Introduction: Navigating the Global Market for bad car starter symptoms

In the complex landscape of automotive maintenance, identifying bad car starter symptoms is crucial for B2B buyers in the global market. As vehicles are essential for transportation and logistics, a malfunctioning starter can lead to costly downtime and operational inefficiencies. This guide aims to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe (including Germany and Vietnam), with the knowledge needed to effectively navigate this challenge.

The comprehensive scope of this guide includes an in-depth analysis of various types of starter issues, their applications in different vehicle models, and practical troubleshooting techniques. Furthermore, it covers essential aspects of supplier vetting, enabling buyers to source high-quality starter components confidently. Cost considerations are also addressed, ensuring that buyers can make informed financial decisions while maintaining their fleet’s reliability.

By providing actionable insights and expert guidance, this resource empowers businesses to enhance their purchasing strategies, mitigate risks associated with starter failures, and ultimately improve their operational performance. In an environment where every decision counts, understanding the nuances of bad car starter symptoms can lead to significant savings and a smoother path to successful procurement.

Table Of Contents

- Top 2 Bad Car Starter Symptoms Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bad car starter symptoms

- Understanding bad car starter symptoms Types and Variations

- Key Industrial Applications of bad car starter symptoms

- 3 Common User Pain Points for ‘bad car starter symptoms’ & Their Solutions

- Strategic Material Selection Guide for bad car starter symptoms

- In-depth Look: Manufacturing Processes and Quality Assurance for bad car starter symptoms

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bad car starter symptoms’

- Comprehensive Cost and Pricing Analysis for bad car starter symptoms Sourcing

- Alternatives Analysis: Comparing bad car starter symptoms With Other Solutions

- Essential Technical Properties and Trade Terminology for bad car starter symptoms

- Navigating Market Dynamics and Sourcing Trends in the bad car starter symptoms Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bad car starter symptoms

- Strategic Sourcing Conclusion and Outlook for bad car starter symptoms

- Important Disclaimer & Terms of Use

Understanding bad car starter symptoms Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Uncharacteristic Sounds | Clicking, grinding, or no sound when starting | Automotive repair shops, fleet maintenance | Pros: Quick diagnosis; Cons: May indicate severe issues. |

| Dashboard Lights On | Dashboard lights illuminate but engine fails to start | Vehicle diagnostics, fleet management | Pros: Easy to identify; Cons: May confuse with battery issues. |

| Engine Non-Responsiveness | Engine does not respond after multiple attempts | Emergency roadside assistance, repair shops | Pros: Clear indicator of starter failure; Cons: Requires professional evaluation. |

