Introducción: Navegando por el mercado mundial del relé de arranque frente al relé de arranque

En el complejo mundo de los componentes de automoción, entender las diferencias entre un motor de arranque y un relé de arranque es crucial para los compradores B2B que buscan optimizar sus estrategias de aprovisionamiento. Esta guía aborda el reto de abastecerse de sistemas de arranque fiables y sus relés asociados, que son esenciales para el rendimiento y la fiabilidad del vehículo. Con la rápida evolución de la industria de la automoción, especialmente en regiones como África, Sudamérica, Oriente Medio y Europa, es vital que los compradores internacionales comprendan los matices de estos componentes para tomar decisiones de compra informadas.

Esta completa guía profundiza en los distintos tipos de arrancadores y relés, sus aplicaciones específicas y las diferencias críticas que los distinguen. Exploraremos los procesos de selección de proveedores, garantizando que los compradores puedan identificar a los fabricantes de confianza capaces de suministrar productos de alta calidad. Además, ofreceremos información sobre estructuras de precios y consideraciones de costes, lo que permitirá a las empresas presupuestar con eficacia y maximizar el retorno de la inversión.

Al proporcionar a los compradores B2B conocimientos detallados y perspectivas prácticas, esta guía constituye un valioso recurso para las empresas que navegan por el mercado mundial. Tanto si tiene su sede en Nigeria como en Alemania, comprender los entresijos de los arrancadores y relés mejorará su estrategia de compras y garantizará que sus operaciones se desarrollen con fluidez y eficiencia.

Índice

- Lista de los 4 mejores fabricantes y proveedores de Relé de arranque vs relé de arranque

- Introducción: Navegando por el mercado mundial del relé de arranque frente al relé de arranque

- Tipos y variaciones del relé de arranque y el relé de arranque

- Principales aplicaciones industriales del arrancador frente al relé de arranque

- 3 puntos de fricción habituales entre ‘relé de arranque’ y "relé de arranque" y sus soluciones

- Guía estratégica de selección de materiales para el relé de arranque frente al relé de arranque

- Mirada en profundidad: Procesos de fabricación y garantía de calidad del relé de arranque frente al relé de arranque

- Guía práctica de búsqueda: Una lista de comprobación paso a paso para ‘arranque vs relé de arranque’

- Análisis exhaustivo de costes y precios de los relés de arranque y arranque Sourcing

- Análisis de alternativas: Comparación de relé de arranque vs relé de arranque con otras soluciones

- Propiedades técnicas esenciales y terminología comercial del arrancador frente al relé de arranque

- Dinámica del mercado y tendencias de aprovisionamiento en el sector de los relés de arranque vs. arranque

- Preguntas frecuentes (FAQ) para compradores B2B de relé de arranque frente a relé de arranque

- Conclusión y perspectivas de Strategic Sourcing para el relé de arranque frente al relé de arranque

- Aviso legal importante y condiciones de uso

Tipos y variaciones del relé de arranque y el relé de arranque

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Relé electromecánico | Utiliza bobinas electromagnéticas para controlar circuitos de alta potencia. | Automoción, maquinaria industrial | Ventajas: Rentable y fiable. Contras: Tiempo de respuesta más lento que las opciones de estado sólido. |

| Relé de estado sólido | Utiliza dispositivos semiconductores que ofrecen una conmutación más rápida. | Sistemas de automatización, sistemas HVAC | Ventajas: Más rápido, duradero, sin piezas móviles. Contras: Mayor coste inicial. |

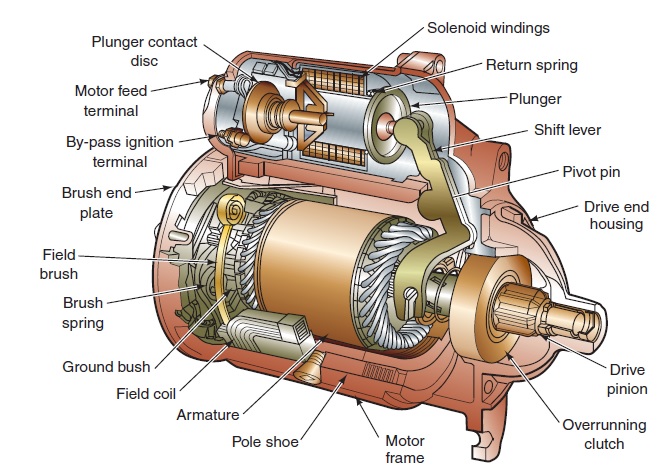

| Solenoide de arranque | Directamente acoplado al motor de arranque, engrana alta corriente. | Aplicaciones de automoción | Ventajas: Alta capacidad de corriente, compacta. Contras: Vida útil limitada, a menudo requiere la sustitución completa del motor de arranque. |

| Relé de arranque remoto | Funciona a distancia, a menudo integrado con el acceso sin llave. | Posventa de automóviles, vehículos de flota | Ventajas: Comodidad, mejora de la seguridad. Contras: Posibles problemas de compatibilidad. |

| Relé de doble función | Combina las funciones del relé de arranque y el solenoide. | Sistemas avanzados de automoción | Ventajas: Ahorro de espacio, multifuncional. Contras: La complejidad puede dar lugar a mayores tasas de fracaso. |

¿Qué características tienen los relés electromecánicos?

Los relés electromecánicos son dispositivos tradicionales que utilizan bobinas electromagnéticas para controlar circuitos. Se utilizan mucho en maquinaria industrial y de automoción por su fiabilidad y rentabilidad. A la hora de comprarlos, los compradores B2B deben tener en cuenta la tensión nominal y la capacidad de conmutación del relé, para asegurarse de que se ajusta a sus requisitos operativos. Aunque estos relés suelen ser robustos, su tiempo de respuesta más lento en comparación con las opciones de estado sólido puede ser un inconveniente en aplicaciones que requieren un accionamiento rápido.

¿En qué se diferencian los relés de estado sólido?

Los relés de estado sólido (SSR) utilizan dispositivos semiconductores para conmutar circuitos, proporcionando tiempos de respuesta más rápidos y una vida útil más larga que sus homólogos electromecánicos. Los SSR, habituales en sistemas de automatización y aplicaciones de calefacción, ventilación y aire acondicionado, son ideales para entornos en los que la durabilidad es esencial. Los compradores deben evaluar la capacidad de disipación térmica del relé y las especificaciones de entrada/salida para garantizar la compatibilidad con sus sistemas. Aunque la inversión inicial es mayor, la fiabilidad a largo plazo puede justificar el coste.

¿Qué papel desempeñan los solenoides de arranque en las aplicaciones de automoción?

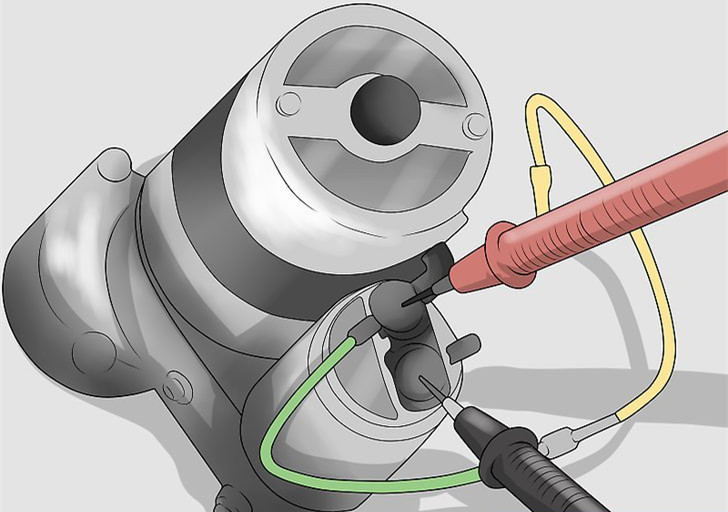

Los solenoides de arranque son componentes críticos en los sistemas de automoción, directamente conectados al motor de arranque. Conectan una corriente elevada para iniciar el arranque del motor, lo que los hace indispensables en las aplicaciones de automoción. Al considerar su compra, los compradores B2B deben evaluar la capacidad de corriente del solenoide y su compatibilidad con modelos específicos de motores de arranque. Aunque son compactos y potentes, los solenoides tienen una vida útil limitada y pueden requerir la sustitución completa del motor de arranque si fallan, lo que podría aumentar los costes de mantenimiento.

