Introduction: Navigating the Global Market for how to replace a car starter

Navigating the complexities of sourcing reliable components for vehicle maintenance, such as a car starter replacement, can be daunting for international B2B buyers. With the automotive market experiencing rapid growth, particularly in regions like Africa, South America, the Middle East, and Europe, understanding how to effectively replace a car starter is essential for maintaining fleet efficiency and minimizing downtime. This comprehensive guide delves into the critical aspects of car starter replacement, including the various types of starters, their specific applications, and the best practices for supplier vetting.

In this guide, B2B buyers will find a wealth of information on identifying the right starter for different vehicle models, alongside insights into the cost implications and procurement strategies. We provide actionable tips on assessing supplier reliability and product quality, ensuring that your purchasing decisions are informed by the latest market trends and technological advancements.

By equipping decision-makers with the necessary knowledge and tools, this resource aims to streamline the replacement process, ultimately enhancing operational efficiency and reducing costs. Whether you are managing a fleet of vehicles in Brazil or sourcing parts in Vietnam, our guide empowers you to make confident, informed decisions that align with your business objectives in the competitive global automotive market.

Índice

- Top 2 How To Replace A Car Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to replace a car starter

- Understanding how to replace a car starter Types and Variations

- Key Industrial Applications of how to replace a car starter

- 3 Common User Pain Points for ‘how to replace a car starter’ & Their Solutions

- Strategic Material Selection Guide for how to replace a car starter

- In-depth Look: Manufacturing Processes and Quality Assurance for how to replace a car starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to replace a car starter’

- Comprehensive Cost and Pricing Analysis for how to replace a car starter Sourcing

- Alternatives Analysis: Comparing how to replace a car starter With Other Solutions

- Essential Technical Properties and Trade Terminology for how to replace a car starter

- Navigating Market Dynamics and Sourcing Trends in the how to replace a car starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to replace a car starter

- Strategic Sourcing Conclusion and Outlook for how to replace a car starter

- Aviso legal importante y condiciones de uso

Understanding how to replace a car starter Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Sustitución directa | Involves swapping the old starter with a new one of identical specifications. | Talleres de reparación de automóviles, servicios de flotas. | Ventajas: Simple process, minimal tools required. Contras: Requires matching specifications exactly. |

| Motor de arranque reacondicionado | Rebuilt starters that meet OEM standards, often with warranty. | Parts distributors, automotive retailers. | Ventajas: Cost-effective, eco-friendly. Contras: Performance may vary based on the quality of remanufacturing. |

| Arrancador de alto rendimiento | Upgraded starters designed for enhanced durability and efficiency. | Equipos de carreras, talleres de vehículos de alto rendimiento. | Ventajas: Improved starting power, reliability under stress. Contras: Higher initial cost, may require additional modifications. |

| Universal Starter | Generic starters compatible with multiple vehicle models. | Automotive parts suppliers, DIY mechanics. | Ventajas: Versatile, can fit various vehicles. Contras: May lack specific fitment, potential performance issues. |

| Starter Motor Assembly | Complete assembly including starter motor and solenoid, pre-wired for installation. | Auto manufacturers, assembly plants. | Ventajas: Quick installation, reduces labor costs. Contras: Higher upfront cost, limited to specific applications. |

What Are the Characteristics of Direct Replacement Starters?

Direct replacement starters are the most straightforward option for replacing a faulty starter. This method entails removing the old starter and installing a new one that matches the original’s specifications. This type is commonly used in automotive repair shops and fleet services where accuracy and reliability are paramount. Buyers should ensure that the new starter matches the old one in terms of voltage, size, and mounting points to avoid installation issues.

Why Choose Remanufactured Starters for Cost-Effective Solutions?

Remanufactured starters are rebuilt to meet OEM specifications, making them a popular choice among parts distributors and automotive retailers. These starters come with a warranty, which adds a layer of security for buyers. They are cost-effective and environmentally friendly, as they reduce waste by reusing components. However, performance can vary depending on the quality of the remanufacturing process, so it is essential to source from reputable suppliers.

How Do High-Performance Starters Benefit Racing and Performance Vehicles?

High-performance starters are designed to provide enhanced starting power and durability, making them ideal for racing teams and performance vehicle shops. These starters can withstand extreme conditions and deliver reliable performance under stress. While they offer significant advantages, such as quicker starts and reduced weight, buyers should consider the higher initial investment and potential modifications required for installation.

What Are the Advantages of Universal Starters for Versatility?

Universal starters are designed to fit a wide range of vehicle models, making them a versatile option for automotive parts suppliers and DIY mechanics. They offer the convenience of being able to stock fewer parts while still catering to multiple vehicles. However, the lack of specific fitment may lead to installation challenges or performance issues, so buyers should assess compatibility carefully before purchasing.

Why Consider Starter Motor Assemblies for Efficient Installations?

Starter motor assemblies come as complete units that include the starter motor and solenoid, often pre-wired for easy installation. This type is favored by auto manufacturers and assembly plants for its efficiency, as it reduces labor costs and installation time. While the upfront cost may be higher, the ease of installation and reliability can justify the investment, particularly in high-volume applications.

