Introduction: Navigating the Global Market for car alternator for generator

In the ever-evolving landscape of power generation, sourcing a reliable car alternator for generator applications can pose significant challenges for international B2B buyers. With the growing demand for efficient and cost-effective energy solutions, understanding the intricacies of car alternators—ranging from their types and applications to their performance metrics—is crucial. This guide aims to empower businesses across diverse regions, including Africa, South America, the Middle East, and Europe (notably Germany and Nigeria), by providing a comprehensive overview of the market.

Navigating the global market involves critical considerations such as supplier vetting, cost analysis, and technical specifications. This guide will delve into the various types of car alternators, their adaptability in generator setups, and the potential return on investment they offer. Buyers will also gain insights into the best practices for evaluating suppliers to ensure quality and reliability, helping them make informed purchasing decisions.

By addressing common challenges and equipping B2B buyers with actionable knowledge, this guide serves as a valuable resource for businesses looking to optimize their energy generation capabilities. Whether you are a seasoned industry player or a newcomer, understanding the dynamics of sourcing car alternators will enhance your strategic approach to achieving sustainable energy solutions.

Table Of Contents

- Top 4 Car Alternator For Generator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car alternator for generator

- Understanding car alternator for generator Types and Variations

- Key Industrial Applications of car alternator for generator

- 3 Common User Pain Points for ‘car alternator for generator’ & Their Solutions

- Strategic Material Selection Guide for car alternator for generator

- In-depth Look: Manufacturing Processes and Quality Assurance for car alternator for generator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator for generator’

- Comprehensive Cost and Pricing Analysis for car alternator for generator Sourcing

- Alternatives Analysis: Comparing car alternator for generator With Other Solutions

- Essential Technical Properties and Trade Terminology for car alternator for generator

- Navigating Market Dynamics and Sourcing Trends in the car alternator for generator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car alternator for generator

- Strategic Sourcing Conclusion and Outlook for car alternator for generator

- Important Disclaimer & Terms of Use

Understanding car alternator for generator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Automotive Alternator | Typically 12V output, designed for vehicle electrical systems | Automotive repair shops, vehicle manufacturers | Pros: Widely available, cost-effective. Cons: Limited voltage output for industrial applications. |

| High-Output Alternator | Higher amperage output (up to 300A), designed for performance vehicles | Racing teams, heavy machinery, custom builds | Pros: Supports high electrical loads. Cons: Higher cost and may require modifications for installation. |

| Modified Alternator | Altered to produce higher voltages (e.g., 24V, 48V) | Renewable energy systems, backup power generators | Pros: Customizable for specific needs. Cons: Requires technical knowledge for modification. |

| Dual-Voltage Alternator | Capable of producing both 12V and 24V outputs | Marine applications, heavy-duty vehicles | Pros: Versatile, suitable for diverse applications. Cons: More complex and potentially higher maintenance. |

| Permanent Magnet Alternator | Uses permanent magnets for higher efficiency and lower RPMs | Off-grid solar systems, wind turbines | Pros: Efficient, compact design. Cons: Generally more expensive and less common. |

What Are the Characteristics of Standard Automotive Alternators?

Standard automotive alternators are commonly found in vehicles, providing a consistent 12V output to power electrical systems. They are ideal for general automotive applications and are readily available, making them a cost-effective option for repair shops and vehicle manufacturers. However, their limited voltage output makes them less suitable for industrial applications where higher voltages are required.

How Do High-Output Alternators Differ from Standard Models?

High-output alternators are designed to deliver significantly higher amperage, often reaching up to 300A, catering to performance vehicles and heavy machinery. These alternators are essential for applications requiring substantial electrical loads, such as racing teams and custom builds. While they provide enhanced performance, buyers should consider the higher costs and potential modifications needed for installation.

What Are the Benefits of Using Modified Alternators?

Modified alternators can be adjusted to produce higher voltages, such as 24V or 48V, making them suitable for renewable energy systems and backup power generators. These units offer flexibility and customization, allowing buyers to tailor them to specific needs. However, modifying an alternator requires technical expertise, which may pose a barrier for some businesses.

Why Choose Dual-Voltage Alternators for Diverse Applications?

Dual-voltage alternators are capable of producing both 12V and 24V outputs, making them versatile for marine applications and heavy-duty vehicles. Their adaptability to various electrical systems is a significant advantage for businesses operating in different sectors. However, the complexity of these systems may lead to increased maintenance requirements.

What Are the Advantages of Permanent Magnet Alternators?

Permanent magnet alternators utilize magnets for improved efficiency and can operate at lower RPMs. They are particularly beneficial in off-grid solar systems and wind turbines, where space and efficiency are critical. While their compact design is appealing, buyers should be prepared for a higher initial investment, as these units are generally less common in the market.

Key Industrial Applications of car alternator for generator

| Industry/Sector | Specific Application of car alternator for generator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Off-grid power generation for irrigation systems | Reliable power supply for pumps, reducing dependency on grid electricity | Availability of compatible voltage regulators and efficient pulleys |

| Construction | Mobile power for tools and machinery | Enhanced productivity with portable power solutions | Durability of components for harsh environments and ease of installation |

| Telecommunications | Backup power for remote communication towers | Ensures uninterrupted service in areas with unstable power supply | Sourcing of high-capacity alternators to meet energy demands |

| Emergency Services | Emergency power supply for medical facilities | Critical for maintaining operations during outages | Compliance with safety standards and reliability of components |

| Renewable Energy | Integration in hybrid systems for solar or wind energy | Increased energy efficiency and reduced operational costs | Compatibility with existing renewable energy setups and local regulations |

How is a Car Alternator Used in Agriculture for Off-Grid Power Generation?

