Introduction: Navigating the Global Market for how long does starter last

In the dynamic world of automotive parts, understanding how long a starter lasts is crucial for B2B buyers who prioritize efficiency and cost-effectiveness. Sourcing reliable starters that meet the demands of diverse markets—particularly in regions like Africa, South America, the Middle East, and Europe—can be challenging. With varying environmental conditions and vehicle usage patterns, the longevity of starters can significantly impact operational costs and vehicle reliability.

This comprehensive guide delves into key aspects of starter longevity, offering insights into types of starters, their applications across different vehicle models, and factors that influence their lifespan. We also provide guidance on supplier vetting, ensuring that you partner with manufacturers who uphold quality standards. Additionally, we explore the cost implications of starters and the potential savings associated with preventive maintenance and timely replacements.

By equipping international B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to mitigate the risks associated with starter failures and enhance fleet reliability. Whether you are operating in bustling urban centers or remote regions, understanding the intricacies of starter longevity will empower you to optimize your procurement strategies and drive your business forward.

Table Of Contents

- Top 5 How Long Does Starter Last Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long does starter last

- Understanding how long does starter last Types and Variations

- Key Industrial Applications of how long does starter last

- 3 Common User Pain Points for ‘how long does starter last’ & Their Solutions

- Strategic Material Selection Guide for how long does starter last

- In-depth Look: Manufacturing Processes and Quality Assurance for how long does starter last

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does starter last’

- Comprehensive Cost and Pricing Analysis for how long does starter last Sourcing

- Alternatives Analysis: Comparing how long does starter last With Other Solutions

- Essential Technical Properties and Trade Terminology for how long does starter last

- Navigating Market Dynamics and Sourcing Trends in the how long does starter last Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long does starter last

- Strategic Sourcing Conclusion and Outlook for how long does starter last

- Important Disclaimer & Terms of Use

Understanding how long does starter last Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Starter | Typical lifespan of 80,000 to 100,000 starts; suitable for most vehicles. | Automotive repair shops, fleet services | Pros: Widely available, cost-effective. Cons: Limited to standard applications. |

| High-Performance Starter | Designed for high-stress environments; can exceed 300,000 starts. | Racing teams, heavy-duty vehicles | Pros: Enhanced durability, improved efficiency. Cons: Higher initial cost. |

| Remanufactured Starter | Rebuilt from used starters; offers a cost-effective solution. | Budget-conscious repair shops | Pros: Lower cost, sustainable option. Cons: Potentially shorter lifespan than new units. |

| Mini Starter | Compact design; ideal for vehicles with limited space. | Custom automotive builds, vintage cars | Pros: Space-saving, lightweight. Cons: May have lower power output. |

| OEM Starter | Original Equipment Manufacturer parts; guaranteed compatibility. | Dealerships, high-end repair facilities | Pros: Reliable performance, exact fit. Cons: Generally more expensive than aftermarket options. |

What Are the Characteristics of Standard Starters for B2B Buyers?

Standard starters typically last between 80,000 to 100,000 starts and are commonly used in most vehicles. They are ideal for automotive repair shops and fleet services that require a reliable, cost-effective solution. When purchasing standard starters, B2B buyers should consider factors such as compatibility with various vehicle models and their availability in bulk, as this can reduce costs and streamline inventory management.

How Do High-Performance Starters Benefit Specific Applications?

High-performance starters are engineered for environments where reliability and endurance are critical, often exceeding 300,000 starts. They are essential for racing teams and heavy-duty vehicles that demand superior performance. Buyers in these sectors should focus on durability and efficiency metrics, as well as the supplier’s ability to provide timely replacements to minimize downtime during operations.

What Should Buyers Know About Remanufactured Starters?

Remanufactured starters are refurbished from used components, presenting a cost-effective alternative for budget-conscious repair shops. While they offer significant savings, B2B buyers must weigh the potential for a shorter lifespan against the initial investment. Ensuring that remanufactured starters meet quality standards is vital, as this can affect long-term customer satisfaction and service reliability.

Why Choose Mini Starters for Custom Applications?

Mini starters are compact and designed for vehicles with limited installation space, making them a popular choice for custom automotive builds and vintage cars. B2B buyers should assess the power output relative to the vehicle’s needs, as mini starters may not deliver the same torque as standard models. Understanding the specific requirements of their applications will help buyers make informed decisions.

What Are the Advantages of OEM Starters for B2B Buyers?

OEM starters are manufactured to meet the exact specifications of vehicle manufacturers, ensuring compatibility and reliable performance. They are often preferred by dealerships and high-end repair facilities that prioritize quality and customer satisfaction. While they tend to be more expensive than aftermarket options, the assurance of performance and fit can justify the investment for businesses focused on long-term reliability.

Key Industrial Applications of how long does starter last

| Industry/Sector | Specific Application of how long does starter last | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Quality control in starter production | Ensures reliability and performance of vehicles | Supplier certifications, material quality, and testing |

| Transportation & Logistics | Fleet management and maintenance scheduling | Reduces downtime and maintenance costs | Bulk purchasing agreements, warranty terms, and support |

| Construction Equipment | Equipment reliability and maintenance planning | Maximizes uptime and productivity of machinery | Compatibility with existing equipment, lead times, and cost |

| Mining Operations | Starter lifecycle tracking for heavy machinery | Enhances operational efficiency and safety | Performance history, environmental conditions, and service |

| Agriculture | Starter performance in farming machinery | Ensures timely operations during critical planting seasons | Local supplier availability, durability, and support |

How is ‘how long does starter last’ applied in Automotive Manufacturing?