¿Cómo mejoran los relés de arranque a distancia la funcionalidad del vehículo?

Los relés de arranque remoto permiten encender el vehículo a distancia, a menudo integrados con sistemas de acceso sin llave. Resultan especialmente beneficiosos en aplicaciones de posventa de automoción y vehículos de flota, ya que mejoran la comodidad y la seguridad de los usuarios. Los compradores B2B deben asegurarse de la compatibilidad con los sistemas existentes en el vehículo y tener en cuenta la gama y las características del relé. Aunque ofrecen importantes ventajas, pueden surgir problemas de compatibilidad, por lo que es necesario investigar a fondo antes de comprarlos.

¿Qué ventajas ofrecen los relés de doble función?

Los relés de doble función combinan las características de los relés de arranque y los solenoides, proporcionando una solución que ahorra espacio para los sistemas avanzados de automoción. Estos relés son ventajosos en vehículos modernos en los que el espacio y el peso son factores críticos. Al evaluar los relés de doble función, los compradores deben tener en cuenta la complejidad de la instalación y las posibles tasas de fallo, ya que la naturaleza multifuncional puede conllevar mayores riesgos. A pesar de estas preocupaciones, su versatilidad los convierte en una opción convincente para aplicaciones de automoción sofisticadas.

Principales aplicaciones industriales del arrancador frente al relé de arranque

| Industria/Sector | Aplicación específica del arrancador frente al relé de arranque | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Fabricación de automóviles | Sistemas de arranque del motor | Garantiza un encendido fiable del motor, reduciendo el tiempo de inactividad. | Compatibilidad con varios modelos de vehículos y potencias. |

| Maquinaria pesada | Puesta en marcha de maquinaria de construcción | Proporciona una gestión robusta de la energía para operaciones de alta resistencia. | Durabilidad en condiciones extremas y altas intensidades de corriente. |

| Agricultura | Tractores y maquinaria agrícola | Mejora la eficacia operativa al garantizar arranques fiables. | Resistencia al polvo y la humedad, junto con los requisitos de tensión. |

| Industria naval | Sistemas de encendido de motores de barcos | Garantiza un arranque fiable del motor para la disponibilidad operativa. | Resistencia a la corrosión y compatibilidad con entornos marinos. |

| Energía renovable | Sistemas de arranque de aerogeneradores | Facilita un arranque fiable en condiciones meteorológicas variables. | Abastecerse de proveedores expertos en aplicaciones de energías renovables. |

¿Cómo se utilizan los arrancadores y los relés de arranque en la fabricación de automóviles?

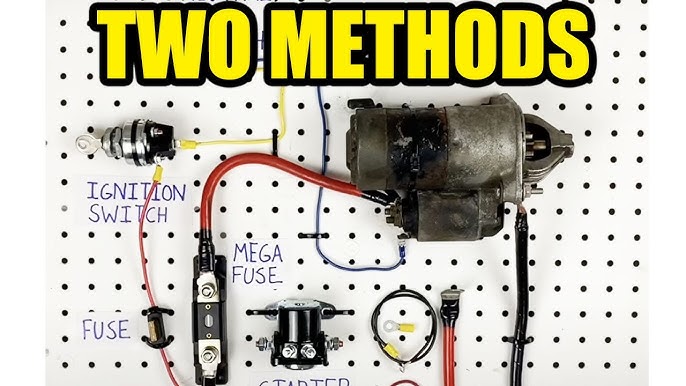

En la fabricación de automóviles, los arrancadores y los relés de arranque forman parte integral de los sistemas de arranque del motor. Permiten que una señal de baja potencia procedente del interruptor de encendido active el motor de arranque de alta potencia, garantizando un encendido fiable del motor. Esta fiabilidad minimiza el tiempo de inactividad durante la producción y mejora la eficiencia general. Los compradores de este sector deben tener en cuenta la compatibilidad con diversos modelos de vehículos, las potencias nominales y la posible necesidad de personalización en función de tipos de motor específicos.

¿Qué papel desempeñan los arrancadores y los relés de arranque en la maquinaria pesada?

En el sector de la maquinaria pesada, los arrancadores y relés de arranque son esenciales para el funcionamiento de los equipos de construcción. Estos componentes gestionan la elevada potencia necesaria para arrancar motores de gran tamaño, garantizando un rendimiento constante incluso en condiciones extenuantes. Las empresas se benefician de la reducción de las interrupciones operativas y la mejora de la productividad. A la hora de adquirir estos componentes, la durabilidad, la alta intensidad nominal y la capacidad de soportar condiciones ambientales extremas son consideraciones fundamentales.

¿Cómo se utilizan los arrancadores y los relés de arranque en la agricultura?

Para aplicaciones agrícolas, los arrancadores y relés de arranque son cruciales en tractores y otros equipos agrícolas. Garantizan que la maquinaria arranque de forma fiable, lo que es vital para mantener la eficacia operativa durante las temporadas de siembra y cosecha. Los compradores deben dar prioridad a componentes que ofrezcan resistencia al polvo, la humedad y otros factores ambientales, además de asegurarse de que los valores nominales de tensión cumplan las especificaciones de los equipos agrícolas modernos.

¿Por qué son importantes los arrancadores y los relés de arranque en la industria naval?

En la industria náutica, los arrancadores y los relés de arranque desempeñan un papel fundamental en los sistemas de encendido de los motores de las embarcaciones. Garantizan un arranque fiable del motor, lo que es crucial para la disponibilidad operativa y la seguridad en el agua. El corrosivo entorno marino exige componentes resistentes al agua salada y otros elementos corrosivos. La compatibilidad con distintos tipos de motor y requisitos de potencia también es esencial para los compradores de este sector.

¿Cómo ayudan los arrancadores y relés de arranque a las aplicaciones de energías renovables?

Los arrancadores y relés de arranque son cada vez más importantes en el sector de las energías renovables, sobre todo en los sistemas de turbinas eólicas. Estos componentes facilitan el arranque fiable de las turbinas, incluso en condiciones meteorológicas adversas. Las empresas se benefician de una mayor fiabilidad y eficiencia operativa, cruciales para maximizar la producción de energía. Los compradores deben centrarse en abastecerse de proveedores con experiencia en aplicaciones de energías renovables, asegurándose de que los componentes cumplen los requisitos operativos específicos y las normas medioambientales.

3 puntos de fricción habituales entre ‘relé de arranque’ y "relé de arranque" y sus soluciones

Escenario 1: Malentendido entre las funciones del arrancador y del relé de arranque

El problema:

Muchos compradores B2B, especialmente los que se dedican al mantenimiento de vehículos o a la gestión de flotas, suelen confundir las funciones de un motor de arranque y un relé de arranque. Este malentendido puede llevar a un diagnóstico erróneo de los problemas del vehículo, lo que da lugar a reparaciones o sustituciones innecesarias. Por ejemplo, una empresa puede sustituir el motor de arranque cuando el problema real radica en un relé defectuoso. Esto no sólo supone una pérdida de tiempo, sino que también aumenta los costes y afecta a la eficacia operativa general.

La solución:

Para superar este reto, es fundamental ofrecer una formación completa a los técnicos y al personal sobre las distintas funciones de los arrancadores y los relés de arranque. Una guía o recurso detallado que explique cómo funciona el sistema de encendido, incluidas las funciones de ambos componentes, puede ser de gran valor. Además, invertir en herramientas de diagnóstico que puedan evaluar con precisión si el problema reside en el motor de arranque o en el relé puede evitar diagnósticos erróneos. Asegúrese de que sus proveedores ofrecen asistencia técnica e información, lo que permitirá a su equipo tomar decisiones informadas basadas en los síntomas específicos observados en el vehículo.

Escenario 2: Dificultad para abastecerse de componentes de calidad para diversos modelos de vehículos

El problema:

Los compradores B2B se enfrentan a menudo al reto de abastecerse de arrancadores y relés de calidad que se adapten a una amplia gama de modelos de vehículos, sobre todo cuando se trata de marcas internacionales. El mercado está inundado de componentes de calidad inferior que pueden no cumplir las normas del sector, lo que provoca averías frecuentes y un aumento de las reclamaciones de garantía. Esto es especialmente preocupante para las empresas que operan en regiones donde el rendimiento del vehículo es crítico, como en África y Sudamérica, donde la fiabilidad puede afectar significativamente a la prestación de servicios.