In the agricultural sector, car alternators are repurposed as generators to provide reliable off-grid power for irrigation systems. This is particularly valuable in regions where electricity access is limited or inconsistent, such as parts of Africa and South America. By converting mechanical energy from a small engine into electrical energy, these systems can efficiently power water pumps, ensuring crops receive necessary irrigation without relying on the grid. Buyers should consider sourcing alternators that can be easily integrated with existing irrigation setups and ensure they have the appropriate voltage regulators for optimal performance.

What Role Does a Car Alternator Play in Construction for Mobile Power?

In the construction industry, car alternators serve as effective mobile power sources for tools and machinery, especially on job sites far from electrical outlets. They can be coupled with small gasoline engines to create portable generators that power tools, lights, and equipment, enhancing productivity. For international buyers, particularly in developing regions, it’s crucial to source durable alternators that can withstand rugged conditions and are easy to install. Ensuring compatibility with local power needs and voltage requirements is also vital for successful implementation.

How Can Telecommunications Benefit from Car Alternators as Backup Power?

Telecommunications companies utilize car alternators in backup power systems for remote communication towers, ensuring continuous operation during power outages. This application is critical in areas where grid reliability is low, such as in parts of the Middle East and Africa. By integrating car alternators into their infrastructure, these companies can maintain essential services, thereby improving customer satisfaction. Buyers should prioritize sourcing high-capacity alternators that meet the energy demands of their specific applications and ensure compliance with local regulations.

Why Are Car Alternators Important for Emergency Services?

In emergency services, car alternators are vital for providing backup power to medical facilities and emergency response vehicles. They ensure that critical operations can continue during electrical outages, which is essential for patient care and emergency response efforts. Sourcing reliable alternators that comply with safety standards is crucial for these applications, as any failure can have dire consequences. Additionally, buyers should consider the efficiency and maintenance requirements of these alternators to ensure they are always operational when needed.

How Are Car Alternators Integrated into Renewable Energy Solutions?

Car alternators can be effectively integrated into hybrid systems for renewable energy sources like solar or wind. They help increase energy efficiency by converting mechanical energy into electrical energy, which can be stored or used immediately. This is particularly beneficial for businesses looking to reduce operational costs and reliance on fossil fuels. Buyers should focus on sourcing alternators that are compatible with their existing renewable energy systems and comply with local regulations to ensure seamless integration and optimal performance.

3 Common User Pain Points for ‘car alternator for generator’ & Their Solutions

Scenario 1: Inconsistent Power Output from Car Alternators

The Problem: One of the significant challenges B2B buyers face when using car alternators for generators is the inconsistency in power output, especially when operating at varying RPMs. This inconsistency can lead to insufficient voltage levels, particularly in regions where stable power supply is critical, such as in remote construction sites or agricultural operations. For businesses relying on continuous power for tools, machinery, or lighting, experiencing voltage drops can halt operations, leading to productivity losses and increased downtime.

The Solution: To ensure a stable power output, buyers should invest in high-quality voltage regulators that can handle the specific demands of their application. Additionally, modifying the alternator setup by implementing a belt and pulley system allows for optimal RPM adjustments, thus maintaining consistent voltage levels. By selecting alternators with higher output ratings and ensuring the compatibility of diodes and regulators, businesses can create a robust system that minimizes fluctuations. Regular maintenance and monitoring of the alternator’s performance can also prevent unforeseen issues, ensuring uninterrupted operations.

Scenario 2: Inefficiency and High Energy Losses in DIY Alternator Generators

The Problem: Many B2B buyers attempting to build generators from car alternators face the challenge of inefficiency, often resulting in high energy losses. This issue is particularly prevalent in regions with limited access to reliable energy sources, where every watt counts. Buyers may find that their homemade systems do not deliver the expected power output, leading to frustration and potential project delays.

The Solution: To combat inefficiency, buyers should focus on sourcing alternators specifically designed for generator applications rather than repurposing standard automotive alternators. Selecting alternators with a proven track record for energy efficiency—ideally with a higher efficiency rating of 70% or more—can significantly reduce energy losses. Furthermore, pairing the alternator with a suitable engine that matches its power requirements can enhance overall performance. Implementing thorough testing during the assembly phase, including load testing, can identify inefficiencies early, allowing buyers to make necessary adjustments before deployment.

Scenario 3: Difficulty in Sourcing Compatible Parts for Custom Builds

The Problem: A common pain point for B2B buyers is the difficulty in sourcing compatible parts for custom generator builds using car alternators. This issue is exacerbated in regions with limited access to diverse suppliers, leading to prolonged project timelines and increased costs. Buyers may struggle to find the right voltage regulators, diodes, or even the correct specifications for the alternators themselves, causing delays in production or installation.

