Introduction: Navigating the Global Market for car starter cost

Navigating the complexities of sourcing car starters can pose significant challenges for international B2B buyers, especially when trying to balance quality with cost-effectiveness. Understanding the nuances of car starter costs, including the variations between new and remanufactured options, is crucial for making informed purchasing decisions. This guide delves into the various types of car starters, their applications across different vehicle models, and the essential criteria for vetting suppliers, ensuring that buyers from Africa, South America, the Middle East, and Europe—particularly Germany and Saudi Arabia—are well-equipped to navigate the global market.

In this comprehensive resource, we explore critical aspects such as market trends, pricing structures, and the impact of regional supply chains on costs. By providing actionable insights and data-driven analysis, this guide empowers B2B buyers to optimize their procurement strategies, reduce overheads, and enhance operational efficiency. Whether you are looking to source bulk orders or establish long-term supplier relationships, understanding the dynamics of car starter costs will enable you to make strategic choices that align with your business objectives.

Table Of Contents

- Top 5 Car Starter Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car starter cost

- Understanding car starter cost Types and Variations

- Key Industrial Applications of car starter cost

- 3 Common User Pain Points for ‘car starter cost’ & Their Solutions

- Strategic Material Selection Guide for car starter cost

- In-depth Look: Manufacturing Processes and Quality Assurance for car starter cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car starter cost’

- Comprehensive Cost and Pricing Analysis for car starter cost Sourcing

- Alternatives Analysis: Comparing car starter cost With Other Solutions

- Essential Technical Properties and Trade Terminology for car starter cost

- Navigating Market Dynamics and Sourcing Trends in the car starter cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car starter cost

- Strategic Sourcing Conclusion and Outlook for car starter cost

- Important Disclaimer & Terms of Use

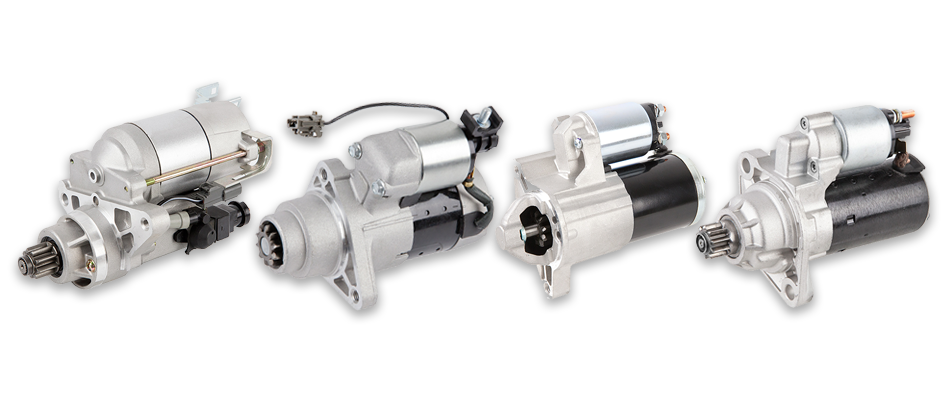

Understanding car starter cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| New Starters | Brand new, factory-tested components | Automotive dealerships, repair shops | Pros: Reliable performance, warranty coverage. Cons: Higher initial cost. |

| Remanufactured Starters | Reconditioned parts with replaced components | Independent garages, wholesalers | Pros: Cost-effective, eco-friendly. Cons: May have limited warranty. |

| High-Performance Starters | Enhanced power output and durability | Performance vehicles, racing teams | Pros: Improved engine cranking, longevity. Cons: Premium pricing. |

| OEM Starters | Original Equipment Manufacturer parts | Vehicle manufacturers, authorized dealers | Pros: Perfect fit, guaranteed compatibility. Cons: Often expensive. |

| Universal Starters | Versatile options that fit multiple vehicle models | Aftermarket suppliers, repair shops | Pros: Wide applicability, often lower cost. Cons: Potential compatibility issues. |

What are the Characteristics of New Starters for B2B Buyers?

New starters are brand new components that have undergone rigorous factory testing to ensure optimal performance. They are ideal for B2B buyers such as automotive dealerships and repair shops that prioritize reliability and warranty coverage. While the upfront cost is typically higher than alternatives, the assurance of a long-lasting and dependable part makes them a preferred choice for critical applications.

How Do Remanufactured Starters Offer Value to Businesses?

Remanufactured starters are reconditioned parts that have had key components replaced to restore functionality. This option is particularly attractive to independent garages and wholesalers looking for cost-effective solutions. While they provide an eco-friendly alternative, offering significant savings, buyers should consider the possibility of a limited warranty compared to new parts.

Why Choose High-Performance Starters for Specialized Applications?

High-performance starters are designed for enhanced power output and durability, making them suitable for performance vehicles and racing teams. B2B buyers in these sectors often seek these starters to improve engine cranking capabilities, especially under extreme conditions. However, the premium pricing associated with these products may deter some buyers, necessitating a careful evaluation of their specific needs.

What Are the Benefits of OEM Starters for Businesses?

OEM starters are manufactured by the original equipment manufacturer, ensuring a perfect fit and guaranteed compatibility with specific vehicle models. They are commonly used by vehicle manufacturers and authorized dealers who prioritize quality and reliability. Although often more expensive, the assurance of using parts designed specifically for the vehicle can justify the cost for many B2B buyers.

How Do Universal Starters Cater to a Diverse Market?

Universal starters offer versatility as they are designed to fit multiple vehicle models, making them ideal for aftermarket suppliers and repair shops. These starters typically come at a lower cost, appealing to budget-conscious buyers. However, potential compatibility issues may arise, requiring thorough checks to ensure they meet the specific needs of diverse vehicle applications.

