Introduction: Navigating the Global Market for how to change a headlight on a

Navigating the global market for changing a headlight on a vehicle presents a unique set of challenges, particularly for B2B buyers in regions like Africa, South America, the Middle East, and Europe. Sourcing the right headlight bulbs and understanding their installation is not just about ensuring safety on the road; it also impacts operational efficiency and customer satisfaction for automotive businesses. This guide comprehensively covers the various types of headlight bulbs, their applications across different vehicle models, and essential considerations for supplier vetting and cost analysis.

B2B buyers will find detailed insights into selecting the appropriate bulbs, including factors such as light output, longevity, and compatibility with specific vehicle makes and models. Additionally, the guide addresses common issues encountered during installation and maintenance, equipping buyers with the knowledge to make informed purchasing decisions. Understanding regional preferences and regulatory requirements further empowers businesses to tailor their offerings, ensuring compliance and enhancing customer trust.

By leveraging this guide, international buyers can streamline their procurement processes, enhance their product offerings, and ultimately improve their bottom line. Whether you are a distributor, retailer, or service provider, mastering the intricacies of headlight replacement will position your business for success in a competitive market landscape.

Table Of Contents

- Top 2 How To Change A Headlight On A Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to change a headlight on a

- Understanding how to change a headlight on a Types and Variations

- Key Industrial Applications of how to change a headlight on a

- 3 Common User Pain Points for ‘how to change a headlight on a’ & Their Solutions

- Strategic Material Selection Guide for how to change a headlight on a

- In-depth Look: Manufacturing Processes and Quality Assurance for how to change a headlight on a

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to change a headlight on a’

- Comprehensive Cost and Pricing Analysis for how to change a headlight on a Sourcing

- Alternatives Analysis: Comparing how to change a headlight on a With Other Solutions

- Essential Technical Properties and Trade Terminology for how to change a headlight on a

- Navigating Market Dynamics and Sourcing Trends in the how to change a headlight on a Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to change a headlight on a

- Strategic Sourcing Conclusion and Outlook for how to change a headlight on a

- Important Disclaimer & Terms of Use

Understanding how to change a headlight on a Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Incandescent Headlights | Traditional bulb technology; lower cost; shorter lifespan | Automotive repair shops, fleet services | Pros: Low initial cost; widely available. Cons: Frequent replacements; less energy-efficient. |

| Halogen Headlights | Enhanced brightness; better performance in cold weather | Commercial vehicle maintenance | Pros: Brighter than incandescent; moderate lifespan. Cons: Higher heat generation; may require more frequent replacements. |

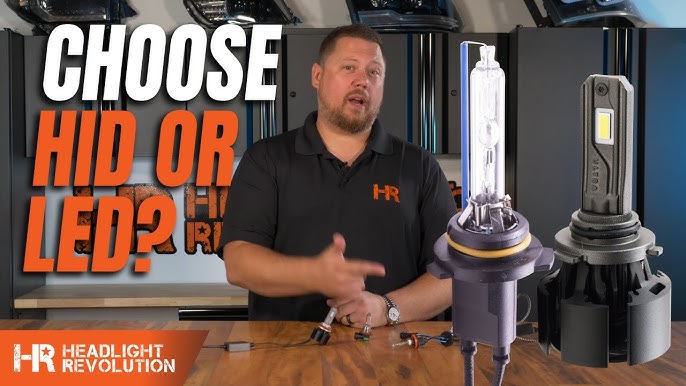

| HID (High-Intensity Discharge) | High brightness; longer lifespan; color temperature options | Luxury vehicle servicing, aftermarket upgrades | Pros: Excellent visibility; energy-efficient. Cons: Higher initial cost; complex installation. |

| LED Headlights | Long lifespan; energy-efficient; low heat emission | Automotive manufacturers, aftermarket retailers | Pros: Durable; low power consumption; modern aesthetic. Cons: Initial cost can be high; may require complete assembly replacement. |

| Adaptive Headlights | Dynamic lighting adjustments based on driving conditions | Advanced vehicle repair, luxury car service | Pros: Improved safety and visibility; enhances driving experience. Cons: Complex and costly to install; may require specialized knowledge. |

What Are Incandescent Headlights and Their B2B Relevance?

Incandescent headlights are the traditional choice for many vehicles, utilizing a filament that produces light when heated. They are cost-effective and easy to replace, making them a popular option for automotive repair shops and fleet services where budget constraints are crucial. However, their shorter lifespan and lower energy efficiency mean that frequent replacements can increase long-term costs, making them less appealing for businesses focused on sustainability.

How Do Halogen Headlights Compare in the Market?

Halogen headlights improve upon incandescent technology by providing brighter illumination and better performance in cold conditions. They are commonly used in commercial vehicle maintenance, where visibility is essential for safety. While halogen bulbs have a moderate lifespan and are more effective than traditional bulbs, they generate more heat, which can be a consideration for businesses focused on energy efficiency and reduced maintenance costs.

What Are the Advantages of HID Headlights for B2B Buyers?

High-Intensity Discharge (HID) headlights are known for their exceptional brightness and longer lifespan compared to halogen and incandescent options. They are frequently utilized in luxury vehicle servicing and aftermarket upgrades, appealing to businesses that prioritize high performance and visibility. Although they come with a higher initial cost and require a more complex installation, their energy efficiency can lead to savings in the long run, making them an attractive option for B2B buyers aiming for quality and durability.

