Introduction: Navigating the Global Market for alternator and starter parts wholesale

Navigating the intricate landscape of the global market for alternator and starter parts wholesale presents a significant challenge for B2B buyers. The need for reliable sourcing of high-quality components, essential for maintaining the performance of various vehicles, can often feel daunting, especially when considering the diverse requirements across different regions. This comprehensive guide serves as an invaluable resource for international buyers, particularly those operating in Africa, South America, the Middle East, and Europe, including key markets like Germany and Nigeria.

In this guide, we delve into the myriad types of alternator and starter parts available, including premium quality starter parts, rebuild kits, and repair components. We explore their applications across various sectors, from automotive and commercial vehicles to marine and industrial uses. Additionally, we provide insights into the supplier vetting process, helping you identify reputable manufacturers and distributors. Cost considerations are also addressed, ensuring you can make informed purchasing decisions that align with your budgetary constraints.

By equipping you with the knowledge to navigate the complexities of sourcing alternator and starter parts, this guide empowers you to enhance your procurement strategy. Armed with actionable insights and a clear understanding of the market landscape, you can confidently select the right components that meet your operational needs while maximizing profitability.

Table Of Contents

- Top 5 Alternator And Starter Parts Wholesale Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator and starter parts wholesale

- Understanding alternator and starter parts wholesale Types and Variations

- Key Industrial Applications of alternator and starter parts wholesale

- 3 Common User Pain Points for ‘alternator and starter parts wholesale’ & Their Solutions

- Strategic Material Selection Guide for alternator and starter parts wholesale

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator and starter parts wholesale

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator and starter parts wholesale’

- Comprehensive Cost and Pricing Analysis for alternator and starter parts wholesale Sourcing

- Alternatives Analysis: Comparing alternator and starter parts wholesale With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator and starter parts wholesale

- Navigating Market Dynamics and Sourcing Trends in the alternator and starter parts wholesale Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator and starter parts wholesale

- Strategic Sourcing Conclusion and Outlook for alternator and starter parts wholesale

- Important Disclaimer & Terms of Use

Understanding alternator and starter parts wholesale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Starter Parts | Includes solenoids, brushes, and rebuild kits for starters. | Automotive, heavy trucks, marine vehicles. | Pros: Cost-effective, customizable. Cons: Potential for quality variations. |

| Alternator Parts | Comprises voltage regulators, bearings, and repair kits. | Automotive, agricultural, industrial. | Pros: High-quality aftermarket options. Cons: Compatibility issues if not verified. |

| Rebuild Kits | Complete kits with essential components for rebuilding starters or alternators. | Automotive repair shops, DIY mechanics. | Pros: Convenient, often includes all necessary parts. Cons: May require technical skills for assembly. |

| Performance Upgrade Parts | High-output components like heavy-duty rectifiers and stators. | Motorsports, heavy-duty vehicles. | Pros: Enhanced performance, durability. Cons: Higher cost, may require specialized installation. |

| OEM Replacement Parts | Original Equipment Manufacturer components for direct replacements. | Dealerships, fleet management. | Pros: Assurance of compatibility and quality. Cons: Higher price point than aftermarket options. |

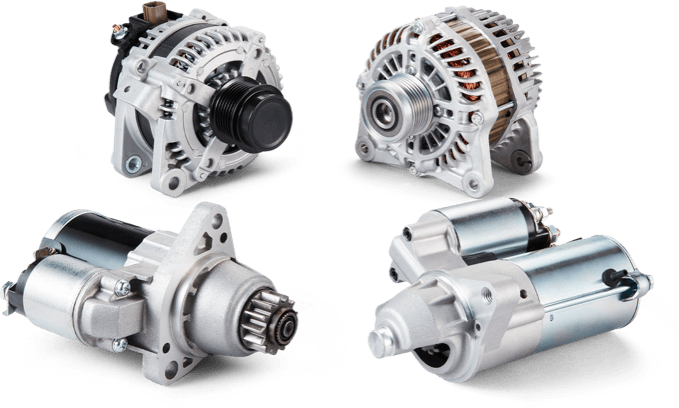

What Are Starter Parts and Their Key Features for B2B Buyers?

Starter parts are essential components that facilitate the ignition process in vehicles. This category includes items such as solenoids, brushes, and starter motors. For B2B buyers, particularly those in automotive and heavy truck sectors, sourcing high-quality starter parts is crucial for ensuring reliability and performance. When purchasing, consider the supplier’s inventory, warranty policies, and the potential for customization to meet specific vehicle requirements.

How Do Alternator Parts Differ and What Should Buyers Consider?

Alternator parts are critical for maintaining the electrical system of vehicles, providing power to various components. This category includes voltage regulators, bearings, and repair kits. B2B buyers in industries like agriculture and industrial machinery should focus on the quality of these parts, as they directly impact the longevity and efficiency of the vehicles. It’s advisable to verify compatibility with specific vehicle models and assess the reliability of the supplier to avoid costly downtimes.

