Introduction: Navigating the Global Market for various parts of a car

In today’s rapidly evolving automotive industry, sourcing various parts of a car can be a complex endeavor for international B2B buyers. With an increasing demand for high-quality components, navigating the global market requires a strategic approach to ensure both reliability and cost-effectiveness. This comprehensive guide delves into the intricate world of automotive parts, exploring key components such as engines, transmissions, braking systems, and electrical systems, while also highlighting their applications in diverse vehicle types.

Buyers will gain invaluable insights into supplier vetting processes, enabling them to identify trustworthy partners who meet stringent quality standards. Additionally, the guide addresses cost considerations, helping businesses make informed purchasing decisions that align with their budgetary constraints. With a particular focus on the unique needs of buyers from Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Brazil—this resource equips stakeholders with the knowledge necessary to navigate the complexities of sourcing automotive parts.

By leveraging the information presented, B2B buyers can confidently approach their procurement strategies, ensuring they secure the right components that enhance their operational efficiency and contribute to long-term success in the competitive automotive landscape.

Table Of Contents

- Top 2 Various Parts Of A Car Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for various parts of a car

- Understanding various parts of a car Types and Variations

- Key Industrial Applications of various parts of a car

- 3 Common User Pain Points for ‘various parts of a car’ & Their Solutions

- Strategic Material Selection Guide for various parts of a car

- In-depth Look: Manufacturing Processes and Quality Assurance for various parts of a car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘various parts of a car’

- Comprehensive Cost and Pricing Analysis for various parts of a car Sourcing

- Alternatives Analysis: Comparing various parts of a car With Other Solutions

- Essential Technical Properties and Trade Terminology for various parts of a car

- Navigating Market Dynamics and Sourcing Trends in the various parts of a car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of various parts of a car

- Strategic Sourcing Conclusion and Outlook for various parts of a car

- Important Disclaimer & Terms of Use

Understanding various parts of a car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engine Components | Includes cylinder block, pistons, crankshaft, and camshaft. | Engine manufacturing, repair, and upgrades. | Pros: High demand for replacement; essential for performance. Cons: Complex assembly; requires skilled technicians for maintenance. |

| Transmission Types | Variants include manual, automatic, and CVT (Continuously Variable Transmission). | Automotive manufacturing and aftermarket parts. | Pros: Diverse options for various vehicle types; potential for fuel efficiency improvements. Cons: Complexity in repairs; higher costs for advanced systems like CVT. |

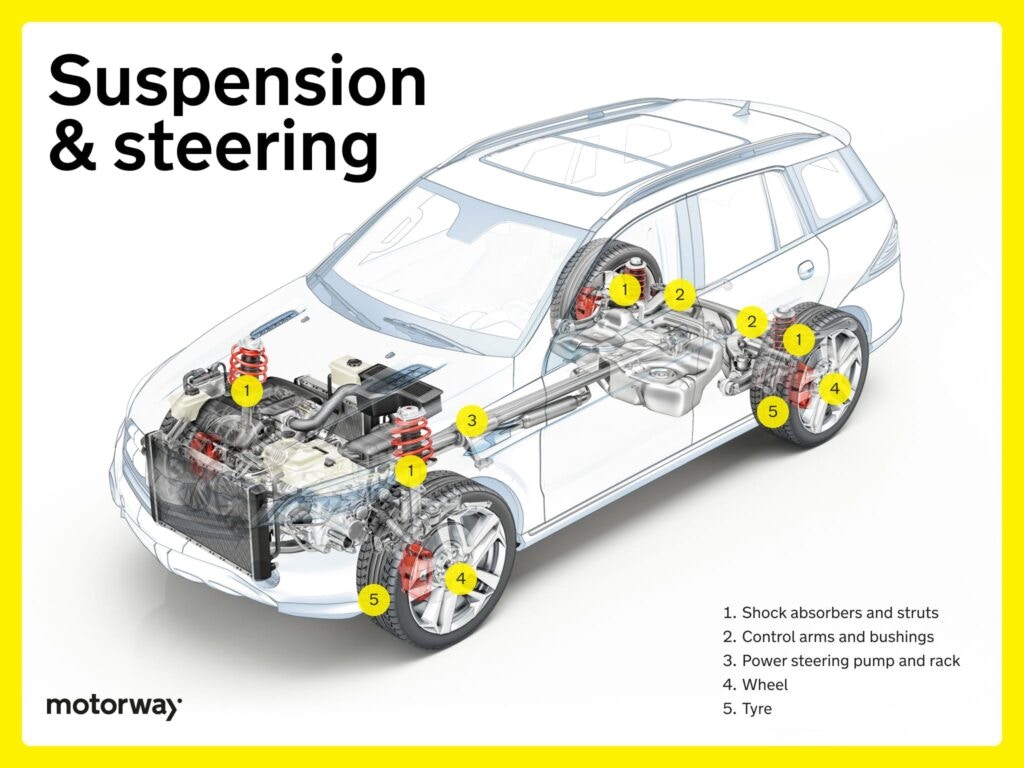

| Suspension Systems | Comprises front and rear suspension components like shocks, struts, and control arms. | Vehicle assembly and aftermarket upgrades. | Pros: Enhances ride quality and safety; critical for vehicle handling. Cons: Can be costly to replace; requires proper alignment post-installation. |

| Braking Systems | Includes disc brakes, drum brakes, and components like pads and calipers. | Safety equipment suppliers and vehicle manufacturers. | Pros: Essential for vehicle safety; consistent demand for replacements. Cons: Variability in quality; potential for compatibility issues across different vehicle models. |