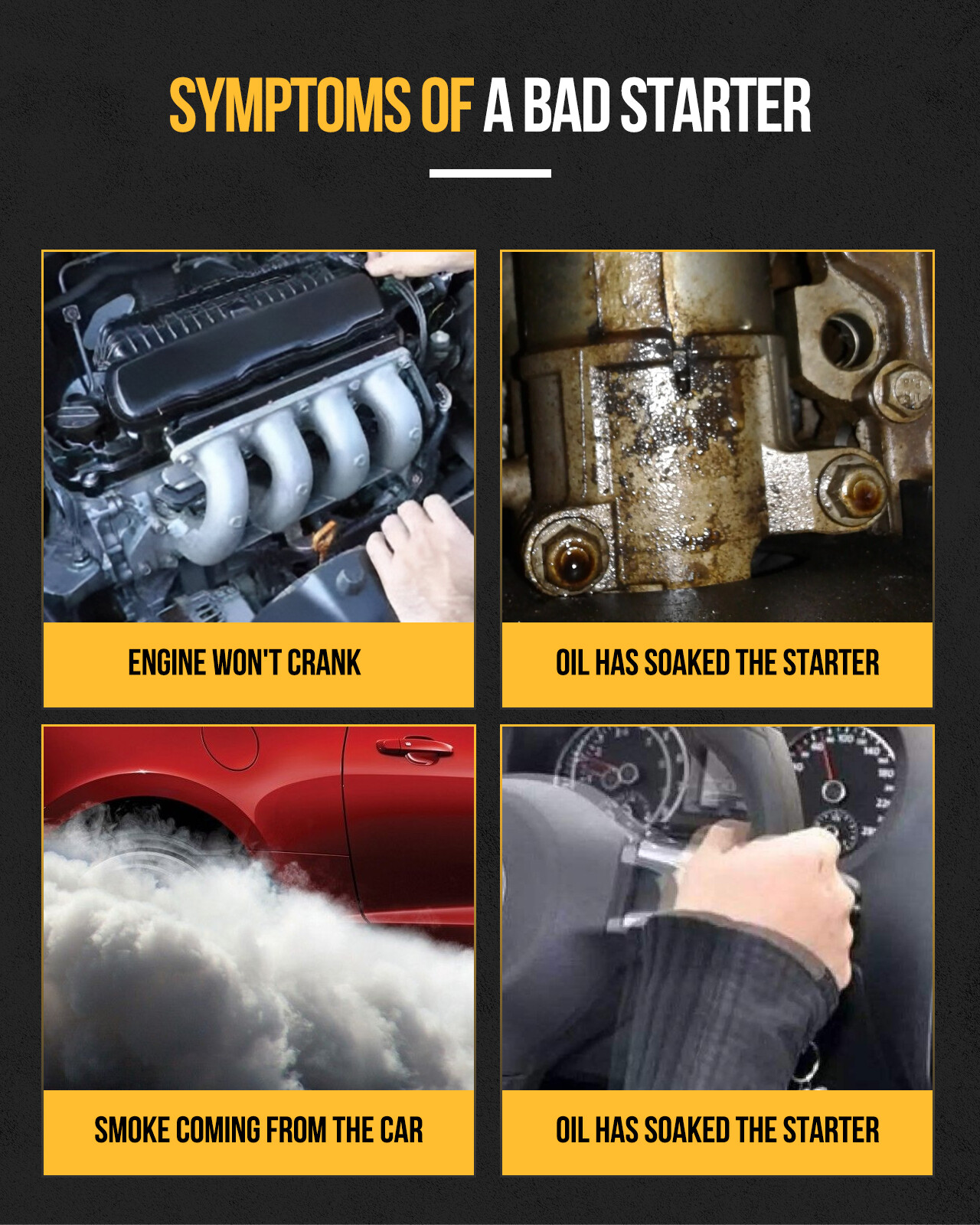

| Smoke Emission | Smoke or burning smell from the starter area | Automotive service centers | Pros: Urgent issue identification; Cons: Risk of further damage if ignored. |

| Oil Leakage | Starter covered in engine oil due to leaks | Engine maintenance, automotive parts supply | Pros: Prevents further starter damage; Cons: Indicates underlying engine problems. |

What Are the Key Characteristics of Uncharacteristic Sounds in Starters?

Uncharacteristic sounds from a starter—such as clicking or grinding—are often the first signs of a failing starter. These sounds indicate potential issues with the starter motor or its electrical connections. For B2B buyers, understanding this symptom is critical for automotive repair shops, as it enables technicians to diagnose the problem quickly. However, these sounds can also signify more severe issues within the vehicle’s electrical system, necessitating thorough inspection and potential replacement of the starter.

How Can Dashboard Lights Help Identify Starter Problems?

When the dashboard lights illuminate but the engine fails to start, it typically suggests a starter issue. This symptom is vital for fleet management and vehicle diagnostics, as it allows for quick identification of potential starter failures. However, it can sometimes be mistaken for battery-related problems, making it essential for technicians to conduct further assessments before concluding that the starter is at fault.

Why Is Engine Non-Responsiveness a Critical Indicator?

Non-responsiveness of the engine after multiple attempts to start is a definitive indicator of starter failure. This symptom is particularly relevant for emergency roadside assistance services and automotive repair shops, as it often requires immediate professional intervention. While this symptom clearly points to starter issues, it may also stem from problems with the battery or alternator, underscoring the need for comprehensive diagnostics.

What Does Smoke Emission Indicate About Starter Condition?

The presence of smoke or a burning smell near the starter area is a serious warning sign of electrical failure or overheating. This symptom is crucial for automotive service centers, as it indicates an urgent need for repair or replacement. Ignoring this issue can lead to more severe damage to the vehicle, increasing repair costs and downtime for businesses relying on fleet vehicles.

How Can Oil Leakage Affect Starter Performance?

Oil leakage around the starter can significantly impair its functionality and lifespan. This symptom is essential for engine maintenance and automotive parts supply businesses, as it highlights the need for prompt attention to oil leaks. Addressing oil leaks not only protects the starter but also prevents potential damage to other engine components, making it a critical consideration for B2B buyers focused on maintaining vehicle reliability.

Illustrative image related to bad car starter symptoms

Key Industrial Applications of bad car starter symptoms

| Industry/Sector | Specific Application of bad car starter symptoms | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Services | Diagnosing starter issues in vehicles | Reduces downtime and enhances customer satisfaction | Quality diagnostic tools, training for technicians |

| Fleet Management | Regular maintenance checks for fleet vehicles | Ensures operational efficiency and minimizes breakdowns | Cost-effective solutions, reliable parts suppliers |

| Logistics and Transportation | Assessing vehicle readiness before dispatch | Increases reliability and reduces delays in service | Partnerships with local mechanics, timely parts availability |

| Vehicle Manufacturing | Quality control in starter system assembly | Enhances product reliability and customer trust | Supplier certifications, adherence to international standards |

| Car Rental Companies | Pre-rental vehicle inspections | Improves customer experience and reduces liability risks | Comprehensive checklists, partnerships with repair shops |

How Are Bad Car Starter Symptoms Utilized in Automotive Repair Services?

In automotive repair services, identifying bad starter symptoms is crucial for diagnosing vehicle issues. Mechanics rely on signs such as unusual sounds or dashboard alerts to pinpoint starter problems, which can prevent vehicles from starting. Addressing these symptoms promptly reduces vehicle downtime, leading to higher customer satisfaction and retention. For international buyers, especially in regions with varying automotive standards, sourcing quality diagnostic tools and ensuring technicians are well-trained in starter systems is vital for effective service delivery.

What Role Does Fleet Management Play in Monitoring Starter Issues?

Fleet management companies must regularly monitor the condition of their vehicles, including the starter systems. By implementing routine checks for bad starter symptoms, they can ensure that vehicles are always operational, significantly minimizing the risk of breakdowns during critical operations. This proactive approach enhances efficiency and reduces repair costs. For businesses in regions like Africa and South America, where parts supply chains may be less stable, sourcing cost-effective solutions and establishing reliable parts suppliers is essential for maintaining fleet performance.

How Do Logistics and Transportation Industries Benefit from Diagnosing Starter Symptoms?

In the logistics and transportation sectors, assessing vehicle readiness before dispatch is vital. Recognizing bad starter symptoms helps ensure that vehicles are in optimal condition, thus preventing delays in service. This reliability is critical for maintaining customer trust and operational efficiency. For international B2B buyers, establishing partnerships with local mechanics for quick diagnostics and ensuring timely availability of parts can significantly enhance service delivery and operational success.

Why Is Quality Control Important in Vehicle Manufacturing?

