Introduction: Navigating the Global Market for how to get starter motor working

In the fast-paced world of automotive maintenance and repair, understanding how to get a starter motor working is crucial for businesses striving to minimize downtime and maximize efficiency. A faulty starter motor can halt operations, leading to costly delays and unsatisfied customers. This guide addresses key challenges faced by B2B buyers—particularly in regions such as Africa, South America, the Middle East, and Europe, including Germany and Nigeria—by providing a comprehensive overview of starter motors, their applications, and effective troubleshooting techniques.

Throughout this guide, readers will discover various types of starter motors, the intricacies of their functions, and the best practices for diagnosing issues. We delve into vital aspects of supplier vetting, ensuring that buyers can make informed decisions when sourcing quality components. Additionally, we outline the cost implications associated with different starter motors and repair methods, empowering businesses to budget effectively while maintaining high operational standards.

By equipping international B2B buyers with actionable insights, this guide serves as a valuable resource for enhancing procurement strategies and optimizing maintenance processes. In navigating the complexities of starter motor functionality and sourcing, businesses can ensure they remain competitive in an increasingly interconnected market.

Table Of Contents

- Top 1 How To Get Starter Motor Working Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to get starter motor working

- Understanding how to get starter motor working Types and Variations

- Key Industrial Applications of how to get starter motor working

- 3 Common User Pain Points for ‘how to get starter motor working’ & Their Solutions

- Strategic Material Selection Guide for how to get starter motor working

- In-depth Look: Manufacturing Processes and Quality Assurance for how to get starter motor working

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to get starter motor working’

- Comprehensive Cost and Pricing Analysis for how to get starter motor working Sourcing

- Alternatives Analysis: Comparing how to get starter motor working With Other Solutions

- Essential Technical Properties and Trade Terminology for how to get starter motor working

- Navigating Market Dynamics and Sourcing Trends in the how to get starter motor working Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to get starter motor working

- Strategic Sourcing Conclusion and Outlook for how to get starter motor working

- Important Disclaimer & Terms of Use

Understanding how to get starter motor working Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Electrical Test | Involves testing voltage and connections directly | Automotive repair shops | Pros: Quick diagnosis; Cons: Requires technical knowledge and tools. |

| Mechanical Impact Method | Tapping or hitting the starter to free stuck components | Fleet management, automotive services | Pros: Simple and cost-effective; Cons: Temporary fix, risk of damage. |

| Battery and Ground Check | Inspecting battery connections and grounding | Maintenance teams | Pros: Often resolves issues quickly; Cons: May not address deeper problems. |

| Solenoid Inspection | Checking solenoid function and connections | Heavy machinery, commercial vehicles | Pros: Targets common failure points; Cons: Requires access to parts and tools. |

| Push Start Technique | Using manual transmission to start the vehicle | Automotive education, mechanics | Pros: Useful for manual cars; Cons: Not applicable for automatics, requires assistance. |

What is the Direct Electrical Test for Starter Motors?

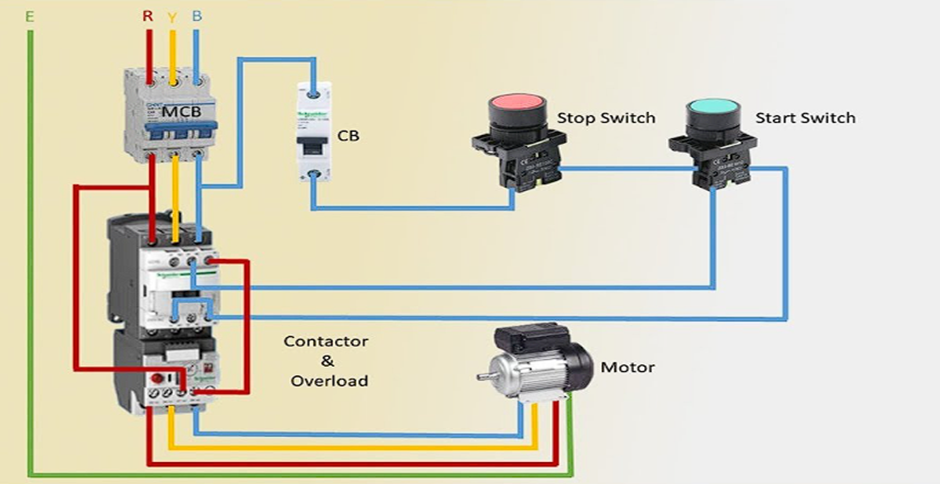

The Direct Electrical Test focuses on assessing the voltage at the starter motor and checking connections. This method is highly effective for automotive repair shops where technicians can quickly diagnose starter issues. B2B buyers should consider the necessity of having the appropriate tools, such as voltmeters, to perform these tests accurately. This method is advantageous for its speed but requires a certain level of technical expertise.

How Does the Mechanical Impact Method Work?

The Mechanical Impact Method involves tapping the starter motor with a tool to dislodge any stuck components. This technique is often employed by fleet management and automotive service providers as a quick fix for intermittent starting issues. While it is a cost-effective solution, it is essential for buyers to recognize that this method is only a temporary fix and could potentially cause further damage if not handled carefully.

Why is Battery and Ground Checking Important?

Battery and Ground Checking is vital for ensuring that the starter receives adequate power. This method is crucial for maintenance teams, as poor connections can often lead to starting failures. B2B buyers should prioritize this approach due to its simplicity and effectiveness in quickly resolving issues. However, it may not uncover deeper electrical problems that could affect the starter’s performance in the long run.

