Introducción: Cómo funciona el motor de arranque de un coche

Entender cómo funciona un motor de arranque en un coche es esencial para los compradores B2B internacionales que buscan componentes de automoción fiables. El motor de arranque desempeña un papel crucial en la puesta en marcha del motor, por lo que es un elemento fundamental en la funcionalidad del vehículo. Sin embargo, abastecerse de motores de arranque de calidad puede resultar complicado debido a las variaciones en el diseño, la aplicación y las normas de rendimiento en los distintos mercados. Esta guía ofrece una visión completa de los motores de arranque, incluidos sus tipos, principios de funcionamiento y aplicaciones.

Además, profundizaremos en los factores críticos para la selección de proveedores, asegurándonos de que elige socios que cumplen los estrictos requisitos de calidad y conformidad. Los compradores también encontrarán información sobre consideraciones de costes, que les ayudará a tomar decisiones de compra informadas que se ajusten a las limitaciones presupuestarias, manteniendo al mismo tiempo un alto rendimiento.

Al abordar las necesidades específicas de los compradores B2B de diversas regiones como África, Sudamérica, Oriente Medio y Europa -incluidos países como Alemania y Brasil-, esta guía le permite navegar con confianza por las complejidades del mercado mundial de la automoción. Tanto si desea mejorar su cadena de suministro como garantizar un rendimiento óptimo del vehículo, comprender las complejidades de los motores de arranque tendrá un impacto significativo en sus estrategias de adquisición y en su eficiencia operativa.

Índice

- Top 4 fabricantes & proveedores de Cómo funciona el motor de arranque de un coche Lista

- Introducción: Cómo funciona el motor de arranque de un coche

- Entender cómo funciona un motor de arranque en un coche Tipos y variaciones

- Aplicaciones industriales clave de cómo funciona un motor de arranque en un coche

- 3 puntos débiles habituales de los usuarios de ‘cómo funciona el motor de arranque de un coche’ y sus soluciones

- Guía estratégica de selección de materiales para cómo funciona un motor de arranque en un coche

- En profundidad: Procesos de fabricación y garantía de calidad para ¿Cómo funciona un motor de arranque en un coche?

- Guía práctica de búsqueda: Una lista de comprobación paso a paso para ‘cómo funciona un motor de arranque en un coche’

- Análisis exhaustivo de costes y precios de Cómo funciona un motor de arranque en un coche Sourcing

- Análisis de alternativas: Comparación de cómo funciona el motor de arranque de un coche con otras soluciones

- Propiedades técnicas esenciales y terminología comercial de cómo funciona un motor de arranque en un coche

- Cómo navegar por la dinámica del mercado y las tendencias de abastecimiento en el sector de cómo funciona un motor de arranque en un coche

- Preguntas frecuentes (FAQ) para compradores B2B de cómo funciona un motor de arranque en un coche

- Strategic Sourcing Conclusion and Outlook for ¿cómo funciona un motor de arranque en un coche?

- Aviso legal importante y condiciones de uso

Entender cómo funciona un motor de arranque en un coche Tipos y variaciones

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Arrancador convencional | Utiliza una conexión eléctrica directa con un solenoide para engranar el motor. | Fabricación de automóviles, talleres de reparación | Ventajas: Económico y ampliamente disponible. Contras: Salida de par limitada para motores más grandes. |

| Arrancador con reducción de engranajes | Incorpora un sistema de reducción de engranajes para aumentar el par y reducir el tamaño del motor. | Vehículos pesados, aplicaciones de carreras | Ventajas: Alto par de salida, diseño compacto. Contras: Más complejo, mayor coste. |

| Arrancador de imán permanente | Utiliza imanes permanentes en lugar de bobinas de campo, lo que resulta en un diseño más ligero. | Vehículos eléctricos, motocicletas | Ventajas: Ligero, eficiente. Contras: Menor par motor en comparación con los arrancadores tradicionales. |

| Arrancador de alto rendimiento | Diseñados para un par elevado y un acoplamiento rápido, a menudo con materiales avanzados. | Coches de altas prestaciones, automovilismo | Ventajas: Rendimiento superior, fiable en condiciones extremas. Contras: Precio más elevado, puede requerir una instalación específica. |

| Generador de arranque integrado (ISG) | Combina las funciones de motor de arranque y generador, de uso común en vehículos híbridos. | Fabricación de vehículos híbridos y eléctricos | Ventajas: Doble funcionalidad, eficiencia energética. Contras: La complejidad puede elevar los costes de reparación. |

¿Qué características tienen los arrancadores convencionales?