La solución:

Para solucionar este problema, establezca relaciones sólidas con proveedores de confianza especializados en piezas de automoción de alta calidad. Investigue a fondo a los fabricantes y considere a los que tengan certificaciones como ISO o normas equivalentes. Elabore una lista de comprobación de las especificaciones esenciales de los arrancadores y relés, incluida la compatibilidad con los modelos de vehículos, los índices de durabilidad y las condiciones de garantía. Este enfoque proactivo le garantizará el suministro de componentes fiables, reduciendo así el riesgo de averías y mejorando la fiabilidad general de la flota.

Escenario 3: Problemas de rendimiento intermitentes que provocan tiempos de inactividad

El problema:

Los problemas de funcionamiento intermitente de los motores de arranque o los relés pueden causar importantes tiempos de inactividad a los compradores B2B, en particular a los que gestionan servicios de logística o transporte. Un vehículo que ocasionalmente no arranca puede alterar los horarios y provocar pérdidas de ingresos. Por ejemplo, una empresa de reparto puede encontrarse con sus vehículos varados, lo que provoca retrasos que afectan a la satisfacción del cliente y a los costes operativos.

La solución:

Implemente un programa de mantenimiento preventivo que incluya inspecciones periódicas de los sistemas de arranque y relés. Este programa debe centrarse en comprobar el estado del cableado, las conexiones de la batería y los propios componentes. Además, considere la posibilidad de invertir en herramientas de diagnóstico avanzadas que puedan detectar signos tempranos de avería, lo que permite intervenir a tiempo antes de que se produzca una avería. Formar al personal para que reconozca los síntomas de problemas con el motor de arranque y los relés, como chasquidos o problemas de arranque intermitente, puede ayudarles a abordar posibles averías de forma proactiva. Al priorizar el mantenimiento e invertir en capacidades de diagnóstico, las empresas pueden minimizar el tiempo de inactividad y mejorar la eficiencia operativa.

Guía estratégica de selección de materiales para el relé de arranque frente al relé de arranque

A la hora de seleccionar materiales para arrancadores y relés de arranque, es fundamental conocer las propiedades, ventajas y limitaciones de los materiales más utilizados para garantizar un rendimiento y una longevidad óptimos. Esta guía analiza cuatro materiales empleados con frecuencia en estas aplicaciones: cobre, aluminio, plástico y acero. Las características de cada material ayudarán a los compradores B2B a tomar decisiones informadas basadas en sus necesidades específicas y consideraciones regionales.

¿Cuáles son las principales propiedades del cobre en las aplicaciones de arrancadores y relés de arranque?

El cobre es un metal altamente conductor, lo que lo convierte en la opción preferida para componentes eléctricos como solenoides de arranque y relés. Su excelente conductividad eléctrica garantiza una transferencia de potencia eficaz, lo que es fundamental para arrancar motores. Además, el cobre tiene un alto punto de fusión (aproximadamente 1.984 °F o 1.085 °C) y una buena resistencia a la corrosión, especialmente cuando se alea con otros metales.

Ventajas e inconvenientes del cobre

La durabilidad del cobre es una ventaja significativa, ya que puede soportar altas temperaturas y presiones. Sin embargo, su coste relativamente alto en comparación con otros materiales puede ser un inconveniente para los compradores preocupados por el presupuesto. La complejidad de fabricación es moderada, ya que el cobre puede moldearse y formarse fácilmente en diversos componentes.

Impacto en la aplicación

La compatibilidad del cobre con diversos medios, incluidos los fluidos de automoción, lo hace adecuado para arrancadores y relés. Sin embargo, puede corroerse si se expone a determinadas condiciones ambientales, por lo que necesita revestimientos protectores.

Consideraciones para compradores internacionales

En regiones como África y Sudamérica, donde la humedad y las fluctuaciones de temperatura son habituales, los compradores deben asegurarse de que los componentes de cobre reciben un tratamiento anticorrosión. El cumplimiento de normas internacionales como ASTM B187 es esencial.

¿Cómo se compara el aluminio en aplicaciones de arranque y relés de arranque?

El aluminio es otra opción popular por su ligereza y buena conductividad, aunque inferior a la del cobre. Tiene un punto de fusión de unos 660 °C (1.221 °F) y presenta una excelente resistencia a la corrosión, sobre todo cuando está anodizado.

Ventajas e inconvenientes del aluminio

La propiedad de ligereza del aluminio lo hace ventajoso para aplicaciones en las que la reducción de peso es fundamental. Sin embargo, su menor conductividad en comparación con el cobre puede provocar pérdidas de eficacia en la transferencia de potencia. Los procesos de fabricación del aluminio suelen ser más sencillos, pero hay que tener cuidado para evitar la corrosión galvánica cuando se utiliza con otros metales.

Impacto en la aplicación

La resistencia del aluminio a la corrosión lo hace adecuado para entornos exteriores y de alta humedad. Sin embargo, su menor resistencia en comparación con el cobre puede limitar su uso en aplicaciones de alto par.

Consideraciones para compradores internacionales

El cumplimiento de normas como la DIN EN 573 es crucial para garantizar la calidad. Es posible que los compradores europeos, sobre todo alemanes, prefieran el aluminio por sus propiedades ligeras, especialmente en aplicaciones de automoción.

¿Qué papel desempeña el plástico en las aplicaciones de arrancadores y relés de arranque?

El plástico se utiliza a menudo para las carcasas y aislantes de los relés de arranque debido a sus excelentes propiedades de aislamiento eléctrico. Los plásticos más utilizados son el policarbonato y el nailon, que pueden soportar temperaturas de hasta 149 °C (300 °F).

Ventajas e inconvenientes del plástico

La principal ventaja del plástico es su ligereza y su resistencia a la corrosión. Sin embargo, los plásticos pueden degradarse con el tiempo cuando se exponen a la luz ultravioleta y a altas temperaturas, lo que puede limitar su vida útil en determinadas aplicaciones. La complejidad de fabricación puede variar en función del tipo de plástico utilizado.

Impacto en la aplicación

Los componentes de plástico se utilizan normalmente para piezas que no soportan carga, proporcionando aislamiento y protección. Son compatibles con diversos fluidos de automoción, pero pueden requerir tratamientos adicionales para mejorar la resistencia a los rayos UV.

Consideraciones para compradores internacionales

Los compradores deben asegurarse de que los componentes de plástico cumplen las normas pertinentes, como la JIS K 6768, en materia de durabilidad. En regiones con alta exposición a los rayos UV, puede ser necesario adoptar medidas de protección adicionales.

¿Cómo se comporta el acero en aplicaciones de arranque y relés de arranque?

El acero se utiliza a menudo para componentes estructurales de arrancadores y relés debido a su gran resistencia y durabilidad. Tiene un punto de fusión de unos 1.370 °C (2.500 °F) y puede tratarse para resistir la corrosión.

Ventajas e inconvenientes del acero

La resistencia del acero lo hace adecuado para aplicaciones de alto par, pero es más pesado que el aluminio y puede ser propenso a oxidarse sin un tratamiento adecuado. La complejidad de fabricación es moderada, ya que el acero puede mecanizarse y soldarse fácilmente.

Impacto en la aplicación

La compatibilidad del acero con diversos entornos automovilísticos es generalmente buena, pero requiere revestimientos protectores para evitar la oxidación. Es especialmente adecuado para aplicaciones pesadas en las que la resistencia es primordial.

Consideraciones para compradores internacionales

El cumplimiento de normas como la ASTM A36 es esencial para garantizar la calidad. Los compradores de Oriente Medio, donde las altas temperaturas y la humedad pueden acelerar la corrosión, deben dar prioridad a los componentes de acero tratado.

Tabla resumen

| Material | Caso típico de uso del arrancador frente al relé de arranque | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Cobre | Conexiones eléctricas en solenoides | Excelente conductividad | Coste elevado | Alto |

| Aluminio | Carcasas de relé ligeras | Ligero y resistente a la corrosión. | Conductividad inferior a la del cobre. | Medio |

| Plástico | Aisladores y componentes no portantes | Ligero y resistente a la corrosión. | Degradación UV con el tiempo | Bajo |

| Acero | Componentes estructurales en arrancadores y relés | Alta resistencia y durabilidad | Más pesado y propenso a oxidarse. | Medio |

Este análisis ofrece una visión completa de las opciones de materiales para arrancadores y relés de arranque, lo que permite a los compradores B2B tomar decisiones informadas y adaptadas a sus necesidades operativas específicas y a los requisitos regionales.