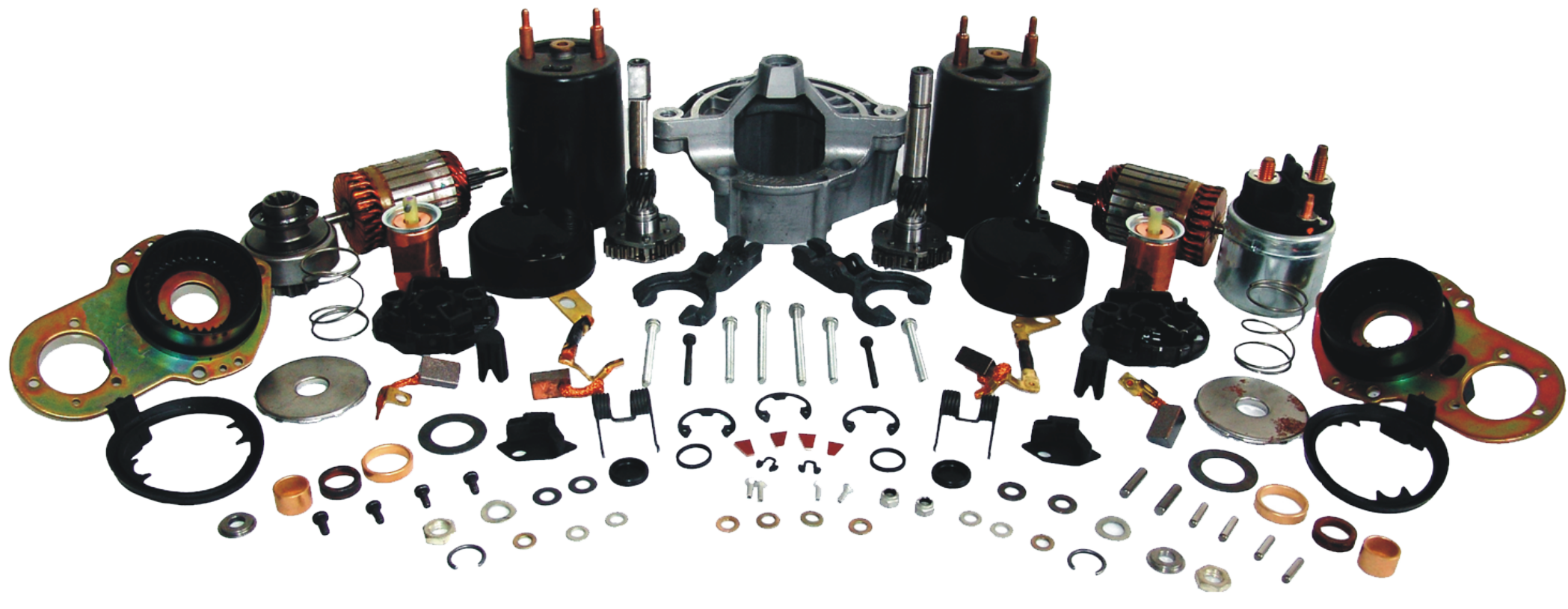

Why Are Rebuild Kits Essential for Automotive Repair Shops?

Rebuild kits are comprehensive packages that include all necessary components for refurbishing starters or alternators. These kits are particularly valuable for automotive repair shops and DIY mechanics, as they streamline the repair process and reduce the need for multiple orders. Buyers should evaluate the completeness of the kit, the quality of individual components, and the ease of installation, as these factors can significantly influence repair turnaround times and customer satisfaction.

What Are Performance Upgrade Parts and Their Applications?

Performance upgrade parts are designed to enhance the output and efficiency of starters and alternators, featuring components like heavy-duty rectifiers and high-amperage stators. These parts are commonly sought after in motorsports and heavy-duty vehicle applications where superior performance is paramount. B2B buyers should weigh the benefits of increased power against the higher costs and potential need for specialized installation expertise.

How Do OEM Replacement Parts Benefit Fleet Management?

OEM replacement parts are manufactured to meet the exact specifications of original vehicle components, ensuring a perfect fit and optimal performance. They are essential for dealerships and fleet management companies that prioritize reliability and warranty coverage. While these parts often come at a higher price point than aftermarket options, they provide peace of mind regarding quality and compatibility, making them a preferred choice for many B2B buyers in the automotive sector.

Key Industrial Applications of alternator and starter parts wholesale

| Industry/Sector | Specific Application of alternator and starter parts wholesale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive & Light Truck | Replacement of starters and alternators for vehicles | Ensures vehicle reliability and performance | Quality assurance, compatibility with various models |

| Commercial & Heavy Truck | Maintenance of fleet vehicles’ electrical systems | Reduces downtime and maintenance costs | Volume discounts, fast shipping options |

| Agricultural & Industrial | Powering machinery and equipment in farming | Enhances productivity and operational efficiency | Availability of specialized parts, global shipping |

| Marine & Power Sports | Supporting boat and recreational vehicle electrical systems | Ensures safety and operational readiness | Certification for marine applications, warranty terms |

| Renewable Energy & Power Generation | Components for wind turbines and solar power systems | Supports sustainable energy initiatives | Compliance with international standards, reliability |

How Are Alternator and Starter Parts Used in the Automotive and Light Truck Industry?

In the automotive and light truck sector, alternator and starter parts are critical for maintaining vehicle performance. Wholesale suppliers provide a wide range of replacement starters and alternators that ensure vehicles start reliably and maintain optimal electrical function. International B2B buyers, particularly those in regions like Africa and Europe, must focus on sourcing parts that are compatible with various vehicle models. Issues such as prolonged lead times and quality discrepancies can affect operations, making it essential to partner with reputable suppliers who offer quality assurance and a robust inventory.

What Role Do Alternator and Starter Parts Play in Commercial and Heavy Truck Operations?

For commercial and heavy truck fleets, the reliability of starters and alternators is paramount. These components are vital for powering the electrical systems that support various functions, from ignition to lighting. Maintaining these systems reduces vehicle downtime and associated maintenance costs, which is crucial for businesses operating in competitive markets. Buyers should consider sourcing from suppliers that provide volume discounts and fast shipping options, ensuring they can keep their fleets operational and efficient, particularly in regions with challenging logistics.

How Are Alternator and Starter Parts Essential in Agricultural and Industrial Applications?

In agricultural and industrial settings, alternator and starter parts are used to power essential machinery and equipment. These components help ensure that machinery operates efficiently, thereby enhancing productivity in farming and industrial processes. International buyers must consider the availability of specialized parts that can withstand the rigors of agricultural use, as well as reliable global shipping options. Sourcing from experienced suppliers who understand the unique demands of this sector can significantly impact operational efficiency.

