Introduction: Navigating the Global Market for how much does it cost to replace headlights

Navigating the global market for headlight replacement costs presents a unique challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding how much it costs to replace headlights can be a complex task, influenced by various factors such as the type of vehicle, the specific bulb technology—be it halogen, HID, or LED—and the intricacies of installation. This guide delves into these variables, providing a comprehensive overview of headlight types, applications, and the corresponding costs, empowering businesses to make informed purchasing decisions.

In addition to cost analysis, we will explore supplier vetting processes, offering insights into sourcing reliable parts that meet safety and quality standards. Whether you’re looking to replace simple halogen bulbs or advanced LED assemblies, this guide is designed to equip international buyers with the knowledge needed to navigate the complexities of headlight replacement.

With detailed information on labor costs, installation challenges, and the importance of selecting the right components, this resource aims to streamline your procurement strategy, ensuring your fleet remains safe and operational. Empowering B2B buyers with actionable insights, we strive to simplify the decision-making process and enhance your purchasing efficiency in a competitive global market.

Table Of Contents

- Top 4 How Much Does It Cost To Replace Headlights Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much does it cost to replace headlights

- Understanding how much does it cost to replace headlights Types and Variations

- Key Industrial Applications of how much does it cost to replace headlights

- 3 Common User Pain Points for ‘how much does it cost to replace headlights’ & Their Solutions

- Strategic Material Selection Guide for how much does it cost to replace headlights

- In-depth Look: Manufacturing Processes and Quality Assurance for how much does it cost to replace headlights

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does it cost to replace headlights’

- Comprehensive Cost and Pricing Analysis for how much does it cost to replace headlights Sourcing

- Alternatives Analysis: Comparing how much does it cost to replace headlights With Other Solutions

- Essential Technical Properties and Trade Terminology for how much does it cost to replace headlights

- Navigating Market Dynamics and Sourcing Trends in the how much does it cost to replace headlights Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much does it cost to replace headlights

- Strategic Sourcing Conclusion and Outlook for how much does it cost to replace headlights

- Important Disclaimer & Terms of Use

Understanding how much does it cost to replace headlights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Halogen Bulbs | Affordable, short lifespan (500-1,000 hours) | Fleet vehicles, budget-conscious | Pros: Low initial cost; easy to replace. Cons: Frequent replacements needed. |

| HID (High-Intensity Discharge) Bulbs | Brighter light output, longer lifespan (2,000-10,000 hours) | Luxury vehicles, performance cars | Pros: Excellent visibility; energy-efficient. Cons: Higher cost; complex installation. |

| LED (Light Emitting Diode) | Very long lifespan (up to 40,000 hours), energy-efficient | Modern vehicles, electric cars | Pros: Long-lasting; low power consumption. Cons: Expensive initial investment; may require special fixtures. |

| Sealed Headlight Assemblies | Integrated design, often non-serviceable | Newer vehicles, luxury models | Pros: Improved aesthetics; advanced features (adaptive lighting). Cons: High replacement cost; entire assembly must be replaced if damaged. |

| Laser Headlights | Cutting-edge technology, exceptional brightness | High-end luxury vehicles | Pros: Superior visibility; energy-efficient. Cons: Extremely high cost; limited availability. |

Halogen bulbs are the most common type of headlight replacement, favored for their affordability and ease of installation. They are suitable for fleet vehicles or budget-conscious buyers who prioritize low initial costs. However, their relatively short lifespan necessitates frequent replacements, which can add up over time, making them less economical in the long run.

HID bulbs offer a significant upgrade in brightness and lifespan, making them ideal for luxury vehicles and performance cars. Their energy efficiency and superior visibility are compelling advantages. However, the higher upfront cost and potential complexity in installation can be barriers for some buyers, particularly in markets where skilled labor may be scarce.

