Introduction: Navigating the Global Market for how much should a starter cost

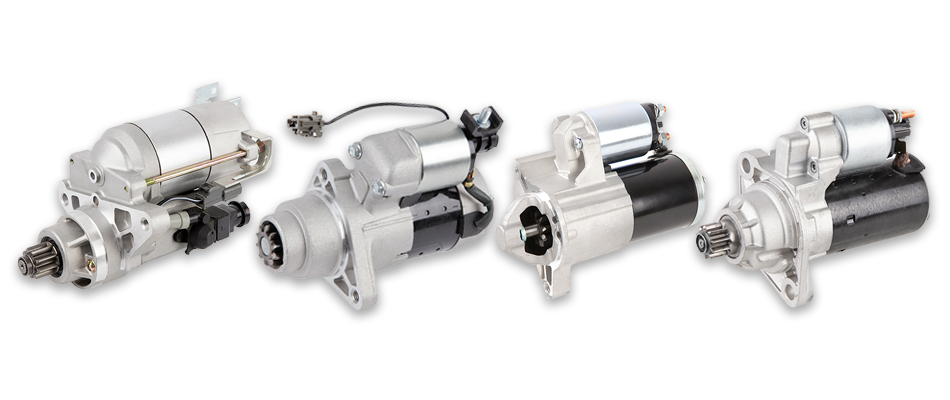

Navigating the complexities of sourcing automotive starters can be a daunting task for international B2B buyers. Understanding how much a starter should cost is crucial for businesses aiming to maintain their fleet or ensure seamless operations in various markets, including Africa, South America, the Middle East, and Europe, such as Brazil and Germany. This comprehensive guide delves into the various types of starters available, their applications across different vehicle models, and the critical factors that influence pricing.

In this guide, we will explore the intricacies of starter costs, including the distinctions between new and rebuilt starters, labor costs for replacement, and the impact of regional pricing variations. We will also discuss essential strategies for vetting suppliers, ensuring that you partner with reputable manufacturers or distributors who can meet your specific requirements. By providing actionable insights and detailed comparisons, this guide empowers B2B buyers to make informed purchasing decisions, ultimately enhancing operational efficiency and cost-effectiveness.

With the automotive industry continually evolving, understanding the nuances of starter pricing and sourcing can lead to significant savings and improved reliability. This resource serves as a vital tool for those seeking to navigate the global market effectively, ensuring that you can procure the right products at competitive prices while maintaining the quality and performance standards your business demands.

Table Of Contents

- Top 5 How Much Should A Starter Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much should a starter cost

- Understanding how much should a starter cost Types and Variations

- Key Industrial Applications of how much should a starter cost

- 3 Common User Pain Points for ‘how much should a starter cost’ & Their Solutions

- Strategic Material Selection Guide for how much should a starter cost

- In-depth Look: Manufacturing Processes and Quality Assurance for how much should a starter cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much should a starter cost’

- Comprehensive Cost and Pricing Analysis for how much should a starter cost Sourcing

- Alternatives Analysis: Comparing how much should a starter cost With Other Solutions

- Essential Technical Properties and Trade Terminology for how much should a starter cost

- Navigating Market Dynamics and Sourcing Trends in the how much should a starter cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much should a starter cost

- Strategic Sourcing Conclusion and Outlook for how much should a starter cost

- Important Disclaimer & Terms of Use

Understanding how much should a starter cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| New Starters | Brand new parts, often OEM; higher reliability and warranty | Fleet maintenance, automotive repair | Pros: High reliability; Cons: Higher cost |

| Rebuilt Starters | Refurbished components; lower cost than new | Cost-sensitive repairs | Pros: Cost-effective; Cons: Variable quality |

| Aftermarket Starters | Non-OEM parts; may offer enhanced features or lower prices | Independent repair shops | Pros: Competitive pricing; Cons: Quality variance |

| High-Performance Starters | Designed for high-torque applications; specialized parts | Racing, heavy-duty vehicles | Pros: Enhanced performance; Cons: Premium pricing |

| Universal Starters | Generic fit for multiple models; versatile | Small garages, DIY mechanics | Pros: Flexibility; Cons: May require modification |

What Are the Key Characteristics of New Starters?

New starters are manufactured to meet original equipment manufacturer (OEM) specifications, ensuring a perfect fit and optimal performance. They typically come with warranties that guarantee reliability over time. B2B buyers in sectors such as fleet maintenance or automotive repair often prefer new starters due to their dependability, despite the higher upfront costs. When purchasing, buyers should consider the warranty terms and the specific vehicle compatibility to ensure they are making a sound investment.

How Do Rebuilt Starters Compare in Cost and Quality?

Rebuilt starters are refurbished parts that have been restored to working condition. They are often significantly cheaper than new starters, making them an attractive option for cost-sensitive repairs. However, quality can vary based on the refurbishment process and the supplier. B2B buyers should evaluate the reputation of the supplier and any guarantees offered. This type is particularly suitable for small repair shops looking to minimize costs while still providing reliable service.

What Are the Advantages of Aftermarket Starters?

Aftermarket starters are produced by third-party manufacturers and can often be more affordable than OEM parts. They may also offer enhanced features, such as improved efficiency or lighter weight. This type of starter is particularly popular among independent repair shops that prioritize competitive pricing. However, buyers must be cautious about potential quality differences and should seek reputable suppliers to ensure they receive reliable products.

When to Choose High-Performance Starters?

High-performance starters are specifically designed for vehicles that require more torque, such as racing cars or heavy-duty trucks. They often feature advanced materials and designs that enhance performance under extreme conditions. While these starters come with a higher price tag, B2B buyers in racing or heavy-duty applications will find their benefits outweigh the costs. Buyers should assess the specific performance requirements of their vehicles to determine if this investment is justified.

What Makes Universal Starters a Flexible Option?

Universal starters are designed to fit a wide range of vehicle makes and models, making them a versatile choice for small garages or DIY mechanics. They can be particularly useful for shops that frequently deal with various vehicle types. However, the trade-off is that these starters may require modifications for proper installation. B2B buyers should weigh the convenience of flexibility against potential installation challenges when considering universal starters for their operations.

