Introduction: Navigating the Global Market for best brand alternator

In the competitive landscape of automotive parts procurement, sourcing the best brand alternator can be a daunting task for international B2B buyers. With the increasing demand for reliable electrical power in vehicles, selecting a high-performance alternator is crucial for ensuring optimal functionality and longevity. This comprehensive guide addresses the myriad challenges faced by buyers, including understanding different types of alternators, their specific applications, and crucial factors to consider during the selection process.

Within these pages, you will find detailed insights on the leading alternator brands, a breakdown of performance characteristics, and guidance on how to vet suppliers effectively. We also explore cost considerations, helping you navigate the complexities of pricing while ensuring you receive maximum value for your investment. By empowering B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Germany and Nigeria—this guide is designed to facilitate informed purchasing decisions that align with your operational needs.

Whether you are looking to enhance the performance of your fleet or seeking reliable replacements for existing systems, our expert analysis and practical recommendations will help you make confident choices in the global market for alternators.

Índice

- Top 2 Best Brand Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best brand alternator

- Understanding best brand alternator Types and Variations

- Key Industrial Applications of best brand alternator

- 3 Common User Pain Points for ‘best brand alternator’ & Their Solutions

- Strategic Material Selection Guide for best brand alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for best brand alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best brand alternator’

- Comprehensive Cost and Pricing Analysis for best brand alternator Sourcing

- Alternatives Analysis: Comparing best brand alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for best brand alternator

- Navigating Market Dynamics and Sourcing Trends in the best brand alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best brand alternator

- Strategic Sourcing Conclusion and Outlook for best brand alternator

- Aviso legal importante y condiciones de uso

Understanding best brand alternator Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Alternadores de alto rendimiento | Produces 130-220 amps, designed for high electrical demands | Performance vehicles, heavy-duty machinery | Ventajas: Supports advanced electrical systems, durable. Contras: Higher cost, may require additional modifications. |

| Alternadores normales | Standard amperage output, uses carbon brushes | Vehículos estándar, aplicaciones ligeras | Ventajas: Económico y ampliamente disponible. Contras: Shorter lifespan, less efficient under high loads. |

| Alternadores reacondicionados | Rebuilt to meet OE specifications, cost-effective | Vehículos de flota, compradores con presupuesto ajustado | Ventajas: Affordable, reliable performance. Contras: Potential variability in quality, shorter warranty. |

| Alternadores sin escobillas | No carbon brushes, lower maintenance, high efficiency | Modern vehicles, electric vehicles | Ventajas: Longer lifespan, less wear and tear. Contras: Higher initial cost, limited availability. |

| Alternadores de doble voltaje | Offers both 12V and 24V outputs, versatile usage | Vehículos comerciales, equipos de construcción | Ventajas: Flexibility for various applications, efficient power supply. Contras: Complexity in installation, higher price point. |

What Are the Key Characteristics of High-Output Alternators?

High-output alternators are engineered to deliver between 130 to 220 amps, making them ideal for vehicles with extensive electrical systems, such as performance cars and heavy-duty machinery. Their design incorporates advanced technology to ensure optimal performance under high electrical loads. B2B buyers should consider the specific amperage requirements of their vehicles and whether additional modifications are necessary for installation, as these alternators can be more expensive than standard options.

Why Choose Regular Alternators for Standard Vehicles?

Regular alternators are the go-to choice for most standard vehicles, providing a reliable power supply at a lower cost. They typically use carbon brushes and have a standard amperage output suitable for everyday driving needs. While they are widely available and affordable, B2B buyers should be aware of their shorter lifespan compared to high-output models and the potential for overheating under high demand.

¿Cuáles son las ventajas de los alternadores refabricados?

Remanufactured alternators offer a cost-effective solution for businesses looking to maintain their fleet without the expense of new parts. These units are rebuilt to meet original equipment (OE) specifications, ensuring reliable performance at a fraction of the cost of new alternators. However, buyers should consider the variability in quality and warranty terms, as they may not always match the reliability of new units.

How Do Brushless Alternators Improve Efficiency?

Brushless alternators are designed without carbon brushes, significantly reducing maintenance needs and enhancing efficiency. They are particularly suited for modern vehicles and electric cars that demand reliable power without the wear associated with traditional designs. B2B buyers should weigh the higher upfront costs against the long-term savings from reduced maintenance and improved lifespan.

Why Are Dual-Voltage Alternators Ideal for Commercial Use?

Dual-voltage alternators provide flexibility by offering both 12V and 24V outputs, catering to a wide range of commercial applications, including construction equipment and commercial vehicles. Their ability to efficiently supply power for various electrical systems makes them a valuable asset. However, buyers must consider the complexity of installation and the higher price point associated with these versatile units.

Key Industrial Applications of best brand alternator

| Industria/Sector | Specific Application of best brand alternator | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Fabricación de automóviles | Powering assembly line equipment | Ensures efficient operation of machinery, reducing downtime | Compatibility with existing systems and voltage requirements |

| Maquinaria pesada | Electrical systems in construction machinery | Enhances reliability and performance in demanding environments | Durability under extreme conditions and high output capacity |

| Energía renovable | Wind turbine electrical systems | Facilitates energy conversion and storage, boosting efficiency | Size, weight, and output specifications to match turbine design |

| Industria naval | Power supply for onboard electrical systems | Ensures reliability for navigation and communication systems | Corrosion resistance and compliance with marine standards |

| Maquinaria agrícola | Powering irrigation systems and tractors | Increases operational efficiency and minimizes equipment failures | Environmental adaptability and compatibility with various engines |

¿Cómo se utilizan los alternadores de las mejores marcas en la fabricación de automóviles?