The Solution: To streamline the sourcing process, businesses should establish relationships with multiple suppliers that specialize in automotive and generator components. Utilizing online platforms that aggregate suppliers can also help in comparing prices and availability. Additionally, buyers should consider standardizing their designs around commonly available parts, which can reduce lead times and ensure that replacements are easily obtainable. Engaging with industry forums or networks can provide insights into reputable suppliers and recommendations on the best components for their specific needs. This proactive approach not only enhances supply chain efficiency but also mitigates the risks of project delays.

Strategic Material Selection Guide for car alternator for generator

What Materials Are Commonly Used in Car Alternators for Generators?

When selecting materials for car alternators repurposed as generators, several factors come into play, including performance characteristics, cost, and manufacturing complexity. Below, we analyze four common materials used in the construction of car alternators, focusing on their properties, advantages and disadvantages, and considerations for international B2B buyers.

How Does Copper Impact the Performance of Car Alternators?

Copper is widely utilized in the windings of car alternators due to its excellent electrical conductivity. Key properties include a high melting point (approximately 1,984°F or 1,085°C) and good corrosion resistance, which enhances durability.

Pros: Copper’s high conductivity ensures efficient energy transfer, leading to better performance in generating electricity. It is also relatively easy to work with, allowing for complex winding designs that improve output.

Cons: The primary drawback is the cost, as copper is significantly more expensive than alternatives like aluminum. Additionally, while copper is durable, it is susceptible to corrosion if not properly insulated.

Impact on Application: Copper’s compatibility with various media and its ability to withstand high temperatures make it suitable for automotive applications, especially in regions with extreme weather conditions.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the availability and cost fluctuations of copper. Compliance with international standards such as ASTM B170 for copper wire may also be necessary.

What Role Does Aluminum Play in Car Alternator Manufacturing?

Aluminum is often used as a cost-effective alternative to copper in alternator windings. It has a lower density, which can reduce the overall weight of the alternator.

Pros: The main advantage of aluminum is its lower cost compared to copper, making it an attractive option for budget-conscious buyers. It is also lightweight, which can be beneficial for applications where weight is a concern.

Cons: Aluminum has lower electrical conductivity than copper, which can lead to reduced efficiency in energy transfer. It is also more prone to oxidation, which can impact performance if not properly treated.

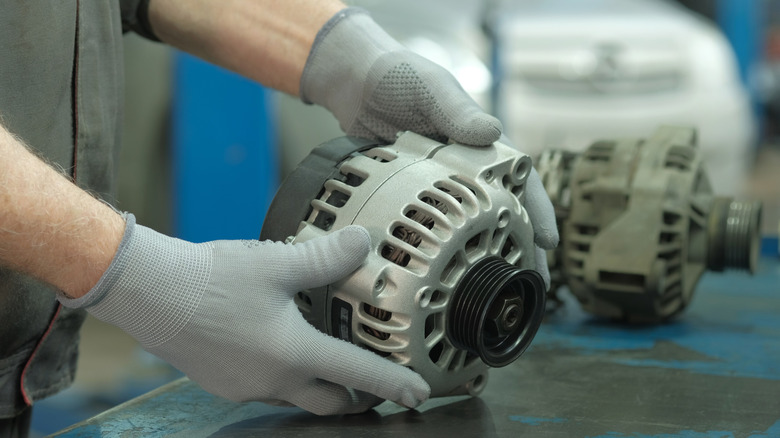

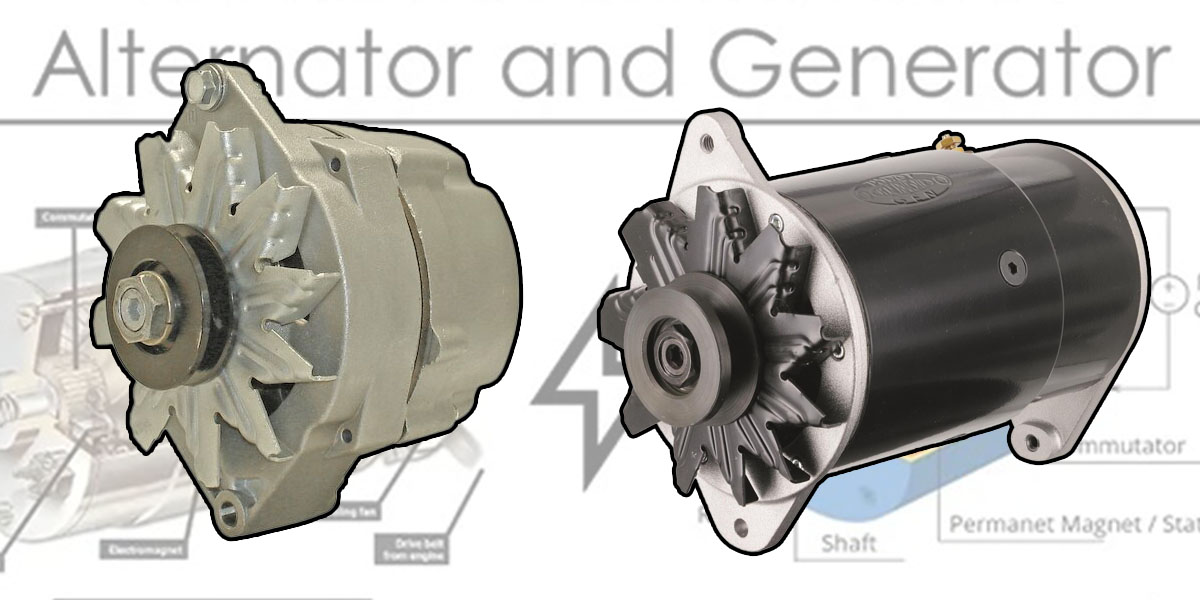

Illustrative image related to car alternator for generator

Impact on Application: Aluminum’s lower conductivity may limit its effectiveness in high-demand applications, but it can still be suitable for smaller generators or less demanding environments.