Why Choose LED Headlights for Modern Applications?

LED headlights represent the cutting edge of automotive lighting technology, offering long lifespans and high energy efficiency. They are increasingly popular among automotive manufacturers and aftermarket retailers due to their low heat emissions and modern aesthetic appeal. While the initial investment may be higher, their durability and reduced power consumption can lead to significant cost savings over time, making them a wise choice for businesses looking to enhance their product offerings.

What Are Adaptive Headlights and Their Benefits for Businesses?

Adaptive headlights adjust their brightness and direction based on driving conditions, significantly improving nighttime visibility and safety. They are commonly found in advanced vehicle repair shops and luxury car services. While they provide a superior driving experience, the complexity and cost of installation can be a barrier for some businesses. However, the safety benefits and enhanced customer satisfaction can justify the investment for companies looking to differentiate themselves in a competitive market.

Key Industrial Applications of how to change a headlight on a

| Industry/Sector | Specific Application of how to change a headlight on a | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Routine maintenance for fleet vehicles | Reduces downtime, enhances safety, and maintains compliance with regulations | Availability of vehicle-specific bulbs and tools, cost-effectiveness, and supplier reliability |

| Transportation & Logistics | Ensuring operational safety of delivery trucks | Improved visibility reduces accident risk and enhances driver safety | Quality of bulbs, compatibility with various vehicle models, and bulk purchasing options |

| Public Transportation | Maintenance of public transit vehicles | Ensures passenger safety and adherence to transport regulations | Compliance with local regulations, durability of bulbs, and ease of installation |

| Construction & Heavy Machinery | Maintenance of construction vehicles | Minimizes operational disruptions and enhances site safety | Availability of rugged bulbs, compatibility with heavy machinery, and supplier support for installation |

| Automotive Manufacturing | Quality control in assembly lines | Ensures high standards for vehicle safety and performance | Sourcing from reputable manufacturers, ensuring compliance with industry standards, and bulk purchasing agreements |

How is ‘how to change a headlight on a’ Applied in the Automotive Repair Industry?

In the automotive repair industry, changing headlights is a routine maintenance task that ensures vehicles remain safe and compliant with road regulations. Fleet operators benefit from regular headlight replacements as it minimizes vehicle downtime and enhances overall operational safety. Suppliers must provide vehicle-specific bulbs that meet quality standards and offer tools that facilitate quick installations. Given the diverse vehicle models in use, sourcing reliable parts and tools is critical for maintaining efficiency and ensuring safety.

What Role Does Headlight Maintenance Play in Transportation & Logistics?

In the transportation and logistics sector, maintaining the visibility of delivery trucks is paramount. Headlight maintenance not only improves visibility during night-time or adverse weather conditions but also significantly reduces the risk of accidents. Businesses in this sector must prioritize sourcing high-quality, durable bulbs that can withstand various environmental conditions. Additionally, compatibility with different truck models is essential, as is the ability to purchase in bulk to keep operational costs low.

How Does Headlight Maintenance Impact Public Transportation?

For public transportation systems, the maintenance of headlights is crucial for ensuring passenger safety and compliance with transport regulations. Regularly changing headlight bulbs prevents accidents and enhances the visibility of buses and trains, particularly in urban environments. Buyers in this sector should focus on sourcing bulbs that meet local safety standards and provide easy installation options, as well as consider the durability and longevity of the products to minimize maintenance frequency.

Why is Headlight Maintenance Important for Construction & Heavy Machinery?

In the construction industry, the maintenance of headlights on heavy machinery is vital for ensuring safety on job sites. Properly functioning headlights enhance visibility during early morning or late evening operations, reducing the risk of accidents. Suppliers must offer rugged bulbs that can withstand the harsh conditions typical on construction sites. Moreover, compatibility with various machinery models and support for installation is essential to keep operations running smoothly.

How is Quality Control in Automotive Manufacturing Related to Headlight Replacement?

In automotive manufacturing, quality control is crucial, and this extends to the installation of headlights. Ensuring that all vehicles meet safety standards requires careful sourcing of high-quality bulbs during assembly. Manufacturers must establish partnerships with reputable suppliers to ensure compliance with industry standards and to facilitate bulk purchasing agreements. This not only enhances vehicle safety but also boosts consumer confidence in the brand.

Illustrative image related to how to change a headlight on a

3 Common User Pain Points for ‘how to change a headlight on a’ & Their Solutions

Scenario 1: Difficulty Sourcing the Right Headlight Bulb

The Problem: B2B buyers often encounter challenges in sourcing the correct headlight bulb for a diverse fleet of vehicles. With numerous bulb types, sizes, and specifications available, selecting the right one can feel overwhelming, particularly for businesses that operate across various regions. Additionally, factors such as vehicle model compatibility, local regulations regarding bulb types, and varying quality standards can complicate the purchasing process. This confusion can lead to purchasing the wrong parts, resulting in wasted time and increased operational costs.