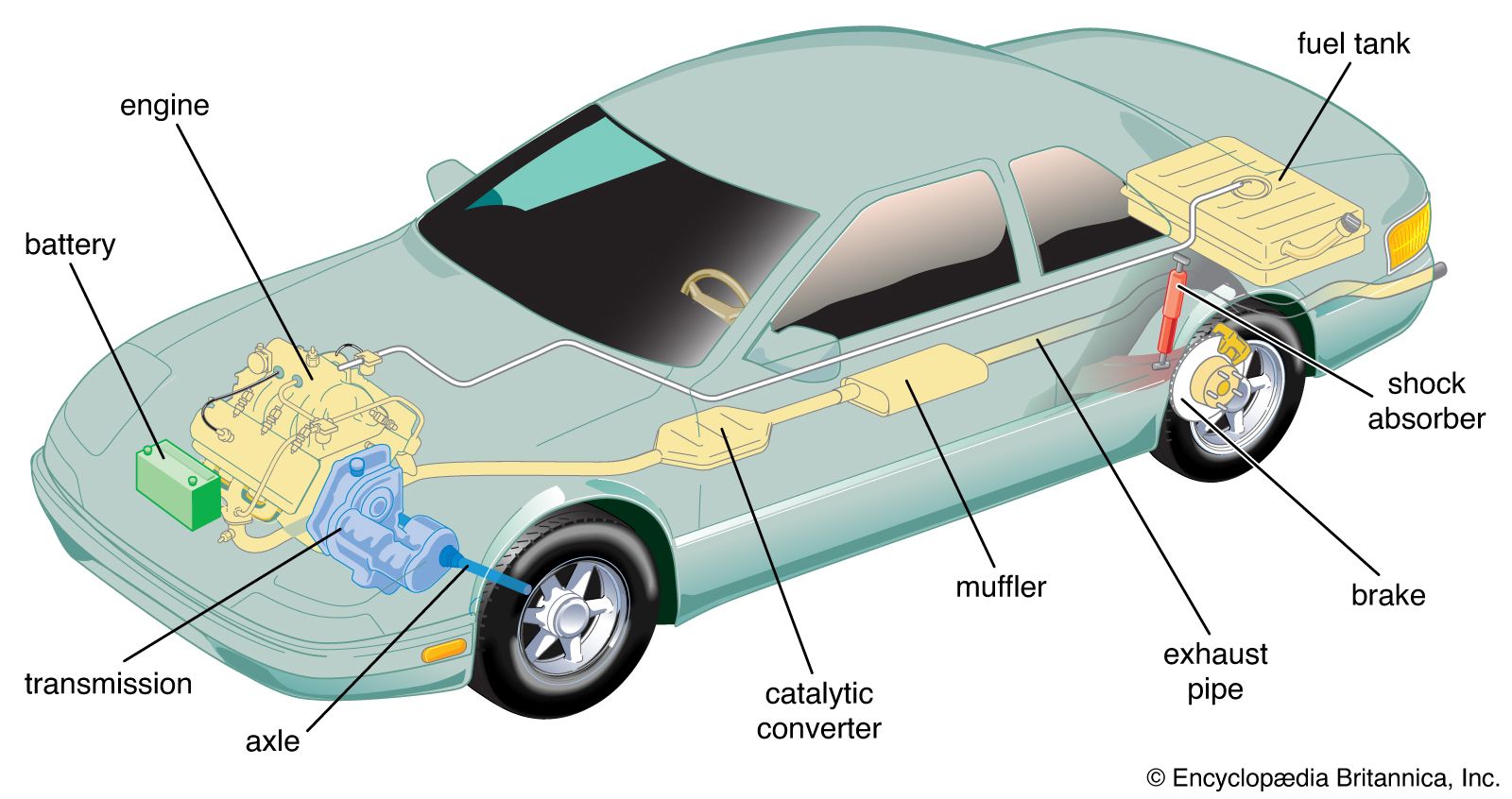

| Exhaust Systems | Comprises catalytic converters, mufflers, and tailpipes. | Emissions control and aftermarket parts. | Pros: Regulatory compliance needs drive demand; can enhance performance. Cons: Vulnerable to corrosion; may require frequent replacements in harsh environments. |

What Are the Key Characteristics of Engine Components?

Engine components are crucial for the performance and efficiency of any vehicle. Key parts such as the cylinder block, pistons, crankshaft, and camshaft work in unison to convert fuel into mechanical energy. B2B buyers in the automotive industry should focus on the quality and compatibility of these components, as they directly impact engine performance. Suppliers offering high-quality engine parts can cater to both original equipment manufacturers (OEMs) and aftermarket repair services, ensuring a steady demand.

How Do Different Transmission Types Affect Vehicle Performance?

Transmission types, including manual, automatic, and CVT, play a vital role in vehicle operation. Manual transmissions provide driver control, while automatics offer convenience, and CVTs optimize fuel efficiency through seamless gear changes. B2B buyers should consider the specific needs of their target market when selecting transmission components. Understanding the performance characteristics and maintenance requirements of each type can help businesses make informed purchasing decisions, ultimately leading to improved vehicle performance and customer satisfaction.

What Are the Benefits of Upgrading Suspension Systems?

Suspension systems significantly influence a vehicle’s ride quality and handling. Comprising various components like shocks, struts, and control arms, these systems can be upgraded to enhance safety and performance. B2B buyers should evaluate the durability and compatibility of suspension parts to ensure they meet the demands of diverse driving conditions. Investing in high-quality suspension components can lead to better customer retention and increased sales, particularly in markets focused on performance vehicles.

Why Are Braking Systems Critical for Vehicle Safety?

Braking systems are fundamental to vehicle safety and include essential components like disc brakes, drum brakes, and brake pads. As a B2B buyer, understanding the importance of these systems can lead to better product selection and customer satisfaction. The consistent demand for high-quality braking components presents an opportunity for suppliers to establish themselves as trusted partners in the automotive industry. Additionally, staying updated on regulatory changes regarding vehicle safety can provide a competitive edge.

How Do Exhaust Systems Contribute to Vehicle Efficiency?

Exhaust systems, which include catalytic converters, mufflers, and tailpipes, are essential for managing emissions and enhancing vehicle efficiency. B2B buyers should prioritize suppliers that offer reliable and compliant exhaust components, as regulatory standards continue to evolve globally. Understanding the impact of exhaust system quality on vehicle performance can help businesses make strategic purchasing decisions. Furthermore, suppliers can differentiate themselves by offering products that enhance both performance and environmental compliance.

Key Industrial Applications of various parts of a car

| Industry/Sector | Specific Application of various parts of a car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Engine components (pistons, crankshafts) | Enhanced efficiency and performance leading to better fuel economy | Quality certifications, compatibility with existing models, bulk pricing |

| Transportation & Logistics | Braking systems (disc brakes, calipers) | Improved safety and reliability, reducing accident-related costs | Supplier reliability, maintenance support, compliance with safety standards |

| Aftermarket Parts Retail | Suspension systems (shocks, struts) | Increased customer satisfaction through improved ride quality | Availability of parts, warranty terms, customer service capabilities |

| Electric Vehicle (EV) | Battery systems and electrical components | Meeting growing demand for EVs while ensuring sustainability | Technology advancements, lifecycle management, sourcing for rare materials |

| Fleet Management | Transmission systems (automatic, manual) | Reduced operational costs and enhanced vehicle longevity | Total cost of ownership, service agreements, part availability |

How Are Engine Components Critical for Automotive Manufacturing?

In the automotive manufacturing sector, engine components such as pistons and crankshafts are crucial for enhancing vehicle performance and fuel efficiency. These parts directly influence the engine’s power output and overall functionality. Buyers in this sector must prioritize sourcing high-quality components that meet strict industry standards and certifications to ensure compatibility with various vehicle models. Additionally, competitive pricing for bulk orders can significantly impact cost management in production processes, especially for international buyers looking to optimize their supply chains.

What Role Do Braking Systems Play in Transportation & Logistics?

Braking systems, including disc brakes and calipers, are essential in the transportation and logistics industry to ensure vehicle safety and reliability. These components are critical in preventing accidents, which can lead to substantial financial losses and liability issues. B2B buyers in this sector should focus on sourcing reliable suppliers that comply with safety regulations and offer maintenance support. This consideration is particularly important for companies operating in regions with varying safety standards, ensuring that their fleets remain compliant and safe across all operational areas.

