Introduction: Navigating the Global Market for how to change a headlight

In the fast-paced world of automotive maintenance, understanding how to change a headlight is crucial for ensuring vehicle safety and compliance across international markets. B2B buyers often face the challenge of sourcing reliable automotive parts, including headlights, that meet varying regional standards and preferences. This comprehensive guide delves into the intricacies of headlight replacement, encompassing various bulb types—such as halogen, HID, and LED—as well as the specific applications suited for different vehicles.

Moreover, we address the critical aspects of supplier vetting and cost considerations that international buyers must navigate, particularly in diverse markets like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Germany. By offering actionable insights on selecting the right headlight bulbs, understanding installation processes, and recognizing signs of wear, this guide equips decision-makers with the knowledge needed to make informed purchasing choices.

With this resource, B2B buyers can streamline their procurement strategies, ensuring they acquire high-quality headlights that enhance safety and visibility while complying with local regulations. Ultimately, the goal is to empower businesses to foster stronger partnerships with suppliers, optimize inventory management, and improve customer satisfaction through reliable automotive lighting solutions.

Table Of Contents

- Top 2 How To Change A Headlight Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to change a headlight

- Understanding how to change a headlight Types and Variations

- Key Industrial Applications of how to change a headlight

- 3 Common User Pain Points for ‘how to change a headlight’ & Their Solutions

- Strategic Material Selection Guide for how to change a headlight

- In-depth Look: Manufacturing Processes and Quality Assurance for how to change a headlight

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to change a headlight’

- Comprehensive Cost and Pricing Analysis for how to change a headlight Sourcing

- Alternatives Analysis: Comparing how to change a headlight With Other Solutions

- Essential Technical Properties and Trade Terminology for how to change a headlight

- Navigating Market Dynamics and Sourcing Trends in the how to change a headlight Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to change a headlight

- Strategic Sourcing Conclusion and Outlook for how to change a headlight

- Important Disclaimer & Terms of Use

Understanding how to change a headlight Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Incandescent Bulbs | Traditional lighting, easily replaceable, cost-effective | Budget-conscious fleets | Pros: Low cost, easy to replace. Cons: Short lifespan, less energy-efficient. |

| Halogen Bulbs | Brighter than incandescent, better longevity | Commercial vehicles needing reliability | Pros: Improved brightness, longer lifespan. Cons: Higher heat output, can be more expensive. |

| HID (High-Intensity Discharge) | Produces a very bright light, longer range | Luxury vehicles, high-performance fleets | Pros: Excellent visibility, energy-efficient. Cons: Higher initial cost, complex installation. |

| LED (Light Emitting Diodes) | Long lifespan, low energy consumption, cooler operation | Modern fleets seeking efficiency | Pros: Very long lifespan, low heat output. Cons: Higher upfront cost, may require assembly replacement. |

| Xenon Bulbs | Produce a bright, white light, good for visibility | High-end vehicles and specialized applications | Pros: Enhanced visibility, stylish appearance. Cons: More expensive, potential compatibility issues. |

What Are the Key Characteristics of Incandescent Bulbs for Headlight Replacement?

Incandescent bulbs are the most traditional type of headlight, known for their simplicity and affordability. They are commonly used in budget-conscious fleets where cost is a primary concern. The ease of replacement makes them attractive for businesses looking to minimize maintenance time. However, they have a shorter lifespan and lower energy efficiency compared to newer technologies, which can lead to more frequent replacements.

How Do Halogen Bulbs Enhance Headlight Performance?

Halogen bulbs are an upgrade over incandescent options, offering brighter light and a longer lifespan. They are particularly suited for commercial vehicles that require reliable lighting for safety and performance. While they are more expensive than incandescent bulbs, their enhanced brightness and longevity can justify the investment, especially in applications where visibility is critical.

Why Choose HID Bulbs for High-Performance Vehicles?

HID bulbs are favored for their exceptional brightness and long-range visibility, making them ideal for luxury and high-performance fleets. They are energy-efficient and provide excellent illumination, which can be crucial for nighttime driving or in adverse weather conditions. However, their higher initial cost and complex installation process may deter some buyers, making it essential to consider the overall value they bring to a fleet.

What Advantages Do LED Bulbs Offer for Modern Fleets?

LED headlights are gaining popularity due to their long lifespan and low energy consumption. They produce less heat and have a significantly longer operational life, which can reduce maintenance costs for businesses. However, the initial investment is higher, and some vehicles may require complete assembly replacements rather than just bulb changes. Businesses focused on sustainability and efficiency may find LED options particularly appealing.

How Do Xenon Bulbs Compare in Terms of Visibility and Cost?

Xenon bulbs deliver a bright, white light that enhances visibility, making them a popular choice for high-end vehicles and specialized applications. They offer better aesthetics and performance than traditional bulbs, but their higher cost and potential compatibility issues can be drawbacks. For B2B buyers, understanding the specific requirements of their vehicle types and operational needs is crucial when considering xenon options.

