Introduction: Navigating the Global Market for how much does replacing a starter cost

In the ever-evolving automotive landscape, understanding how much replacing a starter costs is crucial for B2B buyers navigating the global market. This challenge is particularly pronounced for businesses in regions such as Africa, South America, the Middle East, and Europe—where varying market conditions and labor rates can significantly impact expenses. Factors such as vehicle type, quality of the starter, and regional service costs create a complex pricing environment that demands careful consideration.

This comprehensive guide delves into the multifaceted aspects of starter replacement costs, addressing key components such as types of starters available, their applications across different vehicle models, and essential criteria for supplier vetting. By examining both new and remanufactured options, as well as associated labor costs, this resource equips international buyers with the insights necessary to make informed purchasing decisions.

Moreover, understanding the nuances of starter replacement can mitigate the risk of unexpected expenses and help businesses maintain operational efficiency. As you explore the guide, you will find actionable information that empowers you to navigate the complexities of the automotive parts market with confidence, ensuring that your procurement strategies align with your operational needs and budgetary constraints.

Table Of Contents

- Top 5 How Much Does Replacing A Starter Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much does replacing a starter cost

- Understanding how much does replacing a starter cost Types and Variations

- Key Industrial Applications of how much does replacing a starter cost

- 3 Common User Pain Points for ‘how much does replacing a starter cost’ & Their Solutions

- Strategic Material Selection Guide for how much does replacing a starter cost

- In-depth Look: Manufacturing Processes and Quality Assurance for how much does replacing a starter cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does replacing a starter cost’

- Comprehensive Cost and Pricing Analysis for how much does replacing a starter cost Sourcing

- Alternatives Analysis: Comparing how much does replacing a starter cost With Other Solutions

- Essential Technical Properties and Trade Terminology for how much does replacing a starter cost

- Navigating Market Dynamics and Sourcing Trends in the how much does replacing a starter cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much does replacing a starter cost

- Strategic Sourcing Conclusion and Outlook for how much does replacing a starter cost

- Important Disclaimer & Terms of Use

Understanding how much does replacing a starter cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Economy Starters | Budget-friendly, aftermarket options | Small repair shops, budget-conscious fleets | Pros: Lower cost; Cons: Shorter lifespan and reliability concerns. |

| OEM (Original Equipment Manufacturer) Starters | High-quality, manufacturer-recommended parts | Dealerships, premium service centers | Pros: Guaranteed fit and performance; Cons: Higher price point. |

| High-Performance Starters | Specialty components for enhanced performance | Performance automotive shops, racing teams | Pros: Improved durability and power; Cons: Significant investment required. |

| Remanufactured Starters | Rebuilt from used parts, offering a middle-ground option | Cost-sensitive repair shops, fleet operations | Pros: Cost-effective; Cons: Potentially shorter lifespan than new. |

| DIY Starter Replacement Kits | All necessary components for self-installation | Independent mechanics, DIY enthusiasts | Pros: Cost savings on labor; Cons: Requires expertise and tools, risk of errors. |

What Are Economy Starters and Their Suitability for B2B Buyers?

Economy starters are aftermarket options designed for cost-sensitive applications. They are typically priced between $75 and $200, making them attractive for small repair shops and budget-conscious fleets. While they provide a lower upfront cost, B2B buyers should consider the potential trade-offs in lifespan and reliability. Economy starters may not be suitable for high-performance vehicles or critical applications where reliability is paramount.

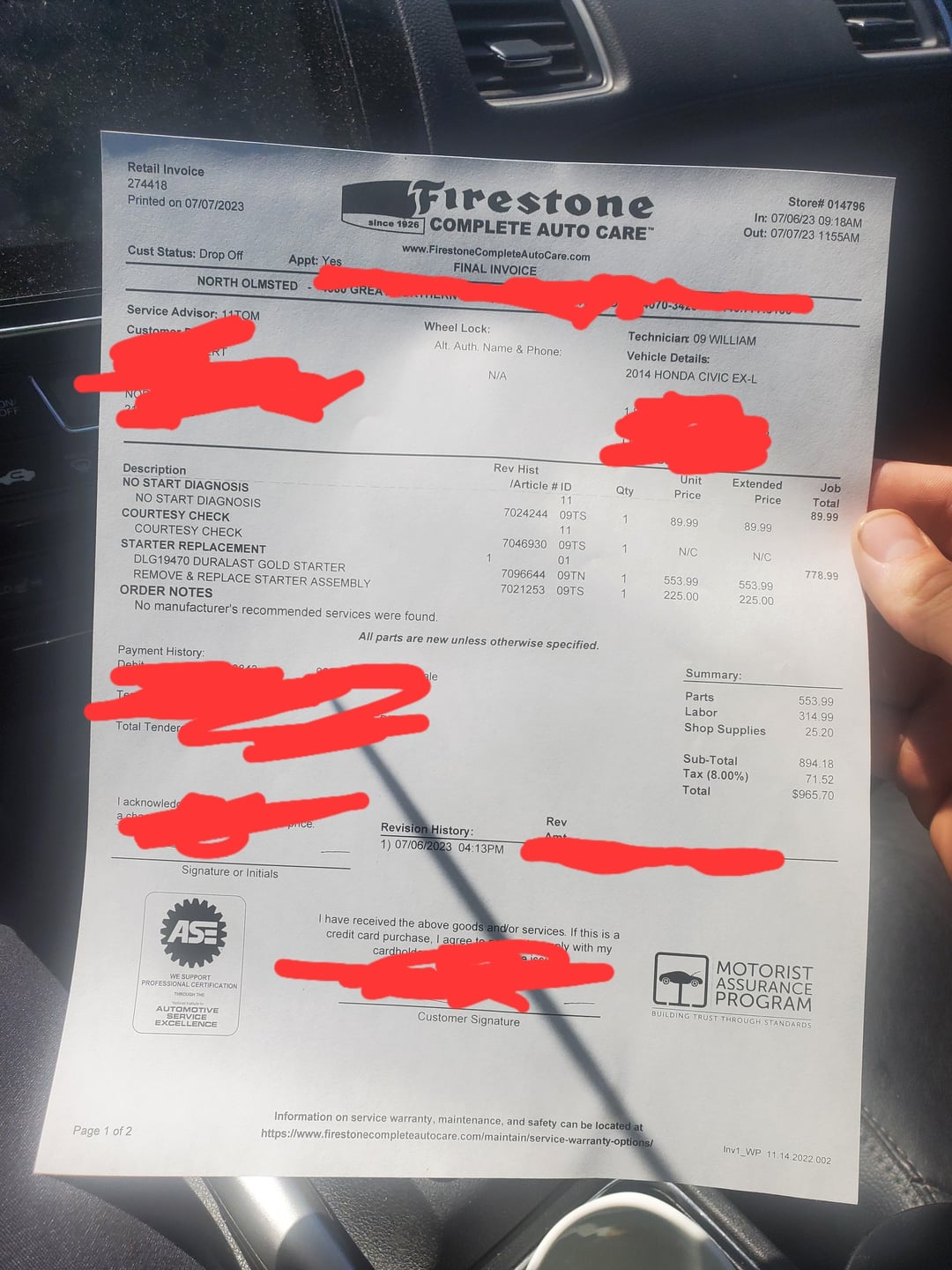

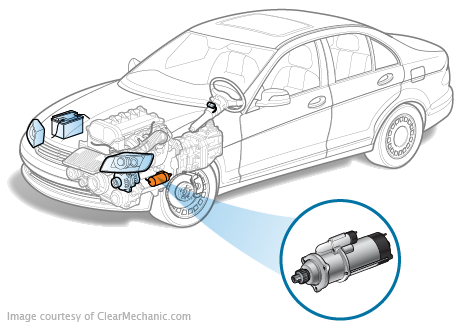

Illustrative image related to how much does replacing a starter cost

Why Choose OEM Starters for Professional Applications?