Key Industrial Applications of car starter cost

| Industry/Sector | Specific Application of car starter cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicles requiring high-performance starters | Enhanced vehicle reliability and performance | Supplier reliability, OEM certification, and warranty terms |

| Fleet Management | Maintenance of commercial vehicle fleets | Reduced downtime and operational efficiency | Bulk purchasing discounts, compatibility with various vehicle models |

| Automotive Repair Services | Replacement parts for vehicle repairs | Improved customer satisfaction and service speed | Quality assurance, availability of remanufactured options, and pricing |

| Electric Vehicle (EV) | Integration in hybrid and electric vehicles | Support for innovative technologies and sustainability | Advanced technology compatibility, sourcing of specialized components |

| Industrial Equipment | Use in heavy machinery and equipment | Ensured operational readiness and reduced failure rates | Durability standards, voltage and power specifications, and lead times |

How is Car Starter Cost Used in Automotive Manufacturing?

In the automotive manufacturing sector, car starter costs are integral to the production of vehicles that demand high-performance starters. Manufacturers seek reliable and efficient starters to enhance vehicle reliability and performance. International buyers, particularly in regions like Europe and the Middle East, must consider supplier reliability and OEM certification when sourcing starters. These factors ensure that the products meet stringent quality standards, thereby minimizing potential recalls and warranty claims.

What is the Role of Car Starter Cost in Fleet Management?

Fleet management companies rely on car starter costs to maintain their commercial vehicle fleets effectively. By investing in quality starters, these companies can significantly reduce vehicle downtime, which translates to improved operational efficiency. For businesses in Africa and South America, bulk purchasing discounts can provide substantial savings. Compatibility with various vehicle models is another critical consideration, as fleet operators often manage a diverse range of vehicles.

Why is Car Starter Cost Important for Automotive Repair Services?

Automotive repair services depend on car starter costs for sourcing replacement parts. A well-priced starter can enhance customer satisfaction and speed up service delivery, which is vital for maintaining a competitive edge. Buyers in Europe and the Middle East should prioritize quality assurance and the availability of remanufactured options to optimize their inventory and reduce costs. Pricing strategies should also reflect the local market dynamics to attract more customers.

How is Car Starter Cost Relevant to Electric Vehicle (EV) Development?

In the rapidly growing electric vehicle market, car starter costs play a critical role in integrating starters into hybrid and electric vehicles. These components must support innovative technologies while aligning with sustainability goals. International buyers, particularly from Germany and Saudi Arabia, should focus on advanced technology compatibility and sourcing specialized components that meet the unique demands of EVs. This attention to detail can lead to enhanced performance and customer satisfaction.

What is the Significance of Car Starter Cost in Industrial Equipment?

Car starter costs are also relevant in the industrial equipment sector, where they are used in heavy machinery and equipment. Ensuring operational readiness is crucial, as any failure can lead to costly downtimes. Buyers should look for starters that meet durability standards and specific voltage and power specifications to ensure reliability. Additionally, understanding lead times for sourcing can help businesses avoid operational disruptions, especially in industries with high demand for machinery.

3 Common User Pain Points for ‘car starter cost’ & Their Solutions

Scenario 1: Understanding the Impact of Starter Quality on Cost

The Problem: A B2B buyer, responsible for sourcing car starters for a fleet of vehicles, struggles with the balance between cost and quality. While lower-priced options may seem attractive, they often lead to frequent failures, resulting in higher long-term costs associated with replacements and downtime. This buyer faces the challenge of justifying the investment in higher-quality starters to their management team, especially when budgets are tight, and the focus is on immediate savings.

The Solution: To navigate this dilemma, it’s essential for the buyer to conduct a thorough cost-benefit analysis. Start by gathering data on the failure rates and warranty claims associated with various starter brands. Engaging with suppliers who provide detailed performance metrics and customer testimonials can help in making an informed decision. Consider forming partnerships with reputable manufacturers that offer not only quality products but also extended warranties. This approach not only mitigates the risk of costly breakdowns but also enhances fleet reliability, ultimately leading to cost savings in maintenance and operation.

Scenario 2: Navigating Import Tariffs and Shipping Costs

The Problem: A procurement officer in a South American automotive company faces the challenge of fluctuating import tariffs and shipping costs that significantly impact the total cost of car starters. With the volatility in global trade policies, the buyer finds it difficult to predict expenses accurately, making budget planning a daunting task. This unpredictability can lead to delays in procurement and disrupt the supply chain, ultimately affecting production schedules.

The Solution: To address this issue, the buyer should establish a close relationship with logistics providers and customs brokers who specialize in automotive parts. These professionals can provide insights into current tariffs and help navigate regulatory requirements efficiently. Additionally, consider sourcing starters from local manufacturers or regional suppliers to reduce shipping costs and mitigate tariff impacts. Implementing a just-in-time inventory strategy can also help maintain a steady supply without incurring excessive holding costs, allowing for better cash flow management.

Scenario 3: The Challenge of Specifying the Right Starter for Diverse Vehicle Models

The Problem: An automotive parts distributor serving a diverse clientele struggles with specifying the right starter models for various vehicle types, leading to frequent customer complaints and returns. The complexity of different specifications, such as voltage ratings and torque requirements, complicates the purchasing process. This situation not only affects customer satisfaction but also increases operational costs due to handling returns and re-stocking.

The Solution: To enhance accuracy in sourcing, it is vital for the buyer to implement a robust data management system that catalogs the specifications of starters across different vehicle models. Collaborate with manufacturers to obtain detailed technical datasheets and build a comprehensive database that can be easily accessed by the sales team. Additionally, investing in training for staff on product knowledge and compatibility can significantly reduce errors in order fulfillment. Finally, consider offering a streamlined online platform where customers can input their vehicle details to receive tailored starter recommendations, thereby improving customer experience and reducing return rates.

Strategic Material Selection Guide for car starter cost

What Are the Key Materials Used in Car Starters and Their Impact on Cost?

In the automotive industry, particularly for car starters, the selection of materials plays a critical role in determining performance, durability, and overall cost. Below, we analyze four common materials used in car starters, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Copper Influence Car Starter Performance and Cost?