Key Industrial Applications of how to change a headlight

| Industry/Sector | Specific Application of how to change a headlight | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Routine maintenance for vehicle lighting | Enhances customer safety and satisfaction | Availability of compatible bulbs and tools, bulk purchasing options |

| Fleet Management | Regular headlight replacements for commercial vehicles | Reduces downtime and improves fleet safety | Need for durable, high-performance bulbs suitable for various vehicles |

| Transportation Services | Ensuring compliance with lighting regulations | Minimizes legal risks and enhances road safety | Understanding of local regulations, sourcing quality bulbs that meet standards |

| Construction Equipment | Maintenance of headlights on construction vehicles | Improves visibility and safety on job sites | Access to specialized bulbs for heavy machinery, reliable suppliers for urgent needs |

| Automotive Parts Retail | Selling headlight replacement kits and tools | Generates additional revenue streams | Diverse inventory that caters to various vehicle models, competitive pricing |

How is ‘how to change a headlight’ utilized in the Automotive Repair Industry?

In automotive repair shops, changing headlights is a common service that technicians perform. This task not only addresses customer complaints about dim or non-functioning lights but also plays a critical role in vehicle safety. Shops must ensure they stock a variety of headlight bulbs compatible with different makes and models, including halogen, HID, and LED options. For international buyers, understanding local vehicle specifications and regulations is essential to provide effective service and maintain customer trust.

What are the implications for Fleet Management when it comes to headlight maintenance?

For fleet management companies, regularly changing headlights is crucial to ensure the safety and reliability of their vehicles. A well-maintained fleet minimizes accidents caused by poor visibility, thereby reducing liability and maintenance costs. Fleet managers need to source high-quality, durable bulbs that can withstand extensive use, especially in varying climates across regions like Africa and the Middle East. Establishing relationships with reliable suppliers for bulk purchases can lead to cost savings and streamlined operations.

How does headlight maintenance impact Transportation Services?

In transportation services, compliance with local lighting regulations is paramount. Regular headlight maintenance and replacement not only ensure legal compliance but also enhance driver safety during night operations. Transportation companies must be aware of the specific regulations in their operating regions, which vary significantly across continents like Europe and South America. Sourcing high-performance bulbs that meet these standards is critical for maintaining a good reputation and avoiding fines.

Why is headlight maintenance important for Construction Equipment?

Construction sites often require heavy machinery to operate in low-light conditions, making functional headlights vital for safety. Maintenance of these headlights ensures that operators can see and be seen, reducing the risk of accidents. Suppliers must provide specialized bulbs that can endure the harsh conditions typical of construction environments. For international buyers, understanding the specific requirements of different machinery types and sourcing from trusted manufacturers is essential for ensuring reliability.

What opportunities exist in Automotive Parts Retail for headlight replacement products?

Automotive parts retailers can capitalize on the demand for headlight replacement kits and tools by offering a diverse inventory. Providing customers with easy access to installation guides and compatible products can enhance customer experience and drive sales. Retailers must consider the various vehicle models popular in their target markets, especially in regions like Germany and Saudi Arabia, to ensure they stock the right products. Competitive pricing and effective marketing strategies can further boost their position in the market.

Illustrative image related to how to change a headlight

3 Common User Pain Points for ‘how to change a headlight’ & Their Solutions

Scenario 1: Difficulty in Identifying the Correct Bulb Type

The Problem: Many B2B buyers, especially those managing fleets or automotive repair businesses, often struggle with identifying the correct headlight bulb for different vehicle models. This challenge can lead to costly errors, such as ordering the wrong bulbs or experiencing delays in repairs, affecting customer satisfaction and operational efficiency.

The Solution: To mitigate this issue, B2B buyers should invest in a reliable parts catalog or an online database that allows for vehicle-specific searches. Utilizing resources like VIN (Vehicle Identification Number) lookup tools can ensure they are sourcing the exact bulb type required for each vehicle in their fleet. It’s also beneficial to create a standardized inventory management system that categorizes bulbs by vehicle make and model. Training staff to understand the differences between bulb types—such as halogen, HID, and LED—can further streamline the process. Additionally, establishing partnerships with suppliers who provide clear specifications and recommendations can enhance accuracy when ordering.

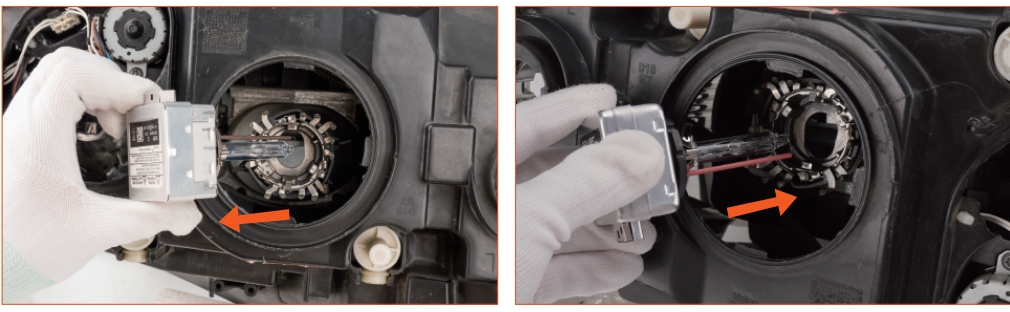

Scenario 2: Time-Consuming Installation Process

The Problem: The headlight replacement process can be time-consuming and complex, especially for vehicles with difficult-to-access bulbs. This complexity can lead to increased labor costs and longer vehicle downtime, which are critical factors for B2B buyers who need to maintain operational efficiency.

