Introduction: Navigating the Global Market for cuanto cuesta un motor de arranque

In the increasingly interconnected global market, sourcing a reliable motor de arranque (starter motor) presents unique challenges for B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. Understanding the cost of a motor de arranque is not just about price; it involves evaluating quality, supplier reliability, and specific application needs. This comprehensive guide aims to demystify the complexities surrounding the sourcing process by providing a detailed analysis of various starter motor types, their applications across different vehicle models, and essential tips for supplier vetting.

International buyers often face hurdles such as fluctuating prices, varying quality standards, and the necessity for compliance with local regulations. This guide empowers decision-makers by equipping them with actionable insights on cost considerations, potential pitfalls, and best practices in procurement. From understanding the factors that influence pricing—such as specifications and brand reputation—to exploring the nuances of global supply chains, our resource serves as a strategic tool for informed purchasing decisions.

By leveraging this guide, B2B buyers will enhance their ability to navigate the market effectively, ensuring they procure the right motor de arranque at a competitive price while fostering long-term supplier relationships. Whether you are based in Vietnam or Nigeria, this guide is designed to meet your specific sourcing needs and challenges.

Table Of Contents

- Top 3 Cuanto Cuesta Un Motor De Arranque Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cuanto cuesta un motor de arranque

- Understanding cuanto cuesta un motor de arranque Types and Variations

- Key Industrial Applications of cuanto cuesta un motor de arranque

- 3 Common User Pain Points for ‘cuanto cuesta un motor de arranque’ & Their Solutions

- Strategic Material Selection Guide for cuanto cuesta un motor de arranque

- In-depth Look: Manufacturing Processes and Quality Assurance for cuanto cuesta un motor de arranque

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cuanto cuesta un motor de arranque’

- Comprehensive Cost and Pricing Analysis for cuanto cuesta un motor de arranque Sourcing

- Alternatives Analysis: Comparing cuanto cuesta un motor de arranque With Other Solutions

- Essential Technical Properties and Trade Terminology for cuanto cuesta un motor de arranque

- Navigating Market Dynamics and Sourcing Trends in the cuanto cuesta un motor de arranque Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cuanto cuesta un motor de arranque

- Strategic Sourcing Conclusion and Outlook for cuanto cuesta un motor de arranque

- Important Disclaimer & Terms of Use

Understanding cuanto cuesta un motor de arranque Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Starter Motor | Basic design, typically 12V, used in most vehicles | Passenger vehicles, light trucks | Pros: Cost-effective, widely available. Cons: Limited performance in extreme conditions. |

| High-Torque Starter | Enhanced power output, designed for heavy-duty use | Commercial vehicles, construction equipment | Pros: Reliable performance under heavy loads. Cons: Higher cost, may require more maintenance. |

| Mini Starter Motor | Compact size, lightweight design | Motorcycles, compact cars | Pros: Space-saving, efficient. Cons: Limited power for larger engines. |

| Gear Reduction Starter | Uses gears to increase torque | Racing vehicles, performance cars | Pros: Improved efficiency and torque. Cons: More complex installation and higher price point. |

| Permanent Magnet Starter | Utilizes permanent magnets for efficiency | Electric vehicles, hybrids | Pros: High efficiency, lightweight. Cons: Higher initial investment, may not suit all applications. |

What Are the Characteristics of Standard Starter Motors?

Standard starter motors are the most common type found in passenger vehicles and light trucks. Operating typically on a 12V system, they provide the necessary torque to start the engine. Their simplicity and widespread availability make them a go-to choice for many B2B buyers. However, while they are cost-effective, their performance may falter in extreme weather conditions or with larger engines, necessitating careful consideration of the application.

Why Choose High-Torque Starters for Heavy-Duty Applications?

High-torque starters are specifically designed for heavy-duty applications, such as commercial vehicles and construction equipment. These motors provide enhanced power output, making them ideal for engines that require more torque to initiate startup. While they are more expensive and may require more frequent maintenance, their reliability under heavy loads makes them a worthwhile investment for businesses that prioritize performance and durability.

What Makes Mini Starter Motors Ideal for Compact Vehicles?

Mini starter motors are characterized by their compact size and lightweight design, making them perfect for motorcycles and compact cars. They are engineered to deliver efficient performance while saving valuable space in smaller vehicles. However, their power output is limited compared to larger starters, which means they may not be suitable for high-performance or larger engine applications. B2B buyers should assess their vehicle specifications before opting for this type.

How Do Gear Reduction Starters Enhance Performance?

Gear reduction starters utilize a gearing system to increase torque, making them particularly beneficial for racing vehicles and high-performance cars. This design enhances efficiency and allows for quicker engine starts. While they offer significant advantages in performance, the complexity of installation and higher price points may deter some buyers. Businesses involved in motorsports or performance tuning will find these starters advantageous.

What Are the Benefits of Permanent Magnet Starters?

Permanent magnet starters leverage the efficiency of permanent magnets, making them an excellent choice for electric vehicles and hybrids. They are lightweight and provide high efficiency, which can translate into better fuel economy and reduced battery drain. However, the initial investment is generally higher, and they may not be compatible with all vehicle types. B2B buyers should consider their long-term operational costs and compatibility when choosing this option.

Key Industrial Applications of cuanto cuesta un motor de arranque

| Industry/Sector | Specific Application of cuanto cuesta un motor de arranque | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Used in assembly lines for vehicle production | Ensures reliable vehicle assembly and reduces downtime | Quality certification, compatibility with various models |

| Agriculture | Powering tractors and farm machinery | Enhances operational efficiency in farming activities | Durability in harsh conditions, maintenance support |

| Transportation & Logistics | Installation in commercial vehicles for fleet operations | Ensures timely deliveries and reduces vehicle breakdowns | Cost-effectiveness, availability of spare parts |

| Mining | Used in heavy machinery like excavators and drills | Increases productivity and minimizes operational delays | Robustness, ability to operate in extreme environments |

| Renewable Energy | Powering generators for off-grid solar and wind systems | Supports sustainable energy solutions and reduces emissions | Energy efficiency, compliance with international standards |

How is ‘cuanto cuesta un motor de arranque’ utilized in the Automotive Manufacturing sector?