Key Industrial Applications of how to replace a car starter

| Industria/Sector | Specific Application of how to replace a car starter | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Servicios de reparación de automóviles | Replacement of starters in vehicles for clients with starting issues | Increased customer satisfaction and retention through reliable service | Quality of replacement starters, availability of parts, and technical expertise |

| Gestión de flotas | Routine maintenance and replacement of starters in commercial vehicle fleets | Reduced downtime and enhanced operational efficiency | Bulk purchasing options, warranty terms, and supplier reliability |

| Transporte y logística | Ensuring operational readiness of delivery vehicles by replacing faulty starters | Improved reliability and reduced risk of delivery delays | Compatibility with various vehicle models and fast delivery timelines |

| Automotive Parts Retail | Selling starter replacement kits to DIY customers and workshops | Increased sales volume and customer loyalty | Product variety, pricing strategies, and marketing support |

| Fabricación de vehículos | Integrating starter replacement processes in quality control for new vehicles | Enhanced product reliability and customer trust | Supplier relationships, quality assurance processes, and certification compliance |

How is ‘how to replace a car starter’ utilized in automotive repair services?

In the automotive repair sector, the process of replacing a car starter is a fundamental service offered to clients experiencing starting issues. Technicians must accurately diagnose starter failures and efficiently replace them to minimize vehicle downtime. International B2B buyers in this sector need to ensure they source high-quality replacement starters that are compatible with a wide range of vehicle models. This ensures reliability and enhances customer satisfaction, ultimately driving repeat business.

Illustrative image related to how to replace a car starter

What are the benefits of starter replacement in fleet management?

Fleet management companies benefit significantly from routine starter replacements, as it ensures the operational readiness of commercial vehicles. By proactively replacing starters, businesses can reduce the risk of unexpected breakdowns, which can lead to costly downtime. For buyers in this sector, considerations include negotiating bulk purchasing agreements for starters and establishing relationships with reliable suppliers who can provide timely deliveries and warranties to safeguard their investments.

How does starter replacement impact transportation and logistics?

In the transportation and logistics industry, the reliability of delivery vehicles is paramount. Replacing faulty starters is essential to maintain consistent operations and avoid delays in delivery schedules. Buyers in this field must focus on sourcing starters that meet the specifications of various vehicle models while ensuring a quick turnaround time for parts. This approach minimizes the risk of operational disruptions and enhances overall service delivery.

Why is starter replacement crucial for automotive parts retail?

Automotive parts retailers can expand their offerings by providing starter replacement kits to both DIY customers and professional workshops. By stocking a variety of starters that cater to different vehicle models, retailers can increase sales volume and foster customer loyalty. Key sourcing considerations include ensuring a diverse inventory, competitive pricing, and effective marketing strategies to attract both individual mechanics and larger repair shops.

How does starter replacement integrate into vehicle manufacturing?

In vehicle manufacturing, integrating starter replacement processes into quality control measures is vital for ensuring that newly manufactured vehicles meet reliability standards. By establishing stringent sourcing criteria for starters, manufacturers can build trust with consumers. International buyers should consider the certification compliance of suppliers and the quality assurance processes in place to ensure that the starters used in production are of the highest standard, ultimately enhancing brand reputation.

3 Common User Pain Points for ‘how to replace a car starter’ & Their Solutions

Scenario 1: Navigating Starter Compatibility Issues

El problema: A common challenge faced by B2B buyers, particularly auto repair shops and fleet managers, is sourcing the correct starter for various vehicle models. With the wide range of makes and models, it can be frustrating to discover that the starter purchased does not fit or function correctly. This can lead to delays in service, increased labor costs, and dissatisfied customers, particularly in regions where vehicle parts may have long lead times.

La solución: To mitigate compatibility issues, buyers should invest in comprehensive parts databases or software that cross-references vehicle specifications with available inventory. When sourcing starters, it’s crucial to gather detailed information about the vehicle, including make, model, year, and engine specifications. Establish relationships with reliable suppliers who can provide OEM (Original Equipment Manufacturer) parts or high-quality aftermarket options that are guaranteed to fit. Additionally, creating a standardized checklist for parts ordering can streamline the process, ensuring all necessary specifications are captured before placing an order. This proactive approach not only reduces the likelihood of purchasing incorrect parts but also enhances overall operational efficiency.

Scenario 2: Overcoming Installation Challenges

El problema: Many B2B buyers, including auto technicians and fleet service providers, often encounter difficulties during the installation of a new starter. Issues such as inaccessible mounting locations, complex wiring configurations, or a lack of proper tools can complicate the installation process, leading to longer downtime and increased labor costs. This can be particularly frustrating when working with older vehicle models that may have unique installation requirements.

La solución: To address installation challenges, buyers should invest in training and resources for their technicians. Providing access to detailed installation manuals, video tutorials, and hands-on training sessions can empower staff with the knowledge needed to tackle complex installations confidently. Moreover, ensuring that all necessary tools are available and in good condition is essential; consider creating a tool inventory checklist specific to starter replacements. When possible, utilizing vehicles with known common issues as training cases can help technicians gain experience and familiarity with specific starter installation challenges. By prioritizing education and preparation, businesses can significantly reduce installation time and enhance service quality.

Illustrative image related to how to replace a car starter

Scenario 3: Managing Customer Expectations During Repairs

El problema: When a vehicle’s starter fails, customers often expect immediate service, which can place immense pressure on repair shops and service centers. This urgency can lead to rushed diagnostics, potentially resulting in incorrect assessments and further complications. Managing customer expectations while ensuring thorough and accurate repairs is a delicate balance that many B2B buyers struggle with.

