Introduction: Navigating the Global Market for how much to get alternator fixed

In today’s rapidly evolving automotive landscape, understanding how much to get an alternator fixed can be a significant challenge for international B2B buyers. Whether you’re sourcing components for vehicle maintenance in Nigeria or negotiating repair services in Vietnam, knowing the intricacies of alternator repairs is essential. This guide delves into the various types of alternators, their applications across different vehicle models, and the factors influencing repair costs.

With estimated replacement costs ranging from $600 to $1,500, it’s crucial for businesses to navigate supplier options effectively to ensure they receive quality parts and services at competitive prices. Additionally, we will explore the importance of vetting suppliers, understanding warranty implications, and distinguishing between new, remanufactured, and aftermarket alternators.

By equipping buyers with actionable insights and comprehensive knowledge, this guide empowers decision-makers to make informed purchasing choices that align with their operational needs. Whether you are a fleet manager in South America or an automotive parts distributor in the Middle East, understanding these dynamics will enhance your procurement strategies and ultimately improve your bottom line. Join us as we navigate the complexities of alternator repairs and replacements to optimize your business operations in the global market.

Table Of Contents

- Top 3 How Much To Get Alternator Fixed Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much to get alternator fixed

- Understanding how much to get alternator fixed Types and Variations

- Key Industrial Applications of how much to get alternator fixed

- 3 Common User Pain Points for ‘how much to get alternator fixed’ & Their Solutions

- Strategic Material Selection Guide for how much to get alternator fixed

- In-depth Look: Manufacturing Processes and Quality Assurance for how much to get alternator fixed

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much to get alternator fixed’

- Comprehensive Cost and Pricing Analysis for how much to get alternator fixed Sourcing

- Alternatives Analysis: Comparing how much to get alternator fixed With Other Solutions

- Essential Technical Properties and Trade Terminology for how much to get alternator fixed

- Navigating Market Dynamics and Sourcing Trends in the how much to get alternator fixed Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much to get alternator fixed

- Strategic Sourcing Conclusion and Outlook for how much to get alternator fixed

- Important Disclaimer & Terms of Use

Understanding how much to get alternator fixed Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Alternator Replacement | Original equipment manufacturer parts; typically new and reliable. | Fleet management, dealerships, repair shops | Pros: High reliability, warranty coverage. Cons: Higher cost. |

| Remanufactured Alternator | Rebuilt units that meet OEM specifications; more affordable option. | Auto repair shops, fleet services | Pros: Cost-effective, environmentally friendly. Cons: Potential variability in quality. |

| Aftermarket Alternator | Non-OEM parts that may offer enhanced performance or features. | Performance upgrades, specialized repairs | Pros: Customization options, competitive pricing. Cons: May lack warranty or reliability. |

| Used Alternator | Second-hand units; often the cheapest option available. | Budget-conscious repairs, older vehicles | Pros: Very low cost, quick availability. Cons: Shorter lifespan, no warranty. |

| Hybrid/EV Alternator Solutions | Specialized components for hybrid or electric vehicles. | Electric vehicle manufacturers, fleet operators | Pros: Long-lasting, often covered under extended warranties. Cons: Limited availability and higher upfront costs. |

What are the Characteristics of OEM Alternator Replacements?

OEM (Original Equipment Manufacturer) alternators are designed to meet the specific standards set by vehicle manufacturers. These parts are new, ensuring optimal performance and reliability. Businesses managing fleets or dealerships often prefer OEM replacements due to their warranty coverage and compatibility with the vehicle’s systems. However, the higher cost can be a consideration for budget-conscious buyers.

How Do Remanufactured Alternators Compare?

Remanufactured alternators are refurbished units that adhere to OEM specifications. They provide a cost-effective solution for businesses, particularly repair shops and fleet services looking to balance quality and expense. While remanufactured parts are generally reliable, there can be variability in quality depending on the remanufacturer. Buyers should inquire about warranties and the reputation of the remanufacturing company.

What are the Benefits of Aftermarket Alternators?

Aftermarket alternators offer an alternative to OEM parts, often incorporating enhancements that improve performance. These are particularly popular among businesses focused on performance upgrades or specialized repairs. However, while they can be competitively priced, aftermarket parts may not always come with warranties or the same level of reliability as OEM parts. Buyers should assess their specific needs and the trade-offs involved.

When Should a Business Consider Used Alternators?

Used alternators are the most budget-friendly option, ideal for businesses managing older vehicles or those looking for quick fixes without significant investment. While they can be readily available and inexpensive, the trade-off includes a shorter lifespan and lack of warranty. For B2B buyers, this option is suitable for non-critical applications where cost savings are paramount.

What are the Unique Considerations for Hybrid/EV Alternator Solutions?

Hybrid and electric vehicles utilize specialized components that differ from traditional alternators. These solutions are typically more durable and may be covered under extended warranties. Businesses operating fleets of hybrid or electric vehicles should invest in these components for long-term reliability. However, the initial costs can be higher, and availability may be limited, necessitating careful procurement planning.

Key Industrial Applications of how much to get alternator fixed

| Industry/Sector | Specific Application of how much to get alternator fixed | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Cost estimation for alternator replacements in service centers | Improved budgeting and service pricing accuracy | Local sourcing for parts, labor rates, warranty options |

| Transportation & Logistics | Ensuring fleet vehicles are operational with reliable alternators | Reduced downtime and increased productivity | Supplier reliability, part availability, and turnaround time |

| Agricultural Machinery | Maintaining agricultural equipment with functioning alternators | Enhanced productivity during critical seasons | Compatibility with specific machinery models, cost-effectiveness |

| Construction Equipment | Managing costs for alternator repairs in heavy machinery | Cost control and efficient project management | Quality of parts, local repair expertise, and lead times |

| Renewable Energy | Upkeep of hybrid or electric vehicles in service fleets | Long-term savings and sustainability goals | Access to advanced parts, service capabilities, and warranties |

How is Cost Estimation for Alternator Replacements Used in Automotive Repair?

