers, demanding transparency regarding labor conditions and material sourcing. This shift is particularly evident in regions like Europe, where consumers and businesses alike are advocating for fair labor practices and responsible sourcing of raw materials. B2B buyers can enhance their brand reputation and customer loyalty by partnering with suppliers who prioritize ethical practices.

Additionally, the use of recycled materials in starter motor production is gaining traction. Manufacturers that incorporate recycled metals and plastics not only reduce waste but also appeal to a growing segment of eco-conscious buyers. By focusing on sustainable and ethical sourcing, B2B companies can align themselves with broader industry trends and contribute positively to the global effort toward sustainability.

What Is the Historical Context of the Car Starter Replacement Sector?

The evolution of the car starter replacement sector can be traced back to the early 20th century when the first electric starters were introduced, replacing the hand-crank systems that were common at the time. This innovation revolutionized vehicle operation, making cars more accessible to the general public. Over the decades, advancements in starter motor technology, including improvements in efficiency and durability, have significantly enhanced vehicle performance.

By the late 20th century, the automotive industry saw the introduction of high-torque starters, which further optimized engine cranking power. The shift towards more complex electrical systems in modern vehicles has necessitated the development of sophisticated starter motors that can withstand increased demands. This historical context is essential for B2B buyers, as it highlights the importance of selecting starter products that not only meet current standards but are also compatible with evolving automotive technologies. Understanding this evolution helps buyers make informed decisions about sourcing and investing in starter replacements that will stand the test of time.

Frequently Asked Questions (FAQs) for B2B Buyers of how to replace car starter

-

How do I identify a failing car starter?

To identify a failing car starter, listen for specific symptoms. Common indicators include slow cranking, intermittent clicking sounds, or grinding noises when turning the ignition. You may also notice a burning smell or smoke, which could indicate electrical issues. If the engine fails to start despite the starter engaging, it’s essential to rule out other issues such as a dead battery or faulty wiring. Early detection can prevent further complications and minimize downtime. -

What tools are required for replacing a car starter?

Replacing a car starter typically requires a standard set of tools including a socket set, ratchet, torque wrench, screwdrivers, and pliers. Additional tools like a pry bar may be necessary for stubborn starters. Always ensure you have jack stands to safely elevate the vehicle. Depending on the vehicle model, specific tools may vary, so consulting the service manual can provide insights into any specialized equipment needed for the job. -

What are the average costs associated with starter replacement?

The costs for replacing a car starter can vary significantly based on the vehicle make and model. Generally, starter motors range from $100 to $400, while labor costs can add an additional $100 to several hundred dollars, depending on the complexity of the installation. For B2B buyers, sourcing parts in bulk may lead to discounts, so it’s advisable to negotiate pricing with suppliers to optimize costs. -

How can I ensure quality when sourcing car starters internationally?

To ensure quality when sourcing car starters internationally, conduct thorough supplier vetting. This includes checking for certifications, reviewing past customer feedback, and requesting product samples. Establishing a quality assurance (QA) process is critical, which may involve setting specifications and conducting inspections before shipment. Engaging with suppliers that adhere to international standards can mitigate risks associated with subpar products. -

What are the minimum order quantities (MOQs) for car starters?

Minimum order quantities for car starters can vary widely among suppliers. Some may set MOQs as low as 10 units, while others might require hundreds. As a B2B buyer, it’s important to communicate your needs clearly and negotiate terms that align with your inventory and budget. Building a strong relationship with suppliers can also lead to more favorable MOQs over time. -

How should I handle payment terms when sourcing starters?

When sourcing starters, payment terms should be clearly defined in your purchase agreement. Common options include upfront payment, partial payment upon order confirmation, or payment upon delivery. Utilizing secure payment methods, such as letters of credit or escrow services, can provide added security. Always ensure that the terms are mutually agreeable to avoid misunderstandings that could impact your supply chain. -

What logistics considerations should I keep in mind when importing starters?

Logistics are crucial when importing car starters. Consider shipping methods, lead times, and customs regulations in the destination country. Engage with logistics partners experienced in automotive parts to streamline the process. Additionally, understanding local import duties and taxes can help you budget accurately and avoid unexpected costs. Proper documentation is essential to ensure smooth customs clearance. -

What are the common challenges faced when replacing car starters in different regions?

Challenges when replacing car starters can vary by region due to factors like climate, vehicle types, and local regulations. In regions with extreme weather, starters may fail more frequently, necessitating more frequent replacements. Additionally, availability of specific starter models may differ, leading to longer lead times. Understanding local market dynamics and establishing relationships with regional suppliers can help mitigate these challenges and ensure timely access to necessary components.

Top 4 How To Replace Car Starter Manufacturers & Suppliers List

1. Reddit – Starter Replacement Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Starter replacement can be relatively simple depending on the car model. It typically involves two electrical connections and two bolts. It’s advisable to diagnose the issue properly before replacing parts to avoid unnecessary expenses. A common troubleshooting step is to check the battery terminals for dirt or corrosion, which can prevent the car from starting.

2. eBay – Electric Starter

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Project Duration: 1 to 2 hours; Skill Level: Intermediate; Description: An electric starter (starter motor) spins the engine for starting. Starters typically last at least 10 years and thousands of start cycles but will eventually wear out. Difficulty: Changing a car starter is suitable for novice DIY mechanics. Most starters can be removed and replaced in 1 to 2 hours, depending on accessibility….