Why Are Alternator and Starter Parts Important for Marine and Power Sports?

In the marine and power sports industries, alternators and starters play a crucial role in ensuring the safety and operational readiness of boats and recreational vehicles. These parts must meet specific marine standards to ensure reliability in challenging environments. International buyers should prioritize suppliers who offer certified parts and clear warranty terms to mitigate risks associated with harsh operating conditions. This focus on quality and compliance is essential for maintaining safety and performance in marine applications.

How Do Alternator and Starter Parts Contribute to Renewable Energy and Power Generation?

In the renewable energy sector, alternator and starter parts are integral to the functioning of wind turbines and solar power systems. These components help convert mechanical energy into electrical energy efficiently, supporting sustainable energy initiatives. For international B2B buyers, sourcing reliable components that comply with international standards is critical. Suppliers should provide assurance of component durability and reliability, as these factors directly impact the long-term success of renewable energy projects.

3 Common User Pain Points for ‘alternator and starter parts wholesale’ & Their Solutions

Scenario 1: Navigating Unclear Part Compatibility

The Problem:

One of the most common challenges B2B buyers face when sourcing alternator and starter parts is the uncertainty around compatibility. With numerous makes, models, and specifications available, buyers often struggle to identify the exact parts that will fit their vehicles or machinery. This issue is exacerbated in international markets where parts may have different designations or specifications, leading to costly errors in ordering. A buyer from Nigeria, for instance, may mistakenly order a starter that is not compatible with the local vehicle models, resulting in wasted time and resources.

The Solution:

To overcome compatibility issues, buyers should prioritize sourcing from suppliers that offer comprehensive catalogs with detailed specifications for each part. Implementing a systematic approach to part selection is crucial. Begin by gathering all necessary vehicle or machinery details, including make, model, and year. Utilize online databases or tools provided by suppliers that allow for cross-referencing part numbers. Additionally, consider engaging with knowledgeable customer service representatives who can provide insights based on their expertise. Developing strong relationships with suppliers can also facilitate quicker resolution of compatibility inquiries, ensuring that the right parts are sourced efficiently.

Scenario 2: The Struggle with Timely Deliveries

The Problem:

Timely delivery is critical in the B2B wholesale sector, especially for businesses that rely on quick turnarounds to maintain their service levels. Buyers often face delays due to logistical issues, customs clearance, or inefficient shipping practices. For example, a South American distributor might find themselves waiting weeks for a shipment of alternator parts, which can jeopardize their ability to serve local automotive repair shops and ultimately affect their bottom line.

The Solution:

To mitigate delivery delays, buyers should partner with wholesalers that have established reliable shipping networks and clear timelines. Look for suppliers that offer expedited shipping options and have experience handling international logistics, particularly in regions like Africa and South America. Additionally, it’s essential to maintain open lines of communication regarding order status and expected delivery times. Implementing a just-in-time inventory system can also help; by ordering smaller quantities more frequently, businesses can adapt to delivery schedules while ensuring they have the necessary parts on hand when demand arises.

Scenario 3: Managing Quality Control Issues

The Problem:

Quality control is a persistent concern for B2B buyers in the alternator and starter parts wholesale market. Issues such as defective parts or substandard quality can lead to significant operational disruptions. A European buyer sourcing components for heavy machinery may receive inferior parts that fail prematurely, resulting in increased warranty claims and customer dissatisfaction. The financial ramifications can be severe, impacting both reputation and revenue.

The Solution:

To ensure quality, buyers should conduct thorough due diligence on potential suppliers. Look for wholesalers that provide warranties and have a robust quality assurance process in place. Request samples or trial orders to evaluate product quality before committing to larger purchases. It’s also beneficial to seek certifications or compliance with international standards, which can serve as a benchmark for quality. Establishing a feedback loop with customers who use the parts can provide valuable insights into performance and help identify any recurring issues early on, allowing for swift corrective actions. Regular audits of suppliers can further reinforce quality assurance measures and help maintain high standards in procurement.

Strategic Material Selection Guide for alternator and starter parts wholesale

What Are the Key Materials Used in Alternator and Starter Parts Wholesale?

When selecting materials for alternator and starter parts, it is essential to consider their properties, advantages, and limitations. The following analysis focuses on four common materials used in the manufacturing of these components: copper, aluminum, steel, and plastic.

Illustrative image related to alternator and starter parts wholesale

How Does Copper Contribute to Performance in Alternator and Starter Parts?

Copper is a highly conductive material, making it ideal for electrical components in alternators and starters. Its excellent conductivity allows for efficient energy transfer, which is crucial for performance. Copper also exhibits good corrosion resistance, especially when coated or alloyed, enhancing its longevity in various environments.

Pros: Copper’s high conductivity leads to superior performance in electrical applications. It is also relatively easy to work with, allowing for complex shapes and designs.

Cons: The primary drawback of copper is its cost, which is higher than many alternatives. Additionally, while it is resistant to corrosion, it can still tarnish over time, potentially affecting performance if not maintained.

Impact on Application: Copper is compatible with various electrical media, making it suitable for high-performance applications in automotive and industrial settings.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B170 for copper wire and consider local material preferences that may favor cost-effective alternatives.

What Role Does Aluminum Play in Alternator and Starter Parts?

Aluminum is another popular material due to its lightweight nature and good corrosion resistance. It is often used in housings and brackets for alternators and starters, where weight reduction is beneficial.

Pros: Aluminum’s lightweight property contributes to overall vehicle efficiency. It is also more cost-effective compared to copper, making it a preferred choice for many manufacturers.

Cons: While aluminum is resistant to corrosion, it is not as strong as steel, which may limit its use in high-stress applications. Additionally, it can be more challenging to weld, impacting manufacturing complexity.