In the automotive repair industry, understanding the costs associated with alternator replacements is vital for service centers. By accurately estimating these costs, repair shops can provide competitive pricing, ensuring transparency with customers. This application is crucial for building trust and loyalty, especially in regions where consumers are price-sensitive. Buyers need to consider local labor rates, parts sourcing, and warranty options to ensure they remain competitive while maintaining quality service.

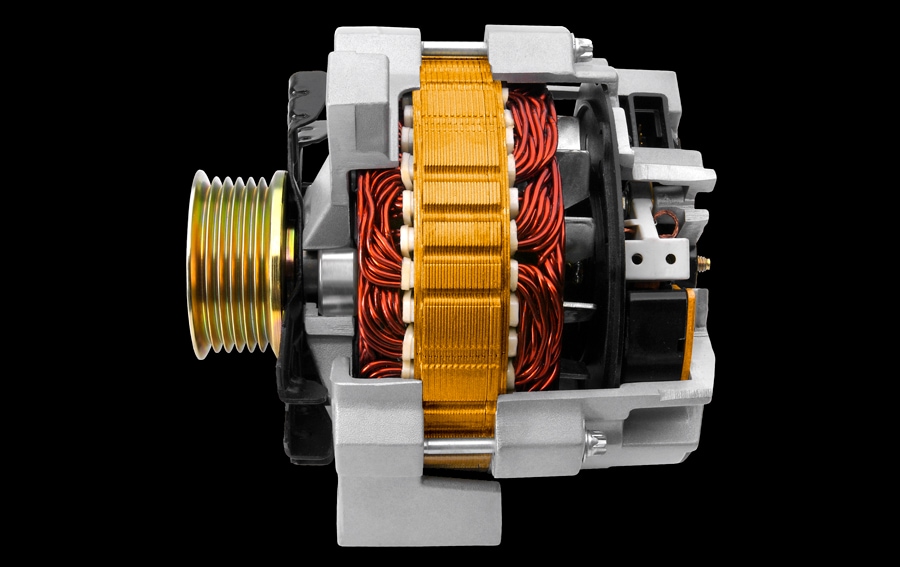

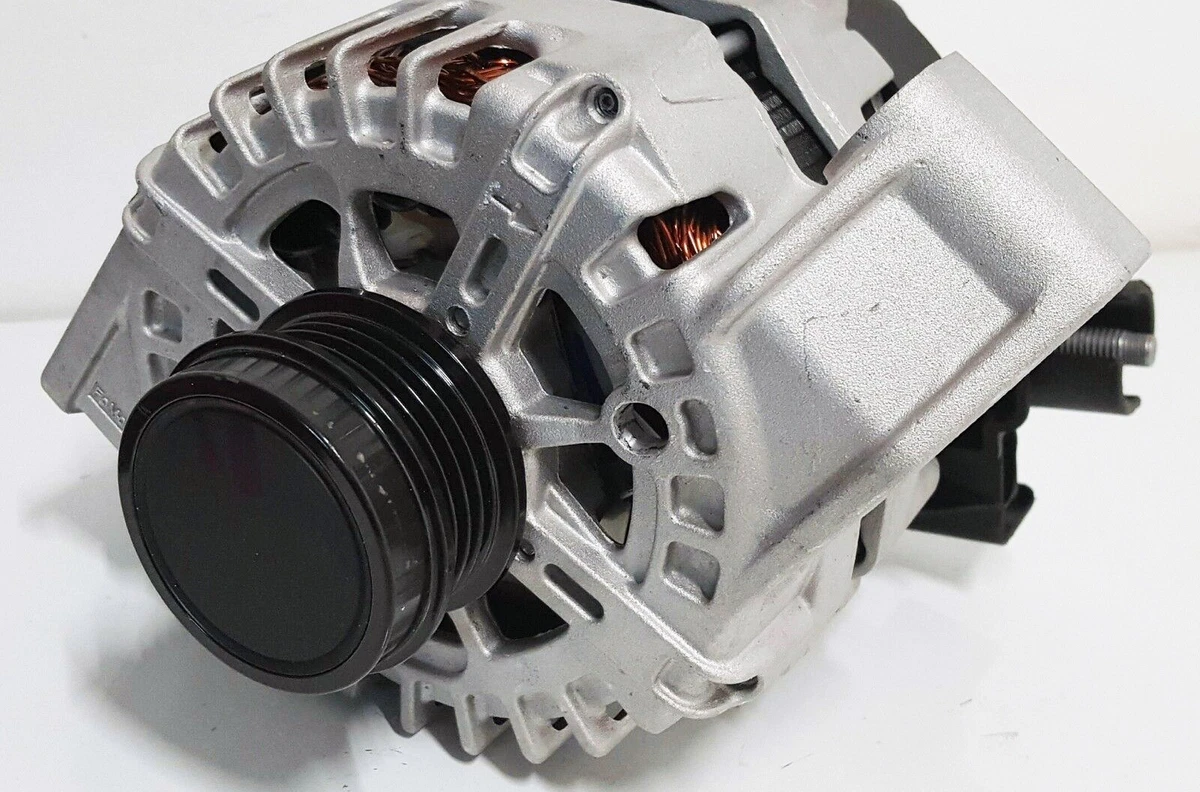

Illustrative image related to how much to get alternator fixed

What Role Does Alternator Repair Cost Play in Transportation & Logistics?

For businesses in transportation and logistics, the reliability of fleet vehicles is paramount. Knowing how much it costs to fix alternators helps fleet managers plan maintenance schedules and budgets effectively. This proactive approach minimizes downtime, ensuring that logistics operations run smoothly. Buyers should focus on supplier reliability and the availability of parts to prevent delays, which can be critical in regions with less developed supply chains.

How Does Agricultural Machinery Depend on Alternator Repair Costs?

In agriculture, machinery often relies on well-functioning alternators for optimal performance. Understanding repair costs allows farmers to budget for necessary maintenance, especially during peak seasons when equipment is critical. This application helps avoid costly breakdowns that can lead to lost productivity. Buyers should prioritize compatibility with specific machinery models and seek cost-effective solutions that do not compromise quality.