In the automotive manufacturing industry, the motor de arranque is a critical component in the assembly of vehicles. It is responsible for initiating the engine, ensuring that vehicles can be reliably produced and tested. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality starter motors that meet specific vehicle model requirements is essential. Buyers must consider compatibility with various engine types and the availability of technical support to ensure seamless integration into production lines.

What role does ‘cuanto cuesta un motor de arranque’ play in Agriculture?

In agriculture, starter motors are vital for powering tractors and other farm machinery. These motors ensure that equipment can start reliably, which is crucial for maintaining productivity during planting and harvesting seasons. Buyers in regions with challenging climates, such as the Middle East and parts of Africa, should prioritize durability and performance under extreme conditions. Additionally, sourcing motors that require minimal maintenance can significantly reduce operational costs in the long run.

How does ‘cuanto cuesta un motor de arranque’ benefit the Transportation & Logistics sector?

In the transportation and logistics sector, the motor de arranque is essential for commercial vehicles, including trucks and vans. A reliable starter motor contributes to timely deliveries by reducing the risk of vehicle breakdowns. For B2B buyers, particularly in Europe, understanding the cost-effectiveness of different starter motors can lead to better fleet management. Buyers should focus on sourcing motors that are not only affordable but also provide longevity and easy access to replacement parts.

What is the significance of ‘cuanto cuesta un motor de arranque’ in Mining operations?

In the mining industry, starter motors are used in heavy machinery such as excavators and drills. These motors are crucial for ensuring that equipment operates efficiently in demanding environments. Buyers from regions with active mining operations, like South America and Africa, should consider the robustness of the starter motors they source. This includes evaluating their ability to withstand dust, moisture, and extreme temperatures, which can affect machinery performance.

How does ‘cuanto cuesta un motor de arranque’ support Renewable Energy initiatives?

In the renewable energy sector, starter motors are often used in generators for off-grid solar and wind systems. These applications are essential for providing power in remote areas, contributing to sustainable energy solutions. International buyers, particularly from emerging markets, should look for motors that offer energy efficiency and comply with international standards. This ensures that the systems they install are reliable and environmentally friendly, which is increasingly important in global energy markets.