For vehicle manufacturers, quality control in starter system assembly is paramount. Identifying bad starter symptoms during production helps enhance the reliability of the final product, which is crucial for customer trust and brand reputation. Manufacturers must focus on sourcing components from certified suppliers and adhering to international standards to ensure quality. This approach is particularly important for European manufacturers, where compliance with strict regulations is mandatory.

How Do Car Rental Companies Manage Starter Issues for Customer Satisfaction?

Car rental companies prioritize pre-rental inspections to identify bad starter symptoms, ensuring that vehicles are in excellent working condition before being leased to customers. This diligence enhances the customer experience and reduces the risk of liability due to vehicle failures. For B2B buyers in the rental sector, utilizing comprehensive inspection checklists and forming partnerships with reliable repair shops can facilitate effective management of vehicle fleets, particularly in diverse markets across the Middle East and Europe.

3 Common User Pain Points for ‘bad car starter symptoms’ & Their Solutions

Scenario 1: Difficulty in Diagnosing Starter Issues Accurately

The Problem:

B2B buyers, such as fleet managers or automotive repair shop owners, often face challenges in accurately diagnosing starter issues. The symptoms of a failing starter can overlap with problems related to the battery or alternator, leading to misdiagnosis. For instance, a fleet manager might receive reports of vehicles that fail to start, prompting them to replace the battery first, only to find that the problem persists. This not only increases repair costs but also leads to vehicle downtime, impacting overall operational efficiency.

The Solution:

To address this issue effectively, it is essential to implement a systematic troubleshooting protocol. Start by educating your technicians on the interdependence of the starter, battery, and alternator. Encourage them to perform thorough checks, such as testing battery voltage and inspecting battery connections before jumping to conclusions about the starter’s condition. Utilizing diagnostic tools can help identify whether the issue lies with the starter motor or another component. Providing training sessions or workshops on electrical systems in vehicles can also enhance your team’s competency in diagnosing these problems accurately, reducing unnecessary repairs and vehicle downtime.

Scenario 2: Unplanned Vehicle Downtime Due to Starter Failures

The Problem:

For businesses that rely on a fleet of vehicles, unplanned downtime due to starter failures can be a significant concern. Fleet operators may experience delays in deliveries or service appointments when a vehicle fails to start unexpectedly. This scenario can lead to lost revenue and damage to customer relationships, especially if the vehicles are essential for operations.

The Solution:

Implementing a proactive maintenance schedule can mitigate the risk of sudden starter failures. Encourage regular inspections of starter systems, including checking for signs of wear such as unusual noises or dashboard warning lights. Additionally, establishing a partnership with a reliable automotive service provider for routine check-ups can ensure that potential issues are identified early. Consider integrating telematics solutions that monitor vehicle health in real-time, allowing you to receive alerts for any anomalies related to starting systems. By adopting a preventive approach, you can significantly reduce the likelihood of unplanned downtime and enhance your fleet’s reliability.

Scenario 3: High Repair Costs from Ignoring Early Symptoms

The Problem:

Many B2B buyers overlook early warning signs of starter problems, leading to more severe issues and costly repairs. For example, a company may notice a clicking sound when trying to start a vehicle but dismiss it as a minor issue. Over time, neglecting this symptom can result in complete starter failure, necessitating a more expensive replacement and extended repair times.

The Solution:

To combat this, it is crucial to instill a culture of vigilance regarding vehicle maintenance among your team. Develop a standardized checklist for drivers to report any unusual symptoms, including strange noises, dashboard alerts, or difficulty starting. Additionally, provide educational resources on the importance of early symptom recognition and the potential cost savings associated with timely interventions. Investing in diagnostic equipment can also facilitate early detection of starter issues before they escalate. By fostering awareness and proactive measures, you can reduce repair costs and maintain a more efficient fleet operation.

Strategic Material Selection Guide for bad car starter symptoms

What Materials Are Commonly Used in Starter Systems and Their Properties?

When addressing bad car starter symptoms, the selection of materials for components such as the starter motor, solenoid, and electrical connections is critical. Each material offers unique properties that can significantly affect performance, durability, and overall vehicle reliability. Below is an analysis of four common materials used in starter systems.

How Does Copper Influence Starter Performance?

Key Properties: Copper is known for its excellent electrical conductivity, with a conductivity rating of approximately 59.6 x 10^6 S/m. It also has good thermal conductivity, making it effective in dissipating heat generated during operation.

Illustrative image related to bad car starter symptoms

Pros & Cons: Copper’s high conductivity ensures efficient power transfer, which is vital for starter motors. However, it is susceptible to corrosion, especially in humid environments, which can lead to electrical failures. Additionally, while copper is relatively inexpensive, it can be more costly than alternatives like aluminum.

Impact on Application: Copper is ideal for electrical connections and wiring within the starter system. Its compatibility with various media makes it a preferred choice in automotive applications.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should consider corrosion-resistant coatings for copper components. Compliance with international standards like ASTM B187 for copper wire may also be necessary.

What Role Does Aluminum Play in Starter Systems?

Key Properties: Aluminum is lightweight and has a moderate strength-to-weight ratio. Its corrosion resistance is enhanced when anodized, making it suitable for automotive applications.

Pros & Cons: Aluminum is less expensive than copper and is easier to manufacture into complex shapes, which can reduce production costs. However, its lower conductivity compared to copper can lead to less efficient power transfer, which may affect starter performance.

Impact on Application: Aluminum is often used in starter housings and components where weight reduction is essential. Its compatibility with various automotive fluids is advantageous in preventing degradation.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards, such as DIN EN 573 for aluminum alloys. In regions with high temperatures, like the Middle East, thermal expansion properties should be considered to avoid mechanical failures.