Considerations for International Buyers: Buyers should be aware of the specific grades of aluminum being used, as compliance with standards like ASTM B800 is crucial for quality assurance.

How Do Steel and Iron Affect the Durability of Car Alternators?

Steel and iron are commonly used in the structural components of car alternators, particularly in the casing and mounting brackets. These materials provide strength and stability.

Pros: The durability of steel and iron makes them ideal for withstanding mechanical stress and environmental factors. They are also relatively inexpensive, making them a cost-effective choice for manufacturers.

Cons: The primary disadvantage is susceptibility to rust and corrosion, especially in humid environments. Protective coatings can mitigate this, but they add to manufacturing complexity.

Impact on Application: Steel and iron are suitable for rugged applications, but their weight may be a drawback in portable generator designs.

Considerations for International Buyers: Buyers in regions with high humidity, such as parts of the Middle East, should prioritize corrosion-resistant coatings and ensure compliance with standards like ASTM A36 for structural steel.

What Advantages Does Plastic Offer in Car Alternator Components?

Plastic is increasingly being used for non-structural components, such as housings and insulators, in car alternators.

Pros: Plastic is lightweight, resistant to corrosion, and can be molded into complex shapes, allowing for innovative designs. It is also relatively inexpensive compared to metals.

Cons: The main limitation of plastic is its lower heat resistance and potential for degradation over time, especially in high-temperature environments.

Impact on Application: While suitable for non-load-bearing components, plastics may not be ideal for high-stress areas of the alternator.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with relevant standards, such as ISO 9001 for quality management, to guarantee performance and safety.

Summary Table of Material Selection for Car Alternators

| Material | Typical Use Case for car alternator for generator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings for electrical connections | Excellent electrical conductivity | High cost; corrosion susceptibility | High |

| Aluminum | Windings as a cost-effective alternative | Lightweight and lower cost | Lower conductivity; oxidation risk | Medium |

| Steel/Iron | Structural components (casings, brackets) | Durable and cost-effective | Prone to rust; heavier weight | Low |

| Plastic | Non-structural components (housings, insulators) | Lightweight and corrosion-resistant | Lower heat resistance; potential degradation | Low |

This strategic material selection guide aims to equip international B2B buyers with the insights necessary to make informed decisions when sourcing components for car alternators used in generator applications.

In-depth Look: Manufacturing Processes and Quality Assurance for car alternator for generator

What Are the Main Stages of Manufacturing Car Alternators for Generators?

The manufacturing process of car alternators suitable for generator applications involves several critical stages, each designed to ensure optimal performance and reliability.

Material Preparation: What Materials Are Used in Manufacturing?

The first step in the manufacturing process is material preparation, which typically includes sourcing high-quality raw materials such as copper, aluminum, and various alloys for the rotor and stator components. Copper is predominantly used for windings due to its excellent conductivity, while aluminum is often employed for the casing and other structural components due to its lightweight and corrosion-resistant properties. Manufacturers must ensure that materials meet international standards to guarantee durability and performance.

How Are Components Formed and Shaped?

Following material preparation, the next stage is forming. This involves several techniques, including:

- Casting: Aluminum casings and other components are often produced using die-casting techniques, which allow for high precision and a smooth finish.

- Machining: Components such as rotors and stators undergo machining processes to achieve the required specifications. This can include turning, milling, and grinding to ensure accurate dimensions and surface finishes.

- Winding: The winding of copper wire around the stator is a critical step. Automated machines typically handle this process to maintain consistency and precision, ensuring the right number of turns and tension.

What Does the Assembly Process Involve?

After forming, the assembly process begins. This stage includes the following key activities:

- Component Integration: The stator, rotor, and other parts are assembled together, often using automated assembly lines to enhance efficiency.

- Electrical Connections: Proper electrical connections are vital for performance. This includes soldering or crimping wires to ensure low resistance and reliability.

- Installation of Voltage Regulators: Voltage regulators are crucial for maintaining output voltage stability. They are installed during assembly to ensure the alternator can function effectively under varying loads.

What Finishing Techniques Are Commonly Used?

Once assembled, alternators undergo several finishing processes to enhance their durability and performance:

- Coating: Protective coatings are applied to prevent corrosion and wear. This is particularly important for components exposed to harsh environments.

- Testing: Preliminary testing is conducted to identify any defects or malfunctions before the final quality checks. This may involve running the alternator under load conditions to assess performance.

What Quality Assurance Standards Are Relevant for Car Alternators?

Quality assurance (QA) is a crucial aspect of manufacturing car alternators for generators. Manufacturers often adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. This ensures that products consistently meet customer and regulatory requirements.

How Are Quality Control Checkpoints Structured?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards and requirements.

- In-Process Quality Control (IPQC): During the production process, various checkpoints are established to monitor critical parameters, such as dimensions and electrical performance.

- Final Quality Control (FQC): Once the alternators are fully assembled, they undergo rigorous testing to ensure they meet performance specifications. This can include load testing, voltage output testing, and durability assessments.