OEM starters are manufactured to meet the original specifications of the vehicle, ensuring a perfect fit and performance. These starters are recommended for dealerships and premium service centers that prioritize quality and customer satisfaction. Although OEM parts come at a higher price (typically between $150 and $400), they often provide superior reliability and a warranty, making them a wise investment for businesses focused on long-term vehicle performance.

When to Consider High-Performance Starters?

High-performance starters are specialized components designed for enhanced engine cranking power and durability. Priced between $300 and $1,000, they are ideal for performance automotive shops and racing teams looking to optimize their vehicles. While they provide significant benefits in terms of power and reliability, B2B buyers should evaluate the return on investment, especially in high-stakes environments where performance is crucial.

What Are the Benefits of Remanufactured Starters?

Remanufactured starters are rebuilt from used parts, offering a cost-effective alternative for businesses looking to save on repairs. Typically ranging from $50 to $300, they serve as a suitable option for cost-sensitive repair shops and fleet operations. While they can reduce upfront costs, B2B buyers must consider the potential for shorter lifespans compared to new starters, which may lead to more frequent replacements.

How Do DIY Starter Replacement Kits Fit into the Market?

DIY starter replacement kits provide all necessary components for self-installation, appealing to independent mechanics and DIY enthusiasts. These kits can save businesses on labor costs but require a certain level of expertise and tools. B2B buyers should weigh the potential savings against the risks of improper installation, which could lead to further repairs and costs.