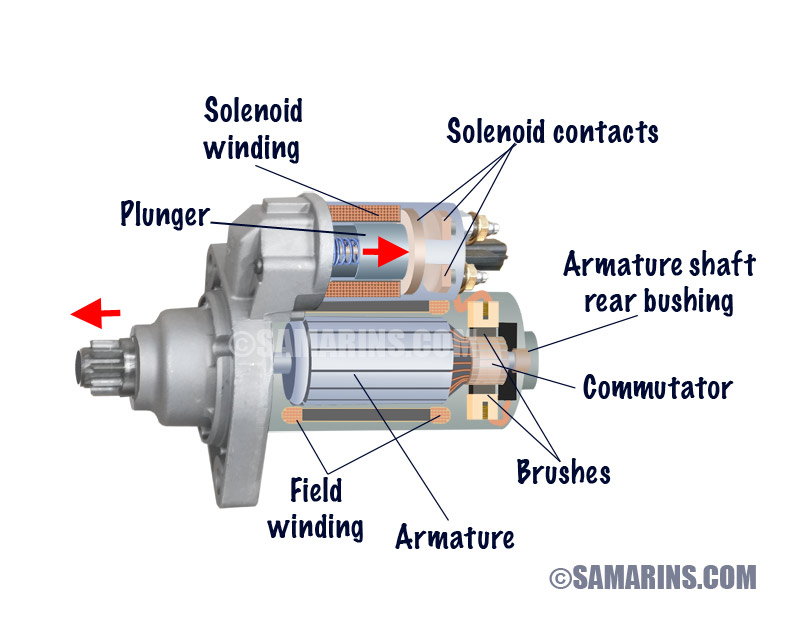

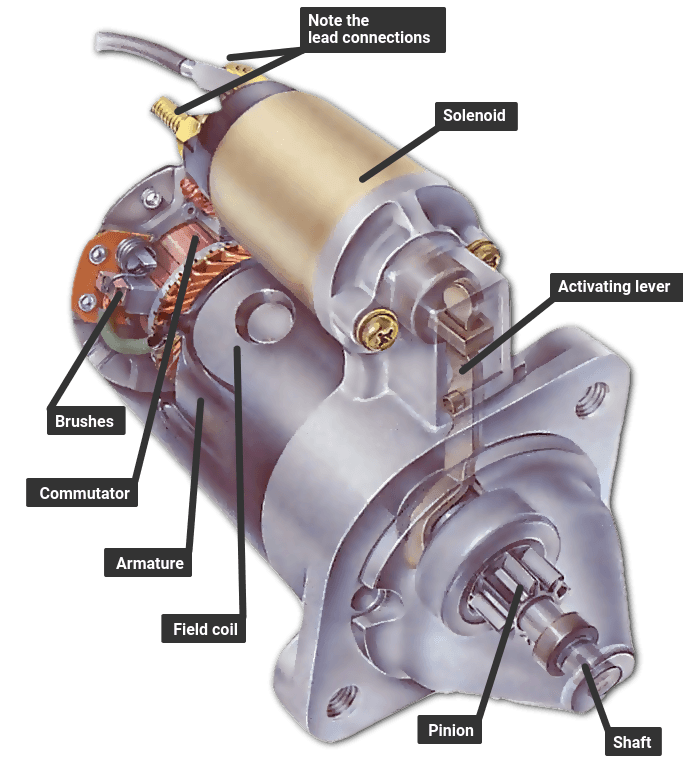

What Should Be Considered in Solenoid Inspection?

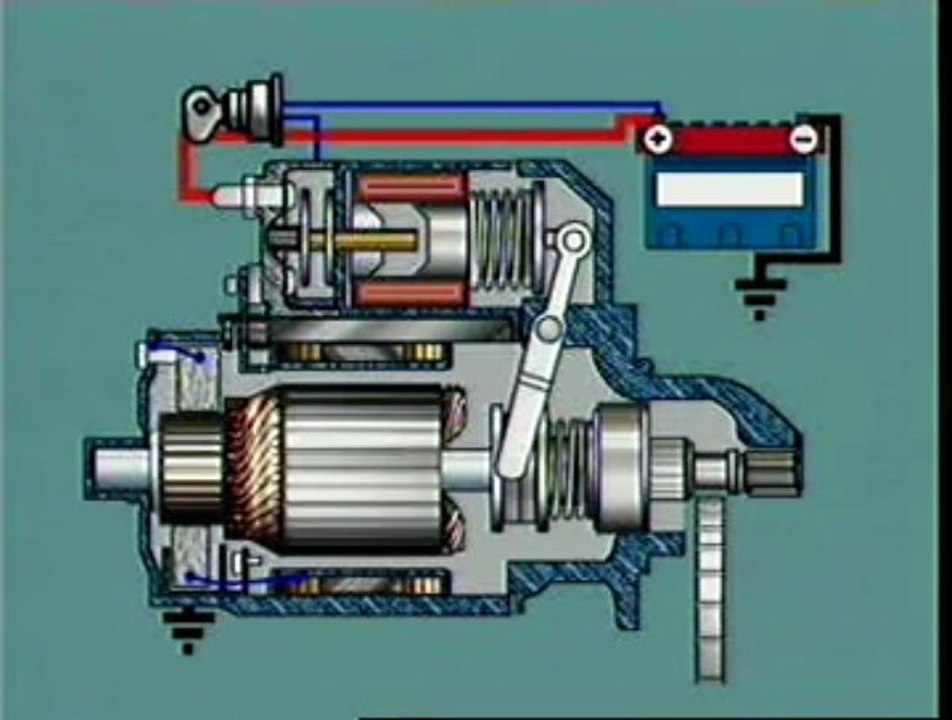

Solenoid Inspection is focused on the solenoid’s functionality, which is crucial for converting the ignition switch’s small current into the large current needed for the starter motor. This method is particularly relevant for businesses dealing with heavy machinery and commercial vehicles. Buyers should be aware that while solenoid inspections can pinpoint common failure points, they require access to components and tools, which may increase maintenance costs.

How Can the Push Start Technique Be Utilized?

The Push Start Technique is a practical method for starting manual transmission vehicles by using physical force to engage the engine. This technique is beneficial for automotive education and mechanics, providing a hands-on learning experience. However, this method is not applicable to automatic vehicles and requires assistance from others, which may not always be feasible in a commercial setting. Buyers should consider this technique as a last resort when traditional methods fail.

Key Industrial Applications of how to get starter motor working

| Industry/Sector | Specific Application of how to get starter motor working | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnosing and repairing starter motor issues in vehicles | Improved vehicle uptime and customer satisfaction | Availability of diagnostic tools and skilled technicians |

| Heavy Machinery | Ensuring reliable starting of construction and agricultural machinery | Enhanced operational efficiency and reduced downtime | Quality of starter components and access to maintenance services |

| Transportation & Logistics | Maintaining fleet vehicle starter motors for reliable operations | Reduced operational costs and improved fleet reliability | Sourcing high-quality parts and ensuring timely delivery |

| Mining Operations | Starting and maintaining heavy mining equipment | Increased productivity and minimized equipment failures | Access to specialized parts and expertise in starter motor repair |

| Renewable Energy | Operating starter motors in wind turbines and solar trackers | Enhanced energy generation efficiency and reliability | Sourcing durable components capable of withstanding harsh conditions |

How Does ‘How to Get Starter Motor Working’ Apply to Automotive Repair?

In the automotive repair sector, understanding how to get starter motors working is crucial for diagnosing and addressing vehicle issues. Automotive technicians often encounter faulty starters that can lead to customer dissatisfaction due to vehicle downtime. By using diagnostic tools and techniques, such as checking battery connections and solenoid functionality, they can effectively resolve these issues. For international B2B buyers, sourcing reliable diagnostic equipment and ensuring access to skilled technicians are essential to maintaining high service standards.