In the automotive manufacturing sector, understanding the lifespan of starters is crucial for quality control processes. By tracking how long starters last, manufacturers can ensure that the components they produce meet reliability and performance standards. This not only enhances customer satisfaction but also minimizes warranty claims. For international buyers, especially those in emerging markets, sourcing from certified suppliers who adhere to stringent quality measures is vital to maintain production efficiency.

What role does starter lifespan play in Transportation & Logistics?

For transportation and logistics companies, managing a fleet requires precise maintenance scheduling based on the expected lifespan of vehicle starters. Knowing how long starters typically last allows fleet managers to replace components proactively, reducing unexpected breakdowns and associated costs. This proactive approach is particularly beneficial in regions where access to parts may be limited, emphasizing the need for bulk purchasing agreements that ensure a steady supply of reliable starters.

How does starter longevity impact Construction Equipment?

In the construction industry, the reliability of machinery is paramount. Understanding how long starters last aids in planning maintenance schedules, ensuring that equipment remains operational during critical project phases. This can significantly reduce downtime and improve productivity. Buyers should consider the compatibility of starters with their existing machinery and the availability of local suppliers who can provide quick support and replacement parts, especially in remote areas.

Why is starter performance crucial in Mining Operations?

Mining operations rely heavily on heavy machinery, where starter failures can lead to significant operational disruptions. Tracking the lifecycle of starters in this sector allows companies to enhance their operational efficiency and safety. Buyers need to assess the performance history of starters and consider environmental conditions that may affect their longevity. Additionally, sourcing from suppliers who offer comprehensive service agreements can help mitigate risks associated with unexpected failures.

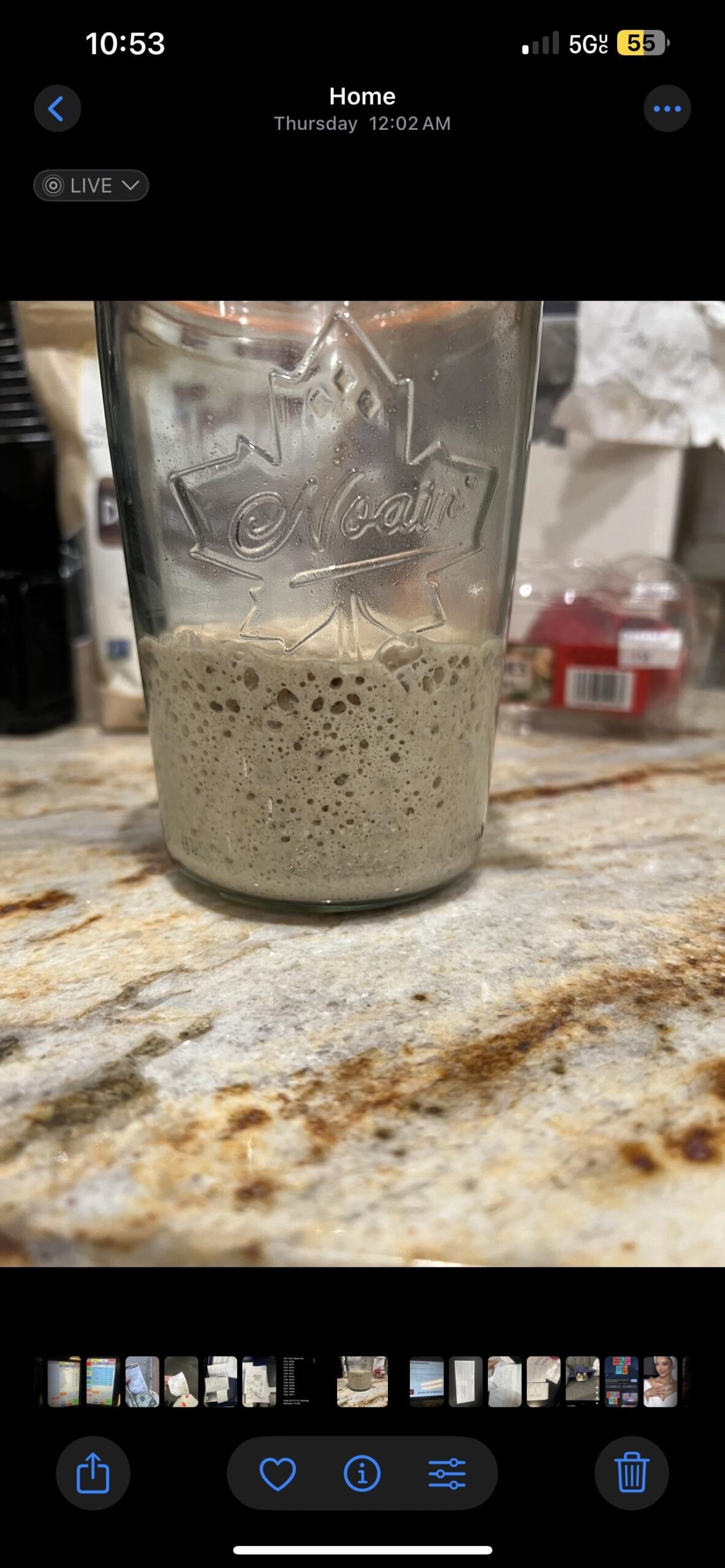

Illustrative image related to how long does starter last

How does starter durability affect Agriculture?