In automotive manufacturing, best brand alternators are integral to powering assembly line equipment. These alternators convert mechanical energy into electrical energy, ensuring that machines operate smoothly and efficiently. By minimizing downtime, manufacturers can significantly enhance productivity and maintain competitive pricing. Buyers should focus on sourcing alternators that are compatible with their existing systems and meet specific voltage requirements to ensure seamless integration.

What Role Do Alternators Play in Heavy Equipment Operations?

Heavy equipment, particularly in construction, relies on best brand alternators to power their electrical systems. These alternators are designed to handle demanding environments where reliability is crucial. They provide consistent power to essential functions such as hydraulic systems and lighting, which are vital for safe operations. When sourcing alternators for heavy machinery, businesses must prioritize durability and high output capacity to withstand harsh working conditions.

How Do Alternators Contribute to Renewable Energy Systems?

In the renewable energy sector, best brand alternators are used in wind turbines to convert mechanical energy into electrical energy. This conversion is essential for efficient energy storage and distribution. By utilizing high-performance alternators, companies can enhance the overall efficiency of their energy systems. Buyers should consider the size, weight, and output specifications of alternators to ensure they align with the design and operational requirements of their wind turbine systems.

Why Are Alternators Essential in the Marine Industry?

The marine industry depends on best brand alternators to power onboard electrical systems, including navigation and communication tools. A reliable power supply is critical for ensuring safety and operational efficiency on vessels. When sourcing alternators for marine applications, businesses must ensure that products are corrosion-resistant and compliant with industry standards to withstand the harsh marine environment.

In What Ways Do Alternators Improve Agricultural Operations?

In agriculture, best brand alternators are vital for powering irrigation systems and tractors, significantly enhancing operational efficiency. By providing a reliable power source, these alternators help reduce the likelihood of equipment failures, which can disrupt farming operations. Buyers in the agricultural sector should seek alternators that are adaptable to various environmental conditions and compatible with a range of engines to maximize performance and reliability.

3 Common User Pain Points for ‘best brand alternator’ & Their Solutions

Scenario 1: Overwhelmed by Compatibility Issues When Choosing an Alternator

El problema: B2B buyers often face the challenge of ensuring that the alternator they select is compatible with their specific vehicle models. This is particularly true for buyers managing fleets with diverse vehicles across different regions. Incompatibility can lead to significant downtime, increased repair costs, and wasted resources if the alternator does not fit or function properly within the vehicle’s electrical system. Additionally, variations in engine models, year of manufacture, and even regional specifications can complicate the selection process.

La solución: To overcome compatibility issues, B2B buyers should prioritize detailed research and data collection on the vehicles in their fleet. Begin by compiling a comprehensive list of the vehicle makes and models, including their engine specifications and electrical requirements. Engage directly with manufacturers or reputable suppliers who can provide detailed compatibility charts or databases. This ensures that the alternator selected meets the necessary specifications, including size, mounting location, and electrical output. Furthermore, consider investing in diagnostic tools that can assess the vehicle’s electrical load and requirements, allowing for a more informed selection of alternators that can handle the specific demands of each vehicle.

Scenario 2: Struggling with High Electrical Demand in Modern Vehicles

El problema: Many modern vehicles, especially those equipped with advanced technologies such as infotainment systems, GPS, and multiple electronic accessories, place a higher demand on the electrical system. B2B buyers may find themselves purchasing alternators that do not meet the required amperage, leading to frequent battery failures, system malfunctions, and increased maintenance costs. This is especially critical in regions where vehicles are expected to perform in extreme conditions, such as high temperatures or heavy usage.

La solución: To effectively address the high electrical demand, B2B buyers should assess the total electrical load of each vehicle before purchasing an alternator. It’s advisable to opt for high-output alternators that provide at least 50% more amperage than the vehicle’s maximum electrical load. This ensures that even at idle, when the demand for power is highest, the alternator can adequately supply electricity to all components without straining the system. Additionally, consider collaborating with alternator manufacturers who specialize in high-performance products tailored for modern vehicles. They can provide insights on the best options available and might even offer custom solutions that fit specific fleet requirements.