Why is Understanding Alternator Repair Costs Important for Construction Equipment?

Construction companies depend on heavy machinery, where alternator functionality is essential for operations. Knowing the costs associated with repairs allows for better project management and financial planning. This understanding helps control costs and ensures that projects remain on schedule. Buyers need to assess the quality of parts and local repair expertise to mitigate risks associated with prolonged downtime.

Illustrative image related to how much to get alternator fixed

How Do Renewable Energy Fleets Benefit from Knowledge of Alternator Repair Costs?

In the renewable energy sector, particularly with hybrid and electric vehicles, maintaining operational efficiency is crucial. Understanding the costs of alternator repairs or replacements aids in long-term financial planning and sustainability goals. This knowledge helps businesses optimize their fleets for performance and reliability. Buyers should focus on access to advanced parts and service capabilities to ensure their fleets operate efficiently and sustainably.

3 Common User Pain Points for ‘how much to get alternator fixed’ & Their Solutions

Scenario 1: Unexpected High Repair Costs

The Problem:

B2B buyers often face sticker shock when receiving quotes for alternator repairs. The costs can range from $600 to $1,500, depending on the vehicle model and labor rates in different regions. For companies managing fleets, an unexpected repair bill can disrupt budgeting and financial planning. This is particularly true for businesses in emerging markets, where financial resources may be more constrained. Understanding the sudden rise in repair costs can also be challenging due to fluctuating prices for parts and labor.

The Solution:

To navigate unexpected high repair costs, B2B buyers should implement a proactive vehicle maintenance strategy that includes regular diagnostics and inspections. Establishing relationships with multiple trusted mechanics or automotive service providers can also foster competitive pricing and greater transparency. Requesting detailed quotes that break down parts and labor costs can help in identifying areas for potential savings. Additionally, consider investing in extended warranties or service plans that cover alternator replacements, which can mitigate the financial impact of sudden repairs. Conducting market research on typical repair costs in different regions can provide valuable insights, enabling buyers to negotiate better terms or seek more affordable options.

Illustrative image related to how much to get alternator fixed

Scenario 2: Difficulty in Finding Qualified Technicians

The Problem:

In many regions, especially in emerging markets, finding qualified technicians capable of diagnosing and replacing alternators can be a significant challenge. This scarcity can lead to prolonged downtime for vehicles, negatively impacting business operations and productivity. Companies may struggle with inexperienced technicians who might not perform repairs correctly, leading to further complications and additional costs down the line.

The Solution:

To address the challenge of finding qualified technicians, B2B buyers should consider investing in training programs for their existing staff. Collaborating with local vocational schools or technical institutes can create a pipeline of skilled technicians. Additionally, maintaining an updated database of certified service providers can streamline the repair process. When selecting a repair shop, prioritize those with strong reputations, verified reviews, and a history of working with similar vehicle models. Establishing long-term partnerships with reliable service providers can also ensure that technicians are familiar with the specific needs of your fleet, leading to quicker and more effective repairs.

Scenario 3: Confusion Over Warranty Coverage

The Problem:

B2B buyers often encounter confusion regarding warranty coverage for alternators. Many new vehicle warranties cover alternators only for a limited time, leaving businesses uncertain about their financial responsibilities as the warranty expires. This uncertainty can lead to overspending on repairs or overlooking critical replacement needs, resulting in further vehicle downtime.

The Solution:

To eliminate confusion over warranty coverage, B2B buyers should maintain meticulous records of warranty documentation and service history for each vehicle in their fleet. Regularly reviewing these documents, especially before the warranty expiration, can help identify which repairs are covered. Moreover, engaging directly with manufacturers or dealerships to clarify warranty specifics can provide peace of mind. Buyers should also explore the option of purchasing extended warranties specifically covering alternators and other critical components. Understanding the terms and conditions of these warranties will allow for better financial forecasting and decision-making regarding vehicle maintenance.

Illustrative image related to how much to get alternator fixed

Strategic Material Selection Guide for how much to get alternator fixed

What Are the Key Materials Used in Alternator Repair?

When considering the repair or replacement of an alternator, the selection of materials is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials used in alternator components, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Copper in Alternator Components?

Copper is widely used in alternators primarily for its excellent electrical conductivity. It can efficiently transfer electrical current, which is essential for the alternator’s function of charging the battery and powering electrical components in the vehicle. Copper also offers good corrosion resistance, making it suitable for automotive applications where exposure to various environmental conditions is common.

Pros & Cons: The durability of copper is high, but its cost can be significant, especially with fluctuating market prices. Manufacturing complexity is moderate, as copper can be easily shaped and formed into wires and connectors. However, its weight can be a disadvantage in applications where weight reduction is critical.

Impact on Application: Copper’s compatibility with various media is excellent, as it does not react adversely with automotive fluids. However, its thermal expansion properties must be considered in high-temperature applications.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of local sourcing options for copper, as import tariffs can affect overall costs. Compliance with international standards such as ASTM B170 is also essential to ensure quality.

How Does Aluminum Compare for Alternator Components?

Aluminum is another common material used in alternators, particularly in the housing and structural components. It is lightweight and has good thermal conductivity, which helps dissipate heat generated during operation.

Pros & Cons: The primary advantage of aluminum is its low weight, which can improve fuel efficiency in vehicles. However, aluminum is less durable than copper and can be prone to corrosion if not properly treated. Manufacturing complexity is lower than that of copper, as aluminum can be easily extruded or cast.

Illustrative image related to how much to get alternator fixed

Impact on Application: Aluminum is suitable for environments where weight savings are prioritized, but it may not perform as well in high-stress applications compared to steel or copper.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local standards, such as DIN 1725 for aluminum alloys, and consider the availability of treated aluminum to prevent corrosion.

What Role Does Steel Play in Alternator Durability?

Steel is often used for the structural components of alternators, including the frame and brackets. Its high strength and durability make it suitable for applications that require robust support.

