Introduction: Navigating the Global Market for parts for alternator

In the fast-evolving landscape of global commerce, sourcing high-quality parts for alternators can pose significant challenges for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, navigating the complexities of supplier selection, product authenticity, and logistical considerations is crucial. This guide aims to demystify the market for alternator parts by providing comprehensive insights into various components, their applications across industries, and effective supplier vetting strategies.

From essential components like diodes and voltage regulators to advanced parts such as droop kits and rectifier assemblies, our guide covers a wide spectrum of options tailored to meet the diverse needs of your operations. We delve into cost analysis, helping you understand pricing structures and potential savings, while also emphasizing the importance of quality assurance to ensure long-term reliability of your equipment.

Empowering informed purchasing decisions, this resource equips B2B buyers with the knowledge needed to optimize their supply chain and enhance operational efficiency. By leveraging expert insights and actionable strategies, you can confidently navigate the global market for alternator parts, ensuring your business remains competitive and responsive to ever-changing demands.

Table Of Contents

- Top 4 Parts For Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts for alternator

- Understanding parts for alternator Types and Variations

- Key Industrial Applications of parts for alternator

- 3 Common User Pain Points for ‘parts for alternator’ & Their Solutions

- Strategic Material Selection Guide for parts for alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for parts for alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts for alternator’

- Comprehensive Cost and Pricing Analysis for parts for alternator Sourcing

- Alternatives Analysis: Comparing parts for alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for parts for alternator

- Navigating Market Dynamics and Sourcing Trends in the parts for alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts for alternator

- Strategic Sourcing Conclusion and Outlook for parts for alternator

- Important Disclaimer & Terms of Use

Understanding parts for alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stators | Stationary part of the alternator; generates AC power | Power generation, industrial machinery, generators | Pros: High durability; Cons: Requires careful installation |

| Rotors | Rotating part that creates magnetic field | Automotive, heavy machinery, marine applications | Pros: Efficient power generation; Cons: Can be costly to replace |

| Voltage Regulators | Maintains output voltage within specified limits | Electrical systems in vehicles, generators | Pros: Protects equipment from overload; Cons: May require calibration |

| Diodes & Rectifiers | Converts AC to DC; protects against voltage spikes | Electrical systems, backup power supplies | Pros: Enhances reliability; Cons: Sensitive to heat and overload |

| Bearing Kits | Reduces friction between moving parts | Generator maintenance, automotive applications | Pros: Increases lifespan of alternators; Cons: Installation can be complex |