The Solution: To address this challenge, B2B buyers should prioritize investing in comprehensive training for their technicians on headlight replacement procedures tailored to specific vehicle models. Providing access to detailed instructional videos or manuals can help technicians familiarize themselves with the necessary tools and techniques before starting the job. Additionally, suppliers can offer specialized installation kits that include all required tools and components for specific vehicles, thereby reducing installation time. Implementing a streamlined process for headlight replacement, including pre-emptive checks on bulb conditions during routine maintenance, can also minimize the need for urgent replacements, ultimately saving time and costs.

Scenario 3: Ensuring Compliance with Local Regulations

The Problem: B2B buyers operating in various international markets face the challenge of ensuring that the headlight bulbs they install comply with local regulations and safety standards. Non-compliance can lead to legal issues, fines, and increased liability, which can severely impact business operations.

Illustrative image related to how to change a headlight

The Solution: To navigate this regulatory landscape, B2B buyers should conduct thorough research on the specific headlight regulations in each market they operate. Establishing relationships with local automotive regulatory bodies can provide insights into compliance requirements. Additionally, sourcing products from manufacturers that provide certification and compliance documentation can help ensure that the bulbs meet all necessary standards. Implementing a compliance checklist for headlight installations can further safeguard against legal repercussions. Regular training sessions for technicians on compliance-related topics will also reinforce the importance of adhering to local regulations, thus minimizing risks associated with non-compliance.

Strategic Material Selection Guide for how to change a headlight

What Materials Are Commonly Used in Headlight Components?

When it comes to changing headlights, the materials used in the manufacturing of headlight bulbs and their assemblies significantly affect performance, durability, and overall user experience. Here, we analyze four common materials: glass, polycarbonate, aluminum, and halogen.

How Does Glass Perform in Headlight Applications?

Key Properties: Glass is known for its excellent optical clarity and high-temperature resistance, making it a traditional choice for headlight lenses. It can withstand significant thermal stress, which is crucial for the heat generated by bulbs.

Pros & Cons: The primary advantage of glass is its durability against scratches and environmental factors. However, it is heavier and more prone to shattering upon impact compared to other materials. Additionally, glass manufacturing involves complex processes, which can increase costs.

Impact on Application: Glass lenses are often used in high-end automotive applications due to their superior light transmission properties. However, they require careful handling to avoid breakage during installation.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, especially in regions like Europe where safety regulations are stringent. Buyers should also consider the availability of glass lenses in local markets to avoid long lead times.

Illustrative image related to how to change a headlight

What Role Does Polycarbonate Play in Headlight Assemblies?

Key Properties: Polycarbonate is a lightweight thermoplastic known for its impact resistance and flexibility. It can endure temperature fluctuations and is less prone to shattering than glass.

Pros & Cons: The primary advantage of polycarbonate is its lightweight nature, which can contribute to overall vehicle efficiency. However, it is more susceptible to scratching and UV degradation over time, which can affect clarity. The manufacturing process is typically less complex than glass, resulting in lower costs.

Impact on Application: Polycarbonate is commonly used in modern automotive lighting due to its resilience and ease of molding into complex shapes. However, it may require additional coatings to enhance UV resistance.

Considerations for International Buyers: Buyers in regions like Africa and South America should assess the local climate conditions, as UV exposure can significantly impact the longevity of polycarbonate lenses. Ensuring compliance with regional quality standards is also crucial.

Why Is Aluminum Important in Headlight Housing?

Key Properties: Aluminum is lightweight yet strong, offering good thermal conductivity and corrosion resistance. Its ability to dissipate heat effectively is vital for maintaining bulb performance.

Pros & Cons: The lightweight nature of aluminum contributes to overall vehicle efficiency, while its corrosion resistance enhances durability. However, aluminum can be more expensive than plastic alternatives, and its manufacturing process can be complex.

Impact on Application: Aluminum is often used in headlight housings to improve heat dissipation, which prolongs bulb life. However, it may require additional treatment to prevent oxidation in humid environments.

Considerations for International Buyers: Buyers from regions with high humidity, such as the Middle East, should prioritize aluminum components with protective coatings to ensure longevity. Compliance with local standards for materials is also essential.

Illustrative image related to how to change a headlight

How Do Halogen Bulbs Compare to Other Options?

Key Properties: Halogen bulbs are filled with a gas that allows them to operate at higher temperatures, resulting in brighter light output. They have a relatively short lifespan compared to LED options but are widely used due to their cost-effectiveness.

Pros & Cons: The main advantage of halogen bulbs is their affordability and ease of replacement. However, they are less energy-efficient and have a shorter lifespan than newer technologies like LEDs.

