Introduction: Navigating the Global Market for how do you test a starter solenoid

In today’s competitive automotive industry, understanding how to test a starter solenoid effectively is crucial for ensuring operational efficiency and minimizing downtime. For international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe, the challenge lies in sourcing reliable components while navigating varying levels of expertise and infrastructure. This comprehensive guide not only delves into the essential methods for testing starter solenoids but also explores their types, applications, and the importance of supplier vetting to secure high-quality parts.

As businesses face pressures to reduce costs and enhance productivity, knowing how to accurately diagnose solenoid issues can lead to significant savings in both time and resources. This guide empowers B2B buyers with actionable insights, providing a thorough understanding of the testing process and the factors influencing performance. By highlighting key considerations such as cost analysis, compatibility with different vehicle models, and supplier reliability, this resource positions your organization to make informed purchasing decisions.

Whether you are an automotive manufacturer, repair shop, or parts distributor, mastering the art of testing starter solenoids is vital for maintaining a competitive edge in the global market. Engage with this guide to ensure that your operations run smoothly and effectively, regardless of your location or market challenges.

Table Of Contents

- Top 2 How Do You Test A Starter Solenoid Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you test a starter solenoid

- Understanding how do you test a starter solenoid Types and Variations

- Key Industrial Applications of how do you test a starter solenoid

- 3 Common User Pain Points for ‘how do you test a starter solenoid’ & Their Solutions

- Strategic Material Selection Guide for how do you test a starter solenoid

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you test a starter solenoid

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you test a starter solenoid’

- Comprehensive Cost and Pricing Analysis for how do you test a starter solenoid Sourcing

- Alternatives Analysis: Comparing how do you test a starter solenoid With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you test a starter solenoid

- Navigating Market Dynamics and Sourcing Trends in the how do you test a starter solenoid Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you test a starter solenoid

- Strategic Sourcing Conclusion and Outlook for how do you test a starter solenoid

- Important Disclaimer & Terms of Use

Understanding how do you test a starter solenoid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Visual Inspection | Quick assessment; looks for physical damage or corrosion. | Automotive repair shops, fleet maintenance. | Pros: Fast and low-cost. Cons: May miss internal issues. |

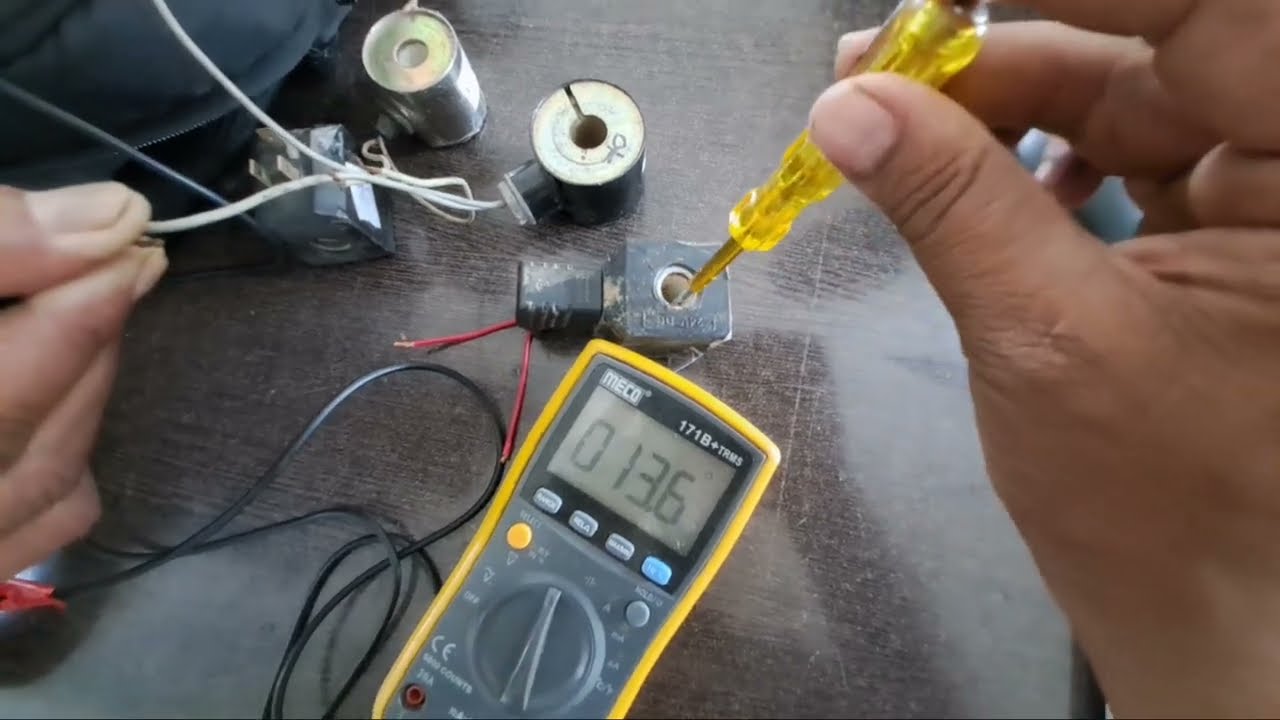

| Electrical Testing with a Multimeter | Measures voltage and current for a detailed analysis. | Heavy machinery, automotive, and industrial equipment. | Pros: Accurate diagnostics. Cons: Requires technical knowledge. |

| Test Light Method | Uses a simple test light to check electrical continuity. | Small engine repair, automotive diagnostics. | Pros: Easy to use and understand. Cons: Limited in-depth analysis. |

| Load Testing | Simulates actual operating conditions to assess performance. | Industrial applications, commercial vehicle testing. | Pros: Comprehensive evaluation. Cons: More time-consuming and equipment-intensive. |

| Resistance Testing | Measures the resistance across the solenoid terminals. | Quality control in manufacturing, automotive repair. | Pros: Identifies internal failures. Cons: Requires specialized tools. |

What are the Key Characteristics of Visual Inspection for Starter Solenoids?

Visual inspection is the most straightforward method for assessing a starter solenoid’s condition. This technique involves checking for any visible signs of wear, corrosion, or physical damage. It is particularly suitable for automotive repair shops and fleet maintenance operations, where quick assessments can save time and labor costs. However, while this method is cost-effective and fast, it may overlook internal issues that could lead to solenoid failure.

How Does Electrical Testing with a Multimeter Work for Solenoid Diagnostics?

Electrical testing using a multimeter provides a more detailed analysis of a starter solenoid’s performance. This method measures voltage and current to determine whether the solenoid is functioning correctly. It is commonly employed in heavy machinery and automotive sectors, where precision is critical. While this approach is highly accurate, it requires technicians to have a certain level of expertise and familiarity with electrical systems, which can be a barrier for some buyers.