La solución: Clear communication is critical in managing customer expectations. Establish a standardized protocol for diagnosing starter issues that includes a thorough inspection of related components, such as the battery and ignition system, before confirming the need for a starter replacement. Providing customers with a transparent timeline for repairs and possible delays can help them understand the process better. Additionally, consider implementing a customer relationship management (CRM) system to track service history and communicate proactively about repairs. This not only builds trust but also enhances customer satisfaction, ultimately leading to repeat business and positive referrals. By fostering clear communication and thorough diagnostics, B2B buyers can effectively manage customer expectations while delivering high-quality service.

Strategic Material Selection Guide for how to replace a car starter

When considering the replacement of a car starter, the selection of materials is critical for ensuring performance, durability, and compliance with international standards. Here, we analyze four common materials used in car starters: steel, aluminum, copper, and plastic. Each material has distinct properties, advantages, and limitations that can influence the decision-making process for B2B buyers.

What Are the Key Properties of Steel for Car Starters?

Steel is widely used in automotive applications due to its high strength and durability. It typically features excellent temperature resistance, making it suitable for the high-stress environment of a car engine. Steel components can withstand significant mechanical loads and are less prone to deformation under pressure. However, steel is susceptible to corrosion, which can be a concern in humid or saline environments.

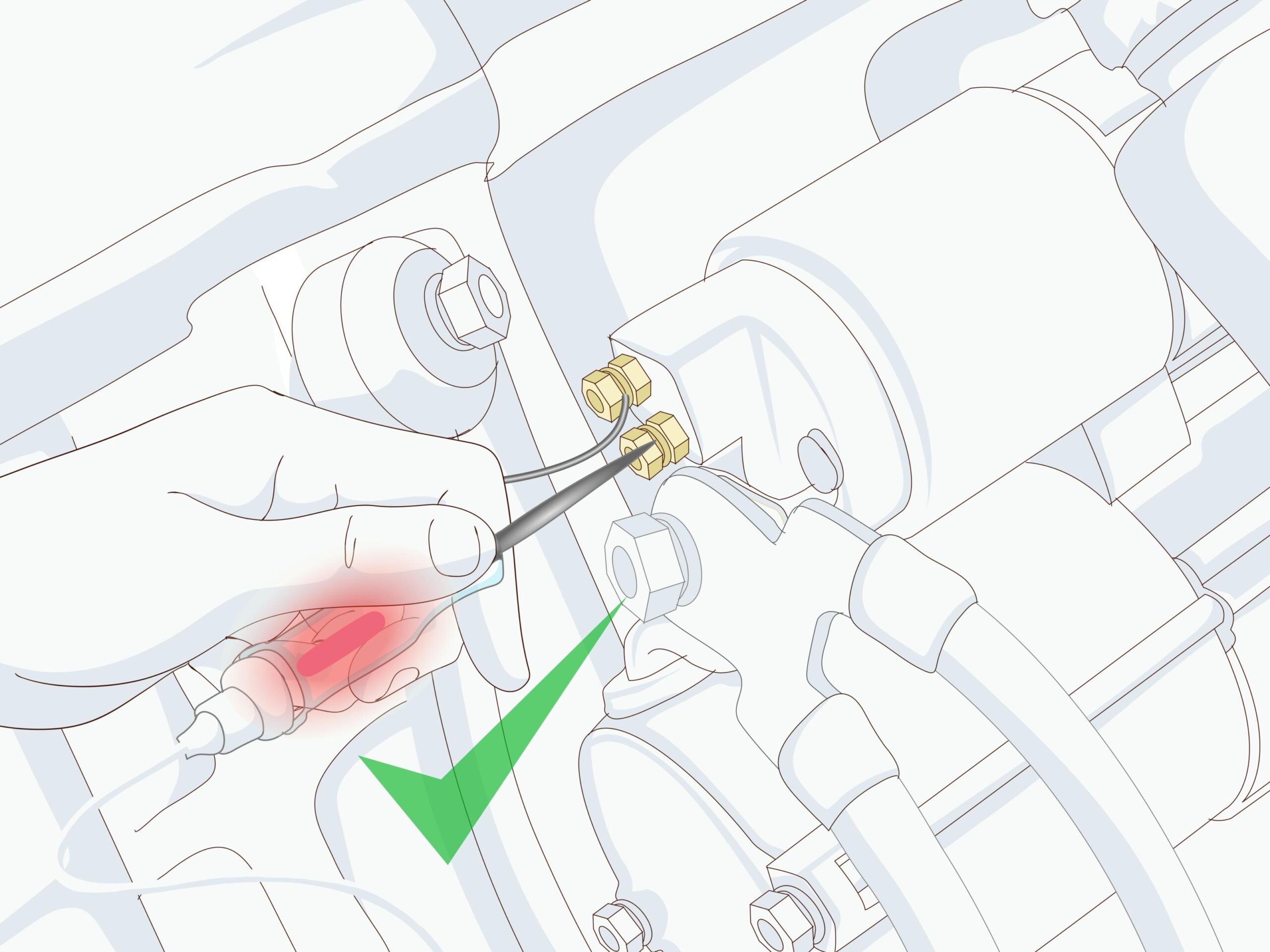

Illustrative image related to how to replace a car starter

Ventajas y desventajas:

The primary advantage of steel is its strength, which translates to long-lasting performance in demanding conditions. However, its weight can be a disadvantage, potentially affecting the overall vehicle efficiency. Additionally, manufacturing processes for steel components can be complex and costly, especially if specialized coatings are required for corrosion resistance.

