Introduction: Navigating the Global Market for what type of alternator do i need

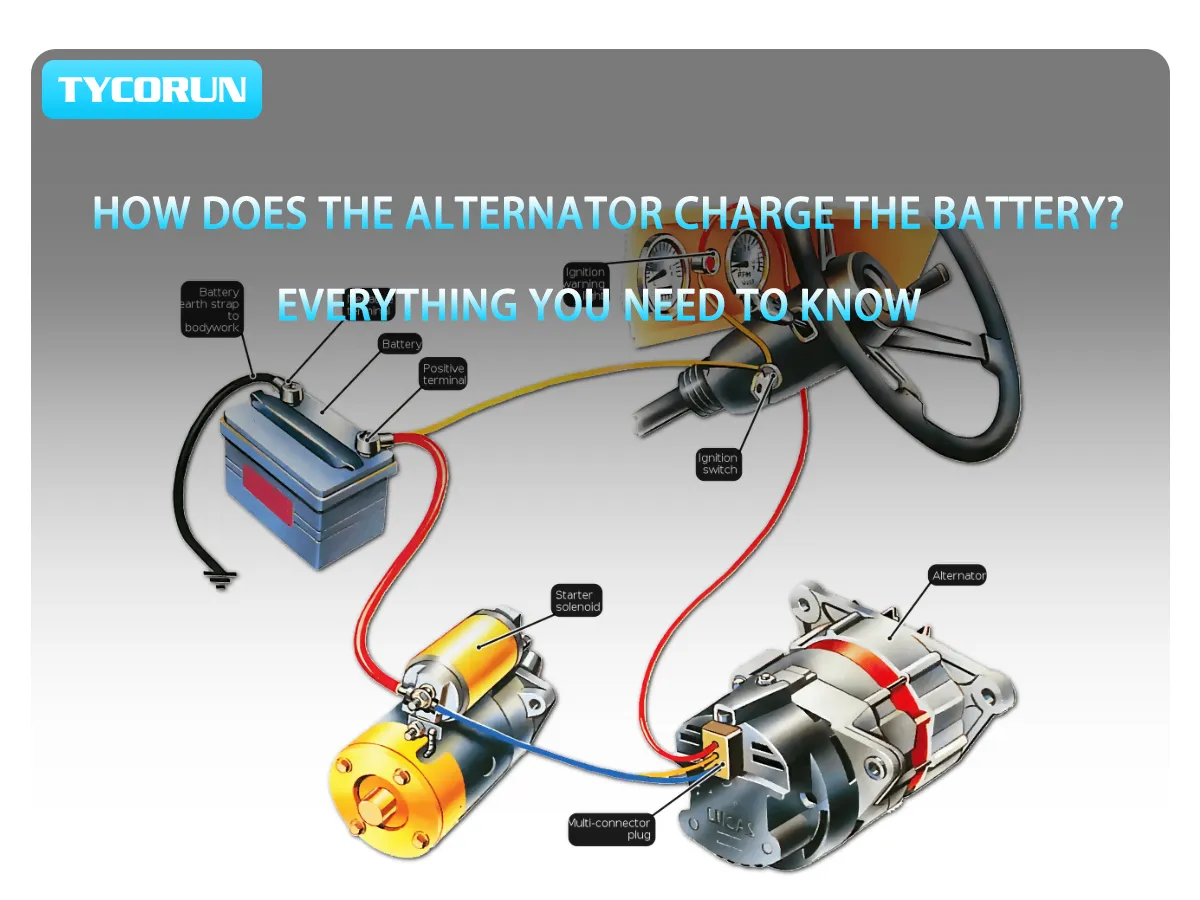

Navigating the global market for the right type of alternator can be a daunting challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Understanding the specifics of alternators—whether for automotive applications, industrial machinery, or renewable energy systems—is crucial for making informed purchasing decisions. This comprehensive guide delves into the various types of alternators available, their applications, and the essential factors to consider when sourcing these critical components.

With the ever-evolving demands of modern electrical systems, selecting the appropriate alternator is not just about matching specifications; it’s about ensuring reliability and efficiency in your operations. The guide outlines how to assess your electrical load, the importance of amperage, and the necessity of proper wiring and installation. Additionally, we provide insights on supplier vetting and pricing strategies tailored to the unique market dynamics of countries like Brazil and Nigeria.

By leveraging this guide, international B2B buyers will gain the knowledge needed to navigate the complexities of alternator procurement confidently. Armed with actionable insights and practical tips, you can streamline your sourcing process, mitigate risks, and ultimately enhance the performance of your electrical systems. Whether you are upgrading existing equipment or starting a new project, understanding what type of alternator you need is vital for sustaining your business operations.