Copper is widely used in electrical components due to its excellent conductivity. It has a high-temperature rating, enabling it to perform efficiently under various operating conditions. Additionally, copper exhibits good corrosion resistance when properly treated.

Pros: Copper’s high conductivity leads to efficient energy transfer, which is crucial for reliable starter performance. It is relatively easy to manufacture and can be shaped into various forms, enhancing its adaptability in starter designs.

Cons: The primary drawback is its cost; copper can be expensive, impacting the overall cost of the starter. Additionally, it is susceptible to corrosion over time if not adequately protected, which can lead to performance issues.

Impact on Application: Copper is well-suited for high-current applications, making it ideal for starters that require substantial power to engage the engine.

Considerations for International Buyers: Compliance with international standards such as ASTM for material properties is essential. Buyers in regions like Europe and the Middle East should ensure that suppliers adhere to these standards to avoid performance issues.

What Role Does Aluminum Play in Car Starter Manufacturing?

Aluminum is another popular choice for car starters, particularly for components like housings and brackets. It offers a favorable strength-to-weight ratio and is resistant to corrosion, making it suitable for various environmental conditions.

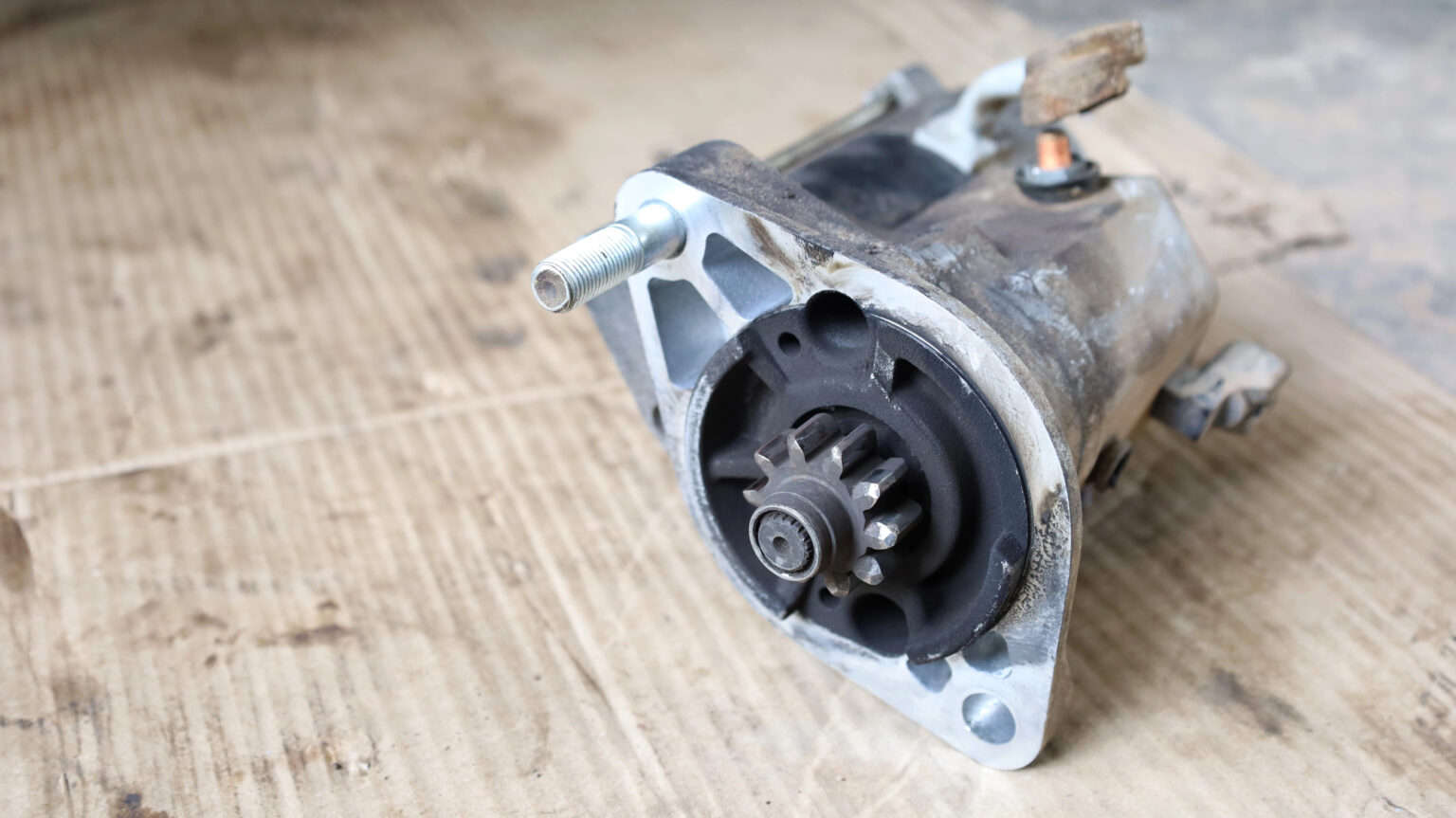

Illustrative image related to car starter cost

Pros: The lightweight nature of aluminum contributes to overall vehicle efficiency, potentially improving fuel economy. It is also less expensive than copper, which can help reduce production costs.

Cons: While aluminum is strong, it is not as durable as other metals like steel, which may lead to wear and tear over time. Additionally, its lower thermal conductivity compared to copper can impact performance in high-temperature environments.

Impact on Application: Aluminum is particularly effective in applications where weight savings are critical, such as in electric vehicles or performance cars.

Considerations for International Buyers: Buyers should be aware of regional preferences for aluminum grades and ensure compliance with relevant standards, such as DIN in Germany, to maintain quality.

Illustrative image related to car starter cost

How Does Steel Contribute to the Durability of Car Starters?

Steel is often used in car starters for structural components due to its strength and durability. It can withstand high pressure and temperature, making it suitable for demanding automotive environments.