Illustrative image related to bad car starter symptoms

How Does Steel Contribute to Starter Durability?

Key Properties: Steel is known for its high tensile strength and durability. It can withstand significant mechanical stress and has good fatigue resistance.

Pros & Cons: Steel’s strength makes it suitable for structural components within the starter system. However, it is heavier than aluminum and copper, which can affect overall vehicle weight. Additionally, steel is prone to rust unless properly coated.

Impact on Application: Steel is commonly used in starter mounting brackets and gears. Its ability to handle high torque loads is essential for reliable starter operation.

Considerations for International Buyers: Compliance with standards like ASTM A36 for structural steel is crucial. Buyers in humid regions should prioritize galvanized or stainless steel options to prevent corrosion.

What Advantages Does Plastic Offer in Starter Components?

Key Properties: Plastics are lightweight and can be molded into complex shapes. They exhibit good electrical insulation properties, which is essential for preventing short circuits.

Pros & Cons: The use of plastic can significantly reduce the weight of starter components, contributing to overall vehicle efficiency. However, plastics may not withstand high temperatures as well as metals, leading to potential deformation under extreme conditions.

Impact on Application: Plastics are often used for insulating covers and housings in starter systems. They are compatible with various automotive fluids, making them versatile.

Considerations for International Buyers: Buyers should verify that the plastics used meet standards like ISO 9001 for quality management. In regions with extreme temperatures, such as Europe, selecting high-temperature resistant plastics is advisable.

Summary Table of Material Selection

| Material | Typical Use Case for bad car starter symptoms | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections and wiring | Excellent electrical conductivity | Susceptible to corrosion | Medium |

| Aluminum | Starter housings and lightweight components | Lightweight and cost-effective | Lower conductivity than copper | Low |

| Steel | Structural components like brackets and gears | High strength and durability | Heavier and prone to rust | Medium |

| Plastic | Insulating covers and housings | Lightweight and good insulation | Limited high-temperature resistance | Low |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that enhance the reliability and performance of starter systems in vehicles across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for bad car starter symptoms

What Are the Main Stages of Manufacturing Car Starters?

The manufacturing of car starters involves several key stages, each crucial for ensuring the final product meets quality and performance standards. Understanding these stages can help B2B buyers identify reliable suppliers and ensure they are investing in high-quality components.

Material Preparation: Which Materials Are Used in Starter Manufacturing?

The first step in manufacturing starters is material preparation, where high-quality raw materials are sourced. Common materials include:

- Copper: Used for wiring and connections due to its excellent conductivity.

- Steel and Aluminum: Utilized for the housing and structural components, providing strength and durability.

- Plastic Composites: Employed in non-load-bearing parts to reduce weight and improve efficiency.

These materials are carefully selected based on their mechanical and thermal properties, ensuring they can withstand the rigors of automotive environments.

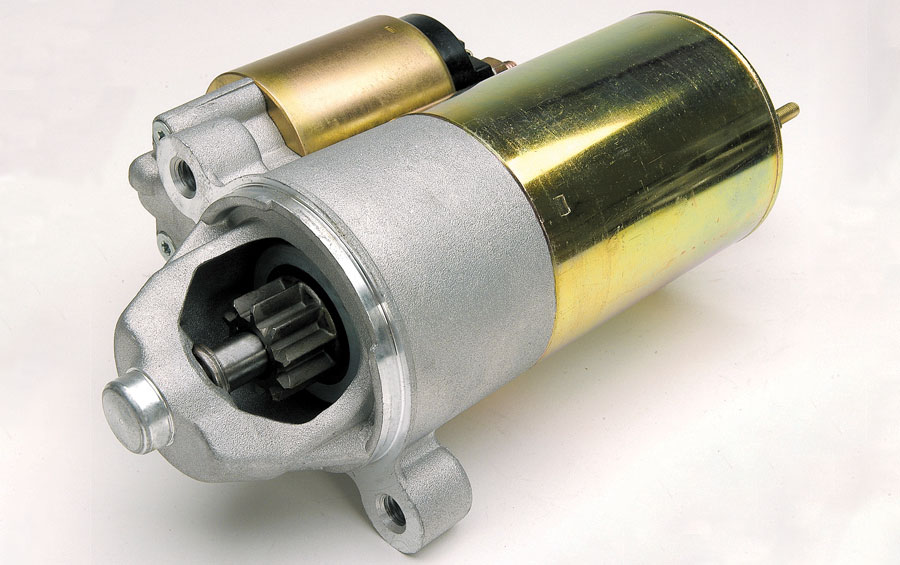

How Is the Forming Process Conducted for Car Starters?

Once the materials are prepared, they undergo various forming processes. Techniques include:

- Stamping: Metal sheets are stamped into specific shapes for the starter casing and internal components.

- Molding: Plastic parts are created using injection molding, allowing for complex shapes and reducing manufacturing waste.

- Machining: Precision machining is employed to create parts like gears and shafts, ensuring tight tolerances for optimal performance.

These forming techniques are essential for producing components that fit together seamlessly and function reliably.

What Does the Assembly Process Involve for Car Starters?

The assembly stage is where all the prepared parts come together. This process typically involves:

- Component Integration: Individual components, such as the motor, solenoid, and drive gear, are assembled in a clean environment to prevent contamination.

- Electrical Connections: Wiring is carefully routed and connected to ensure proper functionality. This stage often includes applying thermal paste to improve heat dissipation.

- Quality Checks: Throughout the assembly process, technicians conduct visual inspections to identify any defects or misalignments.

By adhering to strict assembly protocols, manufacturers can enhance the reliability and longevity of the starters produced.