The Solution: To navigate the complexities of sourcing headlight bulbs, B2B buyers should invest in a reliable parts catalog or database that details the specifications for each vehicle model within their fleet. Utilizing online platforms that offer vehicle identification features can streamline this process. For instance, buyers can input their vehicle’s make, model, and year to receive tailored recommendations for compatible bulbs. Furthermore, establishing relationships with trusted suppliers who can provide expert guidance on bulb selection will enhance the purchasing process. It’s also advisable to keep a standardized list of preferred bulbs for common vehicle models to reduce the chances of errors in future orders.

Scenario 2: Complexity of the Installation Process

The Problem: Many B2B buyers, particularly those managing vehicle maintenance for fleets, struggle with the installation process of headlight bulbs. The complexity of accessing the headlight assembly varies by vehicle, leading to frustration and potential damage if improper techniques are used. In some cases, workers may lack the necessary tools or knowledge, resulting in longer downtime for vehicles and increased labor costs.

The Solution: Providing comprehensive training and resources for maintenance staff is essential. Companies can create or invest in instructional materials, such as video tutorials and step-by-step guides that detail the installation process for different vehicle models. Additionally, sourcing headlight bulbs that come with easy-to-follow installation instructions can significantly reduce the complexity involved. For more intricate installations, consider partnering with local auto repair shops or technicians who can assist with training or even offer installation services. Investing in the right tools—like specialized screwdrivers or socket sets—can also streamline the installation process and ensure that workers can perform the task efficiently and safely.

Scenario 3: Misdiagnosing Headlight Issues

The Problem: A common pain point for B2B buyers is misdiagnosing headlight issues, which can lead to unnecessary replacements or repairs. When a headlight fails, it may not always be due to a burnt-out bulb; the problem could stem from a blown fuse, damaged wiring, or a faulty switch. This misdiagnosis can result in increased costs and vehicle downtime, as businesses may replace parts that do not address the underlying issue.

The Solution: Implementing a systematic diagnostic approach can mitigate this issue. B2B buyers should train their maintenance teams on basic electrical troubleshooting techniques, allowing them to identify whether the problem lies with the bulb, the fuse, or the vehicle’s wiring. Utilizing diagnostic tools, such as multimeters, can aid in verifying electrical continuity and determining if the bulb or fuse is the culprit. Additionally, maintaining a detailed maintenance log that tracks previous issues with specific vehicles can help in diagnosing recurring problems. By fostering a culture of thorough inspection and accurate diagnosis, businesses can avoid unnecessary expenses and improve the efficiency of their vehicle maintenance operations.

Strategic Material Selection Guide for how to change a headlight on a

When it comes to changing a headlight, the selection of materials plays a crucial role in ensuring optimal performance, longevity, and compliance with international standards. Below, we analyze four common materials used in headlight components, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Glass in Headlight Applications?

Glass is commonly used for headlight lenses due to its excellent optical clarity and resistance to UV radiation. It can withstand high temperatures, making it suitable for the heat generated by halogen bulbs. Glass lenses typically have a temperature rating of around 200°C, ensuring they can handle the thermal stress during operation.

Pros and Cons:

– Pros: High optical clarity, UV resistance, and durability against scratches.

– Cons: Heavier than plastic alternatives, can shatter upon impact, and more expensive to manufacture.

Impact on Application:

Glass provides superior light transmission, which is critical for visibility at night. However, its fragility can be a concern in regions with rough road conditions, necessitating protective measures.

Considerations for International Buyers:

Buyers in regions like Africa and South America should consider the availability of replacement glass lenses, as they may be more prone to breakage in harsh environments. Compliance with local automotive standards is essential, as regulations may vary significantly.

Illustrative image related to how to change a headlight on a

How Does Polycarbonate Compare as a Material for Headlight Lenses?

Polycarbonate is a popular alternative to glass for headlight lenses due to its lightweight and impact-resistant properties. It can withstand temperatures up to 125°C, making it suitable for most automotive applications.

Pros and Cons:

– Pros: Lightweight, shatter-resistant, and cost-effective.

– Cons: Susceptible to scratching and UV degradation over time unless treated.

Impact on Application:

Polycarbonate lenses can provide good light transmission, but their longevity may be compromised in regions with high UV exposure unless they are coated.

Considerations for International Buyers:

In Europe and the Middle East, polycarbonate is widely accepted, but buyers should ensure that the material meets local standards for UV resistance and durability.

Illustrative image related to how to change a headlight on a

What Role Does Aluminum Play in Headlight Housing?

Aluminum is often used in headlight housings due to its corrosion resistance and lightweight properties. It can handle temperatures up to 300°C, making it ideal for high-performance applications.

Pros and Cons:

– Pros: Lightweight, excellent thermal conductivity, and corrosion-resistant.

– Cons: More expensive than steel and can be prone to dents.

Impact on Application:

Aluminum housings can dissipate heat effectively, prolonging the lifespan of the headlight bulbs. However, they may require additional coatings for enhanced durability in corrosive environments.

Illustrative image related to how to change a headlight on a

Considerations for International Buyers:

In regions like Germany, where corrosion resistance is paramount, aluminum is a preferred choice. Buyers should verify compliance with standards like DIN for material specifications.

How Do Sealants Affect Headlight Assembly Durability?

Sealants, often made from silicone or polyurethane, are critical for ensuring that headlight assemblies are watertight and resistant to environmental factors. They typically withstand temperatures up to 150°C.