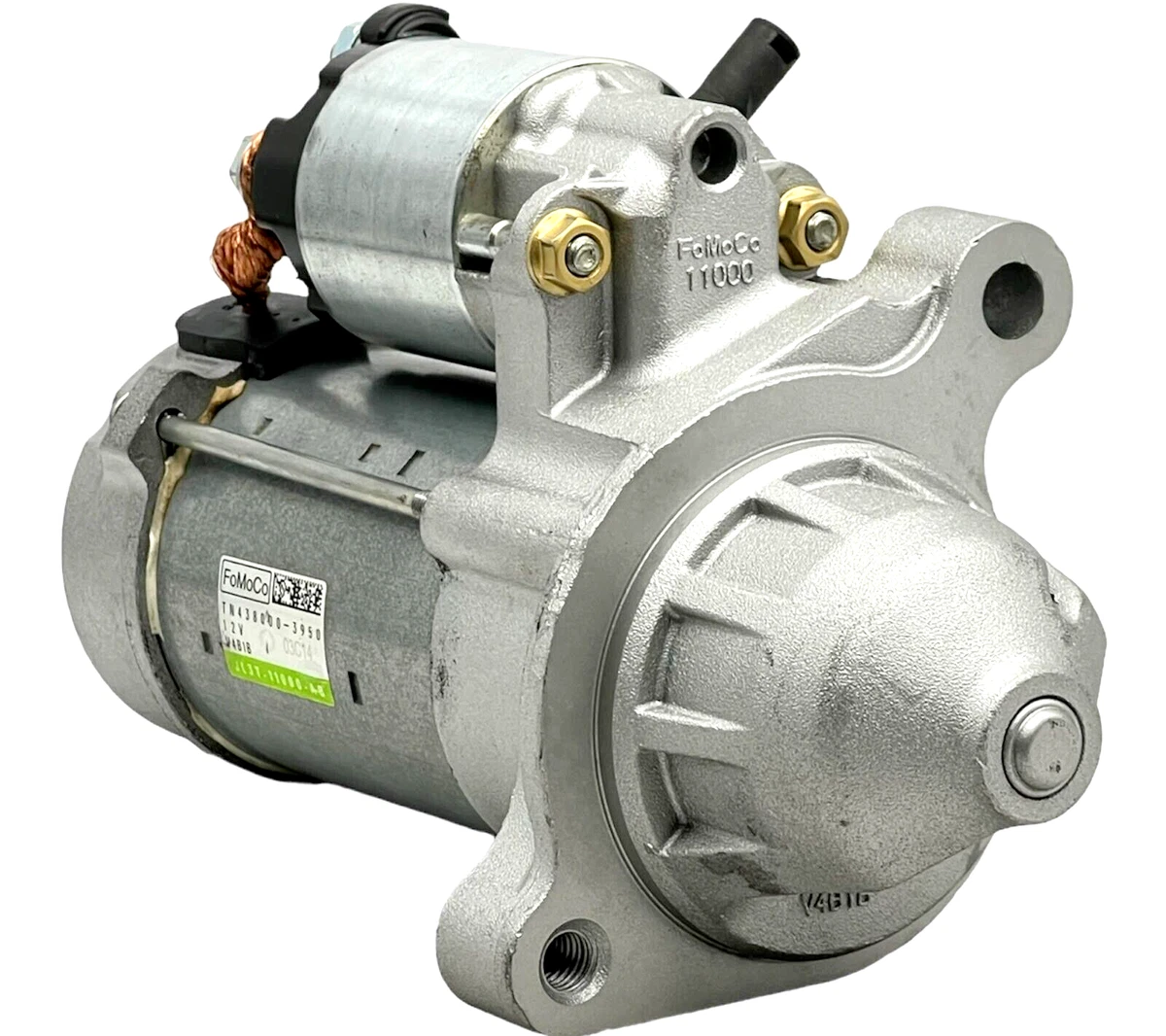

Illustrative image related to cuanto cuesta un motor de arranque

3 Common User Pain Points for ‘cuanto cuesta un motor de arranque’ & Their Solutions

Scenario 1: Understanding the True Costs of Starter Motors

The Problem: Many B2B buyers struggle with understanding the total cost of a starter motor beyond the initial purchase price. This includes factors such as shipping, tariffs, potential import duties, and the cost of installation. Buyers often receive quotes that seem competitive at first glance, only to discover hidden fees that inflate the final expense. This can lead to budget overruns and project delays, especially for businesses operating in regions with complex import regulations.

The Solution: To mitigate this issue, buyers should adopt a comprehensive cost analysis approach when sourcing starter motors. Start by obtaining multiple quotes from various suppliers, ensuring that each quote includes all potential fees. It’s also advisable to inquire about the shipping terms and any additional charges related to customs. Utilize a cost breakdown template to compare these aspects systematically. Furthermore, consider partnering with local distributors who may offer more favorable shipping rates and can assist with installation. This proactive approach not only clarifies the total cost but can also help in negotiating better deals.

Scenario 2: Quality Assurance and Performance Expectations

The Problem: Another common pain point for B2B buyers is the uncertainty surrounding the quality and reliability of starter motors. In many cases, buyers opt for the cheapest option, only to face performance issues such as frequent breakdowns or compatibility problems with existing vehicle systems. This not only leads to increased maintenance costs but can also disrupt operations, particularly for businesses relying on a fleet of vehicles.

The Solution: To ensure quality assurance, buyers should prioritize sourcing from reputable manufacturers or suppliers known for their commitment to quality. Request certifications or warranties that guarantee the performance of the starter motors. Engaging in thorough research, including reading reviews and case studies from other businesses, can also provide valuable insights into the reliability of specific brands. Additionally, conducting pilot tests with a small batch before full-scale procurement can help assess performance and compatibility. This strategic approach will safeguard against poor-quality purchases and enhance operational efficiency.

Scenario 3: Navigating Technical Specifications and Compatibility

The Problem: B2B buyers often face challenges in navigating the technical specifications of starter motors, which can lead to purchasing errors. Different vehicles require specific types of starter motors, and failing to understand these requirements can result in incompatible parts being ordered. This not only wastes time and resources but can also lead to significant downtime for operations that depend on these vehicles.

The Solution: To tackle this challenge, buyers should invest time in understanding the technical specifications necessary for their specific applications. Create a checklist that includes essential details such as the vehicle model, engine size, and power requirements of the starter motor. Collaborating with technical experts or engineers can provide additional insights into the exact specifications needed. Furthermore, establishing a strong relationship with suppliers who can offer expert guidance on compatibility can streamline the purchasing process. By being diligent in this area, buyers can ensure they select the right starter motor, reducing the risk of costly mistakes and improving overall operational reliability.

Strategic Material Selection Guide for cuanto cuesta un motor de arranque

What Are the Common Materials Used in Starter Motors and Their Properties?

When selecting materials for starter motors, various factors come into play, including performance, cost, and compliance with international standards. Here, we analyze four common materials used in the construction of starter motors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it an excellent choice for components that require structural integrity. It typically withstands high temperatures and pressures, with a corrosion resistance that can be enhanced through coatings.

Pros & Cons:

The primary advantage of steel is its strength and durability, which ensures long-lasting performance in demanding environments. However, it is heavier than other materials, which could impact the overall weight of the starter motor. Additionally, the manufacturing process can be complex and costly, especially when precision machining is required.

Illustrative image related to cuanto cuesta un motor de arranque

Impact on Application:

Steel is well-suited for applications where high mechanical stress is expected. It is compatible with various media, including oil and fuel, which is crucial for automotive applications.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A36 or DIN 17100, which govern steel quality. In regions like Africa and South America, sourcing local steel can reduce costs and lead times.

2. Aluminum

Key Properties:

Aluminum is lightweight and offers excellent corrosion resistance, making it ideal for applications where weight reduction is crucial. It has a lower melting point than steel, which allows for easier machining and fabrication.

Pros & Cons:

The primary advantage of aluminum is its weight, which contributes to improved fuel efficiency in vehicles. However, it has lower tensile strength compared to steel, which may limit its use in high-stress applications. Additionally, aluminum components can be more expensive due to the cost of raw materials and processing.

Impact on Application:

Aluminum is particularly effective in applications where weight is a critical factor, such as in electric vehicles. Its compatibility with various automotive fluids also makes it a suitable choice.

Considerations for International Buyers:

Aluminum components should adhere to standards like ASTM B221 or JIS H4000. Buyers in Europe may prefer aluminum for its recyclability, aligning with sustainability goals.

3. Copper

Key Properties:

Copper is an excellent conductor of electricity and has good thermal conductivity. It is resistant to corrosion and can withstand high temperatures, making it suitable for electrical components.

Pros & Cons:

The key advantage of copper is its superior electrical conductivity, which ensures efficient performance of starter motors. However, copper is relatively expensive compared to other materials, and its weight can be a drawback in applications where minimizing weight is essential.

Illustrative image related to cuanto cuesta un motor de arranque

Impact on Application:

Copper is primarily used in electrical windings and connections within starter motors. Its compatibility with various electrical systems makes it indispensable for reliable performance.

Considerations for International Buyers:

Compliance with standards such as ASTM B170 is crucial. Buyers should also consider the availability of copper in their region, as fluctuations in global copper prices can affect costs.