Pros & Cons: Steel’s primary advantage is its strength and resistance to deformation under load. However, it is heavier than aluminum and can be susceptible to rust if not properly coated. Manufacturing complexity is higher due to the need for welding or machining.

Illustrative image related to how much to get alternator fixed

Impact on Application: Steel is ideal for components that experience high mechanical stress, but its weight may negatively impact vehicle performance.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ASTM A36 for structural steel and consider local availability to avoid high shipping costs.

How Important Is Plastic in Modern Alternator Design?

Plastic is increasingly used in alternators for non-structural components such as covers and insulation. It offers excellent electrical insulation properties and can be molded into complex shapes.

Pros & Cons: The lightweight nature of plastic is a significant advantage, along with its resistance to corrosion. However, plastics may not withstand high temperatures as well as metals, leading to potential failures in extreme conditions. Manufacturing complexity can vary based on the type of plastic used.

Impact on Application: Plastic is suitable for components that require insulation from electrical currents, but its thermal limitations must be considered.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with standards like ISO 9001 for quality management systems, particularly in regions with stringent automotive regulations.

Summary Table of Material Selection for Alternator Repair

| Material | Typical Use Case for how much to get alternator fixed | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and electrical connections | Excellent conductivity | High cost and weight | High |

| Aluminum | Housing and structural components | Lightweight and good thermal conductivity | Prone to corrosion | Medium |

| Steel | Structural components like frames | High strength and durability | Heavier and rust-prone | Medium |

| Plastic | Covers and insulation | Lightweight and corrosion-resistant | Limited temperature resistance | Low |

This analysis provides a comprehensive overview of the materials commonly involved in alternator repairs. Understanding these properties and considerations can help B2B buyers make informed decisions tailored to their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how much to get alternator fixed

What Are the Key Stages in the Manufacturing Process of Alternators?

Understanding the manufacturing process of alternators is crucial for B2B buyers who are considering sourcing these components. The production of alternators typically involves several stages: material preparation, forming, assembly, and finishing.

Illustrative image related to how much to get alternator fixed

Material Preparation

The first stage involves sourcing high-quality raw materials. Alternators are primarily made of metals such as aluminum for the housing and copper for the winding. Quality assurance begins at this stage, as materials are inspected for purity and structural integrity. Suppliers often provide certificates of conformity to ensure that materials meet specific international standards.

Forming

Once the materials are prepared, they undergo various forming processes. For the metal housing, techniques such as die casting or stamping are commonly used. These methods allow for precise shapes and sizes, which are critical for the alternator’s performance. During this stage, manufacturers might employ CNC (Computer Numerical Control) machining to ensure high precision in components like the rotor and stator.

Assembly

The assembly stage is where the alternator’s components are brought together. This includes fitting the rotor, stator, and other electrical components into the housing. Automated assembly lines are often used to improve efficiency and reduce human error. Quality checkpoints are crucial here; each assembled unit may undergo functional testing to ensure that it meets specifications before moving on to the next stage.

Finishing

The final stage involves surface treatment and finishing processes. This can include anodizing or painting the exterior for corrosion resistance and aesthetic appeal. At this stage, additional quality checks are performed to ensure the alternator can withstand environmental conditions, especially for buyers in regions with extreme weather.

How Is Quality Assurance Implemented in Alternator Manufacturing?

Quality assurance is integral to the manufacturing process of alternators. International and industry-specific standards guide these practices to ensure reliability and performance.

International Standards and Certifications

Most manufacturers adhere to ISO 9001, a globally recognized standard for quality management systems. Compliance with ISO 9001 ensures that manufacturers have robust processes in place for continuous improvement and customer satisfaction. Additionally, CE marking may be required for products sold in Europe, indicating that the alternator meets EU safety, health, and environmental protection standards.

Quality Control Checkpoints

Quality control (QC) checkpoints are critical at various stages of production:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival. Materials that do not meet specified standards are rejected.

- In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted. This may include measuring dimensions and testing electrical components.

- Final Quality Control (FQC): Before shipping, each alternator undergoes comprehensive testing, including load testing and performance assessments. This ensures that every unit functions correctly under operational conditions.

What Common Testing Methods Are Used in Alternator Quality Assurance?

Testing methods play a pivotal role in ensuring the reliability of alternators. Various techniques are employed to assess different aspects of the product.

Electrical Testing

Electrical testing verifies the alternator’s ability to generate and regulate electrical power. Common methods include:

- Load Testing: Simulates the operational conditions to ensure the alternator can handle the required electrical load without overheating or failing.

- Voltage Regulation Testing: Ensures that the alternator maintains a consistent voltage output under varying loads.

Mechanical Testing

Mechanical integrity is tested through methods such as:

- Vibration Testing: Assesses how well the alternator can withstand operational vibrations without compromising performance.

- Thermal Testing: Evaluates the alternator’s ability to operate under high-temperature conditions, which is critical for longevity.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to ensure product reliability and compliance with regional standards.

Supplier Audits

Conducting audits of potential suppliers is one effective way to assess their quality control measures. This can include on-site inspections of manufacturing facilities and reviewing their quality management systems. It’s advisable to create an audit checklist based on international standards such as ISO 9001.

Requesting Quality Reports

B2B buyers should request detailed quality reports from suppliers. These reports should outline the results of IQC, IPQC, and FQC processes, as well as any certifications achieved. A thorough review of these documents can provide insights into the supplier’s commitment to quality.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control. These inspectors can verify that the manufacturing processes meet international standards and that the finished products comply with specifications.

What Are the Quality Control Nuances for International Buyers?

Navigating quality control nuances is particularly important for B2B buyers in diverse international markets. Buyers should be aware of specific regulations and standards that may vary by region.

Understanding Local Regulations

Different regions may have varying standards for automotive components. For instance, while CE marking is essential in Europe, buyers in Africa or South America may need to consider local certifications. Understanding these differences can prevent compliance issues and ensure smoother logistics.

Cultural Considerations

Cultural factors may also influence quality expectations. Buyers should foster clear communication with suppliers to ensure that quality standards align. Language barriers or differing business practices can lead to misunderstandings, so establishing a rapport is crucial.