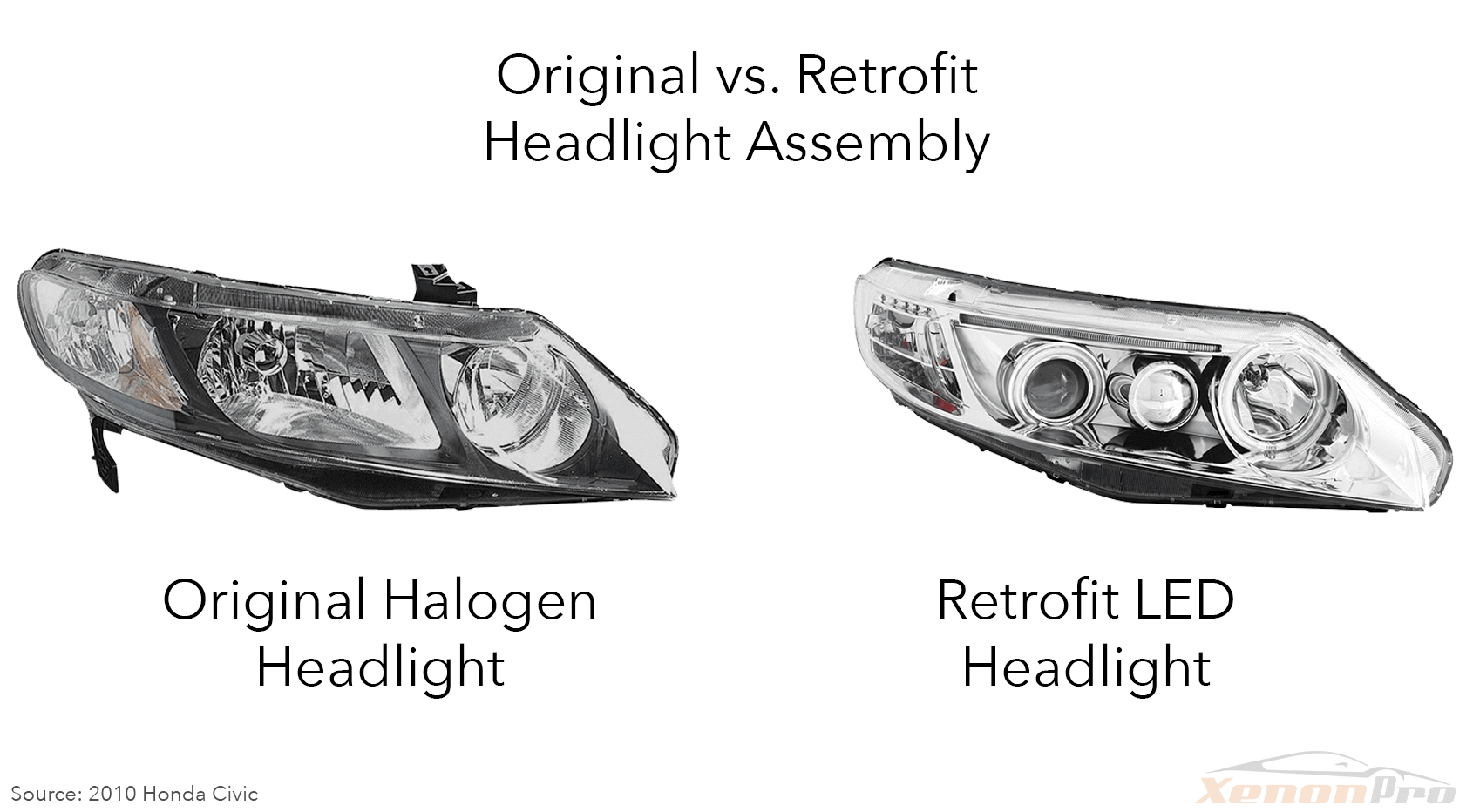

LED headlights are increasingly popular due to their longevity and energy efficiency, lasting up to 40,000 hours. They are commonly used in modern and electric vehicles, appealing to environmentally-conscious buyers. Despite their advantages, the initial investment is substantial, and they may require specific fixtures or adaptations, which could complicate the purchasing decision.

Illustrative image related to how much does it cost to replace headlights

Sealed headlight assemblies are designed as integrated units, often found in newer and luxury vehicles. While they enhance the vehicle’s aesthetic appeal and may include advanced features like adaptive lighting, the cost of replacement can be prohibitively high, especially if the entire assembly must be replaced due to damage or malfunction.

Laser headlights represent the cutting edge of headlight technology, offering exceptional brightness and energy efficiency. However, they are typically reserved for high-end luxury vehicles and come with a very high price tag. Their limited availability and cost may deter many buyers, particularly in regions with budget constraints.

Key Industrial Applications of how much does it cost to replace headlights

| Industry/Sector | Specific Application of how much does it cost to replace headlights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Estimating costs for headlight replacement services | Enhances customer trust and satisfaction through transparency | Supplier reliability, part compatibility, labor rates |

| Fleet Management | Managing headlight maintenance costs for vehicle fleets | Reduces operational downtime and extends vehicle lifespan | Bulk purchasing options, warranty terms, service agreements |

| Vehicle Manufacturing | Costing out headlight assemblies for new models | Helps in competitive pricing and market positioning | Supplier certifications, technological advancements, lead times |

| E-commerce Auto Parts Retailers | Pricing strategies for online headlight replacement parts | Increases sales through competitive pricing and visibility | Inventory management, supplier partnerships, shipping costs |

| Insurance Companies | Assessing claims related to headlight damage and replacement | Streamlines claims processing and improves customer experience | Cost analysis, repair shop partnerships, regional pricing variations |

How Do Automotive Repair Shops Utilize Headlight Replacement Cost Information?

Automotive repair shops leverage information on headlight replacement costs to provide accurate estimates to customers. By understanding the price range for different types of bulbs and assemblies, shops can enhance customer trust and satisfaction. This transparency allows them to manage customer expectations effectively, ultimately resulting in repeat business. For international B2B buyers, understanding local pricing variations and sourcing reliable suppliers is critical for maintaining competitive service offerings.

What Role Does Cost Assessment Play in Fleet Management?

In fleet management, assessing the costs associated with headlight replacements is vital for controlling maintenance budgets. Fleet operators can better manage headlight maintenance schedules, reducing operational downtime and extending the lifespan of vehicles. This proactive approach can lead to significant cost savings over time. International buyers must consider bulk purchasing options and warranty terms when sourcing headlight components, as these factors can significantly impact overall costs.

How Do Vehicle Manufacturers Benefit from Headlight Cost Analysis?

Vehicle manufacturers analyze headlight replacement costs to determine pricing for new models. Understanding the price points for various headlight technologies, such as halogen, HID, or LED, helps manufacturers position their vehicles competitively in the market. They must consider supplier certifications and technological advancements in sourcing headlight components to ensure quality and compliance with international safety standards.

Why Is Pricing Information Critical for E-commerce Auto Parts Retailers?

E-commerce auto parts retailers utilize headlight replacement cost data to develop effective pricing strategies. By analyzing market trends and competitor prices, they can adjust their offerings to attract more customers. This approach not only increases sales but also enhances visibility in a crowded marketplace. For B2B buyers in emerging markets, managing inventory and establishing strong supplier partnerships are essential for maintaining competitive pricing.

Illustrative image related to how much does it cost to replace headlights

How Do Insurance Companies Use Headlight Replacement Cost Data?

