Introduction: Navigating the Global Market for faulty starter car

In the competitive landscape of the automotive industry, sourcing reliable components such as faulty starters for vehicles poses a significant challenge for B2B buyers. Understanding the intricacies of starter systems is crucial for international buyers, particularly those operating in markets across Africa, South America, the Middle East, and Europe, such as Nigeria and Germany. This guide aims to equip you with comprehensive insights into identifying, evaluating, and purchasing faulty starters, ensuring your operations run smoothly and efficiently.

Throughout this guide, we delve into various types of starters, their applications across different vehicle models, and the common signs of malfunction that can impede vehicle performance. Additionally, we will address critical factors in supplier vetting, helping you identify trustworthy partners who can provide quality components that meet your specifications. Cost considerations will also be examined, enabling you to make informed financial decisions that align with your budget and operational needs.

By leveraging the knowledge presented in this guide, you will be empowered to navigate the complexities of the global market for faulty starters. Our objective is to help you minimize downtime, enhance vehicle reliability, and ultimately drive profitability in your automotive ventures. With actionable insights and expert recommendations, you can confidently approach your procurement strategy and secure the best solutions for your business.

Table Of Contents

- Top 2 Faulty Starter Car Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faulty starter car

- Understanding faulty starter car Types and Variations

- Key Industrial Applications of faulty starter car

- 3 Common User Pain Points for ‘faulty starter car’ & Their Solutions

- Strategic Material Selection Guide for faulty starter car

- In-depth Look: Manufacturing Processes and Quality Assurance for faulty starter car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faulty starter car’

- Comprehensive Cost and Pricing Analysis for faulty starter car Sourcing

- Alternatives Analysis: Comparing faulty starter car With Other Solutions

- Essential Technical Properties and Trade Terminology for faulty starter car

- Navigating Market Dynamics and Sourcing Trends in the faulty starter car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faulty starter car

- Strategic Sourcing Conclusion and Outlook for faulty starter car

- Important Disclaimer & Terms of Use

Understanding faulty starter car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solenoid Failure | Clicking noise upon ignition attempts, engine fails to start. | Automotive repair shops, fleet services | Pros: Easy diagnosis; Cons: May require full starter replacement. |

| Electrical Short Circuit | Smoke or burning smell, dashboard lights may flicker. | Vehicle maintenance providers | Pros: Identifies serious issues quickly; Cons: Repair costs can escalate. |

| Worn Starter Motor | Grinding noise, intermittent starting issues. | Auto parts suppliers, workshops | Pros: Common issue; easy to source replacements; Cons: May lead to complete failure if unaddressed. |

| Oil Contamination | Oil-soaked starter, potential engine leaks. | Engine repair specialists, dealerships | Pros: Prevents larger engine problems; Cons: Requires thorough inspection and repair. |

| Faulty Relay or Fuse | Non-responsive starter, dashboard lights operational. | Electrical component suppliers | Pros: Often inexpensive to fix; Cons: Misdiagnosis can lead to unnecessary expenses. |

What are the Characteristics of Solenoid Failure in Starters?

A solenoid failure typically manifests as a clicking noise when attempting to start the vehicle, with the engine remaining unresponsive. This issue often arises from electrical problems or wear and tear over time. For B2B buyers, automotive repair shops and fleet services can leverage this knowledge to provide quick diagnostics and repairs. While diagnosing solenoid issues can be straightforward, the potential for needing a full starter replacement can increase costs.

How Can Electrical Short Circuits Affect Starters?

Electrical short circuits in the starter system can lead to severe symptoms, including smoke or a burning smell during ignition attempts. This situation often indicates a more serious underlying issue that could compromise the vehicle’s electrical system. B2B maintenance providers should be prepared to address these concerns swiftly, as they can escalate repair costs if not managed promptly. While this type of failure allows for quick identification of serious problems, the associated repair costs can be significant.

What Signs Indicate a Worn Starter Motor?

A worn starter motor is characterized by grinding noises and intermittent starting issues, which can frustrate drivers and disrupt operations for businesses relying on their vehicles. This is a common issue that auto parts suppliers and workshops can expect, making it essential for them to maintain a stock of replacement starters. Although sourcing replacements is typically easy, neglecting this issue can lead to a complete starter failure, resulting in more extensive and costly repairs.

Why is Oil Contamination a Concern for Starters?

Oil contamination occurs when engine oil leaks onto the starter, significantly hampering its performance. This issue can lead to further engine problems if not addressed, making it a critical area for engine repair specialists and dealerships to monitor. B2B buyers should prioritize thorough inspections to detect oil leaks early, as addressing them promptly can prevent larger, more expensive engine repairs down the line.

How Do Faulty Relays or Fuses Impact Starter Functionality?

Faulty relays or fuses can cause a non-responsive starter while allowing dashboard lights to remain operational. This scenario often leads to confusion among drivers and mechanics alike. Electrical component suppliers should ensure they have a range of relays and fuses in stock to facilitate quick repairs. Although fixing these components is typically inexpensive, misdiagnosis can result in unnecessary expenses for both buyers and service providers.

Key Industrial Applications of faulty starter car

| Industry/Sector | Specific Application of faulty starter car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostic tools for faulty starter issues | Reduces downtime and enhances customer satisfaction | Availability of quality diagnostic equipment and parts |

| Fleet Management | Replacement parts for fleet vehicles | Ensures reliability and minimizes operational disruptions | Bulk purchasing agreements and warranty considerations |

| Construction Equipment | Starter systems for heavy machinery | Increases equipment uptime and productivity | Compatibility with various machinery types and after-sales support |

| Transportation Services | Maintenance services for commercial vehicles | Enhances vehicle lifespan and service reliability | Access to skilled technicians and service centers |

| Agriculture | Starter replacements for farming equipment | Improves efficiency and reduces harvest delays | Availability of specialized agricultural starters and local support services |

How Can Automotive Repair Businesses Utilize Faulty Starter Car Components?