Pros: Steel’s strength provides excellent durability, which is essential for components that undergo significant stress during operation. It is also relatively inexpensive compared to other materials.

Cons: Steel is heavier than aluminum and copper, which could negatively impact vehicle performance. Additionally, it is prone to corrosion if not treated properly, requiring protective coatings.

Impact on Application: Steel is ideal for components that require high strength and durability, such as the starter motor casing and gears.

Considerations for International Buyers: Buyers must consider the type of steel used and ensure it meets international standards to avoid issues related to corrosion and performance.

Illustrative image related to car starter cost

What Advantages Does Plastic Offer in Car Starter Components?

Plastic is increasingly being used in car starters, particularly for non-structural components like covers and insulators. It offers several advantages, including lightweight properties and resistance to corrosion.

Pros: Plastic is lightweight, which can contribute to overall vehicle efficiency. It is also cost-effective and can be molded into complex shapes, allowing for innovative designs.

Cons: The primary limitation of plastic is its lower thermal and electrical conductivity compared to metals, which may affect performance in high-stress applications. Additionally, it may not withstand high temperatures as effectively as metals.

Illustrative image related to car starter cost

Impact on Application: Plastic is suitable for components that do not require high strength but need to be insulated from electrical components.

Considerations for International Buyers: Compliance with material safety standards is crucial, especially in regions with strict regulations regarding automotive components.

Summary Table of Material Selection for Car Starters

| Material | Typical Use Case for Car Starter Cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections | High conductivity for efficient power | Expensive and corrosion-prone | High |

| Aluminum | Housings and brackets | Lightweight, cost-effective | Less durable than steel | Medium |

| Steel | Structural components | Excellent durability | Heavier and prone to corrosion | Low |

| Plastic | Covers and insulators | Lightweight, moldable | Lower thermal/electrical conductivity | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions regarding the materials used in car starters while considering performance, cost, and compliance with regional standards.

Illustrative image related to car starter cost

In-depth Look: Manufacturing Processes and Quality Assurance for car starter cost

What Are the Main Stages in the Manufacturing Process of Car Starters?

The manufacturing process of car starters involves several critical stages that ensure the product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality raw materials, typically metals and alloys that can withstand high temperatures and stresses. Common materials include steel for the housing and copper for the windings. Suppliers often conduct quality checks on these materials to ensure they meet specific standards before they are used in production.

-

Forming: In this stage, raw materials undergo various forming techniques such as stamping, forging, or casting to create the starter’s components. Precision is crucial here, as any defects in forming can lead to inefficiencies or failures in the starter’s operation.

-

Assembly: Once the components are formed, they are assembled into the final product. This process may involve automated machinery for precision tasks, but skilled technicians also play a role in ensuring that each part fits correctly and functions as intended. Quality control measures, such as torque checks and electrical tests, are often performed during assembly to catch any issues early.

-

Finishing: The final stage involves finishing processes like coating or painting to protect against corrosion and wear. This stage may also include additional testing to ensure that the starter meets all performance specifications before it is packaged and shipped.

How Do Quality Assurance Processes Impact Car Starter Costs?

Quality assurance (QA) is an integral part of the manufacturing process that directly impacts the cost of car starters. International standards such as ISO 9001 provide a framework for ensuring consistent quality across production processes.

-

International Standards: ISO 9001 certification indicates that a manufacturer adheres to quality management principles, including a strong customer focus, the involvement of top management, and a process approach. For B2B buyers, sourcing from ISO-certified manufacturers can reduce the risk of defective products and lower the total cost of ownership.

-

Industry-Specific Certifications: In addition to ISO, various industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain automotive applications may be relevant. These certifications assure buyers that products meet specific regulatory and safety standards.

-

Quality Control Checkpoints: Implementing a robust quality control system involves several checkpoints:

– Incoming Quality Control (IQC): This step involves inspecting raw materials before they enter production to ensure they meet specifications.

– In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor the quality of components and processes.

– Final Quality Control (FQC): Before products are shipped, final inspections ensure that each starter meets all performance and safety criteria.

What Testing Methods Are Commonly Used in Car Starter Manufacturing?

Testing methods are vital for ensuring that car starters perform reliably under various conditions. Common testing methods include:

-

Electrical Testing: This involves checking the electrical characteristics of the starter, including voltage, current draw, and resistance. Ensuring that the starter meets the specified electrical parameters is crucial for performance.

-

Load Testing: This test simulates the actual working conditions the starter will face in a vehicle. Load testing helps determine whether the starter can handle the necessary power to start an engine under various conditions.

-

Durability Testing: Starters are subjected to repetitive cycles of operation to assess their lifespan and reliability. This testing helps identify potential failure points and ensures that the product can withstand the rigors of daily use.

-

Environmental Testing: Given the diverse climates in which vehicles operate, starters are tested under extreme temperatures, humidity, and vibration conditions to ensure they perform reliably across different environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for mitigating risks associated with product quality.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems directly. Audits can provide insights into the supplier’s commitment to quality and compliance with international standards.

-

Quality Reports and Certifications: Requesting documentation such as quality assurance reports, test results, and certifications can help buyers verify a supplier’s claims. This documentation should detail the quality control processes and results of any testing conducted.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality practices. These agencies can conduct inspections at various stages of production, ensuring that the products meet the specified standards before shipment.

-

Understanding Regional Compliance Nuances: B2B buyers must be aware of the specific quality standards and regulations applicable in their regions. For example, buyers in Europe may need to ensure compliance with EU regulations, while those in the Middle East might focus on local standards that vary by country.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in Car Starter Costs

Understanding the intricacies of manufacturing processes and quality assurance practices is essential for B2B buyers in the automotive sector. By focusing on these areas, buyers can make informed decisions, ensuring they source reliable car starters that meet their performance and quality standards. Ultimately, investing time in evaluating manufacturing practices and quality assurance can lead to significant cost savings and enhanced product reliability in the long run.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car starter cost’

In the competitive landscape of automotive parts procurement, understanding the cost and specifications of car starters is critical for making informed purchasing decisions. This guide provides a structured approach to sourcing car starters, ensuring that B2B buyers can navigate the complexities of the market efficiently.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the car starter, including voltage ratings (e.g., 12V, 24V), power output (kW ratings), and the type of starter (new vs. remanufactured). Clearly defined specifications help streamline the sourcing process and reduce the risk of purchasing incompatible parts.