In agriculture, the performance of farming machinery during critical planting and harvesting seasons is essential. Knowing the expected lifespan of starters helps farmers and agricultural businesses plan for replacements, ensuring that operations run smoothly. Buyers should focus on local supplier availability to minimize downtime and consider the durability of starters in various environmental conditions, which can vary significantly across regions like Africa and South America.

3 Common User Pain Points for ‘how long does starter last’ & Their Solutions

Scenario 1: Understanding the Lifespan of Starters for Fleet Management

The Problem:

B2B buyers managing fleets often face uncertainty regarding the lifespan of starters. With vehicles operating under various conditions and usage patterns, it becomes challenging to predict when a starter might fail. This unpredictability can lead to unexpected downtime, increased maintenance costs, and disruptions in service delivery. Fleet managers, particularly those in regions with harsh climates like Africa and the Middle East, may find that starters wear out more quickly due to environmental factors, adding another layer of complexity to their maintenance schedules.

The Solution:

To address this challenge, fleet managers should implement a proactive maintenance schedule based on the average lifespan of starters, which is typically between 100,000 and 300,000 miles or 80,000 to 100,000 starts. Regularly track each vehicle’s usage patterns and mileage to anticipate when a starter may require replacement. Investing in telematics can provide real-time data on vehicle performance and alert you to potential starter issues before they lead to failure. Furthermore, consider sourcing high-quality starters from reputable manufacturers that offer warranties. This ensures that you receive a reliable product that lasts longer and reduces the need for frequent replacements.

Scenario 2: Sourcing Quality Starters Amidst Supply Chain Disruptions

The Problem:

International buyers often struggle with sourcing quality starters, especially during times of supply chain disruptions. This issue can be exacerbated when dealing with local suppliers who may not have consistent access to reliable starter brands. Consequently, businesses may end up with subpar products that fail prematurely, leading to increased operational costs and potential reputational damage if vehicles are out of service.

The Solution:

To mitigate these sourcing challenges, buyers should establish relationships with multiple suppliers across different regions. This diversification not only provides backup options during supply chain issues but also allows for competitive pricing. Conduct thorough research on suppliers to ensure they provide starters that meet industry standards. Consider joining industry networks or associations that can offer insights into reliable suppliers. Additionally, leverage digital platforms for sourcing, which can connect you with manufacturers directly, thus ensuring that you acquire high-quality products. Regularly review supplier performance and gather feedback from your maintenance teams to ensure continued reliability.

Illustrative image related to how long does starter last

Scenario 3: Diagnosing Starter Issues Before They Lead to Failures

The Problem:

B2B buyers often encounter the challenge of diagnosing starter issues before they escalate into complete failures. In many cases, early signs of starter wear, such as slow cranking or intermittent starting issues, go unnoticed until they lead to vehicle breakdowns. This not only affects operational efficiency but also incurs additional repair costs and delays in service delivery.

The Solution:

To proactively diagnose starter issues, implement a regular inspection routine focusing on the starting system. Train your maintenance team to recognize early warning signs of starter problems, such as unusual noises or sluggish performance. Utilize diagnostic tools that can monitor the electrical system’s health and pinpoint specific issues related to the starter. Additionally, maintain an open line of communication with your suppliers about the latest advancements in starter technology, which may include features designed to alert users of impending failure. By fostering a culture of preventive maintenance, you can significantly reduce the likelihood of unexpected starter failures and maintain operational continuity.

Strategic Material Selection Guide for how long does starter last

What Materials Impact the Longevity of Starters in Automotive Applications?

When considering how long a starter lasts in automotive applications, the choice of materials used in its construction is critical. The materials must withstand various operational stresses, including temperature fluctuations, mechanical wear, and exposure to corrosive elements. Below, we analyze several common materials used in starter manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Copper in Starters?

Copper is widely used in electrical components of starters due to its excellent conductivity and thermal properties. It can handle high temperatures and provides efficient electrical transfer, which is crucial for the starter’s performance.

Pros: Copper’s high conductivity ensures minimal energy loss, enhancing the starter’s efficiency. It is also relatively easy to work with during manufacturing, allowing for complex designs.

Illustrative image related to how long does starter last

Cons: However, copper is susceptible to corrosion, which can degrade its performance over time. Additionally, the rising cost of copper can affect overall production costs.

Impact on Application: In regions with high humidity or exposure to corrosive environments, such as coastal areas in Africa or South America, the longevity of copper components may be compromised unless adequately protected.

How Does Steel Contribute to Starter Durability?

Steel, particularly alloy steel, is often used in the structural components of starters due to its strength and durability. It can withstand high mechanical stresses and is less prone to deformation under load.

Pros: The robustness of steel makes it suitable for high-performance applications. It is also relatively cost-effective compared to other materials.

Cons: While steel is strong, it is heavier than alternatives, which can impact the overall weight of the starter system. Additionally, steel can corrode if not properly treated or coated.

