Introduction: Navigating the Global Market for how much does it cost to replace a headlight assembly

Navigating the complexities of how much it costs to replace a headlight assembly can be a daunting challenge for international B2B buyers. With varying regulations, market prices, and supplier reliability across regions such as Africa, South America, the Middle East, and Europe, making informed purchasing decisions becomes crucial. This guide delves into the multifaceted aspects of headlight assembly replacement costs, addressing everything from the types of assemblies available and their applications to the intricacies of sourcing high-quality components.

Understanding the financial implications of headlight assembly replacement is essential for optimizing operational budgets and ensuring safety standards in vehicle fleets. The guide covers essential considerations such as the differences between OEM and aftermarket parts, the impact of vehicle type on costs, and labor expenses associated with installations. Additionally, we provide insights into effective supplier vetting processes, ensuring you choose reliable partners who meet your specific needs.

By leveraging this comprehensive resource, B2B buyers will be empowered to make strategic decisions that align with their operational goals. Whether you’re in Germany seeking high-tech LED assemblies or in Brazil looking for cost-effective halogen solutions, this guide offers the information necessary to navigate the global market confidently and effectively.

Table Of Contents

- Top 4 How Much Does It Cost To Replace A Headlight Assembly Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much does it cost to replace a headlight assembly

- Understanding how much does it cost to replace a headlight assembly Types and Variations

- Key Industrial Applications of how much does it cost to replace a headlight assembly

- 3 Common User Pain Points for ‘how much does it cost to replace a headlight assembly’ & Their Solutions

- Strategic Material Selection Guide for how much does it cost to replace a headlight assembly

- In-depth Look: Manufacturing Processes and Quality Assurance for how much does it cost to replace a headlight assembly

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does it cost to replace a headlight assembly’

- Comprehensive Cost and Pricing Analysis for how much does it cost to replace a headlight assembly Sourcing

- Alternatives Analysis: Comparing how much does it cost to replace a headlight assembly With Other Solutions

- Essential Technical Properties and Trade Terminology for how much does it cost to replace a headlight assembly

- Navigating Market Dynamics and Sourcing Trends in the how much does it cost to replace a headlight assembly Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much does it cost to replace a headlight assembly

- Strategic Sourcing Conclusion and Outlook for how much does it cost to replace a headlight assembly

- Important Disclaimer & Terms of Use

Understanding how much does it cost to replace a headlight assembly Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Halogen Headlight Assembly | Simple design, lower cost, widely available | Budget-conscious vehicle fleets | Pros: Affordable, easy to replace. Cons: Shorter lifespan compared to LEDs and HIDs. |

| HID Headlight Assembly | High-intensity discharge technology, brighter output | Luxury vehicles, high-performance cars | Pros: Superior visibility, energy-efficient. Cons: Higher replacement costs, complex installation. |

| LED Headlight Assembly | Long-lasting, energy-efficient, modern aesthetics | Electric vehicles, premium brands | Pros: Extended lifespan, lower energy consumption. Cons: Higher initial investment, potential compatibility issues. |

| Adaptive Headlight Assembly | Features auto-leveling and directional lighting | High-end automotive markets | Pros: Enhanced safety, improved visibility. Cons: Expensive, requires precise installation and calibration. |

| Aftermarket Headlight Assembly | Cost-effective alternatives to OEM parts | Repair shops, independent mechanics | Pros: Lower costs, varied options. Cons: Quality may vary, potential fitment issues. |