Table Of Contents

- Top 2 What Type Of Alternator Do I Need Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what type of alternator do i need

- Understanding what type of alternator do i need Types and Variations

- Key Industrial Applications of what type of alternator do i need

- 3 Common User Pain Points for ‘what type of alternator do i need’ & Their Solutions

- Strategic Material Selection Guide for what type of alternator do i need

- In-depth Look: Manufacturing Processes and Quality Assurance for what type of alternator do i need

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what type of alternator do i need’

- Comprehensive Cost and Pricing Analysis for what type of alternator do i need Sourcing

- Alternatives Analysis: Comparing what type of alternator do i need With Other Solutions

- Essential Technical Properties and Trade Terminology for what type of alternator do i need

- Navigating Market Dynamics and Sourcing Trends in the what type of alternator do i need Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what type of alternator do i need

- Strategic Sourcing Conclusion and Outlook for what type of alternator do i need

- Important Disclaimer & Terms of Use

Understanding what type of alternator do i need Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternators | Typically rated between 65-100 amps, basic design | Automotive, light-duty trucks | Pros: Cost-effective, reliable for standard applications. Cons: Limited capacity for high-demand electrical systems. |

| High-Output Alternators | Higher amperage (100+ amps), designed for heavy loads | Performance vehicles, commercial vehicles | Pros: Supports high electrical loads, enhances performance. Cons: Higher cost, may require upgrades to wiring. |

| One-Wire Alternators | Simplified installation with a single wire connection | Classic cars, custom builds | Pros: Easy installation, less wiring complexity. Cons: Limited adjustability, may not suit all applications. |

| Marine Alternators | Corrosion-resistant, designed for marine environments | Boats, yachts, offshore equipment | Pros: Built for harsh conditions, reliable in wet environments. Cons: Higher price point, specialized application. |

| Diesel Alternators | Built for durability, higher output for diesel engines | Heavy machinery, commercial trucks | Pros: Robust construction, high efficiency for diesel applications. Cons: Bulkier size, more expensive than standard options. |

What are the Key Characteristics of Standard Alternators?

Standard alternators are typically rated between 65 to 100 amps and are commonly used in everyday vehicles. Their design efficiently powers basic electrical components such as headlights, gauges, and fuel pumps. For B2B buyers, these alternators are ideal for automotive applications where the electrical load is relatively low. However, they may not suffice for vehicles equipped with high-demand accessories, leading to potential electrical failures.

How Do High-Output Alternators Enhance Performance?

High-output alternators are specifically designed to meet the demands of vehicles with extensive electrical systems, such as those used in performance applications or commercial vehicles. With amperage ratings exceeding 100 amps, they provide a reliable power supply for advanced audio systems, lighting, and additional electronic components. B2B buyers should consider the specific electrical demands of their applications, as investing in a high-output alternator can prevent system failures and improve overall vehicle performance.

What Makes One-Wire Alternators Unique?

One-wire alternators simplify the installation process by requiring only a single wire connection to the battery. This design is particularly beneficial for classic cars and custom builds where space and wiring complexity are concerns. For B2B buyers, the ease of installation can translate into reduced labor costs. However, these alternators may lack the adjustability and features of more complex systems, making them less versatile for varied applications.

Why Choose Marine Alternators for Marine Applications?

Marine alternators are engineered to withstand harsh marine environments, featuring corrosion-resistant materials and designs. They are essential for powering boats and yachts, ensuring reliable performance in wet conditions. B2B buyers in the marine industry must consider these specialized alternators to maintain operational reliability. While they provide excellent durability, marine alternators often come at a higher price point due to their specialized construction.

What are the Advantages of Diesel Alternators?

Diesel alternators are built to handle the rigorous demands of diesel engines, providing higher output and durability. They are commonly used in heavy machinery and commercial trucks, where reliability and efficiency are paramount. For B2B buyers, selecting a diesel alternator means investing in longevity and performance under demanding conditions. However, their bulkier size and higher cost compared to standard options may require careful consideration of application needs.

Key Industrial Applications of what type of alternator do i need

| Industry/Sector | Specific Application of what type of alternator do i need | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy machinery powering | Ensures reliable operation of equipment, reducing downtime | Compatibility with existing machinery, power output needs |

| Agriculture | Irrigation systems and equipment | Supports efficient water management, critical for crop yield | Durability in harsh conditions, voltage stability |

| Telecommunications | Backup power for cell towers and communication systems | Provides uninterrupted service, essential for connectivity | Size, weight, and efficiency to fit space constraints |

| Automotive | Upgrading vehicle electrical systems | Enhances performance of high-demand accessories | Amperage requirements, compatibility with vehicle models |

| Mining | Power supply for drilling and extraction equipment | Increases operational efficiency and safety | Robustness, high output capacity, and environmental resistance |

How is ‘what type of alternator do I need’ utilized in the construction industry?

In the construction sector, heavy machinery such as excavators, bulldozers, and cranes often require robust electrical systems to function effectively. A high-output alternator ensures that these machines can operate their hydraulic systems and other electrical components without interruption. For international buyers, particularly in developing regions, sourcing alternators that can withstand rugged environments and provide reliable power is crucial to minimize downtime and enhance productivity.

What role does ‘what type of alternator do I need’ play in agricultural applications?

Agricultural operations, especially in regions like Africa and South America, depend heavily on efficient irrigation systems. Alternators are vital in powering pumps that deliver water to crops. Selecting the right type of alternator can significantly impact water management efficiency, directly influencing crop yields. Buyers must consider factors such as the alternator’s durability against harsh weather conditions and its capacity to deliver stable voltage under varying loads.

How does ‘what type of alternator do I need’ support telecommunications?

In the telecommunications industry, particularly in remote areas, cell towers require reliable backup power systems to maintain connectivity. An appropriate alternator ensures that communication systems remain operational during power outages. For B2B buyers, sourcing alternators that are compact yet powerful enough to support critical infrastructure while being energy-efficient is essential to optimize operational costs.

Why is ‘what type of alternator do I need’ important for automotive upgrades?