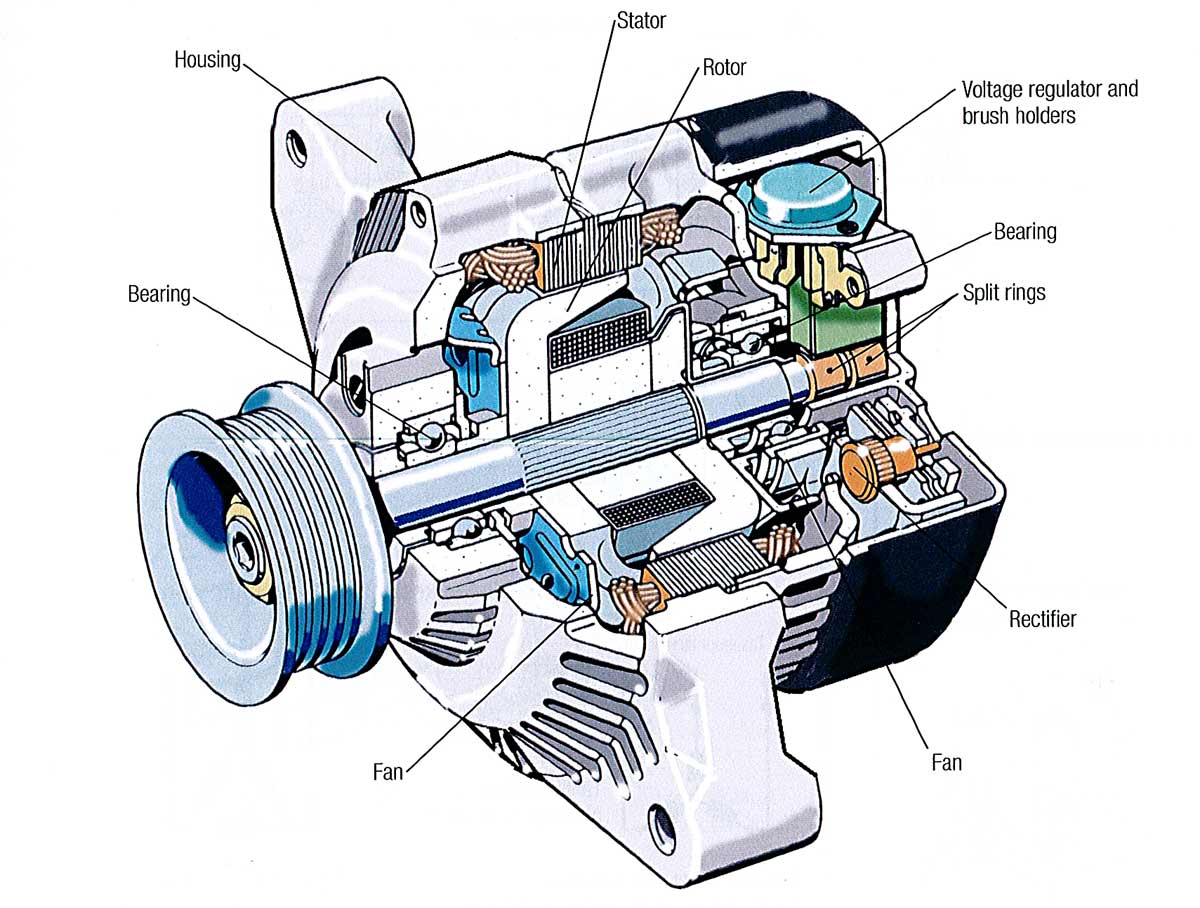

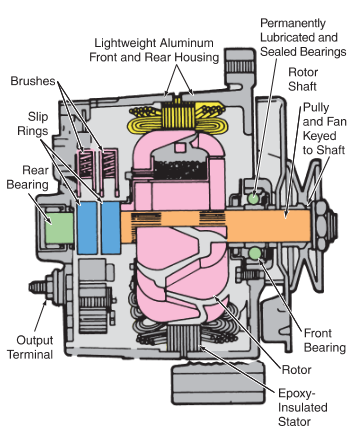

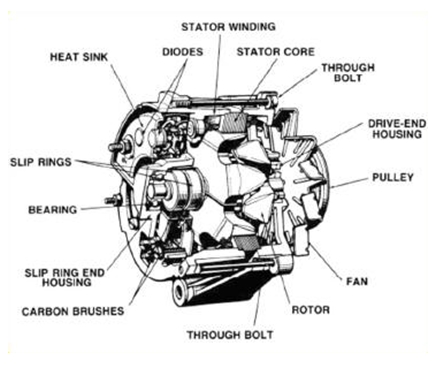

What are Stators and Why are They Essential in Alternators?

Stators are crucial components of alternators, acting as the stationary core that generates alternating current (AC) power through electromagnetic induction. They are widely used in power generation applications, including industrial machinery and generators. When purchasing stators, B2B buyers should consider factors such as compatibility with existing systems, material quality for durability, and the manufacturer’s reputation for reliability. High-quality stators can significantly enhance the efficiency and longevity of power generation systems.

How Do Rotors Function in Alternators?

Rotors are the rotating elements within alternators that create a magnetic field necessary for electricity generation. Commonly found in automotive and heavy machinery applications, rotors contribute to efficient power conversion. B2B buyers should focus on compatibility with specific alternator models, as well as the rotor’s construction materials and design. While high-performance rotors can be more expensive, they often yield better energy efficiency and reliability, making them a worthwhile investment for businesses reliant on consistent power supply.

What Role Do Voltage Regulators Play in Alternator Systems?

Voltage regulators are integral to maintaining stable output voltage in alternator systems, ensuring that connected equipment operates within safe parameters. They are particularly important in automotive and generator applications. When sourcing voltage regulators, buyers should evaluate the specifications for voltage range and load capacity, as well as the ease of installation and maintenance. While voltage regulators can add to the initial cost, their ability to protect sensitive equipment from overloads justifies the investment.

Why are Diodes and Rectifiers Critical for Alternator Performance?

Diodes and rectifiers are essential components in alternators that convert AC to direct current (DC) and protect the system from voltage spikes. They find applications in various electrical systems, including backup power supplies. For B2B buyers, it’s crucial to assess the thermal management of these components, as they can be sensitive to heat and electrical overload. Investing in high-quality diodes and rectifiers can greatly improve the reliability and safety of electrical systems.

How Do Bearing Kits Enhance Alternator Longevity?

Bearing kits play a pivotal role in reducing friction between moving parts within alternators, which is vital for smooth operation and longevity. These kits are commonly used in generator maintenance and automotive applications. Buyers should consider the compatibility of bearing kits with their existing alternator models, as well as the quality of materials used in construction. While installation can be complex, the benefits of increased lifespan and reduced maintenance costs make bearing kits a valuable addition to any alternator system.

Key Industrial Applications of parts for alternator

| Industry/Sector | Specific Application of parts for alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Replacement parts for generators in remote locations | Ensures reliability and uptime of power supply | Availability of OEM parts, quick shipping times, and technical support |

| Transportation & Logistics | Alternator components for commercial trucks and fleets | Reduces downtime and maintenance costs, enhancing fleet efficiency | Compatibility with various vehicle models and compliance with local regulations |

| Agriculture | Parts for alternators in agricultural machinery | Improves operational efficiency and reduces equipment failure | Quality assurance and performance standards for harsh environments |

| Marine & Offshore | Alternator parts for marine generators | Guarantees reliable power for navigation and onboard systems | Resistance to corrosion and reliability under extreme conditions |

| Emergency Services | Components for alternators in emergency backup systems | Critical for maintaining power during outages | Rapid availability of parts and support for urgent repairs |

How Are Parts for Alternators Used in Power Generation?

In the power generation sector, alternator parts are essential for maintaining and repairing generators, particularly in remote locations where reliable electricity is crucial. Components like stators, rotors, and voltage regulators are frequently replaced to ensure the generators operate efficiently, minimizing downtime. Buyers in regions such as Africa and South America should prioritize sourcing OEM parts to guarantee compatibility and performance under varying environmental conditions, ensuring that power supply remains uninterrupted.

What Role Do Alternator Parts Play in Transportation & Logistics?

For the transportation and logistics industry, alternator parts are vital for the performance of commercial trucks and fleet vehicles. Components such as voltage regulators and rectifiers are essential for ensuring that these vehicles maintain optimal power levels, reducing the risk of breakdowns. Buyers must consider sourcing high-quality parts that comply with local regulations and are compatible with a wide range of vehicle models, particularly in regions like Brazil and the Middle East, where vehicle diversity is significant.

How Do Alternator Parts Enhance Agricultural Operations?

In agriculture, alternator parts are crucial for the functionality of machinery such as tractors and harvesters. Reliable alternators ensure that these machines operate efficiently, reducing the risk of equipment failure during critical periods like planting and harvesting. Buyers should focus on sourcing durable parts that can withstand harsh working conditions, emphasizing the importance of quality assurance and performance standards to enhance productivity in agricultural operations across various regions.

Why Are Alternator Parts Important in Marine & Offshore Applications?

In marine and offshore industries, alternator parts are critical for ensuring that generators provide reliable power for navigation and onboard systems. Components must be resistant to corrosion and capable of functioning in extreme conditions. Buyers in this sector should prioritize sourcing parts that meet stringent marine standards, ensuring reliability during operations at sea, particularly in regions like the Middle East where marine activities are prevalent.