What Testing Methods Are Commonly Used?

Several testing methods are employed to validate the quality and performance of car alternators:

- Electrical Testing: This involves measuring output voltage, current, and efficiency under different load conditions to ensure compliance with specifications.

- Thermal Testing: Alternators are tested for heat dissipation to ensure they operate within safe temperature ranges, preventing overheating during extended use.

- Vibration Testing: This assesses the mechanical integrity of the alternator by simulating real-world operating conditions and identifying potential weaknesses.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure the reliability of products:

Illustrative image related to car alternator for generator

- Supplier Audits: Conducting audits of suppliers can help assess their adherence to quality standards and manufacturing practices. This can include on-site visits and evaluations of their facilities and processes.

- Requesting Quality Reports: Buyers can request quality assurance documentation, including test reports, certificates of compliance, and any relevant certifications, such as CE or API standards.

- Third-Party Inspections: Engaging third-party inspection services can provide unbiased assessments of product quality and compliance with international standards. This is particularly important when dealing with suppliers in regions with varying quality control practices.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from different regions may face unique challenges when it comes to quality control:

- Regulatory Differences: Understanding the regulatory environment in the supplier’s country is crucial, as standards may vary significantly. Buyers should ensure that products comply with both local and international regulations.

- Cultural Considerations: Different cultures may have varying approaches to quality and reliability. Establishing clear communication and expectations can help bridge these gaps.

- Logistics and Supply Chain: Buyers should also consider how logistics and supply chain factors can impact product quality. Delays or improper handling during shipping can lead to damage or degradation of quality.

By understanding the manufacturing processes and quality assurance measures for car alternators, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator for generator’

Introduction

Navigating the procurement of car alternators for generators requires a strategic approach, particularly for B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe. This guide provides a structured checklist to streamline the sourcing process, ensuring that you obtain the right products at competitive prices while minimizing risks.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes voltage output, amperage, and compatibility with your generator setup. Understanding these specifications ensures you select alternators that meet your operational needs and avoids costly mismatches.

- Consider the type of engine you will use with the alternator and the desired output voltage (e.g., 12V, 24V, or 48V).

- Assess any additional features required, such as built-in voltage regulators or specific mounting configurations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers that specialize in automotive components, particularly car alternators. A well-informed selection process can lead to better pricing and support.

- Look for suppliers with a proven track record in your target market regions.

- Utilize platforms like industry trade shows, online marketplaces, and trade directories to gather potential supplier options.

Step 3: Evaluate Supplier Certifications

It is essential to verify that your chosen suppliers hold relevant certifications and adhere to international quality standards. This step mitigates risks associated with subpar products and ensures compliance with industry regulations.

- Check for certifications such as ISO 9001 or equivalent, which indicate a commitment to quality management.

- Inquire about their testing processes and warranty offerings for the alternators.

Step 4: Request Samples and Technical Documentation

Before finalizing your order, request product samples and technical documentation from suppliers. This allows you to assess the quality and compatibility of the alternators with your intended applications.

- Ensure that the samples meet your specifications for performance and durability.

- Review any accompanying documentation for installation guidelines and maintenance recommendations.

Step 5: Negotiate Terms and Pricing

Once you have identified suitable suppliers, engage in negotiations to secure favorable terms. This includes pricing, delivery timelines, and payment terms.

Illustrative image related to car alternator for generator

- Aim for volume discounts if you plan to make bulk purchases, as this can significantly reduce costs.

- Clarify return policies and warranties to protect your investment in case of defects or performance issues.

Step 6: Establish Clear Communication Channels

Maintaining effective communication with your supplier is vital throughout the procurement process. Establish clear lines of communication to address any questions or concerns promptly.

- Utilize email, phone calls, and even video meetings to facilitate discussions.

- Ensure that both parties have a mutual understanding of expectations regarding delivery and product specifications.

Step 7: Plan for Logistics and Delivery

Finally, develop a logistics plan to manage the transportation of the alternators to your location. This includes selecting the right shipping methods and ensuring all customs and import regulations are met.

- Consider the cost-effectiveness of different shipping options based on urgency and distance.

- Stay informed about local regulations to avoid delays at customs.

By following this checklist, B2B buyers can streamline the sourcing of car alternators for generators, ensuring they make informed decisions that align with their operational needs and market conditions.

Comprehensive Cost and Pricing Analysis for car alternator for generator Sourcing

What Are the Key Cost Components for Sourcing Car Alternators for Generators?

When considering the sourcing of car alternators for generator applications, a comprehensive understanding of the cost structure is essential. The primary cost components include:

-

Materials: The core materials used in manufacturing car alternators—such as copper for windings, aluminum for casings, and various electronic components—significantly influence the overall price. Fluctuations in raw material costs, especially copper, can lead to price volatility.

-

Labor: Labor costs vary by region and can significantly impact the final price. In countries with lower labor costs, such as those in Africa and South America, sourcing can be more economical compared to Europe.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help keep these costs down.

-

Tooling: Initial setup costs for machinery and tools required for manufacturing can be substantial. These costs are often amortized over production runs, making them a crucial factor in per-unit pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can add to the cost. Certifications like ISO 9001 may also be required, especially for buyers in Europe, impacting overall pricing.