Automotive repair shops often encounter vehicles with faulty starters, making diagnostic tools essential for identifying issues quickly. By investing in high-quality diagnostic equipment and replacement parts, these businesses can reduce vehicle downtime, leading to improved customer satisfaction and loyalty. For international buyers, sourcing reliable parts from reputable suppliers is crucial to ensure compatibility with various vehicle models.

What Role Does Faulty Starter Car Play in Fleet Management?

In fleet management, the reliability of vehicles is paramount. Faulty starters can lead to unexpected breakdowns, which disrupt operations and increase costs. By maintaining a stock of replacement starter parts, fleet managers can ensure that vehicles are serviced promptly, minimizing operational disruptions. International buyers should consider bulk purchasing agreements to leverage cost savings and ensure consistent supply.

How Is Faulty Starter Car Relevant to Construction Equipment?

Heavy machinery used in construction often relies on robust starter systems. Faulty starters can lead to equipment failures, causing costly delays on job sites. By investing in high-quality starter replacements, construction companies can enhance equipment uptime and productivity. Buyers in this sector must ensure that the starters are compatible with various machinery types and that suppliers offer comprehensive after-sales support.

Why Is Maintenance of Commercial Vehicles Important for Transportation Services?

Transportation services depend heavily on the reliability of their commercial vehicles. Faulty starters can lead to service interruptions and decreased customer satisfaction. Regular maintenance, including checking and replacing faulty starters, is vital for enhancing vehicle lifespan and ensuring service reliability. International buyers should prioritize sourcing from trusted suppliers who offer skilled technicians and robust service centers to support their maintenance needs.

How Do Agricultural Operations Benefit from Replacing Faulty Starters?

In agriculture, machinery such as tractors and harvesters must operate efficiently to avoid delays during critical harvest periods. Faulty starters can hinder these operations, resulting in lost productivity. By replacing faulty starters promptly, agricultural businesses can improve efficiency and ensure timely harvests. Buyers in this sector should focus on sourcing specialized agricultural starters and ensuring local support services are available to address any issues swiftly.

3 Common User Pain Points for ‘faulty starter car’ & Their Solutions

Scenario 1: Inconsistent Vehicle Start-Up in Fleet Operations

The Problem: For B2B buyers managing a fleet, such as logistics companies or transportation services, an unreliable starter can lead to significant operational disruptions. Vehicles that fail to start due to faulty starters can cause delays in deliveries, affect schedules, and lead to increased operational costs. The unpredictability of vehicle performance can frustrate drivers and decrease overall productivity, making it crucial for fleet managers to address these issues promptly.

The Solution: To mitigate these risks, B2B buyers should implement a robust maintenance schedule focusing on regular inspections of the starter systems across their fleet. This includes training technicians to recognize the signs of a failing starter, such as unusual sounds or dashboard warning lights. Additionally, sourcing high-quality, OEM or aftermarket starter components can ensure reliability. Establishing a partnership with a reputable automotive parts supplier that provides warranties and technical support can further enhance the fleet’s operational reliability, allowing for quick replacements when needed. Regular training and updates on best practices for vehicle maintenance can empower drivers and maintenance teams to address minor issues before they escalate.

Scenario 2: Rising Repair Costs from Faulty Starter Symptoms

The Problem: B2B buyers in the automotive service industry may encounter rising repair costs linked to faulty starters. When starters fail, they often present symptoms that can be misdiagnosed, leading to unnecessary parts replacements and labor costs. This not only affects profitability but can also harm customer trust when vehicles are not repaired correctly the first time.

The Solution: To combat this issue, service providers should invest in diagnostic tools that accurately identify starter issues without guesswork. Utilizing advanced diagnostic equipment can help technicians pinpoint whether the starter, battery, or alternator is at fault, reducing the likelihood of misdiagnosis. Additionally, creating a transparent communication strategy with customers about the diagnostic process can enhance trust and satisfaction. Training staff on the latest technologies and repair techniques ensures that your team is equipped to handle starter issues efficiently, ultimately leading to reduced labor costs and improved customer retention. Consider establishing a follow-up process post-repair to verify that the issue has been resolved satisfactorily, which can further strengthen customer relationships.

Scenario 3: Increased Downtime Due to Starter Failures in Remote Areas

The Problem: B2B buyers operating in remote regions, such as mining or agricultural sectors, face unique challenges when dealing with faulty starters. The downtime caused by vehicle failures not only halts operations but can also lead to costly delays in project timelines. Limited access to immediate repair services means that vehicles may remain inoperable for longer periods, impacting productivity and overall business performance.

Illustrative image related to faulty starter car

The Solution: To address these challenges, businesses should consider investing in portable starter repair kits and training local staff to perform basic starter diagnostics and repairs. This not only reduces reliance on external service providers but also empowers teams to address issues quickly on-site. Additionally, creating a stockpile of essential starter components at remote locations ensures that repairs can be conducted swiftly, minimizing downtime. Collaborating with local automotive suppliers for rapid access to parts can further enhance operational efficiency. Implementing a monitoring system that tracks vehicle performance can also alert teams to potential starter issues before they lead to complete failures, thereby improving fleet reliability and productivity in challenging environments.

Strategic Material Selection Guide for faulty starter car

What Are the Common Materials Used in Faulty Starter Car Components?