How Do Parts for Alternators Support Emergency Services?

For emergency services, alternator components are crucial in backup power systems that ensure operations continue during outages. Reliable alternator parts like diodes and voltage regulators help maintain power to critical equipment in ambulances and fire trucks. Buyers should seek suppliers who can provide rapid availability of parts and expert support for urgent repairs, ensuring that emergency services can respond effectively to crises, especially in regions prone to power disruptions.

3 Common User Pain Points for ‘parts for alternator’ & Their Solutions

Scenario 1: Difficulty in Sourcing Authentic Alternator Parts

The Problem: B2B buyers often struggle with the authenticity and quality of alternator parts. In regions like Africa and South America, where counterfeit parts are rampant, the risk of sourcing subpar components can lead to equipment failure, increased downtime, and financial losses. Buyers may find themselves overwhelmed by the sheer volume of suppliers and the difficulty in verifying the legitimacy of the parts they are purchasing.

The Solution: To effectively source authentic alternator parts, it is crucial to partner with reputable suppliers who have a proven track record in the industry. Conduct thorough research by checking for certifications, customer reviews, and testimonials. When reaching out to potential suppliers, inquire about their quality control measures and whether they offer warranties on their products. Additionally, leveraging technology, such as supplier rating platforms or industry forums, can help buyers identify trusted vendors. For instance, suppliers like General Power have a long-standing reputation and provide genuine parts tested for reliability. Establishing a long-term relationship with a trusted supplier can not only ensure quality but also streamline the procurement process.

Scenario 2: Managing Inventory for Alternator Parts

The Problem: Another common challenge is managing inventory effectively. B2B buyers often face the dilemma of overstocking, which ties up capital, or understocking, which can lead to project delays and customer dissatisfaction. This issue is exacerbated in regions with erratic supply chains, where the availability of parts may fluctuate due to economic or logistical challenges.

The Solution: Implementing an inventory management system tailored to alternator parts can significantly alleviate this pain point. Buyers should adopt a just-in-time (JIT) inventory strategy, which minimizes excess stock while ensuring that critical components are available when needed. This can be facilitated by utilizing software that tracks usage rates, forecasts demand based on historical data, and alerts buyers when stock levels fall below a predetermined threshold. Additionally, establishing strategic partnerships with suppliers for consignment stock can provide a buffer, allowing businesses to maintain essential inventory without the financial burden of ownership until the parts are used. Regularly reviewing and adjusting inventory practices based on changing market conditions can further enhance efficiency.

Scenario 3: Lack of Technical Support and Guidance

The Problem: Many B2B buyers encounter difficulties when it comes to the technical aspects of alternator parts, such as installation, compatibility, and maintenance. This is particularly true for businesses that lack in-house expertise or operate in regions where technical support is limited. The consequence of this knowledge gap can be incorrect installations or suboptimal performance, leading to increased operational costs and equipment failures.

The Solution: To overcome this challenge, buyers should prioritize suppliers who offer comprehensive technical support alongside their products. This can include detailed product specifications, installation guides, and access to customer service representatives with technical expertise. Engaging with suppliers that provide training sessions or workshops can also empower teams with the knowledge needed to handle alternator parts effectively. Furthermore, creating a network with other businesses in the industry can foster knowledge sharing and best practices. Utilizing online resources, such as instructional videos or forums, can also serve as valuable tools for troubleshooting and enhancing product understanding. By ensuring that technical support is readily available, buyers can improve the reliability and performance of their alternator systems, ultimately leading to better operational outcomes.

Strategic Material Selection Guide for parts for alternator

What Are the Key Materials Used in Alternator Parts?

When selecting materials for alternator parts, it is crucial to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of alternator components, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Copper Influence Alternator Performance?

Copper is widely used in alternator windings and connectors due to its excellent electrical conductivity and thermal properties. It can withstand high temperatures, making it suitable for applications that require efficient energy transfer.

Pros: Copper’s high conductivity ensures minimal energy loss, enhancing the overall efficiency of the alternator. It is also relatively easy to work with, allowing for complex designs and configurations.

Cons: The primary drawback of copper is its susceptibility to corrosion, particularly in humid or saline environments, which can be a concern for buyers in coastal regions. Additionally, copper is more expensive than some alternatives, which can impact overall production costs.

Impact on Application: Copper’s superior conductivity makes it ideal for high-performance alternators, especially in heavy-duty applications like mining and industrial machinery.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local corrosion risks and may need to consider protective coatings. Compliance with international standards such as ASTM B170 is also essential for quality assurance.

What Role Does Aluminum Play in Alternator Manufacturing?

Aluminum is another common material used in alternator parts, particularly in housings and casings. Its lightweight nature and good thermal conductivity make it a popular choice for manufacturers.

Pros: Aluminum is resistant to corrosion, especially when anodized, which extends the lifespan of alternator components. Its lightweight properties can lead to reduced overall weight in applications, improving fuel efficiency in vehicles.

Cons: While aluminum is less expensive than copper, it has lower electrical conductivity, which can affect performance in high-load applications. Additionally, aluminum can be more challenging to machine, which may increase manufacturing complexity.

Impact on Application: Aluminum is suitable for applications where weight reduction is critical, such as in automotive alternators.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local and international standards, such as DIN EN 573, to ensure quality and compatibility.