Mirada en profundidad: Procesos de fabricación y garantía de calidad del relé de arranque frente al relé de arranque

¿Cuáles son las etapas clave de la fabricación de arrancadores y relés de arranque?

El proceso de fabricación de arrancadores y relés de arranque es complejo e implica varias etapas críticas que garantizan que los productos finales cumplan las normas de rendimiento y durabilidad necesarias. Comprender estas etapas puede ayudar a los compradores B2B a tomar decisiones informadas a la hora de adquirir estos componentes.

1. Preparación del material: ¿Qué materiales se utilizan?

El primer paso en el proceso de fabricación es la preparación del material. Los materiales más comunes para los arrancadores incluyen acero de alta calidad para la carcasa, cobre para los bobinados y diversas aleaciones para los componentes internos. Para los relés de arranque, los materiales suelen incluir plásticos duraderos para la carcasa y metales como el cobre o el aluminio para los contactos. Los proveedores suelen abastecerse de materiales que cumplen las normas internacionales para garantizar la calidad y el rendimiento.

2. Conformado: ¿Cómo se conforman los componentes?

Una vez preparados los materiales, se someten a procesos de conformado. Esta etapa puede implicar técnicas como el estampado, el mecanizado y el moldeado. En el caso de los arrancadores, componentes como el inducido y los devanados de campo se moldean con precisión para garantizar un funcionamiento eficaz. Los relés de arranque suelen requerir el moldeo por inyección para crear sus carcasas de plástico, mientras que los componentes metálicos se estampan o mecanizan según especificaciones exactas. La precisión en esta etapa es crucial, ya que cualquier desviación puede provocar problemas de rendimiento más adelante.

3. Montaje: ¿Qué técnicas de montaje se emplean?

Tras el conformado, la siguiente fase es el montaje. En esta fase se unen los distintos componentes. En el caso de los motores de arranque, se ensamblan el motor, el mecanismo de accionamiento y el solenoide. En el caso de los relés de arranque, el montaje suele incluir la colocación de la bobina, los contactos y la carcasa. Las líneas de montaje automatizadas se utilizan habitualmente para aumentar la eficacia y reducir los errores humanos. Técnicos cualificados suelen supervisar estas líneas para garantizar que cada componente se instala correctamente y cumple las normas de calidad.

4. Acabado: ¿cómo se terminan los productos?

La fase de acabado implica varios procesos diseñados para mejorar la durabilidad y la estética del producto final. Puede incluir tratamientos superficiales como el chapado, la pintura o el revestimiento para proteger contra la corrosión y el desgaste. En el caso de los arrancadores, puede aplicarse un tratamiento térmico para mejorar su resistencia y rendimiento. En el caso de los relés de arranque, las inspecciones finales suelen incluir pruebas de integridad eléctrica y dimensiones físicas.

¿Qué medidas de garantía de calidad se aplican?

El aseguramiento de la calidad (QA) es esencial en todo el proceso de fabricación para garantizar que los arrancadores y relés de arranque cumplen las normas internacionales y las expectativas de los clientes. He aquí un resumen de las principales medidas de aseguramiento de la calidad que deben tener en cuenta los compradores B2B.

Normas internacionales: ¿Qué normas deben buscar los compradores?

Los fabricantes de arrancadores y relés de arranque suelen cumplir normas de calidad internacionales como la ISO 9001, que establece los requisitos de un sistema de gestión de calidad. Además, también pueden aplicarse normas específicas del sector, como el marcado CE en Europa y las normas API para componentes de automoción. Estas certificaciones indican que el fabricante ha establecido procesos para mantener la calidad en toda la producción.

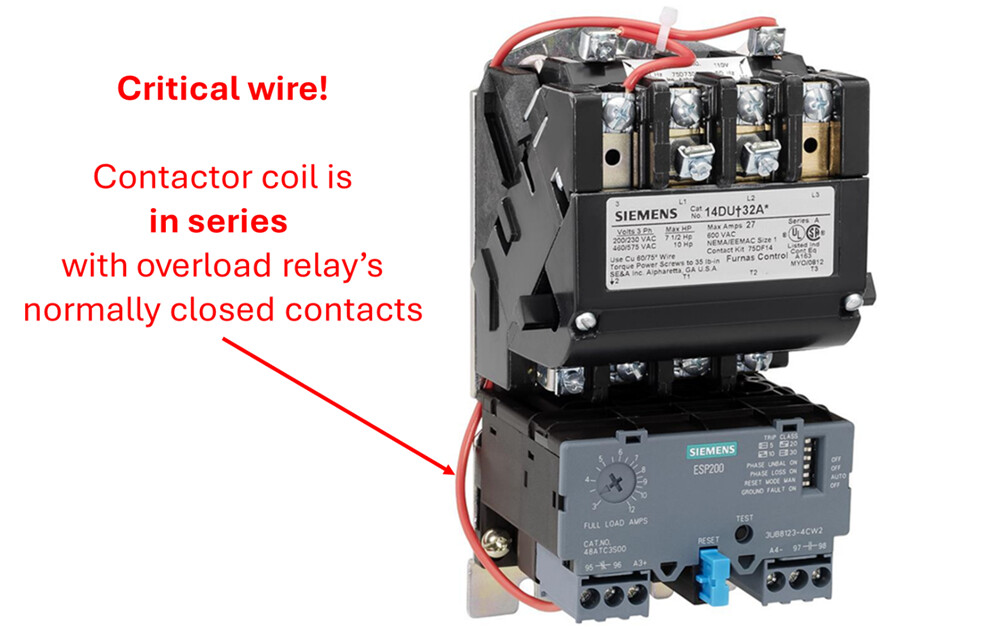

Imagen ilustrativa relacionada con arrancador vs relé de arranque

Puntos de control de calidad: ¿Cuáles son los principales puntos de control de calidad?

Los puntos de control de calidad (CC) se aplican en varias fases del proceso de fabricación. Los puntos de control clave son:

-

Control de calidad de entrada (IQC): Consiste en inspeccionar las materias primas a su llegada para asegurarse de que cumplen los requisitos especificados. Los materiales que no cumplen las normas se rechazan o se vuelven a procesar.

-

Control de calidad durante el proceso (IPQC): La supervisión continua durante la producción ayuda a identificar y rectificar los defectos a tiempo. Esta etapa puede incluir auditorías de procesos y pruebas de componentes en distintas fases de montaje.

-

Control de calidad final (FQC): Inspección minuciosa del producto acabado antes de su envío. Suele incluir pruebas funcionales, pruebas eléctricas e inspecciones visuales para detectar cualquier defecto.

¿Qué métodos de ensayo se utilizan habitualmente en el sector?

Los fabricantes utilizan diversos métodos de ensayo para garantizar la fiabilidad y el rendimiento de los arrancadores y los relés de arranque. Entre los métodos de prueba más comunes se incluyen:

-

Pruebas eléctricas: Verificación de características eléctricas como la resistencia, la continuidad y la funcionalidad en condiciones de carga. Esto es crucial tanto para los arrancadores como para los relés, para garantizar que funcionan eficazmente en condiciones reales.

-

Pruebas mecánicas: Evaluación de la integridad física de los componentes mediante pruebas de tensión, vibración y ciclos térmicos. Estas pruebas ayudan a predecir cómo se comportarán los productos en entornos difíciles.

-

Pruebas de durabilidad: Los productos pueden someterse a pruebas de vida útil acelerada para simular un uso prolongado, lo que garantiza que puedan soportar los rigores de las aplicaciones de automoción.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

Los compradores B2B deben emplear varias estrategias para verificar los procesos de control de calidad de los proveedores potenciales:

-

Auditorías de proveedores: La realización de auditorías in situ de las instalaciones de fabricación puede proporcionar información sobre los sistemas de gestión de la calidad implantados. Los compradores deben evaluar el cumplimiento de las normas internacionales y la limpieza y organización de la zona de producción.

-

Informes de calidad: Solicitar informes detallados de garantía de calidad puede ayudar a los compradores a comprender los procesos de control de calidad del proveedor. Estos informes deben incluir los resultados de las fases de IQC, IPQC y FQC, junto con las medidas correctivas adoptadas en caso de no conformidad.

