Introduction: Navigating the Global Market for partes de un coche

In today’s rapidly evolving automotive landscape, sourcing high-quality partes de un coche can pose significant challenges for international B2B buyers. The complexity of the global market, combined with varying standards and regulations across regions such as Africa, South America, the Middle East, and Europe, necessitates a thorough understanding of the components available and their applications. This comprehensive guide is designed to equip buyers with essential insights into the diverse types of car parts, including critical systems like engines, transmissions, and braking components, while also addressing supplier vetting processes and cost considerations.

As you navigate the intricacies of sourcing automotive parts, this guide empowers you to make informed purchasing decisions. We delve into the key factors that influence the selection of reliable suppliers, the importance of compliance with local regulations, and strategies for negotiating competitive pricing. With a focus on practical applications and real-world scenarios, this resource serves as a valuable tool for businesses looking to enhance their procurement strategies and ensure the longevity and performance of their automotive offerings. Whether you are in Vietnam, Nigeria, or any other market, understanding the global landscape of car parts is crucial for maintaining a competitive edge in the automotive industry.

Índice

- Top 2 Partes De Un Coche Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for partes de un coche

- Understanding partes de un coche Types and Variations

- Key Industrial Applications of partes de un coche

- 3 Common User Pain Points for ‘partes de un coche’ & Their Solutions

- Strategic Material Selection Guide for partes de un coche

- In-depth Look: Manufacturing Processes and Quality Assurance for partes de un coche

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘partes de un coche’

- Comprehensive Cost and Pricing Analysis for partes de un coche Sourcing

- Alternatives Analysis: Comparing partes de un coche With Other Solutions

- Essential Technical Properties and Trade Terminology for partes de un coche

- Navigating Market Dynamics and Sourcing Trends in the partes de un coche Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of partes de un coche

- Strategic Sourcing Conclusion and Outlook for partes de un coche

- Aviso legal importante y condiciones de uso

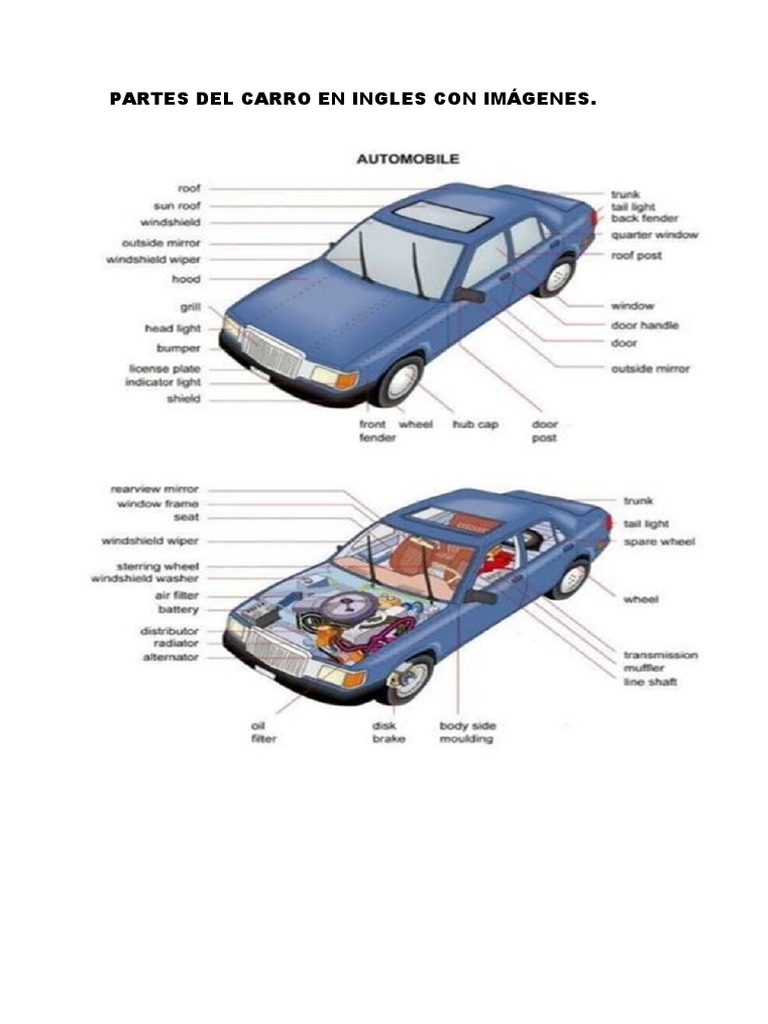

Understanding partes de un coche Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Engine Components | Includes pistons, crankshafts, and fuel injectors; critical for vehicle performance. | Fabricación y reparación de automóviles | Ventajas: High demand, essential for performance upgrades. Contras: Complex to source, requiring technical expertise. |

| Chassis | The structural framework of the vehicle; supports all other parts. | Vehicle manufacturing and assembly | Ventajas: Vital for vehicle integrity, customizable. Contras: High cost, requires specialized materials. |

| Sistemas eléctricos | Comprises batteries, wiring harnesses, and control units; powers vehicle functions. | Automotive electronics suppliers | Ventajas: Growing market with electric vehicles; essential for modern cars. Contras: Rapidly evolving technology can complicate sourcing. |

| Brake Systems | Includes disc brakes, brake pads, and hydraulic components; crucial for safety. | Parts suppliers and aftermarket retailers | Ventajas: High turnover, essential for safety compliance. Contras: Must meet stringent safety standards, potential for recalls. |

| Sistemas de suspensión | Consists of springs, shock absorbers, and control arms; affects ride quality. | Automotive repair shops and parts suppliers | Ventajas: Important for vehicle handling; growing aftermarket. Contras: Requires precise specifications for compatibility. |

What Are the Key Characteristics of Engine Components in Automobiles?