Key Industrial Applications of how much should a starter cost

| Industry/Sector | Specific Application of how much should a starter cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Evaluating costs for starter components in vehicle assembly | Optimizes production budgets and enhances profitability | Quality assurance, supplier reliability, and part compatibility |

| Transportation & Logistics | Cost assessment for fleet maintenance and starter replacements | Reduces downtime and maintenance costs | Availability of parts, regional supplier networks, and lead times |

| Heavy Equipment | Determining starter costs for construction machinery | Ensures operational efficiency and minimizes delays | Durability of parts, service support, and warranty terms |

| Agriculture | Sourcing starters for farming equipment | Increases equipment uptime and productivity | Compatibility with various machinery types and local support |

| Energy Sector | Assessing starter costs for generators and turbines | Enhances reliability and performance of energy production | Technical specifications, environmental compliance, and sourcing flexibility |

How is ‘how much should a starter cost’ applied in Automotive Manufacturing?

In the automotive manufacturing sector, accurately assessing the cost of starter components is crucial for optimizing production budgets. Manufacturers need to evaluate the pricing of both new and rebuilt starters to ensure they remain competitive while maintaining quality. This application addresses challenges such as fluctuating material costs and the need for reliable suppliers. B2B buyers in this sector, particularly in regions like Europe and South America, must focus on sourcing from suppliers that offer consistent quality and can meet their production timelines.

