Introduction: Navigating the Global Market for parts of a alternator

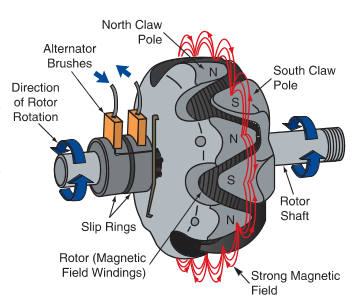

In today’s competitive landscape, sourcing high-quality parts of an alternator can pose significant challenges for international B2B buyers. With various components like rotors, stators, rectifiers, and voltage regulators playing pivotal roles in alternator functionality, understanding these elements is crucial for making informed purchasing decisions. This guide offers a comprehensive overview of alternator parts, their applications across different industries, and key considerations for selecting reliable suppliers.

Buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Nigeria and Germany—will find valuable insights into the nuances of sourcing these components. The guide delves into the types of alternator parts available, their specific functions, and market trends that influence pricing and availability. Additionally, it provides a framework for vetting suppliers, ensuring that buyers can identify trustworthy partners who meet their quality and compliance standards.

By empowering B2B buyers with knowledge about the intricacies of alternator parts and practical sourcing strategies, this guide aims to streamline the procurement process. Whether you are looking to enhance your supply chain efficiency or seeking to reduce operational costs, understanding the market dynamics of alternator components is essential for success in today’s global economy.

Índice

- Top 5 Parts Of A Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts of a alternator

- Understanding parts of a alternator Types and Variations

- Key Industrial Applications of parts of a alternator

- 3 Common User Pain Points for ‘parts of a alternator’ & Their Solutions

- Strategic Material Selection Guide for parts of a alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for parts of a alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a alternator’

- Comprehensive Cost and Pricing Analysis for parts of a alternator Sourcing

- Alternatives Analysis: Comparing parts of a alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for parts of a alternator

- Navigating Market Dynamics and Sourcing Trends in the parts of a alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts of a alternator

- Strategic Sourcing Conclusion and Outlook for parts of a alternator

- Aviso legal importante y condiciones de uso

Understanding parts of a alternator Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Alternadores sin escobillas | No brushes; uses electronic circuits for control | Heavy machinery, renewable energy | Ventajas: Lower maintenance; longer lifespan. Contras: Mayor coste inicial. |

| Integrated Alternators | Combines alternator and starter functions | Automotive, hybrid vehicles | Ventajas: Space-saving; improved efficiency. Contras: Complex design may complicate repairs. |

| Alternadores de alto rendimiento | Designed for increased power output | Performance vehicles, audio systems | Ventajas: Supports high-demand applications. Contras: May require upgrades to vehicle systems. |

| Alternadores estándar | Traditional design with brushes and rectifier | Aplicaciones generales de automoción | Ventajas: Widely available; cost-effective. Contras: More frequent maintenance needed. |

| Alternadores inteligentes | Features advanced electronics for efficiency | Modern vehicles, fleet management | Ventajas: Optimizes energy usage; reduces emissions. Contras: May be more expensive to replace. |

What Are Brushless Alternators and Their Applications?

Brushless alternators eliminate the need for brushes, relying instead on electronic circuits to manage power output. This design is particularly beneficial for heavy machinery and renewable energy applications, where reliability and low maintenance are paramount. B2B buyers should consider the long-term savings associated with reduced maintenance and longer operational life, despite the higher upfront investment.

How Do Integrated Alternators Work and Where Are They Used?

Integrated alternators combine the functions of an alternator and a starter, making them ideal for automotive and hybrid vehicle applications. Their compact design saves space and enhances efficiency. However, buyers should be aware of the complexities involved in repairs, as the integrated design can complicate maintenance and replacement processes.

¿Cuáles son las ventajas de los alternadores de alto rendimiento?

High-output alternators are engineered to deliver greater power, making them suitable for performance vehicles and high-demand audio systems. They cater to applications that require robust electrical support. While they provide the necessary power for demanding systems, B2B buyers must consider potential upgrades to vehicle electrical systems to accommodate the increased output.

Why Choose Standard Alternators for General Applications?

Standard alternators, characterized by their traditional design with brushes and rectifiers, are commonly used in general automotive applications. They are cost-effective and widely available, making them a go-to choice for many businesses. However, buyers should factor in the need for more frequent maintenance due to wear and tear on the brushes.

¿Qué son los alternadores inteligentes y cuáles son sus ventajas?

Smart alternators utilize advanced electronics to optimize energy usage and improve vehicle efficiency, making them increasingly popular in modern vehicles and fleet management. They help reduce emissions and enhance fuel efficiency. Buyers should weigh the benefits of these innovative systems against their potentially higher replacement costs.

Key Industrial Applications of parts of a alternator

| Industria/Sector | Specific Application of parts of a alternator | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Automoción | Manufacturing of electric vehicles (EVs) | Enhances battery life and efficiency in EV systems | Quality assurance, compliance with international standards |

| Agricultura | Operation of irrigation systems | Provides reliable power for automated irrigation | Durability in harsh environments, availability of spare parts |

| Marina | Generación de energía para barcos y buques | Ensures consistent electrical supply for navigation systems | Resistance to corrosion, capacity for high output |

| Construcción | Powering construction machinery | Supports heavy equipment operation with stable power | Reliability under load, serviceability and maintenance ease |

| Energía renovable | Integración con sistemas de energía solar y eólica | Facilitates energy conversion and storage | Compatibilidad con los sistemas existentes, índices de eficiencia |

How Are Parts of an Alternator Utilized in the Automotive Industry?