Engine components are fundamental to a vehicle’s functionality, encompassing essential parts like pistons, crankshafts, and fuel injectors. These components are vital for converting fuel into motion and ensuring optimal performance. For B2B buyers, sourcing high-quality engine components is crucial, as they directly impact vehicle reliability and efficiency. The complexity of these parts often necessitates a deep understanding of mechanical engineering, making it essential for buyers to partner with reputable manufacturers who can provide reliable specifications and compatibility.

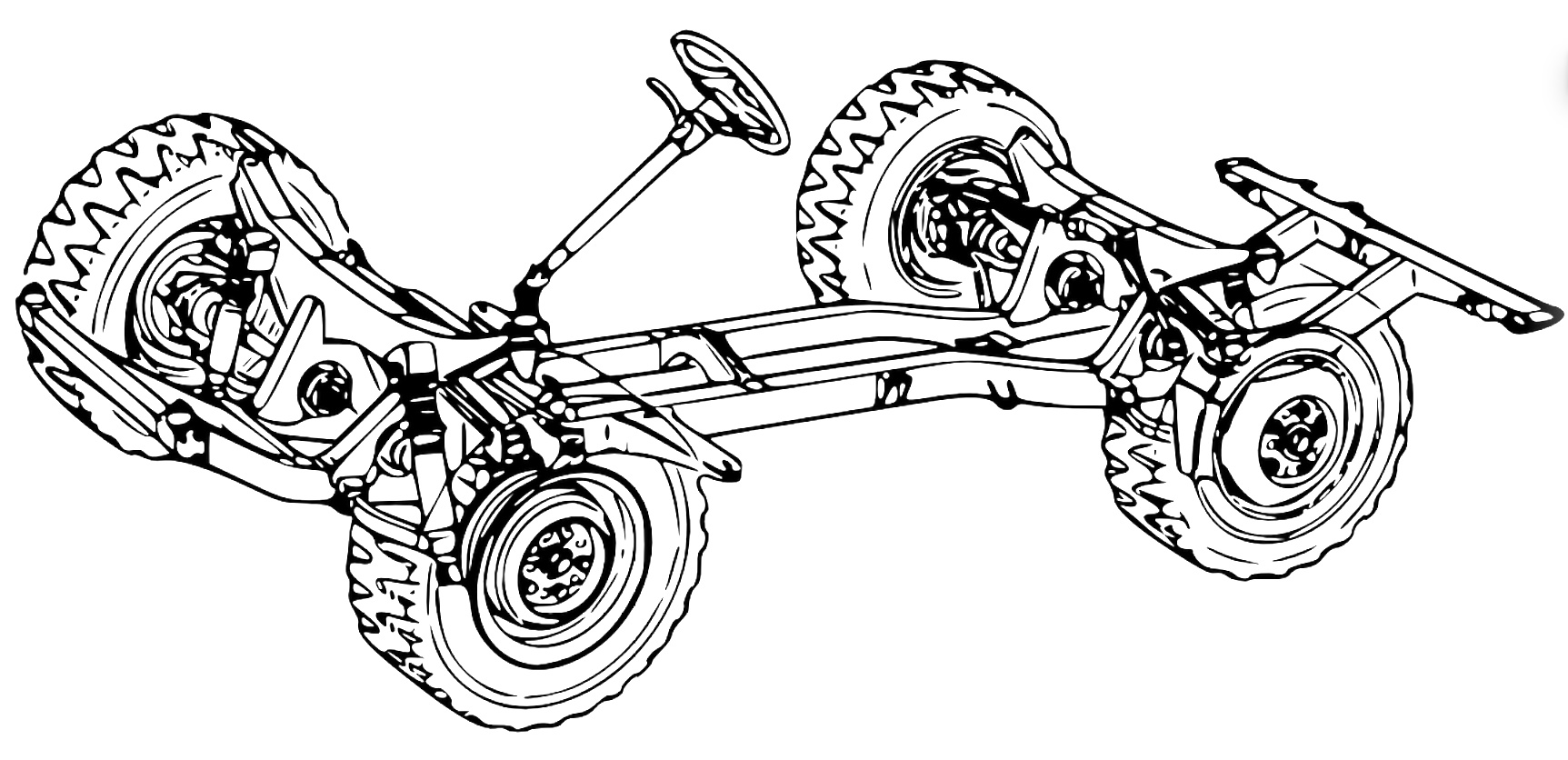

Why Is the Chassis Considered the Backbone of a Vehicle?

The chassis serves as the structural foundation of a vehicle, connecting and supporting all other components, including the engine and body. Its design is critical, as it must balance strength and weight to optimize performance. B2B buyers in the automotive sector should consider the materials used in chassis construction, such as high-strength steel or aluminum, as these influence durability and cost. Additionally, custom chassis solutions can be tailored for specific vehicle types, enhancing marketability for manufacturers.

How Do Electrical Systems Impact Modern Automotive Design?

Electrical systems in vehicles are increasingly complex, comprising batteries, wiring harnesses, and electronic control units that manage various functions. As electric and hybrid vehicles gain popularity, the demand for advanced electrical components is rising. B2B buyers should focus on suppliers that offer innovative solutions and adhere to the latest industry standards. However, the rapid pace of technological advancement means that businesses must stay informed about the latest developments to ensure compatibility and performance in their offerings.

What Makes Brake Systems a Critical Component for Safety?

Brake systems are indispensable for vehicle safety, comprising various elements such as disc brakes, brake pads, and hydraulic components. Ensuring high-quality parts is essential for compliance with safety regulations and minimizing liability risks. B2B buyers should prioritize suppliers with a strong track record in quality assurance and certifications. While the market for brake systems is robust, the need for compliance with stringent safety standards can complicate sourcing and increase costs.

Why Is the Suspension System Important for Vehicle Performance?

The suspension system, including springs, shock absorbers, and control arms, plays a crucial role in vehicle handling and ride comfort. A well-designed suspension system enhances stability, especially in challenging driving conditions. For B2B buyers, understanding the specifications and compatibility of suspension components is vital to meet customer demands effectively. The aftermarket for suspension systems is growing, offering opportunities for suppliers to provide performance upgrades that can attract a niche market segment.