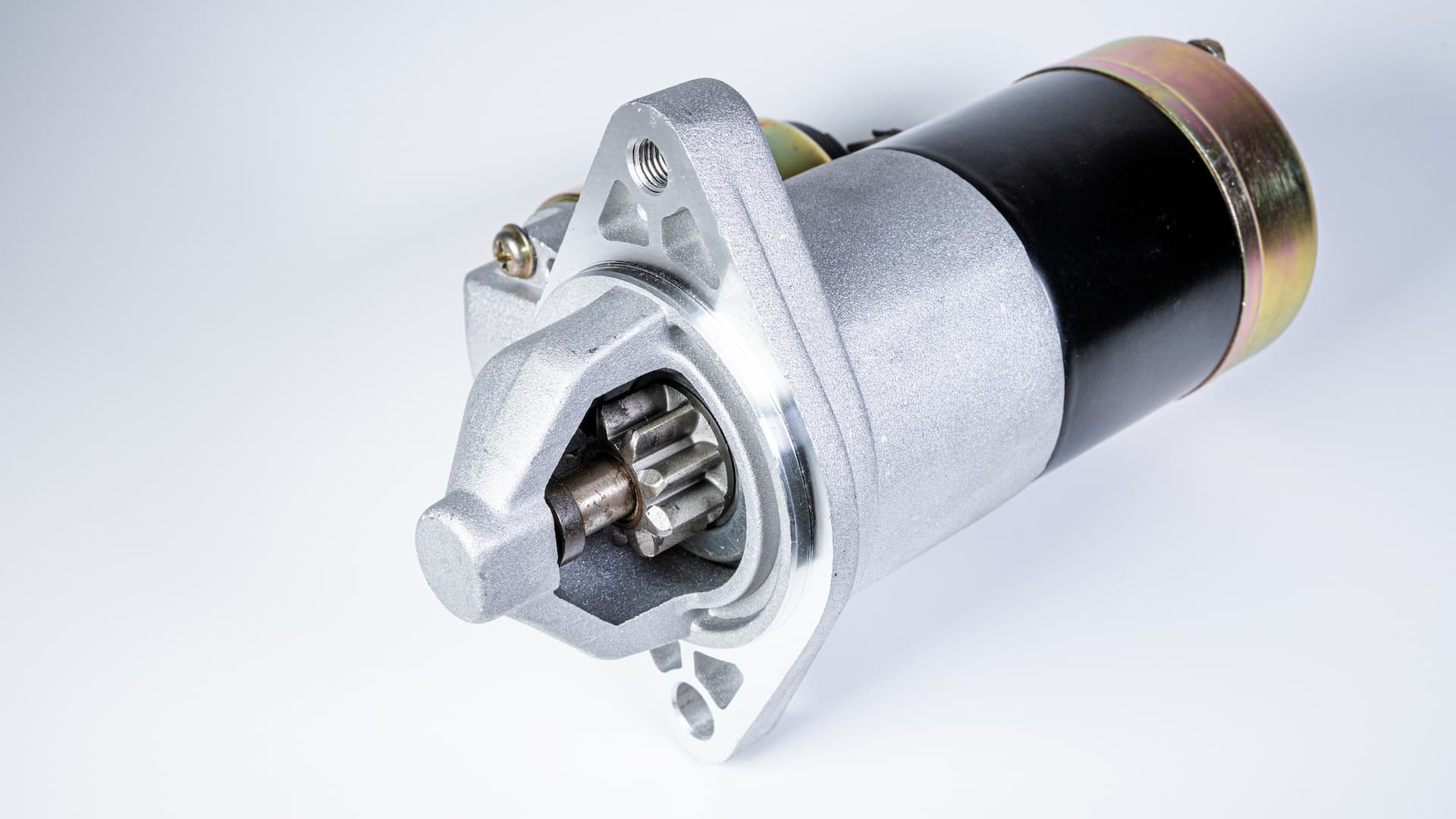

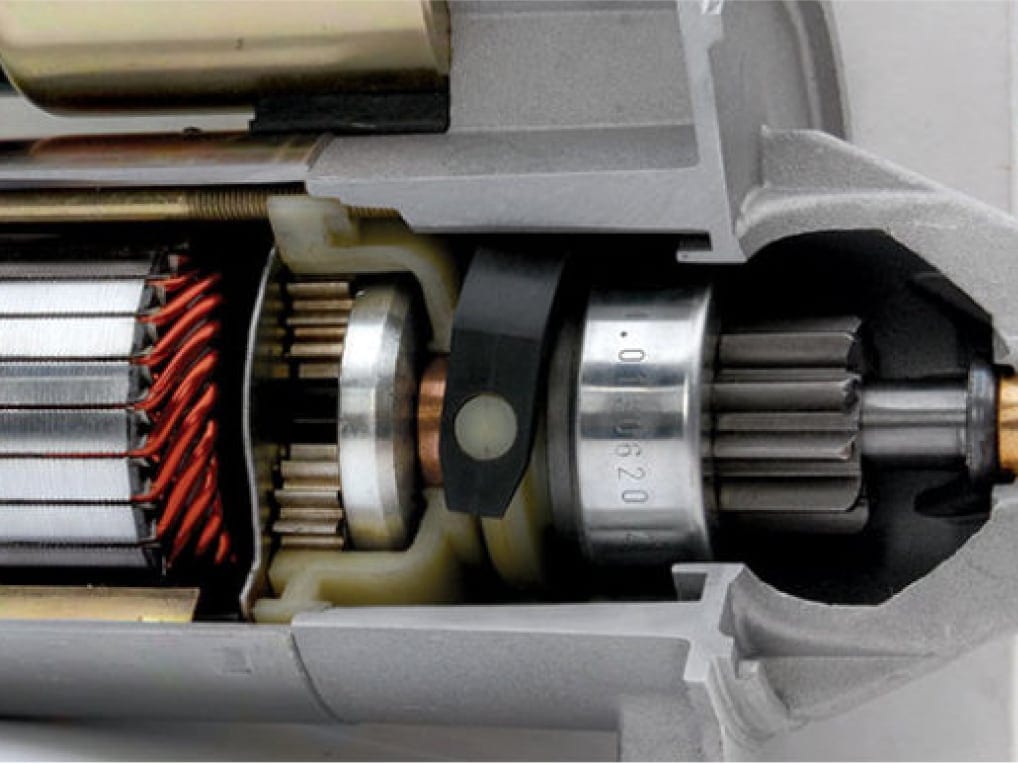

Illustrative image related to how much should a starter cost

What role does starter cost play in Transportation & Logistics?

In the transportation and logistics industry, evaluating the cost of starter replacements is vital for effective fleet maintenance. Businesses must factor in the cost of parts and labor to minimize vehicle downtime, which can lead to significant financial losses. By understanding how much starters cost, fleet managers can make informed decisions about when to replace or repair starters, ultimately enhancing operational efficiency. Buyers in Africa and the Middle East should consider local suppliers who can provide timely support and parts availability to reduce lead times.

Why is starter cost important for Heavy Equipment?

In heavy equipment sectors, such as construction and mining, the cost associated with starters directly impacts machinery uptime. A thorough understanding of starter pricing allows companies to budget effectively for maintenance and repairs, which is essential for project timelines. Additionally, buyers must prioritize sourcing durable parts that can withstand harsh working conditions. Companies in South America and Africa should evaluate suppliers based on their ability to deliver robust solutions tailored for heavy-duty applications.

How does starter cost affect Agricultural operations?

For the agriculture industry, the cost of starters in farming equipment can significantly influence overall productivity. Farmers need to ensure that their machinery is operational and reliable, as any delays can affect harvest schedules and profitability. Understanding the cost structure of starters helps farmers budget for repairs and replacements effectively. B2B buyers in regions like Africa should focus on sourcing parts that are compatible with various types of agricultural machinery and come with robust local support to ensure quick turnaround times.

What is the significance of starter cost in the Energy Sector?

In the energy sector, particularly for generators and turbines, understanding starter costs is critical for ensuring operational reliability. The cost of starters can influence the overall maintenance budget for energy production facilities. B2B buyers must consider technical specifications that meet environmental compliance and performance standards. Additionally, sourcing flexibility is essential, especially for companies operating in diverse regions such as Europe and the Middle East, where regulatory requirements may vary.

3 Common User Pain Points for ‘how much should a starter cost’ & Their Solutions

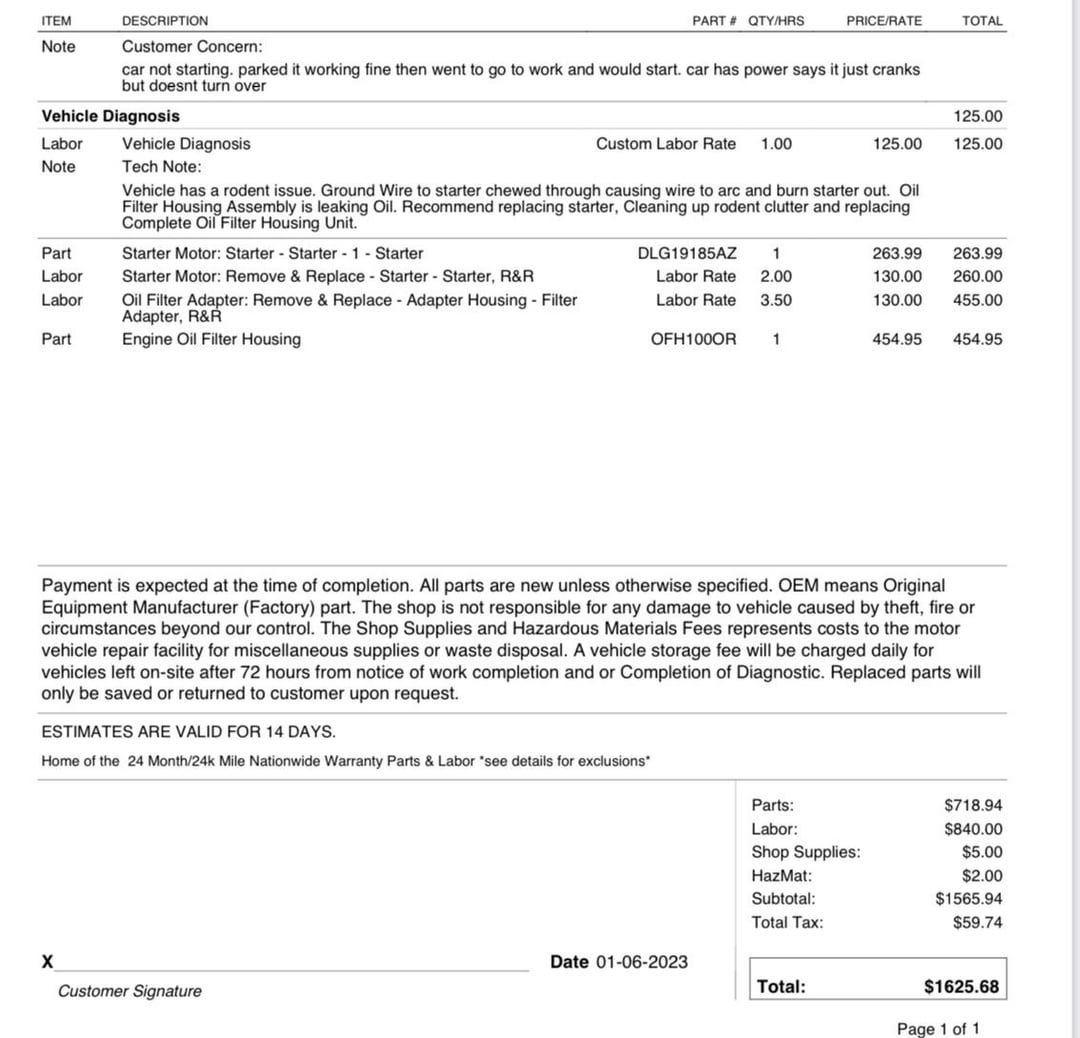

Scenario 1: Difficulty in Estimating Total Replacement Costs for Starters

The Problem:

B2B buyers often face challenges when trying to estimate the total costs associated with replacing starters in their fleet vehicles. The variability in prices—ranging from $50 to over $1,100—can create confusion and lead to budget overruns. Buyers may not be aware that the cost of the starter itself is only part of the equation; they must also consider labor costs, potential additional parts required, and the specific make and model of their vehicles. This lack of clarity can result in over- or under-budgeting, impacting financial planning.