Impact on Application: In regions with extreme temperature variations, such as the Middle East, steel components may require additional coatings to prevent rust and ensure longevity.

What Role Does Plastic Play in Starter Design?

High-performance plastics are increasingly used in starters, particularly for insulating components and housings. These materials offer excellent electrical insulation and are lightweight.

Pros: Plastics can reduce the overall weight of the starter, improving efficiency. They are resistant to corrosion and can be molded into complex shapes, allowing for innovative designs.

Illustrative image related to how long does starter last

Cons: The main drawback is that plastics may not withstand high temperatures as well as metals, which can limit their use in certain high-heat applications.

Impact on Application: For international buyers, especially in Europe, compliance with environmental regulations regarding plastic use is crucial. Selecting plastics that meet these standards can enhance marketability.

How Do Composites Enhance Starter Performance?

Composite materials, which combine different substances to leverage their strengths, are increasingly being explored for starter applications. They can offer a balance of strength, weight, and thermal resistance.

Pros: Composites can be engineered to provide specific properties, such as high strength-to-weight ratios and resistance to thermal expansion.

Illustrative image related to how long does starter last

Cons: The manufacturing complexity of composites can lead to higher costs and longer production times. Additionally, they may require specialized knowledge for effective use.

Impact on Application: In regions like Africa and South America, where resource availability may vary, the cost and complexity of sourcing composite materials must be considered in the supply chain.

Summary Table of Material Selection for Starters

| Material | Typical Use Case for how long does starter last | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections in starters | Excellent electrical conductivity | Susceptible to corrosion | High |

| Steel | Structural components of starters | High strength and durability | Heavier than alternatives | Medium |

| Plastic | Insulating components and housings | Lightweight and corrosion-resistant | Limited high-temperature resistance | Low |

| Composites | Advanced starter designs | Tailored properties and lightweight | Higher manufacturing complexity | High |

In conclusion, selecting the right materials for starters is essential for optimizing their longevity and performance. International B2B buyers should consider not only the properties and costs of these materials but also regional factors such as environmental conditions and compliance with local standards to ensure successful applications.

In-depth Look: Manufacturing Processes and Quality Assurance for how long does starter last

What Are the Key Stages of Manufacturing Car Starters?

The manufacturing process for car starters is intricate and requires precision at every stage. For B2B buyers, understanding these stages can help in assessing potential suppliers and ensuring product reliability.

How Is Material Prepared for Car Starters?

The first stage in the manufacturing process involves the preparation of materials. High-quality materials, such as copper for electrical components and durable metals for structural parts, are sourced. These materials undergo rigorous quality checks upon receipt, ensuring they meet specific standards. This initial inspection is critical, as any defects at this stage can lead to failures later in the manufacturing process.

What Forming Techniques Are Used in Starter Manufacturing?

Once materials are prepared, they move on to the forming stage. This includes processes such as stamping, machining, and casting to create the various components of the starter. For instance, the starter motor housing is often die-cast, allowing for precise dimensions and strength. Techniques like CNC machining are used to manufacture parts with high tolerances, ensuring they fit perfectly during assembly. These processes are vital for the performance and longevity of the starter.

Illustrative image related to how long does starter last

How Are Starters Assembled?

The assembly stage involves fitting together the components produced in the previous stages. This is typically done in a clean room environment to minimize contamination risks. Skilled technicians or automated systems assemble parts like the motor, solenoid, and gear mechanism, ensuring that each component is aligned correctly. Proper assembly is crucial; misalignments can lead to premature failure, which is a significant concern for B2B buyers.

What Finishing Processes Are Applied to Starters?

After assembly, starters undergo finishing processes, which may include painting, coating, or polishing. These finishes not only enhance the appearance but also provide protective layers against corrosion and wear. Quality control checks are performed at this stage to ensure that the finishing meets industry standards, which is particularly important for international buyers concerned about environmental conditions in their regions.

What Quality Control Measures Are Implemented in Starter Manufacturing?

Quality assurance is a critical component of the manufacturing process for car starters. It ensures that products meet both industry standards and customer expectations.

Which International Standards Are Relevant for Starter Quality Assurance?

Manufacturers often adhere to international quality management standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards demonstrates a commitment to quality and continuous improvement, making it a vital factor for B2B buyers when evaluating suppliers. In addition to ISO, specific industry certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) certifications may apply, depending on the starter’s intended application.

What Are the Key Quality Control Checkpoints During Production?

Quality control checkpoints are strategically placed throughout the manufacturing process. Initial Quality Control (IQC) checks materials upon arrival, ensuring they meet specifications. In-Process Quality Control (IPQC) involves monitoring production processes and assembly to catch defects early. Finally, Final Quality Control (FQC) involves comprehensive testing of the assembled starters to ensure they function correctly and meet performance standards. These checkpoints help mitigate risks and ensure product reliability.

What Common Testing Methods Are Used for Starters?

Testing methods play a vital role in validating the performance and durability of car starters. Common testing procedures include:

- Electrical Testing: This checks the starter’s electrical integrity, ensuring it can handle the required voltage and current.

- Load Testing: Starters are tested under simulated load conditions to ensure they can crank an engine effectively.

- Durability Testing: Components may undergo fatigue tests to evaluate how they perform under repeated use, simulating real-world conditions.