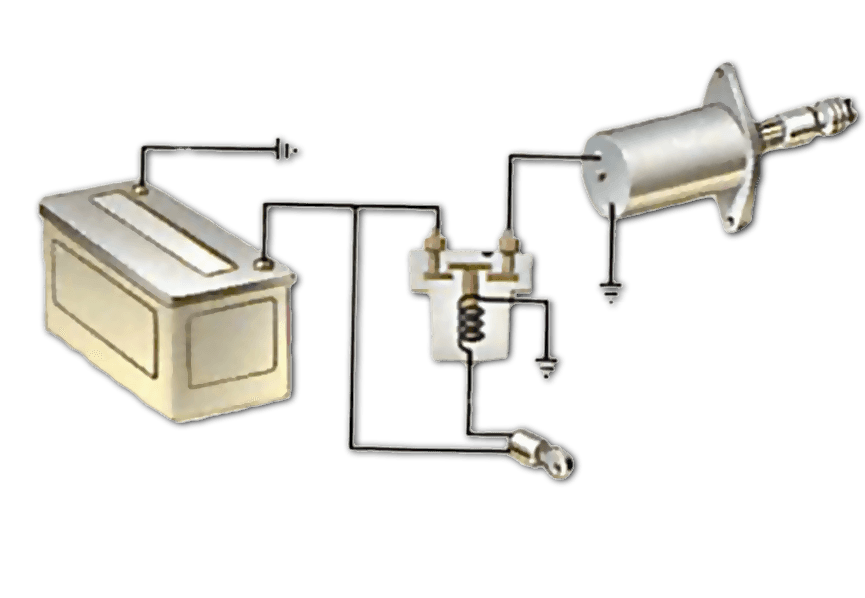

Los motores de arranque convencionales son los más comunes en los vehículos con motor de combustión interna. Funcionan mediante un solenoide que acciona el motor de arranque, el cual hace girar el volante para arrancar el motor. Este tipo de motor de arranque es rentable y está ampliamente disponible, por lo que es ideal para la fabricación de automóviles y talleres de reparación. Sin embargo, pueden tener dificultades para proporcionar un par motor suficiente para motores más grandes, lo que puede provocar problemas de rendimiento en aplicaciones pesadas.

¿Cómo mejoran el rendimiento los arrancadores reductores?

Los arrancadores de engranajes reductores utilizan un sistema de engranajes para amplificar el par producido por el motor minimizando su tamaño. Este diseño es especialmente beneficioso en vehículos pesados y aplicaciones de competición, donde un par elevado es esencial para el arranque del motor. Aunque estos arrancadores ofrecen diseños compactos y un rendimiento mejorado, su complejidad y costes más elevados pueden ser un problema para los compradores que buscan opciones asequibles.

¿Qué hace que los arrancadores de imanes permanentes sean adecuados para los vehículos eléctricos?

Los arrancadores de imanes permanentes sustituyen las bobinas de campo tradicionales por imanes permanentes, lo que da lugar a un diseño más ligero y eficiente. Esta tecnología se utiliza cada vez más en vehículos eléctricos y motocicletas, donde el ahorro de peso es crucial para el rendimiento y la eficiencia. Aunque ofrecen un rendimiento excelente, su menor par de salida en comparación con los arrancadores convencionales puede limitar su uso en vehículos más grandes o en aplicaciones exigentes.

¿Por qué son esenciales los arrancadores de alto rendimiento en el automovilismo?

Los motores de arranque de alto rendimiento están diseñados específicamente para ofrecer un par máximo y un acoplamiento rápido, lo que los hace ideales para coches de altas prestaciones y aplicaciones de automovilismo. A menudo incorporan materiales avanzados para soportar condiciones extremas. Aunque estos arrancadores ofrecen un rendimiento superior, su precio más elevado y los posibles requisitos de instalación pueden suponer un obstáculo para algunos compradores.