Insurance companies assess headlight replacement costs to streamline claims related to vehicle damage. Understanding the typical expenses associated with headlight replacements allows insurers to process claims more efficiently, improving customer experience. For international insurers, regional pricing variations and partnerships with local repair shops are crucial for accurate cost assessments and claims management.

3 Common User Pain Points for ‘how much does it cost to replace headlights’ & Their Solutions

Scenario 1: Navigating High Replacement Costs for Advanced Headlight Systems

The Problem: B2B buyers often face the challenge of replacing headlights in vehicles equipped with advanced lighting systems such as LED or HID. These systems are not only more expensive to replace but can also come with complex installation requirements that significantly increase labor costs. For buyers managing fleets or purchasing vehicles for commercial use, the unpredictability of these expenses can strain budgets, especially when the total cost can range from hundreds to thousands of dollars.

The Solution: To mitigate these costs, it’s essential for buyers to conduct thorough research before making a purchase. Start by consulting the vehicle’s owner manual or a reputable auto parts supplier to identify the specific headlight type required. When sourcing headlights, consider bulk purchasing options from suppliers that offer competitive pricing for fleet operators. Additionally, invest in quality components from trusted brands to ensure longevity and reduce future replacement frequency. Establishing relationships with local mechanics who can provide installation services at a discounted rate for bulk jobs can also help manage labor costs effectively. By planning for replacements ahead of time and ensuring that the right parts are sourced, businesses can avoid unexpected financial burdens.

Scenario 2: Understanding the Variability in Headlight Replacement Costs

The Problem: A common pain point for B2B buyers is the significant variability in headlight replacement costs depending on the vehicle model and headlight type. For instance, while a basic halogen bulb might cost around $10, a complete assembly for luxury vehicles can exceed $4,000. This disparity creates confusion, making it difficult for fleet managers and procurement officers to budget accurately for vehicle maintenance and repair.

Illustrative image related to how much does it cost to replace headlights

The Solution: To address this challenge, B2B buyers should implement a systematic approach to understanding their vehicle fleet’s maintenance needs. Begin by creating a comprehensive inventory of all vehicles, including details such as the make, model, and type of headlight system. Utilize this data to establish a baseline for replacement costs. Regularly consult industry-specific databases or auto parts suppliers to obtain updated pricing information. Additionally, consider utilizing online tools or calculators that can provide cost estimates based on specific vehicle criteria. By keeping meticulous records and regularly reviewing this information, businesses can forecast maintenance costs more accurately and make informed decisions when budgeting for headlight replacements.

Scenario 3: Managing Installation Challenges for Different Headlight Types

The Problem: Many B2B buyers encounter difficulties regarding the installation of headlights, particularly with modern vehicles that often require specialized tools or techniques. This is especially problematic when the complexity of installation can significantly affect labor costs, adding hundreds of dollars to the overall replacement price. For companies operating on tight schedules or with limited resources, the prospect of vehicle downtime can lead to operational disruptions.

The Solution: To alleviate installation challenges, B2B buyers should consider investing in training for their maintenance staff or partnering with professional service providers experienced in headlight installation. Offering workshops or online training sessions can equip in-house teams with the necessary skills to perform these replacements efficiently, thus reducing reliance on external mechanics. Additionally, when purchasing headlights, opt for those that come with clear installation instructions or video tutorials. This approach not only empowers staff but also streamlines the replacement process, ensuring that vehicles are back on the road quickly. Moreover, establishing a strategic partnership with a reliable automotive service provider can provide access to expertise when needed, allowing businesses to maintain operational efficiency while managing costs effectively.

Strategic Material Selection Guide for how much does it cost to replace headlights

What Materials Are Commonly Used in Headlight Replacement and Their Costs?

When considering headlight replacement, the materials used in bulbs and assemblies significantly influence both performance and cost. This analysis focuses on four common materials: glass, polycarbonate, LED components, and HID (High-Intensity Discharge) materials. Each material has distinct properties, advantages, and limitations that affect B2B purchasing decisions.

Illustrative image related to how much does it cost to replace headlights

What Are the Key Properties of Glass in Headlight Applications?

Glass is traditionally used in headlight bulbs, particularly in halogen types. Its key properties include high-temperature resistance and excellent optical clarity, which allows for efficient light transmission. Glass can withstand significant thermal stress, making it suitable for high-heat applications. However, it is prone to shattering upon impact, which can lead to safety issues.

Pros:

– Excellent light clarity and transmission.

– High-temperature resistance.

– Cost-effective for basic applications.

Cons:

– Fragile and prone to breakage.

– Heavier than alternative materials.

– Limited durability in harsh environments.

Impact on Application:

Glass is suitable for standard halogen bulbs but may not be ideal for vehicles requiring advanced lighting systems that demand greater durability.

Illustrative image related to how much does it cost to replace headlights

Considerations for International Buyers:

B2B buyers should ensure compliance with local safety standards, such as ASTM or DIN, especially in regions with varying environmental conditions.

How Do Polycarbonate Materials Enhance Headlight Performance?

Polycarbonate is increasingly used in headlight assemblies due to its lightweight and impact-resistant properties. It offers good optical clarity and can be molded into complex shapes, making it suitable for modern vehicle designs. Polycarbonate also provides better UV resistance compared to glass, reducing yellowing over time.

Pros:

– Lightweight and impact-resistant.

– Excellent UV resistance.

– Versatile for complex designs.

Cons:

– Prone to scratching without proper coatings.

– Generally more expensive than glass.

– May require specific manufacturing processes.

Impact on Application:

Polycarbonate is ideal for modern vehicles with intricate headlight designs, contributing to improved aerodynamics and aesthetics.

Illustrative image related to how much does it cost to replace headlights

Considerations for International Buyers:

Buyers should verify that polycarbonate products meet international standards for UV resistance and impact performance, particularly in regions with extreme weather conditions.