These tests provide critical data that can influence manufacturing processes and design improvements.

Illustrative image related to how long does starter last

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are some actionable steps:

What Audit Processes Should Buyers Consider?

Conducting audits of potential suppliers is a proactive approach. This can include on-site inspections to assess manufacturing practices, quality control measures, and adherence to international standards. Buyers should request documentation of past audits and certifications to verify compliance.

How Can Buyers Obtain Quality Reports?

Buyers should request detailed quality reports that outline testing results, manufacturing processes, and any corrective actions taken in response to quality issues. These documents provide transparency and help buyers assess the reliability of the products they are purchasing.

Illustrative image related to how long does starter last

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspections can occur at various stages of production and provide additional assurance that the products meet required standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, must consider additional factors in quality control:

- Regulatory Compliance: Different regions have specific regulations governing automotive components. Buyers should ensure that suppliers comply with local laws, which may differ significantly from international standards.

- Cultural Considerations: Understanding cultural nuances can facilitate better communication with suppliers regarding quality expectations and standards.

- Logistical Challenges: Transportation and environmental conditions can impact product quality. Buyers should discuss how suppliers mitigate risks associated with shipping and storage.

By understanding the manufacturing processes and quality assurance measures in place for car starters, B2B buyers can make informed decisions that minimize risks and enhance supply chain reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does starter last’

Introduction

Understanding the lifespan of starters is critical for B2B buyers, particularly those involved in automotive parts procurement. This guide provides a practical checklist to ensure you make informed decisions when sourcing starters for vehicles, maximizing both performance and cost-effectiveness.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications of the starters you require. This includes understanding the voltage, size, and compatibility with specific vehicle models. Having a defined set of requirements helps streamline the selection process and ensures that the starters will perform optimally within the intended applications.

Step 2: Research Industry Standards

Familiarize yourself with the relevant industry standards and certifications applicable to starters. Compliance with standards such as ISO or SAE can indicate a manufacturer’s commitment to quality and reliability. Make sure to check if the products meet environmental regulations, especially if you operate in regions with stringent automotive guidelines.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, including their manufacturing capabilities, quality assurance processes, and case studies from similar industries. It’s essential to look beyond the supplier’s website; reach out to previous clients for firsthand accounts of their experiences.

- Check for Reviews and Testimonials: Investigate online reviews and testimonials to gauge customer satisfaction and product reliability.

- Consider Supplier Location: Proximity can affect shipping times and costs, so factor in the geographical location of potential suppliers.

Step 4: Verify Product Durability and Warranty

Inquire about the expected lifespan of the starters and the warranty offered by the supplier. A robust warranty period can reflect the manufacturer’s confidence in their product’s durability. Understanding the failure rates and common issues associated with specific starter models will help in assessing their longevity and reliability.

Step 5: Assess After-Sales Support and Service

Evaluate the level of after-sales support provided by the supplier. Efficient customer service can be invaluable, especially when dealing with technical issues or product failures. Ensure that the supplier offers comprehensive support, including installation guidance, maintenance tips, and a responsive customer service team.

Step 6: Negotiate Pricing and Payment Terms

Once you’ve shortlisted potential suppliers, engage in negotiations regarding pricing and payment terms. Consider bulk purchasing discounts, payment flexibility, and any additional costs such as shipping and handling. Establishing clear financial terms can lead to better cash flow management for your business.

Step 7: Conduct a Trial Order

Before making a large commitment, consider placing a trial order to evaluate the product quality and supplier reliability. A smaller order allows you to assess the performance of the starters in real-world conditions without significant financial risk. Collect feedback from your team regarding the starters’ performance to inform future purchasing decisions.

By following this checklist, you can effectively navigate the sourcing process for starters, ensuring that your procurement decisions align with your operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for how long does starter last Sourcing

Understanding the cost structure and pricing nuances associated with sourcing car starters is crucial for B2B buyers, especially those operating in diverse international markets. This analysis will delve into the various cost components involved, the factors influencing pricing, and offer strategic tips for buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing Car Starters?

When evaluating the cost of car starters, several essential components contribute to the overall price:

-

Materials: The primary materials used in manufacturing starters include high-grade metals for the motor and housing, as well as electronic components for the relay and solenoid. The quality of these materials can significantly impact durability and performance.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as Vietnam or Nigeria, manufacturers may offer competitive pricing. Conversely, regions with higher wage standards may see increased production costs.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial tooling costs for molds and machinery can be substantial but are amortized over the production volume. Custom designs or modifications will further increase tooling expenses.

-

Quality Control (QC): Stringent QC measures ensure product reliability. The costs associated with quality assurance practices can vary, impacting the final price. Certifications such as ISO can add to the credibility and cost of the product.

-

Logistics: Shipping and handling costs are crucial, particularly for international buyers. Factors such as distance, shipping method, and Incoterms can significantly affect logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary depending on market demand, competition, and the supplier’s reputation.

What Influences the Pricing of Car Starters?

Several factors can influence the pricing of car starters, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts. Understanding the supplier’s MOQ can aid in negotiating better pricing.

-

Specifications and Customization: Custom starters tailored to specific vehicle models or performance requirements may incur additional costs. Clear communication of specifications is vital to avoid unexpected expenses.