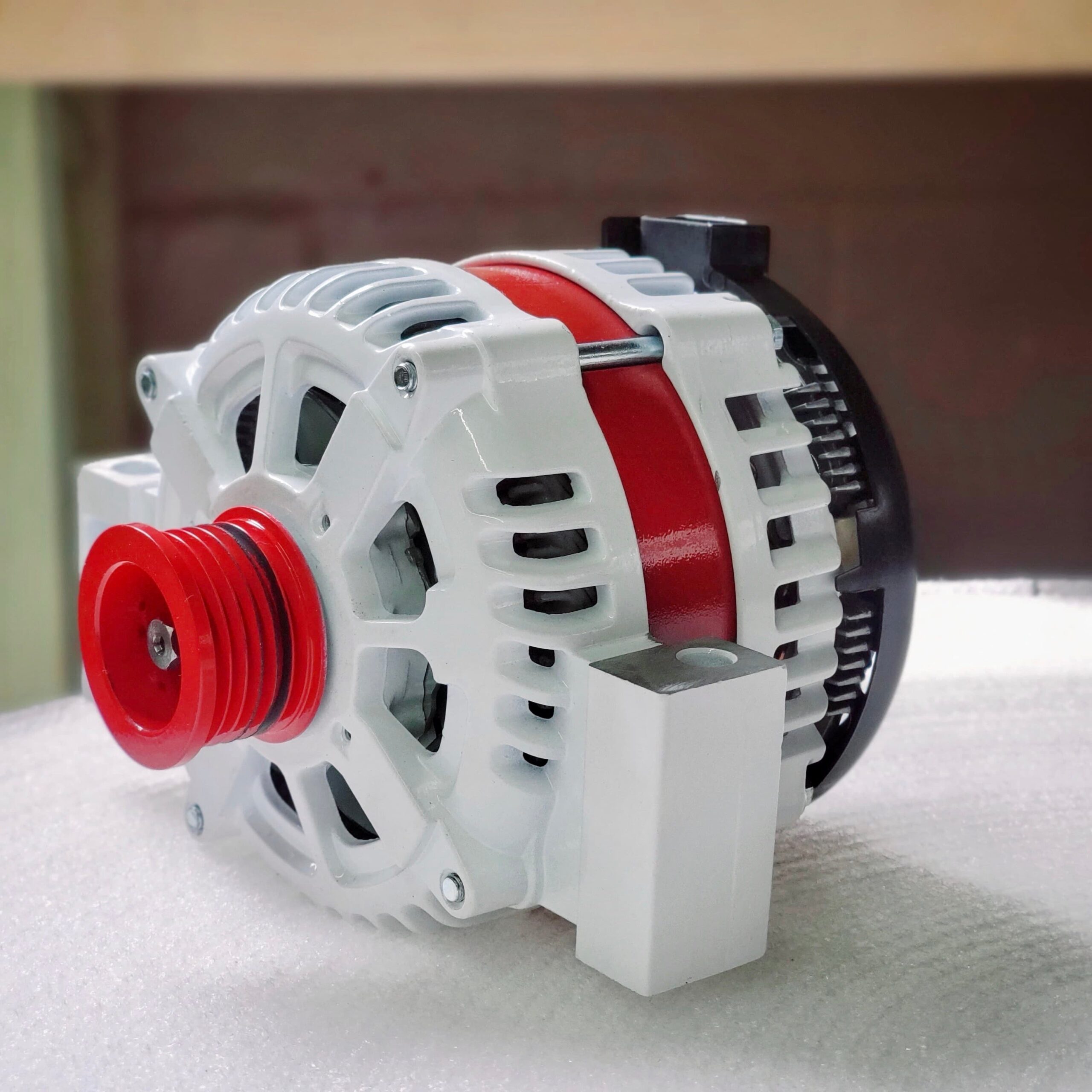

Illustrative image related to best brand alternator

Scenario 3: Navigating the Choice Between New and Remanufactured Alternators

El problema: B2B buyers often grapple with the decision of whether to purchase new or remanufactured alternators. New alternators typically come with a higher price tag, which can strain budgets, especially for larger fleets. Conversely, while remanufactured alternators are more cost-effective, concerns about reliability, warranty coverage, and performance can create hesitation. This decision can significantly impact overall operational costs and vehicle reliability.

La solución: To make an informed choice between new and remanufactured alternators, B2B buyers should conduct a thorough analysis of their budget constraints alongside the expected lifespan and performance needs of their fleet. Establish relationships with reputable suppliers who offer remanufactured alternators that are rigorously tested and come with solid warranties. Understanding the remanufacturing process—ensuring that worn-out components are replaced and that the unit meets or exceeds OEM specifications—can alleviate concerns about reliability. Additionally, consider creating a mix-and-match strategy where high-demand vehicles receive new alternators for maximum reliability, while less critical vehicles can be equipped with remanufactured units, balancing cost and performance effectively.

Strategic Material Selection Guide for best brand alternator

What Materials Are Commonly Used in Best Brand Alternators?

When selecting the best brand alternators, the choice of materials significantly influences performance, durability, and overall functionality. Here, we analyze four common materials used in alternator manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to best brand alternator

How Does Aluminum Affect Alternator Performance?

Aluminum is a popular choice for alternator housings and components due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating up to 150°C and offers good corrosion resistance, especially when anodized.

Ventajas: Aluminum is durable and resistant to rust, making it suitable for various environmental conditions. Its lightweight property enhances fuel efficiency in vehicles, which is a crucial factor for buyers focused on performance.

Contras: While aluminum is cost-effective, it can be less durable than other metals, especially under high-stress conditions. Manufacturing complexity can increase if intricate designs are required.

Impacto en la aplicación: Aluminum’s compatibility with various media makes it suitable for automotive applications, especially in regions with varying climates.

Consideraciones para compradores internacionales: Buyers from regions like Africa and South America should ensure that the aluminum used complies with international standards such as ASTM or DIN, particularly regarding corrosion resistance in humid or saline environments.

Illustrative image related to best brand alternator

¿Qué papel desempeña el cobre en la eficiencia del alternador?

Copper is primarily used in the windings of alternators due to its exceptional electrical conductivity, which is crucial for efficient power generation. It can withstand high temperatures and has a melting point of approximately 1,085°C.

Ventajas: The high conductivity of copper allows for efficient energy transfer, reducing energy loss and improving overall performance. Its durability ensures longevity, making it a preferred choice for high-performance applications.

Contras: Copper is relatively expensive compared to alternatives like aluminum, which can increase the overall cost of the alternator. It is also prone to corrosion if not properly insulated.

Impacto en la aplicación: Copper’s compatibility with electrical systems makes it ideal for high-demand applications, particularly in vehicles requiring robust electrical performance.