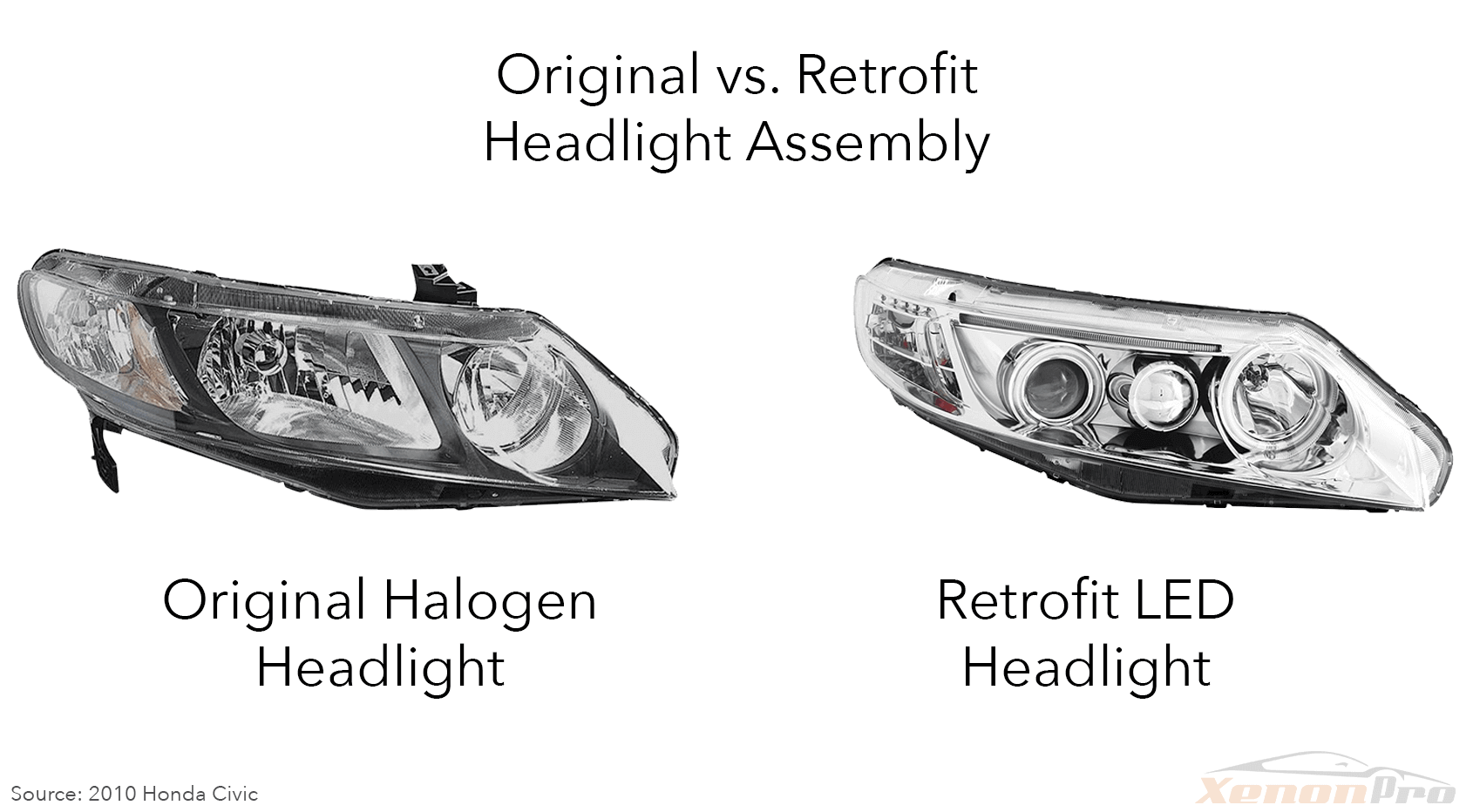

What are Halogen Headlight Assemblies and Their Suitability for B2B Buyers?

Halogen headlight assemblies are the most basic and cost-effective option available. They are characterized by their simple design and are widely used in budget-conscious vehicle fleets. B2B buyers, particularly those managing fleets or looking for economical repairs, may find halogen assemblies suitable due to their low cost and straightforward installation process. However, the shorter lifespan compared to more advanced technologies can lead to more frequent replacements, impacting long-term cost efficiency.

How Do HID Headlight Assemblies Benefit Luxury Vehicle Markets?

High-Intensity Discharge (HID) headlight assemblies are designed for superior brightness and visibility, making them ideal for luxury vehicles and high-performance cars. B2B buyers in the automotive sector focusing on premium markets will appreciate the enhanced safety features and energy efficiency that HID systems offer. While they come at a higher replacement cost and require more complex installation, the benefits in terms of visibility and performance can justify the investment for high-end applications.

What Advantages Do LED Headlight Assemblies Offer for Electric Vehicles?

LED headlight assemblies are known for their longevity and energy efficiency, making them increasingly popular in electric vehicles and premium brands. B2B buyers should consider LED options for their modern aesthetics and lower energy consumption, which can lead to reduced operational costs. However, the higher initial investment and potential compatibility issues with older vehicle models are important considerations that may affect purchasing decisions.

Illustrative image related to how much does it cost to replace a headlight assembly

Why Choose Adaptive Headlight Assemblies for High-End Automotive Markets?

Adaptive headlight assemblies feature advanced technology that allows for auto-leveling and directional lighting, significantly enhancing safety for drivers. These systems are particularly suitable for high-end automotive markets where safety and performance are paramount. B2B buyers must be aware that while these assemblies offer exceptional benefits, they come with a high price point and require precise installation and calibration, which can increase overall service costs.

What Should B2B Buyers Know About Aftermarket Headlight Assemblies?

Aftermarket headlight assemblies provide cost-effective alternatives to OEM parts, making them appealing to repair shops and independent mechanics. B2B buyers can benefit from the lower costs and varied options available in the aftermarket space. However, it’s crucial to assess the quality of these parts, as they can vary significantly, potentially leading to fitment issues and affecting the overall performance of the vehicle.

Key Industrial Applications of how much does it cost to replace a headlight assembly

| Industry/Sector | Specific Application of how much does it cost to replace a headlight assembly | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Estimating costs for headlight assembly replacements for customers | Enhances customer trust and satisfaction by providing transparent pricing | Access to a diverse range of OEM and aftermarket parts |

| Fleet Management | Budgeting for headlight assembly replacements across a fleet of vehicles | Reduces unexpected expenses and improves fleet safety | Reliable suppliers with bulk purchasing options |

| Insurance Companies | Evaluating repair costs for claims involving headlight assembly damage | Streamlines the claims process and ensures accurate settlements | Partnerships with automotive repair shops for accurate estimates |

| E-commerce Retailers | Setting competitive pricing for headlight assembly products | Increases sales by aligning with market expectations | Inventory management for diverse headlight assembly types |

| Vehicle Manufacturers | Cost analysis for warranty claims related to headlight assembly failures | Improves warranty management and customer service | Collaboration with suppliers for quality assurance and pricing |

In the automotive repair shops sector, understanding the cost to replace a headlight assembly is crucial for service transparency. Shops can provide customers with accurate estimates, which fosters trust and encourages repeat business. Additionally, they must ensure they have access to a variety of parts, including both OEM and aftermarket options, to meet diverse customer needs.

Illustrative image related to how much does it cost to replace a headlight assembly

For fleet management, budgeting for headlight assembly replacements is essential to maintain operational efficiency and safety. Fleet managers need to anticipate these costs to avoid unexpected expenses that could disrupt service. Reliable suppliers that offer bulk purchasing options are important, as they help manage costs effectively while ensuring all vehicles remain roadworthy.

In the realm of insurance companies, evaluating headlight assembly replacement costs is vital for processing claims accurately. Insurers benefit from having a clear understanding of these costs, which facilitates quicker settlements and enhances customer satisfaction. Establishing partnerships with automotive repair shops can provide insurers with accurate estimates that streamline the claims process.

E-commerce retailers selling headlight assemblies must set competitive pricing to attract buyers. Understanding the market rates for various assembly types allows them to align their pricing strategies with customer expectations. Effective inventory management is crucial, as retailers need to stock a diverse range of products to meet varying demands.

Lastly, vehicle manufacturers can utilize cost analyses of headlight assembly replacements to manage warranty claims effectively. By understanding the costs associated with assembly failures, manufacturers can enhance their warranty management processes and improve overall customer service. Collaborating with suppliers ensures that manufacturers maintain quality while also staying competitive in pricing.