Impact on Application: Aluminum is suitable for applications where weight savings are critical, but care must be taken in high-stress environments.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades suitable for their applications, such as 6061 or 6063, and ensure compliance with standards like DIN EN 573.

Why Is Steel a Common Choice for Alternator and Starter Parts?

Steel is widely used in alternator and starter components due to its strength and durability. It is commonly found in structural parts, such as frames and shafts.

Pros: Steel offers excellent strength and wear resistance, making it ideal for high-stress applications. It is also relatively inexpensive compared to other metals.

Cons: Steel is heavier than aluminum and can be prone to corrosion if not properly treated or coated. This can increase maintenance needs over time.

Illustrative image related to alternator and starter parts wholesale

Impact on Application: Steel’s strength makes it suitable for heavy-duty applications, but its weight may affect overall vehicle performance.

Considerations for International Buyers: Buyers should consider the type of steel used (e.g., carbon steel, stainless steel) and ensure compliance with relevant standards such as ASTM A36 or DIN 17100.

How Does Plastic Enhance the Functionality of Alternator and Starter Parts?

Plastic is often used for insulation and housing components in alternators and starters due to its lightweight and insulating properties. It is commonly found in connectors and covers.

Pros: Plastic is lightweight, cost-effective, and provides excellent electrical insulation. It also resists corrosion and can be molded into complex shapes.

Cons: The main limitation of plastic is its lower strength compared to metals, which may restrict its use in high-stress applications. It can also degrade under high temperatures.

Impact on Application: Plastic is suitable for non-load-bearing components and electrical insulation, but careful selection of temperature-resistant plastics is necessary for high-heat environments.

Considerations for International Buyers: Buyers should ensure that the plastics used meet international standards such as ISO 9001 and consider local preferences for specific plastic grades.

Summary Table of Material Selection for Alternator and Starter Parts Wholesale

| Material | Typical Use Case for alternator and starter parts wholesale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections and windings | High conductivity | Higher cost, potential tarnishing | High |

| Aluminum | Housings and brackets | Lightweight, cost-effective | Lower strength, difficult to weld | Medium |

| Steel | Structural components like frames and shafts | Excellent strength and durability | Heavier, prone to corrosion | Low |

| Plastic | Insulation and housing components | Lightweight, good insulation | Lower strength, temperature sensitivity | Low |

This guide provides a foundational understanding of material selection for alternator and starter parts, helping international B2B buyers make informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator and starter parts wholesale

What Are the Main Stages in the Manufacturing Process of Alternator and Starter Parts?

The manufacturing process for alternator and starter parts involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the quality and reliability of the final product.

Material Preparation: What Materials Are Used and How Are They Processed?

The manufacturing of alternator and starter parts typically starts with the selection of high-grade materials, including steel, aluminum, and copper. These materials are chosen for their durability and electrical conductivity. During the material preparation phase, raw materials undergo various processes such as cutting, machining, and surface treatment to meet precise specifications. For example, steel components may be treated to improve corrosion resistance, while copper wires are often insulated to prevent electrical failures.

How Are Alternator and Starter Parts Formed?

The forming stage involves shaping the prepared materials into the components required for alternators and starters. This can include processes such as stamping, forging, and die casting. Advanced manufacturing techniques like CNC machining are commonly used to achieve high precision in parts such as rotors and stators. The use of automated machinery enhances consistency, reducing the likelihood of human error, and improving overall efficiency.

What Assembly Techniques Are Commonly Used for These Parts?

Once the individual components are formed, they move on to the assembly stage. This phase often employs both manual and automated assembly techniques. For instance, skilled technicians may assemble complex components like starter solenoids, while automated systems may be used for simpler tasks, such as attaching brushes or regulators. Quality assurance is crucial at this stage; components are frequently checked for fit and functionality to ensure they meet the design specifications.

How Is the Finishing Process Conducted to Enhance Product Quality?

The finishing process encompasses additional treatments aimed at enhancing the product’s performance and longevity. This may include surface treatments like anodizing or powder coating to improve corrosion resistance and aesthetic appeal. Additionally, components may undergo testing for electrical performance, ensuring they meet specific voltage and current requirements.

What Quality Control Standards Are Relevant for Alternator and Starter Parts?

Quality control (QC) is an integral part of the manufacturing process for alternator and starter parts. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers maintain consistent quality throughout their processes. Industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are also important for meeting regulatory requirements and enhancing market acceptance.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are established at various stages of production to monitor and maintain product quality. These include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon delivery to ensure they meet specified standards. Non-conforming materials may be rejected or sent back to suppliers.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to verify that production adheres to quality standards. This may include monitoring dimensions, tolerances, and assembly procedures.

-

Final Quality Control (FQC): The final product undergoes comprehensive testing before shipment. This includes functional tests, electrical tests, and visual inspections to ensure that all components operate correctly and meet customer specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of suppliers can help assess their manufacturing practices and quality control measures. This can include reviewing their quality management system, production processes, and employee training programs.

-

Request Quality Reports: Buyers should ask for detailed quality reports that outline the results of inspections and tests conducted throughout the manufacturing process. These reports can provide insight into the supplier’s adherence to quality standards.

-

Utilize Third-Party Inspection Services: Employing third-party inspectors can offer an unbiased evaluation of a supplier’s manufacturing and quality control processes. These services can validate compliance with international standards and help identify any potential issues before products are shipped.

What Quality Control and Certification Nuances Should International Buyers Consider?

When sourcing alternator and starter parts internationally, buyers should be aware of specific certification requirements that may vary by region. For instance:

-

Compliance with Local Standards: In Europe, products must meet CE marking requirements, which signify compliance with health, safety, and environmental protection standards. In contrast, African and South American markets may have different regulatory frameworks that must be adhered to.