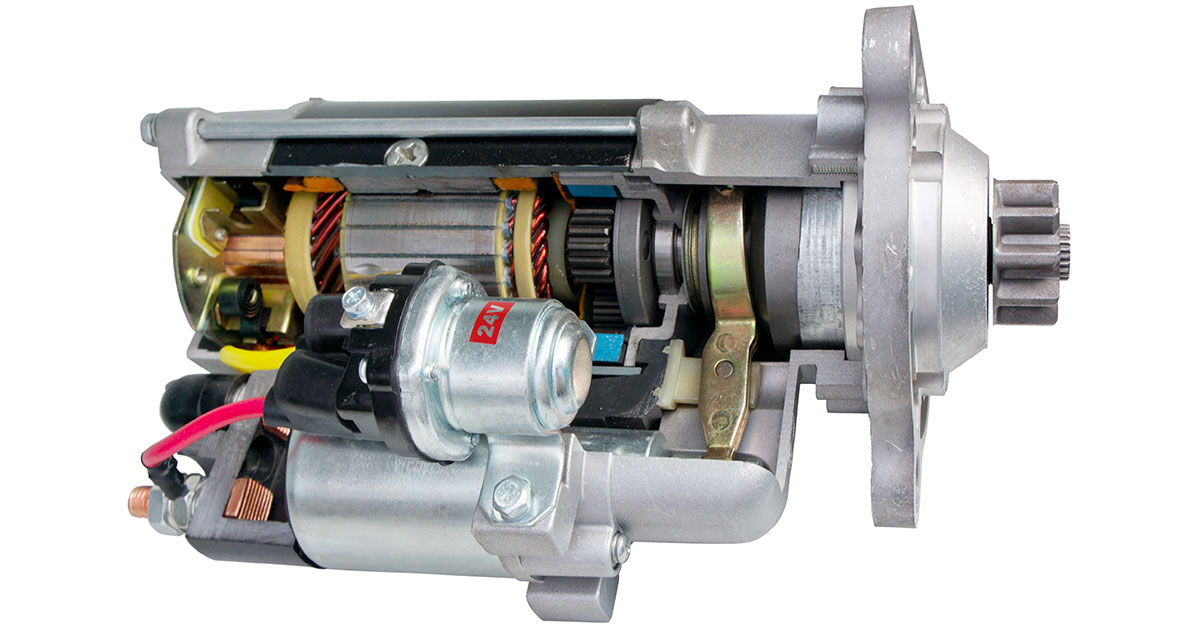

What is the Importance of Starter Motor Functionality in Heavy Machinery?

Heavy machinery, including construction and agricultural equipment, relies heavily on starter motors for reliable operation. A malfunctioning starter can lead to significant downtime, impacting project timelines and operational costs. Businesses must ensure that their starter motors are regularly maintained and repaired to prevent failures. Key considerations for buyers in this sector include sourcing high-quality starter components and establishing relationships with service providers that specialize in heavy machinery repairs.

How Does Starter Motor Maintenance Impact Transportation & Logistics?

In the transportation and logistics sector, the functionality of fleet vehicles is paramount. A faulty starter motor can lead to unexpected breakdowns, resulting in increased operational costs and delays. Ensuring that starter motors are in optimal working condition is essential for maintaining fleet reliability. B2B buyers should focus on sourcing high-quality parts and establishing preventive maintenance schedules to minimize disruptions and enhance overall fleet performance.

Why is Starter Motor Reliability Critical in Mining Operations?

Mining operations depend on heavy machinery that requires reliable starter motors to function effectively. Any failure in starting these machines can lead to significant productivity losses and increased operational costs. Understanding how to maintain and repair starter motors is essential for mining companies to ensure continuous operation. Buyers should prioritize sourcing specialized parts and services that cater to the unique demands of the mining environment, ensuring that their equipment remains operational under challenging conditions.

How Do Starter Motors Function in Renewable Energy Applications?

In renewable energy sectors, such as wind and solar, starter motors play a crucial role in the operation of various systems, including turbines and solar trackers. Ensuring that these motors function correctly is vital for maximizing energy generation and system reliability. B2B buyers should focus on sourcing durable starter components that can withstand harsh environmental conditions, as well as ensuring that maintenance services are readily available to address any potential issues swiftly.

3 Common User Pain Points for ‘how to get starter motor working’ & Their Solutions

Scenario 1: Troubleshooting a Non-Responsive Starter Motor

The Problem:

B2B buyers, particularly those in industries reliant on vehicle fleets or machinery, often encounter situations where a starter motor fails to respond. This can lead to unplanned downtime, affecting operational efficiency. The challenge lies in diagnosing whether the issue stems from the starter itself, a weak battery, or electrical connections. Without the right tools or knowledge, identifying the root cause can be time-consuming and frustrating, leading to unnecessary costs and delays.

The Solution:

To effectively troubleshoot a non-responsive starter motor, begin by conducting a comprehensive diagnostic check. First, verify the battery’s condition using a voltmeter; a healthy battery should read at least 12.5 volts. If the voltage is low, jump-starting the vehicle may resolve the issue temporarily. If the vehicle still doesn’t start, inspect the battery terminals for corrosion or loose connections, which are common culprits. Cleaning these connections with a wire brush and ensuring a tight fit can often restore functionality.

For a more thorough diagnosis, check the starter motor’s wiring and connections. If the starter has an external solenoid, inspect the solenoid wires for damage or looseness. Reconnecting and cleaning these connections can sometimes resolve the issue. If the starter motor is still unresponsive, consider employing a temporary fix by gently tapping the starter with a mallet. This can sometimes free up stuck components, allowing the starter to engage. However, this should be treated as a stop-gap measure, prompting a full repair or replacement as soon as possible.

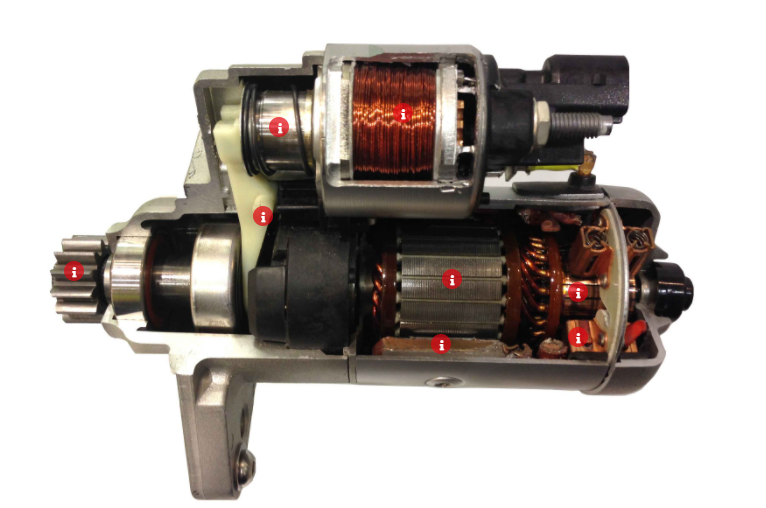

Illustrative image related to how to get starter motor working

Scenario 2: Identifying Intermittent Starter Motor Issues

The Problem:

In many B2B scenarios, such as in logistics or construction, vehicles may start intermittently due to a failing starter motor. This inconsistency can lead to operational disruptions, as drivers cannot reliably depend on their vehicles to start. For fleet managers, the inability to predict vehicle performance can complicate scheduling and resource allocation, ultimately impacting customer service and operational costs.