When addressing issues related to faulty starters in vehicles, the selection of materials for various components is critical. The performance, durability, and cost-effectiveness of these materials can significantly influence the overall functionality of the starter system. Here, we analyze four common materials used in starter components, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Metals Like Steel Impact Starter Performance?

Key Properties: Steel is well-regarded for its high tensile strength and durability. It can withstand significant mechanical stress and is often treated for corrosion resistance.

Pros & Cons: Steel components are generally cost-effective and relatively easy to manufacture. However, they can be heavier than alternative materials, which may impact the overall weight of the starter assembly. Additionally, untreated steel can be prone to rust, particularly in humid environments.

Impact on Application: Steel is suitable for components that require strength, such as the starter housing and mounting brackets. However, its weight may necessitate careful consideration in performance-oriented applications.

International Considerations: Buyers in regions like Africa and South America should ensure that steel components comply with local corrosion resistance standards, as environmental factors can vary significantly. In Europe, adherence to DIN standards is crucial for quality assurance.

Why Is Aluminum a Preferred Choice for Starter Components?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. Its low density makes it an attractive option for automotive applications.

Illustrative image related to faulty starter car

Pros & Cons: The primary advantage of aluminum is its weight-saving properties, which can enhance vehicle efficiency. However, it is generally more expensive than steel and may require specialized manufacturing processes.

Impact on Application: Aluminum is particularly beneficial for components like the starter motor casing, where weight reduction is essential. Its thermal properties also help in dissipating heat generated during operation.

International Considerations: For buyers in the Middle East, where temperatures can soar, aluminum’s heat resistance is a significant advantage. Compliance with international aluminum standards, such as ASTM, is vital to ensure quality and performance.

What Role Does Copper Play in Electrical Connections?

Key Properties: Copper is known for its excellent electrical conductivity and thermal properties, making it ideal for electrical connections within the starter system.

Illustrative image related to faulty starter car

Pros & Cons: Copper components facilitate efficient power transmission, reducing energy loss. However, copper is relatively expensive and can corrode if not properly insulated.

Impact on Application: Copper is commonly used in starter wiring and terminals, where reliable electrical connections are critical. Its high conductivity ensures that the starter receives sufficient power from the battery.

International Considerations: Buyers should be aware of the varying regulations regarding copper usage in electrical applications across different regions. Compliance with JIS standards in Japan or ASTM standards in the U.S. may be necessary for international trade.

Illustrative image related to faulty starter car

How Does Plastic Enhance Starter Component Design?

Key Properties: Engineering plastics, such as nylon or polycarbonate, offer lightweight, corrosion-resistant, and insulating properties.

Pros & Cons: Plastics can significantly reduce the weight of starter components, and their insulating properties help prevent electrical shorts. However, they may not withstand high temperatures as effectively as metals, which could limit their application in certain areas.

Impact on Application: Plastics are ideal for covers and insulation components, where weight and electrical insulation are priorities. However, they should be used cautiously in high-heat areas.

International Considerations: For buyers in Europe, compliance with REACH regulations regarding chemical safety in plastics is essential. In regions like Africa, the availability of high-quality engineering plastics may vary, impacting sourcing decisions.

Summary Table of Material Selection for Faulty Starter Car Components

| Material | Typical Use Case for faulty starter car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Starter housing and mounting brackets | High tensile strength | Heavier than alternatives | Low |

| Aluminum | Starter motor casing | Lightweight and corrosion-resistant | More expensive | Med |

| Copper | Wiring and electrical connections | Excellent electrical conductivity | Prone to corrosion | High |

| Plastic | Insulation covers and lightweight parts | Lightweight and insulating | Limited high-temperature resistance | Med |

This analysis provides a comprehensive overview of the materials used in faulty starter car components, highlighting their properties, benefits, and considerations for international buyers. Understanding these factors will aid in making informed purchasing decisions that align with regional standards and performance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for faulty starter car

What Are the Main Stages in the Manufacturing Process of Faulty Starter Cars?

Manufacturing a starter motor involves several critical stages, each requiring precision and attention to detail. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation

The manufacturing process begins with the selection of high-quality materials. Common materials include steel for the casing, copper for the windings, and various plastics for components such as the housing. Quality assurance starts here, as materials undergo inspection to ensure they meet specific standards for strength and conductivity. Suppliers should provide certificates of compliance, which B2B buyers can verify to ensure they are sourcing from reliable manufacturers. -

Forming

In this stage, the raw materials are shaped into components. Techniques such as stamping and machining are employed to create parts like the starter housing, gears, and electrical connections. The forming process must adhere to strict tolerances to ensure that components fit together seamlessly. B2B buyers should inquire about the machinery used and the precision of the forming techniques, as these factors significantly impact the starter’s performance and durability. -