4. Plastic Composites

Key Properties:

Plastic composites offer lightweight solutions with good chemical resistance. They can be engineered to provide specific properties, such as increased impact resistance or thermal stability.

Pros & Cons:

The lightweight nature of plastic composites can lead to significant weight savings in starter motor applications. However, they may not provide the same level of mechanical strength as metals, which could limit their use in high-stress areas.

Illustrative image related to cuanto cuesta un motor de arranque

Impact on Application:

Plastic composites are often used in non-structural components, such as housings or covers, where weight savings and corrosion resistance are desired.

Considerations for International Buyers:

Buyers should ensure that plastic composites meet relevant standards such as ASTM D638. In regions with high temperatures, the thermal properties of plastics should be carefully evaluated to ensure reliability.

Summary Table of Material Selection for Starter Motors

| Material | Typical Use Case for cuanto cuesta un motor de arranque | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and durability | Heavier and complex to manufacture | Medium |

| Aluminum | Lightweight components | Reduced weight | Lower strength than steel | High |

| Copper | Electrical windings and connections | Excellent electrical conductivity | Expensive and heavier | High |

| Plastic Composites | Non-structural components like housings | Lightweight and corrosion-resistant | Limited mechanical strength | Medium |

This guide provides a comprehensive overview of material selection for starter motors, aiding international B2B buyers in making informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cuanto cuesta un motor de arranque

What are the Main Stages of Manufacturing a Motor de Arranque?

The manufacturing process of a motor de arranque (starter motor) involves several critical stages, each essential for ensuring the quality and performance of the final product. Here’s a breakdown of these main stages:

-

Material Preparation:

The first step involves sourcing high-quality raw materials, such as copper for windings, steel for housing, and various alloys for internal components. Quality assurance begins at this stage, where suppliers are evaluated based on their ability to meet specified material standards. Materials are then cut and processed to the required specifications for subsequent stages. -

Forming:

In this stage, components such as the armature, stator, and housing are formed. Techniques like stamping, machining, and forging are commonly used. Precision is crucial here; any inaccuracies can lead to malfunctions. Advanced technologies such as CNC machining may be employed to enhance precision and efficiency. -

Assembly:

The assembly process involves integrating various components, including the motor windings, brushes, and housing. This stage often requires skilled labor to ensure that all parts fit correctly and function cohesively. Automated assembly lines may be utilized to improve production speed and consistency, but human oversight is essential for quality control. -

Finishing:

The final stage includes surface treatment, painting, and testing of the assembled motor. Finishing processes are vital for enhancing durability and aesthetics. Testing at this stage ensures that the motor meets performance specifications, such as torque and power output.

How is Quality Assurance Implemented in Motor de Arranque Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for motors de arranque. It ensures that products meet international and industry-specific standards. Here are key aspects of QA in this context:

Illustrative image related to cuanto cuesta un motor de arranque

-

What International Standards are Relevant?

Compliance with international standards such as ISO 9001 is essential for manufacturers targeting global markets. ISO 9001 outlines criteria for a quality management system, emphasizing customer satisfaction and continuous improvement. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant for specific applications, particularly in regions like Europe and the Middle East. -

What are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. These typically include:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Regular checks during the manufacturing process to monitor adherence to quality standards.

– Final Quality Control (FQC): Comprehensive testing of the finished product to verify performance and reliability. -

Which Testing Methods are Commonly Used?

Various testing methods are utilized to ensure the quality and functionality of motors de arranque, including:

– Electrical Testing: Verifying resistance, voltage, and current to ensure proper functionality.

– Load Testing: Assessing performance under simulated operating conditions.

– Vibration and Noise Testing: Evaluating the motor’s operational smoothness and compliance with noise regulations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is paramount. Here are some strategies to achieve this:

-

Conducting Audits:

One of the most effective ways to verify a supplier’s quality control processes is through on-site audits. Audits allow buyers to assess manufacturing practices, QC checkpoints, and adherence to standards firsthand. These audits can be scheduled regularly or as needed based on supplier performance. -

Requesting Quality Reports:

Suppliers should provide detailed reports on their quality control practices, including documentation of tests performed, results, and any corrective actions taken. These reports help buyers understand how suppliers maintain quality and address issues. -

Engaging Third-Party Inspectors:

In regions where buyers may have limited access to suppliers, employing third-party inspection services can be beneficial. These independent organizations can conduct thorough assessments of the manufacturing process and product quality, providing an unbiased evaluation.

What are the Quality Control and Certification Nuances for International Buyers?

When navigating the global marketplace, B2B buyers must be aware of specific quality control and certification nuances that may affect their procurement process:

-

Understanding Regional Standards:

Different regions may have unique standards and regulations governing the manufacturing of automotive components. Buyers should familiarize themselves with these standards to ensure compliance and avoid potential legal issues. -

Language and Communication Barriers:

Effective communication is vital for ensuring that quality expectations are understood and met. Buyers may face challenges if suppliers are located in regions with different languages and business practices. Establishing clear communication protocols can help mitigate these challenges. -

Cultural Differences in Business Practices:

Cultural differences can influence how quality control is perceived and implemented. For instance, certain regions may prioritize speed over precision, while others may focus on meticulous detail. Understanding these cultural nuances can help buyers select suppliers that align with their quality expectations.

Conclusion

For international B2B buyers, understanding the manufacturing processes and quality assurance practices associated with motors de arranque is crucial for making informed purchasing decisions. By focusing on the manufacturing stages, implementing robust quality control measures, and verifying supplier practices, buyers can ensure they procure reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cuanto cuesta un motor de arranque’

To facilitate an effective procurement process for starter motors (‘motor de arranque’), this guide offers a structured checklist tailored for B2B buyers. By following these steps, you can ensure a strategic approach to sourcing that aligns with your technical needs and business objectives.