- Key Considerations:

- Voltage compatibility with your vehicle models.

- Required power output for optimal performance.

- Preference for new or remanufactured starters based on budget and reliability.

Step 2: Research Market Prices and Trends

Conduct comprehensive market research to understand the pricing landscape for car starters across different regions. This knowledge will empower you to negotiate better terms and identify competitive suppliers.

- Action Points:

- Use industry reports and online marketplaces to track price ranges.

- Consider factors such as demand fluctuations and regional pricing variations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, assess their credibility and reliability. Request company profiles, case studies, and references from previous clients in similar industries or regions. This vetting process is vital to ensure you are partnering with a reputable source.

- What to Look For:

- Supplier certifications and quality assurance processes.

- Testimonials or case studies showcasing successful collaborations.

Step 4: Verify Quality Assurance Processes

Ensure that potential suppliers have robust quality control measures in place. This step is crucial to guarantee that the starters meet industry standards and will perform reliably under various conditions.

- Quality Indicators:

- ISO certifications or equivalent.

- Detailed information about testing procedures for starters.

Step 5: Assess After-Sales Support and Warranty

Evaluate the after-sales services offered by suppliers, including warranty terms and technical support. Reliable after-sales support can significantly impact your long-term satisfaction with the product.

Illustrative image related to car starter cost

- Considerations:

- Length and coverage of warranties.

- Availability of technical assistance for installation or troubleshooting.

Step 6: Negotiate Payment Terms and Conditions

Once you have shortlisted suppliers, engage in negotiations to secure favorable payment terms. This can include bulk purchase discounts, extended payment periods, or flexible financing options.

- Negotiation Tips:

- Be clear about your budget constraints and expected volumes.

- Explore options for trial orders before committing to large purchases.

Step 7: Finalize the Order and Confirm Delivery Logistics

After selecting a supplier, confirm the order details, including quantities, specifications, and delivery timelines. Clear communication at this stage can help prevent misunderstandings and ensure timely delivery.

- Logistical Considerations:

- Confirm shipping methods and costs.

- Discuss contingency plans for potential delays or issues.

By following this checklist, B2B buyers can navigate the complexities of sourcing car starters effectively, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for car starter cost Sourcing

What Are the Key Cost Components in Car Starter Manufacturing?

When sourcing car starters, understanding the cost structure is critical for informed decision-making. The main cost components include:

-

Materials: The quality and type of materials used (e.g., copper for windings, durable plastics for housings) significantly impact the overall cost. Premium materials may increase the initial expense but often lead to better performance and longevity.

-

Labor: Labor costs vary depending on the region and the skill level required for assembly. Regions with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize overhead costs, which can be a significant portion of the total expense.

-

Tooling: Initial tooling costs for specialized machinery or molds can be high, especially for custom starters. These costs are typically amortized over the production volume, making them more manageable for larger orders.

-

Quality Control (QC): Rigorous QC processes ensure the reliability of car starters. Investing in quality assurance can increase upfront costs but reduces the risk of returns and warranty claims.

-

Logistics: Transportation and warehousing costs vary based on location and shipping methods. Effective logistics planning can optimize costs and delivery times.

-

Margin: Supplier margins can vary widely depending on market conditions and competition. Buyers should seek transparent pricing to understand how much of the cost is attributable to supplier profit.

How Do Price Influencers Affect Car Starter Sourcing?

Several factors can influence the pricing of car starters:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to better pricing due to economies of scale. Negotiating MOQs with suppliers can yield significant savings.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials and relevant certifications (such as ISO or automotive standards) can add to the cost but also enhance product reliability and compliance with regulatory requirements.

-

Supplier Factors: The reputation and reliability of suppliers affect pricing. Established suppliers with a track record of quality may charge more, but they often provide better service and fewer complications.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly impact costs by determining who is responsible for shipping, insurance, and tariffs. Understanding these terms is crucial for accurate budgeting.

What Are the Best Practices for Negotiating Car Starter Costs?

To achieve cost-efficient sourcing of car starters, consider the following tips:

-

Conduct Market Research: Understand the market rates for car starters and analyze competitor pricing. This knowledge will empower you during negotiations.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often result in mutual benefits, including discounts for loyalty.

-

Evaluate Total Cost of Ownership (TCO): Assess not just the purchase price but also the long-term costs associated with maintenance, warranties, and potential downtime. A lower-priced starter may lead to higher TCO if it requires frequent replacements or repairs.

-

Explore Alternative Suppliers: Diversifying your supplier base can create competitive pressure, potentially leading to better pricing. However, ensure that all suppliers meet your quality standards.

-

Understand Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, be aware of regional pricing variations, currency fluctuations, and import tariffs. These factors can significantly impact overall costs.

Disclaimer on Indicative Prices

Prices for car starters can fluctuate based on market demand, raw material costs, and geopolitical factors. Therefore, it is essential to obtain current quotes from multiple suppliers and consider all cost components and influences before finalizing a purchase.