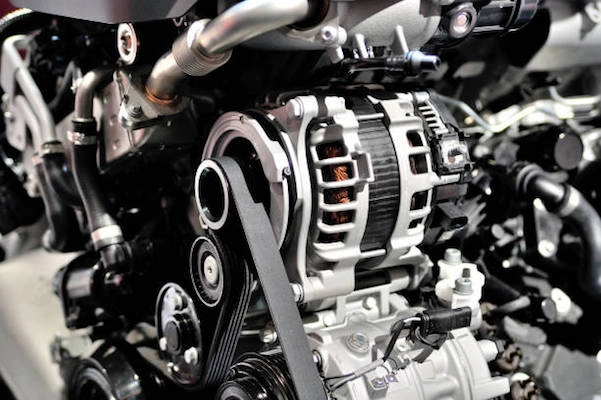

Illustrative image related to how much should a starter cost

The Solution:

To effectively estimate the total replacement costs for starters, buyers should conduct thorough research on the vehicles in their fleet. Start by creating a spreadsheet that includes the make, model, and year of each vehicle. Research the average cost of starters for these specific vehicles from various suppliers, considering both new and rebuilt options. Additionally, engage with multiple mechanics to get quotes on labor costs, including any potential complications that could arise during installation. This proactive approach allows buyers to build a comprehensive budget that accounts for all variables, enabling informed financial decisions.

Scenario 2: Identifying the Root Cause of Starting Issues

The Problem:

Many B2B buyers encounter the frustration of dealing with starting issues in their vehicles without knowing whether the problem lies with the starter or another component of the starting system. This uncertainty not only delays repairs but also leads to unnecessary expenditures on new starters when the actual issue might be a dead battery or a faulty ignition switch. Such misdiagnosis can severely affect the operational efficiency of businesses that rely on their vehicles for daily operations.

The Solution:

To avoid misdiagnosis and unnecessary spending, buyers should invest in a systematic troubleshooting process. Start by training staff to perform basic diagnostic checks, such as testing the battery voltage and inspecting connections for corrosion. Implement a checklist that includes signs of starter failure, such as erratic cranking or unusual noises. Additionally, consider investing in diagnostic tools that can pinpoint issues within the starting system. By empowering staff with knowledge and tools, businesses can quickly identify the root cause of starting issues, ensuring that repairs are both timely and cost-effective.

Scenario 3: Navigating Price Variability Across Different Markets

The Problem:

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, often grapple with price variability for automotive parts like starters. Differences in currency, local market conditions, and supplier availability can lead to significant discrepancies in pricing. This variability makes it challenging for businesses to establish a consistent budget for fleet maintenance, leading to potential financial strain.

The Solution:

To navigate price variability effectively, buyers should establish relationships with multiple suppliers across different regions. Create a network of trusted vendors who can provide competitive quotes and insights into local market conditions. Utilize online platforms that aggregate pricing information from various suppliers to compare costs in real-time. Additionally, consider bulk purchasing agreements or contracts that lock in prices for a specified period, thus minimizing the impact of price fluctuations. By diversifying supplier relationships and leveraging technology, buyers can stabilize their procurement costs and enhance budget predictability.

Strategic Material Selection Guide for how much should a starter cost

What Are the Common Materials Used in Starter Manufacturing?

When considering how much a starter should cost, the materials used in its construction play a crucial role in determining both performance and price. Here, we analyze several common materials used in starter manufacturing, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Steel in Starter Manufacturing?

Steel is a widely used material in starter manufacturing due to its excellent strength and durability. It typically offers high temperature and pressure ratings, making it suitable for automotive applications where reliability is critical. Steel components can withstand the mechanical stresses encountered during engine cranking, ensuring long-lasting performance.

Pros & Cons:

Steel’s primary advantage is its durability and resistance to wear, which can extend the lifespan of the starter. However, it is heavier than other materials, which can affect overall vehicle weight and efficiency. Additionally, steel is susceptible to corrosion if not properly treated, which could lead to premature failure in certain environments.

Illustrative image related to how much should a starter cost

Impact on Application:

Steel starters are compatible with a wide range of automotive applications, particularly in vehicles that require robust starting solutions. However, buyers must consider the environmental conditions in their regions, as high humidity or saline environments could accelerate corrosion.

Considerations for International Buyers:

For buyers in regions like Africa or South America, where environmental conditions may vary significantly, it is essential to ensure that the steel used in starters meets local corrosion resistance standards. Compliance with international standards such as ASTM or DIN can provide assurance of quality.

How Does Aluminum Compare as a Material for Starters?

Aluminum is another common material used in starter production, particularly for housing and casing components. It is known for its lightweight properties, which can contribute to improved vehicle efficiency.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which helps reduce the overall weight of the vehicle, enhancing fuel efficiency. However, aluminum may not be as strong as steel, making it less suitable for high-stress applications. Additionally, it can be more expensive to manufacture due to the complexity of machining and forming processes.

Impact on Application:

Aluminum starters are particularly beneficial in applications where weight reduction is a priority, such as in electric vehicles or performance cars. However, they may not be ideal for heavy-duty applications where high torque is required.

Considerations for International Buyers:

For buyers in Europe, where stringent regulations on vehicle emissions exist, the lightweight properties of aluminum can be a significant advantage. Buyers should also consider the availability of aluminum components that meet local manufacturing standards.

What Role Does Copper Play in Starter Performance?

Copper is often used in the electrical components of starters, such as wiring and contacts, due to its excellent electrical conductivity. This property is essential for efficient current transfer, which is critical for starter performance.

Pros & Cons:

Copper’s main advantage is its superior conductivity, which allows for quick and efficient engine cranking. However, copper is more expensive than other conductive materials, and it can be susceptible to corrosion if not properly insulated or treated.