-

Material Quality and Certifications: Starters made from premium materials or those that meet specific certifications may have higher price points. Buyers should assess the long-term value these products offer.

-

Supplier Factors: The supplier’s market position, reliability, and service quality can affect pricing. Established suppliers with a strong reputation may charge a premium.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) is crucial as it dictates who bears the shipping costs and risks, thereby impacting the total landed cost.

How Can International B2B Buyers Optimize Their Sourcing Strategy?

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing and terms. Leverage volume orders or long-term relationships to negotiate better deals.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also installation, maintenance, and potential replacement costs. Higher initial investments in quality products can lead to savings over time.

-

Understand Pricing Nuances: Buyers from regions such as Africa or South America may face unique challenges, including fluctuating currency rates and import tariffs. It’s advisable to factor these elements into the overall cost assessment.

-

Supplier Evaluation: Thoroughly vet potential suppliers for quality, reliability, and service. A supplier with a proven track record can reduce long-term costs associated with product failures or delays.

-

Stay Informed: Regularly monitor market trends and pricing changes in the automotive parts industry. This knowledge can enhance negotiation tactics and sourcing decisions.

Conclusion

Navigating the complexities of sourcing car starters requires a comprehensive understanding of the cost structure and pricing dynamics. By considering the various cost components, influencing factors, and strategic negotiation techniques, international B2B buyers can make informed decisions that enhance their procurement processes and ultimately support their operational objectives.

Alternatives Analysis: Comparing how long does starter last With Other Solutions

Exploring Alternatives to ‘How Long Does Starter Last’

In the automotive industry, understanding the lifespan of a starter is crucial for maintenance and operational efficiency. However, businesses may also consider alternative technologies or methods that can enhance vehicle reliability and performance. This section compares ‘how long does starter last’ with two viable alternatives: Push-Start Systems and Hybrid Start-Stop Technology.

| Comparison Aspect | How Long Does Starter Last | Push-Start Systems | Hybrid Start-Stop Technology |

|---|---|---|---|

| Performance | 80,000 – 100,000 starts | Instant engagement | Reduces fuel consumption |

| Cost | Moderate replacement cost | Higher initial investment | Moderate to high investment |

| Ease of Implementation | Standard installation | Requires advanced wiring | Integrated into vehicle design |

| Maintenance | Regular checks needed | Minimal maintenance | Requires software updates |

| Best Use Case | Traditional gasoline vehicles | High-end or performance cars | City driving and fleets |

What Are Push-Start Systems and How Do They Compare?

Push-start systems are designed to engage the engine with the push of a button rather than using a traditional key ignition. This method typically allows for immediate engine start, enhancing the user experience and reducing wear on mechanical parts.

Pros: The primary advantage of push-start systems is convenience and speed, particularly in high-performance vehicles where quick engagement is vital. Additionally, these systems tend to have fewer mechanical parts that can fail, potentially lowering long-term maintenance costs.

Cons: However, the installation of push-start systems can be more complex and costly, requiring advanced wiring and electronic systems that might not be suitable for all vehicles. Furthermore, these systems still rely on a starter mechanism, so understanding the longevity of the starter remains relevant.

What Is Hybrid Start-Stop Technology and How Does It Compare?

Hybrid start-stop technology automatically shuts off the engine when the vehicle comes to a stop and restarts it when the accelerator is pressed. This technology is becoming increasingly popular in urban environments, where traffic congestion is common.

Pros: The most significant benefit of hybrid start-stop technology is its ability to enhance fuel efficiency, making it an attractive option for fleet vehicles or businesses seeking to reduce operational costs. It can lead to significant savings over time by minimizing fuel consumption during idling.

Cons: On the downside, this technology involves a moderate to high initial investment and can require specialized maintenance. Software updates and diagnostics may also be necessary to ensure optimal performance, which can add to overall operational costs.

Making the Right Choice for Your Business Needs

When selecting the best solution for your automotive needs, consider factors such as performance, cost, ease of implementation, maintenance requirements, and the specific use case. If your operations prioritize longevity and reliability, understanding how long starters last is essential. However, if you aim for cutting-edge technology that enhances efficiency and reduces fuel costs, exploring push-start systems or hybrid start-stop technology may be more beneficial. Ultimately, the right choice will align with your business goals, vehicle types, and operational requirements.

Essential Technical Properties and Trade Terminology for how long does starter last

What Are the Critical Technical Properties of Car Starters?

Understanding the technical properties of car starters is crucial for B2B buyers, especially those involved in the automotive supply chain. Here are some key specifications that influence the performance and longevity of starters:

1. Electrical Specifications

- Voltage Rating: Typically, car starters operate at 12 volts, which is standard for most vehicles. Understanding the voltage requirements is essential for compatibility with the vehicle’s electrical system.

- Current Draw: This refers to the amount of current the starter motor consumes during operation, usually measured in amperes (A). A starter with a high current draw may require a more robust electrical system, affecting installation and operational costs.

2. Material Composition

- Housing Material: Starters are often made from aluminum or steel, which can affect their durability and resistance to environmental factors. Aluminum starters are lighter and corrosion-resistant, while steel options may offer greater strength but can be prone to rust.

- Brush Material: The type of material used for the brushes (commonly copper or carbon) impacts wear resistance and conductivity. High-quality brushes ensure a longer lifespan and better performance.