Conclusion

Understanding the manufacturing processes and quality assurance measures for alternators is vital for B2B buyers looking to make informed purchasing decisions. By focusing on quality control checkpoints, testing methods, and the nuances of international sourcing, buyers can ensure they select reliable suppliers that meet their operational needs.

Illustrative image related to how much to get alternator fixed

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much to get alternator fixed’

Introduction

In the automotive industry, understanding the costs associated with alternator repairs is essential for B2B buyers, particularly those involved in fleet management or automotive services. This practical sourcing guide outlines a step-by-step checklist to help you navigate the process of procuring alternator repairs or replacements effectively, ensuring you make informed decisions that align with your business needs.

Step 1: Assess Your Vehicle’s Requirements

Before seeking repairs, identify the specific needs of your vehicle or fleet. This includes knowing the make, model, and year of the vehicles that require alternator services. Understanding these specifications will enable you to source the correct parts and services tailored to your vehicles.

- Consider the type of alternator: Different vehicles may require specific types of alternators, such as OEM (Original Equipment Manufacturer) or aftermarket options.

Step 2: Research Local Repair Facilities

Investigate repair shops or service centers in your region. Look for facilities with a strong reputation for quality work and customer service. This step is critical as it helps ensure that you partner with reliable service providers who can meet your repair needs efficiently.

- Check reviews and testimonials: Online platforms and local business directories can provide insights into the experiences of other customers.

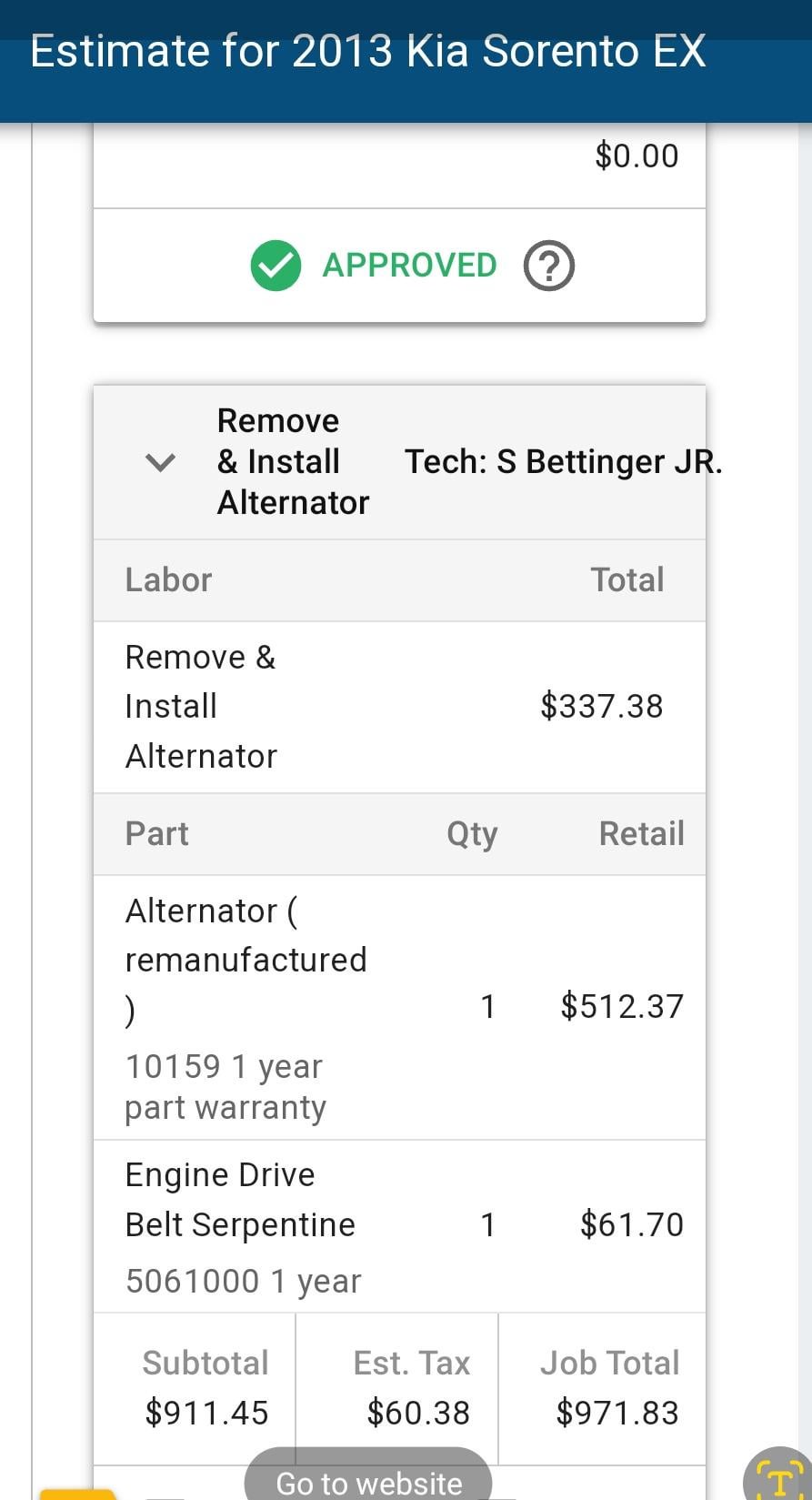

Step 3: Evaluate Cost Estimates

Request detailed estimates from multiple service providers. Understanding the cost breakdown of parts and labor is vital for budgeting purposes.

- Compare quotes: Make sure to compare not only the total cost but also the specifics, such as warranties offered on parts and services, as these can vary significantly.

Step 4: Verify Supplier Certifications

Ensure that the repair shops or suppliers you consider are certified and have the necessary qualifications. Certifications indicate that the technicians have undergone training and adhere to industry standards, which can lead to better service quality.

- Look for industry-specific certifications: Certifications from recognized organizations can provide additional assurance of quality and reliability.