Illustrative image related to bad car starter symptoms

What Finishing Techniques Are Used in Car Starter Manufacturing?

Finishing processes are crucial for enhancing the durability and aesthetics of car starters. Common techniques include:

- Coating: Protective coatings, such as powder coating or electroplating, are applied to prevent corrosion and enhance the appearance of metal components.

- Surface Treatment: Processes like anodizing for aluminum parts improve surface hardness and resistance to wear.

- Final Inspection: After finishing, a comprehensive inspection is conducted to ensure all components meet specifications before packaging.

These finishing techniques not only improve performance but also ensure compliance with international standards.

How is Quality Assurance Implemented in Car Starter Manufacturing?

Quality assurance (QA) is critical in ensuring that manufactured starters meet the required standards for safety and performance. A robust QA program typically incorporates several international and industry-specific standards.

Which International Standards Are Relevant for Starter Manufacturing?

For B2B buyers, understanding the relevant international standards is crucial. Key standards include:

- ISO 9001: This standard outlines a framework for quality management systems, ensuring consistent quality in production processes.

- ISO/TS 16949: A technical specification for the automotive industry, focusing on continuous improvement and defect prevention.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Compliance with these standards assures buyers of the manufacturer’s commitment to quality.

What Are the Key QC Checkpoints in Starter Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival for quality and compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during production help identify issues early, allowing for corrective actions before final assembly.

- Final Quality Control (FQC): The completed starters undergo rigorous testing, including electrical tests, mechanical performance assessments, and visual inspections.

These checkpoints help minimize defects and ensure that only high-quality starters are shipped to customers.

Illustrative image related to bad car starter symptoms

What Testing Methods Are Commonly Used for Car Starters?

Effective testing methods are vital for validating the performance and reliability of starters. Common methods include:

- Electrical Testing: Assessing voltage, current draw, and resistance to ensure optimal performance under load.

- Durability Testing: Simulating real-world conditions to evaluate the starter’s ability to withstand extreme temperatures, vibrations, and repeated use.

- Functional Testing: Testing the starter’s operation in actual vehicle conditions to verify performance before shipment.

These testing methods provide valuable data to B2B buyers about the reliability and performance of starters.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some strategies:

Illustrative image related to bad car starter symptoms

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, processes, and adherence to quality standards.

- Quality Reports: Requesting detailed quality assurance reports can provide insight into the supplier’s QC practices, including defect rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control practices and product reliability.

By employing these verification methods, buyers can mitigate risks associated with sourcing starters from international suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with suppliers from diverse regions like Africa, South America, the Middle East, and Europe, buyers should be aware of the following nuances:

- Regulatory Compliance: Different regions have varying regulations regarding automotive components. Understanding these can help buyers ensure compliance and avoid legal issues.

- Cultural Differences: Business practices and communication styles can vary significantly. Building strong relationships with suppliers can facilitate better collaboration and understanding.

- Logistics and Supply Chain Management: International shipping can introduce additional challenges, such as customs delays and varying transportation standards. Buyers should plan accordingly to mitigate these risks.

By considering these factors, B2B buyers can enhance their sourcing strategies and ensure they receive high-quality car starters that meet their operational needs.

Illustrative image related to bad car starter symptoms

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bad car starter symptoms’

Introduction

This practical sourcing guide is designed to assist B2B buyers in identifying and addressing symptoms of a faulty car starter. Understanding these signs not only aids in timely intervention but also helps in negotiating better terms with suppliers and service providers. By following this checklist, you can make informed decisions that enhance vehicle performance and reliability.

Step 1: Identify Common Symptoms of a Failing Starter

Recognizing the signs of a malfunctioning starter is crucial for effective troubleshooting. Look for indicators such as unusual noises (clicking or grinding), dashboard lights that illuminate without engine response, or persistent engine failure despite jump-start attempts. Identifying these symptoms early can prevent further damage to the vehicle and reduce repair costs.

Step 2: Conduct a Preliminary Diagnosis

Before contacting suppliers or service providers, perform a basic diagnostic test to determine whether the starter is indeed the issue. Check battery connections, inspect for oil leaks around the starter, and ensure the fuel tank is not empty. This preliminary assessment can save time and resources by providing concrete information to your service provider.

Step 3: Define Your Technical Specifications

Establish clear specifications for the type of starter you need. Consider factors such as compatibility with your vehicle model, voltage requirements, and performance ratings. This clarity will streamline the sourcing process and help you communicate effectively with suppliers, ensuring that you receive the appropriate parts.

Step 4: Research Potential Suppliers

Thoroughly investigate potential suppliers who specialize in automotive components, particularly starters. Look for suppliers with a strong reputation in your region or industry. Analyze their product offerings, customer reviews, and case studies to ensure they can meet your technical requirements and service expectations.

Step 5: Evaluate Supplier Certifications and Quality Standards

Verify that your selected suppliers adhere to relevant quality standards and certifications, such as ISO or equivalent. This ensures that the products you receive are reliable and meet safety regulations. Ask for documentation that verifies their quality control processes and compliance with industry standards.

Step 6: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes that outline pricing, delivery times, and warranty options. Comparing these quotes will help you identify the best value for your investment. Remember, the lowest price does not always equate to the best quality, so consider the overall value offered.

Step 7: Establish a Relationship with Your Chosen Supplier

After selecting a supplier, work on building a strong relationship. Open communication channels can lead to better service, potential discounts, and priority support during emergencies. Establishing trust will also facilitate smoother transactions in future procurement cycles.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing solutions for bad car starter symptoms, ensuring that their procurement decisions contribute to the longevity and performance of their vehicle fleets.