Impact on Application: Halogen bulbs are suitable for various automotive applications but may not provide the same level of brightness or longevity as LED alternatives.

Considerations for International Buyers: Buyers should be aware of local regulations regarding headlight brightness and energy consumption. In Europe, for instance, compliance with energy efficiency standards is critical.

Illustrative image related to how to change a headlight

Summary Table of Material Selection for Headlight Components

| Material | Typical Use Case for how to change a headlight | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Headlight lenses | Excellent optical clarity | Heavy and prone to shattering | High |

| Polycarbonate | Modern headlight lenses | Lightweight and impact-resistant | Susceptible to scratching and UV degradation | Medium |

| Aluminum | Headlight housing | Good thermal conductivity and corrosion resistance | More expensive and complex to manufacture | High |

| Halogen | Standard headlight bulbs | Affordable and easy to replace | Shorter lifespan and less energy-efficient | Low |

This analysis provides essential insights for B2B buyers looking to understand the material options available for headlight components, ensuring informed decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how to change a headlight

What Are the Key Stages in the Manufacturing Process of Headlights?

The manufacturing process of headlights involves several critical stages, each designed to ensure the final product meets safety, performance, and aesthetic standards. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Material Preparation: What Materials Are Used in Headlight Manufacturing?

The first step in the manufacturing process is material preparation. Headlights typically consist of several materials, including:

Illustrative image related to how to change a headlight

- Polycarbonate or Glass: Used for the lens, polycarbonate is favored for its lightweight and high impact resistance, while glass offers superior optical clarity.

- Reflectors: Usually made from aluminum or plastic, reflectors are designed to enhance light output and focus.

- Bulbs: Depending on the type of headlight, materials can include halogen, HID, or LED components.

These materials are sourced from certified suppliers, ensuring they meet international quality standards. The selection of high-grade materials is crucial for durability and performance, especially in varying climates faced by consumers in Africa, South America, the Middle East, and Europe.

How Are Headlights Formed and Assembled?

Once materials are prepared, they undergo forming processes. The lens is molded into shape using injection molding or blow molding techniques, depending on whether plastic or glass is used. Reflectors are typically stamped or vacuum-formed to achieve the desired curvature.

During the assembly stage, individual components are brought together. This includes:

- Bulb Installation: The light bulb is secured within the housing.

- Sealing: The assembly is sealed to prevent moisture and dust ingress, which can degrade performance.

- Wiring: Electrical connections are made to ensure proper functionality.

This stage may vary based on vehicle specifications, necessitating a flexible manufacturing approach to accommodate different designs.

What Quality Assurance Measures Are Implemented During Production?

Quality assurance (QA) is vital in the manufacturing of headlights, ensuring that products meet safety and performance standards. Various international and industry-specific standards guide these QA processes.

Which International Standards Are Relevant for Headlight Manufacturers?

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems, and ISO 14001 for environmental management. Compliance with these standards helps ensure that the manufacturing process is efficient and environmentally friendly.

Additionally, industry-specific certifications, such as CE marking in Europe and API standards in the automotive sector, validate that products meet safety and performance criteria. These certifications are critical for B2B buyers looking to ensure compliance with local regulations in their respective markets.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to identify defects early. Common QC checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help catch defects before assembly is completed.

- Final Quality Control (FQC): The assembled headlights undergo rigorous testing for light output, beam pattern, and durability before being packaged for shipment.

What Testing Methods Are Commonly Used to Ensure Headlight Quality?

Manufacturers employ various testing methods to validate the quality of headlights, including:

- Photometric Testing: This measures the light output and distribution of the headlight to ensure it meets regulatory standards.

- Thermal Cycling Tests: These tests assess the durability of headlights under extreme temperature variations, which is crucial for regions experiencing harsh climates.

- Vibration Testing: Headlights must withstand vibrations from road conditions, making this testing essential for performance validation.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control measures is critical to ensuring product reliability. Buyers can take several actionable steps:

- Conduct Audits: Regular audits of suppliers’ facilities can provide insight into their adherence to quality standards and manufacturing processes.

- Request Quality Reports: Suppliers should provide documentation that outlines their quality control procedures, test results, and compliance with relevant standards.

- Engage Third-Party Inspectors: Utilizing independent inspectors can offer unbiased assessments of a supplier’s manufacturing capabilities and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers from different regions face various certification and quality control challenges. For instance:

- Africa: Buyers should be aware of local regulations that may require specific certifications, such as the SABS mark in South Africa.

- South America: Import regulations may necessitate specific labeling and documentation, affecting compliance with local standards.

- Middle East: Buyers should consider certifications like the Gulf Conformity Mark, which ensures compliance with local safety standards.

- Europe: The CE marking process can be complex, requiring thorough documentation and testing to meet EU regulations.

Understanding these nuances allows buyers to navigate the global supply chain more effectively, ensuring they source headlights that not only meet their needs but also comply with local standards and regulations.

Conclusion: Why Is Quality Assurance Crucial for Headlight Manufacturing?