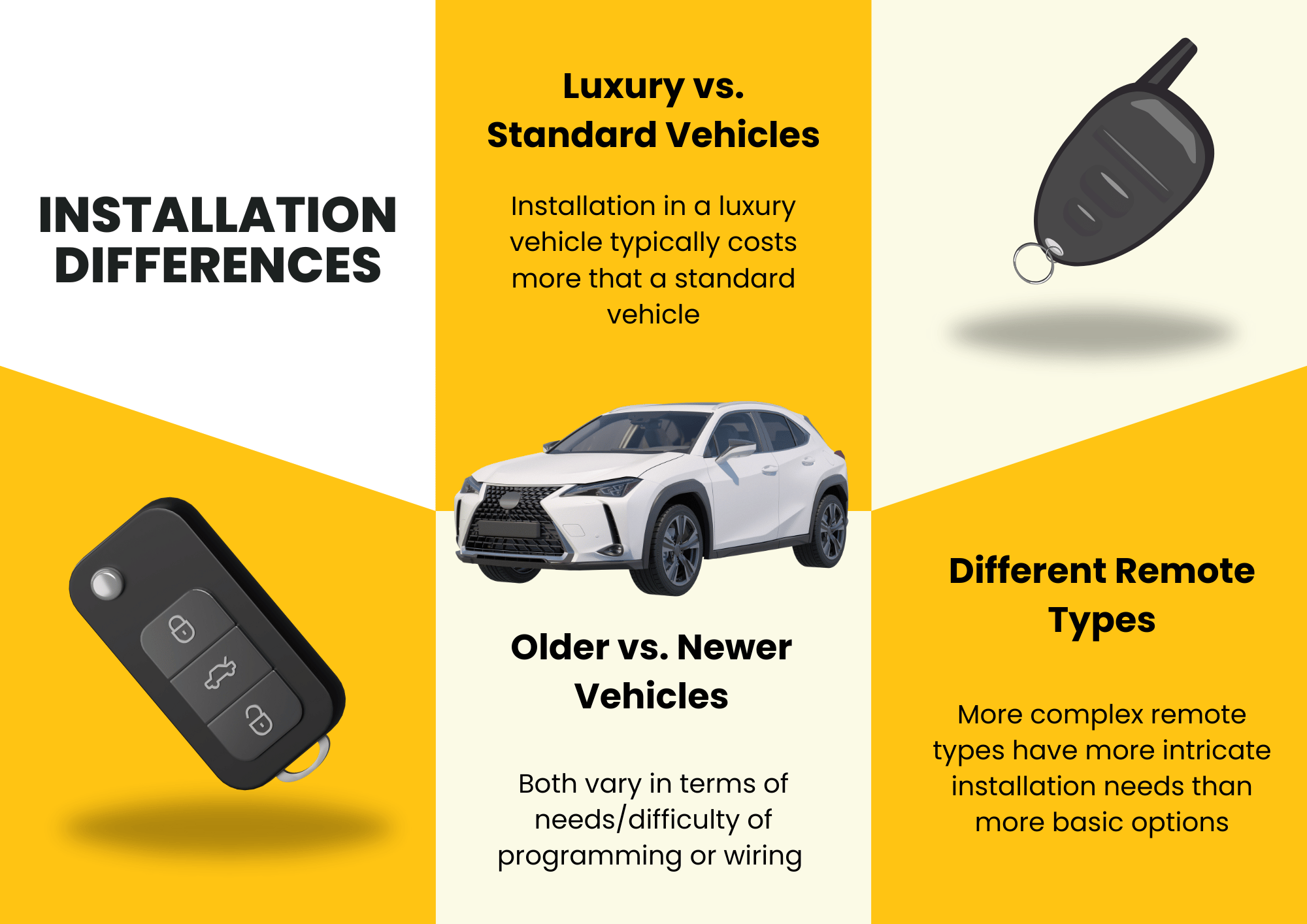

Alternatives Analysis: Comparing car starter cost With Other Solutions

Understanding Alternatives to Car Starter Costs

In the automotive industry, the selection of a car starter or any alternative solution can significantly impact operational efficiency and costs. While traditional car starters are commonly used, various alternatives provide different benefits and drawbacks. This section compares the cost of car starters with alternative technologies such as battery management systems and hybrid starter generators, enabling B2B buyers to make informed decisions based on their specific requirements.

Illustrative image related to car starter cost

| Comparison Aspect | Car Starter Cost | Battery Management System | Hybrid Starter Generator |

|---|---|---|---|

| Performance | Reliable but limited to traditional ignition systems | Enhances battery life and efficiency | Offers quick start and energy recovery |

| Cost | Moderate initial investment, $100-$300 | Higher upfront costs, $300-$600 | Premium costs, $500-$1,000 |

| Ease of Implementation | Straightforward installation | Requires expertise for integration | Complex installation, may need modifications |

| Maintenance | Regular checks needed | Low maintenance, periodic software updates | Moderate, requires system checks |

| Best Use Case | Standard vehicles, low budget | Electric and hybrid vehicles | High-performance and luxury vehicles |

Evaluating Battery Management Systems

Battery management systems (BMS) are designed to optimize battery performance and lifespan, particularly in electric and hybrid vehicles. These systems monitor battery health, charge levels, and temperature, ensuring that batteries operate efficiently and safely. While BMS can significantly enhance vehicle performance, they come with higher initial costs and require specialized knowledge for installation. For companies operating fleets of electric vehicles, investing in BMS could be more beneficial in the long run, despite the upfront investment.

Analyzing Hybrid Starter Generators

Hybrid starter generators (HSG) combine the functions of a starter motor and an alternator, providing a seamless transition between starting the engine and generating electricity. This technology allows for quicker starts and enables energy recovery during deceleration, making it ideal for performance-focused vehicles. However, HSGs come with a premium price tag and can be complex to install, often necessitating modifications to existing vehicle systems. Businesses that prioritize performance and energy efficiency may find HSGs a worthwhile investment, despite the higher costs.

Making the Right Choice for Your Business

When choosing between car starter costs and alternative solutions, B2B buyers should consider their operational needs, budget constraints, and the specific applications of their vehicles. For standard vehicles with traditional engines, a conventional car starter may suffice. In contrast, for companies looking to enhance efficiency and performance, investing in a battery management system or hybrid starter generator may offer greater long-term benefits. Ultimately, understanding the trade-offs between initial costs, maintenance, and performance capabilities will guide businesses in selecting the most suitable solution for their automotive needs.