Automotive applications often necessitate alternator upgrades, especially for vehicles with high-demand electrical systems, such as those equipped with advanced audio systems or additional lighting. Upgrading to a higher amp alternator can enhance performance and longevity of these systems. Buyers should focus on compatibility with specific vehicle models and the total electrical load to ensure optimal performance, particularly in regions where vehicle modifications are common.

What significance does ‘what type of alternator do I need’ have in the mining sector?

In mining operations, heavy equipment such as drills and excavators rely on powerful alternators to operate effectively in challenging conditions. A high-capacity alternator can enhance the efficiency of these machines, ensuring they meet the demands of extraction processes. For international buyers, especially in remote mining locations, sourcing robust alternators that can withstand extreme environments while providing high output is vital for operational success and safety.

3 Common User Pain Points for ‘what type of alternator do i need’ & Their Solutions

Scenario 1: Insufficient Power for High-Demand Applications

The Problem: B2B buyers often face challenges when their existing alternators cannot support the electrical demands of upgraded or specialized equipment. For instance, businesses in sectors such as construction or entertainment may require high-capacity alternators to power heavy machinery, lighting systems, or audio equipment. When these systems exceed the output of a standard alternator, it can lead to significant operational disruptions, including equipment failure or downtime. Buyers may struggle to determine the correct specifications, leading to costly mistakes in their purchasing decisions.

The Solution: To effectively determine the type of alternator needed, begin with a thorough assessment of the total electrical load. This involves calculating the amperage drawn by all connected devices, including machinery, lighting, and auxiliary systems. A reliable method is to use an ammeter to measure the actual draw when all systems are operational. Once the total amperage is established, opt for an alternator that provides at least 50% more amperage than your calculated need to accommodate any future upgrades and ensure smooth operation. Additionally, prioritize sourcing from reputable manufacturers who can provide detailed specifications and support for high-demand applications.

Scenario 2: Compatibility Issues with Existing Equipment

The Problem: Many international B2B buyers encounter compatibility issues when trying to replace or upgrade alternators. Different regions may have varying standards for vehicle electrical systems, and mismatched specifications can lead to installation challenges. This is particularly problematic for businesses in Africa or South America where local vehicles may have unique requirements. Buyers often end up with alternators that either do not fit or fail to integrate properly with their existing systems, resulting in wasted investment and frustration.

The Solution: To mitigate compatibility concerns, it’s essential to conduct comprehensive research before making a purchase. Buyers should identify the specific make, model, and year of the vehicle or machinery requiring the alternator. Utilize manufacturer guidelines and cross-reference with databases that detail alternator specifications for various applications. When sourcing alternators, seek suppliers who offer customization options or who can provide detailed compatibility charts. This proactive approach ensures that the chosen alternator will fit and function correctly, minimizing the risk of installation issues.

Scenario 3: Inadequate Knowledge of Alternator Specifications

The Problem: A significant pain point for B2B buyers is a lack of understanding regarding alternator specifications, such as voltage output, amperage ratings, and physical dimensions. Buyers may feel overwhelmed by the technical jargon and find it difficult to make informed decisions that align with their operational needs. This lack of knowledge can lead to purchasing alternators that do not meet their requirements, resulting in performance issues and increased costs.

The Solution: To empower buyers with the knowledge they need, it’s crucial to develop a clear understanding of key alternator specifications. Start by familiarizing yourself with basic electrical concepts, such as how voltage and amperage correlate with power needs. Utilize online resources, such as manufacturer websites and educational platforms, to gain insights into how to assess the electrical demands of your equipment accurately. Additionally, consider engaging with technical experts or consultants who can provide tailored advice and guidance based on your specific application. This investment in knowledge will enable buyers to make more informed decisions, ensuring they select the right alternator for their needs while optimizing their operational efficiency.

Strategic Material Selection Guide for what type of alternator do i need

What Materials Should You Consider for Your Alternator Selection?

When selecting an alternator, the materials used in its construction significantly influence performance, durability, and compatibility with various applications. Below, we analyze four common materials used in alternator manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It typically withstands temperatures up to 150°C and offers a pressure rating suitable for automotive applications.

Pros & Cons:

Aluminum’s lightweight nature improves fuel efficiency and reduces overall vehicle weight. It is also relatively inexpensive and easy to manufacture. However, it may not provide the same strength as steel, which can be a concern in high-stress environments.

Impact on Application:

Aluminum is suitable for standard automotive alternators, particularly in regions with high humidity or corrosive environments, as it resists oxidation.

Considerations for International Buyers:

Aluminum is widely accepted globally, but buyers should ensure compliance with local standards such as ASTM and EN. In regions like Africa and South America, where humidity can be high, aluminum’s corrosion resistance is a significant advantage.

Illustrative image related to what type of alternator do i need

2. Copper

Key Properties:

Copper has excellent electrical conductivity, thermal conductivity, and corrosion resistance. It can operate effectively at high temperatures, often exceeding 200°C.

Pros & Cons:

Copper’s superior conductivity makes it ideal for windings within alternators, enhancing efficiency. However, its higher cost compared to aluminum and susceptibility to oxidation can be drawbacks. Additionally, copper is heavier, which may affect vehicle weight.

Impact on Application:

Copper is often used in high-performance alternators where maximum electrical efficiency is critical, such as in racing or heavy-duty applications.

Illustrative image related to what type of alternator do i need

Considerations for International Buyers:

Copper is subject to various regulations regarding mining and processing, particularly in Europe. Buyers should verify compliance with local environmental standards and consider the supply chain implications of sourcing copper.