In conclusion, the manufacturing processes and quality assurance measures in headlight production are integral to ensuring safety, reliability, and performance. For B2B buyers, being informed about these processes and standards is essential for making strategic purchasing decisions and building long-term supplier relationships. By prioritizing quality assurance, buyers can mitigate risks and enhance their product offerings in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to change a headlight’

To successfully procure the necessary components for changing a headlight, it’s essential to follow a structured approach. This guide provides a checklist tailored for B2B buyers, focusing on the critical steps to ensure a smooth sourcing process for headlight bulbs and related accessories.

Step 1: Assess Your Vehicle’s Requirements

Understanding the specific headlight needs for different vehicles is paramount. Each make and model may require unique bulb types and specifications. Gather information on the required bulb sizes and types (e.g., halogen, HID, or LED) by consulting vehicle manuals or manufacturer specifications.

Step 2: Identify Reputable Suppliers

Choosing reliable suppliers is vital to ensure quality and compliance. Research potential suppliers by reviewing their business history, industry reputation, and customer feedback. Focus on suppliers that specialize in automotive parts and have a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Product Quality and Standards

It’s essential to ensure that the headlight bulbs meet international safety and quality standards. Look for certifications such as ISO or relevant automotive standards that validate product safety and performance. High-quality bulbs not only enhance visibility but also reduce the likelihood of frequent replacements.

Step 4: Compare Pricing and Bulk Purchase Options

Once you have a list of potential suppliers, compare their pricing structures. Inquire about bulk purchase discounts, as buying in larger quantities often leads to significant cost savings. Additionally, evaluate the total cost of ownership, including shipping and potential tariffs, especially for international transactions.

Step 5: Check Availability and Lead Times

Confirm the availability of the required headlight bulbs and associated products. Understanding lead times for delivery is crucial, especially for businesses that rely on timely repairs and maintenance. Ask suppliers for their inventory levels and typical shipping times to avoid disruptions in service.

Illustrative image related to how to change a headlight

Step 6: Request Samples for Testing

Before finalizing your order, request samples of the headlight bulbs you intend to purchase. Testing these samples ensures they meet your quality expectations and compatibility with your vehicles. This step is crucial for maintaining customer satisfaction and minimizing returns.

Step 7: Establish Terms of Service and Support

Finally, clarify the terms of service, including warranty conditions and after-sales support. Establishing a clear understanding of return policies and technical assistance can save time and resources in case of product issues. A responsive supplier with good support can significantly enhance your operational efficiency.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for headlight bulbs, ensuring quality products that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for how to change a headlight Sourcing

Understanding the cost structure and pricing dynamics for sourcing headlight replacement is crucial for B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. This analysis will dissect the cost components involved, identify key price influencers, and offer actionable tips for buyers to maximize cost efficiency.

What Are the Key Cost Components in Headlight Replacement?

-

Materials: The primary cost component in headlight sourcing is the bulb itself, which can vary significantly in price depending on the type (e.g., halogen, HID, LED). Additional materials may include connectors and gaskets that ensure a proper fit and function.

-

Labor: Labor costs can vary based on the complexity of the installation process. Some vehicles may require specialized skills or tools, particularly if the headlight assembly is difficult to access. This can affect the overall service cost if installation is outsourced.

-

Manufacturing Overhead: This includes costs associated with the production facilities, equipment maintenance, and labor used in manufacturing the headlight units. Efficient manufacturing processes can help lower these costs, which may influence the final pricing.

-

Tooling: Custom tooling may be necessary for specific headlight designs, especially for OEM (Original Equipment Manufacturer) parts. This upfront investment can impact pricing, particularly for lower-volume orders.

-

Quality Control (QC): Ensuring that headlight products meet safety and performance standards incurs additional costs. Certifications and testing contribute to the price but can enhance the reliability and marketability of the product.

-

Logistics: Shipping and handling costs vary depending on the location of suppliers and the destination markets. International shipping may involve customs duties and tariffs, which can further inflate prices.

-

Margin: The profit margin applied by manufacturers and distributors will also influence the final price. This can vary widely based on brand positioning and market demand.

What Factors Influence Headlight Pricing in International Markets?

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with higher order volumes. Buyers should negotiate MOQs that align with their sales forecasts to optimize costs.

-

Specifications and Customization: Customized headlights or those with specific features (e.g., enhanced brightness, extended lifespan) can command higher prices. Buyers should assess whether these features align with their market needs before committing to higher-cost options.

-

Materials and Quality Certifications: The choice of materials significantly affects pricing. High-quality, durable materials may result in higher initial costs but can lead to lower total ownership costs due to reduced failure rates.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with proven track records may charge a premium, but they often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international transactions, as they define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. This knowledge can help buyers avoid unexpected costs.

What Are the Best Buyer Tips for Cost Efficiency in Headlight Sourcing?

-

Negotiate Pricing: Engage suppliers in discussions about pricing flexibility, especially for bulk orders. Highlighting long-term partnership potential can also yield better deals.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation costs, maintenance, and longevity of the product. A higher upfront cost may be justified by lower long-term expenses.