Consideraciones para compradores internacionales: B2B buyers in Europe, such as Germany, should verify that the copper used meets stringent EU regulations regarding material quality and environmental impact.

¿Cómo contribuye el acero a la durabilidad del alternador?

Steel is often utilized in the construction of alternator brackets and internal components due to its strength and durability. With a temperature rating that can exceed 200°C, steel components can handle high-stress environments effectively.

Ventajas: Steel offers superior strength and resistance to wear and tear, making it suitable for heavy-duty applications. Its cost-effectiveness is another advantage, particularly for large-scale production.

Contras: The weight of steel can be a drawback, potentially affecting fuel efficiency. Additionally, it is prone to rust without proper treatment or coating.

Impacto en la aplicación: Steel is particularly effective in heavy-duty vehicles and industrial applications where durability is paramount.

Consideraciones para compradores internacionales: Buyers from the Middle East should ensure that steel components are treated for corrosion resistance, especially in arid climates.

Illustrative image related to best brand alternator

What Advantages Does Plastic Provide in Alternator Design?

Plastic materials, particularly high-performance polymers, are increasingly being used for certain alternator components due to their lightweight and insulating properties.

Ventajas: Plastic is resistant to corrosion and can withstand a wide range of temperatures, making it suitable for various environmental conditions. Its lightweight nature contributes to overall vehicle efficiency.

Contras: While plastic is less expensive, it may not offer the same level of durability as metals, especially in high-stress applications.

Impacto en la aplicación: Plastic components are ideal for non-structural parts of the alternator, such as covers and insulators, where weight reduction is beneficial.

Illustrative image related to best brand alternator

Consideraciones para compradores internacionales: Buyers should check for compliance with international standards regarding chemical resistance and thermal stability, particularly in regions with extreme temperatures.

Summary Table of Material Selection for Best Brand Alternators

| Material | Typical Use Case for best brand alternator | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Aluminio | Componentes estructurales y de vivienda | Ligero y resistente a la corrosión. | Menos duradero bajo condiciones de gran estrés. | Medio |

| Cobre | Bobinados eléctricos | High conductivity and durability | Caro y propenso a la corrosión. | Alto |

| Acero | Soportes y componentes internos | Superior strength and cost-effective | Heavy and prone to rust | Bajo |

| Plástico | Non-structural parts (covers, insulators) | Resistente a la corrosión y ligero | Less durable in high-stress areas | Bajo |

This guide provides a comprehensive overview of material selection for alternators, enabling international B2B buyers to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for best brand alternator

¿Cuáles son las etapas clave en el proceso de fabricación de alternadores de alta calidad?

The manufacturing of high-quality alternators involves a series of well-defined stages, each critical to ensuring the final product meets performance and reliability standards. These stages include material preparation, forming, assembly, and finishing.

¿Cómo se prepara el material para la producción de alternadores?

Material preparation is the foundation of the manufacturing process. High-quality alternators typically utilize premium materials such as copper for windings, aluminum or steel for housings, and high-grade plastics for insulation. The selection of materials not only affects performance but also influences the durability and efficiency of the alternator.

Before production begins, raw materials undergo rigorous quality inspections to ensure they meet the required specifications. This includes checking the purity of metals and the resilience of plastics. Reliable suppliers often provide certifications that document the quality of their materials, which B2B buyers should verify to ensure they are sourcing from reputable manufacturers.

What Techniques Are Used in the Forming Stage of Alternators?

Once materials are prepared, the forming process commences. This stage typically involves several techniques, including die casting for metal components and injection molding for plastic parts.

For instance, the rotor and stator, which are crucial for converting mechanical energy to electrical energy, are often produced using precision machining techniques. These processes ensure the components fit together seamlessly, thereby enhancing the efficiency of energy conversion.

In addition to traditional forming methods, some manufacturers are adopting advanced technologies like 3D printing for prototyping and low-volume production, which allows for rapid iterations and design improvements.

¿Cómo se realiza el montaje de los alternadores?

The assembly stage is where all the formed components come together. This is typically done in a clean, controlled environment to minimize contamination and defects.

Illustrative image related to best brand alternator

During assembly, components such as the rotor, stator, voltage regulator, and cooling fan are meticulously assembled. Automation plays a significant role in this stage, with robotic arms used for tasks requiring precision, such as fastening and wiring.

Quality control checkpoints are integrated throughout the assembly line. For example, initial quality checks (IQC) are conducted to ensure that all components meet specifications before assembly proceeds. This minimizes the risk of defects in the final product.

What Finishing Processes Are Essential for Quality Alternators?

Finishing processes enhance the alternator’s performance and appearance. Common techniques include surface treatments such as anodizing or powder coating, which protect against corrosion and wear.

Additionally, manufacturers may conduct electrical testing to ensure that the alternator meets output specifications and functions correctly under various load conditions. This can involve simulating real-world operational scenarios to assess performance metrics.

How Do Quality Assurance Practices Ensure Reliability in Alternator Manufacturing?

Quality assurance (QA) is an integral part of the alternator manufacturing process. Adhering to international standards, such as ISO 9001, ensures that manufacturers maintain consistent quality and continuous improvement practices.

What International and Industry-Specific Standards Apply to Alternator Production?

ISO 9001 is a widely recognized standard for quality management systems. It requires organizations to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

Illustrative image related to best brand alternator

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) standards may also apply, especially for alternators intended for use in specialized applications, such as marine or heavy-duty vehicles.

B2B buyers should inquire about these certifications when assessing potential suppliers to ensure compliance with relevant safety and performance standards.