What are the Advantages of Using the Test Light Method?

The test light method is a simple yet effective way to check for electrical continuity in a starter solenoid. By using a basic test light, technicians can quickly determine if power is reaching the solenoid and whether it is functioning properly. This method is widely used in small engine repairs and automotive diagnostics due to its ease of use. However, while it is user-friendly, the test light method may not provide a comprehensive analysis of the solenoid’s internal condition.

Why is Load Testing Important for Starter Solenoid Evaluation?

Load testing simulates actual operating conditions to assess the starter solenoid’s performance under stress. This method is crucial in industrial applications and commercial vehicle testing, where reliability is paramount. Load testing provides a thorough evaluation of the solenoid’s ability to handle real-world demands. However, it is more time-consuming and requires specialized equipment, making it less suitable for quick assessments.

How Does Resistance Testing Enhance Quality Control in Solenoid Manufacturing?

Resistance testing measures the electrical resistance across the solenoid terminals to identify potential internal failures. This method is particularly relevant in quality control within manufacturing and automotive repair settings. It ensures that solenoids meet performance standards before being deployed. While resistance testing is effective in identifying issues, it necessitates specialized tools and expertise, which may limit its accessibility for some businesses.

Key Industrial Applications of how do you test a starter solenoid

| Industry/Sector | Specific Application of how do you test a starter solenoid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Testing starter solenoids in vehicles to ensure reliability | Increases vehicle uptime and reduces repair costs | Availability of testing tools, compatibility with various vehicle models, and local support for parts. |

| Heavy Machinery | Verifying solenoid function in construction equipment | Enhances operational efficiency and minimizes downtime | Need for robust testing equipment that can withstand harsh environments and the ability to source parts locally. |

| Transportation & Logistics | Ensuring reliability of fleet vehicles’ starting systems | Reduces maintenance costs and enhances fleet reliability | Access to bulk purchasing options for solenoids and related components, along with timely delivery. |

| Agriculture Equipment | Testing solenoids in tractors and harvesters | Improves equipment reliability during critical harvest periods | Requirement for specialized knowledge of agricultural machinery and sourcing of durable components. |

| Mining Operations | Diagnosing starter issues in mining vehicles | Minimizes operational interruptions and improves safety | Need for rugged testing solutions suited for extreme conditions and immediate access to replacement parts. |

How is Testing a Starter Solenoid Applied in Automotive Repair?

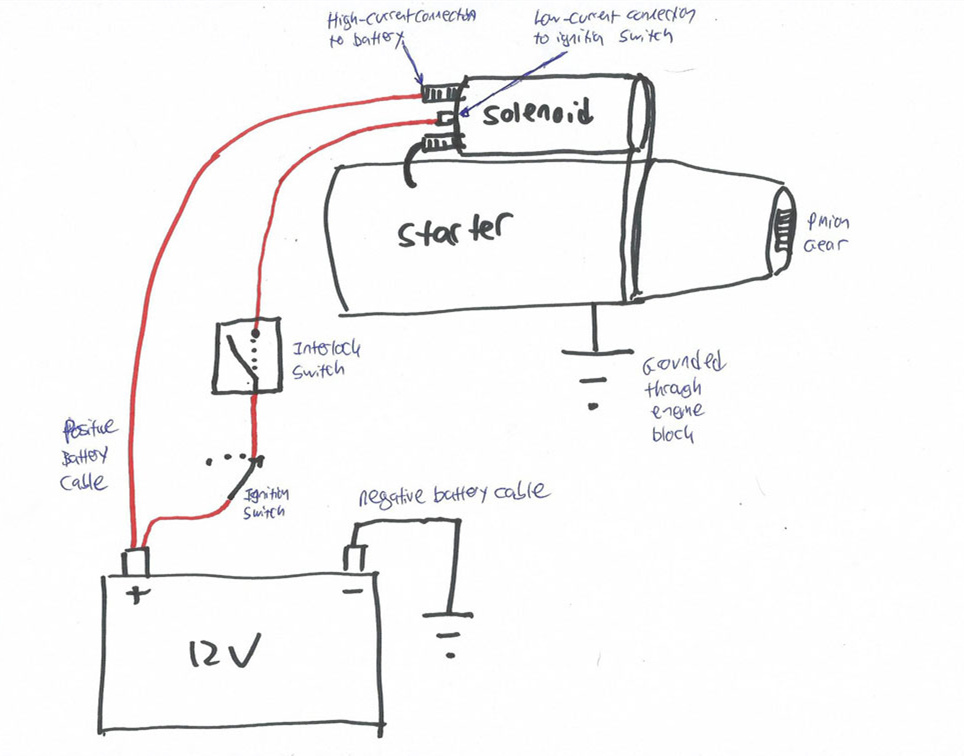

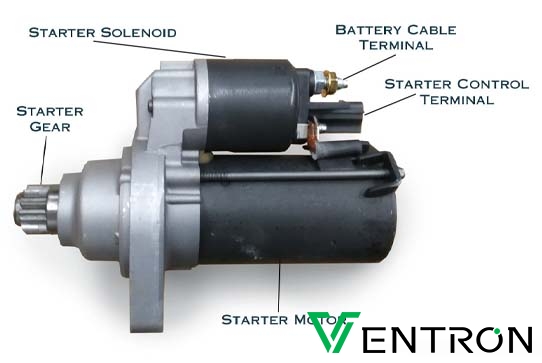

In the automotive repair sector, testing a starter solenoid is crucial for diagnosing starting issues in vehicles. Technicians utilize specific methods to check the solenoid’s functionality, ensuring that the electrical current is effectively transmitted from the battery to the starter motor. This process helps identify whether the problem lies with the solenoid, battery, or starter itself. For international B2B buyers, understanding the compatibility of testing tools with diverse vehicle makes and models is vital, as is ensuring the availability of reliable replacement parts.

What Role Does Starter Solenoid Testing Play in Heavy Machinery?

Heavy machinery, such as bulldozers and excavators, relies on functional starter solenoids to initiate operations. Testing these components is essential to prevent costly downtime in construction projects. A malfunctioning solenoid can lead to equipment failure, affecting productivity. B2B buyers in this sector must consider sourcing robust testing equipment that can endure harsh working conditions and ensure that replacement solenoids are available locally to minimize delays.