Essential Technical Properties and Trade Terminology for car starter cost

What Are the Key Technical Properties of Car Starters That Impact Cost?

Understanding the technical properties of car starters is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential specifications that influence the cost and performance of car starters:

-

Power Rating (kW)

The power rating, measured in kilowatts (kW), indicates the amount of electrical power the starter motor can draw. Higher kW ratings typically correlate with the ability to start larger engines. For B2B buyers, selecting the appropriate power rating is vital to ensure compatibility with the vehicles being serviced or sold, thereby reducing the risk of operational failures. -

Voltage (V)

Car starters generally operate at specific voltage levels, commonly 12V for most passenger vehicles, but also available in 6V and 24V configurations for specialized applications. Understanding the voltage requirement is essential for ensuring that the starter is compatible with the vehicle’s electrical system, which can affect both performance and longevity. -

Rotation Direction

Starters are designed to rotate in either a clockwise or counter-clockwise direction, which is determined by the engine design. This specification is critical for ensuring proper installation and functionality, as using the wrong rotation can lead to engine damage. For B2B buyers, knowing the rotation direction helps in inventory management and matching starters with specific vehicle models. -

Design Type

The design type of a starter, such as gear reduction or direct drive, affects its efficiency and performance. Gear reduction starters are typically more powerful and can handle larger engines, making them more expensive. B2B buyers should assess the design type to ensure they meet the needs of their customers and the vehicles they service. -

New vs. Remanufactured

Starters can be purchased new or remanufactured. New starters usually come with a higher price tag but offer the latest technology and reliability. Remanufactured starters are often more cost-effective but may vary in quality. Understanding the trade-offs between these options is essential for buyers looking to balance cost and reliability in their offerings. -

Number of Pinion Teeth

The number of pinion teeth impacts the starter’s engagement with the flywheel. Starters can have varying numbers of teeth, affecting their compatibility with different engine types. B2B buyers should ensure they are aware of this specification to avoid costly mismatches.

What Common Trade Terms Should B2B Buyers Understand When Sourcing Car Starters?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the same manufacturer that produced the original components of the vehicle. These parts typically offer a guarantee of quality and compatibility, making them a preferred choice for many buyers who prioritize reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and avoid overstocking or stockouts, which can impact operational efficiency. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should use RFQs to compare prices and terms from different suppliers, enabling informed purchasing decisions. -

Incoterms

International Commercial Terms (Incoterms) are standardized trade terms that define the responsibilities of buyers and sellers in global transactions. Understanding Incoterms is essential for B2B buyers to navigate shipping, insurance, and risk transfer effectively. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time is vital for B2B buyers to manage their supply chain efficiently and ensure timely product availability. -

Warranty

A warranty is a guarantee from the manufacturer regarding the product’s quality and performance over a specified period. For B2B buyers, understanding warranty terms can significantly influence purchasing decisions, as it reflects the manufacturer’s confidence in their product.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that optimize their supply chains and enhance customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the car starter cost Sector

What Are the Key Market Dynamics and Trends Influencing Car Starter Costs?

The car starter cost sector is experiencing notable shifts driven by various global and regional factors. Firstly, the increasing demand for electric and hybrid vehicles is reshaping the market landscape, compelling manufacturers to innovate and adapt their product lines. B2B buyers, especially in regions like Africa and South America, are witnessing a surge in interest for advanced starter technologies that cater to electric vehicles (EVs). This trend is complemented by the growing emphasis on automotive safety and security systems, leading to a diversification in starter designs, including remote starters that enhance vehicle accessibility and user experience.

Moreover, the rise of e-commerce and digital platforms is transforming sourcing strategies. International buyers can now access a wider range of suppliers and competitive pricing, enabling them to make more informed purchasing decisions. Platforms that aggregate supplier information and product reviews are becoming invaluable for buyers in Europe and the Middle East, particularly in countries like Germany and Saudi Arabia, where quality and reliability are paramount.

Another significant trend is the move towards localization of supply chains, driven by geopolitical factors and the need for resilience against disruptions. This trend encourages B2B buyers to consider regional suppliers who can offer not only cost advantages but also shorter lead times and improved service levels. As a result, understanding the complexities of local markets and regulations is essential for effective sourcing in the car starter cost sector.

How Can Sustainability and Ethical Sourcing Impact Car Starter Costs?

Sustainability and ethical sourcing are becoming increasingly critical in the car starter cost sector, affecting both pricing and buyer preferences. The environmental impact of automotive manufacturing processes, including the extraction of raw materials for starters, is under scrutiny. B2B buyers are now more inclined to partner with suppliers who demonstrate commitment to sustainable practices, such as using recycled materials and minimizing waste in production.

Certifications such as ISO 14001 for environmental management and adherence to the Responsible Business Alliance (RBA) standards are becoming essential benchmarks for suppliers. Buyers looking to align with green initiatives can leverage these certifications to assess potential partners. Additionally, the use of ‘green’ materials not only enhances the sustainability profile of products but can also lead to cost savings over time, as energy-efficient manufacturing processes often translate to reduced operational costs.

Furthermore, as consumer demand for sustainable products rises, companies that prioritize ethical sourcing may gain a competitive advantage. This trend is particularly evident in markets like Europe, where regulatory pressures and consumer expectations around sustainability are strong. By prioritizing ethical sourcing, B2B buyers can enhance their brand reputation and foster loyalty among environmentally conscious customers.

What is the Historical Context of Car Starters That Shapes Current B2B Sourcing?

The evolution of car starters dates back to the early 20th century when manual cranking was the norm. The advent of the electric starter motor in the 1910s marked a significant technological leap, enhancing vehicle reliability and user convenience. As automotive technology progressed, starters evolved with improvements in efficiency, durability, and design. The introduction of high-performance starters in the late 20th century catered to the growing demands of larger and more powerful engines.