Impact on Application:

Copper components are crucial in ensuring reliable starter operation across various vehicle types. However, the cost implications of using copper may affect the overall pricing of the starter.

Illustrative image related to how much should a starter cost

Considerations for International Buyers:

Buyers in the Middle East and Africa should ensure that copper components comply with international electrical standards to prevent issues with conductivity and reliability in extreme temperatures.

How Does Plastic or Composite Material Fit into Starter Design?

Plastic or composite materials are sometimes used for non-structural components of starters, such as covers or insulating parts. These materials can offer benefits in terms of weight and cost.

Pros & Cons:

The primary advantage of plastic is its lightweight nature and resistance to corrosion. However, it may not withstand high temperatures or mechanical stress as effectively as metals, potentially leading to failure in demanding applications.

Impact on Application:

Plastic components can be suitable for low-stress applications or where weight savings are critical. However, they may not be appropriate for high-performance or heavy-duty starters.

Considerations for International Buyers:

For buyers in regions with varying climate conditions, it is crucial to select plastics that are rated for temperature and UV resistance to ensure longevity and performance.

Summary Table of Material Considerations

| Material | Typical Use Case for how much should a starter cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty starters for conventional vehicles | High durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight starters for performance vehicles | Lightweight | Less strength compared to steel | High |

| Copper | Electrical components in starters | Excellent conductivity | Higher cost, corrosion potential | High |

| Plastic | Non-structural components in starters | Corrosion resistance | Limited temperature tolerance | Low |

This analysis provides valuable insights for international B2B buyers, enabling them to make informed decisions regarding starter material selection based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how much should a starter cost

What Are the Key Stages in the Manufacturing Process of Automotive Starters?

Understanding the manufacturing process of automotive starters is crucial for B2B buyers, as it impacts both cost and quality. The manufacturing process generally involves several key stages: material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves selecting high-quality raw materials, such as steel and copper, which are essential for the starter’s durability and performance. Manufacturers often source materials that meet international standards to ensure reliability. Material testing is conducted to verify that they meet required specifications, such as tensile strength and conductivity.

Forming

In the forming stage, the raw materials undergo various processes such as stamping, machining, and molding. Stamping is commonly used for producing metal components like the starter housing, while machining ensures precision in parts like the armature and solenoid. Techniques like die casting can also be utilized for producing complex shapes efficiently.

Illustrative image related to how much should a starter cost

Assembly

Once the components are formed, they move to the assembly stage. Here, workers or automated systems assemble the starter by combining the various parts, such as the armature, solenoid, and housing. This stage may involve soldering, welding, or using screws and fasteners. Proper assembly is crucial, as it ensures that the starter functions correctly when installed in a vehicle.

Finishing

The finishing stage includes painting or coating the starter to prevent corrosion and enhance aesthetics. Additionally, manufacturers may apply surface treatments to improve wear resistance. Quality checks are often conducted at this stage to ensure that the product meets aesthetic and functional specifications.

How Is Quality Assurance Implemented in Starter Manufacturing?

Quality assurance (QA) is vital in the manufacturing of automotive starters, ensuring reliability and performance. B2B buyers should pay close attention to the quality control processes employed by their suppliers.

International Standards for Quality Assurance

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards indicates that the manufacturer has implemented processes to enhance customer satisfaction and ensure continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the market and application.

Illustrative image related to how much should a starter cost

Quality Control Checkpoints

Quality control is typically divided into three checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: At this initial stage, materials are inspected upon arrival. Tests may include dimensional checks and material property assessments to ensure compliance with specifications.

- IPQC: During the manufacturing process, random samples are tested for defects. This may involve functional testing of components and monitoring the assembly process to ensure that workers follow standard operating procedures.

- FQC: Before products are shipped, a final inspection is conducted. This includes functional tests to ensure that the starter operates correctly under simulated conditions.

What Testing Methods Are Commonly Used in Starter Quality Control?

Various testing methods are employed to ensure that automotive starters meet performance standards. B2B buyers should be familiar with these methods to assess supplier capabilities.

Electrical Testing

Electrical testing is crucial for starters, as they must operate efficiently under various conditions. Testing may include measuring resistance, voltage drop, and current draw to verify that the starter performs within specified parameters.

Illustrative image related to how much should a starter cost

Functional Testing

Functional tests simulate the starter’s operation in a vehicle environment. This may involve bench testing where the starter is engaged with a power source to assess its cranking ability and response time.

Durability Testing

Durability tests assess how well the starter withstands extreme conditions, such as high temperatures and vibrations. These tests often mimic real-world operating conditions to ensure longevity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential for minimizing risks. Here are several methods to consider:

Illustrative image related to how much should a starter cost

Conducting Audits

Performing on-site audits allows buyers to evaluate the manufacturer’s quality control processes firsthand. This includes reviewing documentation related to quality management systems, inspecting equipment, and observing manufacturing practices.

Requesting Quality Reports

Buyers should request quality reports that document the results of testing and inspections. These reports provide insights into the supplier’s adherence to quality standards and any corrective actions taken in response to identified issues.

Engaging Third-Party Inspections

Utilizing third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. These inspectors can verify compliance with international standards and provide detailed reports on findings.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate specific quality control and certification nuances:

Regional Standards

Different regions may have specific quality standards and regulations that affect starter manufacturing. For example, European buyers may prioritize CE certification, while buyers in the Middle East may look for compliance with local regulations.

Illustrative image related to how much should a starter cost

Cultural Considerations

Cultural differences may influence communication and expectations regarding quality assurance. Buyers should be prepared to discuss quality standards openly and establish clear expectations with suppliers.

Understanding Supply Chain Complexity

International sourcing often involves multiple suppliers and logistics challenges. Buyers should assess how each supplier contributes to the overall quality assurance process and ensure that they have robust traceability systems in place.

By understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing automotive starters. Ensuring that suppliers adhere to international standards and implement rigorous quality control processes is essential for maintaining product reliability and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much should a starter cost’

Introduction

This practical sourcing guide provides a comprehensive checklist for B2B buyers aiming to determine the appropriate costs associated with procuring automotive starters. Understanding the pricing structure for starters is essential for making informed purchasing decisions, ensuring quality, and maintaining operational efficiency in your business.

Step 1: Identify Your Vehicle Specifications

Begin by gathering detailed specifications for the vehicles that require starters. This includes the make, model, year, and engine type. Knowing these details will enable you to source the correct starter, as prices can vary significantly based on these factors.