How Does Aluminum Compare as a Material for Car Starters?

Aluminum is another common material, known for its lightweight and good corrosion resistance properties. It can withstand moderate temperature variations and is often used in applications where reducing weight is essential. Aluminum’s lower density compared to steel makes it a preferred choice for manufacturers looking to enhance fuel efficiency.

Ventajas y desventajas:

The key advantage of aluminum is its lightweight nature, which contributes to improved vehicle performance. However, aluminum may not provide the same level of mechanical strength as steel, which can be a limitation in high-torque applications. The cost of aluminum can also be higher than steel, impacting the overall price of the starter.

Why Is Copper Important in Car Starters?

Copper is primarily used for electrical connections in car starters due to its excellent electrical conductivity. It can handle high currents effectively, which is crucial for the starter’s operation. Copper also has good thermal conductivity, allowing it to dissipate heat generated during the starting process.

Ventajas y desventajas:

The main advantage of copper is its superior conductivity, which ensures efficient power transfer. However, copper is more expensive than both steel and aluminum, which can increase the overall manufacturing cost of the starter. Additionally, copper is prone to corrosion if not properly treated, which can affect its long-term reliability.

What Role Does Plastic Play in Car Starter Applications?

Plastic is often utilized for housing and insulation components in starters. It offers excellent electrical insulation properties and is lightweight, making it an attractive option for various automotive applications. Certain plastics can withstand high temperatures, providing adequate protection for sensitive electrical components.

Ventajas y desventajas:

The primary advantage of plastic is its lightweight and insulating properties, which can enhance the efficiency of the starter. However, plastics may not provide the same level of durability as metals, particularly in high-stress environments. The manufacturing process can also vary in complexity depending on the type of plastic used.

Illustrative image related to how to replace a car starter

Considerations for International B2B Buyers

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, it’s essential to consider compliance with local standards such as ASTM, DIN, or JIS. Material selection should also take into account regional climate conditions that may affect performance, such as humidity and temperature extremes. Understanding local preferences for materials can influence procurement strategies and supplier relationships.

| Material | Typical Use Case for how to replace a car starter | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Acero | Structural components of the starter | Alta resistencia y durabilidad | Susceptible a la corrosión | Medio |

| Aluminio | Carcasas de arranque ligeras | Ligero, buena resistencia a la corrosión | Resistencia inferior a la del acero | Alto |

| Cobre | Conexiones eléctricas y terminales | Excelente conductividad eléctrica | Higher cost, prone to corrosion | Alto |

| Plástico | Aislamiento y componentes de la carcasa | Lightweight, good electrical insulation | Less durable under stress | Bajo |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of materials used in car starters. By understanding these factors, buyers can make informed decisions that align with their operational needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how to replace a car starter

What Are the Main Stages in the Manufacturing Process of Car Starters?

The manufacturing process of car starters is intricate and involves several key stages that ensure both functionality and durability. The primary stages include material preparation, forming, assembly, and finishing.

-

Preparación del material: The first step involves sourcing high-quality materials such as steel, copper, and plastic for various components of the starter. Manufacturers typically evaluate the mechanical and electrical properties of these materials to ensure they can withstand the operational stresses of a vehicle’s ignition system.

-

Formación: In this stage, materials are shaped into specific components using techniques such as stamping, forging, and machining. For instance, the starter housing is often stamped from sheet metal, while the rotor may undergo precision machining to ensure a perfect fit. This step is critical as it affects the performance and longevity of the starter.

-

Ensamblaje: After individual components are formed, they are assembled to create the final product. This often involves manual labor alongside automated machinery. Workers fit the starter motor, solenoid, and other components together, ensuring that all parts align correctly. The assembly process must be meticulously managed to prevent defects that could lead to starter failure.

-

Acabado: The final stage includes applying protective coatings and conducting any necessary surface treatments to enhance corrosion resistance. This stage may also involve quality checks to confirm that the finish meets specified standards. Finishing is essential for ensuring that the starter can withstand the harsh environments often encountered in automotive applications.

How Is Quality Assurance Implemented in Car Starter Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, particularly for components like car starters that must perform reliably under various conditions. The implementation of QA can be broken down into several key elements.

Illustrative image related to how to replace a car starter

-

Cumplimiento de las normas internacionales: Many manufacturers adhere to international quality standards such as ISO 9001, which establishes guidelines for a quality management system. Compliance with these standards helps ensure consistent product quality and operational efficiency. Additionally, industry-specific certifications like CE for European markets or API standards for automotive components may be required.

-

Puntos de control de calidad: Quality control (QC) is integrated at various stages of the manufacturing process:

– Control de calidad de entrada (IQC): This involves inspecting raw materials upon arrival to confirm they meet specified standards before production begins.

– Control de calidad durante el proceso (IPQC): Continuous checks during the manufacturing process help identify defects early. Techniques like statistical process control (SPC) may be employed to monitor production variables.

– Control de calidad final (FQC): After assembly, the finished products undergo rigorous testing, including electrical testing and performance assessments, to ensure they function as intended. -

Testing Methods: Common testing methods for car starters include:

– Pruebas eléctricas: Verifying that the starter draws the correct amount of current and can effectively engage the engine.