3 Common User Pain Points for ‘how much does it cost to replace a headlight assembly’ & Their Solutions

Scenario 1: Confusion Over Headlight Assembly Pricing Variability

The Problem: B2B buyers often encounter significant variability in the cost of headlight assemblies, depending on factors like vehicle make and model, assembly type, and whether they choose OEM or aftermarket parts. This unpredictability can complicate budgeting and lead to unexpected expenses, especially for businesses managing fleets or automotive repair shops. Buyers may feel overwhelmed by the options and uncertain about how to make the most cost-effective choice without compromising quality or safety.

The Solution: To navigate this pricing complexity, B2B buyers should conduct thorough research on the specific headlight assemblies suited for their vehicles or inventory. Start by compiling a list of vehicle makes and models you frequently service or operate. Utilize online resources and databases to compare prices between OEM and aftermarket options, paying close attention to warranty and return policies. Establish partnerships with reputable suppliers who can provide bulk purchasing discounts or loyalty programs. By leveraging these relationships, buyers can negotiate better terms and ensure they are obtaining high-quality parts at competitive prices, ultimately streamlining their cost management process.

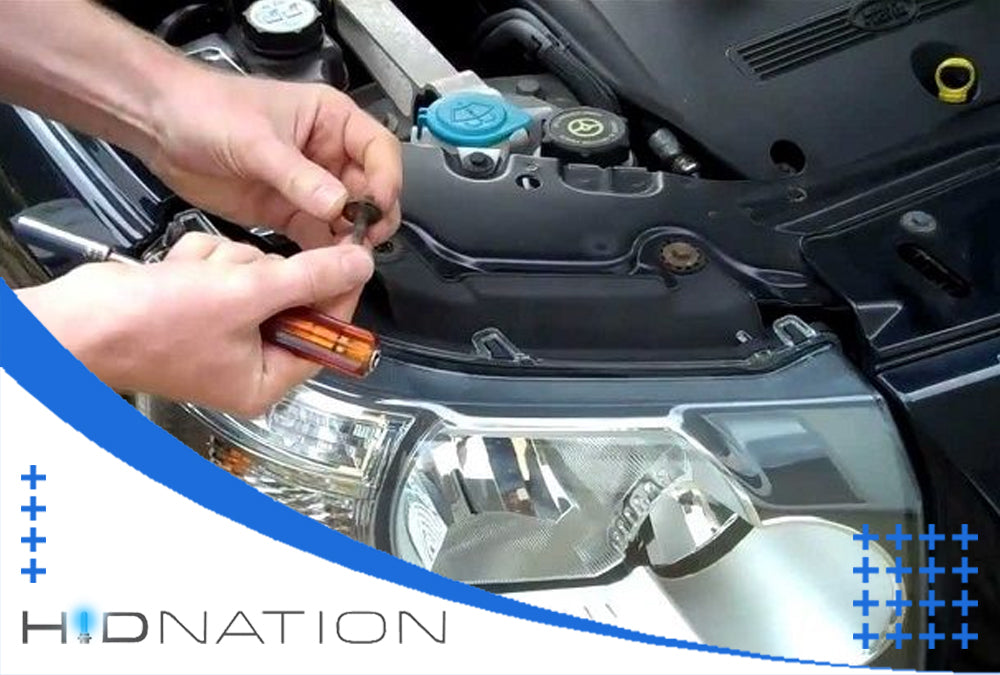

Scenario 2: High Labor Costs Associated with Headlight Assembly Replacement

The Problem: Labor costs for replacing headlight assemblies can be daunting, especially for businesses that rely on professional mechanics. Rates can range significantly, often falling between $100 and $400 for installation, depending on the complexity of the job. For businesses operating on tight margins, these labor costs can quickly add up, impacting profitability and customer pricing strategies.

Illustrative image related to how much does it cost to replace a headlight assembly

The Solution: To mitigate high labor costs, B2B buyers should consider investing in employee training programs to equip in-house staff with the skills needed for headlight assembly replacements. By enabling technicians to perform these repairs, businesses can save on labor expenses and reduce turnaround times for clients. Furthermore, buyers can utilize video tutorials and manufacturer guidelines to standardize the training process. For those who prefer outsourcing, establishing a reliable network of local mechanics who offer competitive rates can help manage costs more effectively. Conducting regular evaluations of labor costs against the volume of replacements needed will also ensure that pricing strategies remain viable while maintaining high service quality.

Scenario 3: Difficulty in Assessing Quality of Aftermarket Headlight Assemblies

The Problem: While aftermarket headlight assemblies can provide cost savings, B2B buyers often struggle to assess their quality and reliability. The risk of purchasing subpar products can lead to increased returns, customer dissatisfaction, and potential safety hazards. This challenge is exacerbated in regions where product reviews and comparisons are less accessible, making it difficult to verify the credibility of suppliers.

The Solution: To ensure the quality of aftermarket headlight assemblies, B2B buyers should implement a thorough vetting process for suppliers. Start by seeking recommendations from industry peers and accessing online forums or trade associations that focus on automotive parts. Request samples or trial products from suppliers to evaluate their performance and durability before making large orders. Additionally, establish clear quality benchmarks based on certifications or industry standards, and ensure that suppliers provide documentation to verify their claims. Regularly reviewing supplier performance and maintaining open lines of communication can help buyers build long-term partnerships with reliable manufacturers, reducing the risk of quality issues in their inventory.

Strategic Material Selection Guide for how much does it cost to replace a headlight assembly

What Are the Common Materials Used in Headlight Assemblies and Their Costs?

When considering the replacement of headlight assemblies, the choice of materials significantly impacts performance, durability, and cost. Understanding the properties and implications of various materials is crucial for B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. Below are analyses of four common materials used in headlight assemblies.

1. Polycarbonate

Key Properties:

Polycarbonate is a lightweight, durable thermoplastic known for its high impact resistance and optical clarity. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environmental conditions.