-

Inspecciones por terceros: Contratar servicios de inspección de terceros puede proporcionar una evaluación imparcial de la calidad del producto y del cumplimiento de las especificaciones. Esto es especialmente útil en las transacciones internacionales, en las que los compradores pueden no tener la posibilidad de inspeccionar los productos de primera mano.

¿Cuáles son los matices del control de calidad y la certificación para los compradores internacionales?

Los compradores B2B de distintas regiones, sobre todo de África, Sudamérica, Oriente Medio y Europa, deben conocer los matices específicos del control de calidad y la certificación:

-

Normas regionales: Las distintas regiones pueden tener normas y certificaciones únicas. Por ejemplo, el marcado CE es esencial para los productos vendidos en el mercado europeo, mientras que la certificación UL puede ser necesaria en Norteamérica. Los compradores deben asegurarse de que los proveedores cumplen las normas pertinentes para su mercado de destino.

-

Consideraciones culturales: Comprender las diferencias culturales en las prácticas empresariales puede ser fundamental. Por ejemplo, los proveedores de algunas regiones pueden poner más énfasis en la creación de relaciones, mientras que otros pueden centrarse estrictamente en las interacciones transaccionales. Crear confianza puede mejorar la comunicación sobre las expectativas de calidad.

-

Consideraciones jurídicas: Las normativas de importación y los requisitos de calidad pueden variar según el país. Los compradores deben asegurarse de que sus proveedores cumplen la legislación local para evitar sanciones o retiradas de productos.

Al conocer los procesos de fabricación y las medidas de garantía de calidad de los arrancadores y relés de arranque, los compradores B2B pueden tomar decisiones con conocimiento de causa, asegurándose de adquirir componentes fiables que satisfagan sus necesidades operativas.

Guía práctica de búsqueda: Una lista de comprobación paso a paso para ‘arranque vs relé de arranque’

En el competitivo panorama de los componentes de automoción, la adquisición del motor de arranque o el relé de arranque adecuados es crucial para garantizar un rendimiento y una fiabilidad óptimos del vehículo. Esta guía sirve como lista de comprobación práctica para compradores B2B que deseen adquirir estos componentes esenciales, ayudándole a navegar por las complejidades de la selección y la adquisición.

Paso 1: Defina sus especificaciones técnicas

Empiece por definir los requisitos técnicos específicos del motor de arranque y el relé de arranque en función de su aplicación. Tenga en cuenta factores como la tensión, la intensidad nominal y la compatibilidad con los vehículos a los que presta servicio. Unas especificaciones claramente definidas le ayudarán a agilizar la búsqueda y a garantizar que los componentes satisfacen sus necesidades operativas.

Paso 2: Credenciales de los proveedores de investigación

Antes de contratar a un proveedor, compruebe sus credenciales y su posición en el sector. Busque certificaciones como ISO o aprobaciones específicas del sector que indiquen el cumplimiento de las normas de calidad. Este paso es vital para asegurarse de que colabora con fabricantes fiables que siguen las mejores prácticas.

Imagen ilustrativa relacionada con arrancador vs relé de arranque

Paso 3: Evaluar posibles proveedores

Realice evaluaciones exhaustivas de los posibles proveedores revisando sus perfiles empresariales y carteras de productos. Solicite estudios de casos y referencias, sobre todo de empresas de regiones o sectores similares. Esto le permitirá conocer su fiabilidad y calidad de servicio, y le ayudará a tomar decisiones con conocimiento de causa.

Paso 4: Evaluar la calidad del producto y las condiciones de la garantía

La garantía de calidad es primordial a la hora de adquirir componentes de automoción. Solicite muestras para evaluar las características físicas y el rendimiento de los arrancadores y relés. Además, revise las condiciones de garantía y el servicio posventa para conocer el compromiso del proveedor con la calidad y la satisfacción del cliente.

Paso 5: Comprender las estructuras de precios y las condiciones de pago

Analice los modelos de precios de los distintos proveedores para asegurarse de que recibe tarifas competitivas sin comprometer la calidad. Preste atención a las condiciones de pago, ya que unas condiciones favorables pueden mejorar la gestión de su tesorería. Considera los descuentos por compras al por mayor o los contratos a largo plazo para conseguir una mayor estabilidad de precios.

Paso 6: Infórmese sobre plazos y logística de entrega

Conocer los plazos de entrega es esencial para planificar el inventario y los calendarios operativos. Discuta la logística de entrega con los proveedores, incluidas las opciones de envío y los plazos. Asegúrese de que los proveedores pueden cumplir sus expectativas de entrega para evitar interrupciones en su cadena de suministro.

Paso 7: Establecer canales de comunicación

Por último, establezca canales de comunicación claros con los proveedores elegidos. Una comunicación regular puede facilitar una mejor colaboración y abordar cualquier problema que pueda surgir durante el proceso de contratación. Asegúrese de que haya un punto de contacto designado para consultas y actualizaciones, a fin de agilizar las interacciones.

Siguiendo esta lista de comprobación paso a paso, los compradores B2B pueden navegar eficazmente por el proceso de aprovisionamiento de arrancadores y relés de arranque, asegurándose de adquirir componentes de alta calidad que cumplan sus requisitos operativos específicos.

Análisis exhaustivo de costes y precios de los relés de arranque y arranque Sourcing

¿Cuáles son los componentes clave del coste de adquisición de arrancadores frente a relés de arranque?

Al analizar la estructura de costes para el suministro de arrancadores y relés de arranque, entran en juego varios componentes clave. Los principales son los materiales, la mano de obra, los gastos generales de fabricación, las herramientas, el control de calidad, la logística y los márgenes de beneficio.

Materiales constituyen una parte importante del coste total, ya que el precio de los componentes utilizados en los arrancadores y relés puede variar mucho en función de la calidad y el lugar de suministro. Por ejemplo, el cobre de alta calidad para el cableado o los metales duraderos para las carcasas pueden encarecer los costes.

Trabajo Los costes también pueden variar significativamente en función de la región. Los países con mano de obra más barata, como algunos de África y Sudamérica, pueden ofrecer precios más competitivos que los proveedores europeos.

Imagen ilustrativa relacionada con arrancador vs relé de arranque

Gastos generales de fabricación incluye los gastos relacionados con el funcionamiento de la fábrica, como los servicios públicos y el mantenimiento de los equipos, que deben tenerse en cuenta en el coste total. Herramientas Los costes son especialmente relevantes en el caso de los productos personalizados o especializados, ya que los diseños únicos pueden requerir moldes o maquinaria específicos, lo que aumenta la inversión inicial.

Por fin, logística Los gastos de envío, manipulación y aduanas son esenciales, sobre todo en las transacciones internacionales. Los compradores también deben tener en cuenta margen añadidos por los proveedores, que pueden variar mucho en función de la demanda del mercado y la competencia.

¿Cómo influyen los precios en el coste de los arrancadores y relés de arranque?

Varios factores influyen en el precio de los arrancadores frente a los relés de arranque. Uno de los más importantes es volumen o cantidad mínima de pedido (MOQ). Un mayor volumen de pedidos puede dar lugar a importantes descuentos, por lo que es crucial que los compradores evalúen sus necesidades con precisión.

Especificaciones y personalización desempeñan un papel fundamental a la hora de determinar el precio. Los componentes hechos a medida o las características especializadas pueden aumentar significativamente los costes, ya que a menudo requieren procesos de fabricación más intrincados y materiales adicionales.

La elección de materiales repercute directamente en el precio. Los compradores deben evaluar si la inversión adicional en materiales de mayor calidad justifica el potencial de mejora del rendimiento y la longevidad.

Certificaciones de calidad también puede afectar a los precios. Los proveedores que cumplen normas internacionales específicas (como las certificaciones ISO) pueden cobrar un sobreprecio debido a la garantía de calidad y cumplimiento, que puede ser fundamental para los compradores internacionales.

Factores del proveedor como la reputación, la fiabilidad y la ubicación geográfica son consideraciones esenciales. Los proveedores de regiones con climas políticos estables y redes logísticas sólidas pueden exigir precios más altos debido a la garantía añadida que ofrecen.

Por último, Incoterms-las condiciones comerciales internacionales que definen las responsabilidades de compradores y vendedores- pueden repercutir en los costes generales. Comprender estos términos puede ayudar a los compradores a mitigar los cargos inesperados y agilizar la logística de envío.

¿Qué consejos pueden utilizar los compradores para garantizar la rentabilidad de sus compras?