Step 5: Inquire About Warranty Coverage

Before finalizing any service agreements, ask about the warranty offered on both parts and labor. A robust warranty can save your business money and time in the long run, especially if issues arise post-repair.

- Understand warranty terms: Ensure you know the duration and coverage specifics, as some warranties may only cover defects in parts, while others might include labor.

Step 6: Consider Remanufactured or Aftermarket Options

Evaluate the possibility of using remanufactured or aftermarket alternators as a cost-saving measure. These options can be less expensive than new parts while still providing reliable performance if sourced from reputable suppliers.

- Research the reputation of remanufactured parts: Check for suppliers who offer warranties on remanufactured parts, as this can indicate quality assurance.

Step 7: Finalize Your Supplier Choice

After completing the previous steps, select the supplier or service provider that best meets your needs based on quality, cost, and service. Establish clear communication regarding timelines and expectations to ensure a smooth repair process.

- Document the agreement: Keep records of all agreements, warranties, and communications for future reference, which can be valuable in case of disputes or follow-up services.

By following this checklist, B2B buyers can make informed decisions regarding alternator repairs, ensuring both cost-effectiveness and quality service.

Comprehensive Cost and Pricing Analysis for how much to get alternator fixed Sourcing

What Are the Key Cost Components for Alternator Replacement?

When considering the cost to fix an alternator, several key components contribute to the overall pricing structure. These include:

Illustrative image related to how much to get alternator fixed

-

Materials: The cost of the alternator itself can vary significantly depending on whether it is a new, remanufactured, or aftermarket part. Prices typically range from $100 to $800 for the part alone, depending on the make and model of the vehicle.

-

Labor: Labor costs can also vary widely based on geographical location and the complexity of the job. On average, labor costs can range from $100 to $300, depending on the shop rates in the region and the expertise required.

-

Manufacturing Overhead: This includes costs related to the production of the alternator, such as utilities, rent, and administrative expenses. These costs are generally passed on to the buyer in the final pricing of the alternator.

-

Tooling: Specific tools may be required for the installation or replacement of the alternator. This is typically a minor component of the overall cost but can influence pricing if specialized tools are needed.

-

Quality Control (QC): Ensuring the alternator meets quality standards is crucial. QC processes may add to the cost of manufacturing, particularly if the alternator is subject to stringent testing.

-

Logistics: Shipping and handling fees can also impact the final price, especially for international buyers. Costs can increase due to customs duties and import taxes.

-

Margin: Suppliers will add a profit margin to the base cost of the alternator, which can vary based on market demand, competition, and the supplier’s pricing strategy.

How Do Price Influencers Affect Alternator Sourcing for B2B Buyers?

Several factors can influence the pricing of alternators in the B2B marketplace:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to reduced unit prices. B2B buyers can negotiate better rates when ordering in bulk.

-

Specifications and Customization: Custom alternators or those with specific features can incur additional costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials affects the durability and performance of the alternator. Alternators with higher quality standards or certifications may come at a premium.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Established suppliers may charge more but offer better warranties and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect total costs.

What Negotiation Tips Should B2B Buyers Consider for Alternator Repairs?

Negotiating effectively can lead to significant cost savings. Here are some tips:

-

Research Market Prices: Before entering negotiations, conduct thorough research on current market prices for alternators and labor in your region. This knowledge will empower you during discussions.

-

Leverage Volume Orders: If your business requires multiple alternators, negotiate for bulk pricing. Suppliers are often willing to provide discounts for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the alternator, including maintenance and potential failures. Sometimes, a higher upfront cost can result in lower overall expenses due to better quality.

-

Explore Alternative Suppliers: Don’t hesitate to obtain quotes from multiple suppliers. This can provide leverage in negotiations and help you find the best deal.

-

Be Aware of Pricing Nuances: For international buyers, be mindful of fluctuating exchange rates, shipping costs, and potential tariffs that can affect the overall price.

Conclusion

In summary, understanding the comprehensive cost structure and pricing factors related to alternator replacement is essential for B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic negotiation tactics, businesses can optimize their sourcing strategies. Always remain vigilant for indicative prices and ensure that you account for all potential costs to make informed purchasing decisions.

Alternatives Analysis: Comparing how much to get alternator fixed With Other Solutions

Exploring Alternatives to Alternator Repair Costs

When faced with the decision of how to address alternator issues, B2B buyers must consider various alternatives beyond simply fixing or replacing the alternator. Understanding the cost, performance, and maintenance implications of these alternatives can significantly impact operational efficiency and budget management. Below, we compare the costs and benefits of fixing an alternator against two viable alternatives: utilizing a hybrid vehicle system and investing in a battery management system (BMS).

| Comparison Aspect | How Much To Get Alternator Fixed | Hybrid Vehicle System | Battery Management System (BMS) |

|---|---|---|---|

| Performance | Restores full vehicle function | Improved fuel efficiency | Enhanced battery life |

| Cost | $600 – $1,500 | Higher initial investment | Moderate setup and maintenance cost |

| Ease of Implementation | Requires professional installation | Complex retrofitting | Moderate complexity |

| Maintenance | Low post-repair maintenance | Requires specific maintenance | Regular updates needed |

| Best Use Case | Standard vehicles with alternators | Eco-conscious fleets | Fleets with extensive battery use |

What Are the Advantages and Disadvantages of a Hybrid Vehicle System?

Hybrid vehicles use a combination of an internal combustion engine and an electric motor, eliminating the need for a traditional alternator. The primary advantage is improved fuel efficiency and reduced emissions, making them ideal for businesses focused on sustainability. However, the initial investment for hybrid vehicles is typically higher than standard vehicles, which may deter some B2B buyers. Additionally, retrofitting existing fleets to hybrid technology can be complex and costly.

Illustrative image related to how much to get alternator fixed

How Can a Battery Management System (BMS) Enhance Operational Efficiency?

A Battery Management System (BMS) is designed to monitor and manage the charging and discharging of batteries, ensuring optimal performance and longevity. For companies that rely heavily on electric or hybrid vehicles, a BMS can significantly enhance battery life and reliability. While the initial setup and maintenance costs are moderate, businesses may find the investment worthwhile for long-term operational efficiency. The BMS requires regular software updates and monitoring, which can add to the overall management workload.