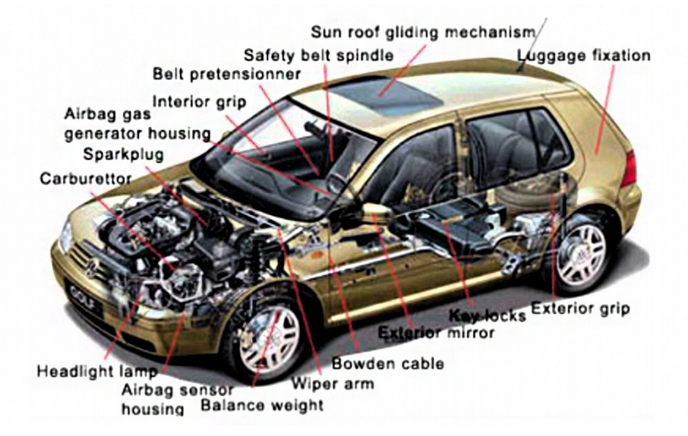

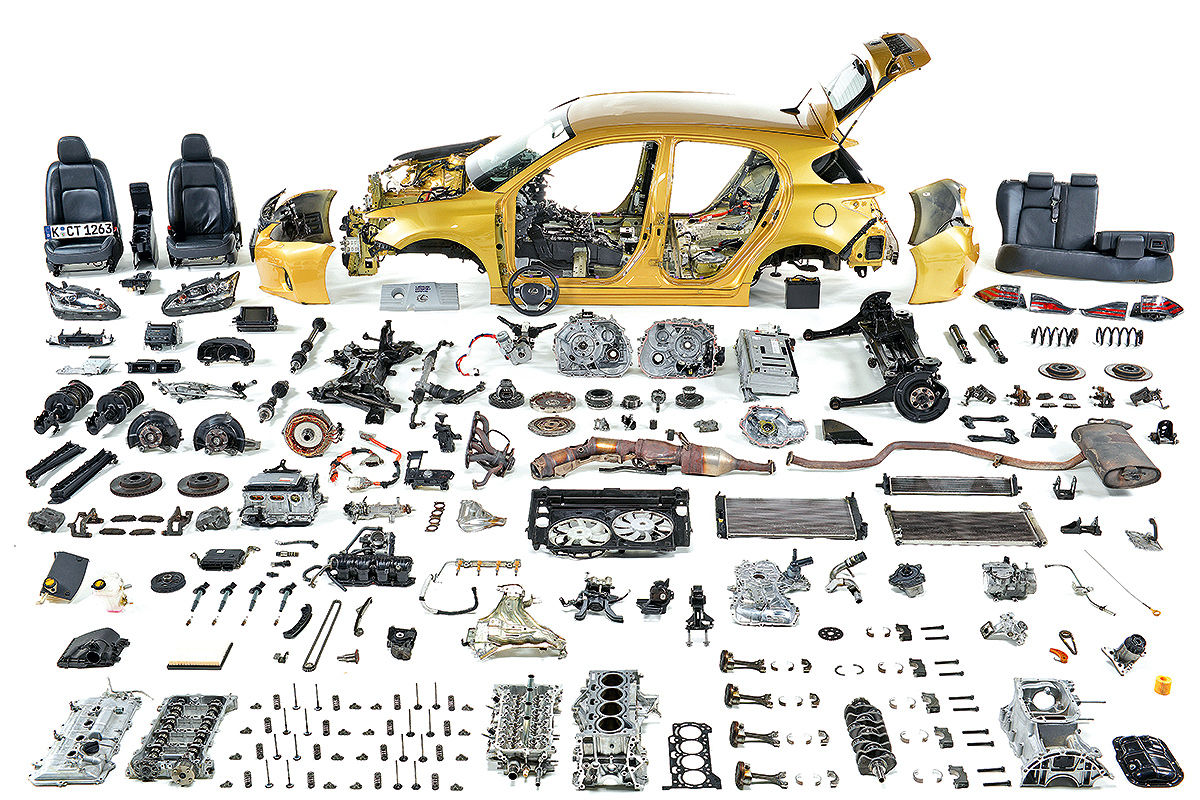

Illustrative image related to various parts of a car

Why Are Suspension Systems Important for Aftermarket Parts Retail?

Suspension systems, comprising shocks and struts, are vital in the aftermarket parts retail industry, directly impacting customer satisfaction and vehicle ride quality. Retailers must ensure that they stock a wide range of parts to cater to different vehicle makes and models, thereby enhancing their market appeal. Buyers should consider the availability of parts, warranty terms, and the supplier’s customer service capabilities to ensure they can support their customers effectively. This is particularly important in regions like Africa and South America, where vehicle diversity is high.

How Do Battery Systems Impact Electric Vehicle Markets?

In the burgeoning electric vehicle (EV) market, battery systems and electrical components are at the forefront of innovation and sustainability. As demand for EVs grows, businesses must source advanced battery technology that meets performance and environmental standards. International buyers should focus on suppliers that can provide the latest technology while managing the lifecycle of these components, ensuring sustainability and efficiency. This focus on technology advancements is crucial in regions like Europe, where regulatory frameworks are increasingly favoring eco-friendly solutions.

What Are the Benefits of Transmission Systems for Fleet Management?

Transmission systems, whether automatic or manual, are critical for fleet management, influencing vehicle performance and longevity. Efficient transmission contributes to reduced operational costs and enhances the overall driving experience. B2B buyers in this sector should evaluate the total cost of ownership, including service agreements and part availability, to ensure their fleets remain operational with minimal downtime. This is especially significant for international fleets operating across diverse geographical terrains, where reliability and efficiency are paramount.

3 Common User Pain Points for ‘various parts of a car’ & Their Solutions

Scenario 1: Sourcing Quality Engine Components for Diverse Markets

The Problem:

B2B buyers often struggle with sourcing high-quality engine components that meet diverse regional standards and specifications. For instance, a buyer in Brazil may face challenges due to the country’s unique emissions regulations, while a buyer in Europe might need parts that comply with stringent safety and environmental standards. This complexity can lead to increased costs and delays in the supply chain, especially if the parts do not align with local requirements. Additionally, the lack of reliable suppliers can result in subpar components that ultimately affect vehicle performance and customer satisfaction.

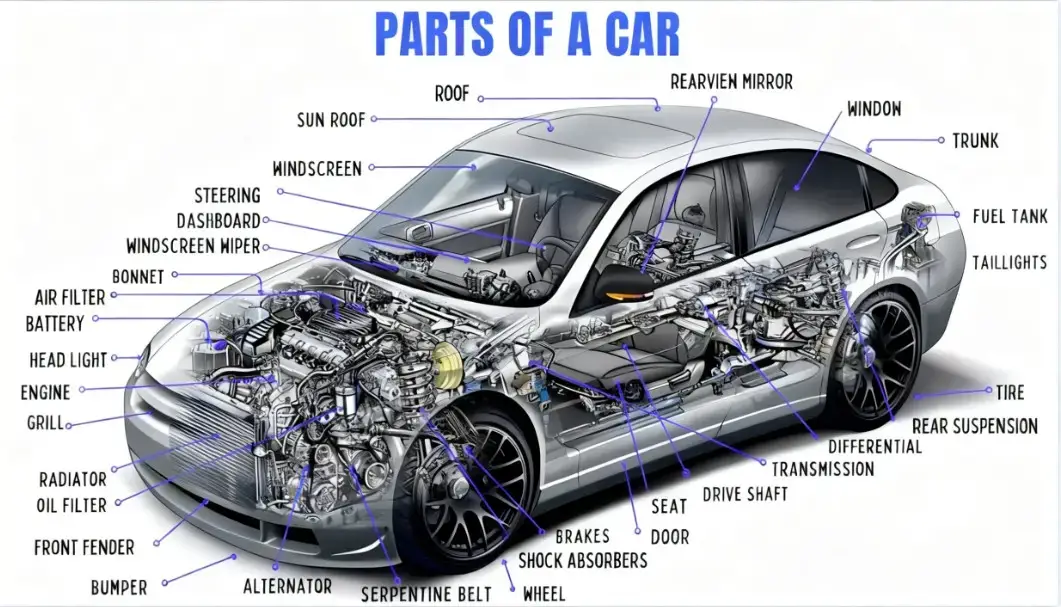

Illustrative image related to various parts of a car

The Solution:

To effectively source engine components, B2B buyers should engage with suppliers that provide comprehensive product specifications and certifications tailored to their region. Establishing relationships with manufacturers who have a proven track record in multiple markets can be beneficial. Additionally, utilizing local distributors who understand regional compliance can simplify the sourcing process. Buyers should also consider leveraging technology such as digital catalogs or B2B marketplaces that allow for easy comparison of parts across different manufacturers, ensuring they select high-quality components that meet both local and international standards. Regularly auditing suppliers for quality assurance and compliance with regional regulations can further mitigate risks and enhance operational efficiency.