What Are the Advantages of LED Components in Headlight Systems?

LED technology has revolutionized automotive lighting, offering longer lifespans and lower energy consumption. LED components are highly efficient, with a lifespan that can exceed 40,000 hours, significantly reducing maintenance costs. They also provide superior brightness and visibility, enhancing safety.

Pros:

– Long lifespan and low energy consumption.

– High brightness and visibility.

– Minimal heat generation.

Illustrative image related to how much does it cost to replace headlights

Cons:

– Higher initial cost compared to halogen bulbs.

– Complex installation and compatibility issues.

– Requires specific heat management systems.

Impact on Application:

LEDs are suitable for high-end vehicles and those requiring adaptive lighting systems, but their installation may necessitate professional assistance.

Considerations for International Buyers:

B2B buyers should consider the availability of replacement parts and ensure compliance with local electrical standards, as LED systems can vary significantly by region.

Why Are HID Materials Important for Advanced Lighting Solutions?

HID systems provide intense brightness and are often used in luxury vehicles. These systems utilize a gas-filled bulb that produces light when an electric arc is created. HID lights are known for their superior illumination range and color temperature options.

Pros:

– Exceptional brightness and range.

– Longer lifespan than halogen bulbs.

– Aesthetic appeal with various color temperatures.

Illustrative image related to how much does it cost to replace headlights

Cons:

– Higher cost for both bulbs and installation.

– Requires a ballast for operation, adding complexity.

– Slower warm-up time compared to LEDs.

Impact on Application:

HID systems are best suited for high-performance vehicles and applications where visibility is paramount, but they require careful consideration regarding installation and maintenance.

Considerations for International Buyers:

Buyers must ensure compliance with local regulations regarding light intensity and color temperatures, as these can vary widely across regions.

Summary Table of Material Selection for Headlight Replacement Costs

| Material | Typical Use Case for how much does it cost to replace headlights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Halogen bulb replacements | Excellent light clarity | Fragile and prone to breakage | Low |

| Polycarbonate | Modern headlight assemblies | Lightweight and impact-resistant | Prone to scratching | Med |

| LED | High-end vehicle lighting systems | Long lifespan and energy-efficient | Higher initial cost | High |

| HID | Luxury vehicle lighting systems | Exceptional brightness | Requires complex installation | High |

This comprehensive analysis of materials used in headlight replacements provides B2B buyers with valuable insights into the costs, benefits, and considerations necessary for making informed purchasing decisions in diverse international markets.

Illustrative image related to how much does it cost to replace headlights

In-depth Look: Manufacturing Processes and Quality Assurance for how much does it cost to replace headlights

What Are the Main Stages of Manufacturing Headlight Components?

The manufacturing process for headlight components involves several critical stages, each designed to ensure high-quality products that meet safety and performance standards. Understanding these stages is essential for B2B buyers looking to source reliable automotive lighting solutions.

Material Preparation: What Raw Materials Are Used?

The manufacturing of headlights typically begins with the selection of raw materials. Common materials include polycarbonate or glass for the lens, aluminum or plastic for housing, and various alloys for electrical components. The choice of materials significantly affects the durability, weight, and cost of the headlights. For example, polycarbonate lenses are favored for their impact resistance and weight reduction, while glass offers better optical clarity but is heavier and more prone to shattering.

Forming: How Are Components Shaped?

After material selection, the forming stage begins. This involves processes such as injection molding for plastic components and glass molding for lenses. Injection molding allows for high-volume production with precise specifications, ensuring that each part meets the required design and performance standards. For glass lenses, processes like blow molding or press molding are employed to achieve the desired shape and thickness.

Assembly: What Techniques Are Employed?

The assembly stage is where various components come together. Automated assembly lines are commonly used, where parts are combined using advanced robotics and manual labor. Techniques such as ultrasonic welding and adhesive bonding are often employed to ensure airtight seals that protect against moisture and dust, which can significantly affect headlight performance. Additionally, the integration of electronic components, such as LED drivers or sensors for adaptive lighting, occurs during this phase.

Finishing: How Are Headlights Prepared for Distribution?

The finishing stage involves several processes to enhance the appearance and performance of headlights. This can include surface treatments to improve scratch resistance, UV protection coatings to prevent yellowing, and final inspections to ensure compliance with quality standards. The headlights are then packaged for shipment, often including protective materials to prevent damage during transit.

What Quality Control Measures Are Implemented in Headlight Manufacturing?

Quality control (QC) is a vital aspect of headlight manufacturing, ensuring that the final products meet international safety and performance standards. For B2B buyers, understanding the QC measures in place can help in selecting reliable suppliers.

What International Standards Govern Headlight Production?

Manufacturers often adhere to international quality management standards such as ISO 9001, which focuses on continuous improvement and customer satisfaction. Additionally, headlights sold in Europe must comply with CE marking requirements, indicating conformity with health, safety, and environmental protection standards. For specific automotive components, certifications from organizations like the American Petroleum Institute (API) may also apply, particularly if the headlights incorporate advanced technologies.

What Are the Key QC Checkpoints During Production?

Quality control in headlight manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified standards. Defective materials are rejected, preventing downstream issues.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and tests are conducted to monitor production quality. This includes verifying dimensions, functionality, and assembly integrity.

-

Final Quality Control (FQC): The final stage involves comprehensive testing of finished products. This may include photometric testing to assess light output, durability tests for environmental resistance, and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

For international B2B buyers, verifying a supplier’s quality control procedures is essential to ensure the reliability and safety of headlight products. Here are several methods to consider:

What Audit Processes Should Be Implemented?