– Pruebas de durabilidad: Simulating extreme conditions to ensure the starter can withstand temperature fluctuations and vibrations.

– Pruebas de rendimiento: Assessing the starter’s ability to crank the engine under various scenarios, including cold starts.

¿Cómo pueden los compradores B2B verificar las prácticas de control de calidad de los proveedores?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, ensuring the quality of car starters is paramount. Here are several strategies to verify supplier QC practices:

-

Realización de auditorías: Buyers should conduct on-site audits of suppliers to assess their manufacturing processes, QC measures, and compliance with international standards. This hands-on approach helps identify any potential issues before placing orders.

-

Solicitud de informes de calidad: Suppliers should be able to provide comprehensive quality reports, including results from IQC, IPQC, and FQC. These documents can offer insights into the supplier’s commitment to maintaining high-quality standards.

-

Inspecciones por terceros: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes. These inspections can occur at various stages of production, ensuring that products meet specified standards before shipment.

-

Understanding Certification Nuances: International buyers should familiarize themselves with the specific quality certifications relevant to their regions. For instance, CE marking is crucial for products sold in Europe, while other certifications may be more pertinent in South America or Africa. Ensuring that suppliers have the necessary certifications can mitigate risks related to product quality and compliance.

¿Qué matices de control de calidad deben tener en cuenta los compradores B2B internacionales?

When sourcing car starters from international suppliers, B2B buyers must be aware of certain nuances that can affect quality assurance:

-

Diferencias culturales en los estándares de calidad: Different regions may have varying interpretations of quality standards. Buyers should ensure that their expectations align with the supplier’s capabilities and regional practices.

-

Logistics and Shipping Considerations: The transportation of car starters can expose them to potential damage. Buyers should inquire about the packaging and handling processes to ensure that products arrive in optimal condition.

-

Cumplimiento normativo: Buyers must ensure that the products comply with local regulations in their respective countries. This may involve understanding import regulations, safety standards, and environmental requirements that differ from one region to another.

-

Long-Term Relationships: Establishing long-term relationships with suppliers can improve consistency in quality. Regular communication and feedback can help suppliers understand buyers’ quality expectations and adapt their processes accordingly.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions and select reliable suppliers for car starters that meet their operational needs.

Illustrative image related to how to replace a car starter

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to replace a car starter’

In the automotive industry, replacing a car starter is a crucial task that requires careful planning and sourcing of the right components. This guide provides a practical checklist for B2B buyers to streamline the process of procuring the necessary parts and ensuring a successful installation.

Paso 1: Identify Your Vehicle’s Specifications

Understanding the specific requirements of the vehicle is the first step. Each make and model has distinct starter specifications, including size, power rating, and connection types. Consult the vehicle’s service manual to gather this information, ensuring that the new starter will be compatible with the existing system.

Paso 2: Buscar proveedores fiables

Finding trustworthy suppliers is critical for acquiring high-quality starters. Look for suppliers with a proven track record in the automotive parts industry, especially those who specialize in starters. Consider their years in business, customer reviews, and any industry certifications they hold, as these factors can indicate reliability and product quality.

Paso 3: Solicitar muestras o especificaciones de productos

Before making a bulk purchase, it is advisable to request samples or detailed specifications of the starters. This step allows you to assess the quality and compatibility of the product with your requirements. Pay attention to materials used, warranty information, and performance data to ensure they meet your standards.

Paso 4: Evaluar las certificaciones de los proveedores

Supplier certifications can be a strong indicator of product quality and adherence to industry standards. Verify that your chosen suppliers hold relevant certifications such as ISO 9001 or other automotive-related standards. This not only assures quality but also enhances your credibility when reselling or utilizing the parts in your own operations.

Paso 5: Compare Pricing and Payment Terms

Cost is always a significant factor in procurement decisions. Collect quotes from multiple suppliers and compare their pricing alongside the quality of products offered. Additionally, review payment terms and conditions, including potential discounts for bulk purchases, to find the most favorable financial arrangement.

Paso 6: Assess After-Sales Support and Warranty Options

A good supplier should offer robust after-sales support and clear warranty policies. Investigate what kind of technical support is available post-purchase, as well as how warranty claims are handled. This can save you time and resources in case of product defects or installation issues.

Paso 7: Finalize Your Order and Establish Delivery Timelines

Once you have selected a supplier, finalize your order while ensuring clarity on delivery timelines. Confirm shipping options, lead times, and tracking capabilities to maintain transparency throughout the process. Clear communication with your supplier can help prevent delays and ensure that you have the necessary parts when needed.

By following this checklist, B2B buyers can effectively navigate the procurement process for car starters, ensuring they select the right components and suppliers for successful installations.

Comprehensive Cost and Pricing Analysis for how to replace a car starter Sourcing

What Are the Key Cost Components in Replacing a Car Starter?

When assessing the costs associated with replacing a car starter, several components must be evaluated to build an accurate cost structure. The primary cost components include:

-

Materiales: The most significant expense is typically the starter itself, which varies in price based on brand, type, and compatibility with different vehicle models. High-quality starters may range from $100 to $500, depending on specifications.

-

Trabajo: Labor costs can vary widely based on geographical location and the complexity of the installation. In regions with higher labor costs, such as Europe or North America, the labor component may add an additional $50 to $150 to the total cost.

-

Gastos generales de fabricación: This includes costs related to production facilities, equipment, and other operational expenses. While often factored into the price of the starter, it’s essential for buyers to understand that these costs can influence the final pricing from suppliers.