Scenario 2: Managing Inventory for Suspension and Steering Parts

The Problem:

Many B2B buyers face challenges in managing inventory for suspension and steering parts due to the rapid turnover of vehicle models and the specific needs of various manufacturers. For instance, a buyer supplying parts to a fleet of vehicles may struggle with overstocking parts that are no longer in demand or running out of critical components needed for repairs. This inefficiency can lead to increased holding costs and potential lost sales, as customers may turn to competitors who can deliver parts more quickly.

The Solution:

Implementing an advanced inventory management system can help buyers accurately track inventory levels and forecast demand for suspension and steering parts. This system should integrate data analytics to analyze sales trends and identify which parts are most frequently requested based on vehicle model and usage patterns. Additionally, establishing partnerships with manufacturers for just-in-time inventory can help ensure that the necessary parts are available without overcommitting resources. By using drop-shipping arrangements, buyers can also reduce the burden of holding excess inventory while maintaining customer satisfaction through timely deliveries. Regularly reviewing and adjusting inventory practices based on market trends can enhance responsiveness and efficiency.

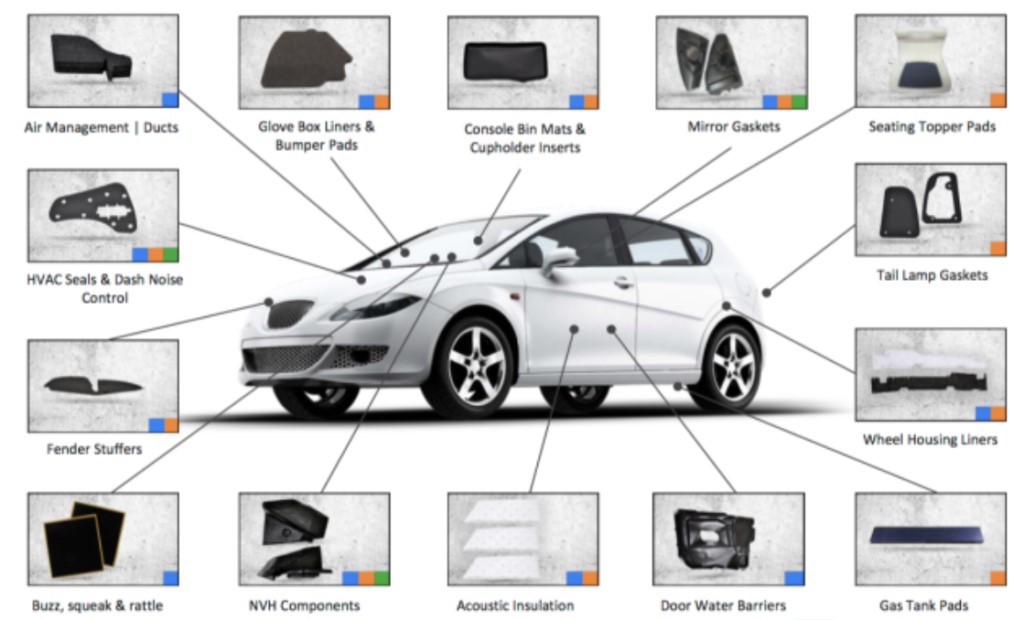

Illustrative image related to various parts of a car

Scenario 3: Understanding the Complexities of Brake System Components

The Problem:

B2B buyers often encounter difficulties in understanding the complexities of brake system components, which can vary significantly between vehicle types and manufacturers. This lack of knowledge can result in incorrect part specifications, leading to costly returns and dissatisfied customers. For example, a buyer in the Middle East may overlook specific requirements for disc brake systems versus drum brakes, potentially compromising vehicle safety and performance.

The Solution:

To navigate the intricacies of brake system components, buyers should invest in training sessions or workshops that focus on the latest developments and specifications in braking technology. Collaborating with technical experts from manufacturers can provide valuable insights into the differences between various brake systems and their applications. Creating a detailed parts catalog that includes not just specifications but also installation guidelines and maintenance tips can empower buyers to make informed purchasing decisions. Additionally, utilizing digital resources, such as online forums or technical databases, can facilitate ongoing education and support for buyers, ensuring they remain updated on the latest trends and best practices in brake system components.

Strategic Material Selection Guide for various parts of a car

When selecting materials for various parts of a car, it is crucial for international B2B buyers to understand the properties, advantages, disadvantages, and specific considerations for each material. This knowledge aids in making informed decisions that affect performance, cost, and compliance with regional standards.

Illustrative image related to various parts of a car

What Are the Key Properties of Aluminum in Automotive Applications?

Aluminum is widely used in automotive manufacturing due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of around 150-200°C, making it suitable for engine components and structural parts. Its low density contributes to improved fuel efficiency, which is a significant consideration in today’s eco-conscious market.

Pros of aluminum include its high strength-to-weight ratio, which enhances vehicle performance and efficiency. However, its cons include a higher manufacturing complexity and cost compared to steel, particularly when forming intricate shapes. Additionally, aluminum’s compatibility with various media makes it suitable for components like radiators and engine blocks, but care must be taken to avoid galvanic corrosion when used with dissimilar metals.

How Does Steel Compare as a Material for Car Components?

Steel remains a staple in automotive manufacturing, particularly for structural components and chassis due to its high tensile strength and durability. It can withstand high temperatures and pressures, making it ideal for parts like the frame and suspension systems. Steel typically has a corrosion resistance that can be enhanced through galvanization or coating.

Illustrative image related to various parts of a car

The key advantage of steel is its cost-effectiveness and ease of manufacturing, which allows for mass production. However, its limitations include increased weight compared to aluminum, which can negatively impact fuel efficiency. International buyers should consider the common standards such as ASTM and ISO for steel grades, ensuring that the selected steel meets specific performance requirements.

What Are the Benefits of Composite Materials in Automotive Parts?

Composite materials, such as carbon fiber reinforced polymers, are increasingly used in high-performance vehicles. They offer excellent strength-to-weight ratios and can withstand significant temperature variations, making them suitable for body panels and performance components.

The advantages of composites include their lightweight nature and superior fatigue resistance. However, they come with disadvantages, such as higher costs and complex manufacturing processes. For international buyers, compliance with standards like JIS and ASTM is crucial, especially when sourcing from different regions. The disposal and recyclability of composites also present challenges that buyers must consider.