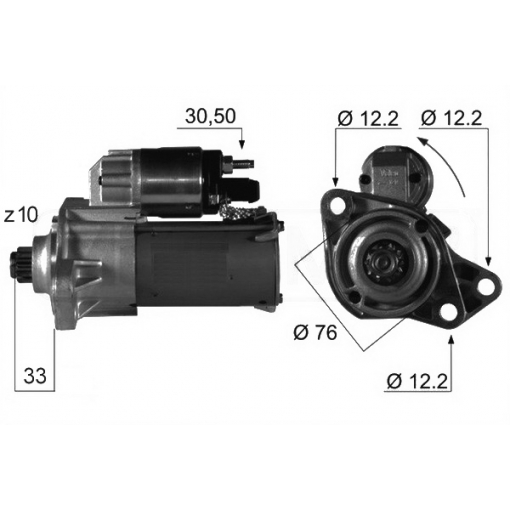

Step 1: Define Your Technical Specifications

Before initiating any sourcing activities, clearly outline the technical requirements for the starter motor. This includes specifications such as the voltage, power output (measured in kW), and the number of teeth on the pinion gear. Understanding these details is essential to ensure compatibility with your vehicles and machinery.

- Identify vehicle type and model: Different vehicles may require specific starter motor designs.

- Consider environmental conditions: If your operations are in extreme climates, look for motors designed to withstand such conditions.

Step 2: Research Market Prices

Gather data on current market prices for starter motors across various suppliers. This step is crucial for establishing a budget and ensuring you are not overpaying.

- Compare multiple vendors: Utilize online platforms and local suppliers to gather price points.

- Look for bulk purchase discounts: Many suppliers offer lower prices for larger orders, which can significantly reduce overall costs.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This ensures that the products you are considering meet safety and quality regulations.

- Check for ISO certifications: This indicates adherence to international quality management standards.

- Look for product-specific certifications: Certain markets may require additional certifications for automotive parts.

Step 4: Request Sample Products

Once you have shortlisted potential suppliers, request samples of the starter motors. Testing samples allows you to assess the quality and performance before making a large investment.

- Conduct performance tests: Evaluate the sample under real-world conditions to ensure reliability.

- Check warranty and return policies: Understand the terms in case the product does not meet expectations.

Step 5: Assess Supplier Reliability

Investigate the reliability and reputation of the suppliers you are considering. A supplier’s reliability can significantly impact your operations, so thorough vetting is essential.

- Read customer reviews and testimonials: Look for feedback from other businesses in your industry.

- Evaluate their delivery timelines: Ensure that the supplier can meet your project deadlines.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to finalize terms and conditions. This includes price, payment terms, delivery schedules, and warranty agreements.

- Seek favorable payment terms: Explore options such as net payment terms to manage cash flow effectively.

- Clarify delivery logistics: Ensure that both parties agree on shipping methods and potential delays.

Step 7: Finalize the Purchase Agreement

After all negotiations are complete, draft and sign a purchase agreement that outlines all terms discussed. This formalizes the transaction and provides legal protection for both parties.

- Include all agreed-upon specifications: Ensure that the agreement reflects the technical and logistical details discussed.

- Establish a clear communication channel: This helps in managing future orders and addressing any issues that may arise.

By following this comprehensive checklist, you can streamline the sourcing process for starter motors, ensuring that your procurement aligns with your operational needs and business goals.

Comprehensive Cost and Pricing Analysis for cuanto cuesta un motor de arranque Sourcing

What Are the Key Cost Components in Sourcing a Starter Motor?

When sourcing a starter motor, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The type and quality of materials used significantly impact the cost. High-performance starter motors require durable materials that can withstand harsh conditions, which may increase the base cost. Common materials include copper for windings and high-grade steel for the casing.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with higher wages will naturally incur higher labor costs. Additionally, skilled labor is often necessary for quality assurance and assembly processes, further influencing labor expenses.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, but in regions with less advanced infrastructure, these costs can be higher.

-

Tooling: Custom tooling can be necessary for specific designs or specifications, which can add to initial costs. However, it may lead to savings in mass production scenarios, where economies of scale can be realized.

-

Quality Control (QC): Ensuring that starter motors meet specific quality standards often requires additional investment in testing and inspection. Certifications such as ISO can further assure buyers of product reliability, but they may also add to the cost.

-

Logistics: Shipping and handling costs play a significant role, especially for international buyers. Factors such as distance, shipping method, and customs duties can vary widely, impacting overall expenses.

-

Margin: Finally, the supplier’s margin will depend on their market positioning and the competitive landscape. Established brands may command higher prices due to perceived quality, while lesser-known manufacturers may offer lower prices to gain market share.

How Do Price Influencers Affect the Cost of Starter Motors?

Several factors can influence the pricing of starter motors, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Understanding the minimum order quantities (MOQ) of suppliers can help negotiate better pricing.

-

Specifications and Customization: Custom specifications can lead to increased costs, particularly if the changes require new tooling or materials. Buyers should clearly define their needs upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications like ISO or OEM specifications can increase costs but often result in better performance and reliability, contributing to a lower Total Cost of Ownership (TCO) over time.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can also influence pricing. Established suppliers may charge more due to their reliability and service quality.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the final landed cost of goods.

What Are the Best Practices for Negotiating Starter Motor Prices?

To ensure cost-efficiency when sourcing starter motors, consider the following tips:

-

Negotiate Based on Total Cost of Ownership (TCO): Evaluate suppliers not just on the initial price, but on the long-term value they offer. A slightly higher upfront cost may lead to savings in maintenance and operational efficiency.

-

Be Informed About Pricing Nuances: Different regions may have varying price points based on local demand and supply dynamics. Understanding these nuances can provide leverage during negotiations.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can prevent costly mistakes and ensure the product meets your specifications.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, terms, and service. A trusted partnership can result in priority service and favorable terms.

-

Stay Updated on Market Trends: Keeping an eye on global market trends and fluctuations in raw material prices can provide insights into when to negotiate or make purchases.