Conclusion: How Should B2B Buyers Decide on the Right Solution?

Choosing the right solution for alternator issues hinges on several factors, including budget constraints, vehicle usage patterns, and long-term operational goals. B2B buyers should evaluate the total cost of ownership for each option, considering both immediate repair costs and potential savings from improved efficiency. While fixing an alternator may be the simplest and most straightforward approach for traditional vehicles, alternatives like hybrid systems and battery management systems may offer strategic benefits that align with sustainability goals and operational efficiency. Ultimately, the best choice will depend on the specific needs and future vision of the business.

Essential Technical Properties and Trade Terminology for how much to get alternator fixed

What Are the Key Technical Properties of Alternators for Cost Estimation?

When considering the repair or replacement of an alternator, understanding its technical properties is crucial for B2B buyers. Here are some critical specifications that influence both performance and pricing:

-

Material Grade

Alternators are typically constructed from high-quality metals such as aluminum and copper. The choice of materials affects durability, weight, and efficiency. For instance, aluminum is lightweight and resistant to corrosion, making it ideal for automotive applications. Understanding the material grade helps buyers evaluate the longevity and reliability of the alternator, thus impacting total cost of ownership. -

Amperage Rating

The amperage rating indicates the electrical output capacity of an alternator. Most standard alternators range from 60 to 150 amps, depending on vehicle requirements. A higher amperage rating is essential for vehicles with numerous electronic features. B2B buyers must match the amperage to the vehicle’s needs to prevent electrical shortages, which could lead to costly repairs. -

Voltage Output

Alternators typically operate at a voltage output of 12 to 14.5 volts. This specification is crucial for ensuring that the vehicle’s battery is adequately charged. Inadequate voltage output can result in battery failure or poor vehicle performance. Understanding voltage requirements helps buyers select the correct alternator for specific applications, avoiding compatibility issues. -

Bearing Type

The type of bearing used in the alternator (ball or roller bearings) impacts its efficiency and lifespan. Ball bearings provide smoother operation but may wear out faster under heavy loads. In contrast, roller bearings can handle heavier loads and offer greater durability. Buyers should consider the bearing type in relation to their operational environment to ensure optimal performance. -

Tolerance Levels

Tolerance levels dictate the allowable variations in the alternator’s dimensions and performance characteristics. High-tolerance components ensure better fit and function, reducing the likelihood of mechanical failure. B2B buyers should verify tolerance specifications to ensure compatibility with their vehicle models, thereby minimizing the risk of premature failure.

What Are Common Trade Terms Related to Alternator Replacement Costs?

Navigating the terminologies used in the automotive parts industry can be challenging. Here are several essential trade terms relevant to alternator repairs:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the manufacturer of the vehicle. These parts are designed to meet specific vehicle requirements and often come with a warranty. B2B buyers may prefer OEM parts for their reliability, although they usually come at a higher price compared to aftermarket options. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for B2B buyers who need to manage inventory effectively. This term helps in negotiating bulk purchases, potentially lowering per-unit costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing on specific products, such as alternators. This allows buyers to compare prices and negotiate terms. An effective RFQ process can lead to better pricing and improved supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. For B2B buyers importing alternators, understanding Incoterms is essential to avoid unexpected costs and ensure smooth transactions. -

Aftermarket Parts

These are parts manufactured by companies other than the original vehicle manufacturer. Aftermarket alternators can be less expensive than OEM parts but may vary in quality. B2B buyers need to assess the reliability of aftermarket options, especially for critical components like alternators. -

Warranty Period

The warranty period is the time frame during which a part is guaranteed to function without defects. Understanding the warranty terms for alternators can help buyers assess the risk associated with their purchase. A longer warranty can indicate higher confidence in the part’s quality, influencing buying decisions.

By comprehending these technical properties and industry terms, B2B buyers can make more informed decisions regarding alternator repairs and replacements, ultimately impacting their operational efficiency and cost-effectiveness.

Illustrative image related to how much to get alternator fixed

Navigating Market Dynamics and Sourcing Trends in the how much to get alternator fixed Sector

What Are the Current Market Dynamics Impacting the Cost of Alternator Repairs?

The global market for automotive parts, including alternators, is shaped by several key trends and dynamics. One significant driver is the increasing complexity of vehicle electrical systems, particularly with the rise of electric and hybrid vehicles. These systems often require more advanced alternators, which can lead to higher repair costs. Additionally, rising consumer demand for high-performance vehicles has prompted manufacturers to invest in enhanced alternator technologies, which can also affect pricing structures.

International B2B buyers, especially those in regions like Africa, South America, and the Middle East, are witnessing a shift towards online sourcing platforms that facilitate easier access to parts and services. This trend is bolstered by advancements in e-commerce technology, which allow buyers to compare prices and specifications quickly. Moreover, the ongoing global supply chain disruptions, exacerbated by geopolitical tensions and the COVID-19 pandemic, have led to fluctuating prices and availability of automotive parts, including alternators. Buyers must navigate these market dynamics carefully, considering both cost implications and the reliability of their suppliers.

How Is Sustainability Influencing Sourcing Practices for Alternator Repairs?

Sustainability has become a critical factor in sourcing decisions for B2B buyers in the automotive sector. The environmental impact of manufacturing and disposing of automotive parts, including alternators, has prompted companies to seek more sustainable sourcing practices. This includes prioritizing suppliers who utilize recycled materials, offer remanufactured parts, or adhere to environmentally friendly production processes.

Furthermore, the demand for ‘green’ certifications is rising, as businesses look to align with sustainable practices that resonate with environmentally conscious consumers. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming increasingly important in supplier selection. Buyers should evaluate their supply chain partners based on these sustainability criteria to ensure compliance with both regulatory standards and corporate social responsibility goals.

What Historical Trends Have Shaped the Alternator Repair Market?