3. Temperature Tolerance

- Operating Temperature Range: Starters should function effectively in various climates. A starter rated for a wider temperature range will perform better in extreme conditions, reducing the risk of premature failure in hot or cold environments.

4. Mechanical Durability

- Gear Ratio: The gear ratio affects how efficiently the starter engages with the engine. A well-designed gear ratio can lead to smoother starts and less wear on components, which is critical for reducing maintenance costs.

What Are Common Trade Terms Related to Car Starters?

In addition to technical specifications, familiarity with industry terminology is essential for effective communication and negotiation. Here are several key terms relevant to the automotive starter market:

1. OEM (Original Equipment Manufacturer)

- This term refers to companies that produce parts that are sold under another company’s brand name. B2B buyers often seek OEM starters due to their guaranteed compatibility and performance, as they are designed specifically for the vehicle.

2. MOQ (Minimum Order Quantity)

- MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers manage inventory levels and negotiate better terms, especially when dealing with multiple suppliers.

3. RFQ (Request for Quotation)

- An RFQ is a document sent to suppliers to request pricing and terms for specific products. It is a critical tool for B2B buyers when sourcing starters, as it facilitates comparison shopping and helps secure the best deal.

4. Incoterms (International Commercial Terms)

- These are standardized terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is essential for buyers to understand shipping costs, insurance, and liability, which can significantly impact the total cost of procurement.

5. Warranty Period

- The warranty period is the time frame during which the manufacturer guarantees the product against defects. This term is crucial for B2B buyers as it affects the total cost of ownership and after-sales support.

6. Aftermarket Parts

- These are components not made by the OEM but designed to fit and function as replacements. Aftermarket starters can often be less expensive than OEM options, providing buyers with alternatives that may offer cost savings without sacrificing quality.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing car starters, ensuring they select the right products for their needs while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the how long does starter last Sector

What Are the Global Drivers Influencing the Lifespan of Starters in Vehicles?

The automotive sector is experiencing significant changes driven by technological advancements, environmental regulations, and shifting consumer preferences. As global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the dynamics of starter longevity becomes crucial for B2B buyers. The average lifespan of a car starter, typically ranging from 80,000 to 100,000 starts or 100,000 to 300,000 miles, is influenced by various factors, including vehicle type, driving conditions, and maintenance practices.

Emerging technologies such as electric and hybrid vehicles are reshaping market expectations. B2B buyers must adapt to the growing demand for starters that are compatible with these new technologies, which often require different specifications and performance standards. Additionally, the rise of telematics and predictive maintenance tools allows fleet managers to monitor starter performance more accurately, enabling timely replacements that minimize downtime and enhance operational efficiency.

Moreover, geopolitical factors and economic fluctuations can impact the availability and pricing of automotive components, including starters. International trade policies, tariffs, and local manufacturing capabilities must be considered when sourcing parts. Thus, B2B buyers should remain vigilant and proactive in their sourcing strategies to navigate these complex market dynamics effectively.

Illustrative image related to how long does starter last

How Can Sustainability and Ethical Sourcing Impact the Starter Supply Chain?

Sustainability has become a pivotal concern in the automotive industry, affecting sourcing decisions for B2B buyers. The environmental impact of automotive components, including starters, necessitates a shift toward sustainable practices. This includes the use of eco-friendly materials and processes that reduce waste and carbon footprints. Buyers are increasingly seeking suppliers who can demonstrate their commitment to sustainability through certifications and transparent supply chains.

Ethical sourcing is equally important, as consumers demand more accountability from brands. B2B buyers must ensure that their suppliers adhere to fair labor practices and environmental standards throughout the production process. This not only mitigates risks associated with reputational damage but also aligns with the growing consumer preference for ethically produced products.

Additionally, suppliers that invest in sustainable technologies often benefit from cost savings and increased efficiency. For instance, using recyclable materials in starter production can lower raw material costs while appealing to environmentally conscious buyers. As such, integrating sustainability and ethical sourcing into procurement strategies is essential for B2B buyers looking to enhance their market competitiveness and meet regulatory requirements.

What Is the Historical Context of Starters and Their Evolution in the Automotive Industry?

The development of automotive starters dates back to the early 20th century, revolutionizing vehicle operation by eliminating the need for hand cranks. Initially, starters were simple DC motors, but advancements in technology have led to the introduction of more reliable and efficient designs. Over the decades, the materials and technologies used in starters have evolved, incorporating features such as improved insulation and advanced solenoid switches.

With the advent of computerized systems in vehicles, modern starters are now integrated with sophisticated electronics that enhance performance and durability. This evolution has enabled starters to last longer under varying operating conditions, aligning with the growing expectations of B2B buyers for high-quality automotive components. Understanding this historical context helps buyers appreciate the technological advancements that influence current sourcing trends and product lifecycles in the automotive sector.