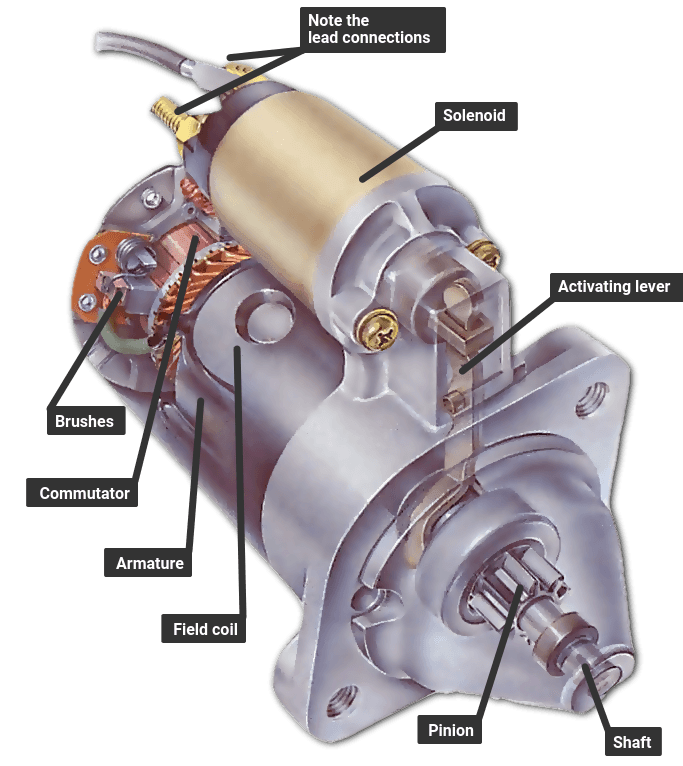

Assembly

Once the components are formed, they are assembled into a complete starter motor. This process often involves manual and automated assembly lines, where workers or robots fit together the various parts, including the armature, solenoid, and housing. Quality control checkpoints during assembly, known as In-Process Quality Control (IPQC), ensure that each unit meets the required specifications before moving to the next stage. B2B buyers should request information on the assembly line’s efficiency and the training of assembly personnel to minimize human error. -

Finishing

The final stage involves finishing processes such as painting, coating, and electrical testing. Coatings are applied to protect against corrosion and wear, while electrical tests ensure that the starter functions properly under load conditions. This stage also includes a final inspection to verify that the starter meets all industry standards. Buyers should look for compliance with international standards such as ISO 9001, which indicates a commitment to quality management systems.

What Are the Key Quality Control Measures for Faulty Starter Cars?

Quality control (QC) is crucial in the manufacturing of starter motors, given their role in vehicle performance. Several international and industry-specific standards govern these processes.

-

Relevant International Standards

Compliance with ISO 9001 ensures that manufacturers maintain a quality management system that meets customer and regulatory requirements. For automotive components, adherence to the IATF 16949 standard is also essential, as it focuses on continuous improvement and defect prevention. B2B buyers should verify that suppliers have the necessary certifications and that their manufacturing processes align with these standards. -

QC Checkpoints: IQC, IPQC, FQC

– Incoming Quality Control (IQC): This is the first checkpoint, where raw materials are inspected for quality before being used in production. Any subpar materials are rejected, ensuring that only the best components enter the manufacturing process.

– In-Process Quality Control (IPQC): During assembly, regular checks are performed to catch defects early. This proactive approach minimizes the risk of faulty products reaching the market.

– Final Quality Control (FQC): After assembly, each starter motor undergoes rigorous testing to ensure it functions correctly. This includes electrical testing, performance assessments, and visual inspections. -

Common Testing Methods for Starters

Various testing methods are employed to ensure the reliability of starter motors. These include:

– Electrical Load Testing: Verifying that the starter can handle the required load and function under various conditions.

– Temperature Testing: Assessing how the starter performs under extreme temperature variations.

– Vibration Testing: Ensuring that the starter can withstand vibrations that occur during vehicle operation without failing.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that they are sourcing high-quality starter motors, B2B buyers can take several steps to verify a supplier’s quality control measures.

-

Conducting Supplier Audits

Regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should assess whether the suppliers adhere to international standards and how they handle non-conformities. -

Requesting Quality Reports

Suppliers should provide detailed quality reports that outline their QC processes, test results, and any corrective actions taken. These reports can help buyers gauge the reliability of the supplier’s products. -

Engaging Third-Party Inspection Services

Third-party inspection services can conduct independent assessments of a supplier’s manufacturing processes and products. These inspections offer an unbiased view of quality and compliance with specified standards.

What Are the QC and Certification Nuances for International B2B Buyers?

For B2B buyers operating in diverse markets, understanding the nuances of quality control and certification is vital. Buyers in regions such as Africa, South America, the Middle East, and Europe may encounter varying standards and regulations.

-

Understanding Regional Standards

Buyers should familiarize themselves with local regulations and standards, which may differ from international norms. For instance, CE marking is crucial for products sold within the European Union, indicating compliance with health, safety, and environmental protection standards. -

Navigating Import Regulations

Each country has specific import regulations that may affect the ability to bring starter motors into the market. Buyers should consult with legal experts or customs brokers to ensure compliance with local laws and to avoid potential delays or fines. -

Building Relationships with Local Partners

Establishing relationships with local distributors or partners can aid in navigating the complexities of quality assurance and regulatory compliance. Local partners can provide insights into market expectations and help ensure that products meet both international and local standards.

In conclusion, the manufacturing processes and quality assurance for starter motors are critical to ensuring product reliability and performance. By understanding these processes and the relevant quality control measures, B2B buyers can make informed decisions, ultimately leading to better partnerships and successful procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faulty starter car’

To assist B2B buyers in procuring vehicles with faulty starters, this guide provides a structured approach to ensure a successful sourcing process. Understanding the complexities of automotive components, especially the starter system, is crucial for making informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the faulty starter car. This includes the make, model, and any particular engine specifications necessary for your market.

– Key Considerations: Assess the vehicle types that are most in demand in your region, such as sedans, SUVs, or trucks.

– Target Market: Identify whether you are focusing on fleet purchases or retail sales, as this will influence your sourcing strategy.

Step 2: Identify Potential Suppliers

Research and compile a list of potential suppliers who specialize in faulty starter cars. Utilize industry networks, trade shows, and online platforms to identify reputable vendors.

– Supplier Reputation: Look for suppliers with a proven track record in your target regions, such as Africa or Europe.

– Local Partnerships: Engage with local distributors who understand regional preferences and regulations.

Step 3: Evaluate Supplier Certifications

Before entering negotiations, ensure that your suppliers possess the necessary certifications and licenses. This adds a layer of reliability to your sourcing process.