Disclaimer

Prices for starter motors can vary significantly based on the aforementioned factors and are subject to change. Always verify current pricing and terms with suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing cuanto cuesta un motor de arranque With Other Solutions

Exploring Alternatives to ‘Cuanto Cuesta Un Motor De Arranque’

In the realm of automotive solutions, understanding the cost and functionality of a starter motor (motor de arranque) is crucial for B2B buyers. However, there are various alternatives that can either complement or replace the need for traditional starter motors in specific applications. This section delves into these alternatives, allowing international buyers to make informed decisions based on performance, cost, and other essential factors.

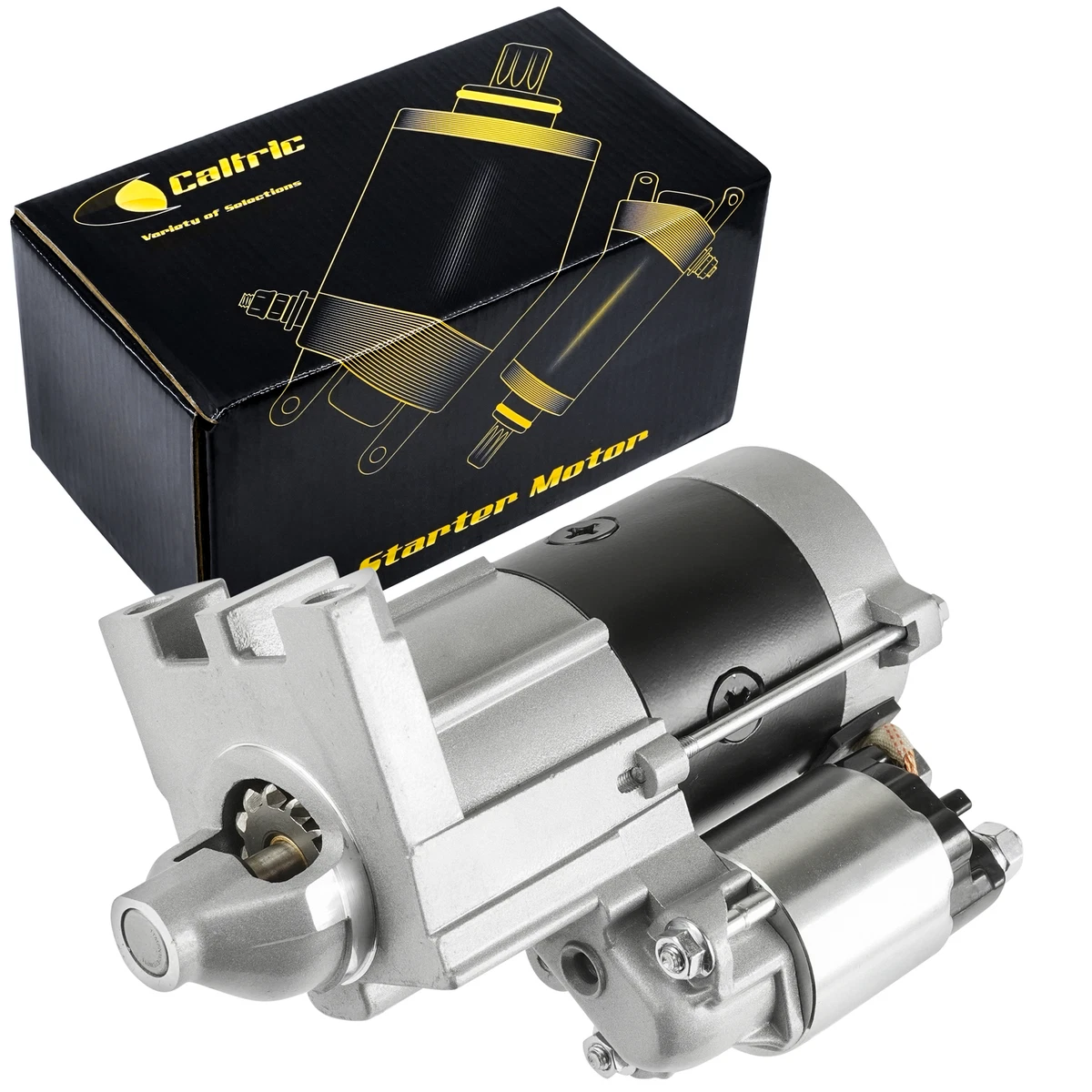

Illustrative image related to cuanto cuesta un motor de arranque

| Comparison Aspect | ‘Cuanto Cuesta Un Motor De Arranque’ | Alternative 1: Electric Starter Systems | Alternative 2: Manual Start Mechanisms |

|---|---|---|---|

| Performance | Reliable for most vehicle types | High efficiency, especially in electric vehicles | Simple but labor-intensive; less reliable in emergencies |

| Cost | Ranges from $50 to $600 | Generally higher initial investment, $300-$800 | Low-cost, typically under $50 |

| Ease of Implementation | Plug-and-play for most vehicles | Requires integration with vehicle’s electrical system | Requires user knowledge and physical effort |

| Maintenance | Moderate; periodic checks needed | Low; maintenance-free in most cases | High; prone to wear and tear |

| Best Use Case | Conventional vehicles and machinery | Modern electric and hybrid vehicles | Older models or emergency tools |

What Are the Advantages and Disadvantages of Electric Starter Systems?

Electric starter systems represent a significant advancement in automotive technology. They provide high efficiency and reliability, particularly for electric and hybrid vehicles. Their integration into a vehicle’s electrical system allows for seamless operation without the need for manual intervention. However, the initial investment can be substantial, often ranging from $300 to $800, which may deter budget-conscious buyers. Additionally, installation can be complex, requiring professional assistance to ensure compatibility with existing systems.

Why Consider Manual Start Mechanisms?