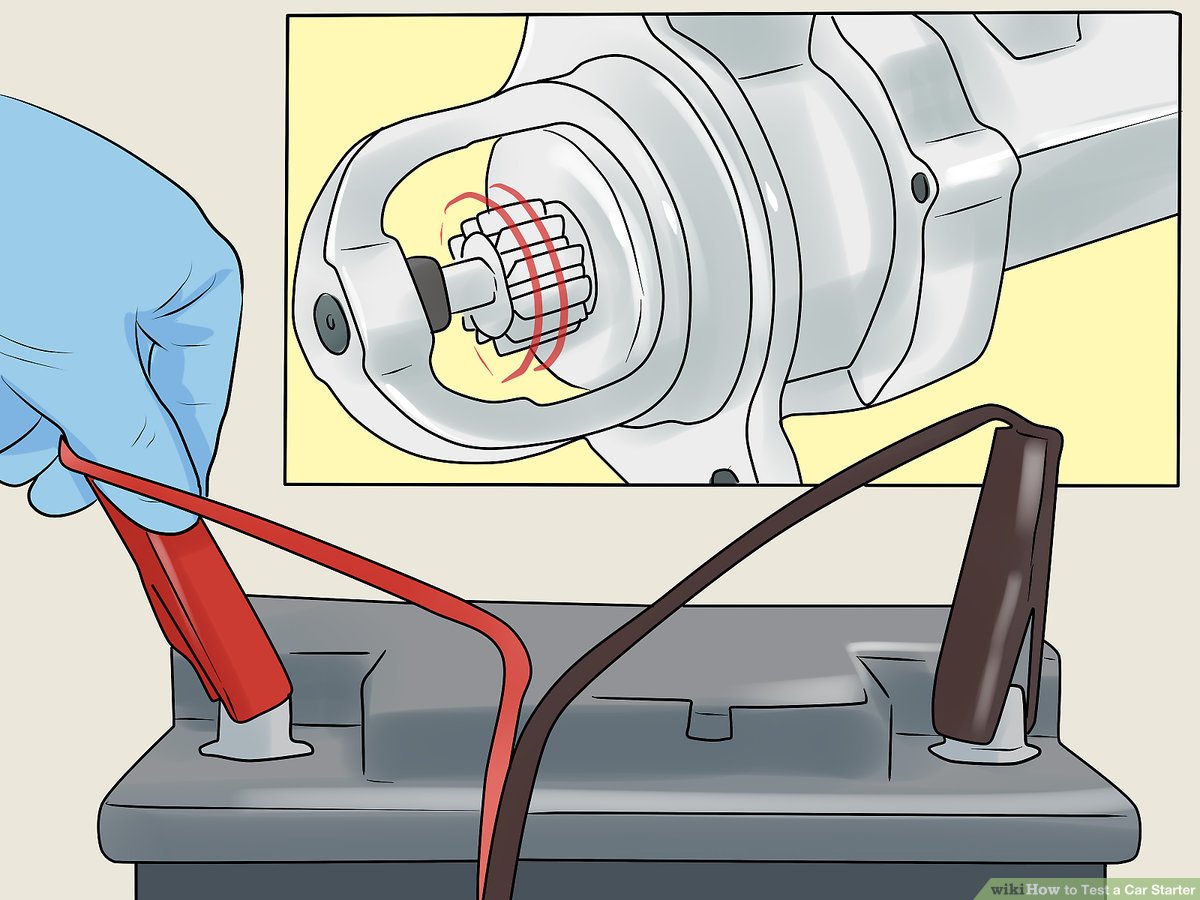

Illustrative image related to how do you test a starter solenoid

Why is Solenoid Testing Important for Transportation Fleets?

For transportation and logistics companies, the reliability of fleet vehicles is paramount. Regular testing of starter solenoids helps maintain optimal vehicle performance and minimizes the risk of breakdowns during transit. This proactive approach reduces maintenance costs and enhances overall fleet reliability. Buyers in this industry should focus on bulk purchasing options for solenoids and related components, ensuring timely delivery to keep their operations running smoothly.

How Does Starter Solenoid Testing Benefit Agricultural Equipment?

In agriculture, the reliability of tractors and harvesters is critical, especially during peak harvesting seasons. Testing starter solenoids ensures that these machines start reliably, preventing delays that could impact crop yields. B2B buyers must be knowledgeable about the specific requirements of agricultural machinery and source durable components that can withstand field conditions, ensuring uninterrupted operations during critical periods.

What is the Significance of Testing Starter Solenoids in Mining Operations?

Mining vehicles operate in extreme conditions, making the reliability of starter solenoids crucial for safety and efficiency. Testing these components helps identify potential failures before they cause operational interruptions. For B2B buyers in the mining sector, sourcing rugged testing solutions and having immediate access to replacement parts is essential to maintain safety standards and minimize downtime, which can be costly in this industry.

3 Common User Pain Points for ‘how do you test a starter solenoid’ & Their Solutions

Scenario 1: Unreliable Vehicle Startup in Fleet Operations

The Problem: Fleet managers often face the frustrating challenge of unreliable vehicle startups, which can disrupt operations and lead to delays. When a vehicle fails to start, it’s not only a logistical headache but can also incur additional costs related to repair services or replacement vehicles. Identifying whether the issue stems from a faulty starter solenoid, battery, or starter motor can be time-consuming and requires technical know-how that may not be readily available in-house. This uncertainty can hinder productivity and affect service delivery to clients.

The Solution: To address this issue effectively, fleet managers should implement a systematic approach to test the starter solenoid. Begin by ensuring that the vehicle’s battery is fully charged; a low battery can often mimic solenoid failure. Utilize a multimeter to check the voltage at the solenoid’s terminals. Confirm that the voltage reading is around 12 volts when the ignition is turned on. If the voltage is adequate but the solenoid does not engage, further testing is necessary. Connect a test light to the solenoid’s output terminal while a colleague turns the ignition. If the light illuminates, the solenoid is likely functioning correctly, and the issue may lie with the starter motor itself. Document these procedures and findings for each vehicle to create a reference guide, enabling quicker diagnostics in the future.

Scenario 2: Difficulty Sourcing Quality Replacement Parts

The Problem: B2B buyers, especially those managing automotive repair shops, often encounter difficulties sourcing quality replacement parts, including starter solenoids. Poor-quality parts can lead to recurrent failures, increased downtime, and ultimately dissatisfied customers. This challenge is compounded in regions where supply chains may be less reliable, making it crucial to find trusted suppliers who offer durable components at competitive prices.

The Solution: Establishing relationships with reputable suppliers is key to overcoming this sourcing challenge. Conduct thorough research to identify manufacturers known for their quality products and check for certifications or industry endorsements. Use trade shows or industry conferences to network and meet potential suppliers directly. When sourcing starter solenoids, request samples or trial orders to assess quality before committing to larger purchases. Additionally, leverage online platforms that provide reviews and ratings of parts suppliers, ensuring that you are selecting partners who consistently deliver reliable components. By building a network of trusted suppliers, you can streamline your procurement process and enhance the reliability of your repair services.