Conducting supplier audits is a key strategy for assessing quality control practices. This can involve on-site visits to review manufacturing processes, QC measures, and compliance with international standards. B2B buyers should inquire about the frequency and scope of these audits and whether they are conducted by internal teams or third-party organizations.

Illustrative image related to how much does it cost to replace headlights

What Documentation and Reporting Should Be Requested?

Buyers should request detailed QC reports, including results from IQC, IPQC, and FQC processes. Documentation should also include certifications from recognized bodies, quality assurance manuals, and records of past audits. This information can provide insight into the supplier’s commitment to quality and reliability.

How Important Is Third-Party Inspection?

Utilizing third-party inspection services can add an extra layer of assurance. These independent organizations can conduct audits and tests to validate the supplier’s claims regarding quality control. This is particularly important for B2B buyers from regions like Africa, South America, the Middle East, and Europe, where varying standards and practices may exist.

What Are the Nuances of Quality Control for International B2B Buyers?

Navigating quality control in international markets presents unique challenges. B2B buyers need to be aware of regional standards and regulations that may differ significantly from their home countries.

Illustrative image related to how much does it cost to replace headlights

How Do Regional Standards Impact Quality Assurance?

Different regions may have specific standards that manufacturers must comply with. For example, automotive lighting regulations in Europe may differ from those in Africa or South America. Buyers should familiarize themselves with these regional standards to ensure that the products they source are compliant and safe for their markets.

What Should Buyers Know About Cultural and Communication Differences?

Cultural differences can impact quality control practices and communication with suppliers. B2B buyers should be prepared to engage in clear and respectful dialogue, ensuring that expectations regarding quality are understood and met. Utilizing local representatives or experts familiar with the region can facilitate smoother interactions and help bridge any gaps in understanding.

Conclusion

The manufacturing processes and quality assurance for headlight replacements are complex and multifaceted. For B2B buyers, understanding these processes is essential for making informed purchasing decisions. By focusing on material preparation, forming, assembly, and finishing, as well as robust quality control measures, buyers can ensure they are sourcing high-quality, compliant products that meet the needs of their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does it cost to replace headlights’

Introduction

This guide serves as a practical checklist for B2B buyers looking to understand the costs associated with replacing headlights. Whether you’re in the automotive supply chain or managing a fleet, knowing the factors that influence headlight replacement costs is essential for making informed purchasing decisions. This checklist will help you navigate through various considerations, from identifying the type of headlights needed to evaluating supplier capabilities.

Step 1: Identify Headlight Type and Specifications

Understanding the type of headlight your vehicles require is the first step in cost estimation. Different vehicles utilize various headlight technologies, including halogen, HID, and LED, each with unique pricing structures and lifespans. Consult your vehicle’s manual or an online database to determine the correct specifications, ensuring you procure the right products for your needs.

Illustrative image related to how much does it cost to replace headlights

Step 2: Estimate Total Replacement Costs

Calculate the total costs involved in headlight replacement, which includes both parts and labor. For simple bulb replacements, costs can range from $10 to $100, while complete headlight assemblies can reach thousands of dollars, especially for modern vehicles with advanced lighting systems. Understanding these costs upfront can help you budget appropriately and make strategic purchasing decisions.

Step 3: Research Supplier Options

Before making a purchase, conduct thorough research on potential suppliers. Look for suppliers that specialize in automotive parts and have a strong reputation in your target market. Pay attention to their inventory, pricing, and the range of products available to ensure they can meet your needs.

- Consider regional suppliers: Local suppliers may offer faster shipping times and reduced costs.

- Evaluate online marketplaces: Platforms like Alibaba or specialized auto parts websites can provide competitive pricing and extensive product selections.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers have the necessary certifications and comply with local and international standards. This is crucial for maintaining safety and quality in your headlight replacements. Look for certifications such as ISO or DOT compliance, which indicate adherence to industry regulations.

Step 5: Request Sample Products

Before finalizing your order, request samples of the headlight products you intend to purchase. This step allows you to assess quality firsthand, ensuring that the products meet your expectations in terms of performance and durability. It also provides an opportunity to evaluate the supplier’s responsiveness and customer service.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure the best possible pricing and terms. Discuss bulk order discounts, payment terms, and return policies. Effective negotiation can significantly impact your overall costs, especially if you’re sourcing for a fleet or multiple vehicles.

Step 7: Plan for Ongoing Maintenance and Replacement

Consider implementing a routine maintenance schedule for headlight inspections and replacements. Establishing a proactive approach will help minimize costs associated with emergency replacements and enhance safety for drivers. This planning can also facilitate better forecasting for future purchases, ensuring you always have the necessary components on hand.

By following these steps, B2B buyers can effectively navigate the complexities of headlight replacement costs and make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for how much does it cost to replace headlights Sourcing

What Are the Key Cost Components in Headlight Replacement?

The cost of replacing headlights involves several key components. Materials are the primary factor, with prices varying significantly based on the type of bulb. Halogen bulbs can cost as little as $10, while high-intensity discharge (HID) and LED bulbs can exceed $100. Additionally, if the entire headlight assembly needs replacement, costs can range from $30 to over $4,000, depending on the vehicle’s make and model.

Labor costs add another layer to the total expenditure. Professional installation can range from $30 to $300 for bulb replacement, while complete assembly replacements can incur labor charges of $100 to $400. The time required for these tasks can vary significantly based on vehicle design, with some requiring bumper removal or other complex steps.

Illustrative image related to how much does it cost to replace headlights

Manufacturing overhead, tooling, and quality control (QC) costs also factor into the overall price. These costs can influence the final pricing of headlight components, particularly for custom or specialized parts. Logistics costs, including shipping and handling, are critical, especially for international buyers who must consider additional fees like tariffs and import duties.