-

Understanding Warranty Policies: Buyers should carefully review warranty policies offered by suppliers. A robust warranty can indicate confidence in product quality and provide peace of mind against defects.

-

Cultural and Language Barriers: Effective communication is essential when dealing with international suppliers. Buyers may encounter language barriers that could hinder understanding of quality control processes and certification requirements. Employing translators or local representatives can facilitate smoother interactions.

Conclusion: Ensuring Quality in Alternator and Starter Parts Manufacturing

In conclusion, understanding the manufacturing processes and quality assurance practices for alternator and starter parts is essential for B2B buyers. By familiarizing themselves with the stages of production, relevant quality standards, and effective verification methods, buyers can make informed decisions and secure high-quality products that meet their operational needs. This knowledge not only enhances supplier relationships but also contributes to the overall success of their business operations in the competitive automotive parts market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator and starter parts wholesale’

In the competitive landscape of alternator and starter parts wholesale, making informed sourcing decisions is crucial for success. This practical guide serves as a comprehensive checklist for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and ensure you partner with reliable suppliers.

Step 1: Define Your Technical Specifications

Start by clearly outlining the specifications of the alternator and starter parts you need. This includes details such as vehicle compatibility, power ratings, and required certifications. Having precise technical specifications helps you communicate effectively with suppliers and ensures that you receive parts that meet your operational needs.

Illustrative image related to alternator and starter parts wholesale

- Consider types of vehicles: Different vehicles may require specific parts, such as commercial trucks versus agricultural machinery.

- Include quality standards: Specify if you need OEM parts or high-quality aftermarket alternatives.

Step 2: Conduct Market Research

Before reaching out to suppliers, conduct thorough market research to understand pricing trends, product availability, and industry standards. This information will empower you to negotiate better terms and make informed purchasing decisions.

- Analyze competitors: Look at what similar businesses are paying and the quality of parts they are sourcing.

- Identify market leaders: Research reputable suppliers known for their reliability and product quality.

Step 3: Evaluate Potential Suppliers

It’s essential to vet potential suppliers rigorously. Request company profiles, case studies, and references from other buyers in similar markets. This step ensures that you choose a partner with a proven track record.

- Check reviews and testimonials: Look for feedback from other customers regarding product quality and service reliability.

- Visit supplier facilities if possible: A facility tour can provide insights into their operations and quality control processes.

Step 4: Verify Supplier Certifications

Confirm that the suppliers you are considering have the necessary certifications and adhere to industry standards. This step is crucial for ensuring that the parts you purchase are safe and compliant with regulations.

- Request documentation: Ask for ISO certifications or other relevant industry standards that indicate quality assurance.

- Understand warranty policies: A good warranty can be indicative of the supplier’s confidence in their products.

Step 5: Assess Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare pricing and payment terms. This evaluation should include not just the cost of parts but also shipping fees, delivery timelines, and any bulk purchase discounts.

Illustrative image related to alternator and starter parts wholesale

- Negotiate terms: Don’t hesitate to negotiate prices and payment options, especially for larger orders.

- Consider total cost of ownership: Factor in shipping costs and potential customs duties when calculating the total expense.

Step 6: Establish a Communication Plan

Effective communication is key to a successful partnership. Develop a clear plan for how you will interact with your supplier, including points of contact and preferred communication channels.

- Set expectations: Clarify response times for inquiries and how issues will be resolved.

- Regular check-ins: Schedule periodic reviews to assess the quality of service and product performance.

Step 7: Finalize Your Order with Clear Terms

Before placing your order, ensure that all terms are clearly defined in a purchase agreement. This should include specifications, pricing, delivery schedules, and return policies.

- Document everything: Keep a written record of all agreements to avoid misunderstandings.

- Confirm order details: Double-check that all specifications and quantities are correct before finalizing the transaction.

By following this step-by-step checklist, B2B buyers can enhance their sourcing process for alternator and starter parts, ensuring they secure high-quality products from reliable suppliers.

Comprehensive Cost and Pricing Analysis for alternator and starter parts wholesale Sourcing

What Are the Key Cost Components in Alternator and Starter Parts Wholesale Sourcing?

When sourcing alternator and starter parts wholesale, understanding the cost structure is crucial. The primary cost components include:

Illustrative image related to alternator and starter parts wholesale

-

Materials: The choice of raw materials significantly impacts overall costs. Higher-quality materials like premium metals and specialized plastics are often more expensive but can enhance durability and performance.

-

Labor: Labor costs can vary based on the geographical location of the manufacturer. Regions with lower labor costs may offer competitive pricing, but this can also correlate with lower quality control.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient management of overhead can lead to more competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom parts. These costs are amortized over production volume, making them less significant for high-volume orders.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection adds to costs. However, this investment can reduce long-term costs associated with returns and warranty claims.

-

Logistics: Transportation and handling costs can vary greatly depending on the shipping method and distance. For international buyers, understanding Incoterms is essential to grasp which party bears these costs.

-

Margin: Suppliers typically apply a markup to cover their costs and ensure profitability. This margin can fluctuate based on market demand, competition, and the supplier’s operational efficiency.

How Do Pricing Influencers Affect Wholesale Costs?

Several factors influence the pricing of alternator and starter parts, including:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better terms and lower per-unit costs.

-

Specifications and Customization: Custom parts generally incur higher costs due to the additional design and manufacturing processes involved. Buyers should weigh the necessity of customization against potential savings from standard parts.

-

Material Quality and Certifications: High-quality materials and recognized certifications (like ISO) can justify higher prices due to increased reliability and performance, which may lower long-term costs.

-

Supplier Factors: The supplier’s reputation, reliability, and historical performance can influence pricing. Well-established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding the shipping and delivery terms specified in Incoterms is vital for determining the total landed cost of parts, including shipping, insurance, and tariffs.

What Tips Can Help Buyers Negotiate Better Prices?