-

Herramientas: Depending on the design of the starter, specialized tools may be required for installation. This cost can be minimized if the buyer or technician already possesses the necessary tools.

-

Control de calidad (QC): Ensuring that the starter meets industry standards may incur additional costs, especially for suppliers that prioritize quality assurance. Certifications and compliance with safety standards can affect the price.

-

Logística: Shipping and handling costs can vary based on the supplier’s location and the buyer’s destination. International shipping, especially to regions like Africa and South America, may introduce additional tariffs or fees.

-

Margen: Suppliers will include a profit margin in their pricing, which can vary based on market competition and demand.

What Influences the Pricing of Car Starters in B2B Transactions?

Several factors can influence the pricing of car starters, particularly for international buyers:

-

Volumen/MOQ (cantidad mínima de pedido): Purchasing in larger quantities often leads to discounts. Buyers should negotiate MOQs to optimize pricing.

-

Especificaciones y personalización: Custom starters designed for specific vehicle models or with unique features may come at a premium. Buyers should assess whether customization is necessary for their operations.

-

Materiales y certificaciones de calidad: Higher-quality materials and certified products typically command higher prices. Buyers should evaluate the Total Cost of Ownership (TCO) and potential long-term savings versus upfront costs.

-

Factores relacionados con los proveedores: Reliability, reputation, and service levels of the supplier can significantly affect pricing. Established suppliers may offer better quality but at higher prices.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect logistics costs and responsibility for shipping and insurance, impacting overall expenses.

What Tips Can Help Buyers Optimize Costs When Replacing a Car Starter?

International B2B buyers should consider the following strategies to ensure cost efficiency:

-

Negociación: Engage in discussions with suppliers to secure favorable terms. Highlighting long-term purchasing potential can yield better pricing.

-

Análisis de rentabilidad: Assess the entire lifecycle costs, including maintenance and replacement frequency, rather than focusing solely on initial purchase price.

-

Matices en los precios para compradores internacionales: Be aware of currency fluctuations, local tariffs, and import duties that may influence the total cost. Understanding these factors will help in making informed purchasing decisions.

-

Relaciones con los proveedores: Build strong relationships with suppliers for better pricing and terms over time. Reliable suppliers may provide better service, faster shipping, and priority in inventory availability.

-

Local Market Insights: Stay informed about local market trends and competitor pricing to ensure that the procurement strategy remains competitive.

Descargo de responsabilidad sobre precios indicativos

It is essential to note that prices for car starters can vary based on location, market conditions, and specific buyer requirements. The figures provided are indicative and should be confirmed with suppliers for accurate and current pricing information.

Alternatives Analysis: Comparing how to replace a car starter With Other Solutions

Exploring Alternative Solutions for Car Starter Replacement

When dealing with a malfunctioning car starter, businesses often seek alternative solutions to replacement. Understanding the options available can help B2B buyers make informed decisions that align with their operational needs and budget constraints. Below, we compare the traditional method of replacing a car starter with two alternative solutions: using a starter repair service and opting for a high-quality starter relay.

Tabla comparativa

| Aspecto comparativo | How To Replace A Car Starter | Starter Repair Service | High-Quality Starter Relay |

|---|---|---|---|

| Rendimiento | Restaura la funcionalidad completa. | Restores functionality, but may vary by service | Can improve starting efficiency |

| Coste | Moderate (cost of starter + labor) | Often lower than replacement, varies by service | Low to moderate (one-time purchase) |

| Facilidad de implementación | Requires mechanical skills | Minimal effort; professional handling | Simple installation, but needs compatibility |

| Mantenimiento | Low (once replaced) | Varies with service quality | Low (if high-quality) |

| Mejor caso de uso | Fallo total del motor de arranque | Minor issues or intermittent failures | Upgrades for efficiency or reliability |

What Are the Benefits and Drawbacks of Using a Starter Repair Service?

A starter repair service is an attractive alternative for businesses looking to minimize costs. This method involves diagnosing and fixing the existing starter rather than replacing it entirely. The primary advantage is cost savings, as repairs can often be less expensive than a full replacement. However, the effectiveness of this solution can be inconsistent, depending on the quality and expertise of the service provider. In cases of significant wear or damage, repairs may not restore the starter to optimal performance, leading to potential future failures.

How Does a High-Quality Starter Relay Compare to Replacing a Starter?

Opting for a high-quality starter relay can also serve as a viable alternative to replacing the entire starter system. A starter relay can enhance starting efficiency by ensuring a stronger electrical connection when initiating the engine. This option is generally lower in cost and easier to implement, as it typically requires only basic electrical knowledge for installation. However, it is essential to ensure compatibility with the existing starter system. While this solution can improve reliability, it may not address underlying issues with the starter itself, which could lead to further complications down the line.

Conclusión: ¿Cómo deben elegir los compradores B2B la solución adecuada?

Selecting the most appropriate solution for car starter issues depends on various factors, including the specific vehicle condition, budget, and operational needs. For businesses facing complete starter failures, direct replacement is often the most reliable option. Conversely, if issues are less severe, exploring starter repair services or investing in high-quality starter relays can provide cost-effective alternatives. B2B buyers should assess the long-term implications of each option, including potential maintenance costs and performance reliability, to ensure they make the best decision for their fleet management needs.