The alternator repair market has evolved significantly over the past few decades. Initially, alternators were simple mechanical devices that required minimal maintenance. However, with advancements in automotive technology, alternators have become more complex, incorporating sophisticated electronic components. This evolution has increased the costs associated with repairs and replacements, influencing market pricing.

Historically, manufacturers primarily focused on producing new alternators. However, the growing emphasis on sustainability and cost-effectiveness has led to a rise in the remanufacturing sector. Companies now offer remanufactured alternators as a viable alternative to new ones, often at a lower price point, while still providing warranties. This shift not only benefits buyers through cost savings but also reduces environmental waste, aligning with the broader trend towards sustainable practices in the automotive industry.

In conclusion, international B2B buyers must stay informed about these evolving market dynamics, sustainability considerations, and historical trends to make strategic sourcing decisions for alternator repairs.

Illustrative image related to how much to get alternator fixed

Frequently Asked Questions (FAQs) for B2B Buyers of how much to get alternator fixed

-

How do I determine the cost of alternator repair for my fleet vehicles?

To ascertain the cost of alternator repair for your fleet, start by evaluating the make and model of each vehicle, as prices can vary significantly. Obtain quotes from multiple local mechanics or authorized dealerships to compare labor and parts costs. Additionally, consider the geographic location, as labor rates can differ across regions. It’s also beneficial to account for any necessary additional services, such as replacing the accessory belt, which may increase the overall cost. -

What factors influence the cost of alternator replacement in different regions?

The cost of alternator replacement can be affected by several factors, including local labor rates, the availability of parts, and import tariffs in specific regions. In areas with a higher cost of living, labor charges tend to be elevated. Furthermore, if parts need to be imported, shipping costs and customs duties can add to the final price. Currency fluctuations can also impact costs, especially for international buyers sourcing parts from different countries. -

How do I choose the right supplier for alternator parts?

Selecting the right supplier for alternator parts involves assessing their reliability and quality standards. Look for suppliers with positive reviews and established reputations in the automotive industry. Verify their certifications and quality assurance processes, as well as their ability to provide warranties for the parts. Engaging in direct communication with potential suppliers can help clarify their capabilities, lead times, and support for custom orders, ensuring they meet your specific business needs. -

What are the minimum order quantities (MOQ) for alternator parts?

Minimum order quantities for alternator parts can vary widely among suppliers. Some manufacturers may set MOQs based on production costs, while others may offer flexibility for smaller orders, especially for B2B buyers. It is crucial to inquire about MOQs upfront and assess whether they align with your purchasing strategy. Consider consolidating orders with other parts to meet MOQs or negotiating terms that accommodate your needs, especially if you are a smaller business. -

Are there customization options available for alternators?

Yes, many suppliers offer customization options for alternators to meet specific operational requirements. Customization may include modifications to the alternator’s output specifications, size, or mounting configurations. When seeking customized solutions, provide detailed specifications and any performance requirements to the supplier. This ensures that the final product aligns with your vehicle’s needs and enhances operational efficiency. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms can vary significantly based on the supplier’s policies and the nature of the transaction. Common terms may include net 30 or net 60 days, requiring payment within that timeframe after invoice receipt. For first-time orders, suppliers may request partial upfront payments or letters of credit to mitigate risk. Always clarify payment terms before finalizing any agreements to ensure alignment with your cash flow management practices. -

How can I ensure quality assurance for alternator parts?

To ensure quality assurance for alternator parts, establish clear criteria and standards that suppliers must meet. Request documentation of their quality control processes, including certifications such as ISO or TS16949. Regular audits and inspections can also be beneficial, especially for larger orders. Additionally, consider sourcing from suppliers who offer warranties on their products, as this can provide added assurance of quality and reliability. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, several logistics considerations are crucial. First, evaluate shipping options based on cost, speed, and reliability. Understand the customs regulations and duties applicable in your country to avoid unexpected expenses. Additionally, ensure that your supplier can provide the necessary documentation for smooth customs clearance. Planning for potential delays and having a contingency strategy in place can also help maintain your supply chain’s efficiency.

Top 3 How Much To Get Alternator Fixed Manufacturers & Suppliers List

1. Toyota – RAV4 Alternator Replacement

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2006 Toyota RAV4, alternator replacement, $450 including labor.

2. Facebook – Car Repair Quotes

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Car Repair Quotes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. CarTalk – Alternator Replacement Costs

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: The cost to replace an alternator ranges from approximately $600 to $1,500. An alternator is a critical component that converts mechanical force into electrical energy, powering the engine, lights, and charging the battery. Symptoms of a failing alternator include a check engine light, dimming headlights, and the need for jump-starts. Alternators can fail due to mechanical wear or electrical compo…

Strategic Sourcing Conclusion and Outlook for how much to get alternator fixed

What Are the Key Cost Factors for Alternator Repairs?

In summary, the costs associated with alternator repairs can range significantly from $600 to $1,500, influenced by factors such as labor rates, the choice between new or remanufactured parts, and regional pricing variances. For B2B buyers, understanding these cost dynamics is crucial for effective budgeting and procurement strategies. Establishing relationships with reliable local mechanics or authorized dealers can also yield significant savings, as independent shops often offer competitive pricing compared to dealerships.

Why is Strategic Sourcing Essential for Automotive Parts?

Strategic sourcing is vital in ensuring that businesses can secure the best prices and quality for alternators and related components. By leveraging supplier networks and negotiating favorable terms, companies can enhance their supply chain efficiency and reduce operational costs. Additionally, staying informed about warranty options and potential manufacturer goodwill gestures can further optimize repair expenditures.

How Can International Buyers Prepare for Future Alternator Needs?

As the automotive landscape evolves, particularly with the rise of electric vehicles, the demand for traditional alternators may decrease. However, understanding the current market and preparing for potential shifts in sourcing strategies will be essential for international buyers, especially in Africa, South America, the Middle East, and Europe. Embrace the opportunity to connect with diverse suppliers and invest in long-term partnerships that can adapt to changing technologies. Take proactive steps today to ensure your business remains competitive in the ever-evolving automotive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how much to get alternator fixed

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.