To navigate the complexities of pricing in the alternator and starter parts wholesale market, consider the following strategies:

-

Negotiate on Volume: Leverage your purchasing power by negotiating for discounts based on order size. Suppliers are often more willing to reduce prices for larger orders.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the initial purchase price, assess the TCO, which includes installation, maintenance, and potential warranty claims. Opting for slightly higher-priced parts may yield better long-term savings.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to tariffs, shipping costs, and local market conditions. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to identify the best sourcing options.

-

Request Transparent Pricing: Ask suppliers for a detailed breakdown of costs. This transparency allows you to identify areas for negotiation and understand the true value of the parts you are sourcing.

Conclusion

Sourcing alternator and starter parts wholesale involves a complex interplay of costs and pricing influencers. By understanding these dynamics, international B2B buyers can make informed decisions that enhance cost-efficiency and value. Always consider the nuances of your specific market and the long-term implications of your purchasing decisions. Remember, the indicative prices may vary based on multiple factors, so continuous market analysis and supplier engagement are essential.

Alternatives Analysis: Comparing alternator and starter parts wholesale With Other Solutions

Understanding Alternatives in Alternator and Starter Parts Sourcing

In the competitive landscape of automotive parts, particularly alternators and starters, B2B buyers often seek the best sourcing solutions. While purchasing from wholesale suppliers offers numerous advantages, it’s essential to explore alternative methods that could meet specific business needs. This analysis provides a comparative overview of ‘alternator and starter parts wholesale’ against other viable solutions, such as remanufactured parts and direct manufacturer sourcing.

Comparison Table

| Comparison Aspect | Alternator and Starter Parts Wholesale | Remanufactured Parts | Direct Manufacturer Sourcing |

|---|---|---|---|

| Performance | High-quality, tested parts | Varies; depends on the quality of the remanufacturing process | Typically high, OEM quality |

| Cost | Competitive pricing for bulk orders | Generally lower than new parts, but quality can vary | Higher due to OEM pricing and less negotiation flexibility |

| Ease of Implementation | Streamlined ordering process, ready-to-ship | May require additional time for sourcing and testing | Longer lead times; often requires minimum order quantities |

| Maintenance | Standard warranties and return policies | Limited warranty; maintenance may vary | Comprehensive support and warranty coverage |

| Best Use Case | Ideal for businesses needing diverse inventory quickly | Suitable for cost-sensitive buyers prioritizing affordability | Best for those requiring guaranteed OEM quality and support |

Detailed Breakdown of Alternatives

Remanufactured Parts

Remanufactured parts are often a cost-effective alternative to new parts. These components undergo a refurbishing process to restore their functionality. The primary advantage is lower costs compared to new components; however, the performance can be inconsistent, depending on the quality of the remanufacturing process. For businesses with tight budgets, remanufactured parts can provide significant savings. However, buyers should be cautious and ensure that they source from reputable suppliers to avoid subpar quality.

Illustrative image related to alternator and starter parts wholesale

Direct Manufacturer Sourcing

Purchasing directly from manufacturers guarantees OEM (Original Equipment Manufacturer) quality, which is often critical for certain applications. This method ensures that parts meet stringent specifications and performance standards. However, the downside is typically higher costs, which can impact profit margins for B2B buyers. Additionally, direct sourcing may involve longer lead times and minimum order quantities, making it less flexible compared to wholesale options. This approach is best suited for businesses that prioritize quality and reliability over cost.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting a sourcing solution for alternator and starter parts, B2B buyers must evaluate their specific needs against the various options available. If immediate availability and cost-effectiveness are paramount, wholesale purchasing is likely the best choice. Conversely, for businesses that prioritize quality and are willing to invest more upfront, direct manufacturer sourcing or remanufactured parts may be more appropriate. Ultimately, understanding the unique demands of your business will guide you in making an informed decision that aligns with your operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for alternator and starter parts wholesale

What Are the Key Technical Properties of Alternator and Starter Parts in Wholesale?

Understanding the technical specifications of alternator and starter parts is crucial for international B2B buyers. Here are some essential properties to consider:

1. Material Grade

The material grade indicates the quality and durability of components used in alternators and starters. Common materials include high-grade steel, aluminum, and copper, which are essential for performance and longevity. For instance, copper wiring is preferred for its excellent conductivity, ensuring efficient power transfer. Selecting parts with appropriate material grades can significantly reduce failure rates and enhance customer satisfaction.

Illustrative image related to alternator and starter parts wholesale

2. Tolerance

Tolerance refers to the allowable variation in dimensions of parts during manufacturing. It is critical in ensuring that components fit together correctly and function as intended. For example, a tolerance of ±0.01mm can make a significant difference in the performance of starter motors and alternators. Tight tolerances are particularly important in high-performance applications, where even minor discrepancies can lead to operational failures.

3. Ampacity

Ampacity denotes the maximum amount of electrical current a conductor or component can carry before overheating. This is particularly crucial for alternators, which must handle varying electrical loads in vehicles. Understanding ampacity helps buyers choose parts that will not only meet their current needs but also accommodate potential future upgrades in vehicle electrical systems.

4. Voltage Rating

The voltage rating of alternator and starter parts indicates the maximum voltage they can safely handle. Components need to be rated appropriately to prevent electrical failures. For instance, a starter motor rated for 12 volts should not be used in a 24-volt system. Ensuring that all parts are compatible with the vehicle’s electrical system is vital for operational efficiency and safety.

Illustrative image related to alternator and starter parts wholesale

5. Performance Testing Standards

Performance testing standards ensure that parts meet specific operational criteria. Many manufacturers provide printed performance sheets that detail how well a component has performed under various conditions. For B2B buyers, this transparency is essential for ensuring the reliability of parts, particularly when sourcing from international suppliers.