-

Understand Pricing Nuances: Be aware of regional pricing variances, especially in emerging markets. Factors such as local demand, currency fluctuations, and import tariffs can significantly affect costs.

-

Conduct Market Research: Regularly review competitors’ pricing and product offerings. Staying informed about market trends can provide leverage in negotiations and help identify cost-effective sourcing options.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better service, faster response times, and more favorable pricing arrangements over time.

Disclaimer for Indicative Prices

Pricing for headlight sourcing can fluctuate based on market conditions, supplier negotiations, and regional factors. Therefore, it is advisable for buyers to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Illustrative image related to how to change a headlight

Alternatives Analysis: Comparing how to change a headlight With Other Solutions

In the automotive industry, changing a headlight is a common maintenance task. However, there are various methods and technologies available to achieve the same end goal: ensuring optimal visibility on the road. This section explores different solutions, comparing the traditional method of changing a headlight bulb with two viable alternatives—headlight restoration kits and LED headlight conversion kits.

| Comparison Aspect | How To Change A Headlight | Headlight Restoration Kit | LED Headlight Conversion Kit |

|---|---|---|---|

| Performance | Restores original brightness | Improves clarity of faded lenses | Significantly brighter, longer-lasting |

| Cost | Moderate (bulb + tools) | Low (one-time purchase) | Higher (conversion kit) |

| Ease of Implementation | Moderate (requires tools) | Easy (user-friendly kits) | Moderate (may require wiring) |

| Maintenance | Periodic bulb replacements | Infrequent (depends on lens condition) | Minimal (lasts for years) |

| Best Use Case | Standard vehicles with traditional bulbs | Vehicles with foggy or yellowed lenses | Vehicles needing enhanced visibility |

What Are the Pros and Cons of Using a Headlight Restoration Kit?

Headlight restoration kits are designed to clear up foggy or yellowed headlight lenses, which can significantly diminish visibility. These kits typically include sandpaper, polish, and a sealant. The primary advantage is cost-effectiveness; they are generally low-cost and easy to use, requiring no special tools. However, they do not address the issue of burned-out bulbs or provide a long-term solution if the lenses degrade again. Therefore, restoration kits are best for maintaining existing headlights rather than replacing them outright.

How Do LED Headlight Conversion Kits Compare?

LED headlight conversion kits offer a modern alternative to traditional halogen bulbs. They provide significantly brighter light and consume less energy, making them an attractive option for many vehicle owners. The installation can be moderately complex, as it may involve wiring changes or the addition of a driver circuit. While the initial investment is higher than standard bulb replacements, the long lifespan and reduced maintenance make LED kits a cost-effective solution over time. However, potential compatibility issues with older vehicles can be a drawback, necessitating careful consideration before purchase.

Conclusion: Which Headlight Solution Is Best for Your Business Needs?

When choosing the right headlight solution for your business, consider the specific needs of your fleet or clients. If the goal is simply to replace a burnt-out bulb, the traditional method of changing a headlight is straightforward and effective. However, for vehicles with deteriorating lenses, a restoration kit may be a more economical choice. Conversely, if upgrading to a more efficient and brighter lighting system is desired, investing in LED conversion kits may yield the best long-term results. Ultimately, understanding the unique requirements and conditions of your vehicles will guide you in selecting the most suitable solution for improved visibility and safety on the road.

Illustrative image related to how to change a headlight

Essential Technical Properties and Trade Terminology for how to change a headlight

What Are the Key Technical Properties to Consider When Changing a Headlight?

When sourcing headlight components for replacement, several critical specifications should be considered to ensure compatibility and performance. Understanding these properties is vital for B2B buyers, particularly in markets where vehicle maintenance plays a significant role in safety and compliance.

1. Bulb Type and Compatibility

Headlight bulbs come in various types, such as halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode). Each type has unique characteristics and compatibility requirements with specific vehicle models. For B2B buyers, knowing the bulb type ensures that the correct products are sourced, minimizing returns and ensuring customer satisfaction.

2. Color Temperature

Measured in Kelvin (K), color temperature affects the light output’s appearance. For instance, halogen bulbs typically emit a warmer light (around 3000K), while HID and LED options can range from 4000K to 6000K or higher, providing a cooler, brighter light. B2B buyers should understand the importance of color temperature not only for aesthetic preference but also for safety, as certain temperatures enhance visibility under different driving conditions.

3. Lifespan and Durability

The lifespan of a headlight bulb is an essential consideration, often indicated in hours. Halogen bulbs may last around 500-1000 hours, while LEDs can last up to 25,000 hours or more. Understanding this specification helps businesses evaluate product performance, reduce frequency of replacements, and improve customer satisfaction through prolonged use.

4. Lumens Output

Lumens measure the total light output of a bulb. Higher lumens indicate brighter light, which can significantly enhance visibility and safety. B2B buyers should prioritize lumens output when selecting headlight products to ensure they meet safety regulations and customer expectations for performance.