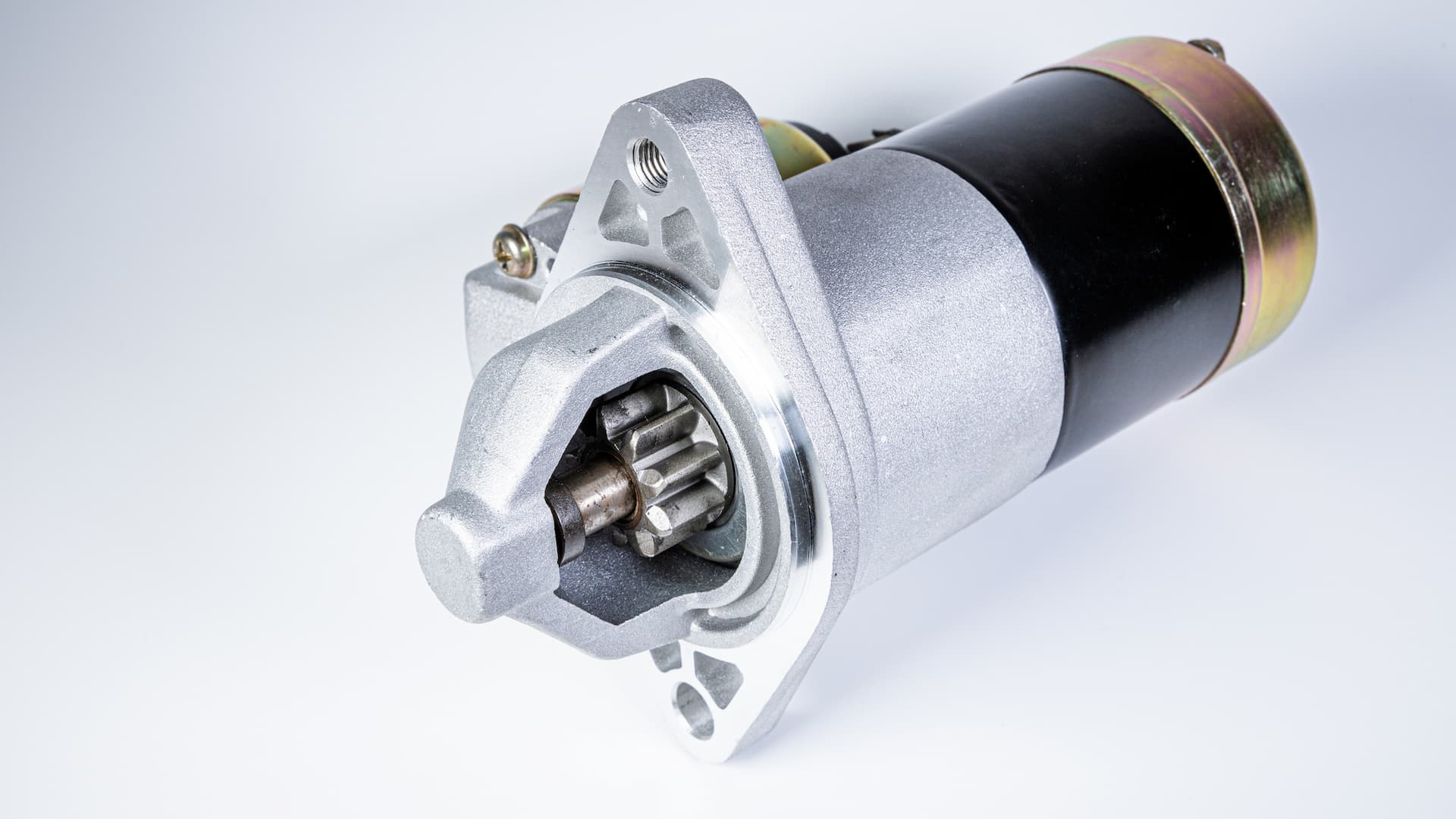

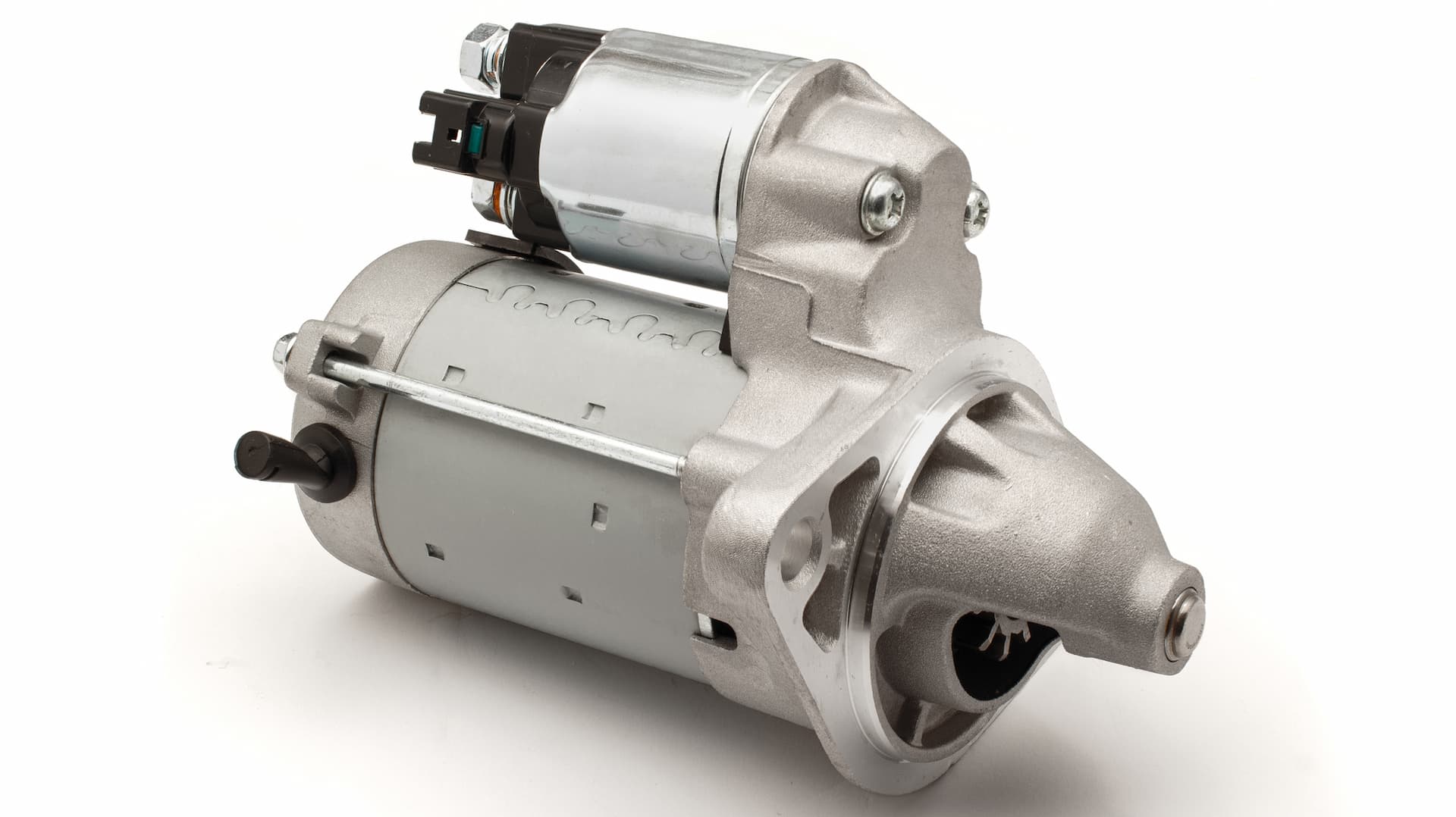

Illustrative image related to how much does replacing a starter cost

Key Industrial Applications of how much does replacing a starter cost

| Industry/Sector | Specific Application of how much does replacing a starter cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Services | Assessing starter replacement costs for customer estimates | Improves customer satisfaction and trust | Availability of quality parts, labor rates, and warranties |

| Transportation & Logistics | Evaluating starter replacement expenses for fleet management | Reduces downtime and maintenance costs | Bulk purchasing options, reliable suppliers, and service agreements |

| Construction Equipment | Cost analysis for starter replacements in heavy machinery | Ensures operational efficiency and minimizes delays | OEM vs. aftermarket parts, compatibility, and service support |

| Agriculture | Estimating starter replacement costs for farm vehicles | Enhances productivity by minimizing equipment failure | Local supplier relationships, part availability, and service times |

| Mining | Budgeting for starter replacements in mining equipment | Maintains safety and productivity in harsh environments | Quality assurance, parts sourcing, and repair service reliability |

How is ‘how much does replacing a starter cost’ utilized in Automotive Repair Services?

In the automotive repair sector, accurately estimating the cost of starter replacements is vital for customer satisfaction. Repair shops need to provide transparent pricing to build trust with clients. This involves assessing the vehicle type, labor requirements, and quality of parts. For international B2B buyers, understanding regional labor rates and parts availability is crucial to ensure competitive pricing and customer retention.

What role does starter replacement cost analysis play in Transportation & Logistics?

In the transportation and logistics industry, companies must evaluate the costs associated with starter replacements for their fleets. This analysis helps manage budgets effectively and minimizes vehicle downtime, which can significantly impact delivery schedules. For businesses operating in diverse regions, sourcing reliable parts and establishing service agreements with local mechanics can lead to cost savings and improved operational efficiency.

How do Construction Equipment firms benefit from understanding starter replacement costs?

Construction equipment often relies on robust starter systems to ensure reliable operation on job sites. By understanding the costs associated with starter replacements, firms can budget effectively and avoid unexpected equipment failures that can delay projects. Buyers in this sector should focus on OEM versus aftermarket parts, compatibility with existing machinery, and the availability of local service support to minimize operational disruptions.

Illustrative image related to how much does replacing a starter cost

Why is estimating starter replacement costs critical for Agriculture?

In agriculture, reliable machinery is essential for maintaining productivity. Estimating starter replacement costs allows farmers to plan for repairs and avoid breakdowns during critical harvest seasons. International buyers should consider local supplier relationships and the availability of parts to ensure timely repairs, which can directly impact crop yield and profitability.

How is the mining sector affected by starter replacement cost considerations?

In the mining industry, the cost of starter replacements is closely linked to safety and productivity. Equipment failures can lead to significant operational delays, making it essential for companies to budget for regular maintenance and quick repairs. Buyers must prioritize quality assurance in sourcing parts, as well as reliable repair services, to maintain safety standards and operational efficiency in challenging environments.

3 Common User Pain Points for ‘how much does replacing a starter cost’ & Their Solutions

Scenario 1: Navigating Cost Variability in Starter Replacement

The Problem:

B2B buyers, particularly fleet managers or automotive service providers, often face significant variability in the costs associated with starter replacement. This variability can stem from differences in vehicle types, labor rates, and parts quality. For instance, a luxury vehicle may require specialized components that can dramatically increase the replacement cost compared to standard vehicles. This unpredictability complicates budgeting and financial forecasting, leading to potential overages and dissatisfaction among clients.

The Solution:

To navigate this cost variability, it is crucial for B2B buyers to establish relationships with multiple suppliers and service providers. Start by conducting thorough market research to identify reliable suppliers who offer competitive pricing on starter motors, both OEM and aftermarket. Create a comparison matrix that outlines costs associated with different vehicle types and potential labor rates. Additionally, consider negotiating bulk purchasing agreements with suppliers to secure better pricing on parts. This proactive approach not only allows for more accurate budgeting but also helps in managing client expectations regarding costs.

Scenario 2: Understanding the Impact of Labor Costs on Starter Replacement

The Problem:

Another pain point for B2B buyers is the understanding of labor costs associated with starter replacement. Labor rates can vary significantly depending on the complexity of the installation and the expertise required. For example, replacing a starter in a compact car might take only 1-2 hours, while a luxury vehicle could require up to 6 hours of labor. This discrepancy can lead to unexpected expenses that affect overall project profitability, especially for businesses that operate on tight margins.

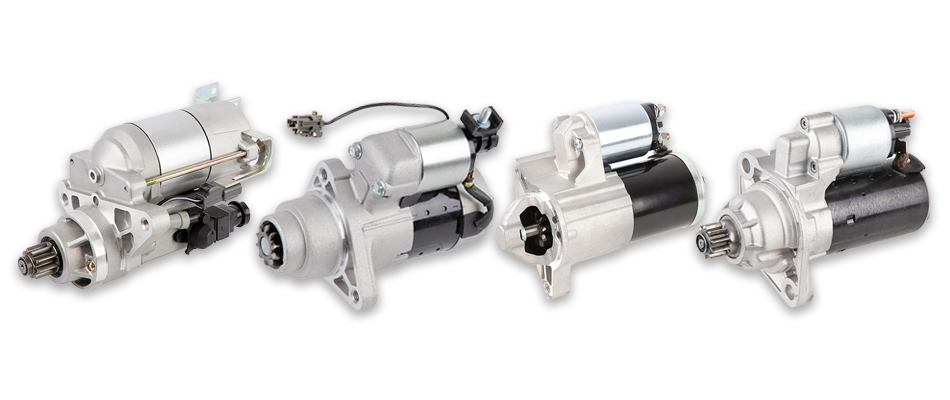

Illustrative image related to how much does replacing a starter cost

The Solution:

To mitigate the impact of labor costs, B2B buyers should invest in training for their technicians to enhance their skills in starter replacement. This investment can lead to faster and more efficient installations, reducing overall labor hours billed. Additionally, consider implementing a standardized pricing guide for labor based on vehicle complexity, which can help streamline communication with clients and set clear expectations. For complex installations, it may be beneficial to offer clients a detailed breakdown of labor costs upfront, ensuring transparency and reducing the likelihood of disputes over charges.