Illustrative image related to various parts of a car

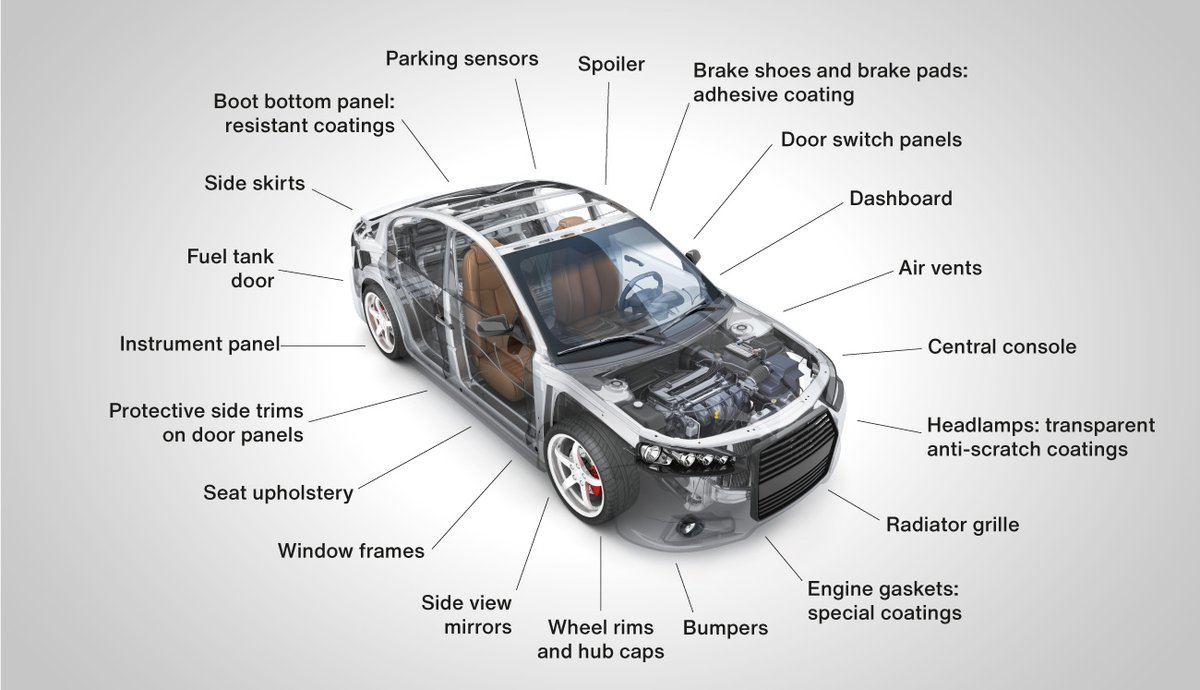

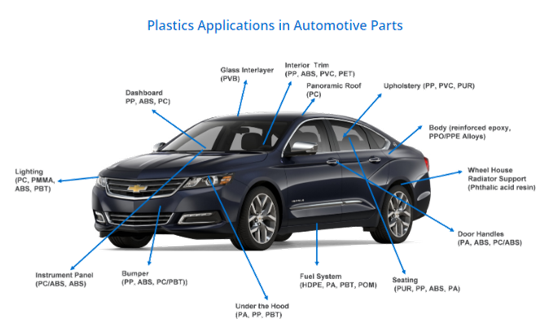

How Do Plastics Fit into the Material Selection for Automotive Parts?

Plastics are commonly used in various automotive applications, from interior components to exterior trims. They offer good temperature resistance (typically up to 100-120°C) and can be engineered for specific applications, providing flexibility in design.

Plastics have the advantage of being lightweight and cost-effective, which makes them suitable for mass production. However, they can have limitations in terms of durability and may not perform well under extreme conditions. Buyers should be aware of the specific plastic grades and their compliance with automotive standards, particularly in regions with stringent regulations regarding material safety and environmental impact.

Summary of Material Selection for Automotive Parts

| Material | Typical Use Case for various parts of a car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, structural parts | Lightweight and corrosion-resistant | Higher manufacturing complexity | Medium |

| Steel | Chassis, suspension systems | Cost-effective and durable | Heavier than aluminum | Low |

| Composites | Body panels, performance components | Excellent strength-to-weight ratio | High cost and complex to manufacture | High |

| Plastics | Interior components, exterior trims | Lightweight and flexible design | Less durable under extreme conditions | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, emphasizing the importance of understanding material properties, advantages, and compliance standards in the automotive industry.

In-depth Look: Manufacturing Processes and Quality Assurance for various parts of a car

What Are the Key Stages in the Manufacturing Process for Car Parts?

The manufacturing of car parts involves several critical stages, each designed to ensure precision, durability, and compliance with international quality standards. These stages typically include material preparation, forming, assembly, and finishing.

How Does Material Preparation Impact the Manufacturing Process?

Material preparation is the foundational step in the manufacturing process. It involves selecting the right materials based on the specific requirements of each car part. Common materials include metals such as steel and aluminum, plastics, and composites. The preparation phase includes processes like cutting, grinding, and heat treatment to enhance the material properties. Proper material selection and preparation are crucial for ensuring the longevity and performance of the car parts.

What Forming Techniques Are Commonly Used in Car Parts Manufacturing?

Once the materials are prepared, they undergo various forming techniques. These may include:

- Casting: Molten metal is poured into molds to create complex shapes.

- Machining: Material is removed using tools to achieve precise dimensions and surface finishes.

- Stamping: Sheets of metal are shaped into parts using dies and high-pressure machinery.

- Injection Molding: Plastics are melted and injected into molds, allowing for the production of intricate components.

Each technique has its advantages and is chosen based on the part’s design, complexity, and volume requirements.

How Is the Assembly Process Managed for Car Parts?

The assembly stage involves putting together the different components to form a complete part. This process may include welding, fastening, and integrating electronic systems. Automation plays a significant role in assembly lines, enhancing efficiency and consistency. A well-managed assembly process reduces the likelihood of defects and ensures that the final product meets design specifications.

What Are the Key Finishing Techniques in Car Parts Production?

Finishing processes are critical for enhancing the aesthetic and functional properties of car parts. Common finishing techniques include:

Illustrative image related to various parts of a car

- Coating: Applying paints, powders, or other finishes to protect against corrosion and enhance appearance.

- Polishing: Smoothing surfaces to improve aesthetic quality and reduce friction.

- Heat Treatment: Strengthening parts through controlled heating and cooling processes.

These finishing techniques not only improve the look of the parts but also contribute to their durability and performance in various operating conditions.

What Quality Assurance Measures Are Crucial in Car Parts Manufacturing?

Quality assurance (QA) is vital for maintaining high standards in the manufacturing process. It involves systematic monitoring and evaluation of the production process and final products.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with relevant international standards, such as:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers meet customer and regulatory requirements consistently.

- ISO/TS 16949: Specifically for the automotive industry, this standard outlines the requirements for a quality management system in the production of automotive parts.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain components are essential for compliance.

What Are the Critical Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to ensuring that the manufacturing process adheres to established standards. These checkpoints typically include:

- Incoming Quality Control (IQC): Verification of materials and components upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify defects in real-time.

- Final Quality Control (FQC): Comprehensive testing and inspection of finished products before they are shipped.

Common testing methods employed in these checkpoints include dimensional checks, functional testing, and material property assessments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure that their suppliers maintain rigorous quality control standards:

-

Audits: Conducting regular audits of suppliers’ manufacturing facilities can provide insights into their quality assurance practices and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports, including inspection results and compliance certifications, can help verify a supplier’s adherence to quality standards.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control processes and product quality.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of specific quality control nuances:

-

Regulatory Compliance: Understanding the regulatory landscape of the target market is essential. Different regions may have varying requirements for automotive parts, which can affect acceptance and marketability.

-

Cultural Differences: Negotiating and managing supplier relationships may involve navigating cultural differences that impact quality perceptions and practices.