Comprehensive Cost and Pricing Analysis for bad car starter symptoms Sourcing

Understanding the cost structure and pricing dynamics for sourcing components related to bad car starter symptoms is essential for B2B buyers in the automotive sector. Here, we break down the various cost components, price influencers, and provide actionable tips for optimizing procurement strategies.

Illustrative image related to bad car starter symptoms

What Are the Key Cost Components in Sourcing Starter Components?

-

Materials: The primary materials for starter systems include metals like copper and aluminum, plastic casings, and electronic components. The cost of these raw materials fluctuates based on market demand and availability, impacting the overall price of the starter.

-

Labor: Labor costs can vary significantly by region. In high-wage countries, the cost of skilled labor for assembly and quality control can be substantial. Conversely, regions with lower labor costs might offer more competitive pricing but may pose challenges in quality assurance.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, positively affecting the final pricing of starter components.

-

Tooling: Initial tooling costs can be high, especially for custom or specialized components. However, these costs can be amortized over larger production runs, making it essential for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Implementing robust QC processes ensures that the starters meet safety and performance standards. While this adds to the upfront costs, it can prevent expensive recalls or warranty claims in the long run.

-

Logistics: Transportation and shipping costs can significantly affect pricing, particularly for international buyers. Factors such as distance, shipping method, and customs duties should be factored into the total cost.

-

Margin: Suppliers will typically include a profit margin based on their overall cost structure and market competition. Understanding the average market margins can help buyers negotiate better prices.

How Do Price Influencers Affect Starter Component Costs?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Buyers should negotiate favorable MOQs to optimize their sourcing strategy.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized materials or tooling. However, they can also lead to enhanced performance and durability, justifying the additional expense.

-

Material Quality and Certifications: Components that meet specific quality certifications (e.g., ISO, TS) may carry a premium price. Buyers should weigh the benefits of high-quality parts against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge higher prices but offer better guarantees and support.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the overall landed cost of components, impacting budgeting and pricing strategies.

What Tips Can Help Buyers Optimize Their Sourcing Strategy?

-

Negotiation Skills: Effective negotiation can lead to significant savings. Buyers should come prepared with market data and be ready to discuss volume discounts or long-term partnerships.

-

Focus on Total Cost of Ownership (TCO): Instead of solely considering upfront costs, evaluate the TCO, which includes maintenance, warranty, and potential downtime costs. This broader perspective can lead to better purchasing decisions.

-

Understand Pricing Nuances for International Sourcing: Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and import duties that may affect pricing. Engaging local partners can provide insights into these factors.

-

Request Samples: Before making large purchases, request samples to assess quality and compatibility. This step can prevent costly mistakes down the line.

-

Monitor Market Trends: Staying informed about changes in material costs, labor rates, and technological advancements can provide a competitive edge in negotiations and sourcing strategies.

Conclusion

In conclusion, navigating the complex landscape of sourcing components related to bad car starter symptoms requires a strategic approach. By understanding the cost components, recognizing the price influencers, and leveraging effective procurement strategies, B2B buyers can optimize their sourcing process and enhance their operational efficiency. Remember, these insights serve as a guideline; actual prices may vary based on specific circumstances and market conditions.

Alternatives Analysis: Comparing bad car starter symptoms With Other Solutions

Exploring Alternatives for Diagnosing Vehicle Start Issues

In the realm of automotive maintenance, understanding the symptoms of a bad car starter is crucial for vehicle reliability. However, there are alternative diagnostic methods and technologies that can also aid in determining vehicle start issues. This section compares ‘bad car starter symptoms’ with two viable alternatives: advanced diagnostic tools and professional automotive services.

Comparison Table

| Comparison Aspect | Bad Car Starter Symptoms | Advanced Diagnostic Tools | Professional Automotive Services |

|---|---|---|---|

| Performance | Identifies common starter issues through observable signs. | Provides precise diagnostics and data for multiple vehicle systems. | Offers expert evaluation and comprehensive repairs. |

| Cost | Low cost; requires minimal tools and knowledge. | Moderate cost for equipment and software. | Higher cost for labor and parts. |

| Ease of Implementation | Straightforward; can be performed by vehicle owners. | Requires training to interpret data effectively. | Convenient; handled by professionals. |

| Maintenance | No ongoing maintenance required; relies on user knowledge. | Software updates and hardware calibration needed. | Regular maintenance and follow-up services. |

| Best Use Case | Suitable for basic troubleshooting and quick fixes. | Ideal for detailed diagnostics in fleet management. | Best for complex issues requiring expert intervention. |

Analyzing Advanced Diagnostic Tools

Advanced diagnostic tools, such as OBD-II scanners and vehicle diagnostic software, offer a higher degree of accuracy in identifying vehicle issues. These tools can analyze various systems beyond just the starter, providing insights into the battery, alternator, and other components. The primary advantage is the ability to diagnose multiple issues simultaneously, leading to more efficient repairs. However, these tools come at a moderate cost and may require training for effective usage, which could be a barrier for smaller businesses or individual operators.

Evaluating Professional Automotive Services

Professional automotive services provide comprehensive solutions for vehicle issues, including starter problems. These services are performed by trained technicians who can diagnose and repair complex issues that might not be apparent through symptom observation alone. The major benefit is the assurance of quality and expertise, significantly reducing the risk of misdiagnosis. However, the cost of professional services is generally higher, making it less accessible for businesses that operate on tight budgets or prefer DIY solutions.