Illustrative image related to how do you test a starter solenoid

Scenario 3: Training Staff on Diagnostic Procedures

The Problem: Many B2B buyers struggle with ensuring that their technicians are adequately trained to diagnose electrical issues like those associated with starter solenoids. Inadequate training can lead to misdiagnosis, resulting in unnecessary repairs or replacements, which can be costly and damage customer trust. This gap in knowledge is particularly challenging in regions where access to technical training resources may be limited.

The Solution: To bridge the knowledge gap, businesses should invest in comprehensive training programs focused on electrical diagnostics and starter system testing. Consider partnering with technical schools or industry experts to develop a curriculum tailored to your team’s needs. Practical hands-on training sessions can be invaluable; set up a workshop where technicians can practice testing starter solenoids using real vehicles. Supplement this training with detailed manuals and online resources that technicians can refer to as needed. Additionally, encourage a culture of continuous learning by providing access to online courses or certifications in automotive electrical systems. By equipping your team with the right skills and knowledge, you can improve diagnostic accuracy, reduce repair times, and enhance customer satisfaction.

Strategic Material Selection Guide for how do you test a starter solenoid

What Materials Are Commonly Used in Testing a Starter Solenoid?

When it comes to testing a starter solenoid, the choice of materials plays a crucial role in ensuring accurate and reliable results. Here, we analyze four common materials used in the testing process, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Copper

Key Properties:

Copper is known for its excellent electrical conductivity, making it ideal for connections in electrical testing. It has a melting point of 1,984°F (1,085°C) and is resistant to corrosion when properly coated.

Pros & Cons:

Copper’s high conductivity ensures minimal resistance in electrical connections, enhancing the accuracy of voltage readings. However, it is relatively expensive compared to other metals and can be prone to oxidation if not properly treated, which may affect performance over time.

Impact on Application:

Copper is particularly suitable for applications requiring high electrical efficiency, such as testing solenoids, where precise current measurements are critical.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should consider compliance with standards such as ASTM B170 for copper wire. In contrast, buyers in Africa and South America may face challenges related to sourcing high-quality copper due to local market conditions.

2. Aluminum

Key Properties:

Aluminum is lightweight and has a melting point of 1,221°F (660.3°C). It is resistant to corrosion and offers decent electrical conductivity, though not as high as copper.

Pros & Cons:

The primary advantage of aluminum is its cost-effectiveness and lightweight nature, making it easier to handle during testing. However, its lower conductivity compared to copper can lead to increased resistance, which may affect the accuracy of tests.

Impact on Application:

Aluminum is suitable for applications where weight is a concern, but its use in high-precision electrical testing may be limited due to its conductivity issues.

Considerations for International Buyers:

Compliance with standards like ASTM B221 for aluminum extrusions is essential, especially for buyers in Europe and Germany. Buyers from regions with less stringent regulations may find aluminum to be a more accessible option.

3. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and strength, with a melting point of around 2,500°F (1,370°C). It is less conductive than copper and aluminum but is durable in harsh environments.

Pros & Cons:

The durability and corrosion resistance of stainless steel make it suitable for long-term applications. However, its lower electrical conductivity can hinder performance in testing scenarios, making it less ideal for precise electrical measurements.

Impact on Application:

Stainless steel is often used in environments where exposure to moisture or corrosive substances is a concern, but it may not be the best choice for direct electrical connections in testing.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM A240 for stainless steel, especially in regions with strict quality controls, such as Germany and Europe. In developing regions, the availability of high-quality stainless steel may vary.

4. PVC Insulation

Key Properties:

Polyvinyl Chloride (PVC) is a synthetic plastic polymer known for its excellent insulating properties and resistance to chemicals. It can withstand temperatures up to 176°F (80°C).

Pros & Cons:

PVC is cost-effective and provides excellent electrical insulation, making it suitable for protecting wires and connections during testing. However, it can degrade over time when exposed to UV light and extreme temperatures.

Impact on Application:

PVC insulation is critical in ensuring safety during electrical testing, preventing short circuits and protecting users.

Illustrative image related to how do you test a starter solenoid

Considerations for International Buyers:

Compliance with international standards such as IEC 60227 for PVC insulated cables is crucial for ensuring safety and reliability, particularly for buyers in Europe and the Middle East.

Summary Table

| Material | Typical Use Case for how do you test a starter solenoid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections in testing solenoids | High electrical conductivity | Prone to oxidation | High |

| Aluminum | Lightweight connections for solenoid testing | Cost-effective and lightweight | Lower conductivity than copper | Medium |

| Stainless Steel | Structural components in harsh environments | Excellent corrosion resistance | Lower electrical conductivity | Medium |

| PVC Insulation | Insulation for electrical connections | Excellent electrical insulation | Degrades under UV exposure | Low |

This strategic material selection guide provides B2B buyers with insights into the materials used in testing starter solenoids, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how do you test a starter solenoid

What Are the Key Stages in the Manufacturing Process of a Starter Solenoid?

The manufacturing process of a starter solenoid involves several critical stages that ensure the final product meets performance standards and customer expectations. These stages include material preparation, forming, assembly, and finishing. Each stage plays a vital role in the solenoid’s operational reliability, particularly for B2B buyers who demand high-quality components.

Illustrative image related to how do you test a starter solenoid

How Is Material Prepared for Starter Solenoid Production?

Material preparation is the foundational step in the manufacturing process. High-quality metals, typically copper and steel, are selected based on their electrical conductivity and mechanical strength. Materials undergo rigorous inspection to ensure they meet specifications. This often includes checking for impurities, dimensional accuracy, and mechanical properties. Suppliers should provide certification for the materials used, detailing their origins and compliance with international standards.

What Techniques Are Used for Forming the Components of a Starter Solenoid?

Once the materials are prepared, forming techniques such as stamping, machining, and injection molding are employed. Stamping is commonly used for creating the solenoid’s housing and other metal components, while machining ensures precise dimensions for critical parts like the plunger and terminals. Injection molding may be utilized for plastic parts, such as insulators. Each technique requires specialized machinery and skilled operators to maintain quality control throughout the process.

How Is Assembly Performed in the Production of Starter Solenoids?

The assembly stage involves bringing together the formed components to create the complete starter solenoid. This process typically occurs in a clean environment to prevent contamination. Components are assembled using techniques like soldering, welding, and mechanical fastening. During this stage, manufacturers conduct initial quality checks to ensure that parts fit correctly and function as intended. Documentation of assembly procedures is crucial for traceability and future audits.