5. Voltage and Wattage Ratings

Each bulb has specific voltage and wattage ratings that dictate its power consumption and compatibility with the vehicle’s electrical system. A mismatch can lead to bulb failure or damage to the vehicle’s wiring. For B2B buyers, understanding these specifications is crucial to avoid costly errors and ensure operational efficiency.

What Are Common Trade Terms Relevant to Headlight Replacement?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms that buyers should be aware of:

1. OEM (Original Equipment Manufacturer)

This term refers to parts made by the vehicle’s original manufacturer. OEM headlights are often preferred for their guaranteed compatibility and quality. B2B buyers should consider OEM options when seeking reliable and long-lasting products.

2. MOQ (Minimum Order Quantity)

This refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses to manage inventory effectively and negotiate better pricing with suppliers.

Illustrative image related to how to change a headlight

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products. For B2B buyers, issuing an RFQ can help in comparing costs and making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. Understanding these terms helps businesses navigate logistics and ensure compliance with trade regulations, especially when sourcing products from different countries.

5. Aftermarket Parts

These are parts made by companies other than the original manufacturer. While they can be more affordable, quality and compatibility can vary. B2B buyers should weigh the cost benefits against potential risks associated with aftermarket parts.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, streamline procurement processes, and enhance their overall operational efficiency in the automotive parts market.

Illustrative image related to how to change a headlight

Navigating Market Dynamics and Sourcing Trends in the how to change a headlight Sector

What Are the Current Market Dynamics for Headlight Replacement Solutions?

The global market for automotive lighting, particularly headlight replacement, is experiencing significant transformation driven by technological advancements and evolving consumer preferences. Key trends include the increasing popularity of LED and HID bulbs due to their superior longevity and energy efficiency, as well as a growing demand for adaptive lighting systems that enhance visibility under varying road conditions. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on sourcing high-quality products that comply with international safety standards while also being cost-effective.

Additionally, the rise of e-commerce and digital platforms is reshaping the purchasing landscape. International buyers are increasingly leveraging online marketplaces to compare products, read reviews, and make informed decisions. This trend is amplified by the demand for vehicle-specific parts, which necessitates accurate product descriptions and compatibility information. Consequently, suppliers are investing in technology to enhance their inventory management and improve customer experience through personalized recommendations and streamlined logistics.

Moreover, there is a noticeable shift towards sourcing from local suppliers in emerging markets, which not only reduces lead times but also fosters community development. Buyers are keen on establishing partnerships with manufacturers that can provide consistent quality and reliable support. Understanding these dynamics is crucial for international B2B buyers as they navigate their sourcing strategies in the headlight replacement sector.

Illustrative image related to how to change a headlight

How Is Sustainability Influencing the Headlight Replacement Industry?

Sustainability is becoming a cornerstone of procurement strategies in the automotive sector, including headlight replacement. B2B buyers are increasingly recognizing the environmental impact of their sourcing decisions, especially regarding the lifecycle of automotive lighting products. The production and disposal of traditional halogen bulbs can contribute to significant waste and energy consumption. As a result, there is a growing emphasis on sourcing LED and other energy-efficient alternatives that not only reduce the carbon footprint but also offer longer service life.

Ethical sourcing is also gaining traction, with buyers prioritizing suppliers who adhere to sustainable practices throughout their supply chains. This includes obtaining ‘green’ certifications that indicate compliance with environmental standards, using recyclable materials, and implementing responsible manufacturing processes. In regions like Europe, where regulatory frameworks around sustainability are stricter, buyers are more likely to favor suppliers who can demonstrate a commitment to ethical practices.

Furthermore, the demand for transparency in supply chains is rising. Buyers are seeking detailed information about the sourcing of raw materials and the environmental policies of their suppliers. This trend underscores the importance of choosing manufacturers who are not only focused on profitability but also on minimizing their environmental impact. Thus, international B2B buyers must align their procurement strategies with sustainability goals to remain competitive and meet the expectations of eco-conscious consumers.

What Is the Historical Context of Headlight Technology Development?

The evolution of headlight technology reflects broader advancements in automotive engineering and consumer safety standards. Initially, vehicles were equipped with simple incandescent bulbs, which offered limited visibility and efficiency. The introduction of halogen bulbs in the 1960s represented a significant improvement, providing brighter light and longer life spans.

The late 20th century saw the advent of High-Intensity Discharge (HID) bulbs, which utilized an electric arc to produce a more intense light, thereby enhancing nighttime visibility. This innovation was followed by the rapid adoption of Light Emitting Diodes (LEDs) in the 21st century. LEDs not only offer superior energy efficiency and longevity but also provide manufacturers with the flexibility to design more compact and stylish lighting solutions.

As regulations around automotive safety have tightened globally, the focus on headlight performance has intensified. Today, B2B buyers are tasked with navigating a complex landscape of products that vary in technology, compliance, and environmental impact. Understanding the historical context of these advancements can provide valuable insights for sourcing decisions, ensuring that buyers select the most effective and sustainable headlight solutions for their markets.

Frequently Asked Questions (FAQs) for B2B Buyers of how to change a headlight

-

How do I solve the problem of a headlight not working after replacement?