How Do Price Influencers Affect Headlight Replacement Costs?

Several price influencers can significantly affect the cost of headlight replacements. Volume and minimum order quantities (MOQ) play a crucial role in B2B transactions. Bulk purchases can lead to significant discounts, allowing companies to optimize their budget for fleet maintenance or inventory stocking.

Specifications and customization of headlights can also drive costs. Custom-designed headlights or those with advanced features such as adaptive lighting may require additional investment in tooling and engineering, leading to higher prices.

Illustrative image related to how much does it cost to replace headlights

Moreover, the quality and certifications of the materials used can impact pricing. For instance, bulbs meeting specific safety standards, such as those endorsed by the U.S. Department of Transportation (DOT), may cost more but offer greater reliability and safety.

Supplier factors, including their reputation, production capacity, and geographic location, can further influence costs. Buyers should assess suppliers based on their ability to meet quality standards and delivery timelines, as these can affect the total cost of ownership.

Incoterms also play a pivotal role in international transactions. Understanding who bears the responsibility for shipping costs, insurance, and customs duties can significantly affect the final price and overall budget.

Illustrative image related to how much does it cost to replace headlights

What Are Effective Buyer Tips for Cost-Efficiency in Headlight Replacement?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, negotiating favorable terms is essential. Understanding the total cost of ownership, which includes initial purchase price, installation, and long-term maintenance, can help in making informed decisions.

Buyers should also consider negotiation strategies to secure better pricing, such as leveraging bulk purchases or forming long-term partnerships with suppliers. Requesting detailed quotes that break down costs into materials, labor, and logistics can provide clearer insights into pricing structures and opportunities for cost savings.

It’s important to be aware of pricing nuances when dealing with international suppliers. Fluctuations in currency exchange rates, regional tariffs, and varying import regulations can all impact final costs.

Lastly, always conduct a thorough assessment of potential suppliers. Factors such as their reliability, quality certifications, and track record in delivering on time can make a significant difference in ensuring a smooth purchasing experience.

Disclaimer for Indicative Prices

The prices mentioned are indicative and can vary based on several factors, including geographical location, supplier pricing strategies, and market demand. Buyers should conduct their own market research and obtain multiple quotes to ensure they are getting the best value for their investment.

Illustrative image related to how much does it cost to replace headlights

Alternatives Analysis: Comparing how much does it cost to replace headlights With Other Solutions

Exploring Alternative Solutions for Headlight Replacement

In the automotive sector, replacing headlights is a critical maintenance task that ensures safety and visibility. However, several alternatives exist for achieving similar outcomes, each with its own set of advantages and challenges. This analysis compares the traditional method of replacing headlights with other viable solutions, providing B2B buyers with comprehensive insights.

| Comparison Aspect | How Much Does It Cost To Replace Headlights | Headlight Restoration Kits | Upgrading to LED Technology |

|---|---|---|---|

| Performance | Restores original brightness and safety. | Improves clarity of existing lenses; may not replace bulbs. | Offers superior brightness and longevity. |

| Cost | $30 to $4,000 depending on assembly and labor. | $15 to $50 for a kit. | $100 to $500+ for high-quality LED systems. |

| Ease of Implementation | Requires professional or DIY skills; may need tools. | DIY-friendly, straightforward application. | Installation may require professional help. |

| Maintenance | Periodic replacement every 1-3 years, depending on type. | Lasts until lenses degrade again; minimal upkeep. | Long-lasting; minimal maintenance. |

| Best Use Case | Necessary for safety compliance; varies by vehicle type. | Ideal for restoring faded or cloudy lenses. | Best for modernizing vehicles with outdated lighting. |

What Are Headlight Restoration Kits and How Do They Compare?

Headlight restoration kits are designed to improve the clarity of existing headlight lenses, which can become cloudy or yellowed over time due to UV exposure and environmental factors. These kits are often DIY-friendly and cost-effective, typically ranging from $15 to $50. While they do enhance visibility by restoring the lens clarity, they do not replace burnt-out bulbs or faulty assemblies. The main advantage is the cost savings and ease of use, but the downside is that they may only offer a temporary fix, requiring reapplication or eventual bulb replacement.

How Does Upgrading to LED Technology Work?

Upgrading to LED technology involves replacing traditional halogen or HID bulbs with LED alternatives. This option can provide brighter illumination, improved energy efficiency, and a longer lifespan, often lasting up to 40,000 hours compared to the shorter lifespan of halogen bulbs. However, the upfront costs for high-quality LED systems can range from $100 to over $500, depending on the vehicle and type of LEDs chosen. While installation can often be completed by a knowledgeable DIYer, many prefer professional installation due to the complexity of some modern vehicles. The primary advantage of this option is enhanced safety and visibility, while the initial investment can be a barrier for some buyers.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate headlight solution, B2B buyers should assess their specific needs, including vehicle type, budget constraints, and intended use. For fleet operators or businesses relying on vehicle safety, investing in high-quality replacements or upgrades may yield long-term benefits in terms of safety and efficiency. Conversely, for companies looking to maintain older vehicles or those with budget limitations, restoration kits might present a cost-effective interim solution. Ultimately, a thorough evaluation of performance, cost, and implementation ease will guide buyers toward the most effective choice for their operations.

Essential Technical Properties and Trade Terminology for how much does it cost to replace headlights

What Are the Key Technical Properties to Consider When Replacing Headlights?