What Are Common Trade Terms in the Alternator and Starter Parts Industry?

Familiarizing yourself with industry terminology will help streamline communication and negotiations in the B2B marketplace. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle or equipment. These parts are typically designed to meet specific standards and specifications. Buyers often prefer OEM parts for their reliability and compatibility, especially in high-stakes applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for budgeting and inventory management, especially for international buyers who may face higher shipping costs for smaller orders.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific parts or services. This is crucial in B2B transactions as it helps buyers compare offers and negotiate better terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping transactions. They clarify who is responsible for shipping, insurance, and tariffs, reducing misunderstandings and disputes.

5. Aftermarket

Aftermarket refers to parts and accessories that are made by third-party manufacturers and are not sourced from the original vehicle manufacturer. These parts can often provide cost-effective alternatives while maintaining quality.

6. Warranty

A warranty is a guarantee from the manufacturer or supplier that a part will perform as promised for a specified period. This is particularly important in the automotive industry, where the reliability of electrical components is critical.

Illustrative image related to alternator and starter parts wholesale

By understanding these technical properties and trade terms, B2B buyers can make informed purchasing decisions that enhance their operational efficiency and customer satisfaction in the alternator and starter parts wholesale market.

Navigating Market Dynamics and Sourcing Trends in the alternator and starter parts wholesale Sector

What Are the Key Market Dynamics and Trends Influencing the Alternator and Starter Parts Wholesale Sector?

The global alternator and starter parts wholesale market is experiencing a transformative phase driven by several key factors. Increased vehicle production and the growing demand for automotive parts in emerging markets, particularly in Africa, South America, and the Middle East, are propelling market growth. Technological advancements, such as the integration of smart automotive technologies and electric vehicles (EVs), are reshaping sourcing strategies. Buyers are increasingly leaning towards suppliers that offer a comprehensive range of parts, including premium quality, remanufactured, and hard-to-find components.

Furthermore, the rise of e-commerce platforms has revolutionized sourcing practices, enabling international buyers to access a wider selection of parts with ease. Enhanced supply chain transparency and efficiency are becoming critical as buyers seek to streamline procurement processes. Additionally, the trend towards just-in-time inventory management is gaining traction, helping businesses reduce overhead costs and improve cash flow. This dynamic environment necessitates that B2B buyers stay informed about supplier capabilities, product availability, and shipping logistics to make well-informed purchasing decisions.

How Is Sustainability Shaping the Sourcing Landscape in the Alternator and Starter Parts Sector?

Sustainability has become a paramount consideration for B2B buyers in the alternator and starter parts wholesale sector. The environmental impact of manufacturing processes and the lifecycle of automotive parts are under increasing scrutiny. Buyers are now prioritizing suppliers that adhere to sustainable practices, such as using recycled materials and reducing waste. Ethical sourcing is not just a regulatory requirement; it has become a competitive differentiator.

Certifications like ISO 14001 for environmental management systems and other green certifications are essential for suppliers aiming to attract conscientious buyers. These certifications assure buyers that the suppliers are committed to minimizing their ecological footprint. Moreover, the demand for ‘green’ materials is on the rise, with buyers seeking products that are manufactured using sustainable practices. This shift towards sustainability not only helps companies enhance their brand image but also aligns with the growing consumer preference for environmentally friendly products, making it a win-win for both suppliers and buyers.

How Has the Alternator and Starter Parts Wholesale Sector Evolved Over Time?

The alternator and starter parts wholesale sector has undergone significant evolution since its inception. Originally dominated by local suppliers and small-scale manufacturers, the market has expanded to include global players that leverage advanced technology and supply chain efficiencies. The rise of aftermarket parts has transformed the landscape, offering a cost-effective alternative to OEM parts while ensuring quality and performance.

In recent decades, the proliferation of e-commerce has further revolutionized the sector, allowing for a more competitive marketplace where buyers can easily compare products and prices. The emphasis on customer service, fast shipping, and warranty offerings has become crucial, as buyers demand greater value and assurance in their purchases. As the industry continues to adapt to technological advancements and changing consumer preferences, it remains poised for further growth, driven by innovation and a commitment to quality.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator and starter parts wholesale

-

How do I ensure the quality of alternator and starter parts from wholesale suppliers?

To guarantee the quality of alternator and starter parts, it’s crucial to partner with reputable suppliers who provide detailed product specifications and certifications. Request samples before placing bulk orders to assess the quality firsthand. Look for suppliers that offer warranties or guarantees on their products, as this indicates confidence in their quality. Additionally, consider suppliers who have undergone third-party quality audits or have industry certifications. Engaging in direct communication with suppliers can also clarify their quality assurance processes. -

What are the best practices for vetting alternator and starter parts suppliers?

When vetting suppliers, start by researching their reputation in the industry through online reviews and testimonials. Verify their business credentials, including registration and certifications. Evaluate their product range to ensure they meet your specific needs, and inquire about their sourcing practices. Establish communication to assess their responsiveness and customer service. It may also be beneficial to request references from other clients to understand their reliability and service quality. -

What is the minimum order quantity (MOQ) for alternator and starter parts?

Minimum order quantities (MOQs) can vary significantly among suppliers and depend on the type of parts being ordered. Typically, MOQs may range from a few units to several hundred, especially for specialized components. Always check with your chosen supplier to confirm their specific MOQ policies. If you require a lower quantity, some suppliers may be willing to negotiate or offer flexibility, especially for long-term business relationships. -

What payment terms should I expect when sourcing alternator and starter parts wholesale?

Payment terms can vary widely depending on the supplier and your negotiation skills. Common practices include upfront payments, partial payments upon order confirmation, or net terms (e.g., net 30 or net 60 days) after delivery. It’s advisable to discuss payment options early in the negotiation process to ensure they align with your cash flow capabilities. Additionally, consider using secure payment methods or letters of credit for larger transactions to mitigate risks. -

How can I customize alternator and starter parts for specific applications?