-

Logistics: The cost of shipping and handling is another critical factor. This includes freight costs, customs duties, and warehousing, which can vary widely based on the shipping destination and chosen Incoterms.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can vary based on the supplier’s market positioning and competition.

What Influences the Pricing of Car Alternators for Generators?

Several factors influence the pricing of car alternators beyond the basic cost components:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Higher volumes often lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Customized alternators designed for specific applications may incur additional costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and recognized certifications can lead to increased costs but may provide better performance and reliability, which are crucial for generator applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their assurance of quality and service.

-

Incoterms: Understanding Incoterms is vital for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting total landed costs.

What Are Effective Buyer Tips for Negotiating Prices on Car Alternators?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are practical tips:

-

Negotiate with Multiple Suppliers: Engaging several suppliers can provide leverage in negotiations. Compare not just prices but also service, quality, and delivery times.

-

Focus on Total Cost of Ownership (TCO): When evaluating offers, consider the TCO, which includes not only the purchase price but also installation, maintenance, and potential downtime costs. A lower upfront cost may not always result in savings.

-

Seek Long-term Relationships: Building long-term partnerships with suppliers can lead to better pricing and terms over time. Suppliers may offer discounts for repeat business or larger orders.

-

Understand Local Market Dynamics: Familiarize yourself with the local market conditions in your target sourcing regions. This knowledge can aid in negotiation and help identify the most cost-effective suppliers.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures based on local demand, availability of materials, and labor costs. Understanding these nuances can help in making informed purchasing decisions.

Disclaimer on Indicative Prices

It is essential to note that pricing for car alternators can fluctuate based on market conditions, raw material costs, and supplier pricing strategies. Therefore, buyers should conduct thorough market research and supplier evaluations to obtain accurate and current pricing information tailored to their specific needs.

Alternatives Analysis: Comparing car alternator for generator With Other Solutions

Exploring Viable Alternatives to Car Alternators for Generators

In the quest for efficient power generation solutions, businesses often consider various technologies that can serve as alternatives to car alternators. This analysis compares the ‘car alternator for generator’ approach with other viable options, allowing B2B buyers to make informed decisions based on performance, cost, and ease of implementation.

| Comparison Aspect | Car Alternator For Generator | Wind Turbine Generator | Portable Gasoline Generator |

|---|---|---|---|

| Performance | Moderate efficiency (60-70%) with adjustable voltage output | High efficiency (up to 40% depending on wind speed) | High power output (1kW to 10kW) but dependent on fuel supply |

| Cost | Low initial investment (~$100 for alternator, ~$200 for engine) | Medium initial investment (~$1,500 for small systems) | High initial investment (~$500 to $2,000) |

| Ease of Implementation | Moderate; requires mechanical skills for setup | Moderate to high; requires structural installation and site assessment | High; ready to use with minimal setup |

| Maintenance | Moderate; may require occasional part replacements | Low; requires periodic inspection and maintenance | High; requires regular fuel checks and engine maintenance |

| Best Use Case | DIY projects, small-scale applications, emergency power | Off-grid homes, farms in windy areas | Construction sites, temporary power needs |

What Are the Advantages and Disadvantages of Wind Turbine Generators?

Wind turbine generators harness wind energy to produce electricity, making them a renewable alternative to car alternators. Pros include high efficiency in appropriate wind conditions and low operational costs after installation. However, they require a significant initial investment and are location-dependent, making them unsuitable for areas with inconsistent wind patterns. Additionally, installation can be complex, requiring site assessments and structural supports.

How Do Portable Gasoline Generators Compare?

Portable gasoline generators are another alternative that offers high power output and ease of use. These generators are typically ready to operate out of the box, making them convenient for temporary needs. Pros include high portability and immediate availability. However, they come with higher operational costs due to fuel consumption and require regular maintenance to ensure reliability. Moreover, their reliance on gasoline makes them less environmentally friendly compared to renewable options.

Illustrative image related to car alternator for generator

Conclusion: How Should B2B Buyers Select the Right Power Generation Solution?

When selecting a power generation solution, B2B buyers must consider their specific needs and operational context. If low initial costs and DIY adaptability are priorities, a car alternator setup might be ideal. For businesses focusing on sustainability and long-term savings, wind turbines may be worth the investment, particularly in suitable locations. Conversely, for those needing immediate and portable power, gasoline generators provide a practical solution despite higher ongoing costs. Ultimately, understanding the trade-offs of each option will empower buyers to choose the most suitable technology for their operational goals.

Essential Technical Properties and Trade Terminology for car alternator for generator

What Are the Key Technical Properties of a Car Alternator for Generators?

Understanding the technical specifications of a car alternator used in generator applications is vital for B2B buyers. Here are some critical properties to consider:

-

Voltage Output

– Definition: The nominal voltage produced by the alternator, typically ranging from 12V to 120V depending on the application.

– Importance: Ensures compatibility with the intended load or battery system. A mismatch can lead to inefficient operation or equipment damage. -

Current Rating (Amperage)

– Definition: The maximum current the alternator can supply, often rated in amperes (A), with common ratings around 100A.

– Importance: Determines the load capacity of the generator. Higher amperage allows for more devices to be powered simultaneously, crucial for commercial applications. -

Efficiency Rating

– Definition: The ratio of useful power output to total power input, expressed as a percentage.