Key Industrial Applications of partes de un coche

| Industria/Sector | Specific Application of partes de un coche | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Fabricación de automóviles | Production of Engine Components | High-performance engines lead to competitive advantage in the market. | Quality certifications, compatibility with existing systems, and cost efficiency. |

| Vehicle Maintenance Services | Replacement Parts for Repairs | Ensures vehicle reliability and safety, boosting customer satisfaction. | Availability of OEM vs. aftermarket parts, lead times, and warranty options. |

| Transporte y logística | Fleet Management and Maintenance | Reduces downtime through timely replacements, improving service delivery. | Bulk purchasing agreements, logistics support, and part compatibility. |

| Export & Import Businesses | Trade of Automotive Parts | Access to diverse markets increases profitability and market reach. | Regulatory compliance, shipping logistics, and supplier reliability. |

How is ‘partes de un coche’ Used in Automotive Manufacturing?

In the automotive manufacturing sector, engine components such as pistons, crankshafts, and camshafts are crucial for producing high-performance vehicles. These parts are engineered for precision, impacting the overall efficiency and durability of the vehicle. International B2B buyers must ensure that suppliers adhere to stringent quality certifications and can provide components compatible with various automotive designs. Additionally, cost efficiency plays a significant role, as manufacturers aim to keep production costs manageable while maintaining high standards.

What Role Do Replacement Parts Play in Vehicle Maintenance Services?

Replacement parts are essential in vehicle maintenance services, where components like brake pads, filters, and batteries are frequently replaced to ensure vehicle safety and performance. Offering high-quality replacement parts can significantly enhance customer satisfaction and loyalty. B2B buyers in this sector should consider the differences between OEM and aftermarket parts, focusing on reliability and warranty options. Quick access to parts inventory and efficient supply chains are also critical to minimize vehicle downtime and maximize service efficiency.

How Do Automotive Parts Impact Transportation and Logistics?

In the transportation and logistics industry, the reliability of vehicles is paramount. Components such as tires, transmissions, and suspension systems directly influence the operational efficiency of fleets. Timely replacement of these parts reduces vehicle downtime, ensuring that logistics companies can meet delivery schedules. B2B buyers should prioritize suppliers that offer bulk purchasing options and logistical support to facilitate rapid part replacement. Compatibility with existing fleet models is another essential consideration to avoid operational disruptions.

How Do Export and Import Businesses Utilize Automotive Parts?

Export and import businesses play a vital role in the global automotive parts market, trading components across various regions. This sector benefits from the ability to access diverse markets, increasing profitability through trade. Buyers must navigate regulatory compliance for different regions, ensuring that parts meet local standards. Additionally, logistics management is crucial, as timely shipping can affect market competitiveness. Establishing reliable supplier relationships is essential for maintaining consistent quality and availability of automotive parts.

3 Common User Pain Points for ‘partes de un coche’ & Their Solutions

Scenario 1: Sourcing Quality Components in Emerging Markets

El problema: B2B buyers in emerging markets often struggle to find reliable suppliers for quality automotive parts. With a plethora of options available, distinguishing between low-quality and high-quality components can be challenging. Buyers may also face issues with inconsistent supply chains, leading to delays in project timelines and increased operational costs. This uncertainty can hinder their ability to meet customer demands and maintain competitive pricing.

La solución: To navigate this challenge, buyers should prioritize building relationships with established suppliers who have a proven track record of delivering quality parts. Conducting thorough due diligence is essential; this includes checking supplier certifications, customer reviews, and their history of compliance with international quality standards. Buyers should also consider forming partnerships with local suppliers who understand the specific needs of the market. Utilizing technology such as supply chain management software can help track orders and maintain communication with suppliers, ensuring timely delivery of quality components. Regular audits and quality checks can further guarantee that the parts meet the necessary specifications, reducing the risk of defects and ensuring customer satisfaction.

Scenario 2: Understanding Technical Specifications and Compatibility

El problema: Many B2B buyers lack the technical expertise required to understand the specifications and compatibility of various automotive parts. This knowledge gap can lead to purchasing incorrect components, resulting in costly returns and project delays. Additionally, with the growing complexity of vehicles incorporating advanced technologies, keeping up with the latest specifications can be overwhelming for buyers.

Illustrative image related to partes de un coche

La solución: To address this issue, buyers should invest in training and resources that enhance their understanding of automotive parts and their specifications. This could involve attending workshops, webinars, or trade shows focused on automotive technology and parts. Moreover, leveraging online databases and resources that provide detailed specifications can help buyers make informed decisions. Collaborating with engineers or technical experts within their organizations can also provide insights into the compatibility of different parts with specific vehicle models. Creating a centralized knowledge repository that includes frequently asked questions, specifications, and compatibility charts can further streamline the purchasing process and reduce errors.

Scenario 3: Managing Inventory and Cost Efficiency

El problema: Managing inventory of automotive parts poses a significant challenge for B2B buyers, particularly regarding cost efficiency. Over-ordering can tie up capital and increase storage costs, while under-ordering can lead to stockouts, impacting service levels and customer satisfaction. Balancing these two extremes requires careful planning and insight into market demand.

La solución: Implementing an effective inventory management system is crucial for optimizing stock levels and costs. Buyers should analyze historical sales data to forecast demand accurately, allowing them to adjust orders based on trends and seasonal fluctuations. Using just-in-time inventory practices can minimize storage costs while ensuring that parts are available when needed. Additionally, establishing strong relationships with suppliers can enable buyers to negotiate better terms and flexible ordering schedules, allowing them to respond quickly to market changes without overcommitting resources. Regularly reviewing inventory turnover rates and adjusting purchasing strategies accordingly can help maintain a lean and cost-effective inventory, ultimately improving profitability and service levels.