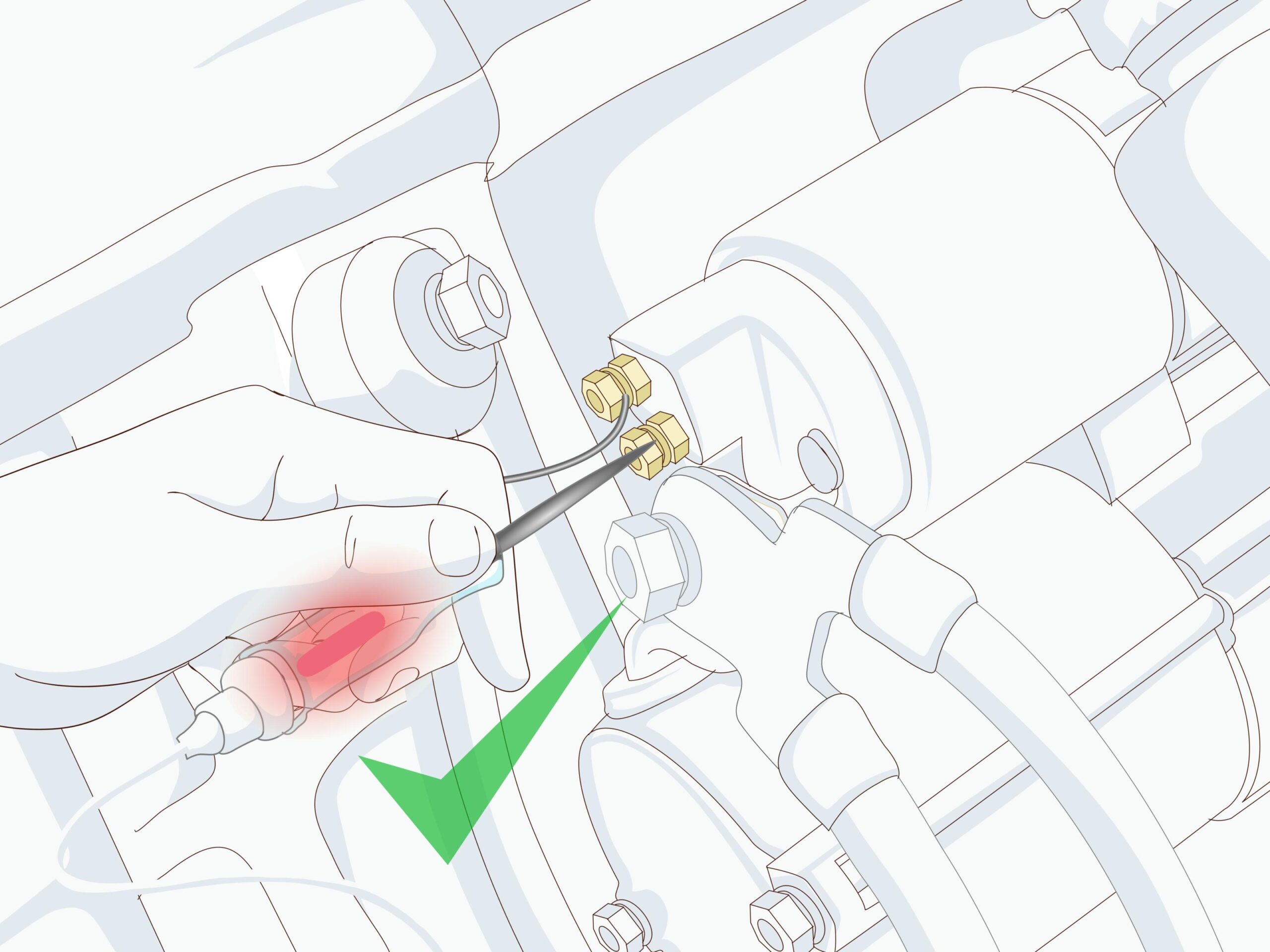

3. WikiHow – Car Starter Installation Guide

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: This article provides a step-by-step guide on how to install a car starter, detailing the process of removing a faulty starter and installing a new one. Key steps include disconnecting the battery, locating the starter, disconnecting wiring, removing retaining bolts, comparing the new starter to the old one, sliding the new starter into place, inserting retainer bolts, and reconnecting wiring to t…

4. Facebook – Social Networking Platform

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Social Networking Platform, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how to replace car starter

In summary, replacing a car starter is a critical task that can directly impact vehicle performance and reliability. For B2B buyers, understanding the nuances of sourcing starter motors and associated components is essential. Considerations such as quality, price, and supplier reliability can significantly affect operational efficiency and customer satisfaction. Strategic sourcing not only enables cost-effective procurement but also fosters long-term partnerships that can lead to better service and innovation.

Illustrative image related to how to replace car starter

As you navigate the global automotive supply chain, prioritize suppliers who offer comprehensive support and adhere to quality standards, especially in regions like Africa, South America, the Middle East, and Europe. By building relationships with trusted manufacturers and distributors, you can ensure access to high-quality starter motors and related parts, enhancing your service offerings.

Looking ahead, the automotive industry is poised for transformation, with advancements in technology and sustainability. Engaging with forward-thinking suppliers will position your business advantageously in this evolving landscape. Take proactive steps to refine your sourcing strategies today, and empower your operations for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how to replace car starter