Today, the landscape continues to shift with advancements in technology, including the integration of smart features and compatibility with electric and hybrid vehicles. Understanding this historical context is crucial for B2B buyers, as it informs current product offerings and highlights the importance of innovation in sourcing strategies. Buyers who recognize the trajectory of starter technology can better anticipate future trends and make informed decisions about their sourcing needs.

In conclusion, navigating the car starter cost sector requires an awareness of market dynamics, a commitment to sustainability, and an understanding of the technological evolution that shapes current offerings. By leveraging these insights, B2B buyers can enhance their sourcing strategies and position themselves for success in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of car starter cost

-

How do I determine the cost of car starters for my business needs?

To accurately determine the cost of car starters, assess your specific requirements such as the type of vehicle, the starter’s power rating (kW), and whether you need new or remanufactured units. Request quotes from multiple suppliers and compare prices. Consider additional factors like shipping costs, import duties, and potential discounts for bulk purchases. Engaging with local distributors may also yield advantageous pricing, especially if you can negotiate long-term contracts. -

What is the best type of car starter for commercial vehicles?

For commercial vehicles, high-torque starters are typically recommended due to their ability to handle larger engines and frequent starts. Look for starters with durable construction and features like heat resistance, especially in hotter climates. Brands like Bosch and ACDelco often provide reliable options. Always evaluate the specifications to ensure compatibility with your fleet’s engine types and power requirements. -

How can I effectively vet suppliers for car starters?

To vet suppliers, start by checking their reputation through industry reviews and testimonials. Request references from previous customers and assess their experience in exporting to your region. Review their certifications and compliance with international standards, such as ISO. Additionally, inquire about their production capabilities and lead times to ensure they can meet your demands. Conducting a site visit or virtual assessment can also provide valuable insights into their operations. -

What is the minimum order quantity (MOQ) for car starters?

The MOQ for car starters varies by supplier and product type. Generally, manufacturers might set an MOQ ranging from 50 to 500 units, depending on the starter’s complexity and production costs. Discuss your specific needs with potential suppliers, as some may be flexible, especially for first-time orders or long-term contracts. Understanding MOQ helps in budgeting and inventory management for your business. -

What payment terms should I expect when sourcing car starters internationally?

Payment terms can vary widely among suppliers. Common arrangements include advance payment, letters of credit, or net 30/60 days after delivery. It’s essential to clarify these terms before finalizing agreements to avoid cash flow issues. Additionally, consider using escrow services for larger transactions to mitigate risks. Always ensure that the payment terms align with your company’s financial policies and capabilities. -

How can I ensure the quality of car starters before purchase?

To ensure quality, request detailed product specifications, certifications, and test reports from potential suppliers. Ask about their quality assurance processes, including any warranties or guarantees. If possible, obtain samples for testing before committing to a larger order. Engaging third-party inspection services can also provide an objective assessment of product quality prior to shipment. -

What logistics considerations should I keep in mind when importing car starters?

When importing car starters, consider shipping methods, transit times, and customs clearance processes. Choose between air or sea freight based on your budget and urgency. Ensure you understand the import duties and taxes applicable in your country to avoid unexpected costs. Working with a reliable freight forwarder can simplify logistics and help navigate any regulatory requirements. -

Are there customization options available for car starters?

Many manufacturers offer customization options for car starters, including modifications to voltage, power ratings, and design features to fit specific vehicle models. Discuss your requirements with suppliers early in the sourcing process to determine feasibility and costs. Customization can enhance performance and compatibility, but it may also affect lead times and pricing, so plan accordingly.

Top 5 Car Starter Cost Manufacturers & Suppliers List

1. Starter Replacement – Cost Breakdown

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Starter replacement, labor charges, diagnostics fees, OEM starter pricing, markup on parts.

2. Best Buy – Remote Car Starters

Domain: bestbuy.com

Registered: 1994 (31 years)

Introduction: Remote Car Starters available at Best Buy, featuring brands like Compustar, Viper, Start-X, AVITAL, MPC, Car Keys Express, and iDataStart. Key features include 2-Way Paging, Keyless Entry, Self-Programmable, Panic Mode, App Compatibility, Remote Car Finder, and Automatic Incident Detection with G-Sensor. Products sorted by best-selling and available for pickup or shipping. Price range from $25 to …

3. Facebook – Car Repair Cost Guide

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: cost to get car to the shop and replace starter

4. Last Chance Auto Repairs – Starter Replacement Costs

Domain: lastchanceautorepairs.com

Registered: 2009 (16 years)

Introduction: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Factors affecting cost: Vehicle type & model, New vs Re-Manufactured starters, Additional repairs. DIY costs: Parts only: $100 – $400, Time investment: 2-6 hours. Professional b…

5. CarParts – Quality Starters

Domain: carparts.com

Registered: 1999 (26 years)

Introduction: Car Starters – Standard, Reverse Rotation from $75 | Wide selection of high-quality replacement starters | New and remanufactured options available | Selected and tested by industry professionals | Guaranteed to fit | Fast shipping | Hassle-free returns.

Strategic Sourcing Conclusion and Outlook for car starter cost

In today’s competitive automotive industry, understanding the dynamics of car starter costs is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Strategic sourcing can significantly enhance procurement efficiency, allowing businesses to leverage cost-effective solutions while ensuring high-quality products. By evaluating suppliers based on performance, reliability, and total cost of ownership, buyers can optimize their supply chains and reduce operational risks.

Moreover, as global supply chains continue to evolve, staying informed about market trends and innovations in starter technology will be vital. Engaging with trusted suppliers who offer a variety of options—such as new and remanufactured starters—can provide flexibility and cater to specific market needs.

As we look towards the future, it is essential for B2B buyers to adopt a proactive sourcing strategy that aligns with their long-term business goals. By fostering strong relationships with suppliers and keeping abreast of industry advancements, companies can position themselves for sustained growth and success in an increasingly interconnected marketplace. Embrace strategic sourcing today to secure a competitive edge in your automotive operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.