-

Supply Chain Logistics: Buyers should consider logistics, including shipping times and customs regulations, which can affect product quality during transit.

By taking a proactive approach to understanding the manufacturing processes and quality assurance measures involved in car parts production, B2B buyers can make informed decisions and establish strong relationships with suppliers that prioritize quality and compliance. This knowledge not only helps in sourcing high-quality automotive components but also contributes to long-term operational success in the automotive industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘various parts of a car’

To assist B2B buyers in sourcing various parts of a car effectively, this guide provides a structured checklist. By following these steps, buyers can ensure they make informed decisions that align with their operational needs and quality standards.

Illustrative image related to various parts of a car

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the car parts. This includes understanding the exact models, dimensions, materials, and performance standards necessary for your application. Providing precise specifications reduces the risk of errors and ensures compatibility with existing systems.

- Key Considerations:

- Engine type and specifications for parts like pistons and crankshafts.

- Compatibility with the vehicle’s transmission system.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in the car parts you need. Utilize online directories, industry trade shows, and professional networks to compile a list of potential vendors. This groundwork is crucial for finding reputable suppliers who can meet your technical and logistical requirements.

- Key Considerations:

- Supplier location and shipping capabilities.

- Industry reputation and customer reviews.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold relevant certifications and quality standards, such as ISO 9001. These certifications indicate a commitment to quality management and can help mitigate risks associated with substandard parts.

- Key Considerations:

- Look for compliance with international automotive standards.

- Check if they have certifications specific to the type of car parts you require.

Step 4: Request Samples and Product Documentation

Once you have shortlisted suppliers, request samples of the car parts along with detailed product documentation. This step allows you to assess the quality of the components firsthand and ensures they meet your technical specifications.

- Key Considerations:

- Evaluate the materials and construction of the parts.

- Ensure that product documentation includes installation guidelines and warranty information.

Step 5: Assess Pricing and Payment Terms

Gather pricing information from multiple suppliers to compare costs effectively. Additionally, clarify payment terms and conditions, including discounts for bulk purchases or extended payment periods. Understanding the financial implications is crucial for budgeting and cash flow management.

- Key Considerations:

- Factor in shipping and import duties, especially for international purchases.

- Assess the overall value rather than just the price.

Step 6: Negotiate Terms and Conditions

Engage in discussions with your selected suppliers to negotiate favorable terms and conditions. This may include warranty coverage, return policies, and lead times for delivery. Strong negotiation can lead to better pricing and service agreements that benefit both parties.

- Key Considerations:

- Ensure clarity on the delivery schedule and penalties for delays.

- Discuss support for after-sales service and parts replacement.

Step 7: Establish a Long-Term Relationship

After the initial transaction, aim to establish a long-term relationship with your suppliers. This can lead to better pricing, priority service, and improved communication. Regularly assess supplier performance and provide feedback to foster a mutually beneficial partnership.

- Key Considerations:

- Schedule regular meetings to discuss performance and any issues.

- Keep an open line of communication for future needs and adjustments.

By following this structured checklist, B2B buyers can streamline their sourcing process for car parts, ensuring they select the right suppliers and products to meet their operational needs.

Comprehensive Cost and Pricing Analysis for various parts of a car Sourcing

Understanding the cost structure and pricing dynamics for various car parts is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the critical components of costs, the factors influencing pricing, and offers actionable tips for buyers to enhance their procurement strategies.

What Are the Key Cost Components in Car Parts Manufacturing?

-

Materials: The primary cost driver in manufacturing car parts is the raw materials used, which can vary significantly based on the type of part. Metals like steel and aluminum, plastics, rubber, and composites are common. Prices fluctuate based on market demand and supply chain stability.

-

Labor: Labor costs encompass wages for skilled workers involved in assembly, machining, and quality control. Labor rates can differ widely by region, affecting overall production costs. Countries with lower labor costs may offer competitive pricing, but this often comes with trade-offs in quality.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, equipment maintenance, and indirect labor. Manufacturers often allocate a portion of these costs to each unit produced, influencing the final price.

-

Tooling: Tooling costs involve the initial investment in molds, dies, and specialized equipment required for production. These costs are amortized over the expected production volume, impacting the unit price especially for low-volume orders.

-

Quality Control (QC): Ensuring that parts meet stringent quality standards incurs additional costs. Implementing rigorous QC processes can enhance product reliability but may also increase prices.

-

Logistics: Transporting parts from the manufacturer to the buyer involves shipping, handling, and customs duties. Logistics costs can vary based on distance, mode of transport, and the complexity of the supply chain.

-

Margin: Suppliers typically add a profit margin to cover their risks and business expenses. Understanding the supplier’s margin can provide insight into pricing flexibility during negotiations.

What Influences Pricing for Car Parts in International Markets?

-

Volume/MOQ: Minimum order quantities (MOQ) and volume purchases can significantly affect pricing. Bulk orders often lead to discounts, while smaller quantities may incur higher unit prices due to less favorable economies of scale.

-

Specifications and Customization: Custom parts or those with unique specifications may attract higher prices due to additional design, manufacturing, and quality assurance efforts. Standard parts are generally more competitively priced.

-

Material Quality and Certifications: Parts made from higher quality materials or those that meet specific industry certifications (like ISO or IATF) can command higher prices. Buyers should evaluate the importance of these factors based on their application.

-

Supplier Factors: The reputation, reliability, and geographical location of suppliers can influence pricing. Established suppliers with a track record of quality and service may charge a premium.

-

Incoterms: Understanding Incoterms is essential for international buyers. These terms dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can affect overall costs.

How Can Buyers Optimize Their Procurement Strategies?

-

Negotiation: Effective negotiation can lead to better pricing. Buyers should prepare by understanding market prices, competitor offers, and potential alternatives.

-

Cost-Efficiency: Focus on Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as longevity, maintenance, and operational efficiency to determine the true value of a part.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, regional economic conditions, and trade tariffs that can impact pricing. Establishing long-term relationships with suppliers may also yield better terms.

-

Market Research: Continuously gather data on market trends, emerging technologies, and new suppliers to inform purchasing decisions. This can help identify cost-saving opportunities and innovative products.

In summary, a thorough understanding of the cost components and pricing influencers in car parts sourcing allows international buyers to make informed decisions. By leveraging negotiation strategies and focusing on overall value, businesses can enhance their procurement processes and build sustainable supply chains.

Alternatives Analysis: Comparing various parts of a car With Other Solutions

Understanding Alternatives in Automotive Parts

In the automotive sector, the choice of components can significantly influence vehicle performance, cost-effectiveness, and maintenance needs. As global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the alternatives available for various car parts becomes crucial for B2B buyers. This analysis compares traditional car parts with emerging technologies and solutions that aim to meet similar objectives.