– Importance: A higher efficiency rating translates to lower operational costs and less waste heat, which is particularly important in regions with high energy costs. -

Material Grade

– Definition: The quality of materials used in construction, such as aluminum for the housing and copper for the windings.

– Importance: Affects durability and performance. Higher-grade materials can withstand harsher conditions, making them suitable for diverse environments, especially in developing regions. -

Operating Temperature Range

– Definition: The temperature limits within which the alternator can function effectively, typically from -40°C to +85°C.

– Importance: Ensures reliable operation in various climates, which is particularly critical for international buyers in regions with extreme weather conditions. -

Regulator Type

– Definition: The type of voltage regulator used (e.g., mechanical, solid-state).

– Importance: Influences the stability of output voltage. A solid-state regulator is generally more efficient and reliable, ensuring consistent performance under varying loads.

What Are Common Trade Terms Related to Car Alternators for Generators?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts that may be marketed by another manufacturer.

– Importance: Understanding OEM components can guide buyers in sourcing reliable parts that meet specific quality standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: This term is crucial for budgeting and inventory management, especially for businesses looking to reduce costs through bulk purchasing. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for a specific quantity of goods.

– Importance: Essential for comparing offers from different suppliers and ensuring the best deal for your business needs. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules for shipping that define the responsibilities of buyers and sellers.

– Importance: Knowledge of Incoterms is vital for international transactions, as they determine shipping costs, risk, and insurance responsibilities. -

Lead Time

– Definition: The time taken from placing an order to its delivery.

– Importance: Crucial for project planning, as understanding lead times can help businesses avoid delays in production or service delivery. -

Warranty Period

– Definition: The duration during which the manufacturer guarantees the performance of the alternator.

– Importance: A longer warranty period often indicates higher quality and reliability, providing peace of mind for buyers in selecting durable products.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing car alternators for generator applications, ensuring compatibility, efficiency, and reliability.

Navigating Market Dynamics and Sourcing Trends in the car alternator for generator Sector

What Are the Key Market Drivers for Car Alternators in Generator Applications?

The global market for car alternators used in generator applications is experiencing notable growth, driven primarily by the increasing demand for reliable power generation solutions in both urban and rural settings. This trend is particularly pronounced in regions such as Africa and South America, where power outages are common and alternative energy sources are being sought. The adoption of automotive alternators in generator setups is appealing due to their cost-effectiveness—typically, a standard car alternator can be acquired for significantly less than traditional generators, making it an attractive option for businesses looking to optimize their operational costs.

Emerging technologies are also influencing sourcing trends. The rise of e-commerce platforms has enabled international B2B buyers to source components directly from manufacturers, reducing reliance on local suppliers and streamlining procurement processes. Additionally, advancements in alternator technology, such as improved efficiency and the ability to produce higher voltages, are shaping market dynamics. For instance, modifications allowing car alternators to generate up to 120V DC at optimized RPMs are becoming increasingly popular, enhancing their versatility for various applications.

How Does Sustainability and Ethical Sourcing Impact the Car Alternator Market?

Sustainability has become a critical focus for B2B buyers, particularly in the context of sourcing car alternators for generator applications. The environmental impact of production processes, including resource extraction and manufacturing emissions, is under scrutiny. Ethical sourcing practices are gaining importance as companies seek to align their operations with global sustainability goals. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical labor practices, responsible sourcing of raw materials, and reduced carbon footprints.

Moreover, the use of ‘green’ certifications and materials is becoming a key differentiator in the marketplace. Certifications such as ISO 14001 and adherence to environmental management standards not only enhance a supplier’s credibility but also appeal to eco-conscious buyers. Sourcing alternators that incorporate recycled materials or have been manufactured using renewable energy sources can further contribute to a company’s sustainability goals. As international regulations around sustainability tighten, B2B buyers must remain vigilant in their sourcing strategies to ensure compliance and promote ethical supply chains.

What Is the Evolution of Car Alternators in Generator Applications?

The evolution of car alternators dates back to the transition from conventional generators in the mid-20th century. Early generators provided insufficient voltage at idle, leading to power deficiencies in automotive applications. The introduction of the modern alternator, which utilizes electromagnets to maintain consistent voltage output even at low RPMs, marked a significant advancement. This innovation has made car alternators not only a staple in vehicles but also a viable option for generator applications.

In recent years, the DIY community has further popularized the use of car alternators in home-built generator systems. This grassroots movement has highlighted the adaptability and potential of alternators to meet diverse power generation needs, particularly in areas facing frequent power disruptions. As technology continues to advance, the versatility of car alternators in generator applications is expected to expand, providing new opportunities for international B2B buyers seeking cost-effective and reliable power solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of car alternator for generator

-

How do I select the right car alternator for my generator project?

Selecting the right car alternator involves understanding your power requirements and compatibility with your engine. Evaluate the alternator’s output voltage and amperage; for most generator applications, a standard 100A unit is effective. Assess the physical size to ensure it fits within your design and consider the type of voltage regulator needed, especially if you plan to modify the output. Finally, check for the availability of spare parts and the manufacturer’s reputation for quality to ensure long-term reliability. -

What is the best voltage output for a car alternator used in generators?