In the automotive sector, particularly in the manufacturing of electric vehicles (EVs), parts of an alternator play a crucial role in optimizing battery performance. The rotor and stator generate electrical power that charges the battery while the vehicle is in motion, enhancing overall efficiency. As EV adoption rises in regions like Europe and South America, sourcing high-quality alternator components that meet stringent international standards is essential. This ensures reliability and longevity, reducing downtime and maintenance costs.

What Role Do Alternator Parts Play in Agriculture?

In agriculture, alternator components are integral to powering automated irrigation systems. The alternator converts mechanical energy from engines into electrical energy, ensuring a consistent power supply for pumps and control systems. This is particularly valuable in regions like Africa, where access to reliable electricity can be limited. Buyers must prioritize sourcing alternator parts that are durable and capable of operating in harsh environmental conditions, as well as ensuring availability of spare parts for maintenance.

How Are Alternator Parts Applied in Marine Applications?

In marine applications, alternators are vital for generating power on boats and ships. They provide electrical energy for navigation systems, lighting, and other onboard equipment. The ability to withstand corrosive marine environments is crucial for these components. Buyers in the Middle East and other coastal regions should focus on sourcing alternator parts that are resistant to saltwater corrosion and have high output capacities to meet the demands of larger vessels.

Why Are Alternator Parts Important for Construction Machinery?

Construction machinery relies heavily on alternators to provide stable electrical power for operation. Parts such as the voltage regulator and rectifier ensure that equipment like excavators and cranes can function efficiently under heavy loads. In this industry, reliability is key, as downtime can lead to significant financial losses. Buyers should consider the serviceability of alternator parts and their performance under load, ensuring that sourced components can handle the rigors of construction environments.

How Do Alternator Parts Enhance Renewable Energy Systems?

In renewable energy systems, particularly solar and wind, alternator components facilitate the conversion and storage of energy. They work by converting the generated AC power into DC power, which can be stored in batteries for later use. As global interest in renewable energy grows, especially in Europe and South America, sourcing efficient and compatible alternator parts becomes crucial. Buyers should focus on components that meet efficiency ratings and can easily integrate with existing renewable energy systems to maximize performance.

3 Common User Pain Points for ‘parts of a alternator’ & Their Solutions

Scenario 1: Difficulty Sourcing High-Quality Alternator Parts

El problema: B2B buyers often struggle to find reliable suppliers for alternator parts that meet both quality standards and cost constraints. This issue is exacerbated in regions with limited local manufacturing capabilities, such as parts of Africa and South America. Buyers may encounter subpar components that lead to frequent failures, resulting in increased downtime for their operations and dissatisfaction among end-users.

La solución: To overcome this challenge, buyers should establish relationships with reputable manufacturers and distributors who have a proven track record in the automotive industry. Conduct thorough background checks and request certifications that demonstrate adherence to international quality standards, such as ISO 9001. Additionally, consider forming partnerships with suppliers that offer warranties or guarantees on their products, as this can provide assurance of quality. Leveraging online platforms that specialize in B2B transactions can also help buyers compare options from multiple suppliers, ensuring they find the best fit for their needs.

Scenario 2: Navigating Compatibility Issues with Alternator Components

El problema: Another common pain point is the compatibility of alternator parts across different vehicle models and brands. B2B buyers often face challenges when trying to source parts that fit a specific alternator design, leading to mismatches that can compromise performance. This issue is particularly prevalent in regions where vehicles from various manufacturers are used interchangeably, making it crucial for buyers to be precise in their specifications.

La solución: To address compatibility issues, buyers should invest in comprehensive cataloging tools or software that provide detailed specifications for each alternator part. This includes dimensions, connector types, and materials used. Collaborating closely with technical teams can also help in identifying the correct part numbers and specifications needed for various applications. Additionally, it’s advisable to maintain a robust inventory of commonly used parts to minimize delays when urgent replacements are needed. Engaging with suppliers that provide detailed product descriptions and compatibility charts can further streamline the selection process.

Scenario 3: Managing the Lifecycle of Alternator Parts

El problema: Many B2B buyers overlook the importance of managing the lifecycle of alternator parts, which can lead to unexpected failures and increased operational costs. Buyers may find themselves with outdated or obsolete components that are no longer supported by manufacturers, resulting in difficulties during repairs and maintenance. This issue can be particularly critical in industries where vehicle uptime is paramount.

La solución: To effectively manage the lifecycle of alternator parts, buyers should implement a proactive maintenance and tracking system that monitors the condition and performance of each part. Regular audits and assessments can help identify parts that need replacement before they fail. Establishing a relationship with suppliers who offer lifecycle management services can also be beneficial. These suppliers can provide insights into upcoming changes in part availability and recommend alternatives well in advance. Additionally, investing in training for maintenance personnel on recognizing signs of wear and tear can enhance the longevity of alternator components, ultimately saving costs and ensuring smooth operations.

Strategic Material Selection Guide for parts of a alternator

¿Cuáles son los materiales clave utilizados en los componentes del alternador?

When selecting materials for alternator components, it’s essential to consider properties that directly affect performance, durability, and manufacturing processes. Below is an analysis of four common materials used in alternators: aluminum, copper, steel, and plastic.