Comparison of Automotive Solutions

| Comparison Aspect | Various Parts Of A Car | Electric Vehicle Components | Hybrid Vehicle Systems |

|---|---|---|---|

| Performance | High efficiency with mechanical parts designed for durability and power. | Instant torque delivery and reduced mechanical wear. | Combines power from both electric and combustion engines for optimal performance. |

| Cost | Generally lower initial costs; ongoing maintenance can add up. | Higher upfront costs due to advanced technology and battery systems. | Moderate initial costs; savings in fuel and maintenance can be significant over time. |

| Ease of Implementation | Established supply chains and availability of parts. | Requires specialized knowledge for installation and maintenance. | More complex integration due to dual systems. |

| Maintenance | Regular maintenance needed; parts may wear out. | Lower maintenance needs; fewer moving parts. | Requires specific knowledge for both electric and combustion systems. |

| Best Use Case | Suitable for traditional driving environments and applications. | Ideal for urban driving with short ranges and frequent stops. | Best for varied driving environments, balancing fuel efficiency and power. |

Analyzing Electric Vehicle Components

Electric vehicle (EV) components represent a significant shift in automotive technology. With electric motors providing instant torque, these systems reduce the mechanical wear typically associated with traditional parts. While the initial investment is higher due to the cost of batteries and advanced technology, ongoing maintenance is generally lower, as EVs have fewer moving parts that require servicing. However, the need for specialized knowledge for installation and repairs can present challenges, especially in regions with limited EV infrastructure.

Illustrative image related to various parts of a car

Exploring Hybrid Vehicle Systems

Hybrid vehicle systems combine the benefits of both traditional combustion engines and electric systems. This dual approach allows for improved fuel efficiency and reduced emissions, making hybrids appealing in diverse driving environments. While the initial costs can be moderate compared to fully electric vehicles, the complexity of integrating both systems can lead to higher maintenance demands. B2B buyers must consider the balance between performance and the dual maintenance requirements when assessing hybrid options.

Making an Informed Decision as a B2B Buyer

When selecting automotive parts or alternative solutions, B2B buyers should evaluate their specific needs based on performance, cost, ease of implementation, and maintenance requirements. For businesses operating in regions with diverse driving conditions, hybrid systems may offer the best flexibility, while electric components could be ideal for urban applications where efficiency is paramount. Ultimately, understanding the trade-offs between traditional car parts and their alternatives will empower buyers to make informed, strategic decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for various parts of a car

What Are the Key Technical Properties for Various Parts of a Car?

In the automotive industry, understanding the essential technical properties of car parts is crucial for making informed purchasing decisions. Here are some critical specifications that B2B buyers should be aware of:

What Are the Critical Specifications to Consider?

-

Material Grade

The material grade of a component determines its strength, durability, and resistance to wear and corrosion. Common materials include steel, aluminum, and composites, each offering different performance characteristics. Selecting the appropriate material is vital for ensuring that parts can withstand the specific demands of their application, especially in varying climatic and road conditions. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. In automotive manufacturing, strict tolerances are crucial for ensuring that parts fit together correctly, which directly impacts performance and safety. For example, tighter tolerances in engine components can lead to better fuel efficiency and lower emissions. -

Load Capacity

This specification indicates the maximum weight or force that a component can withstand during operation. For instance, suspension parts must be designed to handle the weight of the vehicle while providing stability and comfort. Understanding load capacity helps buyers ensure that the parts will perform safely under expected operational conditions. -

Fatigue Strength

This property indicates a material’s ability to withstand repeated loading and unloading cycles without failing. Parts like axles and suspension components experience continuous stress, making fatigue strength a critical specification. Selecting parts with high fatigue strength can lead to longer service life and reduced maintenance costs. -

Corrosion Resistance

Especially important for components exposed to the elements, corrosion resistance measures a material’s ability to withstand degradation due to environmental factors. Parts like brake systems and exhaust components benefit from high corrosion resistance to enhance longevity and reliability. -

Thermal Conductivity

This property measures a material’s ability to conduct heat. In automotive applications, components like radiators and engine blocks must effectively manage heat to prevent overheating. Understanding thermal conductivity helps in selecting materials that will maintain optimal operating temperatures.

What Are Common Trade Terms in the Automotive Industry?

Familiarity with industry jargon can facilitate smoother transactions and enhance communication between buyers and suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts that are used in the original assembly of vehicles. OEM parts are often preferred for their quality and compatibility with the vehicle’s specifications. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ helps buyers plan their inventory and budget effectively, ensuring they don’t overstock or understock critical components. -

RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting pricing and terms for specific parts. This process is essential for comparing quotes and ensuring competitive pricing. -

Incoterms

Short for International Commercial Terms, these are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Knowledge of Incoterms is crucial for B2B transactions, especially in global markets. -

Lead Time

This refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for inventory management and planning, particularly in industries where timely delivery is critical. -

Aftermarket

Refers to parts and accessories that are not sourced from the original manufacturer but are used to replace or enhance vehicle components. The aftermarket is significant for buyers looking for cost-effective alternatives or specialized products.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the most suitable parts for their automotive needs.

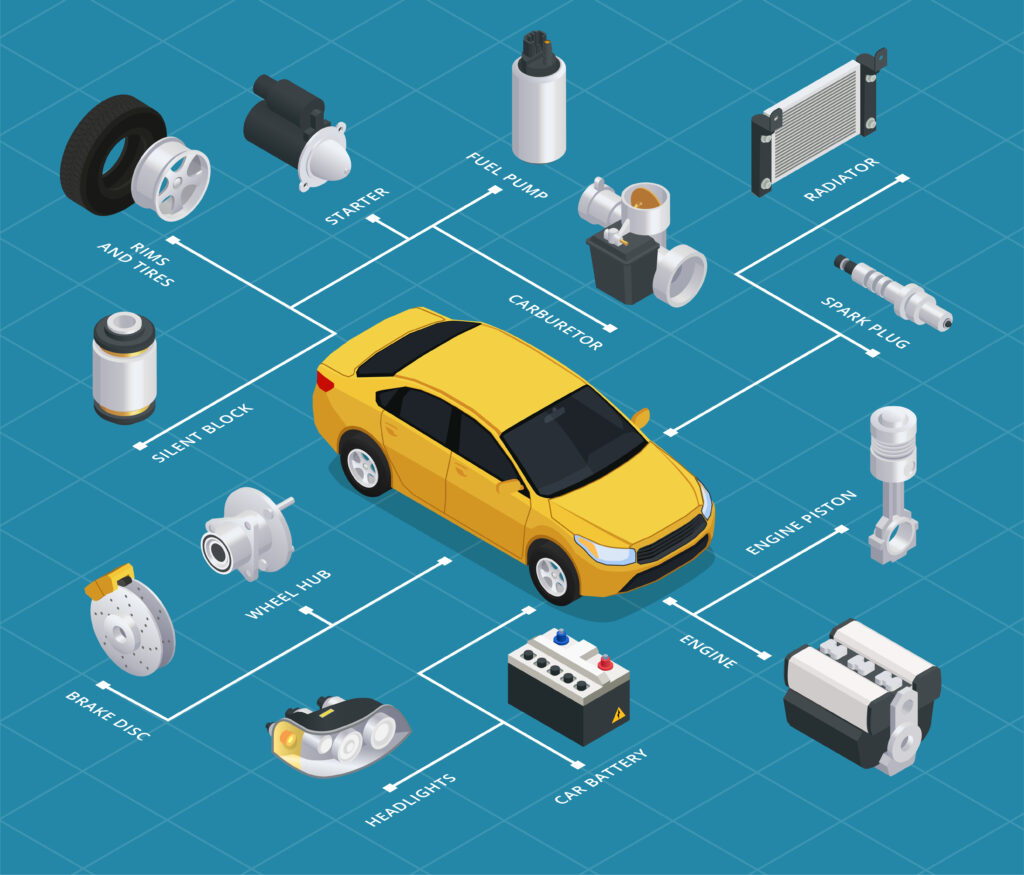

Illustrative image related to various parts of a car

Navigating Market Dynamics and Sourcing Trends in the various parts of a car Sector

What Are the Key Market Trends Impacting Sourcing for Car Parts?