Illustrative image related to partes de un coche

Strategic Material Selection Guide for partes de un coche

When selecting materials for automotive components, it’s essential to consider their properties, advantages, and limitations, especially in the context of international markets. Here, we analyze four commonly used materials in the manufacturing of car parts: steel, aluminum, plastics, and composites. Each material has unique characteristics that influence performance, cost, and suitability for various applications.

What Are the Key Properties of Steel in Automotive Applications?

Steel is a traditional choice in automotive manufacturing due to its strength and durability. It typically has a high tensile strength, making it suitable for structural components like the chassis and body panels. Steel components can withstand high temperatures and pressures, which is crucial for parts like the engine block and suspension systems. However, steel is prone to corrosion, necessitating protective coatings or treatments.

Pros y contras del acero:

– Ventajas: High strength-to-weight ratio, excellent durability, and cost-effectiveness.

– Contras: Heavier than alternatives, susceptible to rust, and requires more complex manufacturing processes.

How Does Aluminum Compare as a Material for Car Parts?

Aluminum has gained popularity in the automotive industry due to its lightweight properties, which contribute to improved fuel efficiency. It has good corrosion resistance and can be easily formed into complex shapes, making it ideal for components like engine blocks and body panels. However, aluminum can be more expensive than steel and may not provide the same level of strength in certain applications.

Ventajas e inconvenientes del aluminio:

– Ventajas: Lightweight, excellent corrosion resistance, and good thermal conductivity.

– Contras: Higher cost compared to steel and lower tensile strength.

What Role Do Plastics Play in Automotive Manufacturing?

Plastics are increasingly used in automotive applications due to their versatility and lightweight nature. They can be molded into intricate shapes and are often used for interior components, dashboards, and exterior trims. While plastics are resistant to corrosion, they may not withstand high temperatures as well as metals, which can limit their use in engine components.

Pros and Cons of Plastics:

– Ventajas: Lightweight, cost-effective, and easy to manufacture.

– Contras: Limited temperature resistance, potential for UV degradation, and lower structural integrity compared to metals.

Why Are Composites Important in the Automotive Sector?

Composites, such as carbon fiber and fiberglass, are valued for their high strength-to-weight ratio and stiffness. They are often used in high-performance vehicles and applications where weight reduction is critical, such as in racing cars. However, composites can be expensive and require specialized manufacturing techniques, which may not be feasible for all manufacturers.

Illustrative image related to partes de un coche

Ventajas e inconvenientes de los compuestos:

– Ventajas: Exceptional strength-to-weight ratio, excellent fatigue resistance, and design flexibility.

– Contras: High manufacturing costs and complexity, limited recyclability, and potential brittleness.

Considerations for International B2B Buyers

When sourcing materials for automotive parts, international buyers must consider compliance with local and international standards, such as ASTM, DIN, or JIS. In regions like Africa, South America, the Middle East, and Europe, understanding local regulations and market preferences is crucial. For instance, buyers in Europe may prioritize materials that meet stringent environmental standards, while those in emerging markets might focus on cost-effectiveness and availability.

In conclusion, selecting the right material for automotive components involves balancing performance, cost, and compliance with regional standards. Each material offers distinct advantages and limitations that must align with the specific application and market requirements.

| Material | Typical Use Case for partes de un coche | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Acero | Chassis, body panels, suspension components | Alta resistencia y durabilidad | Pesado y propenso a la corrosión | Medio |

| Aluminio | Engine blocks, body panels, wheels | Ligero y resistente a la corrosión. | Mayor coste y menor resistencia | Alto |

| Plásticos | Interior components, dashboards, trims | Rentable y versátil | Resistencia limitada a la temperatura | Bajo |

| Compuestos | High-performance vehicle parts, racing components | Exceptional strength-to-weight ratio | Coste y complejidad de fabricación elevados | Alto |

In-depth Look: Manufacturing Processes and Quality Assurance for partes de un coche

What Are the Main Stages of Manufacturing Processes for ‘partes de un coche’?

Manufacturing automotive parts involves a series of meticulous stages designed to ensure quality and precision. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Automotive Parts?

Material preparation is the foundational step in the manufacturing process. It involves selecting the right raw materials, which can range from high-strength steel and aluminum to advanced composites. Buyers should seek suppliers who prioritize sourcing materials that meet international standards, such as ISO 9001, which ensures quality management systems are in place. This stage may also include processes like cutting, machining, and heat treatment to enhance material properties before they proceed to the forming stage.

What Techniques Are Used in Forming Automotive Parts?

Forming techniques vary based on the part being produced. Common methods include stamping, forging, and casting.

-

Estampado is widely used for producing flat parts like panels and brackets. This process involves using dies to shape the material into the desired form.

-

Forja is used for components that require high strength, such as crankshafts and axles. This process involves shaping heated metal through compressive forces.

-

Fundición is suitable for complex geometries, often used for engine blocks and housings. It allows for intricate designs that would be challenging to achieve through other methods.

Each technique has its advantages and is selected based on the part’s specifications and performance requirements.

Illustrative image related to partes de un coche

How Is Assembly Conducted in the Manufacturing of Automotive Parts?

The assembly stage is where various components come together to form a complete part or subsystem. This stage is critical for ensuring that parts fit and function correctly.

Automotive manufacturers typically employ assembly lines that utilize both manual labor and automation. Automation can enhance precision and speed, particularly in high-volume production settings. Quality control checkpoints during this stage include In-Process Quality Control (IPQC), where workers inspect parts as they move through the assembly line, ensuring any defects are caught early.

What Finishing Processes Are Involved in Automotive Parts Manufacturing?

Finishing processes are essential for enhancing the durability and appearance of automotive parts. These may include:

Illustrative image related to partes de un coche

-

Surface treatment such as painting, anodizing, or galvanizing, which provides corrosion resistance and aesthetic appeal.