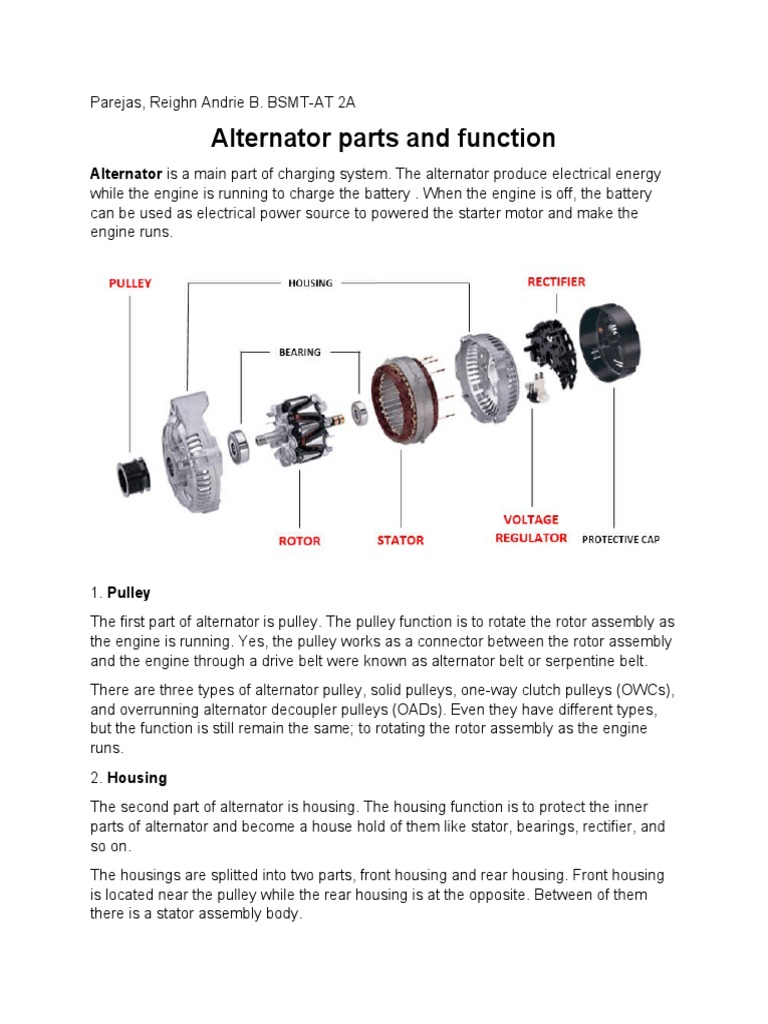

Illustrative image related to parts for alternator

Why Is Steel Important for Structural Integrity in Alternators?

Steel is often used in the structural components of alternators, such as frames and brackets, due to its strength and durability.

Pros: Steel provides excellent mechanical strength and can withstand significant stress and strain, making it ideal for heavy-duty applications. It is also relatively cost-effective compared to other materials.

Cons: Steel is prone to rust and corrosion if not properly treated, which can be a significant concern in humid or coastal environments. Additionally, its weight can be a disadvantage in applications where weight savings are important.

Impact on Application: Steel is particularly well-suited for stationary alternators used in industrial settings where durability is paramount.

Considerations for International Buyers: Buyers should consider the need for protective coatings or galvanization to prevent rust, especially in regions like the Middle East and Africa, where humidity can be high.

How Do Plastics Enhance Alternator Component Design?

Plastics, particularly engineered thermoplastics, are increasingly used in alternator components such as insulators and housings due to their versatility and lightweight properties.

Pros: Plastics are resistant to corrosion and can be molded into complex shapes, allowing for innovative designs. They are also lightweight, which can contribute to overall efficiency.

Cons: Plastics typically have lower thermal and electrical conductivity compared to metals, which may limit their use in high-performance applications. Additionally, they can be less durable under extreme conditions.

Impact on Application: Plastics are suitable for non-load-bearing components where weight reduction and corrosion resistance are priorities.

Considerations for International Buyers: Buyers should verify that plastic components comply with relevant standards like ISO 9001 to ensure quality and performance.

Summary Table of Material Selection for Alternator Parts

| Material | Typical Use Case for parts for alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings and connectors | Excellent electrical conductivity | Susceptible to corrosion | High |

| Aluminum | Housings and casings | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Structural components | High strength and durability | Prone to rust without treatment | Low |

| Plastics | Insulators and non-load-bearing parts | Corrosion-resistant and versatile | Lower thermal/electrical conductivity | Low |

In conclusion, understanding the properties and implications of these materials is essential for B2B buyers in selecting the right alternator parts for their specific applications. By considering these factors, businesses can enhance performance, durability, and compliance with international standards, ultimately leading to more efficient operations.

In-depth Look: Manufacturing Processes and Quality Assurance for parts for alternator

What Are the Key Stages in the Manufacturing Process for Alternator Parts?

Manufacturing alternator parts involves a series of critical stages to ensure high-quality components that meet rigorous performance standards. The main stages of production typically include material preparation, forming, assembly, and finishing.

Material Preparation: Selecting the Right Materials

The manufacturing process begins with the selection of high-grade materials. Commonly used materials for alternator parts include copper for windings, high-carbon steel for rotors and stators, and durable plastics for housings. Suppliers often source materials that comply with international standards to ensure reliability and longevity.

Once the materials are selected, they undergo a thorough inspection to confirm that they meet specified quality criteria. This initial quality control (IQC) step is crucial for preventing defects that could affect the performance of the alternator parts.

How Are Parts Formed in the Production Process?

The next phase is forming, which involves shaping the materials into the desired components. This can include processes such as stamping, casting, or machining.

- Stamping: High-speed presses are used to create components like housings and brackets from flat metal sheets.

- Casting: For complex shapes, metal alloys are poured into molds to create rotors and stators.

- Machining: Precision machining processes, such as CNC (Computer Numerical Control) milling, ensure that parts meet exact specifications and tolerances.

Quality during this stage is paramount, and manufacturers often employ in-process quality control (IPQC) measures to monitor the forming processes.

Illustrative image related to parts for alternator

What Does the Assembly Stage Entail?

After individual components are formed, they move to the assembly stage. This is where various parts, such as stators, rotors, and voltage regulators, are brought together to create complete alternator units.

Assembly can be performed manually or through automated systems, depending on the volume and complexity of the parts. Manufacturers often implement standardized assembly procedures to ensure consistency and reduce the risk of errors.

What Are the Finishing Techniques Used in Alternator Parts Manufacturing?

The finishing stage involves applying protective coatings, conducting surface treatments, and performing final inspections. Common finishing processes include:

Illustrative image related to parts for alternator

- Painting or Powder Coating: To prevent corrosion and enhance aesthetics, parts are coated with protective finishes.