How Does Aluminum Benefit Alternator Housing and Components?

Aluminum is widely used in alternator housings due to its lightweight and non-magnetic properties. It has excellent thermal conductivity, which is crucial for dissipating heat generated during operation. Aluminum can withstand temperatures up to 150°C, making it suitable for automotive applications.

Ventajas: The lightweight nature of aluminum contributes to overall vehicle efficiency, reducing fuel consumption. Additionally, it is relatively inexpensive and easy to machine, which simplifies manufacturing processes.

Contras: While aluminum is corrosion-resistant, it can be susceptible to galvanic corrosion when in contact with dissimilar metals. This requires careful consideration during assembly and design.

Impacto en la aplicación: Aluminum’s thermal properties ensure efficient operation under high temperatures, but it may not be suitable for environments with extreme mechanical stress.

Consideraciones internacionales: Buyers in regions like Europe and the Middle East often look for compliance with standards such as DIN EN 573 for aluminum alloys. Ensuring that suppliers provide materials that meet these standards is crucial for quality assurance.

What Role Does Copper Play in Alternator Wiring?

Copper is the preferred material for electrical wiring in alternators due to its excellent electrical conductivity. With a conductivity rating of 100% IACS (International Annealed Copper Standard), it ensures minimal energy loss during power transmission.

Ventajas: Copper’s high conductivity translates to better performance and efficiency in energy transfer. It is also highly ductile, making it easy to work with during manufacturing.

Contras: The primary drawback of copper is its cost, which is significantly higher than aluminum. Additionally, copper is prone to corrosion, especially in humid environments, which can impact longevity.

Impacto en la aplicación: Copper wiring is essential for efficient power generation and transmission in alternators. However, in humid or corrosive environments, protective coatings or alloying with other metals may be necessary.

Consideraciones internacionales: Compliance with ASTM B170 for copper wire is crucial. Buyers in South America and Africa should ensure that suppliers adhere to these standards to avoid performance issues.

¿Cómo contribuye el acero a la durabilidad del alternador?

Steel is commonly used for components that require high strength, such as the rotor shaft and bearings. Its ability to withstand high mechanical loads makes it an excellent choice for these applications.

Ventajas: Steel’s durability ensures a long lifespan for critical components, reducing the frequency of replacements. It is also cost-effective compared to other high-strength materials.

Contras: Steel is heavier than aluminum, which can impact overall vehicle weight and fuel efficiency. Additionally, it is prone to rust if not properly coated or treated.

Impacto en la aplicación: Steel’s strength is advantageous in high-stress environments, but its weight may be a disadvantage in performance-focused applications.

Consideraciones internacionales: Compliance with JIS G3101 for steel grades is essential, especially for buyers in Asia and Europe. Understanding local regulations regarding steel quality can help avoid supply chain disruptions.

What Is the Role of Plastic in Alternator Insulation?

Plastic is often used for insulation and housing components within the alternator, particularly in the voltage regulator and diode rectifier. Its electrical insulating properties are critical for preventing short circuits.

Ventajas: Plastic is lightweight and can be molded into complex shapes, making it ideal for intricate designs. It is also resistant to corrosion and chemical degradation.

Contras: While plastic is cost-effective, it may not withstand high temperatures as effectively as metals. Prolonged exposure to heat can lead to degradation.

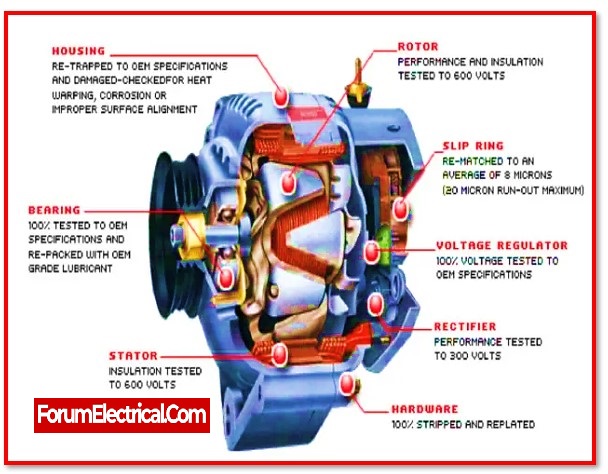

Illustrative image related to parts of a alternator

Impacto en la aplicación: Plastic components are suitable for low-stress applications but may require careful selection of heat-resistant grades for high-temperature environments.

Consideraciones internacionales: Buyers should look for compliance with ISO 9001 for quality management systems when sourcing plastic components, ensuring consistent quality across suppliers.

Resumen de la selección de materiales para las piezas del alternador

| Material | Typical Use Case for parts of a alternator | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Aluminio | Componentes estructurales y de vivienda | Lightweight and excellent thermal conductivity | Susceptible a la corrosión galvánica | Medio |

| Cobre | Cableado y conexiones eléctricas | Alta conductividad eléctrica | Mayor coste y propensión a la corrosión | Alto |

| Acero | Rotor shaft and bearings | Alta resistencia y durabilidad | Heavier than aluminum and prone to rust | Bajo |

| Plástico | Aislamiento y carcasa para componentes eléctricos | Ligero y resistente a la corrosión. | Rendimiento limitado a altas temperaturas | Bajo |

This strategic material selection guide provides insights into the various materials used in alternator components, helping international B2B buyers make informed decisions based on performance, cost, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of a alternator

¿Cuáles son las etapas clave del proceso de fabricación de piezas de alternador?