¿Cuáles son los principales puntos de control de calidad en la fabricación de alternadores?

Quality control involves several checkpoints throughout the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC ensures that raw materials and components meet specified standards before production begins.

- IPQC monitors processes during manufacturing to identify any deviations from quality standards in real-time, allowing for immediate corrective actions.

- FQC verifies that the finished alternator meets all performance and quality specifications before it is shipped to customers.

These checkpoints help maintain a high level of quality throughout production, reducing the likelihood of defects and enhancing customer satisfaction.

What Common Testing Methods Are Used to Validate Alternator Quality?

Testing is a crucial component of quality assurance. Common testing methods for alternators include:

Illustrative image related to best brand alternator

- Pruebas eléctricas: Verifying output voltage and current to ensure the alternator meets performance specifications.

- Pruebas térmicas: Assessing the alternator’s performance under varying temperature conditions to ensure it can operate effectively in different environments.

- Pruebas de vibración: Evaluating the alternator’s resilience to vibrations, which is particularly important for automotive applications.

These tests help identify potential weaknesses or failures before the alternators reach the market.

¿Cómo pueden los compradores B2B verificar las prácticas de control de calidad de los proveedores?

For B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are some actionable steps:

- Solicitar documentación: Ask for quality control reports and certifications that demonstrate compliance with international standards.

- Realizar auditorías: Regular audits of potential suppliers can reveal their manufacturing practices and adherence to quality standards.

- Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of a supplier’s quality control processes and product quality.

What Are the Quality Control Nuances for International Buyers in Different Regions?

International buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, may encounter varying quality control expectations.

In Europe, for instance, strict adherence to CE marking and ISO standards is crucial for market entry. Conversely, buyers in Africa and South America might prioritize cost-effectiveness while still seeking reliable quality. Understanding regional differences in quality expectations can help buyers make informed decisions when sourcing alternators.

In summary, the manufacturing and quality assurance processes for alternators are intricate and designed to ensure that the final product meets high standards of performance and reliability. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers and products that align with their operational needs.

Illustrative image related to best brand alternator

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best brand alternator’

Introducción

When sourcing the best brand alternators for your business, it’s essential to follow a structured approach to ensure that you select a product that meets your technical requirements and budget constraints. This checklist will guide you through the critical steps needed to make informed purchasing decisions while minimizing risks associated with supplier reliability and product quality.

Paso 1: Defina sus especificaciones técnicas

Before diving into the procurement process, clearly outline the specifications your alternators must meet. This includes understanding the electrical load requirements of the vehicles or machinery they will be used in, the compatibility with existing systems, and any specific performance standards needed.

– Consideraciones: Voltage output, amperage, and physical dimensions are vital aspects to document.

Paso 2: Investiga marcas de renombre.

Not all alternator brands are created equal. Conduct thorough research to identify reputable manufacturers known for producing high-quality alternators. Look for brands with a solid reputation in the industry, preferably those that have been recognized for reliability and performance.

– Resources: Utilize industry reviews, forums, and trade publications to gather insights on brand performance and customer satisfaction.

Paso 3: Evaluar las certificaciones de los proveedores

It’s crucial to verify that potential suppliers hold the necessary certifications that demonstrate compliance with international standards, such as ISO or SAE. Certifications can serve as a quality assurance measure, indicating that the supplier adheres to best practices in manufacturing.

– What to Check: Ask for documentation of certifications and quality control processes, as this can mitigate risks related to product defects.

Paso 4: Solicitar muestras para pruebas

Before placing a bulk order, request samples of the alternators you are considering. Testing samples will allow you to assess their quality, compatibility, and performance in real-world conditions, ensuring they meet your specifications.

– Criterios de prueba: Focus on electrical performance, durability, and ease of installation to confirm that the product aligns with your operational needs.

Paso 5: Compare precios y condiciones

Once you have identified a shortlist of potential suppliers, compare their pricing structures and payment terms. Ensure that you are getting value for your investment while also considering the total cost of ownership, which includes warranty and support services.

– Consejos para negociar: Don’t hesitate to negotiate terms, especially if you are considering a long-term partnership or bulk purchases.

Paso 6: Assess Supplier Reliability and Support

Evaluate the reliability of your potential suppliers by checking their track record for delivery times, customer service, and post-sale support. A reliable supplier should be able to provide timely updates and assistance whenever needed.

– Preguntas clave: Inquire about their return policies, warranty coverage, and how they handle disputes or product failures.

Paso 7: Finalizar el acuerdo de compra

Once you have selected a supplier, ensure that all terms are clearly outlined in a purchase agreement. This should include pricing, delivery schedules, and warranties. A well-documented agreement can protect both parties and facilitate smoother transactions.

– Aspectos importantes: Include clauses related to quality assurance and recourse in case of non-compliance with specifications.

By following these steps, you will be better positioned to source high-quality alternators that meet your business’s specific needs while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for best brand alternator Sourcing

What Are the Key Cost Components in Sourcing Best Brand Alternators?

When sourcing alternators from reputable brands, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materiales: The quality of raw materials, such as copper for windings and aluminum for casings, significantly influences the overall cost. Higher quality materials enhance performance and durability, which can justify a higher price point.

-

Trabajo: Labor costs can vary depending on the region where the alternators are manufactured. Countries with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality.

-

Gastos generales de fabricación: This includes costs related to facilities, equipment maintenance, and utilities. Efficient manufacturing processes can lower overhead costs, impacting the final pricing of alternators.