- Surface Treatments: Processes like anodizing or galvanizing enhance durability and resistance to wear.

- Final Inspections: Each assembled unit undergoes rigorous testing to verify functionality and performance.

This stage is critical for ensuring that the alternator parts can withstand operational stresses and environmental factors.

What Quality Assurance Standards Are Relevant for Alternator Parts?

Quality assurance (QA) is essential in the manufacturing of alternator parts, as it ensures that products meet the required standards for performance and safety. Several international and industry-specific standards are relevant.

Which International Standards Should B2B Buyers Look For?

ISO 9001 is one of the most recognized international standards for quality management systems. It provides a framework for manufacturers to ensure consistent quality in their products and services. Compliance with ISO 9001 indicates that a manufacturer follows best practices in quality management.

In addition to ISO standards, other certifications such as CE marking (indicating compliance with European safety standards) and API (American Petroleum Institute) certifications are essential for specific applications.

Illustrative image related to parts for alternator

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. The main checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials and components before production begins.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects early.

- Final Quality Control (FQC): Conducts comprehensive testing of finished products to ensure they meet specifications.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers utilize various testing methods to validate the quality of alternator parts:

- Electrical Testing: Verifies the functionality of components like voltage regulators and diodes.

- Mechanical Testing: Assesses strength and durability through stress tests and fatigue testing.

- Environmental Testing: Simulates real-world conditions to ensure components can withstand temperature variations and humidity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying supplier quality control practices is crucial for ensuring the reliability of alternator parts. Here are actionable steps to consider:

- Conduct Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures.

- Request Quality Reports: Suppliers should be willing to share their quality assurance documentation, including test results and compliance certifications.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes and product reliability.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Factors to consider include:

- Local Regulations: Familiarize yourself with local and international regulations that may affect product quality and safety.

- Cultural Differences: Understand that quality expectations may vary by region; ensure that your suppliers are aligned with your standards.

- Language Barriers: Clear communication is vital. Ensure that all documentation is available in a language that all stakeholders can understand.

By understanding the manufacturing processes and quality assurance protocols involved in alternator parts production, B2B buyers can make informed decisions, ensuring they partner with suppliers who meet their stringent quality requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts for alternator’

In the global marketplace, sourcing parts for alternators requires a strategic approach to ensure quality, compatibility, and reliability. This guide serves as a practical checklist to help B2B buyers navigate the procurement process efficiently.

Illustrative image related to parts for alternator

Step 1: Define Your Technical Specifications

Understanding your specific needs is crucial before reaching out to suppliers. Determine the type of alternator parts required, including components like stators, rotors, voltage regulators, and diodes. This clarity will help streamline your search and ensure that you procure parts that are compatible with your existing systems.

Step 2: Research Potential Suppliers

Take the time to investigate various suppliers who specialize in alternator parts. Look for companies with a strong reputation, ideally those with certifications such as ISO or those recognized as OEMs (Original Equipment Manufacturers). Consider their geographical presence, especially if you are sourcing from regions like Africa, South America, or the Middle East, as local suppliers may offer quicker shipping and support.

Step 3: Evaluate Supplier Certifications and Quality Standards

Before making a purchase, verify that suppliers adhere to stringent quality control measures. Request documentation that confirms compliance with industry standards, such as ISO 9001. This step is vital to ensure that the parts you receive are reliable and will perform effectively in your applications.

Step 4: Request Product Samples

Whenever possible, ask for samples of the alternator parts you intend to purchase. This allows you to assess the quality firsthand and check for compatibility with your existing systems. Inspect the materials used, the craftsmanship, and any certifications that accompany the samples to ensure they meet your requirements.

Illustrative image related to parts for alternator

Step 5: Compare Pricing and Terms of Sale

Once you have a shortlist of potential suppliers, compare their pricing structures and terms of sale. Look for transparency in pricing, including shipping costs, bulk order discounts, and payment terms. A competitive price is important, but ensure that it does not compromise quality or service.

Step 6: Assess Customer Support and After-Sales Service

Strong customer support can significantly impact your purchasing experience. Evaluate the responsiveness of suppliers to inquiries and their willingness to provide technical support. A supplier that offers robust after-sales service can help address any issues that arise post-purchase, ensuring long-term satisfaction.

Step 7: Establish Long-Term Relationships

Building a lasting relationship with your suppliers can lead to better terms, priority service, and exclusive access to new products. Engage with your suppliers regularly and provide feedback on their products and services. This partnership approach can enhance your supply chain efficiency and reliability over time.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing alternator parts, ensuring they procure high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for parts for alternator Sourcing

What Are the Key Cost Components for Alternator Parts Sourcing?

When sourcing alternator parts, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The cost of raw materials, such as copper for windings or aluminum for casings, significantly influences the overall price. Prices can fluctuate based on global demand and supply chain conditions.

-

Labor: Labor costs vary by region and are influenced by local wage standards. Skilled labor is often required for assembly and quality control, impacting the final pricing of the components.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help lower these costs.

-

Tooling: Specialized tools and molds necessary for producing alternator parts can require substantial upfront investment. This cost is often amortized over large production runs, affecting pricing.

-

Quality Control (QC): Ensuring that parts meet rigorous quality standards incurs costs related to testing and inspection processes. High-quality certifications can justify higher prices but also provide reliability for the buyer.

-

Logistics: Transportation, warehousing, and handling costs are crucial, especially for international shipments. Incoterms play a vital role in determining which party bears these costs.

-

Margin: Supplier markups vary depending on competition and market conditions. Established suppliers may have higher margins due to their brand reputation and reliability.

How Do Price Influencers Affect Alternator Parts Costs?

Several factors can significantly influence the pricing of alternator parts:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, as suppliers can optimize production and shipping costs. Understanding the MOQ can help in negotiating better deals.

-

Specifications and Customization: Custom components tailored to specific applications may incur higher costs. Buyers should balance the need for customization with the potential for increased pricing.