What Finishing Processes Are Applied to Ensure Quality in Starter Solenoids?

Finishing processes enhance both the aesthetics and functional performance of starter solenoids. This may include surface treatment, such as coating or plating, to improve corrosion resistance and electrical conductivity. Additionally, final inspections are conducted to verify the absence of defects and ensure compliance with specifications. For B2B buyers, understanding the finishing processes can provide insights into the durability and longevity of the product.

What Quality Assurance Measures Are Implemented in Starter Solenoid Manufacturing?

Quality assurance (QA) is integral to the manufacturing of starter solenoids. It encompasses various international and industry-specific standards, including ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that manufacturers consistently produce high-quality products that meet customer needs.

Illustrative image related to how do you test a starter solenoid

What International Standards Should B2B Buyers Be Aware of?

ISO 9001 is a widely recognized standard that emphasizes quality management principles, including customer focus, leadership, and continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in the European market and API (American Petroleum Institute) standards for components used in the oil and gas sector may be relevant. Buyers should verify whether suppliers hold these certifications, as they demonstrate a commitment to quality and safety.

What Quality Control Checkpoints Are Critical During Manufacturing?

Quality control checkpoints, such as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC), are essential in the manufacturing process.

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet predetermined specifications before entering production.

-

In-Process Quality Control (IPQC): During assembly and forming, periodic checks are conducted to monitor processes and identify any deviations from quality standards in real-time.

-

Final Quality Control (FQC): This final inspection assesses the completed starter solenoid against all specifications and performance criteria before it is packaged and shipped.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. This can include:

-

Conducting Audits: Regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards.

-

Requesting Quality Reports: Suppliers should be able to provide documentation detailing their quality control processes, results from inspections, and certifications.

-

Engaging Third-Party Inspection Services: Utilizing third-party inspectors can offer an unbiased evaluation of the manufacturing process and the quality of the finished product.

What Nuances in Quality Control Should International Buyers Consider?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, it’s essential to understand the nuances of quality control that may vary by region. Different countries may have distinct regulatory requirements, which can affect manufacturing practices and standards. Buyers should familiarize themselves with local regulations and standards applicable to starter solenoids in their respective markets.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear communication channels and expectations from the outset can mitigate misunderstandings and ensure that quality standards are consistently met.

Illustrative image related to how do you test a starter solenoid

Conclusion

Understanding the manufacturing processes and quality assurance measures for starter solenoids is crucial for B2B buyers seeking reliable components. By focusing on material preparation, forming, assembly, and finishing, along with adherence to international standards and robust quality control practices, buyers can make informed decisions when selecting suppliers. Engaging with manufacturers who prioritize quality will ultimately lead to better product performance and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you test a starter solenoid’

In this guide, we aim to provide B2B buyers with a comprehensive checklist for effectively testing a starter solenoid. Understanding how to test this component is essential for ensuring optimal vehicle performance and minimizing downtime. This guide will assist you in sourcing the necessary tools and suppliers, facilitating a seamless testing process.

Step 1: Identify Your Testing Requirements

Before you begin the procurement process, clearly define what you need for testing a starter solenoid. Consider the types of vehicles or machinery you will be working on, as different applications may require specific tools or methods.

– Key Considerations:

– Types of vehicles (e.g., passenger cars, commercial trucks).

– Testing environment (e.g., workshop, field service).

Step 2: Research and Select Testing Tools

Invest in reliable testing equipment, such as multimeters and test lights, which are essential for diagnosing solenoid issues. Look for tools that are durable and suitable for the specific electrical systems you will encounter.

– Recommendations:

– Opt for digital multimeters with a good range for automotive diagnostics.

– Ensure test lights are compatible with the voltage systems of your vehicles.

Illustrative image related to how do you test a starter solenoid

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can provide quality tools and components necessary for testing starter solenoids. Request detailed company profiles and references to gauge their reliability.

– What to Look For:

– Certifications or industry standards that validate product quality.

– Reviews from other businesses in your sector.

Step 4: Verify Supplier Certifications

It’s crucial to verify that your suppliers hold the necessary certifications, such as ISO or automotive-specific standards. This ensures that the products you source are manufactured to high-quality specifications.

– Checklist:

– Request copies of certifications and validate them with issuing bodies.

– Look for compliance with relevant regulations in your region.

Step 5: Request Samples or Demonstrations

Before making a bulk purchase, ask for samples or demonstrations of the testing equipment. This hands-on approach allows you to evaluate the performance and ease of use of the tools.

– Benefits:

– Ensures that the tools meet your operational needs.

– Provides insight into the supplier’s customer service and support.

Step 6: Negotiate Terms and Pricing

Once you’ve identified suitable suppliers, negotiate pricing and payment terms to ensure you receive the best value for your investment. Consider the total cost of ownership, including warranties and support services.

– Negotiation Tips:

– Inquire about bulk purchase discounts or loyalty programs.

– Discuss return policies and warranty coverage to mitigate risk.

Step 7: Establish a Testing Protocol

After procuring the necessary tools, develop a clear protocol for testing starter solenoids. This should include step-by-step instructions that align with best practices in the industry to ensure consistency and accuracy in your testing.

– Key Components:

– Detailed procedures for testing and troubleshooting.

– Documentation for tracking results and identifying recurring issues.

By following this checklist, you will be well-prepared to test starter solenoids effectively, enhancing your operational efficiency and ensuring the reliability of your vehicles or machinery.

Comprehensive Cost and Pricing Analysis for how do you test a starter solenoid Sourcing

What Are the Key Cost Components in Testing a Starter Solenoid?

When evaluating the costs associated with sourcing starter solenoid testing, several components contribute to the overall cost structure. Understanding these components can empower B2B buyers to make informed purchasing decisions.

-

Materials: The primary materials involved in testing a starter solenoid include electrical components such as wires, connectors, and resistors. The quality and specifications of these materials can significantly influence pricing. Premium components may enhance reliability but come at a higher cost.

-

Labor: Labor costs encompass the wages paid to technicians and engineers performing the testing. Skilled labor is essential for accurate diagnostics, and the cost may vary by region. In areas with a high demand for automotive technicians, labor costs can be a significant portion of the overall expense.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility costs, and administrative expenses. Efficient manufacturing processes can help reduce overhead, which in turn can lower the final price for the buyer.

-

Tooling: Specialized tools required for testing solenoids can represent a significant upfront investment. This includes diagnostic tools, multimeters, and test lights. Buyers should consider these costs, especially if they plan to conduct frequent testing.