Illustrative image related to bad car starter symptoms

Conclusion: Choosing the Right Solution for Your Needs

When selecting the best approach for diagnosing vehicle start issues, B2B buyers should consider their specific operational needs, budget constraints, and the complexity of the issues at hand. For quick, basic troubleshooting, understanding bad car starter symptoms may suffice. In contrast, businesses managing fleets or requiring in-depth diagnostics may find advanced diagnostic tools more beneficial. For comprehensive care and assurance of quality repairs, professional automotive services are ideal, albeit at a higher cost. Ultimately, the right choice will depend on the balance between cost, ease of implementation, and the level of expertise required for effective vehicle maintenance.

Essential Technical Properties and Trade Terminology for bad car starter symptoms

What Are the Key Technical Properties Related to Bad Car Starter Symptoms?

Understanding the technical properties of car starters is vital for international B2B buyers in the automotive sector. Here are some essential specifications:

-

Electrical Resistance

Defined as the opposition to the flow of electric current, electrical resistance in starter motors can affect performance. Lower resistance indicates better conductivity, which is crucial for efficient starter operation. In B2B contexts, knowing the resistance specifications can help buyers assess the quality and reliability of starters, especially when sourcing components from different manufacturers. -

Material Grade

The material grade of components such as the starter housing and gears significantly impacts durability and performance. Common materials include aluminum for lightweight applications and high-strength steel for added durability. Buyers should prioritize suppliers who provide detailed material specifications to ensure the starters can withstand harsh operating conditions. -

Torque Rating

Torque rating measures the rotational force produced by the starter motor. It is essential for determining the starter’s ability to turn over the engine, especially in larger vehicles or those with high compression ratios. B2B buyers need to ensure that the torque ratings meet the specific requirements of the vehicles they support to avoid performance issues. -

Operating Temperature Range

This specification indicates the temperature limits within which a starter can function effectively. Starters designed for extreme temperatures—either high or low—will have different materials and insulation. Understanding the operating temperature range is crucial for buyers in regions with extreme climates, as it directly affects the reliability and longevity of the starter. -

Weight

The weight of the starter is an important factor, particularly in performance and racing applications. Lighter starters can improve overall vehicle performance by reducing weight, but they must also maintain adequate power output. Buyers should evaluate the weight specifications when considering performance enhancements.

What Common Trade Terms Should B2B Buyers Know Regarding Bad Car Starter Symptoms?

Navigating the automotive parts market involves familiarizing oneself with specific jargon. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are often preferred for their guaranteed compatibility and reliability. B2B buyers should consider OEM components for critical systems like starters to ensure optimal performance and compliance with warranty requirements. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and negotiate better pricing with suppliers. A high MOQ might be a barrier for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. It is a crucial step in the procurement process, allowing buyers to compare costs and terms. Crafting a precise RFQ can lead to better pricing and favorable contract terms. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, risk management, and cost implications, especially when sourcing parts from different countries. -

Aftermarket

This term refers to parts and accessories made by companies other than the original manufacturer. While aftermarket starters can be more affordable, their quality and compatibility can vary. B2B buyers should carefully evaluate aftermarket options against OEM parts to determine the best fit for their needs. -

Warranty Period

This is the duration during which the manufacturer guarantees the product’s performance. Understanding warranty terms is crucial for B2B buyers, as it reflects the manufacturer’s confidence in their product and provides a safety net for potential defects or failures.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing starters and related components, ensuring reliability and performance across their vehicle offerings.

Navigating Market Dynamics and Sourcing Trends in the bad car starter symptoms Sector

What Are the Key Trends Influencing the Bad Car Starter Symptoms Market?

The global market for automotive components, including starter systems, is experiencing significant shifts driven by technological advancements and evolving consumer preferences. One of the primary drivers is the increasing reliance on electric and hybrid vehicles, which necessitates a reevaluation of traditional starter systems. B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for high-performance starters that can withstand the unique challenges posed by diverse climates and road conditions.

Emerging trends in sourcing and technology include the integration of smart diagnostics in starter systems, allowing for real-time monitoring of performance and potential failure signs. This innovation not only enhances operational efficiency but also reduces maintenance costs. Furthermore, the rise of e-commerce platforms is revolutionizing the way B2B buyers procure automotive parts, enabling easier access to suppliers and competitive pricing. As buyers increasingly seek out suppliers who can provide comprehensive product information and support, the emphasis on transparent supply chains is more pronounced than ever.

International buyers must also be aware of regional market dynamics, including the regulatory landscape and trade agreements that may impact sourcing. For example, European buyers are often subject to stringent environmental regulations, which necessitate compliance from suppliers regarding product sustainability and lifecycle impacts. This trend is mirrored in emerging markets, where local regulations are evolving to promote greener automotive technologies.

Illustrative image related to bad car starter symptoms

How Are Sustainability and Ethical Sourcing Shaping the Bad Car Starter Symptoms Sector?

Sustainability is becoming a cornerstone in the automotive parts industry, with B2B buyers increasingly prioritizing eco-friendly sourcing practices. The environmental impact of automotive components, including starters, is significant, particularly in terms of resource extraction and manufacturing processes. As global awareness of climate change grows, businesses are urged to consider the entire lifecycle of their products, from sourcing raw materials to end-of-life disposal.

Ethical supply chains are essential not only for regulatory compliance but also for enhancing brand reputation. Buyers are encouraged to seek suppliers who adhere to sustainable practices, such as using recycled materials or manufacturing processes that minimize waste and carbon emissions. Certifications like ISO 14001 for environmental management and the use of eco-labels can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the demand for ‘green’ materials in starter systems is rising, prompting manufacturers to explore alternative materials that reduce environmental footprints. For instance, lightweight composite materials can improve fuel efficiency and reduce emissions in vehicles. B2B buyers should prioritize partnerships with suppliers who demonstrate a commitment to sustainability, as this can translate into long-term cost savings and compliance with evolving regulations.