Para los compradores B2B internacionales, sobre todo en regiones como África, Sudamérica, Oriente Medio y Europa, garantizar la rentabilidad requiere una negociación estratégica y un análisis exhaustivo del mercado.

Negociación Los compradores deben estar dispuestos a discutir los precios y las condiciones, aprovechando su poder adquisitivo, sobre todo cuando hacen pedidos al por mayor.

Comprender la Coste total de propiedad (TCO) es crucial. Esto incluye no sólo el precio de compra, sino también los costes de mantenimiento, los posibles tiempos de inactividad y los costes de eliminación, que pueden afectar significativamente a la rentabilidad a largo plazo.

Los compradores también deben tener en cuenta matices de precios que pueden surgir de las condiciones del mercado local, las fluctuaciones monetarias y los distintos climas económicos. Por ejemplo, un cambio repentino de los aranceles comerciales puede repercutir en el coste final de los componentes importados.

Por último, el establecimiento de relaciones sólidas con los proveedores puede dar lugar a mejores precios, un trato preferente y unas condiciones de pago más flexibles, contribuyendo en última instancia a una experiencia de compra más favorable.

Imagen ilustrativa relacionada con arrancador vs relé de arranque

Descargo de responsabilidad sobre precios indicativos

Los precios expuestos en este análisis son indicativos y pueden fluctuar en función de las condiciones del mercado, las negociaciones con los proveedores y los cambios en los costes de los materiales. Se recomienda a los compradores que realicen un estudio de mercado exhaustivo y consulten a varios proveedores para obtener los precios más precisos y competitivos adaptados a sus necesidades específicas.

Análisis de alternativas: Comparación de relé de arranque vs relé de arranque con otras soluciones

Alternativas a las soluciones de arranque y relé de arranque

En el sector de la automoción, sobre todo para los compradores B2B, es esencial comprender la funcionalidad y las diferencias entre un arrancador y un relé de arranque. Sin embargo, existen soluciones alternativas que también pueden satisfacer necesidades similares. Este análisis comparará el motor de arranque y el relé de arranque con dos alternativas viables: un sistema de encendido directo y un sistema de arranque inteligente.

| Aspecto comparativo | Arrancador vs Relé de arranque | Sistema de encendido directo | Sistema de arranque inteligente |

|---|---|---|---|

| Rendimiento | Gran potencia para el arranque del motor; posible desgaste con el tiempo | Encendido rápido, reduce los componentes mecánicos | Ofrece funciones de arranque y diagnóstico a distancia |

| Coste | Moderado; la instalación varía según el vehículo | Mayor coste inicial, pero ahorro en mantenimiento | Mayor coste inicial, pero ahorro potencial a largo plazo. |

| Facilidad de implementación | Generalmente sencillo; puede requerir instalación profesional | Complejidad moderada; puede requerir conocimientos especializados | Requiere conocimientos técnicos para su instalación y configuración |

| Mantenimiento | Necesidad de revisiones periódicas; puede desgastarse con el tiempo | Mínimo; normalmente menos propenso a fallos | Requiere actualizaciones de software; posibilidad de problemas de software |

| Mejor caso de uso | Vehículos tradicionales que necesitan un arranque fiable | Vehículos de altas prestaciones que requieren un encendido rápido | Vehículos modernos que desean comodidad y funciones avanzadas |

¿Cuáles son las ventajas y los inconvenientes de un sistema de encendido directo?

Un sistema de encendido directo elimina la necesidad de un relé de arranque utilizando un módulo de encendido electrónico para gestionar directamente el arranque del motor. Este sistema mejora el rendimiento al proporcionar una respuesta de encendido más rápida, lo que resulta especialmente ventajoso en aplicaciones de alto rendimiento o de carreras. Sin embargo, el coste de configuración inicial puede ser superior al de los sistemas tradicionales, y puede requerir conocimientos especializados para su instalación y mantenimiento. Aunque reduce el desgaste mecánico, la tecnología puede no ser adecuada para todos los tipos de vehículos, especialmente los modelos más antiguos.

¿Cómo se compara un sistema de arranque inteligente?

Los sistemas de arranque inteligentes incorporan tecnología avanzada para ofrecer funciones como el arranque a distancia, la integración con smartphones y el diagnóstico. Estos sistemas pueden mejorar significativamente la comodidad del usuario y proporcionar datos sobre el estado del vehículo. Aunque conllevan una mayor inversión inicial y pueden requerir conocimientos técnicos para su instalación, los beneficios a largo plazo pueden compensar estos costes. Sin embargo, la dependencia del software significa que los usuarios pueden tener problemas con las actualizaciones o el mal funcionamiento del software, lo que puede complicar el mantenimiento.

Conclusión: ¿Cómo deben decidirse los compradores B2B por la solución adecuada?

A la hora de elegir entre un motor de arranque, un relé de arranque y sus alternativas, los compradores B2B deben tener en cuenta varios factores, como las necesidades específicas de su flota o vehículos, las limitaciones presupuestarias y la importancia de las funciones avanzadas. Para las aplicaciones tradicionales, un motor de arranque y un relé fiables pueden ser suficientes, mientras que los vehículos modernos o de alto rendimiento pueden beneficiarse de la eficacia del encendido directo o de la comodidad de los sistemas de arranque inteligentes. En última instancia, alinear la elección con los requisitos operativos y las capacidades de mantenimiento a largo plazo conducirá a la inversión más eficaz.

Imagen ilustrativa relacionada con arrancador vs relé de arranque

Propiedades técnicas esenciales y terminología comercial del arrancador frente al relé de arranque

¿Cuáles son las propiedades técnicas críticas de los arrancadores y los relés de arranque?

Comprender las propiedades técnicas esenciales de los arrancadores y los relés de arranque es crucial para los compradores B2B implicados en la adquisición de piezas de automoción. Estas son algunas de las especificaciones clave que deben tenerse en cuenta:

-

Grado del material

La calidad de los materiales utilizados en los arrancadores y relés puede afectar significativamente a su rendimiento y durabilidad. Los materiales más comunes son el cobre para el cableado y el aluminio o el acero para la carcasa. Los materiales de mayor calidad suelen mejorar la conductividad y la resistencia al desgaste, lo que se traduce en una vida útil más larga y menos fallos. Para los compradores B2B, especificar los grados de los materiales puede ayudar a garantizar la fiabilidad y reducir los costes a largo plazo. -

Intensidad nominal (amperios)

Esta especificación indica la corriente máxima que puede soportar un motor de arranque o un relé sin sobrecalentarse o averiarse. Los motores de arranque suelen requerir corrientes más altas, a menudo superiores a 200 amperios, para arrancar el motor. En el caso de los relés, los valores nominales pueden variar, pero suelen ser más bajos, en torno a los 30-50 amperios. Conocer los valores nominales de corriente ayuda a los compradores a seleccionar componentes que se ajusten a los requisitos de potencia de sus aplicaciones, garantizando así un rendimiento óptimo. -

Rango de temperatura de funcionamiento

La capacidad de un arrancador o relé para funcionar eficazmente a distintas temperaturas es crucial, sobre todo en regiones con climas extremos. Los rangos de temperatura de funcionamiento pueden variar entre -40 °C y +125 °C, en función del diseño y los materiales utilizados. Los compradores B2B deben tener en cuenta estos rangos para asegurarse de que los componentes funcionarán de forma fiable en sus condiciones geográficas y operativas específicas. -

Resistencia de contacto

Esta propiedad mide la resistencia entre los contactos eléctricos dentro del arrancador o relé. Una resistencia de contacto baja es esencial para un funcionamiento eficaz, ya que una resistencia alta puede provocar caídas de tensión y generación de calor. Los responsables de B2B deben prestar atención a las especificaciones de resistencia de los contactos para evitar posibles fallos y garantizar una transferencia de potencia eficiente. -

Ciclo de vida

Se refiere al número de ciclos de funcionamiento que puede soportar un arrancador o un relé antes de averiarse. Los arrancadores suelen tener una vida útil de entre 20.000 y 30.000 ciclos, mientras que los relés pueden tener una vida útil más larga debido a su naturaleza menos exigente. Comprender la vida útil es vital para los compradores que se centran en los programas de mantenimiento y el coste total de propiedad. -

Configuración de montaje

El diseño físico y las opciones de montaje de los arrancadores y relés pueden variar significativamente. Las configuraciones más comunes incluyen el montaje directo en el motor de arranque o dentro de una caja de fusibles eléctricos. Los compradores B2B deben asegurarse de la compatibilidad con los sistemas existentes para facilitar la instalación y evitar costes adicionales relacionados con las modificaciones.