The Solution:

To address intermittent starter motor issues, implement a proactive maintenance routine that includes regular inspections of the starter system. Begin by checking the starter’s electrical connections, ensuring they are clean and securely fastened. Look for signs of wear or damage on the wiring, particularly around the solenoid and starter terminals.

Additionally, consider employing diagnostic tools such as a multimeter to check for continuity and voltage drop across the starter circuit. This can help identify hidden issues that may not be immediately apparent. If problems persist, encourage drivers to report any starting anomalies promptly. This data can be invaluable for identifying patterns and scheduling preventative maintenance before failures occur.

For long-term solutions, investing in high-quality starter motors and components can reduce the frequency of these issues. Partner with reputable suppliers who offer warranties and support, ensuring that replacements are reliable and suited to the specific needs of your vehicles.

Illustrative image related to how to get starter motor working

Scenario 3: Managing Starter Motor Replacement Costs

The Problem:

For B2B buyers managing large fleets or machinery, the financial implications of starter motor failures can be significant. The costs associated with frequent replacements, combined with labor expenses and potential operational downtime, can strain budgets. Buyers often struggle to balance quality with affordability, seeking solutions that minimize long-term costs without compromising on performance.

The Solution:

To manage starter motor replacement costs effectively, consider adopting a strategic procurement approach. Begin by conducting a thorough analysis of your fleet’s starter motor specifications, identifying common failure points and performance requirements. This knowledge will enable you to make informed purchasing decisions that prioritize quality.

Engaging with multiple suppliers can also yield competitive pricing. Request quotes and explore bulk purchasing options, which can often result in substantial savings. Additionally, consider sourcing remanufactured or refurbished starter motors from reputable suppliers. These options can provide a balance of quality and affordability, often backed by warranties.

Furthermore, implementing a robust maintenance program can extend the lifespan of starter motors, reducing the frequency of replacements. Regularly scheduled inspections and cleaning of electrical connections can prevent premature wear and identify potential issues before they escalate. Educating your maintenance team on proper installation and care techniques can also enhance the longevity of starter motors, ultimately leading to lower overall costs.

Illustrative image related to how to get starter motor working

Strategic Material Selection Guide for how to get starter motor working

What Materials Are Commonly Used for Starter Motor Components?

When it comes to ensuring the effective operation of starter motors, the selection of materials is crucial. Various materials are employed in the manufacturing of starter motor components, each with its unique properties, advantages, and limitations. Below is an analysis of some of the most common materials used in starter motors, along with considerations for international B2B buyers.

What Are the Key Properties of Copper in Starter Motors?

Copper is a widely used material in starter motors, particularly for wiring and electrical connections. Its excellent electrical conductivity (approximately 60% better than aluminum) ensures efficient current transfer, which is critical for the starter’s performance. Additionally, copper has good thermal conductivity, allowing it to dissipate heat effectively, which is essential during high-load operations.

Pros: Copper’s high conductivity leads to lower energy losses, enhancing overall efficiency. It is also relatively easy to work with, making it suitable for complex designs.

Cons: The primary drawback of copper is its susceptibility to corrosion, especially in humid environments. This can lead to increased maintenance costs and potential failures over time.

Illustrative image related to how to get starter motor working

Impact on Application: Copper is compatible with various media, including oil and fuel, but it may require protective coatings in corrosive environments.

Considerations for International Buyers: Buyers from regions such as Africa and South America should be aware of local corrosion rates and consider using coated or alloyed copper to enhance durability. Compliance with standards such as ASTM B170 for copper wire may also be necessary.

How Does Aluminum Compare for Starter Motor Applications?

Aluminum is another common choice for starter motor components, particularly in housing and structural parts. Its lightweight nature reduces the overall weight of the starter motor, which can improve fuel efficiency in vehicles.

Pros: Aluminum offers excellent corrosion resistance, especially when anodized, making it suitable for various environmental conditions.

Cons: While aluminum is lighter, it has lower electrical conductivity compared to copper, which can impact performance in high-current applications.

Impact on Application: Aluminum’s compatibility with automotive fluids is generally good, but it may not perform as well as copper in high-temperature scenarios.

Considerations for International Buyers: Buyers should consider local manufacturing capabilities and preferences for lightweight materials. Compliance with European standards like DIN 1725 for aluminum alloys may be relevant.

What Role Does Steel Play in Starter Motor Design?

Steel, particularly stainless steel, is often used for components requiring high strength and durability, such as the starter housing and mounting brackets. Its mechanical properties make it suitable for high-stress applications.

Pros: Steel offers excellent tensile strength and resistance to wear, making it ideal for components subjected to mechanical stress.

Illustrative image related to how to get starter motor working

Cons: Steel is heavier than aluminum and copper, which can negatively affect the overall weight of the starter motor. Additionally, it may require protective coatings to prevent rust.

Impact on Application: Steel is compatible with various automotive fluids but may corrode if not properly treated.

Considerations for International Buyers: Buyers in the Middle East should be aware of the impact of high temperatures on steel performance and consider using corrosion-resistant grades. Compliance with standards such as ASTM A240 for stainless steel may be necessary.

How Important Is Plastic in Starter Motor Components?

Plastics are increasingly used in starter motors for insulation and housing components. They provide electrical insulation and can be molded into complex shapes, reducing manufacturing complexity.

Pros: Plastics are lightweight and resistant to corrosion, making them suitable for various applications.

Cons: Plastics can have lower temperature resistance compared to metals, which may limit their use in high-heat environments.

Impact on Application: Plastics are generally compatible with automotive fluids, but their performance can degrade under extreme conditions.

Considerations for International Buyers: Buyers should consider the specific grades of plastic used, ensuring they meet local standards and environmental regulations, especially in Europe where REACH compliance is critical.

Summary of Material Selection for Starter Motors

| Material | Typical Use Case for how to get starter motor working | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and electrical connections | High electrical conductivity | Susceptible to corrosion | Medium |

| Aluminum | Housing and structural parts | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Housing and mounting brackets | High strength and durability | Heavier and may rust | Low |

| Plastic | Insulation and housing components | Lightweight and corrosion-resistant | Lower temperature resistance | Low |

This analysis provides a comprehensive overview of the materials commonly used in starter motors, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how to get starter motor working

What Are the Key Manufacturing Processes for Starter Motors?

Manufacturing starter motors involves several critical stages, each designed to ensure optimal performance and reliability. Understanding these processes helps B2B buyers assess supplier capabilities and product quality effectively.

How is Material Preparation Conducted for Starter Motors?

The first step in the manufacturing process is material preparation. High-quality materials are crucial for ensuring the durability and functionality of starter motors. Common materials include:

- Copper: Used for windings and connections due to its excellent electrical conductivity.