Manual start mechanisms, although less common in modern vehicles, offer a low-cost alternative, typically priced under $50. They are simple to operate and can be an effective solution for older vehicles or in emergency situations. However, these systems demand a higher level of user involvement, making them less practical in everyday use. They are also more prone to wear and tear, necessitating frequent maintenance. Consequently, while they can serve as a backup option, they may not be the best primary solution for most users.

How to Choose the Right Solution for Your Needs

Choosing the appropriate solution hinges on several factors including vehicle type, budget, and operational requirements. For businesses operating fleets with conventional vehicles, investing in reliable starter motors is advisable. However, companies transitioning to electric or hybrid technologies should consider the benefits of electric starter systems, despite their higher initial costs. Manual start mechanisms can be reserved for niche applications or as a backup solution. Ultimately, understanding the specific operational context and long-term goals will guide B2B buyers in selecting the most suitable option for their needs.

Illustrative image related to cuanto cuesta un motor de arranque

Essential Technical Properties and Trade Terminology for cuanto cuesta un motor de arranque

What Are the Key Technical Properties of a Starter Motor?

Understanding the essential technical properties of a starter motor is crucial for B2B buyers seeking reliable and efficient components for vehicles. Here are some critical specifications:

-

Power Rating (KW)

The power rating of a starter motor, typically expressed in kilowatts (KW), indicates its ability to initiate the engine’s operation. A higher power rating generally results in better performance, especially in larger engines or those requiring more torque to start. For B2B buyers, selecting the appropriate power rating ensures compatibility with the vehicle’s specifications, enhancing reliability and reducing the risk of failure. -

Number of Teeth on the Pinion Gear

The number of teeth on the pinion gear is a vital specification that affects the engagement with the flywheel. Standard pinion gear configurations vary, with common counts being 9, 12, or 19 teeth. Understanding this specification helps ensure that the starter motor will engage correctly with the engine, avoiding potential damage and operational inefficiencies. -

Material Composition

The materials used in the construction of a starter motor, such as high-grade steel or aluminum alloys, influence its durability and performance. Components made from quality materials are more resistant to wear and tear, which is particularly important in regions with harsh environmental conditions. B2B buyers should prioritize starter motors made from robust materials to ensure longevity and reliability. -

Operating Voltage

Most starter motors operate on a standard voltage of 12V or 24V, depending on the vehicle type. This specification is critical for compatibility with the vehicle’s electrical system. Incorrect voltage ratings can lead to performance issues or complete failure. Understanding the operating voltage is essential for B2B buyers to ensure they procure the right product for their specific applications. -

Torque Output

Torque output is a measure of the rotational force the starter motor can exert to turn the engine over. This specification is particularly important for larger engines or those with higher compression ratios, as they require more torque to start. Buyers must consider torque ratings to ensure the selected starter motor can handle the demands of the engine, particularly in commercial applications.

What Common Trade Terms Should B2B Buyers Know?

Navigating the procurement process for starter motors involves understanding key industry terminology that can influence purchasing decisions:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These components are designed to meet the exact specifications and quality standards of the original parts. For B2B buyers, opting for OEM starter motors ensures reliability and compatibility, reducing the risk of operational failures. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it impacts inventory management and cost-effectiveness. Buyers should evaluate their demand to negotiate favorable MOQs that align with their purchasing needs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. By submitting an RFQ, B2B buyers can compare costs, specifications, and delivery terms from different suppliers, enabling informed purchasing decisions. -

Incoterms

Incoterms (International Commercial Terms) are standardized trade terms used in international shipping to clarify the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk transfer. Familiarity with Incoterms helps B2B buyers understand their obligations and rights in international transactions, ensuring smoother logistics and compliance. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is essential for B2B buyers to manage inventory levels and plan production schedules effectively. Buyers should always inquire about lead times when negotiating with suppliers to ensure timely delivery.

By mastering these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing starter motors, ultimately enhancing their operational efficiency and ensuring product reliability.

Navigating Market Dynamics and Sourcing Trends in the cuanto cuesta un motor de arranque Sector

What Are the Key Trends Affecting the ‘cuanto cuesta un motor de arranque’ Market?

The global market for starter motors, or “motores de arranque,” is currently shaped by several dynamic factors that impact pricing, availability, and sourcing strategies. One significant driver is the increasing demand for electric vehicles (EVs) and hybrid models, which require more advanced starter technologies. This shift is particularly pronounced in regions like Europe, where regulatory pressures are accelerating the transition to cleaner transportation solutions. As a result, B2B buyers must stay informed about innovations in starter motor technology, including lightweight materials and energy-efficient designs.

Emerging trends in B2B sourcing also indicate a growing reliance on digital platforms for procurement. International buyers from Africa, South America, and the Middle East are increasingly utilizing online marketplaces and B2B networks to access a wider range of suppliers and products. This digital transformation is not only streamlining the sourcing process but also facilitating better price comparisons and reducing lead times. Furthermore, the rise of Industry 4.0 technologies, such as IoT and AI, is enhancing supply chain visibility and efficiency, enabling buyers to make more informed purchasing decisions.

Market dynamics are also influenced by geopolitical factors and fluctuations in raw material prices. For instance, the recent supply chain disruptions caused by the pandemic have led to increased costs and longer delivery times for starter motors. B2B buyers should consider these factors when negotiating contracts and sourcing agreements to ensure they can maintain operational continuity.

How Can Sustainability and Ethical Sourcing Impact Your Sourcing Decisions for Starter Motors?

Sustainability is becoming a crucial consideration in the sourcing of starter motors, as environmental impact and corporate social responsibility take center stage in global trade. The production of traditional starter motors can involve significant energy consumption and greenhouse gas emissions, prompting buyers to seek out manufacturers that prioritize eco-friendly practices.