Pros and Cons:

– Pros: Excellent adhesion, flexibility, and resistance to moisture.

– Cons: Can degrade over time due to UV exposure and may require reapplication.

Impact on Application:

Effective sealants prevent moisture ingress, which can lead to fogging and electrical failures in headlights.

Considerations for International Buyers:

Buyers in humid regions should prioritize sealants with high moisture resistance. Compliance with local automotive sealing standards is also crucial.

Summary Table of Material Selection for Headlight Change

| Material | Typical Use Case for how to change a headlight on a | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Headlight lenses | High optical clarity | Fragile and heavy | High |

| Polycarbonate | Headlight lenses | Lightweight and shatter-resistant | Susceptible to scratching | Medium |

| Aluminum | Headlight housing | Corrosion-resistant and lightweight | More expensive than steel | High |

| Sealants | Sealing headlight assemblies | Excellent adhesion and flexibility | Can degrade under UV exposure | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to enhance the performance and durability of headlight systems while ensuring compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to change a headlight on a

What Are the Main Stages of Manufacturing Headlight Bulbs?

The manufacturing of headlight bulbs involves a series of precise stages, ensuring that each bulb meets stringent quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials such as glass, tungsten, and various metals. The purity and composition of these materials are critical, as they directly affect the bulb’s longevity and performance. Suppliers should be vetted for compliance with international standards to ensure material integrity.

-

Forming: In this stage, glass is shaped into the desired bulb form through processes such as blowing and molding. This is a crucial step because the glass must withstand high temperatures and mechanical stress. Advanced machinery is often employed to maintain consistency in shape and thickness, which are vital for optimal light output and durability.

-

Assembly: The assembly process involves integrating various components, including the filament, glass envelope, and electrical connections. Automated assembly lines are common, enhancing efficiency and precision. It’s essential that manufacturers adhere to specific tolerances to ensure that the components fit together seamlessly, preventing issues such as light leakage or electrical failure.

-

Finishing: The final stage includes quality control checks, cleaning, and packaging. Bulbs undergo treatments such as coating to enhance performance, reduce glare, and improve longevity. Proper packaging is also vital to prevent damage during transportation, especially for international shipments.

How Is Quality Assurance Implemented in Headlight Manufacturing?

Quality assurance (QA) is a critical aspect of headlight manufacturing, ensuring that products meet both domestic and international standards. Manufacturers typically adopt a multi-tiered approach to QA, which includes adherence to recognized standards and regular inspections throughout the manufacturing process.

Illustrative image related to how to change a headlight on a

-

International Standards Compliance: Many manufacturers seek ISO 9001 certification, which is an internationally recognized quality management standard. This certification ensures that the manufacturer has established a systematic approach to managing quality. Additionally, compliance with CE marking requirements indicates that the products meet EU safety, health, and environmental protection standards.

-

Industry-Specific Certifications: Depending on the market, certain industry-specific certifications may be necessary. For instance, automotive components may require compliance with standards set by the American Petroleum Institute (API) or the Society of Automotive Engineers (SAE).

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections help identify defects or deviations from quality standards. This proactive approach minimizes waste and ensures that any issues are addressed immediately.

– Final Quality Control (FQC): Once the bulbs are manufactured, they undergo a final inspection to test for light output, durability, and compliance with safety standards. Common testing methods include photometric testing to measure light intensity and distribution, as well as thermal testing to assess heat resistance.

What Testing Methods Are Commonly Used for Headlight Quality Control?

Testing methods are crucial for verifying the performance and safety of headlight bulbs. Manufacturers employ various testing techniques to ensure that their products can withstand real-world conditions.

-

Photometric Testing: This method assesses the light output and beam pattern of the bulbs. It helps ensure that the headlights provide adequate illumination without causing glare to other drivers. Testing is conducted in controlled environments using photometric test equipment.

-

Thermal Cycling Tests: These tests evaluate how well the bulbs can withstand extreme temperature fluctuations, simulating conditions encountered in different climates. This is particularly relevant for international markets where temperatures can vary significantly.

-

Vibration Testing: Headlights must endure vibrations caused by vehicle operation. Vibration testing simulates these conditions to ensure that components remain secure and functional throughout the bulb’s lifespan.

-

Life Testing: This involves running bulbs continuously to assess their longevity and performance over time. Life testing helps manufacturers identify potential failure points and improve product design.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in diverse international markets, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with local regulations.

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing and quality assurance processes. Audits can reveal adherence to international standards and the effectiveness of their quality control measures.

-

Requesting Quality Reports: Buyers should request documentation that outlines the quality control processes, including IQC, IPQC, and FQC reports. These documents should detail the testing methods used and the results of any testing conducted.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These inspections can validate that products meet specified standards before shipment.

-

Certifications and Compliance Documentation: Buyers should ensure that suppliers provide copies of relevant certifications (e.g., ISO 9001, CE) and compliance documentation. This information is crucial for understanding the supplier’s commitment to quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control due to varying regulations and standards across regions.

-

Understanding Local Regulations: Buyers must familiarize themselves with the specific regulations governing headlight products in their target markets. For instance, EU regulations may differ significantly from those in Africa or South America, impacting compliance requirements.