Scenario 3: Assessing the Quality of Replacement Starters

The Problem:

B2B buyers often grapple with the decision between purchasing new versus remanufactured starters. While remanufactured starters are typically more affordable, they may come with shorter lifespans and reliability concerns, which can affect the overall quality of service provided to clients. This dilemma can result in either increased costs due to frequent replacements or damage to the buyer’s reputation if unreliable components are used.

The Solution:

To make informed purchasing decisions, B2B buyers should prioritize quality assurance by selecting suppliers that provide warranties on their starter products. Conduct thorough due diligence to understand the remanufacturing process and the quality control measures in place. Additionally, consider implementing a testing protocol for new and remanufactured starters before installation. This could involve simple bench tests to assess functionality. By ensuring that only high-quality starters are used, buyers can maintain service reliability, ultimately protecting their reputation and fostering client trust.

Strategic Material Selection Guide for how much does replacing a starter cost

What Materials Are Commonly Used in Starter Replacement?

When considering the replacement of starters, the choice of materials for the starter motor and its components can significantly impact performance, durability, and cost. Here, we analyze four common materials used in starter assemblies: aluminum, steel, copper, and plastic composites.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is known for its excellent corrosion resistance and lightweight nature. It can withstand moderate temperatures, making it suitable for automotive applications.

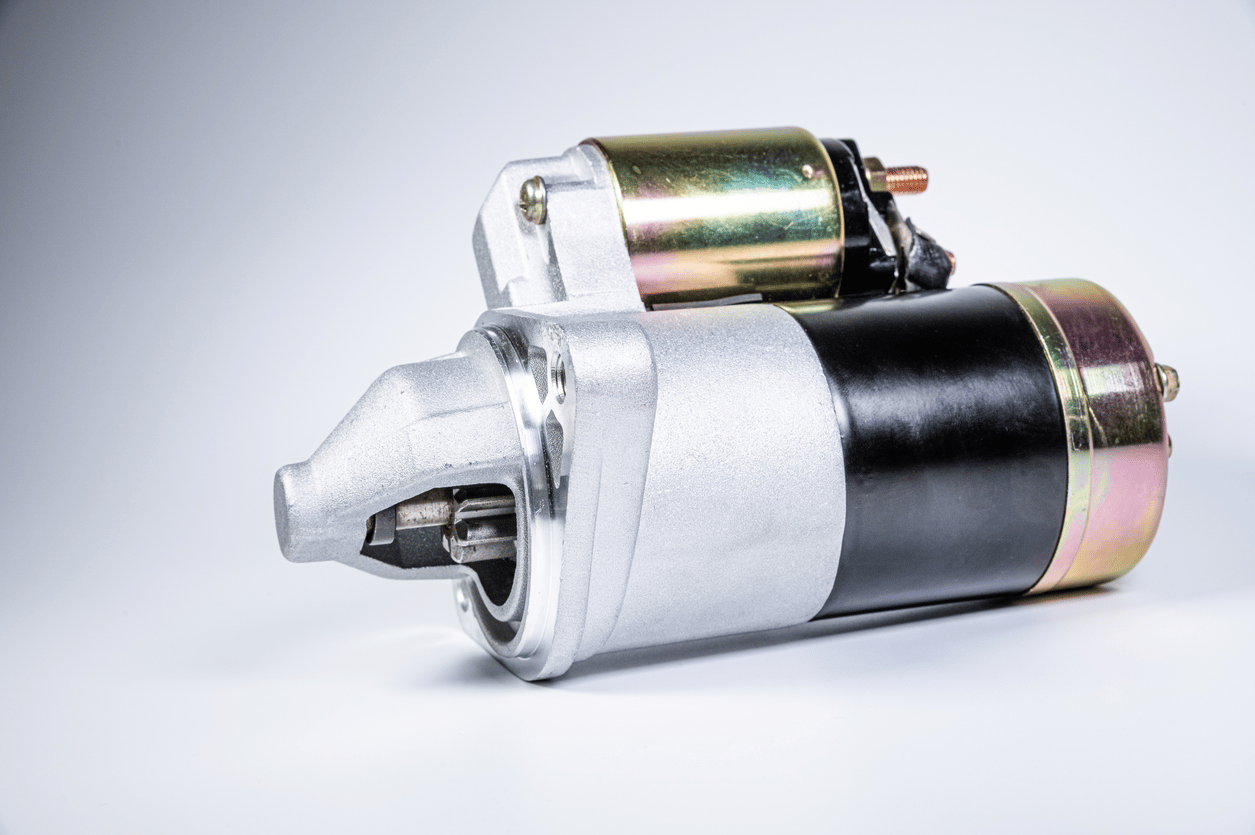

Illustrative image related to how much does replacing a starter cost

Pros & Cons: The primary advantage of aluminum is its low weight, which contributes to overall vehicle efficiency. It is also resistant to rust, ensuring longevity in various environmental conditions. However, aluminum can be more expensive than other materials and may not withstand high-impact forces as well as steel.

Impact on Application: Aluminum is often used in starter housings and brackets, where weight savings are crucial. Its compatibility with automotive fluids and exposure to various temperatures makes it a reliable choice.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with EU regulations regarding material safety. Standards such as DIN can guide material selection for automotive components.

Steel: Strength and Durability

Key Properties: Steel is known for its high strength and ability to withstand significant mechanical stress. It has a high-temperature rating and excellent wear resistance.

Pros & Cons: The main advantage of steel is its durability and ability to handle heavy loads, making it ideal for high-performance applications. However, it is heavier than aluminum and can be prone to rust if not properly treated.

Impact on Application: Steel is often used in the construction of starter motors and internal components, where strength is paramount. Its robustness makes it suitable for heavy-duty vehicles and applications that require high reliability.

Illustrative image related to how much does replacing a starter cost

Considerations for International Buyers: Compliance with ASTM standards is crucial for steel components. Buyers in Africa and South America should consider local sourcing of steel to reduce costs and ensure availability.

Copper: Superior Conductivity

Key Properties: Copper is renowned for its excellent electrical conductivity and thermal properties. It can handle high currents and is resistant to corrosion.

Pros & Cons: The key advantage of copper is its ability to efficiently conduct electricity, making it ideal for electrical connections in starters. However, copper is more expensive than aluminum and steel, which can increase overall replacement costs.

Illustrative image related to how much does replacing a starter cost

Impact on Application: Copper is typically used for starter windings and electrical connections, where efficient power transfer is essential. Its compatibility with various automotive systems enhances its utility.

Considerations for International Buyers: Buyers should be aware of the fluctuating copper prices in international markets, which can affect replacement costs. Compliance with JIS standards may also be relevant for buyers in Asia.