- Steel: Often used for the casing and components to provide strength and structural integrity.

- Plastic: Employed for insulators and housings to reduce weight and prevent electrical shorts.

During this stage, suppliers often conduct a thorough inspection of raw materials to ensure they meet specific standards. This may involve checking for purity, tensile strength, and resistance to corrosion. The selection of materials is guided by industry standards, such as ISO 9001, which emphasizes quality management throughout the supply chain.

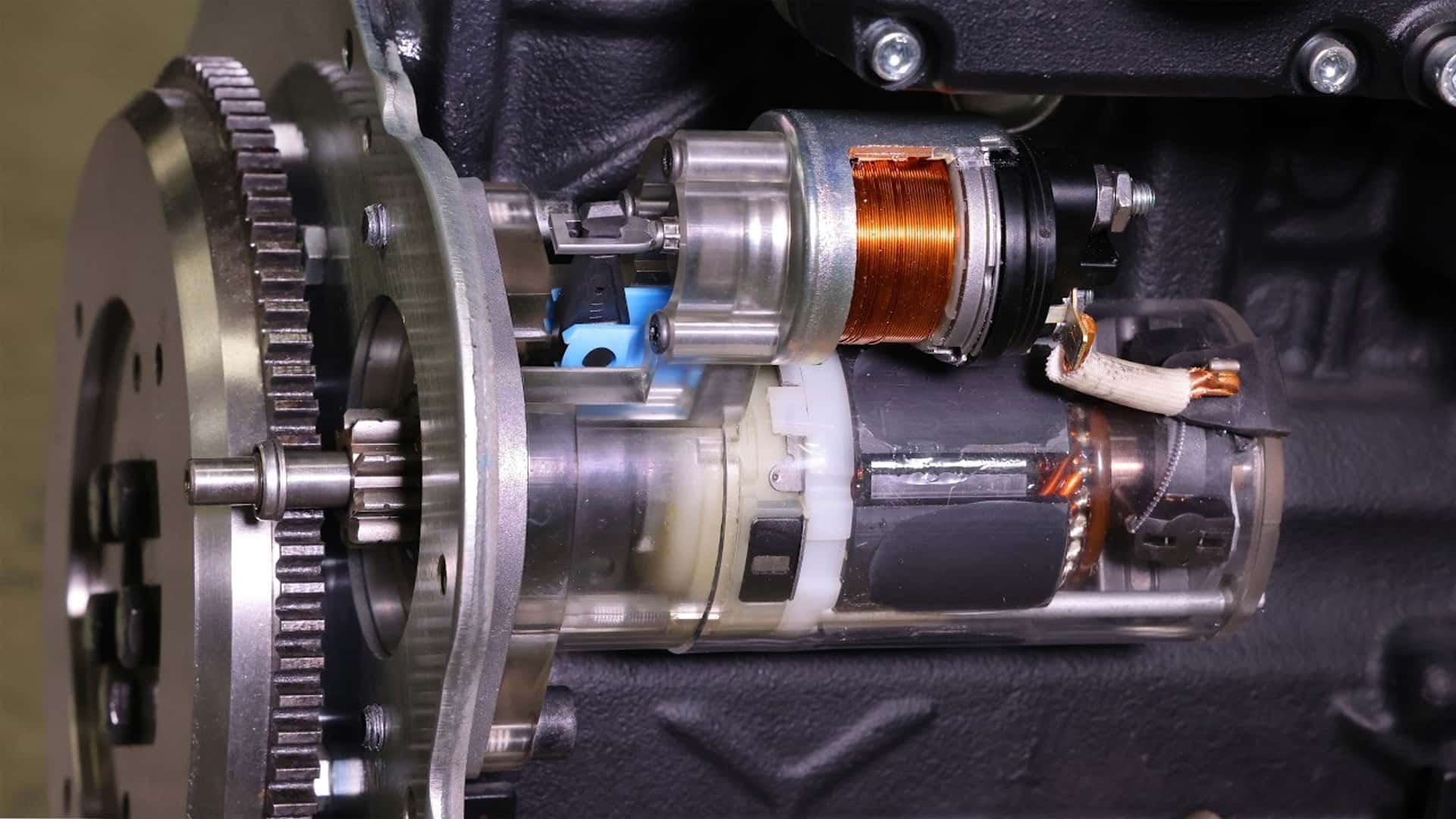

What Forming Techniques Are Utilized in Starter Motor Manufacturing?

Once the materials are prepared, the next stage involves forming the various components of the starter motor. Key techniques include:

- Stamping: This process is used to create metal components, such as the housing and terminal lugs, from flat sheets of metal. Precision stamping ensures that parts fit together seamlessly, reducing assembly errors.

- Winding: Copper wire is wound into coils to create the motor’s electromagnetic field. The winding process must be precise to ensure the correct number of turns, which directly affects performance.

- Casting: Some components, like the motor’s end bell, may be produced through casting processes, allowing for complex shapes and designs that enhance performance.

Each forming technique is closely monitored for dimensional accuracy and material integrity, as these factors significantly impact the motor’s efficiency and lifespan.

How is Assembly Performed on Starter Motors?

The assembly stage is where the various components come together to create the finished product. This process typically involves:

- Component Integration: Parts such as the rotor, stator, solenoid, and casing are assembled in a clean environment to prevent contamination.

- Soldering and Fastening: Electrical connections are soldered, and mechanical fasteners are used to secure components. This stage requires meticulous attention to detail to avoid issues such as short circuits or loose connections.

- Final Assembly Checks: Before moving to the finishing stage, each assembled starter motor undergoes a preliminary inspection to ensure all components are correctly installed and secured.

This stage is critical, as improper assembly can lead to early failure of the starter motor, impacting customer satisfaction and warranty claims.

What Finishing Techniques Are Applied to Starter Motors?

Finishing processes enhance the performance and appearance of starter motors. Common finishing techniques include:

- Coating: Applying protective coatings to prevent corrosion and wear. This is particularly important for components exposed to harsh environments.

- Testing: Each starter motor undergoes a series of tests, including electrical testing to ensure proper operation under load and performance assessments to gauge starting torque and speed.

The finishing stage is essential for ensuring that the starter motor meets or exceeds industry standards for performance and durability.

What Quality Assurance Practices Are Essential for Starter Motor Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for starter motors. It ensures that products meet specific standards and perform reliably in the field.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding relevant international standards is crucial when sourcing starter motors. Key standards include:

- ISO 9001: A global standard for quality management systems that emphasizes continuous improvement and customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: For automotive components, adhering to the American Petroleum Institute standards can be essential, especially for motors used in specific applications.

These standards serve as benchmarks for quality and safety, ensuring that the products meet the expectations of international markets.

What Are the Key Quality Control Checkpoints in Starter Motor Manufacturing?