Illustrative image related to cuanto cuesta un motor de arranque

Ethical sourcing is also gaining traction, with an emphasis on supply chain transparency and fair labor practices. B2B buyers should look for suppliers who adhere to recognized sustainability certifications and standards, such as ISO 14001 for environmental management systems or the Responsible Business Alliance (RBA) code of conduct. These certifications not only reflect a commitment to ethical practices but also often correlate with higher product quality and reliability.

Moreover, the demand for “green” materials is on the rise, pushing manufacturers to explore alternative materials and processes that minimize environmental impact. By prioritizing suppliers that utilize recycled materials or sustainable production methods, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Historical Context of Starter Motors in the Automotive Industry?

The evolution of starter motors has been a pivotal aspect of automotive technology since their introduction in the early 20th century. Initially, vehicles relied on hand-crank methods for starting engines, which were labor-intensive and often impractical. The development of the electric starter motor revolutionized this process, providing a reliable and efficient means of ignition.

Over the decades, advancements in materials and engineering have led to improvements in starter motor design, enhancing performance and durability. The introduction of high-torque starter motors in the 1980s allowed for better engine performance, particularly in larger vehicles. Today, with the rise of electrification in the automotive sector, starter motors are evolving once again, with innovations aimed at supporting hybrid and fully electric vehicle technologies. This historical context underscores the importance of understanding technological advancements for B2B buyers navigating the current market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of cuanto cuesta un motor de arranque

-

How do I determine the cost of a starter motor for my vehicles?

To accurately assess the cost of a starter motor, consider factors such as vehicle type, brand, and specific model requirements. Prices can range significantly based on these criteria. It’s advisable to contact multiple suppliers for quotes and compare the prices of OEM (Original Equipment Manufacturer) versus aftermarket options. Additionally, consider the costs of shipping and import duties if sourcing internationally, as these can impact the final price. -

What is the best way to source starter motors for a fleet of vehicles?

For fleet sourcing, establish relationships with reputable suppliers that offer bulk purchasing options. Look for suppliers with a strong track record in your region and positive reviews from other B2B buyers. Consider suppliers that provide warranties and after-sales support. It may also be beneficial to request samples or trial orders to assess quality before committing to larger purchases. -

What factors influence the price of starter motors in international markets?

The price of starter motors is influenced by several factors, including manufacturing costs, shipping expenses, tariffs, and local market demand. Exchange rates can also play a significant role, particularly when dealing with international suppliers. Understanding these factors can help buyers negotiate better terms and anticipate fluctuations in pricing. -

What are the minimum order quantities (MOQs) for starter motors from suppliers?

Minimum order quantities can vary widely depending on the supplier and the specific starter motor model. Some manufacturers may require MOQs ranging from 10 to 100 units, while others might offer flexible terms for smaller orders. It’s essential to clarify these details upfront to ensure they align with your purchasing needs. -

How can I vet suppliers for starter motors effectively?

To vet suppliers, conduct thorough research that includes reviewing their reputation, checking for certifications, and reading client testimonials. Request references from other businesses that have purchased starter motors from them. Additionally, assess their production capabilities, lead times, and customer service responsiveness to ensure they can meet your demands reliably. -

What customization options are available for starter motors?

Many suppliers offer customization options for starter motors, such as modifications to voltage, power ratings, and physical dimensions to fit specific vehicle models. Discuss your requirements with potential suppliers to understand the extent of their customization capabilities. Be sure to inquire about the implications for lead times and costs associated with custom orders. -

What payment terms should I expect when purchasing starter motors internationally?

Payment terms can vary by supplier, but common options include upfront payment, net 30/60/90 days, or a combination of a deposit and final payment upon delivery. Always clarify payment terms before finalizing any agreements. Using secure payment methods and considering escrow services can provide additional protection during international transactions. -

What quality assurance measures should I look for in starter motors?

When sourcing starter motors, inquire about the supplier’s quality assurance processes. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Suppliers should also provide testing data or guarantees regarding performance and reliability. Requesting samples for inspection before large orders can further ensure the quality meets your specifications.

Top 3 Cuanto Cuesta Un Motor De Arranque Manufacturers & Suppliers List

1. DENSO – Motores de Arranque para Autos

Domain: do.ebay.com

Registered: 1995 (30 years)

Introduction: Motores de arranque para autos y camionetas de diversas marcas como DENSO, ACDelco, Bosch, Honda, Ford, Toyota, Chevrolet, Delco Remy, Motorcraft, Nissan, Powermaster, Mopar, entre otros. Ofertas de productos nuevos y usados, con precios que varían desde RD $2,299.43 hasta RD $16,082.80. Garantías de fabricante que van desde 1 mes hasta de por vida. Voltajes disponibles desde menos de 1 V hasta 85…

2. Autodoc – Motor de Arranque

Domain: autodoc.es

Introduction: This company, Autodoc – Motor de Arranque, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reddit – Car Starter Replacement Cost

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Cost to replace a car starter: approximately $450, with the starter itself costing around $150.

Strategic Sourcing Conclusion and Outlook for cuanto cuesta un motor de arranque

In conclusion, understanding the pricing dynamics of starter motors is crucial for international B2B buyers seeking to optimize their procurement strategies. The cost of a starter motor can vary significantly based on factors such as brand, specifications, and regional market conditions. By leveraging strategic sourcing, businesses can identify reliable suppliers, negotiate favorable terms, and ensure access to high-quality components that enhance vehicle performance and reliability.

For buyers in Africa, South America, the Middle East, and Europe, it is essential to conduct thorough market research and establish strong relationships with manufacturers and distributors. This approach not only mitigates risks associated with supply chain disruptions but also enables companies to adapt to fluctuating prices and evolving market demands.

Looking ahead, the trend toward electric vehicles and advancements in automotive technology may further influence starter motor specifications and pricing structures. By staying informed and agile in their sourcing practices, B2B buyers can position themselves for success in a competitive landscape. Engage with trusted suppliers today to secure the best value and quality for your starter motor needs, ensuring a reliable start for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to cuanto cuesta un motor de arranque

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.