-

Herramientas: The cost of tooling can be substantial, especially for custom or high-output alternators. Investing in advanced tooling can improve production efficiency and product quality.

-

Control de calidad (QC): Rigorous quality control processes ensure that the alternators meet industry standards. Suppliers with strong QC protocols may charge more, but they also reduce the risk of defects and warranty claims.

-

Logística: Shipping costs can vary significantly based on the shipping method, distance, and volume. Incoterms also play a role in determining who bears the shipping costs, which can affect the final pricing.

-

Margen: Suppliers typically apply a markup to cover their costs and ensure profit. Understanding a supplier’s margin can provide insights into their pricing strategy.

How Do Price Influencers Affect the Sourcing of Best Brand Alternators?

Several factors can influence the pricing of alternators, particularly for international buyers.

-

Volumen/MOQ (cantidad mínima de pedido): Larger orders often qualify for volume discounts, which can significantly lower the per-unit cost. Buyers should consider consolidating orders to achieve better pricing.

-

Especificaciones y personalización: Custom alternators tailored to specific vehicle requirements may incur additional costs. Standard models are generally more cost-effective.

-

Materiales y certificaciones de calidad: Alternators built with premium materials and certified to meet international quality standards may command higher prices. However, these investments often lead to lower failure rates and longer service life.

-

Factores relacionados con los proveedores: Supplier reputation and reliability can impact pricing. Established suppliers with a proven track record may charge more due to their perceived quality and service reliability.

-

Incoterms: Understanding the shipping terms is essential for cost management. FOB (Free on Board) and CIF (Cost, Insurance, and Freight) are common terms that can significantly affect the overall cost structure.

What Are Some Negotiation Tips for B2B Buyers Sourcing Alternators?

To maximize cost-efficiency in sourcing alternators, B2B buyers should consider the following strategies:

Illustrative image related to best brand alternator

-

Construir relaciones: Establishing a strong relationship with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable negotiations.

-

Aprovechar el coste total de propiedad (TCO): When assessing pricing, consider not just the initial purchase price but the total cost of ownership, including maintenance, warranty, and potential downtime costs.

-

Tenga en cuenta los matices de los precios: Different regions may have unique pricing structures due to tariffs, shipping costs, and local market conditions. Buyers in Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these nuances.

-

Request Transparency: Ask suppliers for a breakdown of their pricing structure. Understanding the individual components can provide leverage during negotiations.

-

Evaluar múltiples proveedores: Comparing quotes from multiple suppliers can provide insights into market pricing and help identify the best value.

Descargo de responsabilidad

The prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and other influencing factors. Always conduct thorough research and engage in direct discussions with suppliers to obtain accurate and current pricing information.

Alternatives Analysis: Comparing best brand alternator With Other Solutions

Understanding Alternatives to the Best Brand Alternator

When considering the best brand alternator, it’s essential to explore alternative solutions that may meet the needs of various applications. These alternatives can provide different benefits, such as cost-effectiveness, ease of maintenance, or performance suitability based on specific vehicle requirements. This analysis will compare the best brand alternator against two viable alternatives: high-output alternators and remanufactured alternators.

Tabla comparativa

| Aspecto comparativo | Best Brand Alternator | Alternador de alto rendimiento | Alternador refabricado |

|---|---|---|---|

| Rendimiento | Excellent reliability and efficiency | Superior power output for demanding electrical systems | Comparable performance to new, depending on refurbishment quality |

| Coste | Mayor inversión inicial | Generally higher due to advanced technology | Lower cost than new, offering value for money |

| Facilidad de implementación | Instalación estándar | May require modifications for compatibility | Direct replacement, similar to new units |

| Mantenimiento | Low maintenance, durable | Requires regular checks to prevent overheating | Maintenance depends on quality of refurbishment |

| Mejor caso de uso | Everyday vehicles and standard applications | High-performance vehicles, audio systems, heavy-duty applications | Budget-conscious buyers needing reliable replacements |

Desglose detallado de las alternativas

Alternadores de alto rendimiento

High-output alternators are designed to deliver increased electrical output, making them ideal for vehicles with demanding power requirements, such as those equipped with high-end audio systems or additional electrical accessories. The advantages of high-output alternators include their ability to maintain battery charge even under heavy electrical loads. However, they typically come at a higher price point and may require modifications to the vehicle’s wiring or mounting system. Additionally, these alternators can generate more heat, necessitating regular maintenance to ensure they do not overheat, which could lead to premature failure.

Alternadores reacondicionados

Remanufactured alternators present a cost-effective alternative for buyers looking for dependable performance without the higher price tag of new units. These alternators are refurbished to meet original equipment specifications, often providing comparable reliability to new models. The primary advantage lies in their affordability, making them a popular choice for budget-conscious businesses. However, the quality of remanufactured alternators can vary significantly based on the manufacturer’s standards and processes. Buyers must conduct due diligence to ensure they are purchasing from reputable sources that guarantee performance and reliability.

Conclusión: Cómo elegir la solución adecuada para sus necesidades

Selecting the right alternator solution depends on a variety of factors, including the specific electrical demands of your vehicles, budget constraints, and maintenance capabilities. For businesses operating in high-demand environments, investing in high-output alternators may be worthwhile despite the higher cost. Conversely, for those looking for reliable yet economical options, remanufactured alternators can be an excellent choice, provided quality assurance is prioritized. Ultimately, a thorough assessment of performance needs, cost efficiency, and maintenance expectations will guide B2B buyers in making the best decision for their operations.

Essential Technical Properties and Trade Terminology for best brand alternator

What Are the Key Technical Properties of a Quality Alternator?