Quality control (QC) involves systematic checks at various stages of the manufacturing process. Important checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers should provide documentation to verify compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, operators conduct regular checks to ensure that processes are being followed correctly and that components meet dimensional tolerances.

- Final Quality Control (FQC): After assembly and finishing, the final product undergoes rigorous testing to confirm its functionality and reliability. This may include electrical testing, performance tests, and environmental simulations.

Implementing these checkpoints helps identify defects early in the process, reducing waste and enhancing product reliability.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, verifying a supplier’s quality assurance practices is essential. Here are effective methods to ensure quality:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control practices, and compliance with international standards.

- Requesting Quality Reports: Buyers should ask for documentation related to quality inspections, test results, and compliance certifications. This information can provide assurance regarding the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection agencies to evaluate suppliers can offer an unbiased assessment of their quality assurance practices and product reliability.

By implementing these verification strategies, B2B buyers can mitigate risks associated with sourcing starter motors and ensure they are partnering with reliable manufacturers.

What Are the Nuances of Quality Control and Certification for International Markets?

Navigating quality control and certification nuances is vital for B2B buyers, especially those sourcing from different regions. Buyers should consider:

Illustrative image related to how to get starter motor working

- Regional Compliance: Different regions may have varying compliance requirements. For example, products sold in Europe must meet CE marking standards, while those sold in the U.S. may require adherence to different regulations.

- Cultural Differences: Understanding cultural differences in manufacturing practices can help buyers better communicate expectations and quality requirements to suppliers.

- Documentation: Maintaining accurate and comprehensive documentation is critical for compliance and traceability. Buyers should ensure that suppliers provide all necessary certifications and reports for their products.

By being aware of these nuances, B2B buyers can make informed decisions and foster successful partnerships with suppliers in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to get starter motor working’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to understand how to effectively get a starter motor working. It outlines essential steps for diagnosing starter motor issues, ensuring proper procurement, and maintaining operational efficiency. By following these actionable steps, buyers can make informed decisions when sourcing replacement parts or seeking repair services.

Step 1: Identify the Symptoms of a Faulty Starter Motor

Recognizing the signs of a malfunctioning starter motor is the first step in addressing the issue. Common symptoms include unusual clicking sounds, failure to start after turning the key, or intermittent starting issues. Identifying these symptoms early can save time and reduce unnecessary costs associated with misdiagnosis.

Step 2: Define Your Technical Specifications

Before sourcing a starter motor, clearly outline the technical specifications required for your specific vehicle or machinery. Consider factors such as voltage, size, torque ratings, and compatibility with existing systems. This clarity will help you narrow down suppliers who can meet your precise needs.

Illustrative image related to how to get starter motor working

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request detailed company profiles, case studies, and references from other buyers in similar industries or regions. This step is crucial for assessing the supplier’s ability to deliver the right products and services on time.

- Check Certifications: Verify that suppliers hold relevant certifications, such as ISO standards, which indicate adherence to quality management systems.

- Assess Industry Experience: Look for suppliers with extensive experience in your specific market, as they are more likely to understand your unique requirements.

Step 4: Assess Warranty and Return Policies

A robust warranty and flexible return policy are essential when procuring starter motors. Ensure that the supplier offers a warranty that covers defects and workmanship for a reasonable period. Understanding the return process is also vital should the parts fail to meet your expectations or specifications.

Step 5: Inquire About After-Sales Support

Quality after-sales support can significantly enhance your purchasing experience. Inquire whether the supplier provides technical assistance, installation guidance, or troubleshooting services. This support can be invaluable, especially if your team lacks specialized knowledge in starter motor systems.

Illustrative image related to how to get starter motor working

Step 6: Compare Pricing and Payment Terms

Collect quotes from multiple suppliers and compare their pricing structures. While cost is a significant factor, ensure that you are also considering the quality and service levels offered. Additionally, review payment terms to find options that align with your cash flow and budgetary constraints.

Step 7: Establish a Maintenance Plan

Once you have procured the starter motor, it’s essential to implement a maintenance plan to ensure long-term functionality. Regular inspections and cleaning of connections can prevent corrosion and prolong the life of the starter motor. A proactive maintenance approach minimizes downtime and enhances operational efficiency.

By following this checklist, B2B buyers can navigate the complexities of sourcing and maintaining starter motors with confidence, ensuring optimal performance for their vehicles and machinery.

Comprehensive Cost and Pricing Analysis for how to get starter motor working Sourcing

What Are the Key Cost Components for Sourcing Starter Motor Solutions?

Understanding the cost structure associated with sourcing starter motor solutions is crucial for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The cost components can be broken down into several categories:

-

Materials: The primary materials involved in starter motor production include copper, steel, and various plastics. The price of these materials fluctuates based on global supply and demand, which can significantly affect overall costs. Buyers should consider sourcing from regions with competitive material prices or seeking partnerships with suppliers who have strong material procurement practices.

-

Labor: Labor costs will vary significantly based on the manufacturing location. For example, labor in European countries like Germany may be higher than in Nigeria or other African nations. Understanding local labor markets can aid buyers in negotiating better prices or selecting suppliers that optimize labor costs without compromising quality.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and administrative costs necessary for production. Buyers should inquire about a supplier’s overhead costs, as these can vary widely and impact pricing.

-

Tooling: Tooling costs are essential for custom starter motor designs. These costs can be significant, especially for low-volume orders. Buyers should evaluate whether investing in custom tooling is worthwhile based on their expected production volume.

-

Quality Control (QC): Ensuring that products meet quality standards is essential in automotive components. Suppliers may include QC costs in their pricing. Buyers should verify the QC processes in place and consider suppliers with certifications such as ISO 9001, which can enhance trust in product quality.

-

Logistics: Shipping costs can be a major component of the total price, particularly for international transactions. Factors such as shipping methods, distance, and delivery times all play a role. Buyers should assess logistics options to find the most cost-effective solutions while ensuring timely delivery.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and supplier reputation. Buyers should evaluate multiple quotes to determine a fair margin and ensure they are not overpaying.

What Influences Pricing for Starter Motor Solutions?

Several factors can influence pricing dynamics in the starter motor market:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ) that can affect pricing. Larger orders usually attract bulk discounts, so consolidating purchases can be beneficial.

-

Specifications and Customization: Custom specifications can increase costs due to additional tooling and material requirements. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and components can raise prices but may lead to enhanced durability and performance. Certifications can also validate quality and safety, affecting buyer decisions.

-

Supplier Factors: The supplier’s experience, reputation, and geographical location can impact pricing. Established suppliers may command higher prices due to proven reliability, while newer entrants may offer competitive rates to gain market share.

-

Incoterms: Understanding Incoterms is essential for managing logistics costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and responsibilities, impacting the overall pricing structure.

What Tips Should Buyers Consider for Cost-Efficiency?