Plastic Composites: Lightweight and Versatile

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They have moderate temperature resistance, making them suitable for certain automotive applications.

Pros & Cons: The primary advantage of plastic composites is their versatility and lower weight, which can improve fuel efficiency. However, they may not be suitable for high-stress applications and can degrade under extreme temperatures.

Impact on Application: Plastic composites are often used for non-structural components in starters, such as covers and housings. Their resistance to corrosion makes them suitable for various environmental conditions.

Considerations for International Buyers: Buyers should ensure that plastic materials meet local regulatory standards for automotive parts. In regions like Europe, compliance with REACH regulations is essential.

Summary Table of Material Selection for Starter Replacement

| Material | Typical Use Case for how much does replacing a starter cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Starter housings and brackets | Lightweight and corrosion-resistant | More expensive than steel | Medium |

| Steel | Internal components of starter motors | High strength and durability | Heavier and prone to rust | Medium |

| Copper | Electrical connections and windings | Superior electrical conductivity | Higher cost than aluminum/steel | High |

| Plastic Composites | Non-structural components like covers | Lightweight and versatile | Not suitable for high-stress areas | Low |

This analysis provides B2B buyers with insights into material selection for starter replacements, highlighting the properties, advantages, and considerations relevant to different regions. Understanding these factors can help in making informed purchasing decisions that align with operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how much does replacing a starter cost

What Are the Main Stages in the Manufacturing Process of Starters?

The manufacturing process for automotive starters involves several critical stages, each designed to ensure that the final product meets the rigorous demands of performance and reliability. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

This initial stage focuses on sourcing high-quality materials, such as steel and copper, which are essential for the starter’s durability and efficiency. Manufacturers often conduct rigorous supplier assessments to ensure that materials meet specific mechanical and electrical properties.

Forming

Once materials are prepared, they undergo various forming processes. Techniques such as stamping, casting, and machining are employed to create the starter motor components, including the housing, armature, and drive gear. Advanced methods like die-casting can enhance precision and reduce waste, ensuring that components fit together perfectly.

Assembly

In the assembly stage, the individual components are brought together. Automated assembly lines are commonly used to enhance efficiency and consistency. Skilled technicians often perform final assembly, ensuring that each starter is assembled according to strict specifications. Quality checks are integral at this point to catch any defects before the product moves to the next stage.

Illustrative image related to how much does replacing a starter cost

Finishing

The finishing stage includes surface treatments like painting, plating, or coating to protect against corrosion and wear. This stage also involves final inspections to ensure that the product is free from defects and meets the required aesthetic standards.

How Is Quality Assurance Implemented in Starter Manufacturing?

Quality assurance (QA) is a pivotal part of the starter manufacturing process, ensuring that each product not only meets but exceeds industry standards. Key international standards such as ISO 9001 guide manufacturers in establishing robust quality management systems.

International Standards for Quality Assurance

ISO 9001 is crucial for manufacturers, as it outlines criteria for a quality management system. Compliance with this standard indicates that a manufacturer is committed to consistently delivering quality products and services. In addition to ISO certifications, industry-specific standards like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards may apply depending on the starter’s application.

What Are the Key Quality Control Checkpoints in Starter Production?

Quality control (QC) checkpoints are established throughout the manufacturing process to identify and rectify issues before they escalate. These checkpoints typically include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC)

IQC involves inspecting materials and components upon arrival at the manufacturing facility. This stage ensures that all incoming materials meet predetermined specifications, preventing defects from entering the production process.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC is implemented to monitor the production line continuously. This may involve statistical process control (SPC) techniques to analyze production data and ensure that processes remain within acceptable limits. Regular audits of machinery and tools also form part of this stage.

Final Quality Control (FQC)

FQC is the last line of defense before products are shipped. Each starter undergoes rigorous testing, including electrical testing and performance simulations, to verify that it meets all operational standards. Documentation of these tests is crucial for traceability and customer assurance.

Illustrative image related to how much does replacing a starter cost

What Common Testing Methods Are Used in Starter Quality Control?

Various testing methods are employed to ensure that starters perform reliably under different conditions. Common methods include:

- Electrical Testing: This verifies the electrical integrity of the starter, ensuring it can handle the required voltage and current.

- Performance Testing: Starters are subjected to simulations that replicate real-world conditions, assessing their performance under load.

- Durability Testing: This involves running the starter through extensive cycles to test its longevity and reliability, often beyond typical operational limits.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are several strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. This can include reviewing their compliance with international standards like ISO 9001.

-

Quality Reports: Requesting detailed quality assurance reports can help buyers understand a manufacturer’s QC processes and outcomes. These reports should include information on defect rates, testing methods, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. This is especially important for buyers in regions with less stringent regulations.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate several nuances in quality control.

Illustrative image related to how much does replacing a starter cost

Cultural and Regulatory Differences

Understanding regional regulations and cultural attitudes towards quality can significantly affect supplier relationships. For instance, European markets may emphasize compliance with CE marking, while Middle Eastern countries might have specific import regulations that need to be adhered to.

Language Barriers and Documentation

Language differences can lead to miscommunication regarding quality specifications. Buyers should ensure that all documentation, including quality certifications and test results, is available in a language they understand.

Logistical Considerations

Shipping and logistics can impact the quality of starters. Buyers should verify that suppliers have robust logistics management processes to prevent damage during transport and ensure that products arrive in excellent condition.

Conclusion

For B2B buyers, understanding the manufacturing processes and quality assurance practices related to starter replacement is crucial for making informed purchasing decisions. By focusing on the stages of manufacturing, implementing stringent quality control measures, and verifying supplier practices, buyers can ensure they are investing in reliable products that meet their operational needs. This knowledge not only enhances procurement strategies but also builds long-term supplier relationships that can lead to improved business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does replacing a starter cost’

In the automotive sector, understanding the costs associated with replacing a starter is essential for businesses involved in vehicle maintenance and repair. This guide provides a practical checklist for B2B buyers to effectively navigate the procurement process, ensuring they get the best value for their investment.

Step 1: Assess Your Vehicle Fleet’s Needs

Begin by evaluating the types of vehicles in your fleet. Different models have varying starter replacement costs due to parts complexity and labor requirements. Knowing whether you manage economy cars, trucks, or luxury vehicles will help you set a budget and identify suitable suppliers.

Step 2: Research Starter Part Options

Identify the types of starter motors available: new, remanufactured, or aftermarket. Each option has different price points and lifespans.

– New starters typically offer the longest durability but at a higher cost.

– Remanufactured starters are budget-friendly but may have a shorter lifespan.

– Aftermarket options can provide savings, but ensure they meet quality standards.

Illustrative image related to how much does replacing a starter cost

Step 3: Determine Labor Costs in Your Region

Labor costs can significantly influence the total expense of starter replacement. Research average labor rates in your area to gauge what you should expect.

– Consider the complexity of the vehicle models you maintain; some may require more intricate labor.

– Factor in the potential for additional repairs, such as wiring or solenoid issues, which could increase labor time and costs.

Step 4: Identify Reliable Suppliers

Finding trustworthy suppliers is crucial for ensuring quality and reliability. Look for suppliers with a strong reputation in your region or industry.

– Request references and check reviews from other businesses.

– Evaluate their warranty policies on parts and labor, which can protect your investment.

Step 5: Request Detailed Quotes

Once you’ve identified potential suppliers, request detailed quotes for starter replacements. A comprehensive quote should include:

– The cost of the starter motor (indicating whether it’s new, remanufactured, or aftermarket).