– Industry Standards: Verify that they comply with international quality standards, such as ISO certifications.

– Regulatory Compliance: Confirm that they meet local automotive regulations and safety standards specific to your market.

Step 4: Assess Quality Control Measures

Inquire about the quality control processes that suppliers have in place for their faulty starter cars. Understanding their inspection and testing protocols will help you gauge product reliability.

– Testing Procedures: Ask for documentation on how they assess starter functionality and overall vehicle condition.

– Warranty Policies: Investigate their warranty offerings, as robust warranties can indicate confidence in product quality.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that outline pricing, delivery timelines, and payment terms. This will facilitate a transparent comparison between suppliers.

– Cost Breakdown: Ensure that quotes include all associated costs, such as shipping, customs, and any hidden fees.

– Negotiation Leverage: Use this information to negotiate better terms based on competitive offers.

Step 6: Conduct Site Visits or Virtual Inspections

If feasible, conduct site visits to the supplier’s facilities or arrange for virtual inspections to assess their operations and product quality firsthand.

– Facility Standards: Observe the cleanliness, organization, and safety of their operations.

– Product Availability: Ensure that they have sufficient stock and can meet your volume requirements.

Step 7: Finalize Contracts and Agreements

Once you have selected your preferred supplier, finalize contracts that outline all agreed-upon terms. Ensure that the contract covers all aspects of the deal, including delivery schedules and penalties for non-compliance.

– Legal Review: Engage legal counsel to review contracts for potential risks and liabilities.

– Long-term Partnerships: Consider establishing long-term agreements for ongoing supply, which can lead to better pricing and reliability.

Illustrative image related to faulty starter car

By following this structured sourcing checklist, B2B buyers can navigate the complexities of procuring faulty starter cars effectively, ensuring they make informed decisions that benefit their business operations.

Comprehensive Cost and Pricing Analysis for faulty starter car Sourcing

What Are the Key Cost Components in Sourcing a Faulty Starter Car?

When sourcing faulty starter cars, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials, including the starter motor, battery connections, and other electrical components, can vary significantly based on quality and supplier. Sourcing high-quality materials may incur higher initial costs but can lead to lower failure rates and reduced warranty claims.

-

Labor: Labor costs encompass assembly, testing, and quality assurance processes. Skilled labor in regions with higher wage standards, such as Germany, may drive up costs compared to labor in developing countries.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs that are indirectly associated with the production process. Efficient manufacturing practices can minimize these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom or specialized starter designs. However, these costs are typically amortized over a larger production run, making them less impactful per unit in high-volume orders.

-

Quality Control (QC): Investing in robust QC processes ensures that faulty starters are identified and addressed before reaching the market. This can prevent costly recalls and enhance customer satisfaction.

-

Logistics: Transportation and shipping costs must also be considered. These can vary based on distance, mode of transport, and whether the supplier uses cost-effective methods or premium services.

-

Margin: Suppliers typically include a profit margin that reflects the risk and value-added services they provide. Understanding the market rate for margins in the starter car industry can help buyers negotiate better prices.

What Influences Pricing for Faulty Starter Cars?

Several factors can influence pricing when sourcing faulty starter cars, including volume, specifications, materials, quality certifications, supplier reputation, and Incoterms.

-

Volume/MOQ: Purchasing in bulk can significantly reduce per-unit costs. Suppliers often offer discounts for higher minimum order quantities (MOQs), so negotiating a larger order may yield better pricing.

-

Specifications and Customization: Custom specifications can drive up costs due to the need for specialized materials or processes. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials directly impacts both the price and the longevity of the starter. Additionally, sourcing from suppliers with recognized quality certifications can enhance reliability but may come at a premium.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge more, but they also reduce the risks associated with faulty products.

-

Incoterms: The choice of Incoterms can significantly impact the total landed cost of the starter. Buyers should be aware of who bears the risk and costs associated with shipping, insurance, and customs clearance.

How Can International B2B Buyers Negotiate Better Prices for Faulty Starter Cars?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings.

Illustrative image related to faulty starter car

-

Understand Total Cost of Ownership (TCO): Assessing TCO rather than just the initial purchase price can reveal the long-term savings associated with higher-quality starters. This perspective can strengthen your negotiating position.

-

Leverage Local Market Knowledge: Buyers in regions like Nigeria or Germany can utilize local market insights to negotiate better terms. Understanding local trends, currency fluctuations, and supply chain dynamics can be advantageous.

-

Build Long-term Relationships: Establishing a solid relationship with suppliers can lead to better pricing and service. Consistent orders may encourage suppliers to offer discounts or favorable terms.

-

Be Prepared to Walk Away: Having alternative suppliers or options can provide leverage in negotiations. If a supplier knows you have other choices, they may be more willing to negotiate.

Conclusion

Navigating the complexities of sourcing faulty starter cars requires a deep understanding of cost components, pricing influencers, and effective negotiation strategies. By leveraging these insights, international B2B buyers can make informed decisions that lead to cost efficiencies and long-term success. Always remember that the prices discussed are indicative and can fluctuate based on market conditions and specific supplier terms.

Alternatives Analysis: Comparing faulty starter car With Other Solutions

Understanding the Importance of Exploring Alternatives

In the automotive industry, particularly for B2B buyers dealing with vehicle maintenance and repairs, identifying alternatives to a faulty starter car is crucial. A faulty starter can lead to significant downtime and increased operational costs. By comparing different solutions, businesses can make informed decisions that enhance their operational efficiency and reduce vehicle maintenance expenses.