3. Steel

Key Properties:

Steel is known for its strength and durability, with a high tensile strength rating. It can withstand high temperatures (up to 300°C) and is often treated for corrosion resistance.

Pros & Cons:

Steel’s robustness makes it suitable for heavy-duty applications, ensuring longevity under stress. However, it is heavier and can lead to increased vehicle weight, potentially impacting fuel efficiency. Additionally, manufacturing processes for steel can be more complex and costly.

Impact on Application:

Steel is commonly used in alternator housings and brackets, particularly in commercial vehicles and heavy machinery where durability is paramount.

Considerations for International Buyers:

Steel standards vary by region, with ASTM and DIN being common in Europe and the U.S. Buyers in developing regions should consider local availability and the cost implications of importing steel components.

4. Composite Materials

Key Properties:

Composite materials often combine various fibers (like carbon or glass) with resins, providing a lightweight yet strong option. They can withstand a range of temperatures and offer excellent corrosion resistance.

Illustrative image related to what type of alternator do i need

Pros & Cons:

Composites are lighter than metals, improving fuel efficiency and performance. They can also be molded into complex shapes, reducing manufacturing complexity. However, they can be more expensive and may not be as widely available as traditional materials.

Impact on Application:

Composites are increasingly used in specialized alternators, particularly in electric vehicles and applications where weight savings are critical.

Considerations for International Buyers:

While composites are gaining acceptance, buyers should ensure that local regulations regarding material use and recycling are met. In regions like the Middle East, where high temperatures are common, the thermal properties of composites should be evaluated.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for what type of alternator do i need | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Standard automotive alternators | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Copper | High-performance or racing alternators | Excellent electrical conductivity | Higher cost and heavier weight | High |

| Steel | Heavy-duty commercial vehicle alternators | High strength and durability | Increased weight and manufacturing cost | Medium |

| Composite Materials | Specialized or electric vehicle alternators | Lightweight and complex shapes | Higher cost and availability issues | High |

Selecting the right material for your alternator involves understanding the specific requirements of your application, including performance, environmental conditions, and compliance with local regulations. By considering these factors, international B2B buyers can make informed decisions that enhance the efficiency and durability of their electrical systems.

In-depth Look: Manufacturing Processes and Quality Assurance for what type of alternator do i need

What Are the Main Stages of Manufacturing Alternators?

The manufacturing process for alternators involves several critical stages, each requiring precision and adherence to quality standards. Understanding these stages can help B2B buyers ensure they are selecting the right supplier for their needs.

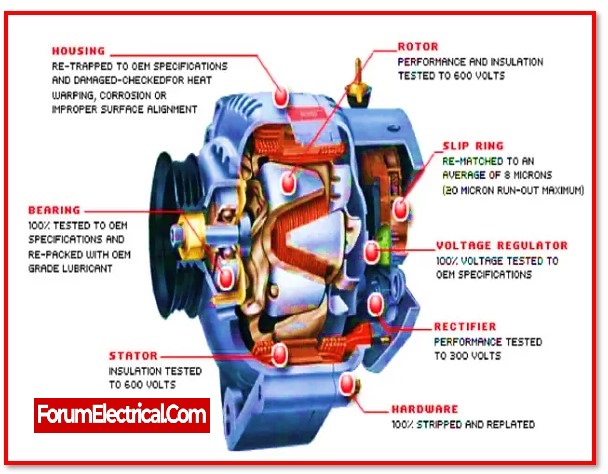

Material Preparation: What Materials Are Used in Alternator Production?

The manufacturing of alternators begins with the selection and preparation of raw materials, primarily metals like aluminum and copper. Aluminum is often used for the housing due to its lightweight and corrosion-resistant properties, while copper is favored for windings due to its excellent electrical conductivity. High-quality steel is also essential for components like the rotor and stator.

During this stage, materials are subjected to processes such as cutting, machining, and surface treatment to meet specific design requirements. Suppliers must ensure that the materials comply with international standards, such as ASTM or ISO specifications, to guarantee performance and longevity.

Forming: How Are Alternator Components Shaped?

The forming stage involves shaping the prepared materials into the necessary components of the alternator. Techniques such as die casting, stamping, and forging are commonly used. For instance, die casting is often employed to create the alternator’s housing, while stamping is used for the rotor and stator laminations.

Illustrative image related to what type of alternator do i need

Precision in this stage is critical, as any deviations can lead to inefficiencies or failures in the alternator’s performance. Advanced manufacturing technologies, such as CNC machining, help achieve the required tolerances and surface finishes.

Assembly: What Are the Key Steps in Alternator Assembly?

Once the components are formed, they move to the assembly stage. This process typically involves:

- Winding the Coils: Copper wire is wound around the stator to create the necessary electromagnetic field.

- Rotor Assembly: The rotor is assembled with bearings and installed in the housing.

- Integration of Components: Various parts, such as voltage regulators and rectifiers, are integrated into the assembly.

The assembly process must be meticulously controlled to prevent misalignments or improper connections. Automated assembly lines are increasingly common, ensuring consistent quality and efficiency.

Finishing: What Surface Treatments Are Applied?

Finishing is the final stage of the manufacturing process, where alternators undergo surface treatments to enhance durability and performance. Common techniques include:

- Anodizing: This is often applied to aluminum components to improve corrosion resistance.