¿Cuáles son los términos comerciales clave relacionados con los arrancadores y los relés de arranque?

Familiarizarse con la terminología del sector es esencial para una comunicación y negociación eficaces en las transacciones B2B. Estos son algunos términos comunes relacionados con los arrancadores y los relés de arranque:

-

OEM (fabricante de equipos originales)

Este término hace referencia a las empresas que producen piezas que se utilizan en la fabricación de vehículos. Los compradores suelen buscar piezas OEM por la garantía de compatibilidad y calidad, ya que estos componentes están diseñados para cumplir las especificaciones del vehículo original. -

MOQ (cantidad mínima de pedido)

MOQ indica la cantidad más pequeña de un producto que un proveedor está dispuesto a vender. Este término es crucial para los compradores B2B, ya que afecta a la gestión del inventario y a la estrategia general de compras. Comprender las MOQ puede ayudar a los compradores a negociar mejores condiciones y gestionar eficazmente los niveles de existencias. -

RFQ (Solicitud de presupuesto)

Una petición de oferta es una solicitud formal de un comprador a los proveedores para que le faciliten presupuestos sobre productos específicos. Este proceso ayuda a los compradores a comparar costes y condiciones, facilitando una toma de decisiones informada. Las peticiones de oferta pueden mejorar los precios y las condiciones de los pedidos al por mayor. -

Incoterms (Términos comerciales internacionales)

Son términos comerciales estandarizados que definen las responsabilidades de compradores y vendedores en las transacciones internacionales. Los Incoterms clave incluyen FOB (franco a bordo) y CIF (coste, seguro y flete), que ayudan a aclarar las responsabilidades, costes y riesgos del envío. -

Plazo de entrega

Este término se refiere al tiempo que transcurre desde que se hace un pedido hasta que se entrega la mercancía. Comprender los plazos de entrega es esencial para que los compradores B2B gestionen los niveles de inventario y planifiquen los calendarios de producción con eficacia. -

Periodo de garantía

El periodo de garantía es la duración durante la cual el fabricante garantiza el funcionamiento del producto. Es un factor importante para los compradores a la hora de evaluar la fiabilidad y el valor a largo plazo de los arrancadores y relés. Un periodo de garantía más largo suele indicar una mayor confianza en la calidad del producto.

Al comprender estas propiedades técnicas y términos comerciales, los compradores B2B pueden tomar decisiones más informadas, asegurándose de que adquieren los arrancadores y relés adecuados para sus aplicaciones específicas.

Dinámica del mercado y tendencias de aprovisionamiento en el sector de los relés de arranque vs. arranque

¿Cuáles son las principales tendencias que influyen en el mercado del relé de arranque frente al motor de arranque?

El mercado mundial de motores de arranque y relés de arranque está experimentando una transformación significativa impulsada por varios factores clave. En primer lugar, la creciente demanda de vehículos eléctricos (VE) está reconfigurando el panorama, ya que estos vehículos suelen incorporar tecnologías avanzadas de relés de arranque para optimizar la eficiencia energética. Los compradores B2B, especialmente en regiones como África y Sudamérica, también están experimentando un aumento en la fabricación de automóviles y plantas de montaje, lo que alimenta la demanda de componentes de arranque fiables.

Las tecnologías emergentes, como los sistemas de automoción inteligentes y la automatización, también influyen en las tendencias de aprovisionamiento. Las empresas adoptan cada vez más plataformas digitales para la contratación, lo que les permite agilizar las cadenas de suministro y mejorar la transparencia. Por ejemplo, se está explorando la tecnología blockchain para rastrear el ciclo de vida de los componentes de arranque, garantizando la calidad y el cumplimiento. Además, el cambio hacia vehículos híbridos y eléctricos requiere diseños innovadores en los relés de arranque, lo que presenta oportunidades para los proveedores que puedan ofrecer soluciones de vanguardia.

La dinámica del mercado también se ve afectada por las normativas regionales destinadas a reducir las emisiones y mejorar el rendimiento de los vehículos. En Europa, las normas más estrictas obligan a los fabricantes a buscar componentes duraderos y de alta calidad que satisfagan estas exigencias. Por el contrario, en los mercados emergentes, la rentabilidad sigue siendo un factor primordial, lo que impulsa a los compradores a buscar precios competitivos sin comprometer la calidad. Los compradores B2B internacionales deben navegar por estas dinámicas variables para optimizar eficazmente sus estrategias de aprovisionamiento.

¿Cómo afectan la sostenibilidad y el aprovisionamiento ético al sector de los relés de arranque frente al de los motores de arranque?

La sostenibilidad se ha convertido en un aspecto fundamental en el sector de los arrancadores y los relés de arranque. A medida que aumenta la preocupación por el medio ambiente en todo el mundo, las empresas dan cada vez más prioridad a las prácticas sostenibles en sus estrategias de abastecimiento. El sector de la automoción está sometido a presiones para reducir su huella de carbono, y los proveedores que adoptan materiales y procesos respetuosos con el medio ambiente obtienen una ventaja competitiva.

El abastecimiento ético es igualmente vital. Los compradores B2B examinan ahora sus cadenas de suministro para comprobar si cumplen la legislación laboral y la normativa medioambiental. Las empresas que pueden demostrar prácticas de abastecimiento responsables tienen más probabilidades de ganarse la confianza de sus clientes y mejorar la reputación de su marca. Por ejemplo, el abastecimiento de componentes fabricados con materiales reciclados o certificados por organizaciones ‘verdes’ reconocidas puede resultar muy atractivo para los compradores preocupados por el medio ambiente.

Certificaciones como la ISO 14001 para sistemas de gestión medioambiental se están convirtiendo en esenciales para los proveedores que desean entrar en el mercado internacional. Además, las empresas que aplican prácticas sostenibles a menudo experimentan menores costes operativos y una mayor eficiencia, lo que puede traducirse en mejores precios para los compradores B2B. En un panorama competitivo, alinear las prácticas de abastecimiento con los objetivos de sostenibilidad no sólo es beneficioso, sino que se está convirtiendo en una necesidad.

¿Cómo ha evolucionado el mercado del motor de arranque frente al de los relés de arranque?

La evolución del mercado de arrancadores y relés de arranque ha estado marcada por importantes avances tecnológicos y el cambio de las preferencias de los consumidores. Al principio, los sistemas de arranque eran dispositivos mecánicos relativamente sencillos. Sin embargo, con el auge de los sistemas de encendido electrónico a finales del siglo XX, el mercado experimentó un cambio hacia relés de arranque más sofisticados, diseñados para soportar mayores cargas eléctricas y mejorar la fiabilidad.

La introducción de la tecnología de microprocesadores en los vehículos ha transformado aún más los sistemas de arranque, permitiendo una gestión más eficiente de la energía y un mayor rendimiento. A medida que los vehículos se hacían más complejos, también lo hacían los sistemas de relés de arranque, incorporando funciones como el diagnóstico y el funcionamiento a distancia. Esta evolución ha dado lugar a una variada gama de productos para diferentes tipos de vehículos, incluidos los modelos convencionales, híbridos y eléctricos.

En la actualidad, el mercado se encuentra en una encrucijada, influido por la creciente demanda de tecnología inteligente y soluciones sostenibles. A medida que las normas mundiales de automoción sigan evolucionando, es probable que el sector de los motores de arranque y los relés de arranque experimente una innovación continua, impulsada por la necesidad de eficiencia, fiabilidad y responsabilidad medioambiental. Los compradores B2B deben mantenerse informados sobre estas tendencias para tomar decisiones estratégicas de aprovisionamiento que se ajusten a sus necesidades operativas y a las demandas del mercado.

Preguntas frecuentes (FAQ) para compradores B2B de relé de arranque frente a relé de arranque

-

¿Cómo identifico un motor de arranque o un relé de arranque defectuoso en mi vehículo?

Para identificar un motor de arranque o un relé de arranque defectuoso, comience por comprobar los síntomas comunes. Si el motor no arranca o emite un único chasquido al girar el contacto, es posible que el problema esté en el relé de arranque. Los problemas de arranque intermitente pueden indicar que el solenoide de arranque está fallando. Además, inspeccione el cableado en busca de corrosión o daños y compruebe el voltaje de la batería. Si el motor de arranque se conecta pero no se desconecta, esto podría indicar un mal funcionamiento del solenoide. La contratación de un técnico cualificado para el diagnóstico puede ayudar a determinar el problema exacto. -

¿Cuál es el mejor relé de arranque para aplicaciones pesadas?