¿Cómo contribuyen los generadores de arranque integrados a los vehículos híbridos?

Los generadores de arranque integrados (ISG) combinan la funcionalidad de un motor de arranque y un generador en una sola unidad, algo habitual en los vehículos híbridos. Esta doble funcionalidad permite mejorar la eficiencia energética y reducir el peso. Aunque los ISG suponen un avance significativo en la tecnología de automoción, su complejidad puede conllevar mayores costes de reparación, por lo que es esencial que los compradores tengan en cuenta las implicaciones de mantenimiento a largo plazo a la hora de adquirirlos.

Aplicaciones industriales clave de cómo funciona un motor de arranque en un coche

| Industria/Sector | Aplicación específica de cómo funciona un motor de arranque en un coche | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Fabricación de automóviles | Producción de motores de arranque para vehículos nuevos | Garantiza un arranque fiable del motor, mejorando el rendimiento del vehículo | Garantía de calidad, cumplimiento de las normas internacionales y rentabilidad en el aprovisionamiento de componentes. |

| Servicios de reparación de automóviles | Servicios de diagnóstico y sustitución del motor de arranque | Mejora de la satisfacción del cliente y repetición del negocio gracias a reparaciones fiables | Acceso a piezas OEM, servicios de garantía y asistencia técnica para la instalación. |

| Gestión de flotas | Mantenimiento de motores de arranque en flotas de vehículos | Reduce el tiempo de inactividad y los costes de mantenimiento, mejorando la eficacia operativa | Acuerdos de compra a granel, fiabilidad de los proveedores y disponibilidad de formación técnica para el personal. |

| Desarrollo del vehículo eléctrico | Integración de motores de arranque en sistemas híbridos | Apoya diseños innovadores de vehículos, mejorando la competitividad del mercado | Compatibilidad con los sistemas existentes, contratación de tecnología avanzada y consideraciones de sostenibilidad. |

| Maquinaria y equipos pesados | Motores de arranque para maquinaria agrícola y de construcción | Garantiza la disponibilidad operativa y la fiabilidad en entornos exigentes | Especificaciones de durabilidad, resistencia medioambiental y abastecimiento de fabricantes reputados. |

¿Cómo se aplica el motor de arranque en la fabricación de automóviles?

En el sector de la fabricación de automóviles, los motores de arranque son componentes cruciales en el montaje de vehículos nuevos. Garantizan un arranque fiable del motor, lo que es esencial para el rendimiento del vehículo y la satisfacción del cliente. Los fabricantes deben dar prioridad al suministro de motores de arranque de alta calidad que cumplan las normas internacionales para mantener su reputación y cumplir los requisitos reglamentarios. Esto implica considerar la rentabilidad de los componentes al tiempo que se garantiza que cumplen las especificaciones de durabilidad y rendimiento.

¿Qué papel desempeña el motor de arranque en los servicios de reparación de automóviles?

Los servicios de reparación de automóviles utilizan motores de arranque para el diagnóstico y la sustitución. Un motor de arranque defectuoso puede provocar una gran insatisfacción entre los clientes debido a los problemas de arranque del vehículo. Al ofrecer servicios fiables de diagnóstico y sustitución, los talleres de reparación pueden fidelizar a sus clientes y hacer que repitan. Los compradores B2B de este sector deben centrarse en el suministro de piezas OEM para garantizar la compatibilidad y la fiabilidad, así como en establecer relaciones con proveedores que ofrezcan una asistencia técnica completa.

¿Cómo se beneficia la gestión de flotas del mantenimiento de los motores de arranque?

En la gestión de flotas, el mantenimiento regular de los motores de arranque es esencial para minimizar el tiempo de inactividad de los vehículos y los costes de mantenimiento. Un motor de arranque bien mantenido garantiza que los vehículos estén operativos y listos para su uso, lo que es vital para las empresas que dependen de entregas puntuales. Los compradores B2B deben considerar acuerdos de compra al por mayor con los proveedores para asegurar precios favorables y garantizar un suministro constante de motores de arranque. Además, la formación del personal de mantenimiento en materia de motores de arranque puede aumentar aún más la fiabilidad de la flota.