-

Cultural Differences in Quality Expectations: Different regions may have varying expectations regarding product quality and performance. Buyers should engage in open communication with suppliers to ensure mutual understanding of quality standards.

-

Logistics and Supply Chain Considerations: The complexity of international logistics can impact product quality. Buyers should consider the entire supply chain, from manufacturing to transportation, to mitigate risks associated with damage or delays that could affect product quality.

By comprehensively understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they source reliable and compliant headlight products for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to change a headlight on a’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure headlight replacement solutions, whether for automotive repair shops or fleet maintenance. Understanding the steps involved in changing headlights can streamline operations, enhance safety, and improve customer satisfaction. By following this checklist, buyers can ensure they are sourcing the right products and services to meet their needs effectively.

Illustrative image related to how to change a headlight on a

Step 1: Identify Vehicle Specifications

Understanding the specific headlight requirements for different vehicle models is crucial. Each vehicle may have unique bulb types, sizes, and installation processes.

– Actionable Tip: Consult manufacturer specifications or vehicle manuals to determine the correct bulb model and type (e.g., halogen, HID, or LED) needed.

Step 2: Assess Quality Standards

Quality is paramount when sourcing headlight bulbs, as inferior products can lead to frequent replacements and safety issues.

– Actionable Tip: Look for bulbs that meet or exceed industry standards such as SAE, DOT, or ECE certifications. This ensures that the bulbs are reliable and safe for use.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to evaluate their credibility and reliability.

– Actionable Tip: Request company profiles, case studies, and references from buyers in similar industries or regions. This provides insights into the supplier’s performance and product quality.

Step 4: Compare Pricing and Warranty Options

Cost-effectiveness is critical in procurement, but the cheapest option may not always be the best.

– Actionable Tip: Compare pricing across multiple suppliers while considering warranty terms. A good warranty can indicate manufacturer confidence and provide peace of mind for future replacements.

Illustrative image related to how to change a headlight on a

Step 5: Understand Installation Procedures

Knowing how headlights are changed can influence your purchasing decisions.

– Actionable Tip: Ensure that the suppliers provide clear installation guides or support. This is especially important for businesses that may not have specialized technicians on hand.

Step 6: Check Availability of Replacement Parts

Headlight bulbs may need to be replaced more frequently than other parts, so ensuring a steady supply is vital.

– Actionable Tip: Confirm that the supplier can consistently provide the necessary bulbs and related components to prevent service delays in your operations.

Step 7: Review Customer Support Services

Strong customer support can make a significant difference in your procurement experience.

– Actionable Tip: Assess the level of support offered by suppliers, including technical assistance, return policies, and response times to inquiries. A responsive supplier can help resolve issues quickly, minimizing downtime.

By following these steps, B2B buyers can make informed decisions when sourcing headlight replacement solutions, ensuring they choose products and suppliers that align with their operational requirements and safety standards.

Comprehensive Cost and Pricing Analysis for how to change a headlight on a Sourcing

What Are the Key Cost Components for Changing a Headlight?

When analyzing the costs associated with changing a headlight in a B2B context, several components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

Illustrative image related to how to change a headlight on a

Materials typically encompass the cost of the headlight bulbs themselves, which can vary significantly based on type (e.g., halogen, LED, HID) and quality. For instance, higher-quality bulbs with longer lifespans or better illumination often come at a premium.

Labor costs involve both the time taken to perform the replacement and the skill level required. Technicians with specialized training may command higher wages, impacting the overall cost.

Manufacturing overhead includes expenses related to production facilities, equipment maintenance, and administrative costs. These factors are crucial for suppliers, as they influence the final pricing of replacement parts.

Tooling costs can also contribute, especially if specialized tools are required for certain vehicle models.

Illustrative image related to how to change a headlight on a

Quality control (QC) is essential in ensuring that the bulbs meet safety and performance standards. This process can add to the cost but is vital for maintaining reliability and customer satisfaction.

Logistics involves the shipping and handling of the headlight bulbs from the manufacturer to the distributor or retailer. The geographical location of suppliers can affect shipping times and costs, particularly for international transactions.

Finally, the margin is the profit that suppliers build into their pricing to sustain operations and growth.

How Do Price Influencers Affect Headlight Replacement Costs?

Several price influencers can significantly impact the overall cost of headlight replacement.

Volume and Minimum Order Quantity (MOQ) are crucial factors. Suppliers often offer discounts for bulk purchases, which can be beneficial for larger businesses that require multiple headlight replacements.

Specifications and customization also play a role. Custom headlight solutions tailored for specific vehicle models may incur additional costs compared to standard options.

Illustrative image related to how to change a headlight on a

Material quality and certifications can influence pricing. For instance, bulbs that are certified for higher performance or energy efficiency may be more expensive.

Supplier factors, including reputation and reliability, can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

Incoterms determine shipping responsibilities and costs, which can impact the final price. Understanding these terms is vital for international buyers to avoid unexpected charges.

What Buyer Tips Can Enhance Cost-Efficiency in Headlight Replacement?

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, understanding negotiation tactics can lead to cost savings.

Negotiation is key; engaging suppliers in discussions about bulk pricing or long-term partnerships can yield favorable terms.