Comparison Table

| Comparison Aspect | Faulty Starter Car | Replacement Starter Motor | Jump Start Solutions |

|---|---|---|---|

| Performance | Inconsistent performance; may fail to start vehicle | Restores full functionality; reliable | Temporary fix; not a permanent solution |

| Cost | Repair costs can vary; potential for high expenses | Moderate upfront cost; long-term reliability | Low cost for equipment, but repeated use may add up |

| Ease of Implementation | Requires professional diagnosis and repair | Straightforward installation; often DIY-friendly | Requires minimal skills; quick setup |

| Maintenance | Frequent issues can arise if not addressed | Low maintenance; typically lasts several years | Needs recharging or new battery; not sustainable |

| Best Use Case | Temporary vehicle downtime; immediate attention needed | Long-term vehicle reliability; essential for fleet operations | Short-term solution during emergencies |

Detailed Breakdown of Alternatives

Replacement Starter Motor

Opting for a replacement starter motor is a common solution for businesses facing issues with a faulty starter car. This alternative restores full functionality to the vehicle, ensuring reliable starts. The initial investment is moderate, but the long-term reliability can save businesses from frequent repairs. Installation can often be a DIY task, which reduces labor costs. However, it is essential to ensure that the replacement part is compatible with the specific vehicle model to avoid future issues.

Jump Start Solutions

Jump start solutions, such as portable jump starters or traditional jump cables, serve as a quick fix when a vehicle fails to start. These solutions are cost-effective and can be implemented with minimal skills. They are particularly useful in emergency situations where immediate action is required. However, relying on jump starts is not sustainable, as they do not address underlying issues with the starter or battery. Frequent use can lead to additional wear on the vehicle’s electrical components, making this an ideal short-term solution rather than a long-term strategy.

Conclusion: How to Choose the Right Solution for Your Needs

When considering alternatives to a faulty starter car, B2B buyers should evaluate their specific needs, including budget constraints, the urgency of repairs, and long-term vehicle reliability. Replacement starter motors offer a dependable long-term solution, while jump start solutions can be beneficial for immediate, short-term needs. By weighing the pros and cons of each alternative, businesses can make strategic decisions that align with their operational requirements and improve overall vehicle performance.

Illustrative image related to faulty starter car

Essential Technical Properties and Trade Terminology for faulty starter car

What Are the Key Technical Properties of a Faulty Starter Car?

Understanding the technical specifications of starter motors is essential for B2B buyers in the automotive sector. Here are some critical properties to consider:

-

Material Grade

The materials used in the construction of starter motors, such as copper for windings and high-grade steel for housing, directly impact durability and performance. High-quality materials reduce the risk of corrosion and enhance the lifespan of the starter. For B2B buyers, sourcing starters made from superior materials ensures reliability, which is crucial for customer satisfaction and brand reputation. -

Tolerance Levels

Tolerance refers to the acceptable range of variation in the physical dimensions of the starter components. Tight tolerances are essential for ensuring that parts fit together correctly and operate efficiently. In a B2B context, understanding tolerance levels helps buyers ensure compatibility with existing vehicle systems, minimizing installation issues and reducing return rates. -

Power Rating

The power rating, typically measured in volts and amps, indicates the electrical capacity of the starter. A higher power rating ensures that the starter can effectively crank the engine under various conditions, especially in extreme weather. For international buyers, considering power ratings is vital to ensure that the starters meet the electrical standards of different regions, such as Europe or Africa. -

Operating Temperature Range

This specification defines the temperature limits within which the starter can function effectively. Starters that can withstand extreme temperatures are essential in markets with varied climates. B2B buyers should prioritize products with a wide operating temperature range to cater to diverse geographical needs, enhancing product versatility. -

Start-Up Torque

Start-up torque refers to the rotational force that the starter motor generates to initiate engine ignition. A higher start-up torque is crucial for larger engines or those that may require more effort to turn over. B2B purchasers need to consider this specification to ensure that the starters they procure can handle the demands of the vehicles they service or sell.

What Common Trade Terms Should B2B Buyers Know When Sourcing Starter Motors?

Familiarity with industry jargon is essential for effective communication and negotiation in the automotive supply chain. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to parts made by the same company that manufactured the original components of a vehicle. OEM starters are often preferred for their guaranteed compatibility and quality. Buyers should consider OEM parts to maintain vehicle performance and warranty compliance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and avoid overstocking or understocking issues. It’s important to negotiate MOQs that align with your purchasing capacity and sales forecasts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for a specific quantity of goods. This term is essential for buyers looking to compare prices and terms from different suppliers. Crafting a detailed RFQ ensures that you receive accurate and comparable quotes, facilitating better decision-making. -

Incoterms (International Commercial Terms)

These are standard trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, costs, and risks. This knowledge helps in negotiating contracts and managing logistics more effectively. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. This term is critical for inventory management and planning. B2B buyers should assess lead times to ensure that they can meet customer demands without delays, thus maintaining service levels and customer satisfaction.

By being informed about these technical properties and trade terms, international B2B buyers can make more strategic purchasing decisions regarding faulty starter motors, ensuring they meet both operational requirements and market expectations.

Illustrative image related to faulty starter car

Navigating Market Dynamics and Sourcing Trends in the faulty starter car Sector

What Are the Current Market Dynamics and Key Trends in the Faulty Starter Car Sector?

The global automotive industry is witnessing significant shifts influenced by technological advancements, changing consumer preferences, and regulatory pressures. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions. One of the key drivers in the faulty starter car sector is the growing demand for reliable automotive parts due to the increasing average age of vehicles on the road. As cars age, the likelihood of starter failures rises, creating a robust market for replacement parts.