-

Material Quality and Certifications: Higher quality materials and certifications may result in elevated costs but can reduce the risk of failures and long-term maintenance expenses.

-

Supplier Factors: The reputation, reliability, and geographic location of the supplier can impact pricing. Suppliers in regions with lower labor costs may offer more competitive pricing.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is essential for managing shipping costs and risks associated with international transactions.

What Are the Best Buyer Tips for Cost Efficiency in Alternator Parts Sourcing?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, the following strategies can enhance cost efficiency:

Illustrative image related to parts for alternator

-

Negotiate Effectively: Leverage volume commitments or long-term contracts to negotiate better pricing. Establishing a strong relationship with suppliers can also lead to favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with quality, reliability, and maintenance. Higher upfront costs may lead to savings over time.

-

Explore Multiple Suppliers: Comparing offers from various suppliers can reveal competitive pricing and highlight different service levels. This can also provide leverage during negotiations.

-

Stay Informed on Market Trends: Understanding fluctuations in material costs and supplier dynamics can help buyers make timely purchases, avoiding price spikes.

-

Plan for Logistics: Be aware of shipping costs and lead times. Consolidating shipments or using local suppliers can reduce logistics expenses.

Conclusion

Understanding the comprehensive cost structure and pricing influencers for alternator parts is vital for making strategic sourcing decisions. By considering cost components, leveraging negotiation tactics, and focusing on total cost of ownership, buyers can enhance their purchasing efficiency and ensure they receive quality components that meet their operational needs. Buyers should also remain aware of the pricing nuances specific to their regions and market conditions to make informed decisions.

Disclaimer: Prices are indicative and may vary based on market conditions, supplier negotiations, and specific requirements. Always consult with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing parts for alternator With Other Solutions

Exploring Alternatives to Parts for Alternators in Power Generation

In the field of power generation, alternators are critical components responsible for converting mechanical energy into electrical energy. While sourcing parts for alternators remains a common solution for maintenance and repair, alternative technologies and methods exist that can provide similar functionalities or enhance system performance. Understanding these options allows B2B buyers to make informed decisions based on their specific operational needs.

| Comparison Aspect | Parts For Alternator | Alternative 1: Integrated Generator Systems | Alternative 2: Battery Storage Solutions |

|---|---|---|---|

| Performance | High reliability and efficiency; OEM parts ensure compatibility and performance. | Offers higher efficiency with integrated systems designed for specific applications. | Provides stable power supply; can reduce reliance on generators. |

| Cost | Initial investment can be high, depending on the part and brand; ongoing maintenance costs. | Higher upfront costs due to advanced technology, but potential long-term savings on fuel and maintenance. | Initial investment varies; costs can be offset by savings on fuel and maintenance in the long run. |

| Ease of Implementation | Straightforward installation for experienced technicians; requires specific parts knowledge. | May require specialized installation and training; simpler for new systems designed around integration. | Installation can be complex; requires proper integration with existing systems. |

| Maintenance | Regular maintenance necessary; OEM parts ensure reliability but require sourcing. | Lower maintenance due to fewer moving parts; however, complex systems may require specialized technicians. | Requires regular monitoring and maintenance; battery lifespan can be an issue. |

| Best Use Case | Ideal for existing generators needing parts replacement or upgrades; suitable for diverse applications. | Best for new installations or upgrades focused on efficiency and reduced emissions. | Suitable for operations focused on sustainability and energy independence; effective in conjunction with renewable energy sources. |

What Are the Benefits and Drawbacks of Integrated Generator Systems?

Integrated generator systems combine generator and alternator functions into a single unit, offering a streamlined solution for power generation. These systems can be more efficient than traditional setups, reducing energy loss during conversion. However, they often come with higher initial costs and may require specialized knowledge for installation and maintenance. They are particularly beneficial for new projects where efficiency and compact design are prioritized.

How Do Battery Storage Solutions Compare to Parts for Alternators?

Battery storage solutions represent a modern approach to energy management, allowing businesses to store excess energy generated during peak production times for use during high demand or outages. This technology can significantly reduce reliance on traditional alternator systems, promoting sustainability and potentially lowering operational costs. However, they require a substantial upfront investment and regular maintenance to ensure longevity. Proper integration with existing systems can also present challenges.

Making the Right Choice: How Should B2B Buyers Decide?

When evaluating options for alternator parts versus alternative technologies, B2B buyers should consider factors such as operational requirements, budget constraints, and long-term goals. For businesses with existing infrastructure, sourcing high-quality parts for alternators may be the most practical solution. Conversely, companies looking to innovate or expand their energy solutions might benefit from investing in integrated systems or battery storage solutions. Assessing both immediate needs and future growth potential will help buyers choose the most suitable option for their specific context.

Essential Technical Properties and Trade Terminology for parts for alternator

What Are the Key Technical Properties of Alternator Parts?

When sourcing alternator parts, understanding critical technical specifications is essential for ensuring compatibility and performance. Here are some key properties to consider:

-

Material Grade

Alternator components are typically made from high-grade materials such as aluminum or copper. Material grade affects conductivity, durability, and resistance to corrosion. Choosing the right material is vital for long-term reliability, particularly in harsh environments common in industries such as mining or marine operations. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In alternator parts, precise tolerances are crucial for ensuring that components fit together correctly. For example, bearings must have specific tolerances to minimize friction and wear. Inaccurate tolerances can lead to equipment failure, impacting productivity and increasing maintenance costs. -

Voltage Rating

Alternator parts are designed to operate at specific voltage levels, commonly 12V or 24V. Understanding the voltage rating is essential for ensuring that the components can handle the electrical demands of the system without overheating or failing. This is particularly important in heavy-duty applications, where power requirements can fluctuate significantly. -

Amperage Capacity

This specification indicates the maximum electrical current a component can handle. For instance, rotors and stators are rated for specific amperages, which must align with the overall system requirements. Choosing parts with inadequate amperage capacity can lead to overheating and potential damage, leading to costly downtimes. -

Insulation Class

Insulation class is a measure of the thermal endurance of the insulating materials used in alternator components. Common classes include A, B, F, and H, with higher classes indicating better resistance to heat. Selecting parts with the appropriate insulation class is critical for ensuring safe and efficient operation, especially in applications subject to extreme temperatures.