Total Cost of Ownership (TCO) should also be considered. While initial costs are important, evaluating the longevity and efficiency of bulbs can lead to better long-term savings. For example, investing in higher-quality bulbs may result in fewer replacements and lower maintenance costs over time.

Pricing nuances for international buyers include understanding regional pricing dynamics, such as tariffs, import duties, and local market demand, which can affect overall costs.

Buyers should also remain vigilant about market trends and new technologies that may introduce cost-effective solutions or alternatives, ensuring they remain competitive.

Illustrative image related to how to change a headlight on a

Conclusion: Why Is It Important to Understand Costs and Pricing in Headlight Replacement?

Understanding the comprehensive cost structure and pricing dynamics associated with headlight replacement is crucial for B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic purchasing tactics, businesses can ensure they make informed decisions that enhance their operational efficiency and profitability.

Buyers should approach sourcing with a clear understanding of both the direct and indirect costs involved, enabling them to optimize their supply chain while ensuring safety and compliance in their operations.

Alternatives Analysis: Comparing how to change a headlight on a With Other Solutions

When it comes to changing a headlight, automotive professionals and businesses have several methods at their disposal. Understanding these alternatives can help buyers make informed decisions based on their specific requirements. Below, we will compare the traditional method of changing a headlight bulb with two alternative solutions: using LED headlight conversion kits and professional installation services.

Illustrative image related to how to change a headlight on a

| Comparison Aspect | How To Change A Headlight On A | LED Headlight Conversion Kits | Professional Installation Services |

|---|---|---|---|

| Performance | Effective for standard bulbs | Superior brightness and longevity | Quick, reliable installation with warranty |

| Cost | Low, typically under $50 | Moderate, usually $100-$300 | Higher, generally $100-$200 per service |

| Ease of Implementation | Requires basic tools and skills | Moderate; some kits require technical knowledge | Minimal effort; professionals handle everything |

| Maintenance | Minimal; occasional bulb replacements | Low; bulbs last longer, but may require driver updates | None; service includes guarantee |

| Best Use Case | DIY maintenance for cost-saving | Upgrading for enhanced visibility | Quick fixes or complex installations |

What Are the Pros and Cons of Changing a Headlight On Your Own?

Changing a headlight bulb on your own is a cost-effective solution that allows for immediate repairs. With basic tools and a bit of knowledge, most automotive professionals can efficiently replace a bulb. However, this method may require some technical skill and can be time-consuming, especially for vehicles with difficult-to-access headlight assemblies. Additionally, the need for regular bulb replacements can add to long-term maintenance.

How Do LED Headlight Conversion Kits Compare?

LED headlight conversion kits offer a modern alternative to traditional bulbs. They provide superior brightness and a longer lifespan, reducing the frequency of replacements. Although these kits can be more expensive initially, their longevity and enhanced visibility make them a preferred option for many businesses focused on safety and performance. However, installation can be complex, requiring some technical expertise, and may involve additional costs for driver updates in certain vehicles.

What Are the Benefits of Professional Installation Services?

Engaging professional installation services ensures that the headlight replacement process is handled quickly and correctly. This option is ideal for businesses that lack the technical skills or resources for DIY repairs. Professionals often provide warranties, ensuring peace of mind regarding the quality of the installation. However, this convenience comes at a higher cost, making it less attractive for budget-conscious buyers.

How Should B2B Buyers Choose the Right Headlight Change Solution?

When evaluating which headlight replacement solution is best, B2B buyers should consider factors such as budget, technical expertise, and the urgency of the repair. For those with limited resources or technical skills, professional installation may be the best choice, despite the higher cost. Conversely, businesses aiming to maintain budget control and who possess the necessary skills may find that changing the headlight themselves is the most effective route. Finally, for those seeking enhanced performance and longevity, investing in LED conversion kits may offer the best long-term value. Each option has its unique advantages, and the right choice will depend on the specific needs and circumstances of the buyer.

Essential Technical Properties and Trade Terminology for how to change a headlight on a

What Are the Key Technical Properties to Consider When Changing a Headlight?

When it comes to changing headlights, several technical properties are crucial for ensuring optimal performance and compliance with safety standards. Understanding these specifications can help B2B buyers make informed purchasing decisions.

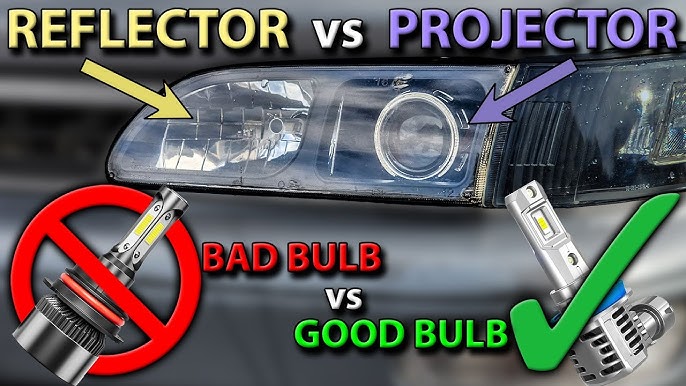

1. Bulb Type and Compatibility

Different vehicles require specific bulb types—commonly halogen, HID (High-Intensity Discharge), or LED (Light Emitting Diode). Each type has unique characteristics regarding brightness, energy consumption, and lifespan. For example, LED headlights often provide superior illumination and longevity compared to traditional halogen bulbs. Ensuring compatibility with the vehicle’s make and model is essential to avoid installation issues and ensure safety on the road.