- Consider vehicle variations: Different models may have unique starter requirements, affecting cost.

- Understand performance needs: Some vehicles may necessitate high-performance starters, which can be pricier.

Step 2: Research Market Pricing Trends

Conduct thorough market research to understand the typical pricing range for starters in your region. This is crucial as it helps you set a baseline for negotiations and ensures you avoid overpaying.

- Utilize online resources: Websites like AutoZone and manufacturer sites can provide valuable insights into starter costs.

- Monitor local suppliers: Compare prices from multiple local suppliers to gauge average costs and identify outliers.

Step 3: Evaluate Supplier Certifications

Before engaging with potential suppliers, verify their certifications and industry standards. This step is vital to ensure that you are sourcing from reputable vendors who comply with safety and quality regulations.

- Look for industry compliance: Certifications such as ISO or similar can indicate a supplier’s commitment to quality.

- Request documentation: Ask for proof of certifications and any relevant safety records.

Step 4: Assess Quality and Warranty Options

Quality should be a top priority when selecting a starter. Assess the materials used and the warranty offered to ensure longevity and reliability in your procurement.

- Inquire about warranty terms: A robust warranty can indicate the supplier’s confidence in their product’s quality.

- Consider OEM vs. aftermarket: Original Equipment Manufacturer (OEM) parts often come with better reliability but may be more expensive than aftermarket options.

Step 5: Request Samples and Technical Support

Engage suppliers by requesting samples of starters for testing. Additionally, ensure that they provide technical support or documentation to aid in installation or troubleshooting.

- Test product reliability: Evaluating a sample can help identify performance issues before a bulk purchase.

- Seek ongoing support: Reliable technical assistance can save time and resources during installation and maintenance.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted potential suppliers, it’s time to negotiate terms. Discuss payment options, delivery timelines, and bulk order discounts to achieve the best deal.

- Understand pricing flexibility: Some suppliers may offer discounts for larger orders or prompt payment.

- Clarify delivery expectations: Ensure that you have clear timelines for when the starters will be delivered to avoid operational disruptions.

Step 7: Finalize the Order and Confirm Logistics

After negotiations, finalize the order and confirm all logistical details. This includes payment methods, delivery schedules, and post-purchase support.

- Document everything: Keep a record of the agreed terms to prevent misunderstandings later.

- Plan for inventory management: Ensure you have a strategy in place for receiving and storing starters upon arrival.

By following this checklist, B2B buyers can navigate the complexities of sourcing automotive starters effectively, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for how much should a starter cost Sourcing

What Are the Key Cost Components Influencing Starter Pricing?

When evaluating the cost of sourcing starters, several critical cost components must be considered. Materials account for a significant portion of the total cost, particularly the quality of metals used in the starter’s construction. High-grade materials can enhance durability but also increase the price.

Labor costs encompass the workforce required for assembly and quality checks. In regions with higher labor costs, such as Europe, the overall pricing may reflect this. Manufacturing overhead includes utilities, facility maintenance, and administrative costs, which also play a role in determining the final price.

Tooling costs are relevant, especially for custom starters that require specific molds or machinery. Quality control (QC) measures ensure that the starters meet industry standards and specifications, adding another layer to the cost structure. Additionally, logistics—including transportation, customs duties, and warehousing—affect the overall pricing, particularly for international buyers.

Finally, the margin set by suppliers must be factored in, as it varies based on the supplier’s market positioning and competitive strategy.

What Price Influencers Should B2B Buyers Consider for Starters?

Several factors can influence the price of starters in the B2B marketplace. Volume and minimum order quantities (MOQ) are pivotal; larger orders typically lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs to ensure they receive competitive pricing without overcommitting.

Specifications and customization also impact pricing. Custom starters designed for specific applications or vehicles often come at a premium. Buyers should weigh the necessity of customization against their budgetary constraints.

Material quality and certifications are essential for ensuring reliability and compliance with local regulations. Higher quality and certified products can command higher prices but may lead to lower maintenance costs and greater longevity.

Supplier factors, such as reputation and reliability, can affect pricing. Established suppliers may offer higher prices due to their proven track record, while newer entrants might provide competitive rates to gain market share.

Incoterms play a crucial role in pricing negotiations for international buyers. Understanding who bears the costs and risks associated with shipping, customs, and delivery can significantly affect the total cost of ownership.

Illustrative image related to how much should a starter cost

What Buyer Tips Can Help Negotiate Better Prices for Starters?

For B2B buyers, effective negotiation strategies can yield better pricing for starters. Start by conducting thorough market research to understand average pricing and identify potential suppliers. This knowledge will empower you to negotiate confidently.

Consider the total cost of ownership (TCO) rather than just the upfront cost. A slightly more expensive starter with a longer lifespan or lower failure rate may offer better value over time.

Pricing nuances are particularly relevant for international buyers. Be aware of currency fluctuations, import tariffs, and regional market conditions, as these can significantly influence the final cost.

Building a strong relationship with suppliers can also lead to better pricing. Suppliers may be more willing to negotiate favorable terms for repeat customers or those who commit to larger volumes.

Lastly, always request samples or prototypes before finalizing orders, especially for customized products. This practice helps ensure that the product meets your specifications and quality expectations, potentially saving costs associated with returns or replacements.

Disclaimer on Indicative Prices

It is important to note that the prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult multiple sources and suppliers to obtain the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing how much should a starter cost With Other Solutions

Exploring Alternatives to Starter Replacement Costs

In the automotive sector, understanding the financial implications of starter replacements is crucial for B2B buyers, especially when considering alternatives. Buyers need to evaluate various solutions that can meet their operational needs while balancing performance and cost. Below, we compare the costs and benefits of traditional starter replacements against two viable alternatives: battery replacements and starter motor upgrades.

| Comparison Aspect | How Much Should A Starter Cost | Battery Replacement | Starter Motor Upgrade |

|---|---|---|---|

| Performance | Essential for starting the engine; varies by vehicle type | Improves electrical power and may resolve starting issues if battery-related | Enhanced cranking power and durability |

| Cost | $80 – $350 for parts; $150 – $1,100 for labor | $50 – $200 for parts; $30 – $100 for labor | $150 – $500 for parts; $100 – $200 for labor |

| Ease of Implementation | Moderate; requires mechanical knowledge for installation | Easy; often can be done by the vehicle owner | Moderate; may require professional installation |

| Maintenance | Low; once replaced, minimal upkeep | Moderate; batteries need regular checks and replacement every few years | Low; designed for longevity but may require occasional inspection |

| Best Use Case | Direct replacement when starter fails | When starting issues are battery-related | For performance vehicles or older models with weak starters |

What Are the Pros and Cons of Battery Replacement?