-

Mecanizado, which ensures that parts meet tight tolerances and specifications.

-

Quality inspection, which is critical to verify that the finished product meets all required standards and specifications before shipping.

What Are the Key Quality Assurance Measures for Automotive Parts?

Quality assurance (QA) is crucial in the automotive industry due to safety and regulatory requirements. International standards such as ISO 9001 and industry-specific certifications like CE and API play a significant role in establishing a manufacturer’s credibility.

How Do International Standards Impact Quality Assurance?

ISO 9001 sets a framework for quality management systems, ensuring consistent quality across manufacturing processes. Compliance with this standard is often a prerequisite for B2B buyers looking to source parts internationally. Additionally, industry-specific certifications, such as the CE mark in Europe, signify that products meet safety, health, and environmental protection standards.

What Are the Common Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

-

Control de calidad de entrada (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards before production begins.

-

Control de calidad durante el proceso (IPQC): Conducted during the manufacturing process, this stage ensures that any deviations from quality standards are addressed immediately.

-

Control de calidad final (FQC): This final inspection checks the completed parts against specifications to confirm they are ready for shipment.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

B2B buyers need to ensure that their suppliers maintain rigorous quality control standards. There are several methods to verify this:

-

Auditorías de proveedores: Conducting on-site audits can provide insight into the supplier’s manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards directly.

-

Informes de calidad: Requesting detailed quality reports can help buyers understand the supplier’s quality history, including defect rates and corrective actions taken.

-

Inspecciones por terceros: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s operations and quality control practices.

¿Qué matices deben tener en cuenta los compradores B2B internacionales en relación con el control de calidad?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding regional regulations and quality requirements is crucial. Different markets may have varying standards for automotive parts, necessitating a thorough understanding of local regulations.

Illustrative image related to partes de un coche

Buyers should also be aware of potential language barriers and cultural differences that may affect communication with suppliers. Establishing clear expectations and quality standards from the outset can mitigate misunderstandings and ensure a smoother procurement process.

Conclusion: Ensuring Quality in Automotive Parts Manufacturing

In conclusion, the manufacturing processes and quality assurance measures for automotive parts are multifaceted and critical for ensuring safety and performance. By understanding each stage of manufacturing and the associated quality control measures, B2B buyers can make informed decisions when sourcing automotive parts. Emphasizing supplier audits, quality certifications, and third-party inspections will help establish reliable supply chains, ultimately leading to successful partnerships in the automotive industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘partes de un coche’

In today’s competitive automotive market, sourcing quality car parts is essential for maintaining operational efficiency and customer satisfaction. This practical sourcing guide will help B2B buyers navigate the complexities of procuring ‘partes de un coche’ effectively.

Paso 1: Defina sus especificaciones técnicas

Begin by outlining the specific technical requirements for the car parts you need. This includes dimensions, materials, and compatibility with existing systems. Clearly defined specifications will ensure that you receive parts that meet performance standards and fit seamlessly into your operations.

- Consideraciones:

- Identify the vehicle models and makes you will be sourcing parts for.

- Specify whether you need OEM (Original Equipment Manufacturer) or aftermarket parts.

Paso 2: Realizar estudios de mercado

Understanding the market landscape is crucial before selecting suppliers. Investigate trends, pricing, and the availability of parts within your target regions, such as Africa, South America, the Middle East, and Europe.

Illustrative image related to partes de un coche

- Key Actions:

- Analyze competitor offerings and pricing strategies.

- Use online platforms and trade shows to gather insights about emerging suppliers.

Paso 3: Evaluar posibles proveedores

It’s vital to vet suppliers thoroughly before making commitments. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. A supplier’s reputation can significantly impact your business operations.

- What to Check:

- Assess the supplier’s production capabilities and quality control processes.

- Verify their compliance with international standards and certifications relevant to automotive parts.

Paso 4: Solicitar muestras y realizar controles de calidad

Before finalizing any orders, request samples of the parts you intend to purchase. This step allows you to assess the quality and compatibility of the products firsthand.

- Garantía de calidad:

- Inspect the samples for material integrity and adherence to specifications.

- Consider conducting stress tests or evaluations to ensure reliability.

Paso 5: Negociar los términos y condiciones

Once you’ve selected a supplier, it’s time to negotiate the terms of the contract. This includes pricing, delivery schedules, payment terms, and warranty provisions. Clear agreements will minimize misunderstandings and protect your interests.

Illustrative image related to partes de un coche

- Aspectos importantes:

- Discuss bulk order discounts or long-term partnership agreements.

- Ensure that delivery timelines align with your operational needs.

Paso 6: Establish a Logistics Plan

Develop a logistics strategy for the timely delivery of parts. This involves coordinating with suppliers on shipping methods and understanding import/export regulations in your target markets.

- Consideraciones logísticas:

- Assess the reliability of shipping options and customs clearance processes.

- Plan for potential delays and develop contingency strategies.

Paso 7: Monitor and Review Supplier Performance

After establishing a relationship with your supplier, continuously monitor their performance regarding quality, delivery times, and responsiveness. Regular evaluations help in making informed decisions about future orders.

- Ongoing Assessment:

- Set up key performance indicators (KPIs) to measure supplier effectiveness.

- Maintain open lines of communication to address any issues promptly.

By following these steps, B2B buyers can streamline their sourcing process for ‘partes de un coche’, ensuring they procure high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for partes de un coche Sourcing

Analyzing the cost structure and pricing for sourcing ‘partes de un coche’ (car parts) involves understanding various cost components and price influencers that are critical for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Car Parts Sourcing?

Understanding the cost components is crucial for negotiating and budgeting. The primary cost elements include:

-

Materiales: The choice of materials significantly affects the overall cost. High-strength steel, aluminum, and composite materials are common in car manufacturing. Prices fluctuate based on global market conditions, which can be volatile, impacting sourcing strategies.