The manufacturing process for alternator components involves several critical stages that ensure the final product meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

Preparación del material: ¿Cómo se seleccionan y procesan las materias primas?

The first step in manufacturing alternator parts is material preparation. High-quality materials are crucial for durability and performance. Most alternator housings are made from aluminum due to its lightweight properties and resistance to magnetization, which aids in heat dissipation. Steel may be used for internal components like the rotor and stator due to its strength and magnetic properties.

During material preparation, suppliers typically conduct a thorough analysis of raw materials to ensure they meet specific standards, such as ASTM or ISO certifications. This includes checking for impurities, mechanical properties, and chemical composition. B2B buyers should inquire about the sourcing of materials and whether suppliers provide certifications that guarantee material quality.

Forming: What Techniques Are Used to Shape Alternator Parts?

Once materials are prepared, the next stage is forming, where raw materials are shaped into the required components. This can include processes such as casting, machining, and stamping.

-

Fundición: For complex shapes like the alternator housing, aluminum casting techniques such as die casting or sand casting are commonly employed. This process allows for intricate designs while maintaining structural integrity.

-

Mecanizado: Components like the rotor and stator may require precision machining to achieve the necessary tolerances. CNC (Computer Numerical Control) machining is often used to ensure high accuracy and repeatability.

-

Estampado: For flat components like covers and brackets, stamping is a cost-effective method that allows for high-volume production with minimal waste.

B2B buyers should assess the forming techniques used by suppliers and their capabilities for producing high-precision parts.

Assembly: How Are Alternator Components Assembled for Optimal Performance?

The assembly stage involves bringing together all the individual components, such as the rotor, stator, diode rectifier, voltage regulator, and cooling fans. This step requires meticulous attention to detail, as proper assembly is crucial for functionality.

Automated assembly lines are often utilized for consistency and efficiency. Key processes in this stage include:

- Alignment: Ensuring that the rotor and stator are properly aligned is essential for effective power generation.

- Connections: Electrical connections, including slip rings and brushes, must be securely attached to facilitate the transfer of current.

- Controles de calidad: Throughout the assembly process, quality checkpoints are established to identify any defects early on.

B2B buyers should inquire about the assembly techniques used and whether suppliers employ automated systems for enhanced precision.

Finishing: What Finishing Techniques Ensure Component Longevity?

After assembly, finishing processes are employed to enhance the durability and aesthetics of alternator parts. Common finishing techniques include:

- Anodizado: Often applied to aluminum housings, anodizing creates a protective layer that enhances corrosion resistance and improves heat dissipation.

- Powder Coating: This process provides a durable finish that can withstand harsh environmental conditions.

- Tratamiento superficial: Components may undergo surface treatments to improve wear resistance and reduce friction.

These finishing techniques contribute to the longevity of the alternator and ensure its performance in various operating conditions.

What Quality Assurance Measures Are Essential for Alternator Parts?

Quality assurance (QA) is a critical aspect of manufacturing alternator parts, ensuring that each component meets international standards and customer specifications.

¿Qué normas internacionales deben conocer los compradores B2B?

Manufacturers of alternator parts often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with this standard indicates a commitment to continual improvement and customer satisfaction.

In addition to ISO standards, specific industry certifications may be relevant, such as CE marking for products sold in Europe, ensuring they meet safety and environmental requirements. For B2B buyers, verifying a supplier’s compliance with these standards is crucial for mitigating risks associated with product quality.

Illustrative image related to parts of a alternator

What Are the Critical Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that products meet established specifications. Key QC checkpoints include:

- Control de calidad de entrada (IQC): Raw materials are inspected upon arrival to ensure they meet quality specifications.

- Control de calidad durante el proceso (IPQC): Regular inspections are conducted during manufacturing to identify defects early in the process.

- Control de calidad final (FQC): The finished products undergo thorough testing and inspection to ensure they meet all performance and safety standards before shipment.

B2B buyers should request information on the QC processes utilized by suppliers and the frequency of these inspections.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

B2B buyers can employ several strategies to verify a supplier’s quality control measures:

-

Auditorías: Conducting on-site audits of the manufacturing facility can provide insights into the supplier’s processes, equipment, and adherence to quality standards.

-

Informes de calidad: Requesting detailed quality reports and documentation from the supplier can help assess their compliance with established standards.

-

Inspecciones por terceros: Engaging independent third-party inspection services can provide unbiased verification of the supplier’s quality practices and product performance.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. These nuances may include:

-

Cumplimiento normativo: Different regions have varying regulatory requirements for automotive components. Buyers should familiarize themselves with local regulations to ensure that the products meet necessary legal standards.

-

Factores culturales: Differences in manufacturing practices and quality expectations can vary by region. Establishing clear communication with suppliers about quality standards and expectations is crucial.

-

Logística y cadena de suministro: International shipping may introduce risks related to product handling and transportation. Buyers should work with suppliers that have robust logistics and quality assurance processes in place to mitigate these risks.

By understanding these aspects of manufacturing processes and quality assurance for alternator parts, B2B buyers can make informed decisions and select reliable suppliers that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a alternator’

In the competitive landscape of automotive components, sourcing the right parts for alternators is critical for ensuring quality and reliability. This guide provides a structured approach for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to effectively procure alternator parts. By following this checklist, you can enhance your procurement strategy and mitigate risks associated with quality and supply chain issues.