Illustrative image related to how much does it cost to replace a headlight assembly

Pros & Cons:

The primary advantage of polycarbonate is its excellent strength-to-weight ratio, which contributes to lower shipping costs and easier installation. However, it is susceptible to UV degradation, which can lead to yellowing over time, necessitating additional coatings or treatments.

Impact on Application:

Polycarbonate is ideal for applications requiring transparency and high durability. Its compatibility with various automotive lighting technologies, including halogen and LED, makes it a popular choice.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for material specifications. In regions with high UV exposure, additional protective coatings may be necessary to enhance longevity.

2. Glass

Key Properties:

Glass is a traditional material known for its excellent optical clarity and resistance to scratching. It can withstand high temperatures and is generally more resistant to UV light than polycarbonate.

Illustrative image related to how much does it cost to replace a headlight assembly

Pros & Cons:

The main advantage of glass is its durability and resistance to environmental factors. However, it is heavier than polycarbonate, which can increase shipping costs and complicate installation. Additionally, glass is more prone to shattering upon impact.

Impact on Application:

Glass is often used in high-end vehicles where aesthetics and performance are prioritized. Its compatibility with advanced lighting systems enhances overall vehicle safety.

Considerations for International Buyers:

Buyers must consider the fragility of glass during transportation and installation. Compliance with safety standards is crucial, especially in regions with stringent automotive regulations.

Illustrative image related to how much does it cost to replace a headlight assembly

3. Acrylonitrile Butadiene Styrene (ABS)

Key Properties:

ABS is a versatile thermoplastic known for its toughness and impact resistance. It operates effectively in a temperature range of -20°C to 80°C and offers good chemical resistance.

Pros & Cons:

ABS is cost-effective and easy to mold, making it suitable for mass production. However, it has lower UV resistance compared to polycarbonate and glass, which may affect its longevity in harsh environments.

Impact on Application:

ABS is commonly used in budget-friendly vehicles where cost savings are a priority. Its lightweight nature contributes to overall vehicle efficiency.

Considerations for International Buyers:

Buyers should be aware of the varying quality of ABS products in the market. Ensuring compliance with local standards and regulations is essential for maintaining product integrity.

4. Aluminum

Key Properties:

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It can withstand high temperatures and is often used in conjunction with other materials.

Illustrative image related to how much does it cost to replace a headlight assembly

Pros & Cons:

The key advantage of aluminum is its strength and resistance to corrosion, which extends the lifespan of headlight assemblies. However, it is more expensive than plastic alternatives and may require specialized manufacturing processes.

Impact on Application:

Aluminum is often utilized in high-performance vehicles where weight reduction and durability are critical. Its ability to dissipate heat effectively makes it suitable for high-intensity lighting systems.

Considerations for International Buyers:

International buyers should consider the cost implications of aluminum, especially in markets where raw material prices fluctuate. Compliance with international quality standards is also vital for ensuring product reliability.

Summary Table of Material Selection for Headlight Assemblies

| Material | Typical Use Case for how much does it cost to replace a headlight assembly | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Standard vehicles with halogen or LED lights | Lightweight and impact-resistant | Susceptible to UV degradation | Medium |

| Glass | High-end vehicles requiring premium aesthetics | Excellent optical clarity | Heavier and prone to shattering | High |

| ABS | Budget-friendly vehicles | Cost-effective and easy to mold | Lower UV resistance | Low |

| Aluminum | High-performance vehicles | Corrosion-resistant and durable | Higher cost and complex manufacturing | High |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in headlight assemblies, facilitating informed purchasing decisions tailored to their specific market needs.

Illustrative image related to how much does it cost to replace a headlight assembly

In-depth Look: Manufacturing Processes and Quality Assurance for how much does it cost to replace a headlight assembly

What Are the Typical Manufacturing Processes for Headlight Assemblies?

Manufacturing headlight assemblies involves a series of intricate processes to ensure that each component meets safety, performance, and aesthetic standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Headlight Assembly Manufacturing?

Material preparation is crucial in ensuring that the components meet the necessary specifications. Typically, manufacturers utilize high-grade materials like polycarbonate or acrylic for lenses, along with aluminum and thermoplastics for housing. These materials are selected based on their durability, optical clarity, and resistance to environmental factors.

In this stage, raw materials undergo various treatments, such as UV coating for lenses to enhance durability against sun exposure. Suppliers must adhere to international standards, ensuring that materials sourced are compliant with regulations like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe.

What Forming Techniques Are Used in Headlight Assembly Production?

Once the materials are prepared, the forming process begins. This stage involves several techniques, including injection molding and blow molding.

Illustrative image related to how much does it cost to replace a headlight assembly

-

Injection Molding: This is commonly used for creating the lens and housing. The process involves melting plastic granules and injecting them into molds. This technique allows for high precision and the production of complex shapes, which is essential for modern headlight designs that often incorporate aerodynamic features.

-

Blow Molding: Used primarily for hollow components, this technique creates lightweight structures and is often employed for specific parts of the assembly.

These forming techniques must be monitored closely to ensure that the dimensions and weights of the components meet stringent specifications, as deviations can lead to performance issues.

How Are Headlight Assemblies Assembled?

The assembly of headlight components is where precision engineering comes into play. Typically, this involves a combination of automated and manual processes. Automated assembly lines are often used for the initial stages, where components like bulbs and wiring are integrated into the assembly.

Manual assembly is crucial for quality assurance, as technicians inspect the assembly process for any defects. They ensure that each component is properly aligned and secured, which is essential for the headlight’s performance and longevity.

What Finishing Techniques Are Employed in Headlight Manufacturing?

Finishing processes enhance both the aesthetic and functional aspects of the headlight assembly. Techniques include:

Illustrative image related to how much does it cost to replace a headlight assembly

- Polishing: This is applied to lenses to ensure clarity and transparency, which is critical for effective illumination.

- Coating: A UV-resistant coating is often applied to protect against yellowing and degradation from sunlight exposure.

- Painting: In some cases, the exterior of the assembly may be painted or treated with a protective finish to enhance durability.

These finishing touches not only enhance the appearance but also contribute to the overall performance and lifespan of the headlight assembly.