2. Lumen Output

Lumen output measures the brightness of the bulb. A higher lumen rating indicates a brighter light, which is vital for visibility during night driving or in adverse weather conditions. For B2B buyers, understanding lumen output can guide the selection of headlights that meet safety regulations and provide adequate illumination for various driving environments.

Illustrative image related to how to change a headlight on a

3. Color Temperature

Color temperature, measured in Kelvins (K), indicates the hue of the light emitted by the bulb. For example, bulbs with a color temperature of 3000K emit a warm yellow light, while those rated at 6000K produce a cool, white light. The choice of color temperature can impact visibility and driver comfort, making it an important consideration for fleet operators seeking to enhance safety and performance.

4. Durability and Material Grade

The durability of headlight bulbs is often determined by the materials used in their construction. For instance, glass and quartz materials are commonly used for their heat resistance and longevity. Understanding material grade is critical for B2B buyers who prioritize long-lasting products that minimize replacement frequency and associated labor costs.

5. Power Consumption

Power consumption, measured in watts, indicates how much energy the bulb requires to operate. Bulbs with lower wattage may consume less energy and generate less heat, which can prolong their lifespan and reduce the risk of electrical issues in the vehicle. For businesses focused on sustainability, energy-efficient options can also lower operational costs.

What Are Common Trade Terms Related to Headlight Changes?

Familiarity with trade terminology is essential for effective communication and decision-making in the automotive industry. Here are some key terms relevant to changing headlights:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer. These components are designed to meet specific performance standards and fit precisely. B2B buyers often prefer OEM parts for their reliability and warranty coverage.

Illustrative image related to how to change a headlight on a

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for businesses looking to optimize inventory levels and manage costs effectively, especially when dealing with bulk purchases of headlight components.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to provide pricing and terms for specific products or services. B2B buyers should utilize RFQs to gather competitive pricing and ensure they are making cost-effective purchasing decisions.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is crucial for B2B transactions, as they dictate who is responsible for shipping costs, insurance, and risk during transportation.

5. Aftermarket Parts

Aftermarket parts are components made by third-party manufacturers rather than the OEM. While often more affordable, they may vary in quality and performance. B2B buyers should weigh the pros and cons of aftermarket options based on their specific needs and budget constraints.

6. E-mark Certification

E-mark certification indicates that a product complies with European safety and environmental regulations. For international buyers, especially in Europe, ensuring that headlights have E-mark certification is crucial for legal compliance and product safety.

By understanding these essential technical properties and trade terms, B2B buyers can make informed decisions that enhance vehicle safety and performance while optimizing operational efficiency.

Illustrative image related to how to change a headlight on a

Navigating Market Dynamics and Sourcing Trends in the how to change a headlight on a Sector

What Are the Key Market Dynamics and Trends for Changing Headlights?

The global automotive market has seen a significant transformation in the way headlight systems are approached. An increasing emphasis on vehicle safety and compliance with stringent regulations has driven demand for efficient headlight replacement solutions. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are adapting to these dynamics by investing in high-quality products that ensure visibility and safety. The trend towards LED and HID bulbs is particularly notable, as these technologies offer longer life spans and improved brightness, catering to the evolving preferences of consumers.

In addition to product evolution, the rise of digital platforms for sourcing automotive parts has streamlined the purchasing process. B2B buyers can now easily compare specifications, prices, and customer reviews online, allowing for informed decisions. Moreover, the growing trend of DIY vehicle maintenance has led to increased demand for comprehensive guides and instructional videos, facilitating a hands-on approach to changing headlights. This shift not only empowers buyers but also encourages manufacturers to provide more accessible, user-friendly products.

How Is Sustainability Impacting the Headlight Replacement Market?

Sustainability is becoming a critical factor in the automotive industry, influencing how headlight components are sourced and manufactured. The environmental impact of traditional manufacturing processes, including the use of hazardous materials and excessive waste, has prompted both buyers and manufacturers to seek greener alternatives. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recyclable materials and minimizing carbon footprints.

Illustrative image related to how to change a headlight on a

In this context, ethical sourcing is also gaining traction. Buyers are more inclined to partner with manufacturers who can provide transparency in their supply chains, ensuring that all materials are sourced responsibly. Certifications like ISO 14001 (Environmental Management) or materials labeled as “green” or “eco-friendly” are becoming essential criteria for procurement decisions. By aligning with suppliers who prioritize sustainability, businesses can enhance their brand reputation while contributing to broader environmental goals.

What Is the Historical Context of Headlight Technology and Its Evolution?

The evolution of headlight technology has been marked by significant milestones that reflect advancements in engineering and design. Initially, vehicles were equipped with simple incandescent bulbs, which provided limited visibility and required frequent replacements. As safety became a priority, automotive manufacturers began to innovate, leading to the introduction of halogen bulbs in the 1960s, which offered brighter illumination and longer life.