Paso 1: Defina sus especificaciones técnicas

Before initiating the sourcing process, clearly outline the technical specifications for the alternator parts you require. Consider factors such as size, material composition, and performance standards. This clarity will guide your supplier selection and ensure compatibility with existing systems.

- Consideraciones clave:

- Identify specific part numbers or standards (e.g., ISO, SAE).

- Determine whether parts need to meet regional compliance standards.

Paso 2: Buscar proveedores fiables

Conduct thorough research to identify potential suppliers who specialize in alternator parts. Use industry networks, trade shows, and online platforms to compile a list of reputable vendors.

- Tips for Research:

- Look for suppliers with a proven track record in the automotive sector.

- Check for online reviews and ratings from other B2B buyers.

Paso 3: Evaluar las certificaciones de los proveedores

Before finalizing any supplier, verify their certifications and compliance with international quality standards. This step is essential to ensure that the parts meet necessary safety and performance criteria.

- Certificaciones importantes:

- ISO 9001 para la gestión de la calidad.

- ISO/TS 16949 for automotive quality systems.

Paso 4: Solicitar muestras para pruebas

Once you have shortlisted suppliers, request samples of the alternator parts for testing. This hands-on evaluation allows you to assess the quality, fit, and performance of the components before placing larger orders.

- Áreas de interés de las pruebas:

- Material durability and resistance to heat.

- Electrical efficiency and performance under load.

Paso 5: Compare precios y condiciones

Gather pricing information from multiple suppliers and compare their terms, including payment options, lead times, and shipping costs. A detailed comparison will help you make an informed decision while optimizing your budget.

- Consideraciones:

- Look for volume discounts or long-term partnership incentives.

- Assess the total cost of ownership, including potential maintenance or warranty services.

Paso 6: Assess Supply Chain Stability

Evaluate the supplier’s supply chain capabilities to ensure they can consistently deliver parts on time. Stability in logistics is crucial to avoid disruptions in your operations.

- Preguntas clave:

- What is their track record for on-time deliveries?

- Do they have contingency plans for supply chain disruptions?

Paso 7: Establecer un plan de comunicación

Finally, establish a clear communication plan with your chosen supplier. This includes setting expectations for regular updates on order status, changes in availability, and any potential issues that may arise.

- Communication Tips:

- Use project management tools for tracking orders.

- Schedule regular check-ins to maintain alignment and address concerns proactively.

By following this structured checklist, B2B buyers can enhance their sourcing strategies for alternator parts, ensuring they partner with reliable suppliers who meet their specific requirements.

Comprehensive Cost and Pricing Analysis for parts of a alternator Sourcing

What Are the Key Cost Components for Alternator Parts Sourcing?

When sourcing parts for an alternator, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materiales: The choice of materials significantly impacts costs. For example, aluminum is commonly used for the housing due to its lightweight properties and heat dissipation capabilities. The rotor and stator require high-quality steel or specialized alloys to ensure durability and performance.

-

Trabajo: Labor costs can vary based on the region and the complexity of the manufacturing process. Skilled labor is essential for assembling sensitive components like the voltage regulator and rectifier, which require precision.

-

Gastos generales de fabricación: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, impacting overall pricing.

-

Herramientas: Custom tooling for specific alternator parts can represent a significant upfront investment. For high-volume orders, this cost can be amortized over time, but for smaller orders, it can considerably inflate the unit price.

-

Control de calidad (QC): Implementing rigorous QC processes ensures that components meet required specifications and certifications, which can influence costs. Investing in quality assurance can prevent costly recalls and enhance customer satisfaction.

-

Logística: Transportation costs vary based on the distance and mode of shipping. International buyers should consider freight charges, customs duties, and insurance, which can add to the total cost.

-

Margen: Suppliers typically include a margin to ensure profitability. Understanding the market dynamics and competitive pricing can help buyers negotiate better deals.

How Do Price Influencers Affect Alternator Parts Costs?

Several factors influence the pricing of alternator parts, including:

-

Volumen/Cantidad mínima de pedido: Bulk purchases generally lower the per-unit cost. Establishing a Minimum Order Quantity (MOQ) with suppliers can help achieve better pricing.

-

Especificaciones y personalización: Custom parts may incur additional costs due to specialized tooling or materials. Clear specifications can help suppliers provide accurate quotes.

-

Materiales: The quality and type of materials used can greatly affect pricing. For instance, higher-grade materials may lead to longer-lasting components but will also increase initial costs.

-

Certificaciones de calidad: Components that meet international quality standards may command higher prices but offer better reliability, which is crucial for automotive applications.

-

Factores relacionados con los proveedores: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers may offer lower prices to gain market entry.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can affect the total landed cost.

What Are the Best Buyer Tips for Cost-Efficiency in Alternator Parts Sourcing?

To enhance cost-efficiency when sourcing alternator parts, consider the following strategies:

-

Negociar con eficacia: Always negotiate terms with suppliers. Leverage volume commitments to secure lower prices and favorable payment terms.

-

Evaluar el coste total de propiedad (TCO): Consider not just the purchase price but also the long-term costs associated with performance, maintenance, and durability of the parts. Investing in higher-quality components may reduce future costs related to failures or replacements.