What Quality Assurance Practices Are Essential for Headlight Assemblies?

Quality assurance (QA) is a fundamental aspect of manufacturing headlight assemblies, ensuring that products meet both international and industry-specific standards.

Which International Standards Are Relevant for Headlight Assembly Quality?

Manufacturers must comply with various international quality standards, such as:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers looking to establish a consistent level of quality in their processes.

- CE Marking: In the European market, headlight assemblies must meet safety, health, and environmental protection standards, which is validated through CE marking.

These certifications assure B2B buyers of the quality and reliability of the products they are sourcing.

What Are the Key Quality Control Checkpoints in Headlight Manufacturing?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

Illustrative image related to how much does it cost to replace a headlight assembly

- Incoming Quality Control (IQC): At this stage, raw materials are inspected to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect any deviations in real-time.

- Final Quality Control (FQC): Once the assembly is complete, a thorough inspection is performed to assess the finished product against quality benchmarks.

These checkpoints help minimize defects and ensure that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are some practical approaches:

- Supplier Audits: Conducting regular audits helps assess a supplier’s adherence to quality standards and production capabilities. This can be done by the purchasing company or through third-party inspection services.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes and past performance.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing processes and product quality.

What Are the Specific QC and Certification Nuances for International B2B Buyers?

International buyers must be aware of specific nuances related to quality certification, as these can vary significantly by region. For example, while CE marking is mandatory in Europe, other regions may have distinct certification requirements.

Illustrative image related to how much does it cost to replace a headlight assembly

In Africa and South America, local regulations may influence the type of certifications required for automotive components. Buyers should familiarize themselves with these regulations to ensure compliance and avoid potential issues during importation.

Additionally, understanding cultural nuances and business practices in different regions can enhance communication with suppliers and foster better partnerships.

Conclusion: The Importance of Manufacturing and Quality Assurance in Headlight Assembly Replacement Costs

Understanding the manufacturing processes and quality assurance practices involved in headlight assembly production is essential for B2B buyers. By evaluating suppliers based on their adherence to international standards and robust QC measures, buyers can make informed decisions that ensure the safety, performance, and cost-effectiveness of the headlight assemblies they procure. This knowledge not only mitigates risks but also enhances the overall value of the procurement process in the competitive automotive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does it cost to replace a headlight assembly’

Introduction

This sourcing guide aims to equip B2B buyers with the essential steps to determine the cost of replacing a headlight assembly. Understanding the factors influencing costs and how to navigate the procurement process can help businesses make informed decisions, optimize spending, and ensure safety and compliance in their vehicle fleets.

1. Assess Your Vehicle Needs

Begin by identifying the specific headlight assembly requirements for your vehicle fleet. Different makes and models will have varying needs, which can significantly affect costs.

- Document the vehicle types in your fleet and their respective headlight specifications.

- Consider any advanced features like adaptive lighting or LED technology, as these will influence both part availability and pricing.

2. Research Market Prices

Conduct thorough market research to understand the price ranges for headlight assemblies. This knowledge will empower you to negotiate better deals with suppliers.

- Look for average costs across different suppliers and regions, noting any discrepancies that may indicate quality differences.

- Take into account both OEM and aftermarket options, as prices can vary widely between these categories.

3. Evaluate Supplier Credentials

Before engaging with suppliers, it’s crucial to verify their credentials. This step helps ensure that you are dealing with reputable vendors.

- Check for certifications such as ISO, which indicate adherence to quality standards.

- Request references or case studies from other businesses that have procured similar parts, particularly in your region.

4. Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes. This step allows for an apples-to-apples comparison of costs, including parts and labor.

- Ensure quotes break down itemized costs, including shipping, taxes, and any potential installation fees.

- Look for warranties or guarantees offered on the parts, as this can save costs in the long run.

5. Consider Total Cost of Ownership

When evaluating replacement options, think beyond the initial purchase price and consider the total cost of ownership (TCO).

Illustrative image related to how much does it cost to replace a headlight assembly

- Factor in installation costs, expected lifespan of the assembly, and potential maintenance expenses.

- Assess the energy efficiency of the lighting technology (e.g., LED vs. halogen), as this can impact operational costs over time.

6. Negotiate Terms and Conditions

Engage in negotiations with your chosen suppliers to secure favorable terms. Strong negotiation can lead to better pricing, delivery schedules, and payment terms.

- Discuss bulk purchase discounts if you plan to order multiple assemblies.

- Ensure you understand the return policy and warranty conditions before finalizing any agreements.

7. Finalize the Order and Monitor Delivery

Once all terms are agreed upon, proceed to finalize your order. It’s essential to monitor the delivery process to ensure timely receipt of parts.

- Set clear delivery timelines and communicate them with your supplier.

- Prepare to conduct a quality check upon receipt to confirm that the products meet your specifications.

By following these steps, B2B buyers can effectively navigate the complexities involved in sourcing headlight assemblies, ensuring that they make informed decisions that balance cost, quality, and safety.

Comprehensive Cost and Pricing Analysis for how much does it cost to replace a headlight assembly Sourcing

What Are the Key Cost Components for Replacing a Headlight Assembly?

When evaluating the cost structure for replacing a headlight assembly, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The type of headlight assembly significantly impacts the cost. Basic halogen assemblies can be relatively inexpensive, typically ranging from $30 to $150, while advanced options like HID or LED assemblies can range from $500 to over $4,000 depending on the vehicle model.

-

Labor: Labor costs can vary widely based on the complexity of the installation. Simple replacements may require only a few minutes of labor, while more advanced assemblies could take hours. Labor costs generally range from $100 to $400, depending on the region and service provider.

-

Manufacturing Overhead: This includes costs associated with production facilities, machinery, and utilities. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive prices.

-

Tooling: For custom or specialized headlight assemblies, tooling costs can be significant. This is particularly relevant for OEM parts, where specific molds and tools are required for production.

-

Quality Control (QC): Ensuring that headlight assemblies meet safety and performance standards incurs additional costs. This is especially important for B2B buyers who may require certifications for quality assurance.