The late 20th century saw the emergence of High-Intensity Discharge (HID) bulbs, which further enhanced visibility and energy efficiency. More recently, LED technology has revolutionized the market, providing not only superior brightness but also greater energy savings and longevity. This historical progression illustrates a continuous drive towards improving driver safety and compliance with regulations, shaping the current market landscape where B2B buyers are increasingly looking for advanced and reliable headlight solutions.

In summary, understanding these market dynamics, sustainability efforts, and the historical context can empower B2B buyers to make informed decisions in sourcing headlight replacement solutions that meet both current demands and future expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of how to change a headlight on a

-

How do I solve a problem with a headlight that won’t turn on after replacing the bulb?

If the headlight remains non-functional after a bulb replacement, the issue may lie with the fuse or wiring. Begin by checking the fuse associated with the headlight circuit; a blown fuse may indicate a deeper electrical issue. If the fuse is intact, inspect the wiring for any signs of damage or loose connections. If you’re unable to diagnose the problem, consider consulting with an automotive technician or a preferred shop for professional assistance. -

What is the best type of headlight bulb for enhancing visibility in various weather conditions?

For optimal visibility in diverse weather conditions, consider using high-quality halogen or LED bulbs. Halogen bulbs offer a warm light that performs well in rainy or foggy conditions, while LEDs provide a cooler, brighter light that enhances contrast and clarity. Look for bulbs with a higher lumen output and a color temperature between 4000K and 6000K for improved visibility. Always verify compatibility with your vehicle’s specifications before purchasing. -

How can I ensure I am sourcing high-quality headlight bulbs from suppliers?

To source high-quality headlight bulbs, start by vetting suppliers thoroughly. Look for manufacturers with established reputations, preferably certified by relevant automotive standards. Request product samples for quality testing and check for compliance with international safety standards. Additionally, consider suppliers that offer warranties or guarantees on their products, ensuring a level of accountability for their quality. -

What minimum order quantities (MOQs) should I expect when sourcing headlight bulbs internationally?

Minimum order quantities (MOQs) for headlight bulbs can vary significantly between suppliers. Generally, MOQs can range from 100 to 1,000 units, depending on the supplier’s production capabilities and your specific requirements. It’s advisable to negotiate MOQs with potential suppliers, especially if you are testing a new product line or entering a new market, to avoid excess inventory costs. -

What payment terms are common when importing headlight bulbs from international suppliers?

Common payment terms for importing headlight bulbs may include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers prefer a partial upfront payment, typically 30-50%, with the balance due upon shipment or delivery. Ensure that you discuss and agree upon payment terms upfront to avoid any misunderstandings and to maintain a positive relationship with your supplier. -

How can I customize headlight bulbs to meet specific market needs?

Customization options for headlight bulbs often include variations in brightness, color temperature, and design. When discussing customization with suppliers, clearly outline your market needs, such as compliance with local regulations or specific performance characteristics. Some suppliers may offer OEM services to create tailored products, so it’s beneficial to establish a collaborative relationship for effective customization. -

What quality assurance (QA) measures should I consider when sourcing headlight bulbs?

When sourcing headlight bulbs, prioritize suppliers that implement rigorous quality assurance (QA) measures. Inquire about their testing protocols, certifications, and adherence to industry standards. Request documentation of QA processes, including batch testing results and compliance with safety regulations. A reliable supplier should be transparent about their QA practices to ensure that you receive consistent and high-quality products. -

What logistics considerations should I keep in mind when importing headlight bulbs?

Logistics considerations are crucial when importing headlight bulbs, including shipping methods, customs clearance, and lead times. Evaluate the supplier’s ability to handle logistics efficiently and inquire about their shipping partners and routes. Ensure that you understand the customs regulations in your destination country to avoid delays. Additionally, factor in potential tariffs and taxes to accurately assess the total cost of your imports.

Top 2 How To Change A Headlight On A Manufacturers & Suppliers List

1. Facebook – Fusion Headlight Design Issue

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: One bad design on the Fusion regarding changing the headlight bulb.

2. Honda – Headlight Replacement Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1999 Honda Civic headlight replacement requires access behind the bumper, possibly removing it or part of it. Typically involves 4 10mm bolts (two on top, one on each side) and disconnecting the wire harness. Basic hand tools needed include a ratchet with a 10mm socket and possibly a Philips screwdriver for bumper screws.

Strategic Sourcing Conclusion and Outlook for how to change a headlight on a

As the automotive industry evolves, the significance of strategic sourcing for headlight replacement components becomes increasingly apparent. By prioritizing the procurement of high-quality, durable headlight bulbs, businesses can enhance vehicle safety, ensure compliance with international regulations, and improve customer satisfaction. Understanding the nuances of different bulb types, such as incandescent, halogen, and LED, allows B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Moreover, efficient sourcing strategies can streamline inventory management and reduce operational costs. Buyers should consider not only the price but also the long-term value of products, including lifespan, performance, and compatibility with various vehicle models. Engaging with trusted suppliers who provide comprehensive technical support and customer service can further mitigate risks associated with headlight replacements.

Looking ahead, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are encouraged to leverage the insights gained from this guide. By adopting a proactive approach to sourcing headlight solutions, businesses can position themselves for success in a competitive market. Begin exploring partnerships with reliable suppliers today to ensure your fleet remains safe and operational on the road.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.