-

Be Aware of Pricing Nuances for International Buyers: Different regions may have varying market dynamics, currency fluctuations, and trade regulations. For instance, buyers in Africa and South America may face higher logistics costs compared to European buyers.

-

Establecer relaciones con los proveedores: Establishing long-term relationships can lead to better pricing and priority service. Suppliers often value repeat business and may offer discounts or incentives.

-

Manténgase informado sobre las tendencias del mercado: Keeping abreast of trends in material costs, manufacturing technologies, and regulatory changes can provide insights that may help in negotiation and sourcing decisions.

Understanding these cost components, pricing influencers, and strategic tips can empower B2B buyers to make informed decisions while sourcing alternator parts effectively.

Alternatives Analysis: Comparing parts of a alternator With Other Solutions

Understanding Alternatives to Parts of an Alternator

In the automotive and industrial sectors, the efficiency and reliability of power generation systems are crucial. While traditional alternators play a significant role in converting mechanical energy into electrical energy, there are several alternative solutions that can achieve similar objectives. This section explores these alternatives, providing B2B buyers with valuable insights into their performance, cost, and suitability for various applications.

Comparison Table of Alternator Parts and Alternatives

| Aspecto comparativo | Parts of an Alternator | Sistema de gestión de baterías (BMS) | Tecnología de pilas de combustible |

|---|---|---|---|

| Rendimiento | High efficiency in energy conversion; reliable for automotive use | Monitors battery health, optimizes performance | Converts hydrogen to electricity; high efficiency |

| Coste | Moderate initial cost; long-term savings on battery life | Variable cost based on complexity; can be high for advanced systems | High initial investment; lower operational costs over time |

| Facilidad de implementación | Straightforward installation in vehicles; requires mechanical expertise | Installation can be complex; requires integration with existing systems | Complex setup; requires specific infrastructure for hydrogen |

| Mantenimiento | Regular maintenance needed; replacement parts readily available | Low maintenance; periodic software updates may be required | Requires specialized maintenance; hydrogen storage safety considerations |

| Mejor caso de uso | Ideal for conventional vehicles and machinery | Best for electric vehicles and renewable energy storage | Suitable for applications requiring clean energy and long run times |

Desglose detallado de las alternativas

Sistema de gestión de baterías (BMS)

A BMS is designed to monitor and manage battery performance in electric vehicles (EVs) and renewable energy systems. It optimizes charging cycles, ensuring battery longevity and safety. The advantages of a BMS include its ability to extend battery life and improve performance metrics. However, the complexity of installation and potential costs can be significant, especially for advanced systems that require integration with existing vehicle architectures.

Illustrative image related to parts of a alternator

Tecnología de pilas de combustible

Fuel cells convert hydrogen into electricity through a chemical reaction, producing only water as a byproduct. This technology is gaining traction in the automotive sector, particularly for heavy-duty applications and longer-range vehicles. While fuel cells offer high efficiency and clean energy, their initial investment can be steep, and the required infrastructure for hydrogen production and storage can be a barrier for widespread adoption. Maintenance is also specialized and may deter some users.

Conclusión: Cómo elegir la solución adecuada para sus necesidades

When evaluating whether to invest in traditional alternator parts or explore alternatives like BMS or fuel cell technology, B2B buyers must consider their specific operational needs, budget constraints, and long-term goals. For conventional applications where reliability and cost-effectiveness are paramount, traditional alternators remain a strong choice. Conversely, for businesses focused on sustainability or transitioning to electric vehicles, investing in a BMS or fuel cell technology may offer significant long-term benefits. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their operational objectives and market demands.

Essential Technical Properties and Trade Terminology for parts of a alternator

¿Cuáles son las principales características técnicas de las piezas del alternador?

Understanding the technical properties of alternator components is crucial for B2B buyers aiming to procure reliable and efficient parts. Here are some essential specifications that impact performance and durability:

-

Grado del material

– Definición: The quality of materials used in the alternator, such as aluminum for the housing and copper for windings.

– Importancia: High-grade materials enhance durability, heat dissipation, and electrical conductivity, which are vital for longevity and performance. For instance, aluminum’s lightweight nature reduces overall weight while maintaining strength, which is critical for automotive applications. -

Niveles de tolerancia

– Definición: The allowable deviation from a specified measurement in the dimensions of components such as the rotor and stator.

– Importancia: Tight tolerance levels ensure that parts fit together correctly, minimizing wear and maximizing efficiency. In the alternator, precise tolerances between the rotor and stator prevent friction and overheating, which can lead to premature failure. -

Clasificación actual

– Definición: The maximum amount of electrical current an alternator can handle, typically measured in amperes (A).

– Importancia: Understanding the current rating is essential for matching the alternator with the vehicle’s electrical system. A higher current rating indicates the alternator can support more electrical accessories, which is particularly important in regions with higher demands for electronics. -

Eficiencia de refrigeración

– Definición: The ability of the alternator to dissipate heat generated during operation, often enhanced by internal fans or vent designs.

– Importancia: Effective cooling is critical for maintaining performance and preventing overheating. For B2B buyers, selecting alternators with superior cooling designs can lead to lower maintenance costs and increased reliability in various climates. -

Voltage Regulation Range

– Definición: The span of voltage levels that an alternator can maintain while supplying power to the electrical system.

– Importancia: A reliable voltage regulation range ensures that electronic components receive stable power, reducing the risk of damage due to voltage spikes. This is particularly vital for vehicles operating in diverse environments, where electrical demands may fluctuate.