When it comes to replacing headlights, understanding the technical properties of different bulb types and assemblies is crucial for international B2B buyers. Here are some critical specifications to consider:

-

Bulb Type

Headlights primarily come in three types: Halogen, High-Intensity Discharge (HID), and Light Emitting Diode (LED). Halogen bulbs are the most affordable but have a shorter lifespan, typically lasting between 500 to 1,000 hours. HIDs offer brighter light but are more costly, ranging from $20 to $100. LEDs last the longest, often up to 40,000 hours, but can cost significantly more, sometimes exceeding $100 per bulb. -

Wattage

The wattage of a headlight bulb affects both brightness and energy consumption. Standard halogen bulbs usually range from 55W to 100W. Higher wattage can provide better illumination but may require adjustments to the vehicle’s electrical system. Understanding wattage is essential for ensuring compatibility with the vehicle’s specifications and for compliance with international safety standards. -

Assembly Material

The materials used in headlight assemblies can vary widely, affecting durability and performance. Most assemblies are made from polycarbonate or glass, with polycarbonate being lighter and more resistant to shattering but prone to yellowing over time. Buyers should consider the material’s longevity and the environmental factors it may encounter, such as UV exposure and extreme temperatures. -

Installation Complexity

The ease or complexity of installation can significantly impact total costs. Some vehicles require specialized tools or may necessitate the removal of components like the front bumper to access the headlights. Understanding the installation process can help businesses make informed decisions about whether to engage professional services or conduct installations in-house. -

Light Output (Lumen)

Light output, measured in lumens, indicates the brightness of the headlight. Higher lumen ratings generally mean better visibility. For B2B buyers, selecting headlights with optimal lumen output for specific vehicles can enhance safety and compliance with regional lighting regulations.

What Are Common Trade Terms Related to Headlight Replacement?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM parts are components made by the vehicle manufacturer. These are often preferred for their guaranteed compatibility and quality. However, they can be more expensive than aftermarket alternatives. Understanding the difference helps buyers assess the value of parts in relation to their budget and quality requirements. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cost calculations. Buyers should negotiate MOQ based on their consumption patterns and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. This process is essential for obtaining competitive pricing and understanding market trends. A well-structured RFQ can lead to better deals and stronger supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, especially regarding shipping and freight costs. Familiarity with these terms is crucial for managing logistics and ensuring that all parties understand their obligations, reducing the risk of misunderstandings. -

Warranty Terms

Warranty terms outline the conditions under which a manufacturer will replace or repair defective products. Understanding these terms is essential for B2B buyers to mitigate risks associated with product failure and ensure they are covered in case of defects.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions regarding headlight replacements, ensuring that they choose the best options for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the how much does it cost to replace headlights Sector

What Are the Key Market Dynamics Affecting the Cost of Headlight Replacement?

The global market for headlight replacement is influenced by several key factors. As vehicle technology advances, the complexity of headlight systems has increased, leading to higher replacement costs. For instance, vehicles equipped with high-intensity discharge (HID) or light-emitting diode (LED) lights often require entire assemblies to be replaced, rather than just the bulbs. This trend is particularly pronounced in high-end vehicles where advanced lighting features are standard. Additionally, the rising demand for vehicle safety has prompted manufacturers to integrate more sophisticated lighting technologies, further driving up costs.

Emerging markets in Africa and South America are witnessing increased vehicle ownership, resulting in heightened demand for replacement parts, including headlights. B2B buyers in these regions should be aware of the diverse product offerings available. For instance, while halogen bulbs remain a cost-effective choice, LED and HID options are becoming increasingly popular due to their longevity and brightness. Furthermore, the trend toward online sourcing is gaining traction, allowing buyers to access a wider array of products and competitive pricing.

The global supply chain is also adapting to shifting consumer preferences. As e-commerce grows, international buyers can leverage platforms that offer transparent pricing and sourcing options. However, they must remain vigilant regarding potential supply chain disruptions, which can affect availability and lead to price fluctuations. Therefore, understanding local market dynamics, including regional preferences and regulations, is crucial for B2B buyers looking to optimize their sourcing strategies.

How Is Sustainability Impacting the Sourcing of Headlight Replacement Parts?

Sustainability is becoming a pivotal concern in the automotive industry, including the sourcing of headlight replacement parts. With growing awareness of environmental impacts, B2B buyers are increasingly seeking suppliers who prioritize ethical sourcing practices. This includes using sustainable materials and ensuring that production processes minimize waste and carbon emissions.

The environmental impact of headlight replacements can be significant, particularly with the disposal of outdated bulbs and assemblies. Buyers are encouraged to opt for suppliers that offer recycling programs for spent parts, as well as those that utilize recyclable materials in their products. Additionally, certifications such as ISO 14001 can indicate a supplier’s commitment to environmental management, making them more attractive partners for B2B transactions.

Illustrative image related to how much does it cost to replace headlights

Moreover, the trend toward “green” headlights, such as energy-efficient LED bulbs, is gaining traction. These products not only reduce energy consumption but also have a longer lifespan, which can lead to lower replacement rates and a smaller environmental footprint over time. As B2B buyers increasingly consider sustainability in their purchasing decisions, they can foster partnerships with manufacturers that align with these values, ultimately contributing to a more sustainable automotive ecosystem.

What Is the Evolution of Headlight Technology and Its Impact on Replacement Costs?

The evolution of headlight technology has significantly influenced the cost and complexity of replacements. Initially, incandescent bulbs were the standard, offering a straightforward and inexpensive replacement process. However, advancements in automotive lighting have introduced halogen, HID, and LED technologies, each with distinct benefits and challenges.

Halogen bulbs, while inexpensive and easy to replace, have a shorter lifespan compared to their modern counterparts. HID and LED systems, although more costly, provide superior brightness and energy efficiency, making them popular choices for contemporary vehicles. This shift has resulted in a marked increase in replacement costs, especially for vehicles that require complete headlight assemblies due to the sealed nature of modern designs.