Which Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some common trade terms relevant to alternator parts:

Illustrative image related to parts for alternator

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in the original assembly of a product. For alternator parts, OEM components are typically synonymous with quality and compatibility. Buyers often prefer OEM parts to ensure that replacements maintain the original performance standards. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it can influence purchasing decisions and inventory management. Suppliers often set MOQs to ensure that production and shipping costs are covered. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting a price quote from suppliers. It typically includes specifications, quantities, and delivery requirements. This process allows buyers to compare pricing and terms from multiple suppliers, helping them make informed purchasing decisions. -

Incoterms

Short for International Commercial Terms, Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping costs, insurance, and risk during transportation. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings regarding shipping and logistics. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times helps buyers plan their inventory and production schedules effectively. Factors such as manufacturing capacity, shipping methods, and supplier location can all influence lead times. -

Certification

This term refers to the validation that a product meets specific standards or regulations. For alternator parts, certifications can include ISO standards or industry-specific qualifications. Verified certification ensures that the components are manufactured to high-quality standards, which is crucial for maintaining operational efficiency and safety.

Understanding these technical properties and trade terms can significantly enhance decision-making for B2B buyers in the alternator parts market, ensuring they select the right components for their applications.

Navigating Market Dynamics and Sourcing Trends in the parts for alternator Sector

What Are the Key Market Drivers and Trends in the Parts for Alternator Sector?

The global market for alternator parts is significantly influenced by the increasing demand for reliable power generation solutions across various sectors, including industrial, commercial, and residential applications. Key drivers include the growing reliance on backup power systems, especially in regions prone to power outages, such as parts of Africa and South America. Furthermore, advancements in technology have led to the development of more efficient and durable alternator components, enhancing their appeal to international B2B buyers.

Emerging trends in sourcing include the integration of digital platforms that facilitate easier procurement processes. Buyers are increasingly utilizing online marketplaces and vendor management systems to streamline their sourcing activities. The rise of data analytics tools also allows businesses to better forecast demand and manage inventory, optimizing their supply chains. Additionally, partnerships with local distributors in target markets, such as Brazil and Saudi Arabia, have become crucial for ensuring timely delivery and support, particularly for OEM parts.

The competitive landscape is evolving, with suppliers focusing on improving customer service and product availability. Companies that offer a comprehensive inventory of essential and specialty alternator parts, along with rapid shipping options, are positioning themselves favorably in the market. As B2B buyers prioritize quality and reliability, the emphasis on sourcing authentic parts from recognized manufacturers is more pronounced than ever.

How Is Sustainability Shaping the Sourcing of Alternator Parts in B2B Markets?

Sustainability is becoming a pivotal consideration for B2B buyers in the alternator parts sector. The environmental impact of manufacturing and sourcing practices is under scrutiny, prompting businesses to seek suppliers who prioritize eco-friendly materials and processes. This shift is particularly relevant in regions like Europe, where regulatory standards are stringent, and consumers are increasingly conscious of sustainability issues.

Ethical sourcing is gaining traction as companies recognize the importance of transparent supply chains. Buyers are now looking for suppliers that can demonstrate compliance with environmental regulations and social responsibility standards. This includes certifications for sustainable practices, such as ISO 14001 for environmental management systems, and adherence to fair labor practices in manufacturing facilities.

Moreover, the demand for ‘green’ alternator parts is rising, with a focus on components made from recycled materials or those designed for energy efficiency. By prioritizing sustainability, B2B buyers not only reduce their environmental footprint but also enhance their brand reputation, appealing to eco-conscious customers and stakeholders.

What Is the Historical Context of Alternator Parts Sourcing in B2B Markets?

The alternator parts sector has evolved significantly over the past few decades, transitioning from a predominantly local sourcing landscape to a global marketplace. Initially, manufacturers relied on regional suppliers for components, which limited options and led to higher costs. However, as globalization took hold, the availability of international suppliers expanded, allowing for more competitive pricing and a broader selection of quality parts.

In the early 2000s, the rise of digital technology revolutionized the way businesses approached sourcing. Online platforms enabled buyers to connect with manufacturers and distributors worldwide, fostering competition and innovation. This shift not only improved access to genuine parts but also enhanced the ability to track and manage supply chains effectively.

Today, the focus is not only on sourcing efficiency but also on the integration of advanced technologies, such as IoT and AI, which are transforming maintenance and operational practices in the alternator industry. As the market continues to evolve, B2B buyers must stay informed about these historical shifts to better navigate current dynamics and make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of parts for alternator

-

How do I solve issues with my alternator not charging?

To address charging issues with your alternator, first check the voltage regulator and ensure it is functioning correctly, as it controls the output voltage. Inspect the battery connections for corrosion or loose terminals, which can impede electrical flow. If the alternator belt is worn or loose, replace it to ensure optimal performance. Additionally, consider testing the alternator itself for faults. If these steps do not resolve the issue, sourcing quality replacement parts, such as diodes or voltage regulators, from a reputable supplier can ensure reliable operation. -

What is the best alternator part for enhancing generator performance?

The best alternator part for enhancing generator performance often depends on the specific generator model and its operational requirements. For many applications, upgrading to high-quality voltage regulators can significantly improve efficiency by managing the power output effectively. Additionally, investing in robust diodes and rectifier assemblies can help protect against voltage spikes, ensuring system stability. Consulting with an experienced supplier can help identify the right components tailored to your generator’s needs, thereby optimizing its overall performance. -

How can I ensure the quality of alternator parts when sourcing internationally?