– An itemized breakdown of labor costs, including estimated hours for replacement.

– Any potential additional costs for extra repairs or components.

Illustrative image related to how much does replacing a starter cost

Step 6: Evaluate Supplier Certifications and Compliance

Verify that your chosen suppliers comply with international standards and regulations. This ensures that the parts you procure meet safety and quality benchmarks.

– Look for certifications such as ISO 9001, which indicates a commitment to quality management.

– Ensure compliance with local regulations, especially if you’re sourcing from international suppliers.

Step 7: Review and Negotiate Terms

Before finalizing your procurement, review all terms and conditions. This includes payment terms, delivery schedules, and return policies.

– Don’t hesitate to negotiate pricing, especially if you’re placing a large order or establishing a long-term relationship.

– Clarify the terms of service, including what happens if parts are defective or do not meet expectations.

By following this checklist, B2B buyers can make informed decisions regarding starter replacements, ultimately enhancing their operational efficiency and ensuring customer satisfaction.

Comprehensive Cost and Pricing Analysis for how much does replacing a starter cost Sourcing

When considering the costs associated with replacing a starter, it is essential to break down the various cost components that contribute to the overall pricing. This analysis will provide B2B buyers with a clear understanding of what influences costs, enabling them to make informed purchasing decisions.

What Are the Key Cost Components for Starter Replacement?

-

Materials: The primary cost component is the starter motor itself. Prices can vary significantly depending on whether the buyer opts for an economy starter ($75 – $200), an OEM starter ($150 – $400), or a high-performance variant ($300 – $1000+). Additionally, wiring and other related components may add to the total material costs.

-

Labor: Labor costs are influenced by the complexity of the vehicle’s design. For basic vehicles, labor can range from $100 to $250, while more complex installations in luxury or performance vehicles can escalate to between $300 and $600. This variation is crucial for businesses that operate fleets or manage multiple vehicles.

-

Manufacturing Overhead: Overhead costs, including facility expenses and utilities, contribute to the final price of starter motors. These costs can be more pronounced for manufacturers with limited production runs, leading to higher per-unit costs.

-

Tooling and Quality Control (QC): The initial investment in specialized tools and quality control processes can add to the upfront costs for manufacturers. Ensuring that starters meet safety and performance standards is critical, particularly for international markets with stringent regulations.

-

Logistics: Transportation costs can vary based on the distance between suppliers and end-users, as well as the mode of transport. Incoterms play a significant role in defining responsibilities and costs associated with shipping, which can impact pricing for international buyers.

-

Margin: Suppliers typically include a profit margin in their pricing structure, which can vary based on market conditions and competitive landscape.

What Influences the Price of Starter Replacement?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted pricing. B2B buyers should consider negotiating for better rates based on volume commitments, which can significantly reduce the overall cost per unit.

-

Specifications and Customization: Custom starter motors tailored for specific vehicle makes and models can drive up costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher-quality materials and certified parts generally come with a higher price tag. B2B buyers should assess the total cost of ownership, factoring in the longevity and reliability of the starter.

-

Supplier Factors: The choice of supplier can greatly impact pricing. Established suppliers with a solid reputation may charge more but offer reliability and warranty coverage, while lesser-known suppliers may provide lower prices but at a potential risk of quality.

-

Incoterms: Understanding the implications of Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost, influencing budget decisions.

What Are Some Buyer Tips for Cost-Efficiency in Starter Replacement?

-

Negotiate Pricing: Don’t hesitate to negotiate with suppliers, especially for bulk purchases. Leveraging your buying power can lead to significant cost savings.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the expected lifespan and maintenance costs associated with the starter. A higher initial investment may lead to lower long-term costs.

-

Research Quality Certifications: Ensure that the starters meet international quality standards. Investing in certified parts may prevent future issues and reduce the need for replacements.

-

Understand Regional Pricing Nuances: Prices may vary significantly by region due to labor costs, tariffs, and local market conditions. Buyers from Africa, South America, the Middle East, and Europe should be aware of these differences when sourcing starters.

-

Stay Informed on Market Trends: Keeping abreast of market trends can help buyers anticipate price fluctuations and make strategic purchasing decisions.

Disclaimer for Indicative Prices

The prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific vehicle requirements. B2B buyers are encouraged to obtain multiple quotes and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing how much does replacing a starter cost With Other Solutions

Exploring Alternatives to Starter Replacement Costs

When considering vehicle maintenance, particularly starter replacements, it’s essential for B2B buyers to evaluate alternative solutions that can address similar issues. This analysis provides a comparison between the costs associated with replacing a starter and other viable methods that can help ensure vehicle reliability and performance.

| Comparison Aspect | How Much Does Replacing A Starter Cost | Re-manufactured Starter | Battery Replacement |

|---|---|---|---|

| Performance | Restores full functionality of the vehicle | Reliable but may have a shorter lifespan | Provides power but does not directly address starter issues |

| Cost | $250 – $1,000+ | $50 – $300 | $100 – $300 |

| Ease of Implementation | Requires professional installation | Generally easy to install | Straightforward, often DIY-friendly |

| Maintenance | Low maintenance post-installation | Moderate, may need replacement sooner | Regular checks needed, especially in extreme conditions |

| Best Use Case | When starter is confirmed faulty | Cost-effective for budget-conscious buyers | When battery is the main issue, not the starter |

What Are the Pros and Cons of Re-manufactured Starters?

Re-manufactured starters can be a more budget-friendly option for businesses looking to minimize costs. They typically range from $50 to $300 and can provide reliable performance. The advantage lies in their affordability, making them a suitable choice for companies operating within strict budget constraints. However, the downside is that re-manufactured starters may have a shorter lifespan compared to new starters, which can lead to more frequent replacements and potential downtime in operations.

How Does Battery Replacement Compare to Starter Replacement?

Battery replacement is another alternative that may sometimes be considered when vehicles fail to start. The cost of replacing a battery generally ranges from $100 to $300. This option is straightforward and often manageable for businesses with in-house maintenance teams. However, it is crucial to note that a battery replacement does not resolve issues related to the starter itself. If the starter is the actual problem, replacing the battery will not fix the underlying issue, potentially leading to ongoing operational challenges.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers evaluating their options, understanding the specific issues at hand is crucial. If the starter is confirmed to be faulty, investing in a new starter or a re-manufactured one is likely the best course of action. Conversely, if the vehicle’s starting issues stem from a weak battery, a battery replacement may suffice. Ultimately, the decision should be based on a thorough assessment of the vehicle’s condition, budgetary constraints, and the long-term reliability needs of the business. By carefully weighing these alternatives, companies can make informed decisions that enhance their operational efficiency and vehicle performance.

Illustrative image related to how much does replacing a starter cost

Essential Technical Properties and Trade Terminology for how much does replacing a starter cost

What Key Technical Properties Should You Consider for Starter Replacement Costs?

When evaluating the costs associated with replacing a starter, understanding certain technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

1. Material Grade

The material grade of a starter motor significantly influences its durability and performance. Most starters are made from high-quality metals like aluminum or steel, which offer strength and resistance to wear. For B2B buyers, selecting a starter with a high material grade ensures longevity and reliability, reducing the frequency of replacements and maintenance costs.

2. Voltage Rating

Starters typically operate at 12 volts in most vehicles, but some high-performance models may require higher voltage ratings. Knowing the voltage rating is essential for compatibility with specific vehicle models. This specification prevents electrical issues and ensures optimal performance, thereby safeguarding the vehicle’s electrical system.