-

Trabajo: Labor costs vary greatly depending on the country of production. Countries with lower labor costs can provide a competitive advantage, but quality and expertise must also be considered.

-

Gastos generales de fabricación: This includes costs related to factory operations, maintenance, utilities, and other indirect costs associated with production. Efficient manufacturing processes can reduce overheads, impacting pricing positively.

-

Herramientas: Initial tooling costs can be significant, especially for custom parts. This cost is amortized over the production volume, making it essential to consider Minimum Order Quantities (MOQ) when negotiating.

-

Control de calidad (QC): Ensuring product quality is paramount, especially for critical components like brakes and engines. Costs associated with QC processes can vary, affecting the final price.

-

Logística: Shipping costs, customs duties, and insurance are vital parts of the total cost. International shipping involves navigating complex logistics, which can add to the overall expense.

-

Margen: Suppliers typically add a profit margin to cover their risks and business expenses. This margin can vary based on competition, demand, and supplier relationships.

How Do Price Influencers Affect Car Parts Sourcing?

Several factors influence the pricing of car parts, which buyers should consider:

-

Volumen/Cantidad mínima de pedido: Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs and negotiate MOQs to maximize cost-effectiveness.

-

Especificaciones/Personalización: Custom parts generally incur higher costs due to unique tooling and manufacturing processes. Buyers must weigh the need for customization against budget constraints.

-

Materiales y certificaciones de calidad: Parts that require specific materials or certifications (e.g., ISO, IATF 16949) can command higher prices. Buyers should ensure that the quality aligns with the intended use.

-

Factores relacionados con los proveedores: The reputation, reliability, and location of suppliers can impact pricing. Established suppliers with proven track records may charge more but offer better assurance of quality and service.

-

Incoterms: Understanding shipping terms is crucial. Different Incoterms (e.g., FOB, CIF) can affect the total cost, as they dictate who is responsible for shipping and insurance at various stages.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

To optimize sourcing strategies, international buyers should consider the following tips:

-

Negociar con eficacia: Building strong relationships with suppliers can lead to better pricing. Effective negotiation can also help in adjusting payment terms and delivery schedules.

-

Céntrese en el coste total de propiedad (TCO): Instead of just considering the purchase price, evaluate the long-term costs associated with maintenance, durability, and performance of the parts. This holistic view can lead to better purchasing decisions.

-

Stay Informed on Pricing Nuances: Be aware of regional market trends, tariffs, and trade agreements that may affect pricing. For buyers in Africa, South America, and the Middle East, understanding local economic conditions can provide leverage during negotiations.

-

Evaluar múltiples proveedores: Do not rely solely on one supplier. Comparing offers can provide insights into market rates and help in identifying the best value for money.

Descargo de responsabilidad sobre precios indicativos

Prices for car parts can fluctuate based on market conditions, supplier capabilities, and global economic factors. Therefore, it is advisable to seek updated quotations and conduct thorough market research to ensure informed purchasing decisions.

Alternatives Analysis: Comparing partes de un coche With Other Solutions

Introduction to Alternatives in Automotive Solutions

In the automotive sector, “partes de un coche” (car parts) represent the foundational components necessary for vehicle function and performance. However, as technology evolves, alternative solutions emerge that may offer enhanced performance, cost-effectiveness, or innovative features. Understanding these alternatives is crucial for B2B buyers seeking to optimize their procurement strategies while ensuring reliability and efficiency in their automotive operations.

Comparison of ‘Partes De Un Coche’ with Alternative Solutions

| Aspecto comparativo | ‘Partes De Un Coche’ | Componentes para vehículos eléctricos | Modular Vehicle Systems |

|---|---|---|---|

| Rendimiento | High; proven technology with extensive testing | High; instant torque, energy-efficient | Variable; depends on configuration and design |

| Coste | Moderate; costs vary by part and manufacturer | Higher initial costs, but lower operational costs | Moderate; costs depend on customization and scalability |

| Facilidad de implementación | Standardized parts; generally straightforward installation | Requiere conocimientos especializados para su instalación | Flexible; can be tailored to specific needs but may require training |

| Mantenimiento | Regular maintenance needed; parts wear over time | Reduced maintenance; fewer moving parts | Maintenance varies; modular components can be easier to replace |

| Mejor caso de uso | Traditional vehicles, proven reliability | Urban environments, eco-conscious consumers | Custom-built vehicles for specific industries (e.g., delivery, emergency services) |

Desglose detallado de las alternativas

Componentes para vehículos eléctricos

Electric vehicle (EV) components replace traditional car parts, utilizing electric motors and batteries instead of internal combustion engines. The performance of EVs is notable for their instant torque delivery, making them agile and responsive. While the initial investment can be significantly higher than conventional vehicles, the lower operational costs and maintenance requirements often balance this out over time. EV components require specialized knowledge for installation and repair, which may pose a challenge for organizations lacking in-house expertise. However, as the demand for eco-friendly solutions grows, EV components are becoming increasingly relevant for businesses looking to align with sustainability goals.

Modular Vehicle Systems

Modular vehicle systems offer a flexible approach to vehicle design, allowing businesses to customize vehicles based on specific operational needs. This adaptability can significantly improve efficiency in industries that require specialized vehicles, such as logistics or emergency services. The performance of these systems can vary depending on the configuration chosen, making them versatile but sometimes unpredictable. The cost can be moderate, as businesses only pay for the modules they need. Maintenance can be simplified due to the ability to replace individual components rather than entire systems. However, training may be required for staff to effectively manage and implement these modular solutions.

Illustrative image related to partes de un coche

Conclusión: Cómo elegir la solución adecuada para su negocio

When selecting between “partes de un coche” and alternative solutions, B2B buyers should consider their specific operational requirements, budget constraints, and long-term maintenance capabilities. Traditional car parts offer proven reliability, while electric vehicle components present a forward-thinking option for sustainability. Modular systems provide flexibility but may require a reevaluation of existing workflows. By thoroughly assessing the unique needs of their operations and the potential impact of each solution, buyers can make informed decisions that align with their strategic goals and enhance their overall vehicle performance.