-

Logistics: Shipping and handling costs can vary based on the distance from the supplier to the buyer, as well as the size and weight of the headlight assemblies. International shipping may involve additional tariffs or duties, affecting total costs.

-

Margin: Suppliers typically add a margin to cover their costs and achieve profitability. This margin can vary based on competition, market demand, and the supplier’s business model.

What Influences Pricing for Headlight Assembly Replacements?

Several factors influence the pricing of headlight assemblies, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders can often secure better pricing due to economies of scale. Buyers should evaluate their needs to determine the optimal order quantity that balances cost and inventory management.

-

Specifications/Customization: Custom specifications may lead to higher costs, particularly if unique features or advanced technologies are involved. Understanding the necessary specifications can aid in negotiating better terms.

-

Materials: The choice between OEM and aftermarket parts will impact pricing. While OEM parts ensure quality and fit, they are generally more expensive than aftermarket alternatives. Buyers should assess the trade-offs between cost and quality.

-

Quality/Certifications: Compliance with international standards or certifications can raise costs but is crucial for ensuring reliability and safety. Buyers should prioritize suppliers who can provide necessary certifications.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with a track record of quality may charge a premium, while newer or less reputable suppliers might offer lower prices but with increased risk.

-

Incoterms: Understanding the terms of trade can influence overall costs. Incoterms define the responsibilities of buyers and sellers in the shipping process, impacting logistics costs and risks.

How Can Buyers Optimize Costs in Headlight Assembly Sourcing?

For B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, there are several strategies to optimize costs:

-

Negotiate Terms: Engaging in negotiations can lead to better pricing, especially when ordering in bulk or establishing long-term supplier relationships.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, installation, and potential replacements. A lower-priced assembly may incur higher overall costs if it requires frequent replacements or repairs.

-

Investigate Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times. This is particularly beneficial in regions with complex import regulations.

-

Stay Informed on Market Trends: Understanding market conditions and emerging technologies can help buyers make informed decisions and anticipate price fluctuations.

-

Utilize Supplier Reviews and References: Checking supplier reviews and seeking references can provide insights into quality and service, helping to avoid costly mistakes.

In summary, the replacement cost of a headlight assembly involves a multifaceted structure that varies widely based on numerous factors. B2B buyers should approach sourcing strategically, considering both immediate costs and long-term value. Prices mentioned are indicative and can fluctuate based on market conditions and specific requirements.

Illustrative image related to how much does it cost to replace a headlight assembly

Alternatives Analysis: Comparing how much does it cost to replace a headlight assembly With Other Solutions

Exploring Alternatives to Headlight Assembly Replacement Costs

When faced with the need to replace a headlight assembly, B2B buyers should consider various alternatives that could achieve similar outcomes while varying in performance, cost, and implementation. Understanding these alternatives allows for informed decision-making, especially in regions where budgets and vehicle maintenance strategies differ significantly. Below, we compare the costs and benefits of replacing a headlight assembly with two viable alternatives: headlight bulb replacement and headlight restoration.

| Comparison Aspect | How Much Does It Cost To Replace A Headlight Assembly | Headlight Bulb Replacement | Headlight Restoration |

|---|---|---|---|

| Performance | Full assembly replacement ensures optimal lighting and safety features. | Limited to bulb function, may not address housing issues. | Improves clarity but does not replace damaged parts. |

| Cost | $150 – $4,000 (varies by vehicle and technology) | $15 – $300 (depending on bulb type) | $20 – $100 (for kits) |

| Ease of Implementation | Requires professional installation or advanced DIY skills. | Generally easy for DIYers; can be done in under an hour. | Moderate; requires some skill and time to apply correctly. |

| Maintenance | Low frequency; depends on vehicle use and technology. | Regularly needed; bulbs have a limited lifespan. | May require reapplication over time; not permanent. |

| Best Use Case | Essential for safety and compliance in older or damaged vehicles. | Cost-effective for quick fixes when only bulbs are burnt out. | Ideal for restoring faded headlights without replacing the assembly. |

In-Depth Analysis of Alternatives

Headlight Bulb Replacement

Replacing just the headlight bulbs can be a cost-effective solution when the assembly itself is intact. This method typically ranges from $15 to $300, depending on the bulb type, and is usually straightforward for individuals with basic mechanical skills. However, this approach only addresses the lighting issue and does not rectify any problems with the headlight housing or assembly. For businesses operating fleets with standard vehicles, this can be a quick and economical fix that maintains visibility without incurring the higher costs associated with complete assembly replacements.

Headlight Restoration

Headlight restoration kits offer another alternative, typically costing between $20 and $100. These kits are designed to clear up foggy or yellowed headlight lenses, improving visibility and aesthetics without the need for a complete replacement. While restoration can significantly enhance performance, it is important to note that this method does not replace any damaged components of the assembly itself. This solution is best suited for businesses looking to improve the appearance of their vehicles while extending the life of existing assemblies, especially in markets where vehicle longevity is crucial.

Illustrative image related to how much does it cost to replace a headlight assembly

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, the decision on how to address headlight issues should be based on a careful analysis of costs, performance requirements, and implementation feasibility. If safety and compliance are paramount, investing in a complete headlight assembly replacement might be the best route, especially for older or damaged vehicles. Conversely, if the issue is limited to bulb failure or minor clarity problems, opting for bulb replacement or restoration could yield significant savings and efficiency. By aligning the chosen solution with the specific needs of the fleet or individual vehicles, businesses can optimize both performance and cost-effectiveness in their maintenance strategies.

Essential Technical Properties and Trade Terminology for how much does it cost to replace a headlight assembly

What Are the Key Technical Properties to Consider When Replacing a Headlight Assembly?

When evaluating the cost and specifications of replacing a headlight assembly, several technical properties are crucial for B2B buyers. Understanding these specifications can help in making informed purchasing decisions that align with safety, performance, and cost-effectiveness.