As manufacturers continue to innovate, the market is likely to see further developments in headlight technology, including adaptive lighting and advanced driver-assistance systems (ADAS). These advancements promise improved safety and visibility but may also lead to higher replacement costs due to the complexity of the components involved. For B2B buyers, staying informed about these technological trends is essential for making strategic sourcing decisions that align with market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of how much does it cost to replace headlights

-

1. How do I determine the cost of replacing headlights for different vehicle models?

To accurately estimate the cost of replacing headlights, first identify the make and model of the vehicle in question. Costs can vary significantly based on factors such as the type of headlight (halogen, HID, LED) and whether you need to replace just the bulb or the entire assembly. Researching local suppliers for parts pricing and consulting with mechanics can provide insight into labor costs. It’s beneficial to gather quotes from multiple sources to ensure competitive pricing. -

2. What is the best type of headlight for commercial vehicles?

For commercial vehicles, LED headlights are often the best choice due to their longevity, energy efficiency, and superior visibility. Although they come at a higher initial cost compared to halogen bulbs, their longer lifespan (up to 40,000 hours) and lower energy consumption can lead to significant savings over time. It’s important to consider the specific requirements of the vehicle and local regulations when selecting headlights, as some regions may have restrictions on certain types. -

3. What factors should I consider when sourcing headlight replacement parts internationally?

When sourcing headlight replacement parts internationally, consider quality, compliance with local regulations, and supplier reliability. Verify that the parts meet the necessary safety and performance standards, such as DOT approval. Additionally, assess the supplier’s reputation through reviews and references, and ensure they can provide consistent product availability and support. Understanding the specific needs of your market, including preferred bulb types and assembly requirements, will also help in making an informed decision. -

4. How can I vet suppliers for headlight replacement parts?

To effectively vet suppliers, start by researching their business history, product quality, and customer reviews. Request samples to evaluate the quality of their headlight components. It’s also wise to check for certifications that align with industry standards. Establish communication with the supplier to gauge their responsiveness and willingness to address your specific needs. Building a relationship based on transparency and reliability will aid in long-term collaboration. -

5. What are common payment terms for international B2B transactions in headlight sourcing?

Common payment terms for international B2B transactions typically include options such as Letter of Credit (LC), bank transfers (T/T), and PayPal. Payment terms may vary based on the supplier’s policies and your negotiation. It’s advisable to establish clear terms upfront, including deposit requirements, payment schedules, and any contingencies related to product quality or delivery timelines. Understanding local currency risks and transaction fees is also essential for budgeting. -

6. What is the minimum order quantity (MOQ) for headlight replacement parts?

Minimum order quantities (MOQs) for headlight replacement parts can vary widely among suppliers. Some may set an MOQ as low as 50 units, while others may require orders of 500 or more. It’s crucial to discuss your needs with potential suppliers and negotiate MOQs that align with your purchasing strategy. Consider whether you can accommodate larger orders to secure better pricing while maintaining inventory levels that suit your business operations. -

7. How can I ensure the quality of headlight replacement parts I source?

To ensure quality, request detailed product specifications and certifications from your suppliers. Implement a quality assurance process that includes inspections upon arrival and before distribution. Establishing a relationship with suppliers who have a proven track record of quality can also mitigate risks. Additionally, consider third-party testing or audits to verify that products meet industry standards and perform reliably. -

8. What logistics considerations should I keep in mind when importing headlights?

When importing headlights, consider shipping methods, customs regulations, and lead times. Assess whether air freight or sea freight is more cost-effective for your needs. Be aware of any import duties and taxes that may apply, as these can significantly impact overall costs. Establish relationships with freight forwarders who specialize in automotive parts to streamline the logistics process and ensure timely delivery of your products.

Top 4 How Much Does It Cost To Replace Headlights Manufacturers & Suppliers List

1. Ford – Fusion Headlight Replacement

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2014 Ford Fusion; front left headlight bulb needs replacement; quoted labor cost of $300; oil change place refused to do the replacement; extensive labor involved, requiring a lift and removal of several body panels.

2. Honda Clarity – Headlight Replacement Costs

Domain: insideevsforum.com

Registered: 2017 (8 years)

Introduction: Headlight replacement for Honda Clarity costs $1500 per headlight, totaling $3000 for both front headlights. The headlights use a sealed assembly with no replaceable bulbs, likely consisting of a string of LEDs. Some users suggest that the dimness may be due to hazy lenses that could potentially be polished.

3. Lexus – RX Headlight Upgrade

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Lexus RX all generations, cost to change headlights to new style

4. Toyota Camry – Low Beam Bulb Replacement

Domain: community.cartalk.com

Registered: 1995 (30 years)

Introduction: Dealer quoted $445 for low beam bulb replacement for a Toyota Camry.

Strategic Sourcing Conclusion and Outlook for how much does it cost to replace headlights

In conclusion, understanding the cost of replacing headlights is essential for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. The costs can range significantly based on the type of bulb and the complexity of the installation, with halogen bulbs being the most economical while high-tech LED or HID assemblies can reach thousands of dollars. By strategically sourcing high-quality components and considering both DIY options and professional installations, businesses can optimize their expenditures and enhance vehicle safety.

Illustrative image related to how much does it cost to replace headlights

Investing in reliable headlight solutions not only ensures compliance with safety standards but also builds trust with customers who prioritize vehicle performance. As automotive technology continues to evolve, staying informed about the latest lighting options and their costs will be critical for maintaining competitive advantage.

We encourage B2B buyers to engage with trusted suppliers and leverage local market insights to make informed purchasing decisions. This proactive approach will facilitate better sourcing strategies and ultimately drive growth in the automotive sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how much does it cost to replace headlights