Essential Technical Properties and Trade Terminology for how to replace a car starter

What Are the Key Technical Properties to Consider When Replacing a Car Starter?

When evaluating starters for replacement, several technical properties are essential for ensuring compatibility, performance, and durability. Understanding these specifications can help B2B buyers make informed decisions that align with their operational needs.

-

Grado del material: The materials used in manufacturing a starter significantly influence its longevity and performance. Common materials include high-grade steel for durability and copper for electrical connections due to its excellent conductivity. Buyers should prioritize starters made from materials that can withstand the operational environment of their vehicles, especially in regions with extreme temperatures or conditions.

-

Par nominal: This specification indicates the amount of rotational force the starter can exert to turn the engine. It is crucial for ensuring that the starter can handle the engine’s demands, especially for larger vehicles or those with high-performance engines. A mismatch in torque can lead to starter failure or engine starting issues, which could impact vehicle uptime.

-

Tensión nominal: Most automotive starters operate on a 12V system, but variations exist. Understanding the voltage rating is vital for ensuring compatibility with the vehicle’s electrical system. A starter with a higher voltage rating than required may damage the vehicle’s components, while a lower rating could lead to inadequate performance.

-

Niveles de tolerancia: Tolerances refer to the permissible limits of variation in the starter’s dimensions and performance characteristics. Tight tolerances ensure proper fit and function within the vehicle’s engine system, preventing issues like vibration or misalignment. Buyers should look for manufacturers that specify tolerance levels in their product descriptions to ensure quality and reliability.

-

Peso: The weight of the starter can impact installation and overall vehicle performance. Heavier starters may require additional support during installation, while lighter models may offer ease of handling. Buyers should consider the weight relative to the vehicle’s specifications and their installation capabilities.

What Common Trade Terms Are Relevant for Car Starter Replacement?

Familiarity with industry terminology is essential for smooth procurement and communication in the automotive parts market. Here are several key terms that B2B buyers should know:

-

OEM (fabricante de equipos originales): This term refers to parts made by the same company that manufactured the original parts for the vehicle. OEM starters are often preferred for their guaranteed fit and performance, making them a reliable choice for replacements. Buyers should evaluate the advantages of OEM versus aftermarket options based on their specific needs.

-

MOQ (cantidad mínima de pedido): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and ensure cost-effectiveness. Negotiating MOQs can lead to better pricing and supply chain efficiency.

-

RFQ (Solicitud de presupuesto): An RFQ is a formal process where buyers request pricing and terms from suppliers. Crafting an effective RFQ can help businesses secure competitive pricing and favorable terms for starters, ensuring they can maintain operational budgets while meeting quality standards.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in shipping transactions. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is critical for managing logistics and ensuring that all parties are clear on their obligations, particularly for international shipments.

-

Mercado de repuestos: This term refers to parts that are not made by the OEM but are designed to fit and function similarly. Aftermarket starters may offer cost advantages but can vary in quality. Buyers should assess the reputation of aftermarket suppliers and the warranties offered to ensure reliability.

By grasping these technical properties and trade terms, B2B buyers can enhance their decision-making processes, ensuring that they procure the right components for their automotive needs.

Navigating Market Dynamics and Sourcing Trends in the how to replace a car starter Sector

What are the Global Market Dynamics for Replacing Car Starters?

The market for car starters is evolving rapidly due to a convergence of technological advancements and changing consumer preferences. One of the primary drivers is the increasing demand for electric vehicles (EVs), which often require specialized starters that differ from traditional internal combustion engines. This shift presents opportunities for international B2B buyers, particularly in emerging markets such as Africa and South America, where the adoption of EV technology is on the rise. Additionally, the proliferation of online marketplaces has transformed sourcing strategies, allowing companies in regions like Europe and the Middle East to access a broader range of suppliers and products.

Current B2B trends include the integration of smart technologies in automotive components, which enhances diagnostics and performance monitoring. This trend is particularly appealing to buyers looking to improve service offerings and efficiency. Furthermore, suppliers are increasingly focusing on modular components, allowing for easier replacements and repairs, thus reducing overall downtime for businesses. For buyers in Vietnam and Brazil, understanding these trends is critical to making informed purchasing decisions that align with market demands.

Illustrative image related to how to replace a car starter

How Can Sustainability and Ethical Sourcing Impact the Car Starter Sector?

Sustainability and ethical sourcing have become paramount in the automotive industry, including the car starter sector. The environmental impact of manufacturing processes and materials used in car starters is under scrutiny, pushing suppliers to adopt greener practices. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials or implementing energy-efficient manufacturing processes.

Moreover, ethical supply chains are essential for mitigating risks associated with labor practices and material sourcing. Buyers should look for certifications such as ISO 14001, which indicates effective environmental management systems, or the Responsible Business Alliance (RBA) certification, which addresses labor rights and ethical sourcing. These certifications not only enhance brand reputation but also align with consumer expectations for corporate responsibility. Companies that embrace these principles will likely gain a competitive edge in markets that are becoming more environmentally conscious.

What is the Historical Context of Car Starters in the Automotive Industry?

The evolution of car starters traces back to the early 20th century when hand-cranking was the norm. The introduction of electric starters in the 1910s marked a significant turning point, making vehicle operation more accessible and user-friendly. This innovation paved the way for the modern automotive industry, allowing for increased vehicle production and a greater focus on reliability.