- Powder Coating: A protective layer is applied to the alternator housing to prevent wear and enhance aesthetics.

- Final Inspection: Before packaging, each alternator is thoroughly inspected for any defects or irregularities.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a crucial aspect of alternator manufacturing, ensuring that the products meet specific performance and safety standards. B2B buyers should be aware of both international and industry-specific quality standards.

What Are the Relevant International Standards for Alternator Manufacturing?

ISO 9001 is one of the most widely recognized quality management standards applicable to alternator manufacturing. It emphasizes a process-oriented approach to managing quality, ensuring that manufacturers consistently meet customer requirements and enhance satisfaction.

Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the intended use of the alternator. These certifications indicate compliance with safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process, with specific checkpoints established to ensure product integrity:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before being accepted for production.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various tests and inspections are conducted to monitor quality and performance.

- Final Quality Control (FQC): Once the alternator is fully assembled, a final inspection is performed to ensure that all components meet the required standards and specifications.

What Common Testing Methods Are Used to Ensure Quality?

Several testing methods are employed to validate the performance and durability of alternators:

- Electrical Testing: This includes measuring output voltage, current, and efficiency under various load conditions.

- Mechanical Testing: Tests are conducted to assess the structural integrity of components, such as stress and vibration tests.

- Environmental Testing: Alternators may be subjected to extreme temperature and humidity conditions to ensure reliable operation in diverse environments.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of potential suppliers is essential. Here are some strategies:

What Are Effective Methods for Auditing Suppliers?

Conducting regular audits is a proactive approach to ensuring that suppliers adhere to quality standards. Buyers can perform on-site audits to assess manufacturing practices, quality control systems, and compliance with international standards.

How Can Buyers Utilize Reports and Certifications?

Buyers should request comprehensive quality assurance reports and certifications from suppliers. These documents should detail the QC processes in place, including any third-party inspections that have been conducted. Look for suppliers who are transparent about their quality assurance practices and willing to share relevant documentation.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, and the Middle East, should be aware of specific nuances in quality certification. Different regions may have varying regulatory requirements, so it’s crucial to ensure that the supplier’s certifications are recognized in the buyer’s country. Additionally, understanding local market conditions and potential barriers can aid in selecting the right supplier.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Processes Essential for B2B Buyers?

A thorough understanding of the manufacturing processes and quality assurance measures in alternator production allows B2B buyers to make informed decisions. By focusing on the key stages of manufacturing and the relevant quality standards, buyers can ensure they select suppliers who deliver reliable, high-quality alternators tailored to their operational needs. This not only enhances product performance but also strengthens the overall supply chain, fostering long-term business relationships.

Illustrative image related to what type of alternator do i need

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what type of alternator do i need’

To assist B2B buyers in procuring the right alternator for their needs, this practical sourcing guide outlines a series of essential steps. These steps will ensure you make an informed decision that aligns with your technical requirements and operational expectations.

Step 1: Define Your Technical Specifications

Understanding your specific electrical requirements is crucial. Assess the total electrical load of your system by identifying all components that will draw power from the alternator. This includes lighting, audio systems, and any additional electronic accessories. Knowing the amperage needs will help you select an alternator that meets or exceeds these demands.

Step 2: Determine Amperage Needs

Once you have a clear picture of your electrical load, calculate the required amperage output. Generally, your alternator’s output should be at least 50% greater than your total amperage draw to ensure reliability. For example, if your system requires 100 amps, opt for an alternator rated for at least 150 amps to accommodate fluctuations and prevent overloading.

Step 3: Evaluate Supplier Certifications

Before engaging with a supplier, verify their certifications and industry standards compliance. Look for ISO certifications or specific automotive industry standards that ensure quality and reliability. This step is vital to mitigate risks associated with subpar products that could lead to operational failures or safety hazards.

Step 4: Research Manufacturer Reputation

Investigate the reputation of potential manufacturers. Seek out reviews, testimonials, and case studies from other businesses in your region or industry. A manufacturer with a solid track record of delivering quality products and customer support is more likely to meet your expectations and provide after-sales service.

Illustrative image related to what type of alternator do i need

Step 5: Compare Pricing and Warranty Options

Obtain quotes from multiple suppliers to compare pricing. However, do not base your decision solely on cost. Assess the warranty options provided, as a longer warranty period can be indicative of a manufacturer’s confidence in their product quality. Ensure you understand what the warranty covers and the process for claiming it.

Step 6: Examine Technical Support and Service

Evaluate the level of technical support offered by the supplier. Reliable suppliers should provide comprehensive technical assistance, including installation guidance and troubleshooting. Good support can save time and money, particularly if you encounter issues during installation or operation.

Step 7: Assess Delivery and Logistics

Finally, consider the supplier’s delivery capabilities, especially if you are sourcing from an international supplier. Check lead times, shipping options, and the supplier’s ability to handle customs for your region. Timely delivery can impact your operations, so ensure that logistics align with your project timelines.

By following these steps, B2B buyers can navigate the complexities of selecting the right alternator, ensuring a reliable and efficient electrical system for their applications.

Comprehensive Cost and Pricing Analysis for what type of alternator do i need Sourcing

What Are the Key Cost Components for Sourcing Alternators?

When sourcing alternators, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The quality and type of materials used in alternators significantly impact costs. High-quality copper for windings, durable housing, and robust bearings are essential for performance and longevity. Sourcing these materials from reliable suppliers can also affect the final cost.