-

Quality Control (QC): Implementing stringent QC measures ensures the reliability of the testing process. Costs associated with QC can vary depending on the complexity of the testing procedures and the certification standards adhered to by the supplier.

-

Logistics: Shipping and handling costs can vary significantly based on the geographic location of both the supplier and the buyer. Incoterms will influence who bears these costs, impacting the overall pricing structure.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on the competitive landscape, demand, and the perceived value of the testing services provided.

What Influences Pricing for Testing a Starter Solenoid?

Several factors can influence the pricing structure for testing starter solenoids, and understanding these can help buyers optimize their procurement strategies.

Illustrative image related to how do you test a starter solenoid

-

Volume and Minimum Order Quantity (MOQ): Larger purchase volumes often lead to reduced per-unit costs. Buyers should negotiate MOQs to ensure they achieve the best pricing, especially for regular maintenance operations.

-

Specifications and Customization: Custom specifications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses associated with custom tooling or materials.

-

Materials Quality and Certifications: Higher quality materials and certifications (e.g., ISO standards) often come at a premium. However, investing in quality can reduce long-term operational costs by minimizing failures and ensuring compliance with international standards.

-

Supplier Factors: The supplier’s reputation, reliability, and experience can affect pricing. Established suppliers may charge more due to their proven track record but can offer better service and support.

-

Incoterms: Understanding the implications of different Incoterms is crucial for international buyers. These terms dictate who is responsible for shipping costs and risks, which can significantly impact the total cost of ownership.

What Tips Can Help International B2B Buyers Optimize Costs?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage suppliers in negotiations to secure better pricing, especially for bulk orders. Leverage competitive quotes to negotiate more favorable terms.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the initial purchase price. Factor in maintenance, potential downtime, and the lifespan of the product to evaluate long-term value.

-

Understand Pricing Nuances: Be aware of currency fluctuations, tariffs, and import duties that may affect the final cost. This understanding is particularly crucial for buyers from regions with volatile economies.

-

Research Local Regulations: Compliance with local regulations can impact sourcing decisions and costs. Ensure that the chosen supplier can meet all regulatory requirements to avoid costly delays and penalties.

By analyzing these components and influencers, B2B buyers can navigate the complexities of sourcing starter solenoid testing services more effectively, ultimately leading to better decision-making and cost savings.

Alternatives Analysis: Comparing how do you test a starter solenoid With Other Solutions

Introduction: Exploring Alternatives for Testing a Starter Solenoid

In the automotive industry, effectively testing a starter solenoid is crucial for diagnosing starting issues in vehicles. However, there are various methods and technologies available that can serve as alternatives to the traditional testing process. Understanding these options can help businesses, especially those in regions like Africa, South America, the Middle East, and Europe, make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | How Do You Test A Starter Solenoid | Digital Multimeter Testing | Remote Starter Diagnostics |

|---|---|---|---|

| Performance | Reliable for basic diagnostics | Highly accurate readings | Quick and efficient diagnostics |

| Cost | Low (tools typically needed) | Moderate (multimeter purchase) | High (advanced equipment) |

| Ease of Implementation | Simple for trained personnel | Requires some technical knowledge | User-friendly, minimal training needed |

| Maintenance | Low maintenance on tools | Moderate (calibration) | High (software updates, hardware upkeep) |

| Best Use Case | Basic vehicle maintenance | Detailed electrical analysis | Fleet operations, high-volume diagnostics |

Detailed Breakdown of Alternatives

What are the advantages and disadvantages of using Digital Multimeter Testing?

Digital multimeter testing involves measuring voltage, current, and resistance to diagnose electrical issues in the starter solenoid. The primary advantage of this method is its accuracy; it provides precise readings that can help identify not just solenoid issues but also problems with the battery and starter. However, it requires a certain level of technical expertise to interpret the readings correctly. Additionally, the initial cost of a quality multimeter can be moderate, making it less accessible for smaller businesses or workshops that may be budget-conscious.

How does Remote Starter Diagnostics compare in terms of efficiency?

Remote starter diagnostics systems are increasingly popular for their efficiency and speed in diagnosing starting issues. These systems can quickly assess the health of the starter solenoid and related components without the need for physical interaction. This method is particularly beneficial for businesses managing a fleet of vehicles, as it allows for rapid assessments and minimizes downtime. However, the initial investment is significantly higher compared to simpler methods, and ongoing maintenance costs can add up due to software updates and hardware checks.

Conclusion: How to Choose the Right Solution for Testing a Starter Solenoid

When selecting the best solution for testing a starter solenoid, B2B buyers should consider their specific operational requirements, budget constraints, and technical capabilities. For businesses focused on basic diagnostics and cost-effectiveness, traditional testing methods may suffice. In contrast, those requiring precision and efficiency in high-volume environments may benefit from investing in digital multimeters or advanced remote diagnostics systems. Ultimately, the right choice will depend on the unique needs and resources of each organization, ensuring optimal performance and reliability in vehicle maintenance.

Essential Technical Properties and Trade Terminology for how do you test a starter solenoid

What Are the Essential Technical Properties to Consider When Testing a Starter Solenoid?

When testing a starter solenoid, understanding its critical technical properties is essential for ensuring optimal performance and compatibility with various vehicle systems. Here are some of the key specifications to consider:

1. Material Grade

The solenoid’s housing and internal components are typically made from materials such as steel, copper, or aluminum. The material grade affects durability, corrosion resistance, and electrical conductivity. Higher-grade materials provide better performance and longevity, which is crucial for B2B buyers looking for reliable components that minimize downtime.

2. Operating Voltage

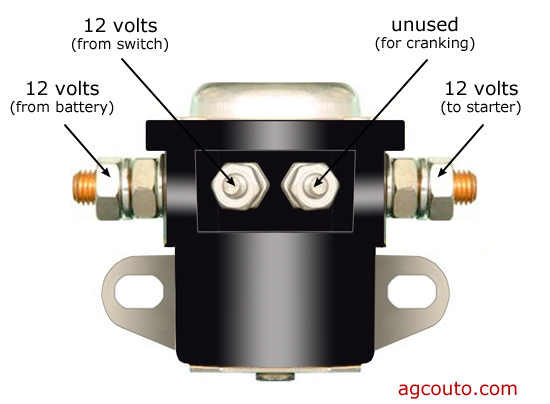

Most starter solenoids operate at 12 volts, aligning with standard automotive battery systems. Understanding the required operating voltage is critical when testing, as using a solenoid with an incorrect voltage can lead to failure or damage. B2B buyers should ensure that the solenoids they procure match the voltage specifications of the vehicles they service.