Essential Technical Properties and Trade Terminology for partes de un coche

What Are the Key Technical Properties of Automotive Parts?

Understanding the technical properties of automotive components is crucial for B2B buyers in the automotive industry. Here are some essential specifications to consider:

-

Grado del material

– Definición: This refers to the classification of materials based on their mechanical properties, such as tensile strength, ductility, and corrosion resistance.

– Importancia: High-grade materials ensure durability and performance, which are vital for safety and longevity. For instance, using high-strength steel in chassis construction can significantly enhance vehicle safety and performance. -

Tolerancia

– Definición: Tolerance specifies the allowable variation in the dimensions of a part, ensuring that components fit and function together correctly.

– Importancia: Precise tolerances are critical in manufacturing to prevent assembly issues and ensure optimal performance. In automotive applications, even minor deviations can lead to significant operational problems. -

Weight-to-Strength Ratio

– Definición: This property indicates how much weight a material can support relative to its own weight.

– Importancia: A favorable weight-to-strength ratio is essential for enhancing fuel efficiency and vehicle dynamics. Lightweight materials, like aluminum or composite materials, can improve acceleration and handling without compromising safety. -

Thermal Conductivity

– Definición: This property measures a material’s ability to conduct heat.

– Importancia: Components such as radiators and engine blocks require good thermal conductivity to dissipate heat effectively, thereby preventing overheating and ensuring optimal engine performance. -

Resistencia a la corrosión

– Definición: This refers to a material’s ability to withstand degradation due to environmental factors.

– Importancia: High corrosion resistance is critical for components exposed to harsh conditions, such as brake systems and exhaust systems. This property prolongs the lifespan of parts and reduces maintenance costs.

What Are Common Trade Terms in the Automotive Parts Industry?

Familiarity with industry jargon is essential for effective communication in the automotive parts trade. Here are some common terms:

-

OEM (fabricante de equipos originales)

– Definición: An OEM produces parts that are used as components in another company’s product.

– Importancia: OEM parts are often preferred for their guaranteed compatibility and quality, making them a significant consideration for buyers looking to maintain vehicle integrity. -

MOQ (cantidad mínima de pedido)

– Definición: This is the smallest number of units that a supplier is willing to sell.

– Importancia: Understanding MOQ is critical for budgeting and inventory management. Buyers need to know how much they must order to meet supplier requirements and avoid excess stock. -

RFQ (Solicitud de presupuesto)

– Definición: An RFQ is a document sent to suppliers to request pricing and terms for specific products.

– Importancia: This process helps buyers compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms. -

Incoterms (Términos comerciales internacionales)

– Definición: These are a series of predefined international trade terms published by the International Chamber of Commerce.

– Importancia: Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risks associated with international transactions. This knowledge helps buyers avoid unexpected expenses and delays. -

Plazo de entrega

– Definición: This term refers to the amount of time it takes from placing an order to receiving the goods.

– Importancia: Knowing lead times is vital for effective supply chain management. Buyers must plan their inventory and production schedules accordingly to avoid disruptions. -

Piezas de recambio

– Definición: These are components made by companies other than the OEM, often designed to replace original parts.

– Importancia: Aftermarket parts can offer cost savings and alternative options for buyers. Understanding their quality and compatibility is essential for making informed purchasing decisions.

In summary, grasping the technical specifications and trade terminology associated with automotive parts is crucial for B2B buyers. This knowledge enables informed decision-making, enhances supplier negotiations, and ultimately contributes to the success of their automotive ventures.

Navigating Market Dynamics and Sourcing Trends in the partes de un coche Sector

What Are the Current Market Dynamics and Key Trends in the partes de un coche Sector?

The global automotive parts market is experiencing significant growth driven by several factors, including increasing vehicle production, rising vehicle ownership, and technological advancements. Emerging markets in Africa, South America, and the Middle East are witnessing a surge in demand for automotive components due to urbanization and improved economic conditions. For instance, countries like Nigeria and Vietnam are ramping up their automotive manufacturing capabilities, creating opportunities for international B2B buyers to source parts locally.

In terms of sourcing trends, digitalization is reshaping the landscape. The adoption of B2B e-commerce platforms is simplifying procurement processes, enabling buyers to access a wider range of suppliers and products. Additionally, the use of data analytics is becoming crucial for understanding market demand and optimizing supply chains. Buyers are increasingly looking for suppliers that can offer just-in-time delivery and flexible logistics solutions to minimize inventory costs.

Moreover, sustainability is becoming a key consideration. International buyers are not only seeking high-quality parts but also suppliers that adhere to environmentally friendly practices. This trend is particularly pronounced in Europe, where regulations around emissions and sustainability are tightening, pushing manufacturers to innovate and adapt.

How Important is Sustainability and Ethical Sourcing in the partes de un coche Sector?

The environmental impact of automotive manufacturing is significant, making sustainability a critical focus for B2B buyers in the partes de un coche sector. The industry is under pressure to reduce carbon footprints, and this has led to a shift towards more sustainable materials and manufacturing processes. Buyers are increasingly interested in suppliers who utilize recycled materials, eco-friendly production methods, and energy-efficient technologies.

Ethical sourcing is equally important as consumers and regulators demand transparency in supply chains. Buyers are encouraged to partner with manufacturers that have robust sustainability certifications, such as ISO 14001 or LEED, which indicate a commitment to environmental management. Furthermore, certifications related to fair labor practices can enhance a supplier’s reputation and appeal to socially conscious buyers.

Incorporating sustainability into sourcing strategies not only mitigates environmental risks but also creates long-term value. Buyers who prioritize these factors can differentiate themselves in the market, appeal to a growing segment of environmentally aware consumers, and comply with international regulations.

How Has the partes de un coche Sector Evolved Over Time?