-

Labor: Labor costs vary by region and can be influenced by the complexity of the alternator design. Skilled labor is often required for assembly, particularly for high-performance or customized units. In regions with lower labor costs, such as parts of Africa and South America, buyers may find more competitive pricing.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient manufacturing processes can reduce overhead, thereby lowering the final product price.

-

Tooling: Initial tooling costs for custom alternator designs can be significant. Buyers should consider these costs when evaluating quotes, especially if they require specific customizations or adaptations for their vehicle models.

-

Quality Control (QC): Investing in rigorous QC processes ensures product reliability and compliance with international standards. While this adds to the cost, it can save buyers from potential failures and warranty claims.

-

Logistics: Transportation costs can vary widely depending on the shipping method and distance. Incoterms will also play a crucial role in determining who bears these costs. Buyers should account for logistics when calculating the total cost of ownership.

-

Margin: Suppliers will include a margin to cover their costs and profit. Understanding typical margins in the industry can help buyers negotiate better deals.

What Influences Pricing for Alternators?

Several factors influence the pricing of alternators, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically lead to discounts. Buyers should assess their needs and negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom alternators with specific performance characteristics or features will generally be more expensive. Buyers should clarify their requirements upfront to receive accurate quotes.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or CE) can increase costs but also enhance product reliability. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may command higher prices due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the implications of Incoterms is vital. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact the overall cost.

What Buyer Tips Can Enhance Cost Efficiency in Alternator Sourcing?

To achieve cost efficiency when sourcing alternators, B2B buyers should consider the following strategies:

-

Negotiate Wisely: Always engage in negotiations with suppliers. Understanding the cost components and being clear about your requirements can lead to better pricing arrangements.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like installation, maintenance, and potential downtime. A slightly more expensive alternator with better longevity could offer significant savings in the long run.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa and South America should be aware of local economic conditions, currency fluctuations, and import tariffs. These factors can significantly impact the final price.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide a clearer picture of the market. This practice not only helps in identifying competitive pricing but also assists in understanding different suppliers’ value propositions.

-

Stay Informed About Market Trends: Being aware of trends in the alternator market, such as advancements in technology or shifts in material costs, can help buyers make informed sourcing decisions.

Disclaimer on Indicative Prices

Prices for alternators can vary widely based on the factors discussed above. Therefore, it is essential for buyers to conduct thorough research and obtain multiple quotes tailored to their specific needs before making purchasing decisions.

Alternatives Analysis: Comparing what type of alternator do i need With Other Solutions

Exploring Alternatives to “What Type of Alternator Do I Need?”

When considering power solutions for vehicles or machinery, understanding the different types of alternators and their alternatives is crucial for international B2B buyers. The right choice can significantly impact operational efficiency, cost-effectiveness, and maintenance needs. Below, we present a comparison of traditional alternators with two viable alternatives: DC Generators and Battery Management Systems (BMS).

Comparison Table

| Comparison Aspect | What Type Of Alternator Do I Need | DC Generators | Battery Management Systems (BMS) |

|---|---|---|---|

| Performance | High output, reliable for various loads | Variable output, depends on RPM | Efficient energy management, prolongs battery life |

| Cost | Moderate initial investment | Higher upfront cost | Lower initial cost, but ongoing monitoring expenses |

| Ease of Implementation | Straightforward installation | Requires more complex setup | Easy to integrate with existing systems |

| Maintenance | Regular checks needed | Requires periodic servicing | Minimal maintenance, software updates necessary |

| Best Use Case | Vehicles with high electrical demands | Heavy machinery, remote locations | Electric vehicles, renewable energy systems |

Detailed Breakdown of Alternatives

1. DC Generators:

DC generators convert mechanical energy into direct current electricity, making them an alternative to traditional alternators. They are particularly useful in applications where variable output is acceptable, such as in heavy machinery or remote power systems. The primary advantages of DC generators are their ability to operate efficiently at low speeds and their robustness in harsh environments. However, their complexity in installation and higher initial costs can be significant drawbacks, particularly for B2B buyers looking for straightforward solutions.

2. Battery Management Systems (BMS):

Battery Management Systems offer a modern approach to managing energy in electric vehicles and renewable energy systems. They ensure optimal battery performance by monitoring charge levels, temperature, and health, thus prolonging battery life and enhancing efficiency. The cost of BMS can be lower compared to traditional alternators, especially when considering the long-term savings on battery replacement and maintenance. However, BMS requires software updates and monitoring, which may add to operational costs. This solution is ideal for businesses focused on sustainability and energy efficiency, particularly in the electric vehicle sector.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate power solution hinges on understanding your specific operational requirements and constraints. For B2B buyers in industries requiring high electrical demand, traditional alternators remain a reliable choice. Conversely, if you’re operating heavy machinery or looking to implement renewable energy solutions, DC generators may provide the necessary power without the limitations of alternators. Finally, for companies prioritizing efficiency in electric vehicles, integrating a Battery Management System can optimize performance and extend battery life. By carefully assessing the pros and cons of each option, businesses can make informed decisions that align with their operational goals and budgets.

Essential Technical Properties and Trade Terminology for what type of alternator do i need

What Key Technical Specifications Should You Consider When Choosing an Alternator?