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing starter motor solutions:

-

Negotiation: Engage in open dialogue with suppliers to negotiate better terms, especially on larger orders or repeat business. Leverage competitive quotes to strengthen your position.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the initial purchase price. Consider factors like maintenance, durability, and potential downtime, which can impact long-term costs.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, tariffs, and trade agreements that could affect pricing. Understanding local market conditions can also provide insights into fair pricing expectations.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Consider establishing long-term partnerships that foster mutual benefits.

By considering these aspects of cost structure, pricing influences, and practical tips, international B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing how to get starter motor working With Other Solutions

Introduction: Exploring Alternatives for Starting a Vehicle with a Faulty Starter Motor

When faced with the challenge of a non-functioning starter motor, it’s essential to explore various solutions that can effectively address the issue. This section presents a comparison of the conventional method of getting a starter motor working against alternative approaches, such as jump-starting, using a portable battery booster, and push-starting (for manual transmission vehicles). Each method has its own set of advantages and considerations that B2B buyers should evaluate based on their specific operational needs.

Comparison Table

| Comparison Aspect | How To Get Starter Motor Working | Jump-Starting | Portable Battery Booster | Push-Starting |

|---|---|---|---|---|

| Performance | Reliable for long-term use | Quick fix for low battery | Effective for instant power | Works under specific conditions |

| Cost | Moderate (parts and labor) | Low (cables) | Moderate (device purchase) | Low (manual labor) |

| Ease of Implementation | Requires mechanical knowledge | Simple for most users | User-friendly, plug-and-play | Requires teamwork |

| Maintenance | Regular checks needed | Minimal, dependent on cables | Low, device needs charging | None, but requires practice |

| Best Use Case | Persistent issues needing repair | Temporary solutions for low batteries | Emergency starts | Manual vehicles with bad starters |

Detailed Breakdown of Alternatives

Jump-Starting

Jump-starting is a widely recognized method that involves connecting a dead battery to a charged one using jumper cables. This approach is particularly effective when the starter motor is functioning properly but the battery is weak. The main advantage of this method is its simplicity and speed, allowing users to quickly revive a vehicle. However, it is a temporary fix and does not address underlying issues with the starter motor itself. B2B buyers should consider jump-starting for immediate needs but recognize its limitations for long-term reliability.

Portable Battery Booster

A portable battery booster, also known as a jump starter, is a compact device that can jump-start vehicles without the need for another car. This solution is especially beneficial for businesses that require mobility and quick response times, such as logistics or transportation companies. The ease of use makes it an attractive option, as users simply connect the device to the vehicle’s battery and start the engine. However, the upfront cost of purchasing a quality booster can be moderate, and the device itself requires regular charging to remain effective.

Push-Starting

Push-starting is a method applicable only to manual transmission vehicles. It involves rolling the vehicle to gain speed and engaging the clutch to start the engine. This technique is advantageous in scenarios where other methods are unavailable, such as remote locations. While it is cost-effective and doesn’t require special equipment, push-starting necessitates a team of people and can be physically demanding. Additionally, it only works under specific conditions, making it less versatile than other alternatives.

Conclusion: How to Choose the Right Solution for Your Needs

When determining the best approach to address starter motor issues, B2B buyers should consider factors such as the nature of the problem, available resources, and operational needs. For businesses seeking a reliable long-term solution, addressing the starter motor directly may be best. In contrast, for temporary fixes or emergencies, jump-starting or using a portable battery booster may suffice. Understanding the nuances of each method will enable buyers to make informed decisions that align with their operational strategies and budget constraints.

Essential Technical Properties and Trade Terminology for how to get starter motor working

What Are the Key Technical Properties of Starter Motors?

When dealing with starter motors, understanding their critical specifications is essential for making informed purchasing decisions. Here are some key properties to consider:

-

Material Grade

The material grade of a starter motor typically refers to the type of metals used in its construction, such as copper, aluminum, or steel. High-grade materials ensure durability and better performance, which is vital for ensuring longevity in various climates. For B2B buyers, selecting a starter motor made from quality materials can mean reduced maintenance costs and increased reliability. -

Torque Rating

The torque rating indicates the rotational force that the starter motor can exert to crank the engine. This specification is crucial for compatibility with different vehicle engines. B2B buyers must ensure that the torque rating aligns with the engine requirements to avoid performance issues, especially in heavy-duty applications. -

Voltage Rating

Starter motors typically operate at 12V or 24V. The voltage rating is critical for ensuring compatibility with the vehicle’s electrical system. For international buyers, particularly in regions with diverse vehicle models, confirming the voltage rating can prevent operational failures and enhance efficiency. -

Tolerance Levels

Tolerance levels define the acceptable limits of variation in the starter motor’s dimensions and performance characteristics. Precision in manufacturing can affect the motor’s fit and functionality. Understanding tolerance levels helps buyers select starter motors that will integrate seamlessly into their existing systems, minimizing installation issues. -

Current Draw

The current draw is the amount of electrical current the starter motor consumes during operation. This specification is important for assessing the impact on the vehicle’s battery and electrical system. For B2B buyers, particularly those in regions with inconsistent power supply, selecting a starter with a manageable current draw can enhance reliability. -

Cycle Life

Cycle life refers to the number of times a starter motor can reliably engage and disengage before failure. A longer cycle life indicates a more durable product, which is particularly valuable for businesses operating fleets or in harsh environments. Understanding cycle life helps B2B buyers forecast replacement needs and manage inventory effectively.

What Are Common Trade Terms Related to Starter Motors?

In the B2B space, familiarity with trade terminology is vital for effective communication and negotiation. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the assembly of a vehicle. For buyers, choosing OEM starter motors can ensure compatibility and quality, as these parts are designed to meet the specific requirements of vehicle manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses looking to manage inventory costs while ensuring they have enough starter motors on hand for repairs or replacements. -

RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers to solicit price quotes for specific products. Utilizing RFQs can streamline the procurement process for starter motors, enabling buyers to compare prices and terms effectively. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help businesses understand shipping costs, insurance, and risk management when sourcing starter motors from different regions. -

Aftermarket

The aftermarket refers to the secondary market for vehicle parts and accessories that are not sourced from the original manufacturer. Buyers may explore aftermarket options for starter motors as they can offer cost-effective alternatives without compromising quality. -

Lead Time

Lead time is the time taken from placing an order to delivery. Understanding lead times for starter motors is essential for businesses to plan their operations, especially in industries where vehicle uptime is critical. Reducing lead time can significantly enhance operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing starter motors, ensuring reliability and compatibility with their vehicle fleets.

Navigating Market Dynamics and Sourcing Trends in the how to get starter motor working Sector

What Are the Key Trends Influencing the Starter Motor Market?

The starter motor market is experiencing significant shifts driven by technological advancements and changing consumer demands. In regions like Africa, South America, the Middle East, and Europe, there’s a growing preference for high-efficiency starter motors that enhance fuel efficiency and reduce emissions. This aligns with global sustainability goals and regulatory pressures aimed at lowering carbon footprints. Additionally, the integration of smart technologies, such as IoT capabilities in vehicle systems, is enabling predictive maintenance and real-time diagnostics, which can significantly reduce downtime and repair costs for businesses.