3. Current Rating

The current rating indicates the maximum amount of electrical current the solenoid can handle without overheating. Typically measured in amps, this property is vital for ensuring that the solenoid can engage the starter motor efficiently. Buyers should prioritize solenoids with appropriate current ratings to prevent premature failure and maintain system integrity.

4. Resistance Measurement

Testing the resistance of the solenoid is crucial for diagnosing potential issues. A high resistance reading can indicate internal failure or a poor connection, while a low reading may suggest short-circuiting. Understanding acceptable resistance values enables B2B buyers to identify malfunctioning components quickly, reducing repair times and costs.

5. Terminal Configuration

Starter solenoids come with different terminal configurations, including the number and arrangement of terminals. This property is essential for ensuring compatibility with specific vehicles. Buyers should verify the terminal configuration against their vehicle specifications to avoid installation errors.

6. Temperature Range

The operational temperature range indicates the conditions under which the solenoid can function effectively. Extreme temperatures can affect performance and durability. B2B buyers should consider solenoids that can withstand the environmental conditions typical of their operational regions, especially in areas with extreme heat or cold.

What Are Common Trade Terms Used in the Starter Solenoid Industry?

Familiarity with industry jargon is essential for effective communication and procurement in the B2B marketplace. Here are some common terms related to starter solenoids:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the same manufacturer that produced the original component for a vehicle. B2B buyers often prefer OEM parts for their guaranteed compatibility and quality, ensuring that replacements function as intended without additional modifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers manage inventory levels and cost-effectiveness when procuring starter solenoids, as larger orders may reduce per-unit costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers use RFQs to compare offers and negotiate favorable terms, ensuring they receive competitive pricing for starter solenoids and related components.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers engaged in international procurement of starter solenoids, as they dictate cost responsibilities and risk management.

Illustrative image related to how do you test a starter solenoid

5. Lead Time

Lead time refers to the time between placing an order and receiving the product. Understanding lead times is essential for inventory management and ensuring that replacement solenoids are available when needed, particularly in markets with high demand.

6. Warranty Period

The warranty period is the duration for which a product is guaranteed against defects. A longer warranty period often indicates higher quality and reliability, making it an important consideration for B2B buyers when selecting starter solenoids.

Navigating Market Dynamics and Sourcing Trends in the how do you test a starter solenoid Sector

What Are the Global Drivers Influencing the Testing of Starter Solenoids?

The market for automotive components, particularly starter solenoids, is significantly influenced by a combination of global trends and regional dynamics. One of the primary drivers is the growing demand for reliable automotive parts due to the increasing complexity of vehicle electronics. As vehicles become more technologically advanced, the need for precise diagnostics and testing solutions has become paramount. Emerging markets in Africa and South America are witnessing a surge in vehicle ownership, driving demand for both new and replacement parts. In Europe, especially in countries like Germany, there is a strong emphasis on innovation, leading to the adoption of advanced testing technologies that enhance the reliability of starter solenoids.

Moreover, the trend towards e-commerce in the automotive sector has transformed sourcing strategies. B2B buyers are increasingly turning to online platforms to procure starter solenoids and testing equipment, enabling them to compare products and prices easily. Additionally, the rise of mobile diagnostics tools allows automotive technicians to test starter solenoids efficiently, making on-site repairs more feasible. This tech-savvy approach is gaining traction in the Middle East and Europe, where there is a push for rapid service delivery.

How Are Sustainability and Ethical Sourcing Impacting the Starter Solenoid Sector?

Sustainability is becoming a critical consideration in the sourcing of automotive components, including starter solenoids. The environmental impact of manufacturing processes, particularly in regions with lax regulations, has prompted B2B buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of recyclable materials and energy-efficient manufacturing techniques. Ethical sourcing is also gaining momentum, with companies increasingly demanding transparency in their supply chains. Buyers are looking for partners who adhere to fair labor practices and contribute positively to their local communities.

The certification of ‘green’ materials is becoming a significant factor in purchasing decisions. Buyers are now inclined to work with suppliers who have recognized certifications such as ISO 14001, which focuses on effective environmental management systems. These certifications not only demonstrate a commitment to sustainability but can also enhance a company’s reputation in the market, making them more attractive to environmentally conscious consumers. As the automotive industry continues to evolve, integrating sustainability into the sourcing of starter solenoids will likely become a key differentiator for B2B buyers.

What Is the Evolution of Testing Technologies for Starter Solenoids?