When selecting an alternator, understanding its technical specifications is crucial for ensuring compatibility and performance. Here are several essential specs to consider:

-

Amperage Rating

The amperage rating indicates the maximum electrical output the alternator can provide. It is vital to match this output with the total electrical load of your vehicle or machinery. An undersized alternator can lead to system failures or reduced performance, particularly in high-demand applications like audio systems or industrial equipment. -

Voltage Output

Most alternators operate at a nominal voltage of 12V or 24V. Ensuring compatibility with your system voltage is critical to avoid electrical malfunctions. A mismatched voltage can result in overcharging or undercharging batteries, leading to decreased lifespan and efficiency. -

Regulator Type

Alternators come with either internal or external voltage regulators. Internal regulators are more common and easier to install, while external regulators allow for more precise control of voltage output. Understanding the regulator type is essential for installation and performance tuning, particularly in specialized applications. -

Physical Dimensions and Mounting Configuration

The size and mounting style of the alternator must fit within your vehicle or equipment’s specifications. This includes the alternator’s pulley size and belt alignment, which can affect performance. Ensuring proper fitment can prevent installation issues and operational inefficiencies. -

Cooling Mechanism

Alternators can have different cooling methods, such as fan-cooled or liquid-cooled designs. High-output alternators may require more effective cooling to maintain performance and longevity. Selecting an alternator with an appropriate cooling mechanism is crucial for applications that demand high amperage over extended periods. -

Efficiency Rating

The efficiency of an alternator measures how well it converts mechanical energy into electrical energy. Higher efficiency ratings mean less energy loss, translating to better performance and reduced fuel consumption in automotive applications. This can be a significant consideration for businesses looking to maximize operational efficiency.

What Common Trade Terms Should You Know When Purchasing an Alternator?

Familiarizing yourself with industry terminology can streamline the procurement process. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts used in the assembly of vehicles or machinery. Choosing OEM alternators ensures compatibility and reliability, as they are designed to meet specific manufacturer standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for budgeting and inventory management, especially when sourcing alternators for large-scale projects. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the context of alternators, sending an RFQ can help you compare costs and options from various suppliers, ensuring you get the best deal. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify responsibilities between buyers and sellers. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help you understand shipping costs and risk management when importing alternators from overseas. -

Lead Time

Lead time refers to the time it takes for an order to be fulfilled. Knowing the lead time is crucial for planning and ensuring that alternators are available when needed, particularly in just-in-time manufacturing environments. -

Warranty Terms

Warranty terms outline the conditions under which a product is guaranteed. Understanding these terms can help businesses assess the reliability of the alternator and the manufacturer’s support in case of defects or performance issues.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when selecting the right alternator for their needs, ultimately leading to enhanced operational efficiency and reliability.

Illustrative image related to what type of alternator do i need

Navigating Market Dynamics and Sourcing Trends in the what type of alternator do i need Sector

What Are the Global Drivers Influencing the Alternator Market?

The alternator market is experiencing significant growth, driven by increasing demand for electric vehicles (EVs) and the growing emphasis on energy efficiency in automotive applications. With countries in Africa, South America, the Middle East, and Europe pushing for greener technologies, international B2B buyers are increasingly seeking alternators that can support higher electrical loads while maintaining efficiency. This shift is further accelerated by advancements in technology, such as the development of high-amperage alternators that cater to the needs of modern vehicles equipped with advanced electronic systems, including infotainment and safety features.

Emerging trends also highlight the rise of smart alternators, which offer integrated solutions for power management and battery health monitoring. These innovations allow businesses to optimize energy consumption and extend the lifespan of their electrical systems. Additionally, the importance of compatibility with various vehicle types—ranging from traditional combustion engines to hybrid and fully electric models—has become paramount. International buyers must therefore prioritize suppliers that offer a diverse product range adaptable to different market requirements.

How Is Sustainability Shaping the Sourcing of Alternators?

Sustainability is becoming a pivotal consideration in the sourcing of alternators. As businesses strive to reduce their environmental footprint, the demand for ethically sourced materials and sustainable manufacturing processes is rising. Buyers are increasingly looking for alternators that comply with international environmental standards and certifications, such as ISO 14001, which focuses on effective environmental management systems.

Incorporating ‘green’ certifications into the supply chain not only enhances brand reputation but also meets regulatory requirements in many regions. For instance, manufacturers who utilize recyclable materials and energy-efficient production methods can significantly minimize waste and energy consumption. This transition is particularly relevant in regions like Europe, where strict environmental regulations are in place.

Furthermore, the emphasis on responsible sourcing is prompting buyers to engage with suppliers who prioritize ethical labor practices and transparency in their supply chains. As a result, international buyers are encouraged to conduct thorough due diligence when selecting alternator suppliers, ensuring that their choices align with both sustainability goals and corporate social responsibility initiatives.

What Is the Historical Context of Alternator Development for B2B Buyers?

The evolution of alternators has been marked by significant technological advancements since their inception in the early 20th century. Initially, vehicles were equipped with generators, which provided limited electrical output. The introduction of the alternator in the 1960s revolutionized automotive electrical systems, offering higher efficiency and power output, which was crucial as vehicles became more reliant on electrical components.

As automotive technology advanced, so did alternators, leading to the development of high-output models capable of supporting modern vehicle demands. The growth of electronic accessories and systems within vehicles further necessitated the need for more robust alternators, setting the stage for today’s market, where buyers are faced with a myriad of options tailored to specific vehicle needs.