Battery replacements can serve as a cost-effective alternative to starter replacements, particularly when starting problems are diagnosed as battery-related. A new battery typically costs between $50 and $200, with installation being straightforward enough for many vehicle owners to manage themselves. However, this solution is only viable if the starting issue stems from the battery rather than the starter itself. One downside is that batteries have a limited lifespan and may require frequent replacements, which can add to long-term operational costs.

Illustrative image related to how much should a starter cost

How Do Starter Motor Upgrades Compare?

Starter motor upgrades provide a robust alternative for businesses operating performance or older vehicles. These upgraded starters often offer improved cranking power and durability, which can be essential in extreme weather conditions or high-demand applications. Costs for starter motor upgrades range from $150 to $500 for parts, with an additional $100 to $200 for professional installation. While they provide enhanced performance, they may not be necessary for every vehicle, and installation could require technical expertise, making them less accessible for DIY enthusiasts.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding on the best approach to address starting issues, B2B buyers should assess their specific circumstances and operational requirements. The traditional starter replacement remains a reliable choice for vehicles with confirmed starter failures, while battery replacements can be a quicker and cheaper fix if the issue lies elsewhere. Conversely, starter motor upgrades are suited for those prioritizing performance and longevity. By carefully weighing these alternatives, businesses can make informed decisions that align with their budget and operational goals.

Essential Technical Properties and Trade Terminology for how much should a starter cost

What Are the Critical Technical Specifications for Evaluating Starter Costs?

Understanding the technical specifications of starters is essential for B2B buyers seeking to make informed purchasing decisions. Here are some critical specs to consider:

1. Material Grade

The material used in the construction of a starter significantly influences its durability and performance. Common materials include aluminum for the housing and copper for the windings. Higher-grade materials can withstand more wear and tear, translating to longer lifespans and lower replacement frequencies. For B2B buyers, selecting starters made from high-quality materials can mean reduced operational costs over time.

Illustrative image related to how much should a starter cost

2. Current Rating (Amperage)

The current rating indicates how much electrical current the starter can handle. Most automotive starters operate within a range of 100 to 200 amps. Choosing a starter with the appropriate amperage for a specific vehicle model ensures efficient engine cranking and prevents overheating. For businesses, this specification is crucial for matching the starter with the vehicle’s requirements to avoid potential failures.

3. Torque Output

Torque output is the rotational force generated by the starter motor. It is typically measured in Newton-meters (Nm) and varies depending on the vehicle’s engine size and type. A higher torque rating is necessary for larger engines, which require more power to initiate cranking. For B2B purchasers, understanding torque specifications helps in selecting the right starter for performance and reliability.

4. Operating Temperature Range

Starters are subjected to various temperature conditions during operation. The operating temperature range specifies the extremes within which the starter can function without failing. Buyers should consider this specification, especially in regions with extreme climates. Ensuring that the starter can withstand local environmental conditions is vital for operational reliability.

5. Mounting Type

Different vehicles have varying mounting configurations for starters, such as side-mounted or top-mounted designs. Knowing the mounting type is essential for compatibility with specific vehicle models. For B2B buyers, this detail is critical for ensuring that the purchased starter can be installed without modifications, thus saving time and labor costs.

What Are the Common Trade Terms Related to Starter Costs?

Familiarity with industry jargon can help B2B buyers navigate the purchasing process more effectively. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the manufacturer of the original equipment in the vehicle. These parts are designed to meet the same specifications and quality standards as the original starter. B2B buyers often prefer OEM parts for their reliability and performance consistency.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B transactions, as it affects inventory management and cost-effectiveness. Buyers should negotiate MOQs to align with their purchasing needs without overcommitting resources.

Illustrative image related to how much should a starter cost

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the context of starters, submitting an RFQ can help buyers compare different suppliers and secure the best deal. It is a standard practice in B2B procurement to ensure transparency and competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. These terms clarify who is responsible for shipping, insurance, and duties. Understanding Incoterms is vital for B2B buyers engaged in international transactions to avoid unexpected costs and delays.

5. Warranty Period

The warranty period refers to the time frame during which the manufacturer guarantees the starter’s performance. A longer warranty period can indicate higher confidence in the product’s durability. For B2B buyers, evaluating warranty terms is essential for risk management and ensuring long-term value from their investment.

Illustrative image related to how much should a starter cost

By grasping these technical properties and industry terms, B2B buyers can navigate the complexities of starter costs more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the how much should a starter cost Sector

What Are the Key Market Dynamics Influencing Starter Costs?

The market for automotive starters is influenced by several global drivers, particularly in regions such as Africa, South America, the Middle East, and Europe. A notable trend is the increasing demand for electric vehicles (EVs), which is reshaping the starter motor landscape. As manufacturers pivot towards producing EVs, traditional starter production may experience fluctuations. Additionally, the globalization of supply chains has led to greater access to diverse sourcing options, enhancing price competition. International B2B buyers need to stay informed about regional differences in manufacturing capabilities, which can affect lead times and pricing structures.

Emerging technologies, such as the integration of smart diagnostics into starter systems, are also changing the market dynamics. These innovations not only streamline the identification of starter issues but can also reduce repair costs, thereby influencing the total cost of ownership for businesses. Furthermore, with the rise of e-commerce platforms, buyers can access a broader range of starter products and replacement options, facilitating better price comparisons and sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact Starter Costs?

In today’s B2B landscape, sustainability and ethical sourcing have become paramount considerations for international buyers. The automotive sector, particularly in regions like Europe and South America, is under increasing pressure to adopt environmentally friendly practices. The sourcing of materials for starters, including metals and plastics, must align with sustainable practices to minimize environmental impact. Buyers should prioritize suppliers who demonstrate compliance with environmental regulations and who utilize recycled or sustainably sourced materials.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers that adhere to fair labor practices and transparent sourcing methods. Certifications such as ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) are becoming essential criteria for procurement decisions. By partnering with ethically responsible manufacturers, businesses not only contribute to environmental sustainability but also enhance their brand reputation, which is crucial in competitive markets.

What Is the Historical Context of Starter Costs in the Automotive Sector?