Emerging trends in sourcing indicate a shift towards localized supply chains to mitigate risks associated with global disruptions. International B2B buyers are increasingly seeking suppliers who can provide reliable, rapid delivery of starter motors and related components. As electric vehicles (EVs) gain traction, the demand for traditional starter motors may decline, but there’s an opportunity for suppliers to pivot towards hybrid systems or components that support EV technology. Furthermore, the rise of e-commerce platforms is facilitating easier access to various starter motor models and parts, allowing buyers to make more informed purchasing decisions.

How Does Sustainability Impact Sourcing for Starter Motors?

Sustainability is becoming a critical factor in the sourcing of starter motors and related components. The environmental impact of manufacturing processes, including resource extraction and waste management, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly practices, such as using recycled materials or renewable energy in production.

Ethical sourcing is also gaining prominence, with buyers seeking transparency in supply chains. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications are becoming essential for suppliers aiming to establish credibility in the market. By investing in sustainable practices, suppliers not only meet regulatory requirements but also enhance their brand reputation, making them more attractive to conscientious buyers. Ultimately, aligning sourcing strategies with sustainability goals can lead to cost savings and improved operational efficiencies.

What Is the Historical Context of Starter Motor Development?

The evolution of starter motors dates back to the early 20th century when vehicles transitioned from hand-crank systems to electric starters. This innovation revolutionized the automotive industry, allowing for easier and more reliable vehicle operation. Over the decades, starter motors have undergone significant advancements, including the development of more compact and efficient designs.

In recent years, the rise of electric and hybrid vehicles has further influenced starter motor technology, leading to the creation of advanced starter systems that integrate seamlessly with electronic control units. As automotive technology continues to evolve, the demand for innovative starter motor solutions that enhance vehicle performance and reliability is expected to grow, creating new opportunities for international B2B buyers in the sector.

By understanding these market dynamics, sustainability considerations, and historical developments, B2B buyers can make informed decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of how to get starter motor working

-

How do I diagnose a faulty starter motor?

To diagnose a faulty starter motor, start by turning the ignition key. If you hear clicking or chattering, the issue may lie with the battery rather than the starter. If the engine turns over but doesn’t start, investigate the ignition system or fuel delivery. A single click or no noise at all typically indicates a bad starter. Additionally, inspect battery terminals for corrosion and ensure solid connections. Using a voltmeter can help confirm if the battery is functioning properly, as it should read at least 12.5 volts. -

What temporary fixes can I use for a bad starter motor?

If you encounter a bad starter motor, several temporary fixes can help get your vehicle running. Cleaning the positive and negative battery connections can often resolve issues caused by corrosion. Tapping the starter lightly with a hammer or mallet may help dislodge stuck components. If you have a manual transmission, you can try a push start, which can bypass a faulty starter. These methods are not permanent solutions but can provide immediate relief until professional repairs can be arranged. -

What is the best way to source high-quality starter motors?

When sourcing starter motors, prioritize suppliers with established reputations for quality and reliability. Look for manufacturers that comply with international standards such as ISO certifications. Request samples and perform quality checks to ensure the motors meet your specifications. Engaging with local distributors can provide insights into market trends and help you understand warranty and return policies. Building relationships with reliable suppliers is crucial for long-term success and operational efficiency. -

How can I vet suppliers for starter motors in international trade?

Vetting suppliers involves a comprehensive assessment of their business practices and product quality. Start by checking their certifications and industry experience. Request references from other clients and conduct background checks to verify their credibility. Evaluate their production capabilities and quality assurance processes. If possible, visit their facilities or arrange virtual inspections. Utilizing trade platforms and industry contacts can also provide valuable insights into a supplier’s reputation and reliability. -

What are typical Minimum Order Quantities (MOQ) for starter motors?

Minimum Order Quantities (MOQ) for starter motors can vary significantly based on the supplier and the specific product. Generally, MOQs may range from 50 to several hundred units, depending on the manufacturer’s production capabilities and inventory policies. Be sure to discuss your needs with potential suppliers to negotiate favorable terms, especially if you are a new buyer or require smaller quantities for initial orders. Understanding the MOQ can help in budgeting and inventory management. -

What payment terms should I negotiate when sourcing starter motors?

When negotiating payment terms, aim for conditions that provide financial flexibility while protecting your interests. Common terms include a deposit upfront (often 30-50%), with the balance due upon shipment or delivery. Consider negotiating for letters of credit or escrow services for larger orders to mitigate risks. Establishing clear terms regarding currency, payment method, and timelines can help avoid disputes and ensure smooth transactions. -

How can I ensure quality assurance (QA) for starter motors?

To ensure quality assurance for starter motors, work with suppliers who have robust QA processes in place. Request documentation of their testing and inspection protocols, including certifications for quality standards. Conduct routine audits and inspections of the products upon receipt to verify compliance with your specifications. Establish a feedback loop with suppliers to address quality issues promptly and maintain a high standard of product reliability. -

What logistics considerations should I keep in mind when importing starter motors?

Logistics plays a crucial role in the successful importation of starter motors. Assess shipping methods, delivery timelines, and costs associated with different carriers. Ensure compliance with customs regulations and have all necessary documentation ready, including bills of lading and certificates of origin. Consider warehousing options in your target market to streamline distribution. Additionally, factor in any potential tariffs or duties that may impact the overall cost of your import.

Top 1 How To Get Starter Motor Working Manufacturers & Suppliers List

1. Starter Motors – Cranking Solutions

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: Starter motors can experience intermittent cranking issues towards the end of their useful life. Hitting or tapping the starter motor can sometimes help it crank the engine by improving contact within the solenoid or brushes. The solenoid contains a copper washer that, when energized, connects to large contacts to allow current flow. If there are bad spots on the washer or contacts, hitting the st…

Strategic Sourcing Conclusion and Outlook for how to get starter motor working

In conclusion, understanding how to effectively diagnose and address starter motor issues is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Key takeaways include the importance of thorough troubleshooting, which involves checking battery connections, assessing solenoid functionality, and utilizing temporary fixes like tapping the starter to gain insights into potential issues.

Strategic sourcing plays a vital role in ensuring access to high-quality starter motors and components, as well as the necessary tools for maintenance and repair. By partnering with reliable suppliers who understand local market dynamics, businesses can enhance operational efficiency and reduce downtime caused by starter motor failures.

As we look ahead, investing in robust sourcing strategies will empower businesses to not only resolve starter motor issues swiftly but also to anticipate future challenges. We encourage B2B buyers to prioritize building strong supplier relationships and embracing innovative solutions that can lead to sustainable operational excellence. Engage with trusted suppliers today to ensure your fleet is always ready to perform at its best.

Illustrative image related to how to get starter motor working

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.