Illustrative image related to bad car starter symptoms

What Is the Historical Context of Bad Car Starter Symptoms in the Automotive Industry?

The evolution of car starter systems has dramatically transformed since the early 20th century, influencing how automotive companies address starter-related symptoms today. Initially, manual cranking systems were standard, requiring significant physical effort from the driver. The introduction of electric starters in the 1910s revolutionized vehicle ignition, significantly enhancing convenience and reliability.

Over the decades, advancements in technology have led to more sophisticated starter systems, including the integration of solenoids and advanced electrical components that improve performance and efficiency. The rise of electronic fuel injection systems and onboard diagnostics has further complicated the landscape, enabling real-time monitoring of starter functionality and related symptoms.

As automotive technology continues to evolve, so does the approach to diagnosing and addressing bad starter symptoms. Today’s B2B buyers must be well-versed in the latest diagnostic tools and technologies to effectively manage starter issues, ensuring that their supply chains are equipped to meet the demands of modern vehicles. Understanding this historical context not only informs sourcing decisions but also highlights the importance of innovation in maintaining competitive advantage in the automotive market.

Frequently Asked Questions (FAQs) for B2B Buyers of bad car starter symptoms

-

How do I solve issues with a bad car starter?

To address problems with a bad car starter, first check the battery and its connections, as a weak battery often mimics starter issues. If the battery is functioning properly, listen for any unusual sounds when attempting to start the vehicle, such as clicking or grinding noises, which may indicate a failing starter. Inspect for oil leaks around the starter area, as they can impair performance. If these checks do not resolve the issue, consult a qualified technician for a thorough diagnosis and repair. -

What are the common signs of a failing starter?

Common signs of a failing starter include hearing a clicking noise when turning the ignition key, dashboard lights illuminating without the engine starting, and the engine remaining unresponsive after multiple attempts. Additionally, smoke or burning smells may indicate overheating components, while an oil-soaked starter suggests potential leaks affecting functionality. Identifying these symptoms early can prevent further damage and costly repairs. -

What type of starter should I consider for my vehicle?

The best starter for your vehicle depends on its make and model, as well as its specific electrical requirements. When sourcing starters, consider factors such as durability, compatibility with your vehicle’s electrical system, and manufacturer reputation. It’s advisable to consult with suppliers who can provide detailed specifications and recommendations based on your vehicle’s needs, ensuring optimal performance and longevity. -

How can I vet suppliers for car starter components?

To vet suppliers for car starter components, begin by researching their reputation in the industry. Look for customer reviews, certifications, and their experience in the automotive sector. Request samples or references from previous clients to assess product quality. Additionally, inquire about their manufacturing processes, quality assurance measures, and compliance with international standards to ensure you partner with a reliable supplier. -

What are the minimum order quantities (MOQ) for car starters?

Minimum order quantities (MOQ) for car starters can vary significantly among suppliers. Some may offer flexible MOQs for smaller businesses, while others may require larger orders to reduce costs. When negotiating with suppliers, clarify your specific needs and explore options for lower MOQs, especially if you are testing new products or entering new markets. Establishing a good relationship with your supplier may also lead to more favorable terms. -

What payment terms are common for international B2B transactions?

Common payment terms for international B2B transactions include options like wire transfers, letters of credit, and payment upon delivery. Terms may vary based on the supplier’s policies and the buyer’s creditworthiness. It’s essential to discuss and agree on payment terms upfront to avoid misunderstandings. Also, consider using escrow services for added security, especially for high-value transactions. -

How do I ensure quality assurance (QA) for car starters?

To ensure quality assurance (QA) for car starters, request detailed product specifications and quality control processes from your supplier. Establish clear standards for performance, durability, and compliance with relevant regulations. Consider implementing periodic inspections during production and pre-shipment checks. Collaborating with a third-party QA firm can also provide an unbiased assessment of product quality before delivery. -

What logistics considerations should I keep in mind when sourcing car starters internationally?

When sourcing car starters internationally, consider factors such as shipping methods, customs regulations, and lead times. Evaluate the total cost of logistics, including freight charges, insurance, and any applicable tariffs. It’s vital to work with logistics partners experienced in handling automotive parts to ensure timely and safe delivery. Additionally, maintaining open communication with your supplier about shipping schedules can help manage expectations and prevent delays.

Top 2 Bad Car Starter Symptoms Manufacturers & Suppliers List

1. Reddit – Bad Starter Diagnosis

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Bad Starter Diagnosis, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Facebook – Starter Motor Issues

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Starter Motor Issues, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for bad car starter symptoms

How Can Strategic Sourcing Mitigate Bad Starter Symptoms?

In conclusion, understanding the symptoms of a failing starter is essential for maintaining vehicle reliability and ensuring efficient operations. Key indicators such as unusual sounds, dashboard alerts, and physical signs like oil leaks can guide your troubleshooting efforts. For B2B buyers in Africa, South America, the Middle East, and Europe, strategically sourcing high-quality starter components can significantly reduce downtime and repair costs. By investing in reliable suppliers, businesses can enhance their service offerings and customer satisfaction.

The value of strategic sourcing extends beyond immediate fixes; it builds long-term partnerships that can streamline supply chains and improve product quality. As the automotive industry evolves, staying informed about the latest technologies and trends in starter systems will be crucial for maintaining a competitive edge.

Moving forward, we encourage international B2B buyers to leverage this knowledge and explore partnerships with trusted suppliers. By prioritizing quality and reliability in your sourcing strategies, you can ensure that your fleet remains operational, ultimately driving growth and success in your market. Take the next step in enhancing your vehicle maintenance strategy today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.