Illustrative image related to how much does replacing a starter cost

3. Torque Output

Torque output is a critical specification that determines how effectively the starter can crank the engine. A higher torque rating translates to better performance, especially in larger vehicles or those with high compression engines. For B2B buyers, understanding torque output helps in selecting starters that meet the specific requirements of various vehicle types, ensuring efficient engine starts.

4. Temperature Rating

The temperature rating indicates the operational limits of a starter motor. Starters that can withstand higher temperatures are crucial for vehicles operating in extreme conditions. Buyers should consider this rating to avoid premature failures, particularly in regions with harsh climates, which can directly impact operational costs.

5. Warranty Period

A robust warranty period is a vital specification that reflects the manufacturer’s confidence in the product’s quality. Longer warranty periods often indicate better construction and materials. For B2B buyers, a strong warranty can minimize risk and provide assurance against defects, making it a key factor in the decision-making process.

What Are Common Terms Used in Starter Replacement Costs?

Understanding industry jargon can help B2B buyers navigate the complexities of starter replacement. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are typically designed to meet the exact specifications of the vehicle, ensuring compatibility and performance. Buyers may prefer OEM parts for their reliability, although they often come at a higher cost compared to aftermarket alternatives.

Illustrative image related to how much does replacing a starter cost

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, particularly those purchasing starters in bulk. It helps in planning inventory and cost management, ensuring that businesses can maintain operational efficiency.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products. For buyers looking to replace starters, issuing an RFQ can help gather competitive pricing and terms, facilitating better negotiation and decision-making processes.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border purchases of starters, ensuring clarity in logistics and reducing potential disputes.

5. Aftermarket Parts

Aftermarket parts are components manufactured by companies other than the OEM. They can offer cost savings but may vary in quality and compatibility. Buyers should weigh the pros and cons of aftermarket options against OEM parts to determine the best fit for their needs and budgets.

Illustrative image related to how much does replacing a starter cost

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when it comes to the costs associated with starter replacements, ultimately leading to better operational outcomes.

Navigating Market Dynamics and Sourcing Trends in the how much does replacing a starter cost Sector

What Are the Key Market Dynamics Influencing Starter Replacement Costs Globally?

The global market for automotive starter replacements is shaped by several critical factors that international B2B buyers must understand. One of the primary drivers is the increasing vehicle ownership rates in emerging economies, particularly in Africa and South America. As disposable incomes rise, more consumers can afford vehicles, leading to higher demand for automotive services, including starter replacements. Additionally, the proliferation of electric and hybrid vehicles in markets such as Europe and the Middle East is prompting a shift in the types of starters required, as these vehicles utilize different technologies compared to traditional internal combustion engines.

Another significant trend is the growing reliance on e-commerce platforms for sourcing automotive parts. B2B buyers are increasingly turning to online marketplaces to procure starter motors, which offers greater convenience and often competitive pricing. The rise of digital tools allows buyers to compare prices and specifications rapidly, enhancing their purchasing decisions. Moreover, advancements in supply chain technologies, such as blockchain and IoT, are improving transparency and efficiency, enabling buyers to track the sourcing of components more effectively.

Lastly, labor costs associated with starter replacements are influenced by regional economic conditions. For instance, countries in Europe, such as Germany, may face higher labor rates compared to markets in Africa or South America. This disparity necessitates careful consideration of total cost calculations for B2B buyers looking to maintain competitive pricing while ensuring quality service delivery.

How Do Sustainability and Ethical Sourcing Impact the Starter Replacement Market?

Sustainability has become a pivotal concern in the automotive sector, affecting how B2B buyers approach starter replacements. The environmental impact of manufacturing processes for starter motors is significant, with concerns about resource depletion and waste generation driving the demand for more sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through eco-friendly manufacturing processes.

Furthermore, ethical sourcing is gaining traction as consumers demand transparency in the supply chain. B2B buyers should seek out manufacturers that adhere to ethical labor practices and provide fair wages, particularly in regions where labor exploitation may be prevalent. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier’s commitment to sustainable and ethical practices.

The adoption of ‘green’ materials in starter production is also on the rise. Manufacturers are exploring options for recyclable or biodegradable components, which not only reduce environmental impact but also appeal to eco-conscious buyers. As sustainability becomes more integral to purchasing decisions, B2B buyers must align their sourcing strategies with these values to maintain competitiveness in the evolving marketplace.

What Is the Historical Context of Starter Replacement Costs in the Automotive Industry?

Understanding the historical evolution of starter replacements provides valuable insights for B2B buyers. The starter motor, a crucial component of the ignition system, has undergone significant advancements since its inception in the early 20th century. Initially, starters were manually operated, requiring significant physical effort to crank engines. The introduction of electric starters in the 1910s revolutionized vehicle operation, leading to widespread adoption in passenger and commercial vehicles.