Understanding this historical context is essential for B2B buyers, as it highlights the importance of selecting alternators that not only meet current performance standards but also anticipate future technological requirements. As the automotive landscape continues to evolve, the ability to source alternators that align with these trends will be critical for businesses looking to maintain a competitive edge.

Frequently Asked Questions (FAQs) for B2B Buyers of what type of alternator do i need

-

How do I determine the correct amperage for my alternator needs?

To determine the correct amperage for your alternator, first assess your vehicle’s total electrical load. This can be done using an ammeter to measure the amperage drawn by each electrical component when activated. Sum these readings and add 50% to ensure the alternator can handle peak loads without strain. If you lack an ammeter, you can estimate by reviewing the amp ratings on the accessory fuses. Most factory alternators range from 65 to 100 amps, but high-demand applications may require a higher output. -

What factors should I consider when selecting an alternator for international shipping?

When selecting an alternator for international shipping, consider the voltage requirements specific to your region, as they can vary significantly. Additionally, assess the potential need for certifications or compliance with local regulations. Packaging is crucial to prevent damage during transit, so ensure the alternator is securely packed. Lastly, factor in shipping costs, delivery times, and the reliability of your logistics partner, particularly when sourcing from or to regions like Africa or South America. -

What are the customization options available for alternators?

Many manufacturers offer customization options for alternators, including modifications to amperage output, mounting configurations, and wiring harnesses. Depending on your specific application—be it automotive, marine, or industrial—you can request tailored features such as unique pulley sizes or specific connector types. It’s advisable to communicate your requirements clearly to suppliers to ensure they can meet your specifications, especially when dealing with diverse international markets. -

What is the minimum order quantity (MOQ) for purchasing alternators?

Minimum order quantities for alternators can vary widely among manufacturers. Some may allow single-unit purchases, while others might set an MOQ of 50 or more units to justify production costs. When sourcing from international suppliers, it’s essential to clarify these terms upfront. Consider negotiating the MOQ based on your projected sales volume or exploring options with multiple suppliers to diversify your inventory while managing costs effectively. -

How can I ensure quality assurance (QA) for the alternators I purchase?

To ensure quality assurance for purchased alternators, request documentation that verifies compliance with international standards, such as ISO certifications. Establish a clear QA process with your supplier, including pre-shipment inspections or third-party testing. Additionally, consider ordering samples before placing large orders to evaluate performance and compatibility. Building strong communication channels with suppliers can facilitate quicker resolutions to any quality concerns. -

What payment terms are typically offered for alternator purchases?

Payment terms for alternator purchases can vary based on the supplier’s policies and your relationship with them. Common arrangements include advance payment, partial upfront deposits with the balance due upon delivery, or net payment terms (e.g., net 30 days). When dealing with international suppliers, it’s wise to discuss secure payment methods, such as letters of credit or escrow services, to mitigate risks associated with overseas transactions. -

What is the lead time for manufacturing and shipping alternators internationally?

Lead times for manufacturing and shipping alternators can vary based on several factors, including the supplier’s production capacity, the complexity of customization, and shipping logistics. Generally, expect a lead time of 4 to 12 weeks for production, plus additional time for international shipping, which may take another 1 to 4 weeks depending on the destination and shipping method. Always request a detailed timeline from your supplier to plan your inventory needs effectively. -

What are the best practices for vetting alternator suppliers?

When vetting alternator suppliers, start by checking their industry reputation through reviews and references. Verify their certifications and compliance with international standards, which can indicate reliability and quality. Assess their production capabilities and experience in your specific market. Additionally, consider conducting factory visits or audits if feasible, and establish clear communication regarding your expectations and requirements to foster a successful partnership.

Top 2 What Type Of Alternator Do I Need Manufacturers & Suppliers List

1. Powermaster – 140 Amp Alternator

Domain: onallcylinders.com

Registered: 2011 (14 years)

Introduction: Powermaster 140 amp alternator (PWM-8-57140) with one wire regulator for easy installation; fits various Ford trucks and Jeeps; 200 amp alternators available for late model 4.6L V8 applications; requires 2-gauge to 00 gauge charging cable depending on length; Taylor Diamondback cable features multistrand copper conductor, polyethylene insulator, braided alloy cover, and solid brass terminals; Pain…

2. Facebook – Powering Your Sound System

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: What size alternator and additional battery are sufficient to efficiently push 2500watts; 1200watts of Subs

Strategic Sourcing Conclusion and Outlook for what type of alternator do i need

In summary, selecting the right alternator is crucial for ensuring optimal performance of your vehicle’s electrical system. Key considerations include understanding your total electrical load and ensuring that your alternator’s output is adequately matched to this load. An underpowered alternator can lead to diminished performance and potential damage to your vehicle’s electrical components, while an appropriately sized or upgraded alternator can enhance efficiency and reliability.

Illustrative image related to what type of alternator do i need

Strategic sourcing plays a pivotal role in this process. By leveraging relationships with reputable manufacturers and suppliers, international B2B buyers can secure quality alternators that meet their specific needs. This not only supports operational efficiency but also contributes to long-term cost savings through reduced maintenance and replacement needs.

As you navigate the global market, particularly in regions like Africa, South America, the Middle East, and Europe, consider establishing partnerships with trusted suppliers who can provide insights into the latest advancements in alternator technology. This proactive approach will position your business for success, ensuring that you are equipped with the right solutions to power your operations effectively. Engage with industry experts and conduct thorough market research to make informed decisions that drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to what type of alternator do i need