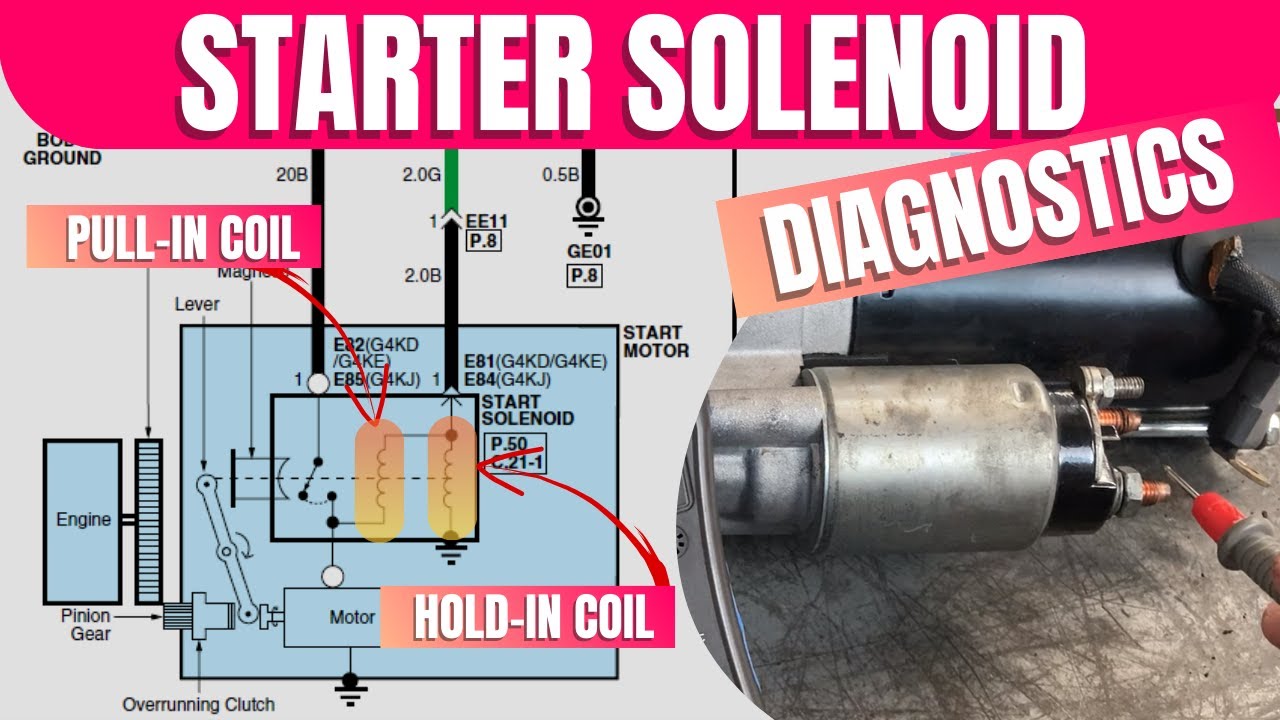

The testing of starter solenoids has evolved significantly over the past few decades. Initially, the process was largely manual and relied on basic tools to check functionality. Technicians would often perform rudimentary tests to assess whether the solenoid was engaging properly, which involved listening for clicks or checking connections visually. As automotive technology advanced, the introduction of electronic testing equipment provided a more accurate and efficient means of diagnosing issues.

In recent years, the rise of digital multimeters and diagnostic scanners has transformed the landscape. These tools allow for precise measurements of voltage, current, and resistance, enabling technicians to pinpoint issues with starter solenoids quickly. Additionally, software integration in diagnostic tools has streamlined the testing process, making it easier for technicians to interpret results and make informed decisions.

The evolution of testing technologies reflects broader trends in the automotive industry, where precision and efficiency are increasingly prioritized. This evolution not only enhances the reliability of starter solenoids but also contributes to improved customer satisfaction and reduced operational costs for B2B buyers across various global markets. As testing technologies continue to advance, buyers can expect even greater efficiencies and accuracy in the maintenance and repair of automotive components.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you test a starter solenoid

-

How do I determine if a starter solenoid is faulty?

To determine if a starter solenoid is faulty, start by listening for a clicking sound when the ignition key is turned. If you hear clicking but the engine doesn’t start, the solenoid may be transferring electricity insufficiently. Use a test light to check for power at the solenoid terminals; if there’s power but the starter doesn’t engage, the solenoid is likely the issue. Additionally, testing the battery voltage before troubleshooting the solenoid is crucial, as a weak battery can mimic solenoid failure. -

What tools do I need to test a starter solenoid?

To test a starter solenoid, you will need a few basic tools: a voltmeter or multimeter to measure voltage, a test light to check for electrical continuity, and possibly a wrench or socket set to access the solenoid terminals. It’s also helpful to have safety gloves and goggles to protect yourself during the testing process. Ensuring you have the right tools will streamline the testing process and help you accurately diagnose any issues. -

What are the common signs of a failing starter solenoid?

Common signs of a failing starter solenoid include a clicking noise when the ignition is turned, intermittent starting issues, or no response at all when trying to start the vehicle. Additionally, if the dashboard lights dim significantly when the ignition is turned, it may indicate a problem with the solenoid or the electrical system. Being aware of these symptoms can save time and help in making informed decisions when sourcing replacement parts. -

How can I ensure I am sourcing quality starter solenoids from suppliers?

To ensure quality when sourcing starter solenoids, conduct thorough supplier vetting. Look for manufacturers with ISO certifications and positive reviews from previous clients. Request samples to evaluate the quality firsthand. Also, inquire about their quality assurance processes and return policies. Establishing communication and transparency with suppliers can help build trust and ensure you receive reliable products. -

What is the minimum order quantity (MOQ) for starter solenoids?

Minimum order quantities for starter solenoids can vary significantly between suppliers. Some manufacturers may offer low MOQs of 50-100 units, while others may require larger orders, especially for customized products. It’s essential to discuss your needs upfront and negotiate terms that align with your business model. Understanding MOQs will help you manage inventory costs and ensure you have sufficient stock to meet demand. -

What payment terms should I expect when purchasing starter solenoids internationally?

Payment terms for international purchases of starter solenoids typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers prefer a deposit upfront, followed by the balance upon shipment or delivery. Be sure to clarify payment methods accepted by the supplier and consider currency exchange rates. Understanding these terms can prevent misunderstandings and facilitate smoother transactions. -

How can I customize starter solenoids for my specific needs?

To customize starter solenoids, communicate your specific requirements to the supplier, including voltage specifications, size constraints, and any unique design features. Many manufacturers offer customization options, but it is crucial to provide detailed specifications and potentially prototypes. Discuss lead times and costs associated with custom orders to ensure they fit within your project timelines and budget. -

What logistics considerations should I keep in mind when importing starter solenoids?

When importing starter solenoids, consider logistics factors such as shipping methods, customs regulations, and duties. Choose a reliable freight forwarder familiar with automotive parts to navigate potential complexities. Ensure that all documentation, such as invoices and packing lists, is accurate and complete to avoid delays at customs. Planning for lead times and potential tariffs will help you maintain efficient inventory management and minimize costs.

Top 2 How Do You Test A Starter Solenoid Manufacturers & Suppliers List

1. LinkedIn – Starter Solenoid

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: A starter solenoid is an electromagnetic switch that engages the starter motor when the ignition key is turned to the ‘start’ position. Its primary function is to control the high current needed to operate the starter motor safely, ensuring it engages and disengages cleanly to reduce wear and tear. Symptoms of a bad starter solenoid include clicking noises when trying to start, failure to crank, d…

2. WikiHow – Starter Solenoid

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: The starter solenoid is a mechanism that transmits electrical current from the battery to the starter, engaging when the key is turned to start the engine. It is typically cylindrical in shape with a smaller cylinder attached, located near the engine and transmission. The solenoid has two terminals, one connected to the battery. A clicking sound when the key is turned indicates engagement, while n…

Strategic Sourcing Conclusion and Outlook for how do you test a starter solenoid

In conclusion, effectively testing a starter solenoid is crucial for ensuring optimal vehicle performance and minimizing downtime. By systematically checking for electrical current and resistance, B2B buyers can accurately diagnose issues, whether they stem from the solenoid itself, the battery, or the starter motor. This knowledge not only aids in making informed purchasing decisions for replacement parts but also enhances overall operational efficiency.

Strategic sourcing of high-quality automotive components is essential for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe. By prioritizing reliable suppliers who offer comprehensive product information and support, international buyers can secure the best value and maintain their fleet’s performance.

As the automotive industry continues to evolve, embracing advanced diagnostic technologies and fostering strong supplier relationships will be key to staying competitive. We encourage B2B buyers to leverage the insights gained from this guide to enhance their sourcing strategies and ensure their operations remain robust and efficient. Explore your options today and invest in the quality components that will drive your success in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.