1. Material Grade

The material of the headlight assembly significantly influences its durability and functionality. Assemblies are typically made from polycarbonate plastic, which is lightweight and resistant to impact, or glass, known for its clarity and resistance to scratches. High-quality materials ensure longevity and can withstand harsh environmental conditions, making them a critical consideration for international buyers operating in diverse climates.

2. Light Output (Lumens)

Light output, measured in lumens, indicates the brightness of the headlight. Higher lumens generally mean better visibility and safety during nighttime or adverse weather conditions. For B2B buyers, selecting assemblies with appropriate lumens is essential for meeting safety regulations and enhancing driving performance, particularly in regions with poor lighting conditions.

Illustrative image related to how much does it cost to replace a headlight assembly

3. Beam Pattern

The beam pattern refers to how light is distributed on the road. Different vehicles require specific beam patterns to comply with legal standards and ensure optimal visibility. Understanding the beam pattern is crucial for buyers to ensure that the assemblies they procure provide adequate illumination without blinding oncoming traffic.

4. Compatibility and Fitment

Compatibility with specific vehicle makes and models is vital when selecting headlight assemblies. Assemblies must fit perfectly to maintain structural integrity and functionality. B2B buyers should verify fitment specifications to avoid costly returns or rework, ensuring a seamless integration into their vehicle inventory.

5. Electrical Specifications

Electrical specifications, including voltage and wattage, are critical for ensuring that the headlight assembly operates efficiently without causing electrical failures. Proper understanding of these specifications helps prevent potential damage to the vehicle’s electrical system, a key consideration for fleet operators and automotive service providers.

What Are Common Trade Terms Related to Headlight Assembly Replacement Costs?

Familiarity with industry terminology is essential for B2B buyers in navigating the procurement process. Here are some common terms relevant to headlight assembly replacement:

Illustrative image related to how much does it cost to replace a headlight assembly

1. OEM (Original Equipment Manufacturer)

OEM parts are components produced by the vehicle manufacturer. These parts are designed to match the original specifications and quality, ensuring perfect fit and performance. While often more expensive, OEM parts are favored for their reliability, especially in critical safety applications such as headlight assemblies.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier requires for an order. Understanding MOQ is important for B2B buyers to manage inventory effectively and ensure cost efficiency. Higher MOQs can sometimes lead to reduced per-unit costs, but they also require careful planning regarding stock levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. This is a vital step in the procurement process, allowing buyers to compare costs, terms, and supplier capabilities before making a purchasing decision.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms helps B2B buyers mitigate risks associated with international shipping and ensure clarity in contractual agreements.

5. Warranty Period

The warranty period is the time frame during which a manufacturer guarantees the performance of the headlight assembly. A longer warranty often indicates confidence in product quality and can be a deciding factor for B2B buyers considering long-term investments in vehicle parts.

Illustrative image related to how much does it cost to replace a headlight assembly

6. Aftermarket Parts

Aftermarket parts are components made by manufacturers other than the original vehicle manufacturer. They are often less expensive than OEM parts but can vary in quality and compatibility. B2B buyers should weigh the cost savings against potential risks related to performance and warranty coverage.

By understanding these technical properties and trade terms, international B2B buyers can make well-informed decisions regarding headlight assembly replacements, ensuring safety, compliance, and cost efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the how much does it cost to replace a headlight assembly Sector

Market Overview & Key Trends: What Influences the Cost to Replace a Headlight Assembly?

The headlight assembly replacement market is shaped by various global drivers, including advances in automotive technology, regulatory changes, and consumer preferences shifting towards higher-quality lighting solutions. In emerging markets across Africa and South America, the demand for affordable yet reliable headlight assemblies is on the rise, driven by an increasing number of vehicles on the road. As consumers become more safety-conscious, there’s a growing preference for advanced lighting technologies such as LED and HID, which not only enhance visibility but also improve energy efficiency.

Current trends indicate a significant movement towards e-commerce platforms for sourcing automotive parts. International B2B buyers are leveraging digital marketplaces to access a wider range of products, including OEM and aftermarket headlight assemblies. This trend is particularly pronounced in regions like Europe and the Middle East, where buyers prioritize convenience and competitive pricing. Additionally, the rise of automation and inventory management technologies is facilitating better sourcing practices, enabling buyers to optimize their supply chains and reduce lead times.

Illustrative image related to how much does it cost to replace a headlight assembly

The economic landscape is also influencing pricing dynamics. Fluctuations in raw material costs, especially for high-tech components, are prompting manufacturers to adjust their pricing strategies. For B2B buyers, understanding these market dynamics is crucial for making informed purchasing decisions and negotiating favorable terms with suppliers.

How Can Sustainability & Ethical Sourcing Impact the Headlight Assembly Replacement Market?

Sustainability is becoming a vital consideration in the sourcing of headlight assemblies. The automotive industry faces increasing scrutiny regarding its environmental impact, pushing manufacturers to adopt eco-friendly practices. B2B buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainability, such as those using recycled materials or energy-efficient manufacturing processes.

Ethical sourcing is equally important, particularly in regions where labor practices may be questionable. Buyers from Europe and North America, for example, are increasingly demanding transparency in supply chains. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility are becoming critical benchmarks for evaluating potential suppliers.

Illustrative image related to how much does it cost to replace a headlight assembly

Furthermore, the integration of ‘green’ certifications and materials into headlight assembly production is a growing trend. For instance, companies that utilize LED technology not only offer longer-lasting products but also contribute to reduced energy consumption, aligning with global sustainability goals. By prioritizing these factors, B2B buyers can enhance their brand reputation and appeal to environmentally-conscious consumers.

What Historical Developments Have Shaped the Headlight Assembly Market?

The evolution of headlight technology has significantly influenced the replacement market. Initially, halogen bulbs dominated the automotive lighting sector due to their affordability and adequate performance. However, the introduction of HID (High-Intensity Discharge) and LED (Light Emitting Diode) technologies in the early 2000s revolutionized the industry. These advanced systems not only provided superior illumination but also offered longer lifespans, changing the landscape of headlight assembly replacements.