When selecting the best brand alternator, understanding its technical properties is crucial for ensuring reliability, performance, and compatibility with various applications. Here are some essential specifications that B2B buyers should consider:

-

Output Amperage

The output amperage indicates how much electrical current the alternator can generate. This is vital for meeting the power demands of a vehicle’s electrical systems. For instance, high-performance vehicles may require alternators that produce 200 amps or more, while standard vehicles may function well with 100-130 amps. Choosing an alternator with the appropriate amperage ensures that all electrical components operate efficiently without risking damage or failure. -

Tensión nominal

Most automotive alternators operate at a voltage output between 13 to 14.8 volts. This rating is essential for charging the vehicle’s battery and powering electrical accessories. Understanding the voltage requirements helps buyers select an alternator that maintains battery health and ensures optimal performance during operation. -

Mecanismo de enfriamiento

Alternators can come with different cooling designs, such as passive or active cooling systems. A well-designed cooling mechanism prevents overheating, which can lead to premature failure. High-output alternators, particularly in demanding applications, often feature enhanced cooling to manage thermal loads effectively. This specification is critical for maintaining longevity and performance, especially in regions with extreme temperatures. -

Size and Mounting Configuration

The physical dimensions and mounting configuration of an alternator are crucial for compatibility with specific vehicle models. B2B buyers must ensure that the selected alternator fits within the allotted space and aligns with the vehicle’s existing mounting points. Incorrect sizing can lead to installation difficulties and operational issues. -

Composición del material

The materials used in the construction of an alternator, such as the rotor and stator windings, influence its durability and efficiency. High-quality copper windings and robust housing materials enhance performance and resistance to wear. Selecting an alternator made from superior materials can reduce maintenance costs and improve reliability.

¿Cuáles son los términos comerciales más comunes relacionados con los alternadores?

Familiarity with industry terminology is essential for B2B buyers, as it enhances communication with suppliers and ensures informed purchasing decisions. Here are several key trade terms to know:

-

OEM (fabricante de equipos originales)

OEM refers to parts made by the original manufacturer of a vehicle. These parts meet specific quality and compatibility standards set by the vehicle manufacturer. B2B buyers often prefer OEM alternators for their reliability and assurance of fitment. -

MOQ (cantidad mínima de pedido)

MOQ represents the minimum number of units that a supplier is willing to sell in a single order. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and purchasing strategies. Negotiating favorable MOQ terms can lead to cost savings and more efficient stock levels. -

RFQ (Solicitud de presupuesto)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products, such as alternators. This process enables buyers to compare offers and negotiate terms, ensuring they secure the best deal for their needs. -

Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers in international transactions, including who bears the cost of shipping, insurance, and customs duties. Understanding these terms is vital for B2B buyers to avoid unexpected costs and ensure smooth logistics. -

Alternador refabricado

A remanufactured alternator is a used unit that has been restored to meet OEM specifications. This option is often more cost-effective than purchasing new, providing similar performance and reliability. B2B buyers should consider the warranty and quality assurance provided with remanufactured units.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing the best brand alternators, ensuring they meet both their operational needs and budgetary constraints.

Navigating Market Dynamics and Sourcing Trends in the best brand alternator Sector

What Are the Key Drivers Influencing the Best Brand Alternator Market?

The global alternator market is witnessing robust growth driven by several factors. The increasing demand for reliable automotive power generation, alongside the rise of electric vehicles (EVs), has prompted manufacturers to innovate and improve alternator efficiency. In regions like Africa and South America, where vehicle ownership is expanding rapidly, the need for dependable alternators is paramount. Moreover, the Middle East’s growing automotive sector is pushing for higher output alternators to support advanced vehicle electronics.

Emerging B2B technology trends are also shaping the sourcing landscape. The integration of artificial intelligence and machine learning in supply chain management is streamlining procurement processes for international buyers. This technological advancement allows for better demand forecasting and inventory management, which is particularly crucial in markets with fluctuating demand. Furthermore, blockchain technology is being explored for enhancing supply chain transparency and traceability, which is vital for buyers concerned with ethical sourcing.

As international B2B buyers look to diversify their supplier base, they are increasingly favoring manufacturers that can offer customized solutions. This trend is especially pronounced in Europe, where stringent regulatory standards require alternators that not only meet performance metrics but also comply with environmental regulations.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in Alternators?

Sustainability and ethical sourcing have become pivotal in the B2B landscape, particularly in the alternator sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, necessitates a shift toward greener practices. Buyers should prioritize suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and production methods.

Illustrative image related to best brand alternator

Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are indicators of a supplier’s dedication to ethical practices. Additionally, sourcing from manufacturers that utilize recycled materials in their alternator production can significantly reduce the carbon footprint associated with new component manufacturing.

The importance of ethical supply chains cannot be overstated, especially in regions like Africa and South America, where local communities are often directly affected by industrial practices. B2B buyers should engage with suppliers who actively support local economies and adhere to fair labor practices. This not only enhances brand reputation but also fosters long-term partnerships built on trust and mutual benefit.

¿Cómo ha evolucionado el mercado de los alternadores?

The evolution of the alternator market reflects broader trends in automotive technology and consumer demands. Initially, alternators were simple devices with limited output capabilities, primarily designed for basic electrical needs. However, as vehicles became more sophisticated, the role of alternators transformed dramatically. Modern alternators are engineered to support complex electronic systems, including advanced infotainment units and high-performance lighting systems, necessitating higher output and efficiency.