Customization options depend on the supplier’s capabilities. When seeking tailored solutions, communicate your specific requirements, such as voltage ratings, sizes, or performance specifications. Many suppliers offer customization for bulk orders or special projects. It’s beneficial to discuss your needs early in the procurement process and ask for any design or engineering support they may provide. Establishing a collaborative relationship can lead to better customization outcomes. -

What are the logistics considerations for importing alternator and starter parts?

Logistics play a crucial role in international trade. Consider shipping costs, delivery times, and customs clearance processes when importing parts. Ensure your supplier has experience with international shipping and can provide necessary documentation, such as invoices and certificates of origin. It’s also wise to explore different shipping options (air vs. sea) based on urgency and budget. Engaging a reliable freight forwarder can simplify the logistics process and help manage compliance with local regulations. -

What quality assurance practices should I look for in alternator and starter parts suppliers?

Quality assurance practices vary among suppliers but should include thorough testing and inspection protocols. Look for suppliers that perform quality checks at various production stages and provide performance data for their products. Certifications from recognized quality standards (e.g., ISO 9001) can also indicate a commitment to quality. Additionally, inquire about their return and warranty policies, as these reflect their confidence in the quality of the parts they supply. -

How do I handle returns or defective parts in a wholesale transaction?

Establish clear return policies before finalizing your purchase. Most reputable suppliers will have a defined return process for defective parts, which typically includes notifying them within a specific timeframe. Understand their warranty terms and conditions, which often cover defective parts. Maintain thorough documentation of your transactions and communications to facilitate any return requests. Building a good relationship with your supplier can also ease the return process and ensure a smoother resolution.

Top 5 Alternator And Starter Parts Wholesale Manufacturers & Suppliers List

1. Maniac Electric Motors – Alternator and Starter Parts

Domain: maniacelectricmotors.com

Registered: 2007 (18 years)

Introduction: Alternator Parts, Starter Parts for Rebuilding, Alternator Rebuild Kits, Bearings, Alternator Brushes / Brush Holders / Assemblies, Alternator Repair Connector, Harness, ‘Pigtail’, Alternator Pulley, Starter Solenoids, Alternator Voltage Regulators, Starter Brushes, Sets, and Brush Holder Assemblies. Specific products include: Alternator for Volvo with Bosch 0125812009, 0125812012 – 21066; Starter…

2. Just Parts, Inc. – Electrical Parts Supplier

Domain: justpartsinc.com

Registered: 2002 (23 years)

Introduction: Just Parts, Inc. is a wholesale supplier of electrical parts, requiring a valid Re-Sellers Number for purchases. They offer a wide range of products including:

– Alternators (brands include Bosch, Delco-Remy, Ford, and more)

– Bearings (ball bearings, needle bearings, tolerance rings)

– Diesel solenoids

– Generators (brands include Bosch, Delco-Remy, and more)

– Hardware (bolts, washers, screws, …

3. Discount Starter & Alternator – High Quality Aftermarket Starters & Alternators

Domain: discountstarterandalternator.com

Registered: 2004 (21 years)

Introduction: High Quality Aftermarket Starters & Alternators at the Lowest Price. Free Same Day Shipping on orders placed by 3 PM EST. 12 Month Warranty on all products with an option for extended warranty. Easy Returns within 30 days for a full refund. Categories include Agricultural, Industrial, Lawn & Garden, Marine, Powersports, Car & Truck, and Commercial. Expert assistance available via phone or email.

4. Alternator Starter Rebuild Kits – High Amp Alternators

Domain: alternatorstarterrebuildkits.com

Registered: 2010 (15 years)

Introduction: Alternator Starter Rebuild Kits, High Amp Alternators, Alternator Parts, Bearings, Voltage Regulators, Diodes, Pulleys, Chrysler, Dodge, Plymouth Mini Van Alternator (2001-2007, 3.3L, 3.8L), Aftermarket add-ons, High Output Audio Systems, Big Rig Starters, Big Rig Alternators, Educational articles on alternators and starters, Rebuilder in a Box concept, Professional rebuilders designed kits, Compo…

5. Quick Start Automotive Electric – Heavy Duty Chrysler Voltage Regulator Kit

Domain: store.alternatorparts.com

Registered: 1999 (26 years)

Introduction: High Output Alternators, Starters, Parts and More from Quick Start Automotive Electric. Contact: Phone: (616) 785-7990, Google Voice: (616) 606-5045. Products include:

– ERCKFRM: Heavy Duty Chrysler, Dodge, Jeep External By-Pass Voltage Regulator Kit with Field Replacement Module – Price: $99.95

– ERCK: External Voltage Regulator Kit for Chrysler Dodge Jeep – Price: $89.95

– W3013: HD Relay with …

Strategic Sourcing Conclusion and Outlook for alternator and starter parts wholesale

In the rapidly evolving landscape of alternator and starter parts wholesale, strategic sourcing emerges as a critical component for international B2B buyers. By focusing on reliable suppliers that offer a broad inventory of premium and hard-to-find parts, businesses can enhance their operational efficiency and reduce downtime. Key takeaways include the importance of quality assurance, timely shipping, and robust customer support, which collectively contribute to a seamless procurement process.

Furthermore, leveraging partnerships with manufacturers and wholesalers who prioritize innovation and quality can yield significant long-term benefits. As the demand for efficient and sustainable automotive solutions grows, companies must stay ahead of market trends to remain competitive.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Germany and Nigeria—should actively seek out suppliers that align with their strategic goals. Emphasizing collaboration, transparency, and adaptability will empower businesses to thrive in this dynamic market. Start your journey today by identifying strategic partners that can help you capitalize on emerging opportunities in the alternator and starter parts sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.