To ensure the quality of alternator parts sourced internationally, start by verifying the supplier’s certifications and industry experience. Look for manufacturers that adhere to international quality standards, such as ISO certifications. Request product samples or detailed specifications before placing large orders. Additionally, consider suppliers who provide warranties and guarantees on their products, as this reflects their confidence in quality. Engaging in thorough communication about quality assurance processes can also help establish a reliable partnership. -

What are the minimum order quantities (MOQs) for alternator parts?

Minimum order quantities (MOQs) for alternator parts can vary significantly depending on the supplier and the specific components you need. Generally, MOQs can range from a few units for common parts to several hundred for specialized or custom components. It’s essential to discuss MOQs with potential suppliers before placing an order, as some may offer flexibility for first-time buyers or bulk purchases. Understanding these terms can help you manage inventory costs and ensure you have the necessary parts on hand. -

What payment terms should I expect when purchasing alternator parts?

Payment terms for purchasing alternator parts can differ based on the supplier and the buyer’s relationship. Common terms include upfront payment, partial payments, or net 30/60 days after delivery. Some suppliers may offer discounts for early payments or bulk orders. It is advisable to negotiate terms that align with your financial strategy while ensuring the supplier’s terms are reasonable. Always confirm payment methods accepted, such as wire transfers, credit cards, or letters of credit, especially for international transactions. -

How do I vet a supplier for alternator parts in my region?

To vet a supplier for alternator parts, start by researching their reputation in the industry through reviews and testimonials from other B2B buyers. Check their experience in international trade and their ability to meet local regulations in your region. Request references from past clients and inquire about their supply chain practices. Additionally, consider visiting their facility if possible, or engaging in virtual meetings to assess their operational capabilities and customer service responsiveness. -

What logistics considerations should I keep in mind when importing alternator parts?

When importing alternator parts, logistics considerations include understanding shipping options, lead times, and customs regulations in your country. Choose a reliable freight forwarder who can navigate international shipping complexities and provide tracking information. Be aware of potential tariffs and taxes that may apply to your imports, as these can affect overall costs. Establishing clear communication with your supplier regarding delivery schedules and packaging standards can also help prevent delays and ensure the safe arrival of your parts. -

Can I customize alternator parts for my specific needs?

Yes, many suppliers offer customization options for alternator parts to meet specific operational requirements. This may include modifying existing parts or creating entirely new components based on your specifications. When considering customization, it’s crucial to communicate your needs clearly and discuss feasibility with the supplier. Be prepared to provide detailed technical drawings or specifications, as well as minimum order quantities, as custom parts often require a more significant investment in terms of time and resources.

Top 4 Parts For Alternator Manufacturers & Suppliers List

1. Chevrolet Performa – Alternators & Accessories

Domain: proformparts.com

Registered: 1997 (28 years)

Introduction: {“category”:”Alternators & Accessories”,”product_types”:[“Alternator”,”Alternator Bracket”,”Alternator Mount Kit”,”Alternator Mounting Spacer”,”Alternator Pulley”],”amperage_outputs”:[“160 AMP”,”140 AMP”,”120 AMP”,”110 AMP”,”100 AMP”,”80 AMP”,”70 AMP”,”60 AMP”,”50 AMP”],”brands”:[“Chevrolet Performance”,”MOPAR”,”Proform Engine”,”Chrysler Big Block”,”Chrysler Small Block”,”Chevy SB Gen 1″,”Chevy SB…

2. Bosch – OEM Voltage Regulators

Domain: alternatorbrush.com

Registered: 2017 (8 years)

Introduction: Alternator Starter Parts Kits Repair Replace Rebuild Options. Key products include: 1. OEM Bosch Voltage Regulator F00M144152 – $59.00 2. Voltage Regulator with Brushes OEM Bosch Brand 1986AE0046 – $64.98 3. OEM Bosch Alternator Voltage Regulator for Mercedes 0121715006 – $79.00 4. Bosch OEM Voltage Regulator with Brushes 1986AE0145 – $74.98 5. Voltage Regulator for 2004-2016 Lexus, Toyota Scion (…

3. DB Electrical – High Output Alternators

Domain: dbelectrical.com

Registered: 2000 (25 years)

Introduction: Alternators & Replacement Parts for Sale | High Output Alternators. Free Same Day Shipping over $50 (USA/48 only). High-quality alternators designed to generate voltage for battery charging and electrical components. Features include high-temperature epoxy, heavy-duty rectifiers, high-quality regulators, well-engineered bearings, and high-temperature grease for durability. Meets OEM standards for …

4. Maniac Electric Motors – Alternator & Starter Parts

Domain: maniacelectricmotors.com

Registered: 2007 (18 years)

Introduction: Alternator Parts, Starter Parts for Rebuilding, Alternator Rebuild Kits, Bearings, Alternator Brushes / Brush Holders / Assemblies, Alternator Repair Connector, Harness, ‘Pigtail’, Alternator Pulley, Starter Solenoids, Alternator Voltage Regulators, Starter Brushes, Sets, and Brush Holder Assemblies. Specific products include: 1. Alternator for Volvo with Bosch 0125812009, 0125812012 – 21066 2. St…

Strategic Sourcing Conclusion and Outlook for parts for alternator

In today’s competitive landscape, effective strategic sourcing of alternator parts is essential for optimizing operational efficiency and ensuring the longevity of power generation systems. By partnering with reputable suppliers, businesses can access a diverse inventory of high-quality components tailored to their specific needs. Key insights from this guide emphasize the importance of sourcing authentic parts from trusted manufacturers, such as Stamford, Leroy Somer, and Delco, to enhance performance and reliability.

Illustrative image related to parts for alternator

International buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers that offer robust support and expertise. Fast response times, in-stock availability, and comprehensive product testing are critical factors that can significantly reduce downtime and maintenance costs.

As we look to the future, the demand for reliable power generation continues to grow, presenting a unique opportunity for businesses to invest in quality alternator parts. We encourage international B2B buyers to take proactive steps in their sourcing strategies, engaging with suppliers that not only meet their immediate needs but also align with their long-term operational goals. Reach out to trusted distributors today to secure the parts essential for your success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to parts for alternator

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.