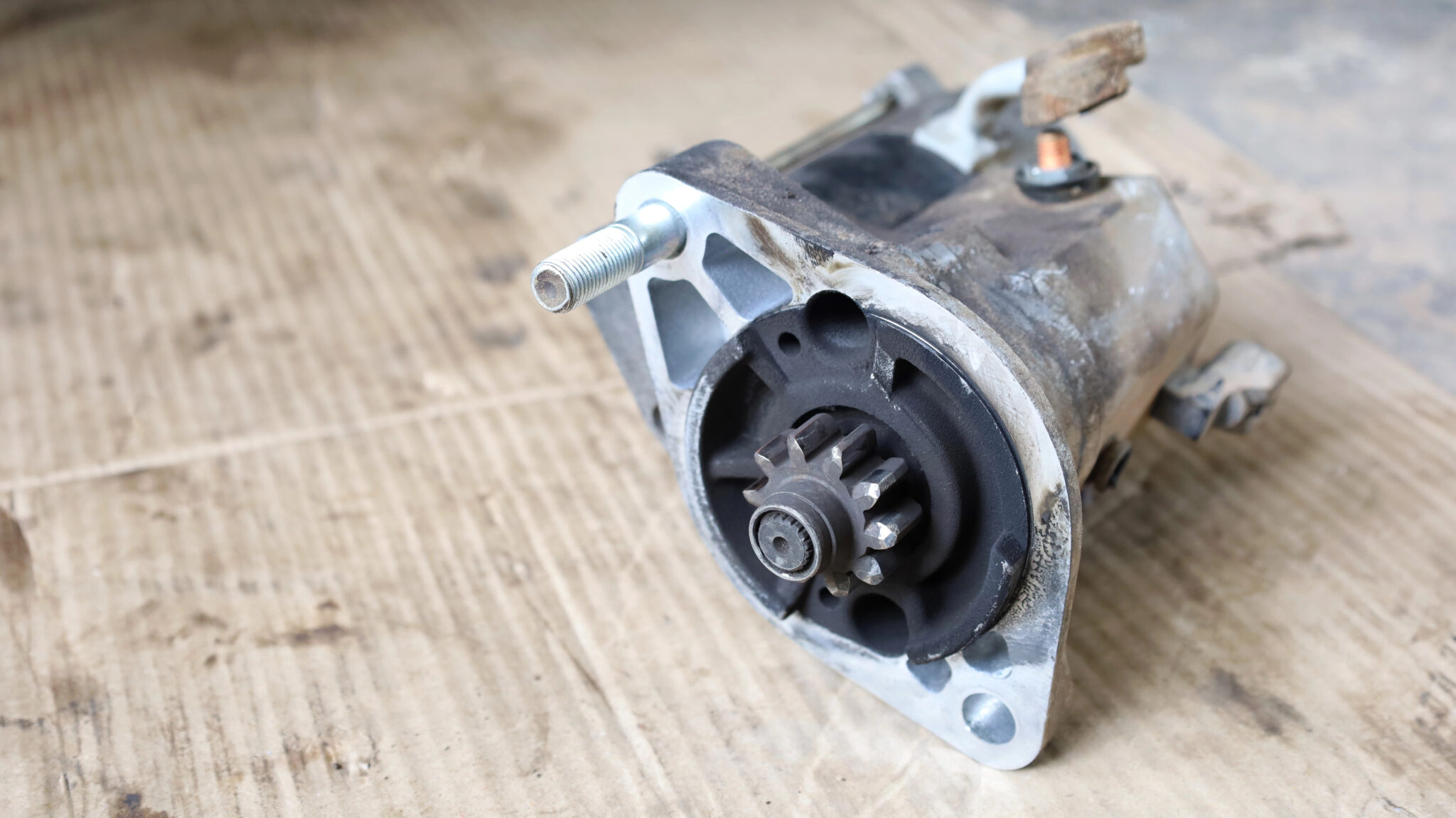

Illustrative image related to how much does replacing a starter cost

Over the decades, technological improvements have enhanced the performance and reliability of starter motors, resulting in longer lifespans and reduced failure rates. However, as vehicles have become more sophisticated, the complexity of starter replacements has increased, often requiring specialized knowledge and tools for installation. This evolution has led to varying costs associated with starter replacements, influenced by factors such as vehicle type and market conditions.

Today, B2B buyers must navigate a landscape where both traditional and advanced starter technologies coexist, making it essential to stay informed about trends, pricing, and sourcing practices to ensure effective procurement strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of how much does replacing a starter cost

-

How much does it typically cost to replace a starter?

The cost to replace a starter varies significantly based on several factors, including vehicle type, brand, and region. On average, B2B buyers can expect to pay between $250 and $1,000, encompassing both parts and labor. Aftermarket starters may range from $75 to $400, while OEM parts can go from $150 to $600. Labor costs can fluctuate between $100 and $600, depending on the complexity of the installation. It’s essential to consider these variables when budgeting for starter replacement. -

What factors influence the cost of starter replacement?

Several key factors affect starter replacement costs. These include the vehicle make and model, as luxury and specialty vehicles typically incur higher costs. Additionally, whether you choose a new or remanufactured starter plays a role—new starters are generally more expensive but offer longer lifespans. Other considerations include labor rates in your region, the condition of related components, and potential additional repairs needed. -

Can I source starter parts from international suppliers?

Yes, sourcing starter parts from international suppliers is a viable option for B2B buyers. Companies can benefit from competitive pricing and a wider selection. However, it’s crucial to conduct thorough research on potential suppliers, focusing on their reputation, certifications, and delivery capabilities. Ensure that the parts meet local regulations and standards to avoid compliance issues upon importation. -

What should I consider when vetting suppliers for starter parts?

When vetting suppliers for starter parts, consider their industry reputation, certifications, and experience in the market. Check for customer reviews and testimonials to gauge reliability. Additionally, inquire about their manufacturing processes, quality assurance measures, and warranties. Establishing clear communication regarding lead times, minimum order quantities (MOQs), and payment terms is also essential for a successful partnership. -

Are there customization options available for starters?

Many suppliers offer customization options for starters, particularly for specialized or high-performance vehicles. Customization can include modifications to specifications, such as voltage or torque ratings. When seeking customized starters, communicate your requirements clearly to the supplier and ensure they have the capabilities to meet your needs. Be aware that customization may affect lead times and costs. -

What are the typical payment terms for international starter part purchases?

Payment terms for international starter part purchases can vary by supplier and region. Common terms include upfront payment, partial payment upon order confirmation, and net payment terms (e.g., net 30 or net 60 days). It’s advisable to negotiate terms that align with your cash flow and business needs. Additionally, consider using secure payment methods that offer buyer protection to mitigate risks associated with international transactions. -

How do I ensure quality assurance for starter parts?

To ensure quality assurance for starter parts, request documentation such as quality control certificates and compliance with international standards. Engage suppliers with ISO certifications or similar quality management systems. Implement a robust inspection process upon receiving parts, including checking for defects or discrepancies. Establishing a clear return policy for defective items is also crucial for maintaining quality standards in your supply chain. -

What logistical considerations should I keep in mind when importing starters?

When importing starters, logistical considerations include shipping costs, lead times, and customs regulations. Understand the import duties and taxes applicable in your country to avoid unexpected expenses. Collaborate with reliable freight forwarders who can navigate the complexities of international shipping. Ensure that all documentation is complete and accurate to facilitate smooth customs clearance, minimizing delays and potential penalties.

Top 5 How Much Does Replacing A Starter Cost Manufacturers & Suppliers List

1. Starter Replacement – Cost Breakdown

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Starter replacement, labor charges, diagnostics fees, OEM starter pricing, price markup, dealership vs. independent shop pricing.

2. Facebook – Auto Repair Costs

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: cost to get car to the shop and replace starter

3. Tundras – Starter Replacement for 2007 Toyota Tundra CrewMax

Domain: tundras.com

Registered: 2000 (25 years)

Introduction: Starter replacement for a 2007 Toyota Tundra CrewMax, quoted cost of $1500 ($900 labor + $650 part). The part to be replaced is denșo 428000-4640. Discussion includes varying opinions on the cost and difficulty of replacement, with some suggesting OEM parts around $200 and labor costs varying by mechanic.

4. CarTalk – Starter Replacement Guide

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: Cost to replace a starter: $600 to $900 for common vehicles; $900 to $1,400 for luxury models. Symptoms of a failing starter include clicking sounds, screeching noises, and intermittent functionality. Options for replacement include new, remanufactured, or repaired starters, with remanufactured parts being the most common. Modern vehicles with stop-start systems are designed to prevent premature s…

5. CARFAX – Vehicle History Reports

Domain: carfax.com

Registered: 1997 (28 years)

Introduction: CARFAX provides access to the largest global database of Vehicle History information, including details on known accidents, damages, theft reports, maintenance and inspections, mileage manipulations, import information, change of ownership, taxi or rental car use, and open recalls. The service covers vehicles from over 20 countries, including the USA and Canada, and aims to enhance transparency in…

Strategic Sourcing Conclusion and Outlook for how much does replacing a starter cost

In conclusion, understanding the costs associated with starter replacement is crucial for international B2B buyers looking to optimize their automotive repair and maintenance budgets. Key factors influencing these costs include the type and model of the vehicle, the choice between new and remanufactured parts, and regional labor rates. By leveraging strategic sourcing, companies can negotiate better prices and ensure high-quality parts that align with their operational needs.

Furthermore, recognizing the signs of a failing starter can prevent costly downtime and additional repairs, enhancing overall vehicle reliability. As buyers from Africa, South America, the Middle East, and Europe navigate this complex landscape, it is essential to partner with trusted suppliers who offer transparency in pricing and comprehensive support.

As we look ahead, investing in quality components and professional services will not only save costs in the long run but also enhance the longevity of your fleet. Engage with suppliers that prioritize durability and performance, and consider conducting regular assessments of your sourcing strategies to stay competitive. The right decisions today will pave the way for smoother operations and greater profitability tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.