¿Cuáles son los términos comerciales habituales en el sector de los alternadores?

Familiarity with industry jargon can facilitate smoother transactions and negotiations in the alternator market. Here are some essential trade terms:

-

OEM (fabricante de equipos originales)

– Definición: A company that produces parts that are used in the manufacturing of a vehicle and are often sold under the vehicle manufacturer’s brand.

– Relevancia: Understanding whether parts are OEM can affect purchasing decisions, as OEM parts are typically seen as more reliable and compatible with specific vehicle models. -

MOQ (cantidad mínima de pedido)

– Definición: Cantidad mínima de un producto que un proveedor está dispuesto a vender.

– Relevancia: Knowing the MOQ is crucial for budgeting and inventory management. B2B buyers should assess their demand to ensure they can meet the supplier’s MOQ without overcommitting. -

RFQ (Solicitud de presupuesto)

– Definición: A document issued by a buyer to solicit price offers from suppliers for specific products or services.

– Relevancia: RFQs are vital for price comparison and ensuring that buyers receive competitive offers. A well-prepared RFQ can streamline the procurement process. -

Incoterms (Términos comerciales internacionales)

– Definición: A series of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international trade.

– Relevancia: Familiarity with Incoterms is essential for understanding shipping costs, insurance, and liability, which can significantly impact the total cost of procurement. -

Plazo de entrega

– Definición: The time required to fulfill an order from the moment it is placed until it is delivered.

– Relevancia: Understanding lead times helps businesses plan their inventory and manage production schedules effectively, ensuring that they do not face delays in operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternator parts, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the parts of a alternator Sector

What Are the Key Market Drivers and Trends in the Alternator Parts Sector?

The global alternator parts market is driven by several factors, including the increasing demand for automotive components, the rise in electric vehicles (EVs), and advancements in manufacturing technologies. The automotive industry is witnessing a shift towards more energy-efficient and high-performance components, which is leading to a surge in the demand for quality alternator parts. This trend is particularly evident in regions such as Africa and South America, where expanding automotive markets necessitate reliable and efficient electrical systems.

Emerging B2B technologies, such as 3D printing and IoT-enabled manufacturing, are revolutionizing the way alternator parts are produced and sourced. These technologies enhance customization and reduce lead times, making it easier for international buyers to procure high-quality components tailored to their specific needs. Additionally, suppliers are increasingly adopting digital platforms for sourcing, which streamline the procurement process and improve transparency.

Market dynamics are also influenced by fluctuating raw material prices and geopolitical factors that affect supply chains. For instance, the ongoing global supply chain disruptions have prompted buyers in Europe and the Middle East to reassess their sourcing strategies, focusing on local suppliers to mitigate risks. As a result, B2B buyers are seeking partnerships with manufacturers who can offer not only quality but also reliability and flexibility in their operations.

How Can Sustainability and Ethical Sourcing Impact the Alternator Parts Industry?

The environmental impact of automotive components, including alternator parts, is a growing concern among B2B buyers. The industry is under pressure to adopt sustainable practices, such as reducing carbon footprints and minimizing waste during production. Ethical sourcing has become a priority, with buyers increasingly seeking suppliers who can demonstrate compliance with environmental regulations and ethical labor practices.

Illustrative image related to parts of a alternator

The use of ‘green’ materials in the manufacturing of alternator parts, such as recycled metals and eco-friendly coatings, is gaining traction. Certifications like ISO 14001 and RoHS compliance are becoming important criteria for B2B buyers when selecting suppliers. These certifications not only ensure that products meet environmental standards but also enhance the credibility of suppliers in a competitive marketplace.

Additionally, companies that prioritize sustainability often report enhanced brand loyalty and customer satisfaction, which can lead to increased market share. B2B buyers are encouraged to engage with suppliers who are committed to ethical sourcing and sustainability, as these partnerships can contribute to a positive corporate image and long-term viability in the market.

How Has the Alternator Parts Sector Evolved Over Time?

The alternator parts sector has seen significant evolution since the introduction of the first automotive alternators in the early 20th century. Initially, these components were relatively simple and primarily used in combustion engine vehicles. Over the decades, advancements in technology have led to the development of more complex and efficient alternators, including those that support hybrid and electric vehicles.

The transition from mechanical generators to modern electronic alternators has revolutionized the industry, allowing for greater efficiency and reliability. As automotive technology continues to advance, the alternator parts sector is expected to further innovate, focusing on lightweight materials and smart technologies that enhance performance. This evolution presents opportunities for international B2B buyers to source cutting-edge components that meet the demands of modern vehicles, ensuring they remain competitive in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of a alternator

-

How do I solve issues with alternator parts sourcing?

To address challenges in sourcing alternator parts, start by identifying reliable suppliers with a proven track record in international trade. Utilize platforms that specialize in B2B transactions, and consider suppliers with certifications like ISO for quality assurance. Establish clear communication regarding specifications, lead times, and shipping logistics. If problems arise, maintain open lines of communication with the supplier to resolve issues promptly, and consider building relationships with multiple suppliers to mitigate risks. -

What is the best alternator part for enhancing vehicle performance?