Emerging trends such as the integration of smart technology in vehicles are also reshaping the sector. Innovations like smart diagnostics can help identify starter issues early, allowing for proactive maintenance and reducing the overall cost of ownership. B2B buyers should seek suppliers who leverage these technologies, as they can offer higher-quality products and services.

Moreover, the rise of e-commerce platforms for auto parts is transforming how businesses source components. This shift facilitates direct connections between manufacturers and buyers, streamlining the procurement process and reducing costs. For instance, platforms specializing in automotive parts can provide real-time inventory updates and competitive pricing, which are essential for buyers in fast-paced markets.

How Can Sustainability and Ethical Sourcing Impact the Faulty Starter Car Sector?

Sustainability is increasingly becoming a priority for businesses worldwide, and the automotive sector is no exception. The environmental impact of sourcing practices in the faulty starter car sector cannot be overlooked. B2B buyers are urged to consider suppliers who adopt sustainable manufacturing processes and materials. This includes utilizing recycled metals and eco-friendly packaging, which can significantly reduce the carbon footprint associated with automotive part production.

Ethical sourcing is equally important. Buyers should prioritize suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to ethical practices. Additionally, sourcing from companies that actively engage in community development initiatives can enhance a buyer’s brand reputation and appeal to environmentally conscious consumers.

Investing in ‘green’ certified materials not only supports sustainability goals but can also lead to long-term cost savings. For instance, products made from sustainable materials often have a longer lifespan, reducing the frequency of replacements and associated waste.

How Has the Faulty Starter Car Sector Evolved Over Time?

The evolution of the faulty starter car sector can be traced back to the early days of automotive engineering. Initially, starters were simple mechanisms reliant on mechanical systems. However, with advancements in electrical engineering, modern starters have become more complex and efficient, integrating electronic components that enhance performance and reliability.

Over the decades, the shift towards automated manufacturing processes and the introduction of quality control measures have further refined starter production. Today, B2B buyers benefit from a wide range of options, including high-performance starters designed for specific vehicle types and driving conditions. This evolution not only reflects technological advancements but also highlights the growing importance of reliability and efficiency in automotive components.

As the automotive landscape continues to change, staying informed about these trends and historical developments is vital for B2B buyers looking to optimize their sourcing strategies in the faulty starter car sector.

Frequently Asked Questions (FAQs) for B2B Buyers of faulty starter car

-

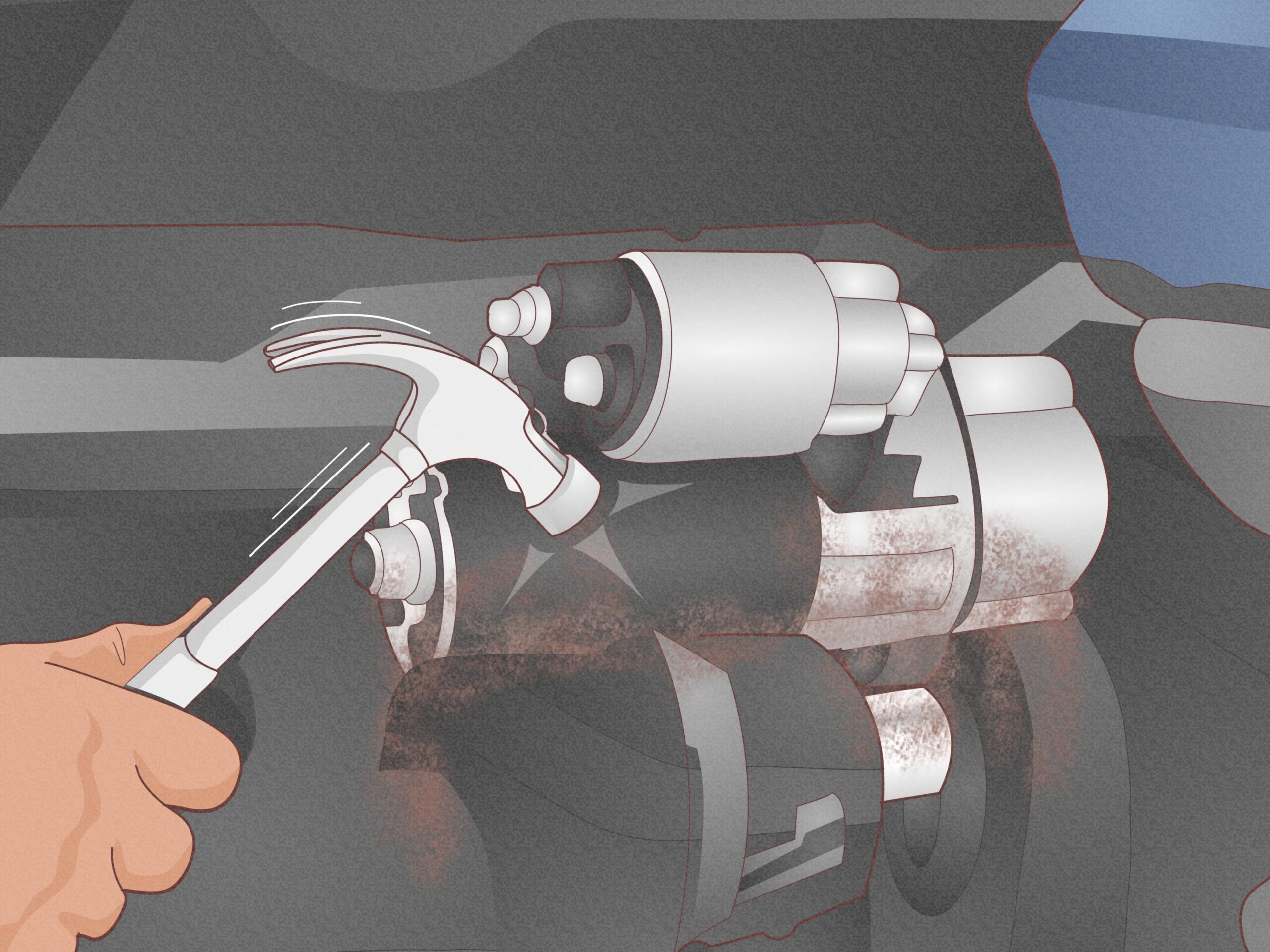

How do I solve persistent starting issues with a faulty starter?