Frequently Asked Questions (FAQs) for B2B Buyers of how long does starter last

-

1. How can I determine the lifespan of a starter for my vehicles?

To assess the lifespan of a starter, consider its expected performance range, typically between 80,000 to 100,000 starts or 100,000 to 300,000 miles. Factors influencing longevity include driving conditions, frequency of use, and vehicle age. Regular maintenance and monitoring of the starting system can help identify wear and tear, allowing for timely replacement before failure, ensuring minimal disruption to operations. -

2. What factors lead to premature starter failure?

Common causes of early starter failure include worn brushes, faulty starter relays, loose wiring, and dirty connectors. Environmental conditions like excessive heat or moisture can also exacerbate these issues. For B2B buyers, understanding these factors is crucial when sourcing starters, as selecting high-quality components can mitigate the risk of premature failure and reduce maintenance costs. -

3. How do I evaluate the quality of starters from suppliers?

When vetting suppliers, look for certifications and quality assurances, such as ISO standards. Request samples for testing and inquire about warranties offered on their starters. Additionally, check for reviews and testimonials from previous clients to gauge reliability and performance. A supplier’s commitment to quality control can significantly impact the longevity and performance of the starters you purchase. -

4. What should I consider regarding minimum order quantities (MOQs) for starters?

MOQs vary by supplier and can impact your purchasing strategy. Assess your immediate needs and future demand to negotiate favorable terms. If you’re uncertain about volume, consider suppliers who offer flexible MOQs or trial orders. This approach allows you to test product quality without committing to large quantities, minimizing financial risk. -

5. What payment terms are typically available for purchasing starters?

Payment terms can vary widely based on supplier policies and your business relationship. Common options include upfront payments, net 30 or 60 days, and letter of credit arrangements. Establishing clear payment terms can help manage cash flow effectively. Always confirm payment methods accepted by the supplier, as international transactions may require specific protocols. -

6. How do logistics and shipping impact the procurement of starters?

Logistics play a critical role in the timely delivery of starters. Factors such as shipping methods, lead times, and import/export regulations must be considered. Collaborate with suppliers to understand their shipping capabilities and choose logistics partners that ensure efficient delivery to your location. This planning helps avoid delays that could affect your operations. -

7. Can I customize starters to fit specific vehicle models?

Many suppliers offer customization options for starters to meet specific vehicle requirements. Discuss your specifications with potential suppliers to determine if they can accommodate your needs. Customization may involve variations in size, power ratings, or connector types. Ensure that the supplier has the capability and expertise to deliver quality customized products. -

8. What quality assurance measures should I expect when sourcing starters?

Quality assurance measures can include thorough testing of starters before shipment, adherence to industry standards, and detailed product specifications. Reputable suppliers will provide documentation verifying that their products meet established quality benchmarks. Requesting a Certificate of Compliance or similar documentation can help ensure that you receive reliable starters that meet your operational needs.

Top 5 How Long Does Starter Last Manufacturers & Suppliers List

1. 2005 Car Starter – Temporary Fix Concerns

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The text discusses a car starter that has been temporarily fixed by banging on it after it failed. The user is concerned about how long the starter will last before needing replacement, as they cannot afford to replace it immediately. The car is a 2005 model, and the user is seeking advice on whether it is safe to drive the car for a few weeks until they can afford repairs.

2. Central Mazda – Car Starter

Domain: centralmazdact.com

Registered: 2016 (9 years)

Introduction: Car Starter: A device that rotates the engine to initiate its firing. Lifespan: Approximately 100,000 to 150,000 miles. Factors Influencing Lifespan: Driving habits, environmental conditions, and vehicle maintenance. Signs of Failure: Clicking noise, engine does not crank, intermittent starting issues. Tips to Extend Lifespan: Adhere to maintenance schedule, keep electrical connections clean, care…

3. Facebook – Social Networking Platform

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Social Networking Platform, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. CC Automotive – Car Starters

Domain: ccautomotive.com

Registered: 1999 (26 years)

Introduction: Average lifespan of a car starter is 100,000 to 150,000 miles. Signs of a failing starter include: clicking sounds when attempting to start, difficulty starting the engine, inability to start the engine while lights are functional, and a burning smell with smoke from overheating. Starters can be compromised by motor oil leaks due to a cracked engine gasket or cylinder block.

5. Harley-Davidson – Starter Longevity Factors

Domain: hdforums.com

Registered: 2003 (22 years)

Introduction: Harley-Davidson starters are expected to last as long as the engine under normal circumstances. Key factors affecting starter longevity include heat exposure and the frequency of use. Symptoms of a failing starter may resemble those of battery issues. Some users reported starters lasting between 5 to 15 years, with some having replaced starter clutches or solenoids during that time. High compressi…

Strategic Sourcing Conclusion and Outlook for how long does starter last

In summary, understanding the lifespan of car starters—typically ranging from 80,000 to 100,000 starts or 100,000 to 300,000 miles—provides essential insights for international B2B buyers in the automotive sector. The factors influencing starter longevity, such as driving habits, environmental conditions, and the overall health of the vehicle, underline the importance of proactive maintenance and timely replacement. For businesses operating in diverse markets like Africa, South America, the Middle East, and Europe, strategic sourcing becomes crucial. By aligning with reliable suppliers who offer high-quality starters and components, organizations can minimize downtime and enhance operational efficiency.

As you navigate the complexities of sourcing automotive parts, prioritize partnerships that understand local market dynamics and can deliver products tailored to your specific needs. This proactive approach not only ensures vehicle reliability but also strengthens your competitive edge in a rapidly evolving marketplace. Embrace the opportunity to optimize your supply chain and enhance your service offerings, ensuring that your operations remain seamless and efficient as you look toward the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.