Illustrative image related to how to replace a car starter

Over the decades, advancements in technology have led to the development of more efficient and compact starter designs, including gear reduction starters and high-performance variants for racing applications. In recent years, the rise of hybrid and electric vehicles has introduced new challenges and opportunities for the starter market, necessitating a shift in sourcing and manufacturing strategies to accommodate these changes. For B2B buyers, understanding this historical context is crucial for navigating current market dynamics and anticipating future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of how to replace a car starter

-

How do I diagnose a faulty car starter?

To diagnose a faulty car starter, first, listen for sounds when attempting to start the vehicle. If the engine makes no sound or produces only a faint clicking, it may indicate insufficient power reaching the starter. Ensure that the battery terminals are clean and securely connected. If the vehicle still fails to start, check the battery’s charge. A fully charged battery and clean connections are essential before concluding that the starter needs replacement. -

What type of car starter should I purchase for my vehicle model?

When sourcing a car starter, it’s crucial to match the starter with your vehicle’s make, model, and engine type. Consult the vehicle’s service manual or contact a reliable supplier for specifications. Ensure that the starter’s dimensions, mounting points, and electrical connections align with your vehicle’s requirements. Investing in a quality starter from a reputable supplier can enhance performance and longevity. -

¿Cuál es la cantidad mínima de pedido (MOQ) para los arrancadores de coche?

The minimum order quantity (MOQ) for car starters can vary significantly depending on the supplier and the type of starter. Typically, manufacturers may set MOQs ranging from 10 to 100 units for bulk purchases. It’s advisable to negotiate MOQs with potential suppliers, especially if you’re a smaller business. Many suppliers may offer flexibility based on your purchasing capacity or future order commitments. -

How can I verify the credibility of a car starter supplier?

To verify a car starter supplier’s credibility, conduct thorough research. Check for industry certifications, customer reviews, and testimonials. Look into their experience in the automotive sector, and ensure they have a solid track record of delivering quality products. Engaging in direct communication can also provide insights into their customer service and responsiveness, helping you make an informed decision. -

What payment terms should I expect when sourcing car starters internationally?

Payment terms for international sourcing can vary widely. Common arrangements include upfront payment, partial deposits, or payment upon delivery. It’s essential to discuss and agree on terms before finalizing orders. Additionally, consider using secure payment methods, such as letters of credit or escrow services, to mitigate risks associated with international transactions. -

How do I handle logistics for importing car starters?

When importing car starters, coordinate with a reliable freight forwarder who understands customs regulations in your destination country. Ensure that all necessary documentation, such as invoices, packing lists, and certificates of origin, are in order. Familiarize yourself with import duties and taxes that may apply. Effective communication with your supplier regarding shipping timelines will also help manage expectations. -

What are common quality assurance practices for car starters?

Quality assurance practices for car starters typically include rigorous testing for performance, durability, and compatibility. Suppliers should provide detailed specifications and test reports. Request samples before placing larger orders to assess quality firsthand. Additionally, consider establishing a quality control agreement with the supplier to ensure that all products meet your standards upon delivery. -

Can I customize car starters to meet specific requirements?

Yes, many manufacturers offer customization options for car starters to meet specific requirements, such as different voltage ratings or connection types. When discussing customization, provide detailed specifications, including dimensions and electrical characteristics. Custom orders may have longer lead times and potentially higher costs, so it’s important to factor these into your planning and budgeting processes.

Top 2 How To Replace A Car Starter Manufacturers & Suppliers List

1. eBay – Electric Starter Motor

Dominio: ebay.com

Registrado: 1995 (30 años)

Introducción: Project Duration: 1 to 2 hours; Skill Level: Intermediate; Product Type: Electric Starter (Starter Motor); Function: Spins the engine to start; Lifespan: At least 10 years and thousands of start cycles; Installation Difficulty: Varies based on accessibility; Common Mounting: Secured with 2 to 4 bolts; Connections: Battery’s positive terminal and trigger wire; Main Power Connection: Ring terminal c…

2. Everything Euro – Starter Replacement Guide

Dominio: todoeuro.com

Registrado: 2011 (14 años)

Introducción: Replacing a starter involves the following steps: 1. Disconnect the negative battery cable using a socket wrench. 2. Locate the starter, usually near the bottom side of the engine. 3. Remove the starter by disconnecting the positive and negative wires and unscrewing the bolts with a socket wrench. 4. Install the new starter by connecting the wires to the correct terminals (positive on top, negativ…

Strategic Sourcing Conclusion and Outlook for how to replace a car starter

In conclusion, successfully replacing a car starter is not just a technical task; it embodies the principles of strategic sourcing that can significantly benefit international B2B buyers. By understanding the key components of starter systems and ensuring the procurement of high-quality parts, businesses can enhance their operational efficiency and reduce downtime. This process involves meticulous planning, from identifying reliable suppliers to negotiating favorable terms that ensure the best value for money.

For buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can pave the way for sustainable partnerships with manufacturers and distributors. Emphasizing quality assurance and compatibility with local vehicle models can foster trust and long-term collaboration.

As the automotive industry continues to evolve, staying ahead of trends in starter technology and sourcing practices will be crucial. We encourage you to adopt a proactive approach—engage with trusted suppliers, invest in training your workforce, and streamline your procurement strategies. By doing so, you will not only improve your service offerings but also position your business for future growth in a competitive market.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Illustrative image related to how to replace a car starter

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.