The best alternator part for enhancing vehicle performance is often the voltage regulator. A high-quality voltage regulator ensures a consistent voltage supply, preventing voltage spikes that can damage electronic components. Additionally, a robust rectifier is crucial for converting AC to DC efficiently. When selecting parts, consider those that are compatible with your vehicle’s specifications and have been tested for performance under various conditions to guarantee reliability. -

What should I look for when vetting alternator parts suppliers?

When vetting alternator parts suppliers, assess their industry experience, customer reviews, and the range of products offered. Confirm their compliance with international quality standards, such as ISO certification. Request samples to evaluate the quality of the parts before making bulk orders. Additionally, inquire about their production capabilities, lead times, and after-sales support to ensure they can meet your business needs effectively. -

What are common minimum order quantities (MOQs) for alternator parts?

Minimum order quantities (MOQs) for alternator parts can vary significantly based on the supplier and the specific components. Typically, MOQs may range from 50 to 500 units, depending on the part’s complexity and manufacturing processes. It’s advisable to discuss your requirements directly with suppliers to negotiate MOQs that align with your business needs while considering potential cost savings for larger orders. -

How can I customize alternator parts for specific applications?

To customize alternator parts for specific applications, communicate your requirements clearly to the supplier. Provide detailed specifications, including dimensions, material preferences, and performance criteria. Many suppliers offer customization options, including alterations in design or materials. Ensure you discuss lead times and additional costs associated with customization to make informed decisions that fit your project timeline and budget. -

What payment terms should I expect when purchasing alternator parts internationally?

Payment terms for international purchases of alternator parts typically vary by supplier but often include options such as advance payment, letter of credit, or payment upon delivery. It’s crucial to discuss and agree on terms that offer both security and flexibility. Consider using escrow services for larger transactions to protect both parties until the goods are received and verified. -

What quality assurance measures should I implement when sourcing alternator parts?

Implementing quality assurance measures involves establishing clear criteria for part specifications and performance. Request certifications and test reports from suppliers to verify compliance with international standards. Consider conducting pre-shipment inspections to ensure parts meet your quality expectations. Additionally, establish a return policy for defective items to safeguard your business against potential losses. -

What logistics considerations are important for importing alternator parts?

When importing alternator parts, logistics considerations include selecting reliable shipping methods that balance cost and delivery time. Understand the customs regulations and import duties applicable to your region to avoid unexpected expenses. Collaborate with logistics providers familiar with the automotive parts industry to ensure efficient handling and transport. Lastly, maintain clear communication with your supplier regarding shipping timelines to manage inventory effectively.

Top 5 Parts Of A Alternator Manufacturers & Suppliers List

1. HowStuffWorks - Alternadores

Dominio: auto.cómofuncionanlascosas.com

Registrado: 1998 (27 años)

Introducción: Los alternadores son pequeños y ligeros, aproximadamente del tamaño de un coco, y están fabricados con una carcasa exterior de aluminio para la disipación del calor. Los componentes clave incluyen:

– Polea motriz acoplada al eje del rotor, que convierte la energía mecánica en energía eléctrica.

– Terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (closes circuit to warning lamp…

2. Electude – Automotive Alternators

Dominio: electude.com

Registrado: 2005 (20 años)

Introducción: El alternador es un componente fundamental del automóvil que convierte la energía mecánica en energía eléctrica, generando energía para los consumidores eléctricos y la batería del vehículo. Entre sus componentes principales se incluyen:

– Polea: Transfiere la energía mecánica del motor al alternador.

– Rotor: crea el campo magnético para generar corriente alterna.

– Stator: The static part where voltage is generat…

3. AutoElectro – Alternators

Dominio: autoelectro.es

Registrado: 1999 (26 años)

Introducción: Alternators generate energy to feed the electrical system and charge the battery in a vehicle. They convert alternating current (AC) to direct current (DC) through a rectifier. Key components include: 1. Regulator – controls power distribution to the battery. 2. Rectifier – converts AC to DC. 3. Rotor – spinning mass acting as an electromagnet. 4. Slip Rings – provide direct current to the rotor. …

4. Bermantec – Alternator Components

Dominio: bermantec.com

Registered: 2018 (7 years)

Introducción: Parts of the alternator include:

1. Rotor – A rotating magnetic field that spins and creates electromagnetic flow.

2. Stator – The static part that consists of an outer frame, stator core, and stator winding, generating alternating current.

3. Rectifier – Converts AC to DC with diodes, available in positive and negative polarity variants.

4. Voltage Regulator – Maintains voltage between 13.5 a…

5. Facebook – Parts of Alternator

Strategic Sourcing Conclusion and Outlook for parts of a alternator

In conclusion, strategic sourcing for alternator components presents a significant opportunity for international B2B buyers to enhance operational efficiency and product reliability. Understanding the intricate roles of parts such as the rotor, stator, rectifier, and voltage regulator is essential for making informed procurement decisions. Sourcing high-quality components not only improves the longevity and performance of alternators but also ensures compliance with regional standards and reduces downtime in automotive applications.

As buyers in Africa, South America, the Middle East, and Europe navigate a competitive market, leveraging strategic sourcing practices can lead to cost savings and stronger supplier relationships. Engaging with trusted manufacturers and suppliers who prioritize innovation and quality is critical to staying ahead in this evolving industry landscape.

Looking forward, now is the time to evaluate your sourcing strategies and consider partnerships that align with your long-term goals. Embrace the advancements in alternator technology and sourcing methodologies to maximize your operational potential and drive growth in your business.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.