The automotive parts market is undergoing significant transformations driven by global economic factors, technological advancements, and shifting consumer preferences. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe evaluate their sourcing strategies, they must consider the growing demand for electric vehicles (EVs) and hybrid technologies. This shift is prompting manufacturers to invest heavily in new technologies and components such as advanced batteries, electric motors, and regenerative braking systems. Furthermore, the integration of smart technology in vehicles—like advanced driver-assistance systems (ADAS)—is reshaping the supply chain, necessitating partnerships with tech companies and software developers.

Current sourcing trends also reflect a move towards digitalization, with platforms that facilitate real-time inventory management and procurement processes gaining traction. B2B buyers are increasingly utilizing data analytics and AI to optimize their supply chains, helping to predict demand fluctuations and manage inventory more effectively. Additionally, the trend towards localization in sourcing is notable, as companies aim to mitigate risks associated with global supply chain disruptions, particularly following the pandemic.

How Can Sustainability and Ethical Sourcing Be Integrated into B2B Strategies?

Sustainability is becoming a crucial consideration for B2B buyers in the automotive parts sector. The environmental impact of manufacturing processes, especially in regions with lax regulations, has led to increased scrutiny from consumers and governments alike. International buyers are now prioritizing suppliers who adhere to sustainable practices, such as reducing carbon emissions, minimizing waste, and using eco-friendly materials.

Moreover, the importance of ethical sourcing cannot be overstated. Buyers are encouraged to vet their supply chains for compliance with labor laws and fair trade practices. Certifications such as ISO 14001 for environmental management and various green certifications for materials provide assurances of a supplier’s commitment to sustainability. In this context, sourcing parts made from recycled materials or those with a lower environmental footprint is becoming increasingly common, aligning with the global push for greener automotive solutions.

How Has the Automotive Parts Market Evolved Over Time?

The automotive parts market has seen a remarkable evolution over the decades. Initially dominated by traditional combustion engine components, the sector has shifted significantly towards more complex systems, including electronics and software integration. This transition reflects broader technological advancements and changing consumer preferences, particularly the rise of electric vehicles.

Historically, the market was characterized by a straightforward supply chain, primarily involving manufacturers, distributors, and retailers. However, the current landscape is marked by a more intricate web of relationships, including tech firms, logistics providers, and even end-users, creating a dynamic environment that requires B2B buyers to remain agile and informed. As these changes continue to unfold, understanding the historical context can provide valuable insights into navigating the current market dynamics effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of various parts of a car

-

How do I source high-quality car parts for my business?

To source high-quality car parts, start by identifying reputable manufacturers or suppliers with positive reviews and certifications. Utilize industry directories and trade shows to connect with potential partners. Request samples to evaluate the quality and compatibility of the parts. Additionally, consider the supplier’s experience in your specific market region, as they may better understand local regulations and customer preferences. -

What is the best type of brake system for different vehicle models?

The best brake system varies by vehicle model and intended use. For high-performance vehicles, disc brakes are preferred for their superior stopping power and heat dissipation. Conversely, drum brakes may be suitable for lighter, less demanding applications. When sourcing brake systems, ensure compatibility with the specific make and model, and consult with technical experts for tailored recommendations based on performance needs. -

How can I verify the reliability of a car parts supplier?

To verify a supplier’s reliability, conduct thorough due diligence. Check for industry certifications, customer testimonials, and case studies. Request references from previous clients and evaluate their experience with the supplier. Additionally, assess their production capacity and quality control processes to ensure they can meet your demands consistently. Engaging in initial small orders can also help gauge their responsiveness and quality before committing to larger purchases. -

What are the minimum order quantities (MOQ) for car parts?

Minimum order quantities (MOQ) for car parts can vary significantly by supplier and product type. Some suppliers may have MOQs as low as 10 units for common parts, while specialized components might require orders of 100 units or more. It’s essential to discuss MOQs with potential suppliers upfront and negotiate terms that align with your business needs, especially if you are entering a new market or trying to manage inventory effectively. -

What payment terms should I expect when purchasing car parts internationally?

Payment terms for international purchases can vary, but common options include advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit (e.g., 30% upfront) with the balance due before shipment. Always clarify payment methods, currency, and any applicable taxes or duties in advance. Establishing clear terms can help mitigate risks associated with international trade and ensure smooth transactions. -

How can I ensure quality assurance for car parts sourced internationally?

To ensure quality assurance, implement a multi-step approach. First, request detailed specifications and certifications from suppliers to confirm compliance with industry standards. Conduct factory audits or engage third-party inspection services before shipment. Additionally, establish clear quality metrics and return policies in your contracts. This proactive approach helps safeguard your business against defects and ensures that the parts meet your operational requirements. -

What logistics considerations should I keep in mind when importing car parts?

When importing car parts, consider shipping costs, customs regulations, and delivery timelines. Work with logistics providers experienced in automotive parts to navigate complexities in international shipping. Evaluate shipping methods (air freight vs. sea freight) based on urgency and budget. Also, be aware of import duties and taxes that may apply, and ensure proper documentation is in place to avoid delays at customs. -

How do I customize car parts for my specific needs?

Customizing car parts often involves working closely with manufacturers who offer bespoke services. Clearly outline your specifications, including materials, dimensions, and performance criteria. Collaborate during the design process to ensure your requirements are met. Be prepared to invest in tooling or molds for unique designs, and consider lead times for production. Establishing a strong partnership with your supplier will facilitate smoother communication and better outcomes for your custom parts.

Top 2 Various Parts Of A Car Manufacturers & Suppliers List

1. Moog – Automotive Parts

Domain: moogparts.com

Registered: 2005 (20 years)

Introduction: Parts of a Car include: Steering Wheel, Engine (with parts like timing chain, camshaft, crankshaft, spark plugs, cylinder heads, valves, pistons), Transmission, Battery, Alternator, Radiator, Front Axle, Front Steering and Suspension (including shocks/struts, ball joints, tie rod ends, rack and pinion steering system, idler/pitman arms), Brakes (disc brakes with brake pads and calipers, drum brake…

2. Facebook – Car Exterior Diagram

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: diagram of a car illustrates the various exterior parts and components, including key structural and functional elements such as the hoods, mirrors

Strategic Sourcing Conclusion and Outlook for various parts of a car

In the evolving landscape of automotive parts sourcing, understanding the intricate components of a vehicle is paramount for international B2B buyers. The engine, transmission, and braking systems represent critical areas where quality and reliability are non-negotiable. Strategic sourcing not only ensures access to high-quality parts but also fosters long-term relationships with suppliers who understand the unique demands of different markets, particularly in regions like Africa, South America, the Middle East, and Europe.

By leveraging data-driven insights and establishing robust procurement processes, businesses can mitigate risks associated with supply chain disruptions and fluctuating costs. It is essential to prioritize partnerships with manufacturers that emphasize innovation, sustainability, and adherence to international standards.

Looking ahead, the automotive industry is poised for transformation, driven by advancements in technology and increasing consumer expectations. Buyers should remain proactive in exploring emerging trends, such as electric vehicles and smart technologies, to stay competitive. Engage with suppliers who are not only capable of meeting current demands but are also aligned with future industry shifts. Taking these steps will position your business for sustained success in the dynamic automotive parts market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to various parts of a car

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.