Over the years, regulatory changes have also played a role in shaping market dynamics. Stricter safety standards and environmental regulations have compelled manufacturers to innovate continuously, resulting in the development of more sophisticated headlight assemblies that meet evolving consumer expectations. As a result, the current market now features a diverse range of products, catering to various preferences and budgets, thus providing B2B buyers with ample options for sourcing headlight assemblies efficiently.

Frequently Asked Questions (FAQs) for B2B Buyers of how much does it cost to replace a headlight assembly

-

How much does it typically cost to replace a headlight assembly?

The cost of replacing a headlight assembly can vary widely based on several factors, including the vehicle’s make and model, the type of headlight technology (halogen, HID, or LED), and whether you choose OEM or aftermarket parts. On average, you can expect to pay between $150 and $800 for most vehicles, with luxury or advanced headlight systems potentially costing $2,000 or more. It’s essential for B2B buyers to consider these variables when budgeting for repairs. -

What factors influence the cost of headlight assembly replacement?

Several key elements affect the cost of headlight assembly replacement. The type of headlight technology used plays a significant role; halogen assemblies are generally the most affordable, while HID and LED options can be much more expensive. Additionally, the make and model of the vehicle, the choice between OEM and aftermarket parts, labor costs for installation, and any additional features like adaptive lighting systems can all impact the overall expense. -

How can I find reliable suppliers for headlight assemblies?

Finding trustworthy suppliers for headlight assemblies involves thorough research. Start by reviewing online directories and trade platforms that specialize in automotive parts. Attend industry trade shows and exhibitions to meet suppliers face-to-face. It’s crucial to vet suppliers by checking their credentials, customer reviews, and product warranties. Establishing strong communication and visiting their facilities, if possible, can further ensure reliability and quality. -

What are the advantages of OEM vs. aftermarket headlight assemblies?

OEM (Original Equipment Manufacturer) parts are designed specifically for your vehicle, ensuring perfect fit and quality, but they often come with a higher price tag. Aftermarket parts can be more cost-effective and may offer competitive quality; however, their longevity and compatibility can vary. B2B buyers should assess the specific needs of their clientele and consider whether the savings from aftermarket parts outweigh the potential risks of lower quality or fit issues. -

What are the common payment terms when sourcing headlight assemblies internationally?

Payment terms can vary significantly among suppliers and regions. Common practices include upfront payments, partial payments upon order confirmation, and balance payments upon delivery. Letters of credit or escrow services can provide security for both parties. B2B buyers should negotiate terms that protect their investment and ensure a reliable transaction, while also considering the financial practices common in the supplier’s country. -

How can I ensure quality assurance (QA) when purchasing headlight assemblies?

Implementing a robust quality assurance process is critical when sourcing headlight assemblies. Buyers should request product samples before placing large orders, and conduct inspections upon receipt to verify quality. Establishing clear specifications and requirements with suppliers can prevent misunderstandings. Additionally, consider working with third-party QA firms to conduct inspections and audits of the supplier’s manufacturing processes to ensure compliance with quality standards. -

What logistics considerations should I be aware of when importing headlight assemblies?

When importing headlight assemblies, logistics can be complex. Key considerations include shipping methods (air vs. sea), customs regulations, and potential tariffs or duties applicable in your region. It’s vital to work with logistics partners experienced in automotive parts to navigate these challenges efficiently. Additionally, ensuring proper packaging to prevent damage during transit and tracking shipments can help mitigate risks associated with international shipping. -

What is the minimum order quantity (MOQ) for headlight assemblies from suppliers?

Minimum order quantities (MOQs) for headlight assemblies can vary widely based on the supplier’s policies and manufacturing capabilities. While some suppliers may allow small orders for testing, others may require larger quantities to ensure profitability. B2B buyers should clarify MOQ during negotiations and consider the potential for bulk discounts. Understanding the supplier’s production capabilities and lead times can also help in planning inventory and managing supply chains effectively.

Top 4 How Much Does It Cost To Replace A Headlight Assembly Manufacturers & Suppliers List

1. Reddit – Headlight Assembly Replacement Cost

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Cost to replace headlight assembly (labor only): $120; Time taken: 45 minutes.

2. Facebook – Head Light Assembly for Hyundai Tucson

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: head light assembly for Hyundai Tucson

3. Honda – Clarity Headlight Replacement Cost

Domain: insideevsforum.com

Registered: 2017 (8 years)

Introduction: The cost to replace a headlight unit for a Honda Clarity is approximately $1500 per headlight, totaling $3000 for both front headlights. The Clarity uses a sealed headlight assembly, meaning individual bulbs cannot be replaced. The headlights may contain a string of LEDs mounted on a board, and there are options available online for replacement, with prices starting around $1300 for a pair. Some u…

4. Lexus – Headlight Replacement Costs

Domain: community.cartalk.com

Registered: 1995 (30 years)

Introduction: Lexus headlight replacement cost: $2200 for a single headlight, $1100 shared cost with dealership; includes potential costs for headlight assembly, labor, and HID bulb. High-end car parts are expensive, especially for features like automatic leveling and position sensing motors.

Strategic Sourcing Conclusion and Outlook for how much does it cost to replace a headlight assembly

In conclusion, understanding the costs associated with replacing a headlight assembly is vital for B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe. The price range for headlight assembly replacement can vary significantly, from as low as $150 to upwards of $4,000, influenced by factors like vehicle type, technology, and the choice between OEM and aftermarket parts.

Strategic sourcing plays a crucial role in optimizing procurement processes, ensuring that businesses can balance quality and cost-effectiveness. By leveraging local and international suppliers, companies can enhance their competitiveness while maintaining operational efficiency.

Illustrative image related to how much does it cost to replace a headlight assembly

As the automotive industry continues to evolve with advancements in lighting technology, buyers should stay informed about market trends and emerging technologies. This proactive approach will not only help in making informed purchasing decisions but also position businesses favorably in a rapidly changing landscape. We encourage international B2B buyers to engage with suppliers who provide transparency in pricing and quality, ensuring long-term value and reliability in their procurement strategies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.