To address persistent starting issues, first check the battery and its connections, as they are often the root cause. Inspect the starter relay and fuses for any signs of damage or corrosion. If the dashboard lights up but the engine doesn’t respond, consider tapping the starter gently to realign its components. If these steps don’t resolve the issue, consult a professional mechanic to conduct a thorough inspection and repair, as continuing to start the vehicle could lead to further damage. -

What is the best way to identify a faulty starter in a vehicle?

Identifying a faulty starter involves observing several key symptoms. Common indicators include unusual clicking noises when attempting to start the vehicle, a non-responsive engine despite a functioning battery, or smoke coming from the starter area. If the engine doesn’t turn over after multiple attempts, it may also suggest a starter issue. Conducting a visual inspection for oil leaks around the starter can also help determine its condition. For accurate diagnosis, consider consulting with an automotive technician. -

What factors should I consider when sourcing faulty starter cars for resale?

When sourcing faulty starter cars, consider factors such as the make and model, the extent of the starter issue, and the vehicle’s overall condition. Assess the potential repair costs and the demand for specific vehicles in your target market. Additionally, ensure that the cars comply with local regulations in your region, as this can affect resale value. Establish relationships with reliable suppliers who can provide detailed histories of the vehicles and transparent pricing. -

How can I vet suppliers for faulty starter cars internationally?

To vet suppliers, start by researching their reputation through online reviews and testimonials. Request references from previous clients to gauge their reliability and service quality. Verify their business licenses and certifications to ensure compliance with local regulations. Conducting factory visits or virtual inspections can also provide insights into their operational standards. Additionally, consider using third-party inspection services to assess the quality of the vehicles before making a purchase. -

What are the minimum order quantities (MOQs) for purchasing faulty starter cars?

Minimum order quantities (MOQs) can vary significantly between suppliers and regions. Typically, suppliers may set MOQs based on their inventory levels, shipping costs, and production capabilities. It’s essential to discuss MOQs directly with potential suppliers to understand their policies. Some may offer flexibility based on your business needs, especially if you are establishing a long-term relationship. Negotiating favorable terms can also provide leverage for better pricing and service. -

What payment terms are common in international transactions for faulty starter cars?

Common payment terms in international transactions include upfront payment, partial payment (deposit) followed by the balance upon delivery, or payment through letters of credit. The choice of terms often depends on the supplier’s policies and your negotiation. Ensure that you establish clear payment terms that protect both parties, including currency exchange considerations and payment methods. Using escrow services can also add a layer of security to the transaction. -

What quality assurance measures should be taken when sourcing faulty starter cars?

Quality assurance measures should include conducting thorough inspections of the vehicles before purchase. Request detailed reports on the condition of the starters and other critical components. Utilize third-party inspection services to verify the quality and authenticity of the vehicles. Establishing clear quality standards with your suppliers can help ensure that the cars meet your expectations and reduce the risk of future repairs. Additionally, consider implementing a warranty policy for further assurance. -

How does logistics affect the procurement of faulty starter cars internationally?

Logistics plays a crucial role in the procurement of faulty starter cars, impacting shipping costs, delivery times, and inventory management. It’s essential to select reliable logistics partners who can handle customs clearance and comply with local regulations in your target market. Consider the mode of transportation (sea, air, or land) that best suits your needs, balancing cost and speed. Planning for potential delays and ensuring proper documentation can facilitate a smoother import process and help maintain a steady supply chain.

Top 2 Faulty Starter Car Manufacturers & Suppliers List

1. Facebook – Ignition Coil Failure

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Ignition Coil Failure, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Northrich Automotive – Starter System Diagnostics & Repairs

Domain: northrichauto.com

Registered: 2001 (24 years)

Introduction: Northrich Automotive offers automotive repair services including starter system diagnostics and repairs. Key signs of a failing starter include slow cranking, refusal to start, intermittent starting issues, dimming interior lights, grinding noises, whirring sounds, continuous running after starting, burning smells, and oil leaks on the starter system. If these issues are not addressed, they can le…

Strategic Sourcing Conclusion and Outlook for faulty starter car

How Can Strategic Sourcing Enhance Your Approach to Faulty Starter Car Issues?

In conclusion, understanding the complexities of faulty starter systems is essential for B2B buyers looking to optimize their vehicle maintenance and repair strategies. By recognizing the key symptoms of starter failures and the underlying causes—such as poor connections, corroded components, and oil leaks—businesses can proactively manage their fleets and reduce downtime. Strategic sourcing plays a vital role in this process, enabling companies to identify reliable suppliers for quality starter parts and professional services, ultimately ensuring that their vehicles remain operational.

International buyers from regions like Africa, South America, the Middle East, and Europe should prioritize partnerships with reputable suppliers who offer robust warranties and support. This approach not only mitigates risks associated with starter failures but also enhances overall operational efficiency. As the automotive landscape continues to evolve, investing in quality components and expert maintenance will be crucial for sustaining vehicle performance.

We encourage you to assess your current sourcing strategies and explore opportunities for improvement. Engage with trusted suppliers today to ensure your fleet remains reliable and ready for the road ahead.

Illustrative image related to faulty starter car

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.