Para aplicaciones pesadas, busque relés de arranque diseñados específicamente para cargas de corriente elevadas, normalmente por encima de 100 amperios. Opte por relés con materiales duraderos que puedan soportar condiciones ambientales adversas. Entre las marcas conocidas por su calidad en los sectores pesados se incluyen Bosch y Omron. Tenga siempre en cuenta la compatibilidad con su modelo de vehículo específico y consulte las especificaciones del producto para garantizar un rendimiento óptimo. Si compra al por mayor, infórmese sobre las opciones de personalización para satisfacer sus necesidades específicas. -

¿Cómo puedo garantizar la fiabilidad de mis proveedores de motores de arranque y relés de arranque?

Para garantizar la fiabilidad, investigue a fondo a los proveedores. Empiece por comprobar su reputación en el sector a través de reseñas y testimonios. Solicite certificaciones que demuestren la garantía de calidad, como las normas ISO. Entable una comunicación directa para evaluar la capacidad de respuesta y la voluntad de resolver sus problemas. Si es posible, visite sus instalaciones de fabricación o pida referencias a otros clientes. Establecer un pedido de prueba también puede ayudar a evaluar la calidad del producto y el servicio antes de comprometerse a grandes cantidades. -

¿Cuáles son las cantidades mínimas de pedido habituales para arrancadores y relés?

Las cantidades mínimas de pedido (MOQ) de arrancadores y relés pueden variar mucho según el proveedor y la región. Por lo general, oscilan entre 50 y 500 unidades, según el tipo de producto y el fabricante. Algunos proveedores pueden ofrecer cantidades mínimas para compradores establecidos o primeros pedidos. Asegúrese de discutir sus necesidades directamente con los proveedores para negociar condiciones favorables. Conocer sus capacidades de producción también puede ayudarle a gestionar su inventario con eficacia. -

¿Qué condiciones de pago debo esperar cuando compro arrancadores y relés a nivel internacional?

Las condiciones de pago pueden variar considerablemente en función de la política del proveedor y de su relación con él. Las condiciones más habituales son el pago por adelantado, el depósito 30% y el pago del saldo en el momento del envío, o el pago neto a 30/60 días después de la entrega. En las transacciones internacionales, considere la posibilidad de utilizar métodos de pago seguros, como cartas de crédito o servicios de custodia, para mitigar los riesgos. Aclare siempre las condiciones en el acuerdo de compra y asegúrese de que ambas partes comprenden las implicaciones de los retrasos en los pagos o las cancelaciones. -

¿Cómo puedo personalizar los arrancadores y relés para aplicaciones específicas?

Las opciones de personalización de arrancadores y relés suelen incluir modificaciones en el tamaño, las tensiones nominales y los tipos de conexión. Hable de los requisitos específicos de su aplicación con los posibles proveedores para determinar las opciones disponibles. Muchos fabricantes ofrecen soluciones a medida para condiciones de funcionamiento únicas, como temperaturas extremas o tipos de vehículos específicos. Asegúrese de comunicar claramente sus necesidades y solicite prototipos, si es posible, para validar el rendimiento antes de la producción en serie. -

¿Qué medidas de garantía de calidad debo tener en cuenta al comprar arrancadores y relés?

A la hora de adquirir arrancadores y relés, dé prioridad a los proveedores que apliquen rigurosas medidas de garantía de calidad. Busque certificaciones como ISO 9001, que indica la adhesión a sistemas de gestión de calidad. Solicite informes detallados de las pruebas del producto que verifiquen su rendimiento en diversas condiciones. También es beneficioso informarse sobre sus políticas de garantía y asistencia posventa, ya que pueden reflejar el compromiso del proveedor con la calidad y la satisfacción del cliente. -

¿Qué consideraciones logísticas son importantes a la hora de importar arrancadores y relés?

Al importar arrancadores y relés, tenga en cuenta factores logísticos como los métodos de envío, los plazos de entrega y la normativa aduanera. Elija un transitario de confianza con experiencia en la manipulación de piezas de automoción para sortear las complejidades del transporte internacional. Familiarícese con los aranceles y derechos de importación que pueden aplicarse en su región, ya que pueden repercutir en los costes totales. Asegúrese de que todos los productos cumplen la normativa local para evitar retrasos en el despacho de aduanas, y considere las opciones de seguro para los envíos de alto valor para mitigar los riesgos.

Lista de los 4 mejores fabricantes y proveedores de Relé de arranque vs relé de arranque

1. Reddit - Relé de arranque vs. Solenoide de arranque

Dominio: reddit.com

Registrado: 2005 (20 años)

Introducción: El relé de arranque y el solenoide de arranque no son lo mismo. Un relé es un interruptor electromagnético que cierra o abre un circuito, mientras que un solenoide es un actuador electromagnético que mueve un objeto físico. La mayoría de los sistemas tienen un relé de arranque que cierra el circuito al solenoide. El solenoide de arranque engrana el piñón de arranque con el volante y cierra el circuito al motor de arranque, funcionando como...

2. Omron - Relé de 4 pines Modelo 12177235

Dominio: comunidad.cartalk.com

Registrado: 1995 (30 años)

Introducción: Relé Omron de 4 patillas modelo 12177235; compatibilidad con el relé del ventilador de refrigeración; coste inferior al $10; relé de arranque de 5 patillas con una patilla 87A no utilizada; problemas con el chirrido del arranque y sonidos de no arranque; posibles problemas con las conexiones de la batería y a tierra; importancia del amperaje nominal del relé.

3. Temporizador Alion - Relé de arranque

Dominio: aliontimer.com

Registrado: 2016 (9 años)

Introducción: 1. Relé de arranque: Componente crítico del sistema de arranque de un vehículo que actúa como completador o interruptor del circuito entre la batería y el motor de arranque. 2. Función: Aumenta la corriente de la batería al motor de arranque cuando se gira la llave de contacto, permitiendo que el motor arranque. 3. Síntomas de fallo: El vehículo no arranca, el relé de arranque permanece abierto después de que el motor arranca, sonido de clic cuando ...

4. NAPA - Relé para cubitos de hielo

Dominio: mgexp.com

Registrado: 2011 (14 años)

Introducción: 1. NAPA Ice Cube Relay: Utilizado como un reemplazo de relé de encendido para un MGB 1977. Coste: $10,00. 2. Solenoide de arranque Ford: Sugerido como una opción barata de relé de arranque, específicamente la versión de montaje en ángulo. 3. Marca estándar RY 115: Identificado como un relé compatible tanto para las funciones de encendido como de arranque. 4. Tipos de relé: SPST (un solo polo, un solo tiro), SPDT (un solo polo, doble tiro), DPST (doble...

Conclusión y perspectivas de Strategic Sourcing para el relé de arranque frente al relé de arranque

En el dinámico panorama del aprovisionamiento de piezas de automoción, entender las diferencias entre arrancadores y relés de arranque es primordial para los compradores B2B internacionales. Ambos componentes desempeñan un papel crucial en el proceso de encendido, pero sus diferencias operativas pueden afectar significativamente a las estrategias de compra. Reconocer los signos de fallo en cualquiera de los componentes puede conducir a decisiones de compra más informadas, garantizando la fiabilidad del vehículo y minimizando el tiempo de inactividad.

El aprovisionamiento estratégico de arrancadores y relés de arranque ofrece una ventaja competitiva, especialmente en regiones como África, Sudamérica, Oriente Medio y Europa. Forjando alianzas con proveedores reputados que ofrezcan garantía de calidad y asistencia técnica, los compradores pueden mejorar la resistencia de su cadena de suministro y reducir los riesgos operativos.

Imagen ilustrativa relacionada con arrancador vs relé de arranque

De cara al futuro, es esencial que los compradores internacionales se mantengan al día de los avances tecnológicos en componentes de automoción, ya que pueden influir en el rendimiento y la compatibilidad. Invertir hoy en estrategias de aprovisionamiento sólidas allanará el camino hacia el crecimiento sostenible y la innovación en el futuro. Colabore con proveedores de confianza para explorar soluciones a medida que satisfagan sus necesidades operativas específicas e impulsen su negocio.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.