Illustrative image related to best brand alternator

Furthermore, the shift towards electric and hybrid vehicles has catalyzed innovation in alternator design, leading to the development of high-output and regenerative alternators that can efficiently convert mechanical energy into electrical energy. This evolution underscores the importance of staying informed about technological advancements and market dynamics, enabling B2B buyers to make strategic sourcing decisions that align with future trends.

In summary, the alternator market is rapidly evolving, driven by technological advancements, sustainability concerns, and the increasing complexity of automotive electrical systems. By understanding these dynamics, B2B buyers can navigate the market effectively, ensuring they source high-quality alternators that meet their operational needs while also aligning with ethical and sustainable practices.

Frequently Asked Questions (FAQs) for B2B Buyers of best brand alternator

-

How do I choose the right alternator for my vehicle?

Choosing the right alternator involves assessing several factors, including compatibility with your vehicle’s engine model and electrical load requirements. Start by checking the specifications of your current alternator, such as its amperage and dimensions. If your vehicle has added electrical accessories or high-performance systems, consider upgrading to a high-output alternator. Ensure the alternator’s output matches or exceeds your vehicle’s total electrical demands, ideally being 50% greater to ensure optimal performance and longevity. -

What are the top brands for high-quality alternators?

Some of the best brands known for reliable alternators include Denso, Remy, Wilson, and Armature DNS. These brands are recognized for their durability, performance, and adherence to OEM specifications. When sourcing for B2B purchases, consider suppliers that offer warranties on their products, as this often indicates confidence in quality. It’s also beneficial to look for brands that have a strong presence in your target market to ensure support and service availability. -

¿Qué debo tener en cuenta al buscar proveedores de alternadores?

When vetting alternator suppliers, evaluate their reputation, product quality, and compliance with international standards. Check for certifications such as ISO or compliance with regional regulations, especially if you are importing from outside your region. Additionally, review customer testimonials and case studies to gauge their reliability and service quality. It’s also wise to verify their supply chain capabilities, including lead times and logistics support, to ensure they can meet your business needs consistently. -

¿Cuáles son las cantidades mínimas de pedido (MOQ) para los alternadores?

Minimum order quantities (MOQ) for alternators can vary significantly by supplier and brand. Typically, manufacturers may require MOQs ranging from 50 to 100 units, especially for custom or high-output models. However, some suppliers may offer flexible MOQs for B2B buyers, particularly if you establish a long-term partnership. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms that align with your inventory management strategies. -

¿Qué condiciones de pago debo esperar al adquirir alternadores a nivel internacional?

Payment terms for international B2B transactions can vary widely based on supplier policies and your negotiating power. Common terms include upfront payments, partial payments before shipping, or net 30/60 days after delivery. Always clarify payment methods accepted, which may include wire transfers, letters of credit, or escrow services. Ensure that the terms are documented in the purchase agreement to avoid misunderstandings and protect both parties’ interests. -

How can I ensure quality assurance (QA) for the alternators I purchase?

To ensure quality assurance for alternators, request certifications and quality control documentation from the supplier. It’s beneficial to establish a QA protocol that includes pre-shipment inspections and testing procedures. Consider working with third-party inspection services to validate the quality before shipment, especially when sourcing from international suppliers. Additionally, having a clear return policy and warranty terms can safeguard your investment against defective products. -

¿Qué consideraciones logísticas debo tener en cuenta al importar alternadores?

Logistics considerations for importing alternators include understanding shipping methods, customs regulations, and potential tariffs. Determine whether air freight or sea freight is more cost-effective based on your urgency and budget. Familiarize yourself with the import regulations of your country, including any documentation required for customs clearance. Collaborating with a reliable freight forwarder can streamline the process and help navigate any complexities involved in international shipping. -

Can I customize alternators to fit specific requirements?

Yes, many manufacturers offer customization options for alternators to meet specific requirements, such as higher output ratings, unique mounting configurations, or specific finishes. Discuss your needs with potential suppliers to explore available customization options. Be mindful that customized orders may have longer lead times and higher costs, so it’s essential to factor these into your procurement strategy. Providing detailed specifications will help suppliers deliver products that align with your operational needs.

Top 2 Best Brand Alternator Manufacturers & Suppliers List

1. Denso – Quality Manufacturing

Dominio: reddit.com

Registrado: 2005 (20 años)

Introducción: This company, Denso – Quality Manufacturing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Cadillac – Alternator Brands

Dominio: facebook.com

Registrado: 1997 (28 años)

Introducción: Cadillac Dhs-Dts-Deville, marcas de alternadores: AC Delco, Duralast

Strategic Sourcing Conclusion and Outlook for best brand alternator

In conclusion, strategic sourcing of alternators is crucial for international B2B buyers seeking reliability and performance in their automotive supply chains. By understanding the various types of alternators, including high-output and remanufactured options, businesses can make informed decisions that align with their operational needs. Key considerations such as electrical load compatibility, manufacturer reputation, and warranty offerings should guide purchasing choices.

Investing in reputable brands like Denso, Remy, and Wilson not only ensures high-quality products but also fosters long-term partnerships that can enhance supply chain resilience. As the demand for advanced automotive technologies continues to rise, staying ahead of market trends will be essential for maintaining competitive advantage.

Looking forward, we encourage buyers from Africa, South America, the Middle East, and Europe to leverage this guide as a roadmap for sourcing the best alternators. By prioritizing quality and strategic partnerships, businesses can position themselves for success in an ever-evolving automotive landscape. Engage with trusted suppliers today to secure your competitive edge in the marketplace.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.