The optimal voltage output for a car alternator in generator applications typically ranges between 12V to 48V, depending on your specific needs. Standard automotive alternators produce around 14V, which is suitable for most small-scale applications. If higher voltage is required, modifications can be made, such as changing the regulator or using pulleys to adjust RPM. Ensure that the components used can handle the increased voltage to avoid damage. -

What factors should I consider when sourcing car alternators internationally?

When sourcing car alternators internationally, consider factors like supplier reliability, quality certifications, and compliance with local regulations. Verify the supplier’s experience in exporting and their understanding of the specific needs of your market, particularly if you are based in Africa, South America, or the Middle East. Investigate shipping costs, lead times, and warranty policies. Additionally, assess the availability of technical support and after-sales service to resolve any issues post-purchase. -

What is the minimum order quantity (MOQ) for car alternators?

The minimum order quantity (MOQ) for car alternators can vary significantly between suppliers. Typically, MOQs range from 10 to 100 units, depending on the manufacturer’s production capacity and the specific model of the alternator. For larger orders, many suppliers are willing to negotiate lower MOQs. It’s advisable to discuss your requirements upfront to ensure that you can meet both your budget and inventory needs without overcommitting. -

What payment terms should I expect when buying car alternators?

Payment terms when purchasing car alternators can differ widely based on the supplier’s policies and your negotiation strength. Common practices include a deposit (usually 30-50%) upfront, with the balance due before shipment or upon delivery. Some suppliers may offer credit terms for repeat customers or larger orders. It’s essential to clarify all payment details, including accepted methods (e.g., wire transfer, credit card), to avoid any misunderstandings during the transaction. -

How can I ensure the quality of car alternators sourced from suppliers?

To ensure quality, request certifications such as ISO 9001 or other relevant industry standards from your suppliers. Conduct a thorough vetting process, including background checks, reviews, and possibly factory visits if feasible. Ask for samples to test before placing a large order. Establishing a clear quality assurance (QA) process, including setting performance benchmarks and conducting inspections upon delivery, can also help maintain quality standards. -

What are the common shipping options for international procurement of car alternators?

Common shipping options for international procurement of car alternators include air freight, sea freight, and express courier services. Air freight is faster but more expensive, suitable for urgent orders or smaller quantities. Sea freight is cost-effective for bulk orders but takes longer. Consider the destination’s infrastructure and customs regulations when selecting a shipping method. Collaborating with a logistics provider can streamline the process and ensure compliance with local import regulations. -

What modifications can be made to car alternators for generator use?

Modifications to car alternators for generator use often include removing or adjusting the voltage regulator to achieve higher voltage outputs. Upgrading diodes to handle increased voltage and current can also enhance performance. Additionally, configuring the alternator with pulleys to optimize RPMs can improve efficiency. Ensure any modifications comply with safety standards and test thoroughly to confirm that the alternator operates reliably under expected load conditions.

Top 4 Car Alternator For Generator Manufacturers & Suppliers List

1. Endless Sphere – 48V Generator from Car Alternator

Domain: endless-sphere.com

Registered: 2005 (20 years)

Introduction: Building a 48V generator from a car alternator using a $200 “Predator” gasoline engine and a common 100A car alternator costing $100. The alternator can produce 120V DC by removing the voltage regulator and connecting the rotor-windings power directly to the system’s 14V. A belt and pulleys can be used to adjust the diameter to produce 48V at the optimum engine RPM. Efficiency is noted to be aroun…

2. Instructables – Wind Generator with Car Alternator

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Wind Generator with Car Alternator designed by Joalex Henry. Intended to charge batteries for powering appliances in areas without electricity. Built with recycled materials, emphasizing safety and durability against high winds. The project highlights the inadequacy of car alternators for small wind turbines due to their weight and required RPM for energy production. The generator’s construction i…

3. DIY Solar Forum – Low Cost Vehicle Alternator Generator

Domain: diysolarforum.com

Registered: 2019 (6 years)

Introduction: DIY Low Cost Generator from Vehicle Alternator (Alternating Generator) features: 1. Available in multiple voltages (6, 8, 12, 18, 24, 36, 48, 56 volts) and amperages (60 to 300 Amps). 2. Adjustable voltage regulator. 3. Isolated negative, allowing for easy reverse polarity. 4. Capability to add a second rectifier externally for heavy loads. 5. External AC taps for direct access to AC production. 6…

4. All About Circuits – Automotive Alternators to Three-Phase AC Generators

Domain: allaboutcircuits.com

Registered: 2003 (22 years)

Introduction: This company, All About Circuits – Automotive Alternators to Three-Phase AC Generators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for car alternator for generator

In summary, strategic sourcing of car alternators for generators presents a lucrative opportunity for international buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. These alternators offer a cost-effective solution for power generation, leveraging readily available components that are often less expensive than traditional generators. As highlighted, the adaptability of car alternators to produce various voltages makes them versatile for different applications, from home energy systems to industrial backup power.

By focusing on reliable suppliers and understanding the technical specifications necessary for their intended use, B2B buyers can optimize their procurement processes. Additionally, the growing demand for sustainable energy solutions further emphasizes the importance of sourcing high-quality components that can efficiently meet energy needs while minimizing costs.

As we look to the future, businesses should actively explore partnerships and supply chain strategies that enhance their operational resilience. Engaging with trusted manufacturers and distributors will be key to securing the best prices and ensuring product availability. Now is the time to invest in strategic sourcing initiatives that will empower your business to thrive in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to car alternator for generator

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.