The evolution of starter motors can be traced back to the early 20th century when hand-cranking was the norm for starting engines. The introduction of electric starters revolutionized the automotive industry, significantly enhancing user convenience and vehicle reliability. Over the decades, advancements in technology have led to more efficient and durable starter designs, contributing to a broader range of costs depending on vehicle type and application.

In the past, starter costs were heavily influenced by the availability of raw materials and manufacturing techniques. Today, while these factors remain relevant, they are compounded by the need for sustainable practices and the integration of advanced technologies. As the industry continues to evolve, understanding this historical context will aid international B2B buyers in making informed purchasing decisions while navigating current market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of how much should a starter cost

-

How do I determine the cost of a starter for my vehicle?

To determine the cost of a starter, consider the make, model, and year of your vehicle, as these factors significantly influence pricing. For most vehicles, a new starter can range from $80 to over $350, while rebuild parts may cost between $50 and $350. Additionally, labor costs for replacement can vary from $150 to over $1,100, depending on accessibility and the complexity of the job. Consulting with local suppliers or online platforms can provide a clearer estimate based on your specific vehicle. -

What factors influence the price of a starter?

Several factors affect the price of a starter, including the vehicle’s make and model, the starter’s design complexity, and whether it is a new or rebuilt part. Luxury and larger vehicles often have higher starter costs due to specialized parts and labor intensity. Additionally, geographical location can impact pricing due to shipping costs and regional market conditions. Understanding these factors can help buyers make informed purchasing decisions. -

What are the common signs that a starter needs replacement?

Signs that a starter may need replacement include erratic cranking, no response when turning the key, or unusual noises during starting attempts. If the engine turns over slowly or makes grinding sounds, it may indicate internal component failure. Regularly inspecting the starter and related electrical systems can help identify issues early and prevent more extensive vehicle damage. -

How can I vet suppliers for starters in international markets?

When vetting suppliers for starters, prioritize those with a proven track record in the automotive parts sector. Check reviews, ask for references, and verify their certifications. Additionally, consider suppliers who offer warranties and clear return policies, as this demonstrates confidence in their products. Networking through trade shows or industry associations can also help identify reputable suppliers in your target regions. -

What are the minimum order quantities (MOQs) for starters from international suppliers?

Minimum order quantities (MOQs) for starters can vary widely depending on the supplier and the type of starter. Some manufacturers may set MOQs at 50 units, while others might require orders of 100 or more. It’s essential to discuss MOQs upfront to ensure they align with your purchasing capabilities and inventory management strategies. Negotiating flexible terms could also be possible, especially for long-term partnerships. -

What payment terms should I expect when sourcing starters internationally?

Payment terms can differ significantly among international suppliers. Common arrangements include upfront payments, 30-50% deposits with the balance due upon delivery, or payment upon receipt of goods. It’s essential to clarify these terms in advance and consider secure payment methods such as letters of credit or escrow services to protect your investment. Establishing clear terms helps prevent misunderstandings and fosters a trustworthy supplier relationship. -

How can I ensure quality assurance (QA) for starters sourced internationally?

To ensure quality assurance for starters, request detailed product specifications, certifications, and quality control processes from your supplier. Conducting pre-shipment inspections or utilizing third-party QA services can help verify that the products meet your standards before they arrive. Additionally, establishing a clear communication channel with the supplier allows for addressing any quality concerns promptly, ensuring that your expectations are consistently met. -

What logistics considerations should I keep in mind when importing starters?

Logistics considerations for importing starters include shipping methods, customs duties, and delivery timelines. Assess whether air freight or ocean freight is more cost-effective based on your urgency and volume needs. Understanding the customs regulations in your destination country is crucial to avoid delays and unexpected fees. Collaborating with a reliable freight forwarder can streamline the logistics process and help manage potential challenges in international shipping.

Top 5 How Much Should A Starter Cost Manufacturers & Suppliers List

1. Last Chance Auto Repairs – Starter Replacement Costs

Domain: lastchanceautorepairs.com

Registered: 2009 (16 years)

Introduction: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Average total cost ranges: $250 – $1,000+. Factors affecting cost: Vehicle type & model, New vs Re-Manufactured starters, Additional repairs. DIY replacement costs: Parts only: …

2. Facebook – Car Repair Costs

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: cost to get car to the shop and replace starter

3. Carfax – Starter Motor Pricing Guide

Domain: carfax.com

Registered: 1997 (28 years)

Introduction: The cost of a car starter motor typically ranges from $100 to $400, depending on the make and model of the vehicle. Labor costs can add an additional $50 to $150. Factors affecting the price include the type of starter motor, vehicle specifications, and whether the part is new or remanufactured.

4. CarTalk – Starter Replacement Guide

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: Cost to replace a starter: $600 to $900 for common vehicles, $900 to $1,400 for luxury models. Symptoms of a bad starter include clicking sounds, screeching noises, and intermittent functionality. Most mechanics will replace the starter rather than repair it. New starters are often remanufactured parts. Modern vehicles with stop-start systems do not experience premature starter failures.

5. CarBuzz – Starter Motor Replacement Costs

Domain: carbuzz.com

Registered: 2003 (22 years)

Introduction: Starter motor replacement costs range from $450 to $600 on average, with specific models like the Toyota Tundra (2000-2005) costing between $650 and $900 due to complex installation. The Honda Civic’s replacement cost is estimated between $490 and $760. Factors affecting costs include labor time (1.5 to 2.5 hours, or up to four hours for complex installations), and the type of starter used (afterm…

Strategic Sourcing Conclusion and Outlook for how much should a starter cost

In conclusion, understanding the cost dynamics of starter motors is crucial for international B2B buyers, especially in emerging markets like Africa, South America, the Middle East, and Europe. The price for starter motors can vary significantly based on vehicle type, brand, and accessibility for replacement. Strategic sourcing not only enables businesses to secure competitive pricing but also ensures access to high-quality components that meet regional standards.

Buyers should focus on evaluating suppliers based on their ability to deliver reliable products, favorable payment terms, and efficient logistics. By developing strong relationships with trustworthy suppliers, companies can mitigate risks associated with fluctuating prices and supply chain disruptions.

Looking ahead, it is vital for B2B buyers to remain proactive in monitoring market trends and technological advancements that could influence starter costs. Engaging in strategic sourcing initiatives can enhance operational efficiency and provide a competitive edge in the marketplace. Take action now by assessing your current supplier relationships and exploring new opportunities to optimize your sourcing strategy for automotive components.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.