If a headlight remains non-functional after you’ve replaced the bulb, the issue may not be with the bulb itself. First, check the fuse associated with the headlight circuit; a blown fuse could indicate a deeper electrical issue. If the fuse is intact, inspect the wiring and connections for any signs of damage or corrosion. If troubleshooting reveals an unresolved problem, consider consulting a professional mechanic or your supplier for assistance, as they can provide insights based on their expertise in automotive lighting systems. -

What is the best type of headlight bulb for increased visibility?

When sourcing headlight bulbs for improved visibility, consider options like LED or HID (High-Intensity Discharge) bulbs, which offer brighter and more efficient lighting compared to traditional halogen bulbs. LED bulbs provide a longer lifespan and consume less energy, while HID bulbs can produce a significant amount of light. Evaluate the specific needs of your vehicles, including color temperature and throw distance, to determine the best fit. Engaging with suppliers who can provide detailed specifications and recommendations will help you make an informed choice. -

What factors should I consider when sourcing headlight bulbs internationally?

When sourcing headlight bulbs internationally, consider the compliance with local regulations and standards, which can vary significantly across regions. Evaluate the supplier’s certifications and product specifications to ensure they meet your market’s requirements. Additionally, assess the quality assurance processes the supplier has in place to avoid subpar products. It’s also beneficial to understand the logistics involved in shipping these products, including potential tariffs and delivery timelines, to ensure a seamless supply chain. -

How can I vet suppliers for headlight bulbs effectively?

To vet suppliers, start by researching their reputation within the industry. Look for reviews and testimonials from other B2B buyers, and verify their experience in manufacturing or distributing automotive lighting products. Request samples to assess product quality firsthand. It’s also advisable to inquire about their production capacity, lead times, and adherence to international quality standards, such as ISO certifications. Establishing clear communication about your specific requirements will further ensure that they can meet your needs. -

What are common minimum order quantities (MOQs) for headlight bulbs?

Minimum order quantities (MOQs) for headlight bulbs can vary widely depending on the manufacturer and the type of bulb. Typically, MOQs can range from 100 to 1,000 units. When negotiating with suppliers, clarify their MOQ policies, as some may offer flexibility for new customers or bulk orders. Understanding your inventory needs and sales forecasts will help you negotiate better terms and avoid overcommitting to stock that may not sell. -

What payment terms should I expect when sourcing headlight bulbs?

Payment terms can differ significantly among suppliers, but common practices include upfront payments, net 30, or net 60 terms. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Additionally, discuss any potential discounts for early payments or bulk purchases. Establishing clear payment terms upfront can prevent misunderstandings and ensure a smooth transaction process. -

How do I ensure quality assurance when purchasing headlight bulbs?

To ensure quality assurance, request detailed specifications and certifications for the headlight bulbs from your supplier. Inquire about their quality control processes, including testing methods and standards compliance. Consider conducting periodic inspections or audits of their manufacturing facilities if feasible. Establishing a clear return and warranty policy is also crucial, as it provides recourse should the products not meet your quality expectations. -

What logistics considerations should I keep in mind when importing headlight bulbs?

When importing headlight bulbs, consider factors such as shipping methods, customs regulations, and potential tariffs. Work with logistics partners who have experience in handling automotive components to streamline the process. Ensure all documentation is in order to avoid delays at customs. Additionally, factor in lead times for production and shipping to align with your inventory needs, helping to maintain a steady supply for your customers.

Top 2 How To Change A Headlight Manufacturers & Suppliers List

1. J.D. Power – Headlight Bulbs Guide

Domain: jdpower.com

Registered: 1995 (30 years)

Introduction: Headlight bulbs are essential for nighttime and foul weather driving. Common causes of headlight failure include age, extreme temperature changes, damage to the light housing, and oxidation. To determine if the issue is a blown bulb or a fuse, check if one or both headlights are out. If only one is out, it’s likely a bulb issue; if both are out, check the fuse. Changing a headlight bulb involves f…

2. Infiniti – Headlight Bulb Replacement Guide

Domain: infinitidanbury.com

Registered: 2021 (4 years)

Introduction: This company, Infiniti – Headlight Bulb Replacement Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how to change a headlight

In summary, understanding the intricacies of headlight replacement is crucial for international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. Strategic sourcing of headlight bulbs and related components not only ensures compliance with regional regulations but also enhances vehicle safety and performance. By selecting high-quality products that match specific vehicle requirements, businesses can reduce the frequency of replacements and improve overall customer satisfaction.

Investing in reliable suppliers who provide a range of options—from standard bulbs to advanced LED systems—can significantly impact maintenance efficiency and operational costs. Moreover, considering the implications of different bulb technologies, such as color temperature and throw distance, can help in making informed purchasing decisions that align with customer needs.

Illustrative image related to how to change a headlight

Looking ahead, businesses should leverage this knowledge to foster partnerships with reputable suppliers and explore innovative solutions in automotive lighting. By prioritizing strategic sourcing, you can enhance your competitive edge in the marketplace. Engage with your suppliers today to ensure that you have access to the best headlight solutions for your fleet, optimizing both safety and performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.