The partes de un coche sector has undergone a remarkable transformation over the past few decades. Initially dominated by traditional manufacturing processes, the industry has embraced automation and advanced manufacturing technologies, such as robotics and 3D printing. This shift has enabled faster production times, greater precision, and reduced costs, which are essential for meeting the demands of modern automotive design.

Furthermore, the rise of electric vehicles (EVs) is reshaping the market landscape. As manufacturers pivot towards EVs, there is a growing demand for specialized components such as batteries and electronic systems. This evolution presents new opportunities for B2B buyers to engage with innovative suppliers who are at the forefront of automotive technology.

Overall, the evolution of the partes de un coche sector reflects broader trends in globalization, technology, and sustainability, all of which are pivotal for international B2B buyers seeking competitive advantage in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of partes de un coche

-

How do I ensure quality when sourcing partes de un coche?

To ensure quality when sourcing car parts, it is crucial to conduct thorough supplier vetting. Start by checking for certifications such as ISO 9001, which indicates a commitment to quality management. Request samples and review product specifications to verify compliance with international standards. Additionally, consider third-party quality assurance inspections before shipment. Establishing a strong communication channel with your supplier can also help address any quality concerns and ensure that all requirements are met consistently. -

What are the best practices for negotiating payment terms with suppliers?

Negotiating payment terms is essential for maintaining cash flow. Aim for terms that align with your financial capabilities, such as net 30 or net 60 days. Consider offering to pay a portion upfront to secure a better overall price. Establishing a good relationship with your supplier can lead to more favorable terms over time. Always ensure that payment methods are secure, and consider using letters of credit or escrow services for larger transactions to mitigate risk. -

What should I know about minimum order quantities (MOQ) for partes de un coche?

Understanding minimum order quantities (MOQ) is vital when sourcing car parts. Different suppliers may have varying MOQs based on their production capabilities and inventory management. It’s advisable to discuss your specific needs upfront to negotiate a suitable MOQ that aligns with your business model. If you’re starting small, seek suppliers willing to accommodate lower MOQs or consider forming partnerships with other businesses to meet MOQ requirements collectively. -

How can I customize car parts to meet specific market needs?

Customization of car parts often requires collaboration with your supplier. Clearly communicate your specifications, including materials, dimensions, and performance characteristics. Some suppliers may offer design services or be open to modifying existing products to suit your requirements. It’s important to discuss lead times and costs associated with customization upfront. Additionally, consider conducting market research to ensure that your customized parts meet local regulations and customer preferences. -

What logistics considerations should I be aware of when importing partes de un coche?

When importing car parts, logistics planning is crucial. Consider factors such as shipping methods, transit times, and customs regulations in your target market. Work with logistics providers experienced in handling automotive components to ensure compliance with international trade laws. Additionally, factor in the costs of tariffs and duties, which can significantly impact overall expenses. Establishing a reliable supply chain with clear timelines will help you manage inventory effectively and meet customer demands. -

How do I assess the reliability of a supplier for automotive parts?

To assess supplier reliability, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from other businesses. Request references and reach out to previous clients to gauge their experiences. Additionally, evaluate the supplier’s production capacity, financial stability, and adherence to quality standards. Conducting site visits can also provide valuable insights into their operational processes and commitment to quality. -

What are the key factors affecting the cost of partes de un coche?

Several factors influence the cost of car parts, including material quality, manufacturing processes, and supply chain dynamics. Raw material prices can fluctuate based on market conditions, impacting overall costs. Additionally, labor costs in the supplier’s location and transportation expenses play a significant role. It’s essential to analyze these factors while sourcing to ensure you are getting competitive pricing without compromising quality. Regularly review market trends to anticipate potential cost changes. -

How can I stay compliant with international trade regulations when sourcing car parts?

Staying compliant with international trade regulations requires a thorough understanding of both local and international laws. Familiarize yourself with import/export regulations, tariffs, and customs procedures relevant to the automotive industry. Engage with trade experts or legal advisors who specialize in international trade to help navigate complex regulations. Keeping accurate documentation and maintaining open communication with suppliers can also facilitate smoother transactions and compliance with legal requirements.

Top 2 Partes De Un Coche Manufacturers & Suppliers List

1. Autoland – Componentes de Motor y Transmisión

Dominio: autoland.com.pe

Introducción: 1. Motor: Compuesto por bloque de cilindros, pistones, cigüeñal, árbol de levas, culata de cilindros, válvulas, colectores de admisión y escape. 2. Caja de cambios: Tipos incluyen manual, automática y CVT. 3. Eje de transmisión y diferencial: Envía potencia a las ruedas y distribuye potencia uniformemente. 4. Sistema de inyección de combustible: Dosifica combustible para una combustión óptima. 5. …

2. Speak Languages – Language Accelerator

Dominio: es.speaklanguages.com

Matriculado: 2000 (25 años)

Introducción: This company, Speak Languages – Language Accelerator, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for partes de un coche

In the competitive landscape of automotive parts sourcing, understanding the intricacies of each component—from the engine to the chassis—is vital for B2B buyers. Strategic sourcing not only ensures the procurement of high-quality parts but also fosters robust supplier relationships that can lead to cost savings and enhanced supply chain efficiency. Leveraging local and international suppliers, especially in emerging markets across Africa, South America, the Middle East, and Europe, can provide buyers with a diverse array of options that meet specific regulatory and market needs.

As the automotive industry continues to evolve with advancements in technology and sustainability, it is crucial for international buyers to stay ahead of trends in parts innovation and procurement strategies. Embracing digital tools and platforms can further streamline the sourcing process, making it easier to compare options and negotiate terms effectively.

Looking ahead, the global automotive market presents significant opportunities for those willing to adapt and innovate. Engage with strategic partners, invest in quality parts, and take proactive steps toward optimizing your supply chain. By doing so, you position your business not just to survive but to thrive in this dynamic environment.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Illustrative image related to partes de un coche

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.