¿Qué innovaciones se introducen en el desarrollo de vehículos eléctricos?

La integración de motores de arranque en vehículos eléctricos híbridos representa un avance significativo en la tecnología del automóvil. Estos sistemas requieren motores de arranque que puedan acoplarse eficazmente a los componentes eléctricos, garantizando al mismo tiempo transiciones suaves entre la energía eléctrica y la de combustión. Los compradores B2B centrados en este mercado deben dar prioridad al abastecimiento de componentes que sean compatibles con los sistemas existentes, y deben tener en cuenta a los proveedores que están a la vanguardia de los avances tecnológicos en componentes para vehículos eléctricos.

¿Cómo se utilizan los motores de arranque en maquinaria y equipos pesados?

Los motores de arranque son vitales para la maquinaria pesada y los equipos agrícolas, donde son necesarios mecanismos de arranque fiables para la disponibilidad operativa. Estos entornos suelen exponer a los motores de arranque a condiciones extremas, por lo que requieren componentes duraderos y resistentes a los factores ambientales. Los compradores B2B de este sector deben centrarse en el suministro de motores de arranque que cumplan requisitos específicos de durabilidad, garantizando que puedan soportar un uso riguroso al tiempo que mantienen la eficiencia de su rendimiento.

3 puntos débiles habituales de los usuarios de ‘cómo funciona el motor de arranque de un coche’ y sus soluciones

Escenario 1: Comprender la complejidad de la funcionalidad motriz del motor de arranque

El problema: Los compradores B2B suelen encontrar dificultades a la hora de explicar a sus clientes el intrincado funcionamiento de los motores de arranque, especialmente en mercados en los que los conocimientos técnicos pueden variar considerablemente. El reto consiste en explicar cómo un motor de arranque inicia el funcionamiento del motor, que es crucial para la funcionalidad general del vehículo. Los malentendidos pueden llevar a una selección inadecuada del producto, con la consiguiente pérdida de recursos y la posible insatisfacción del cliente.

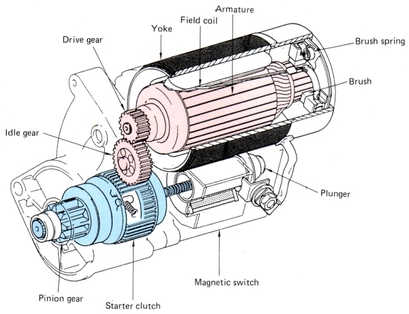

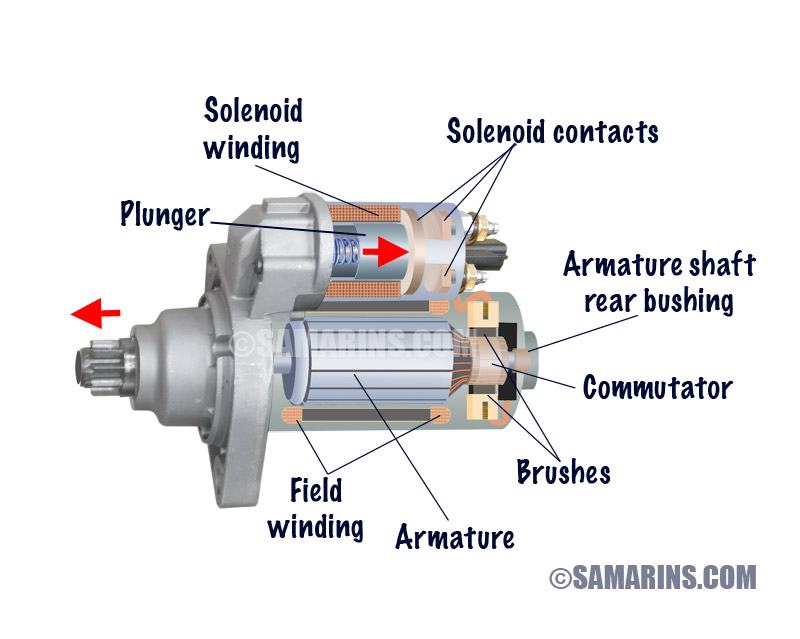

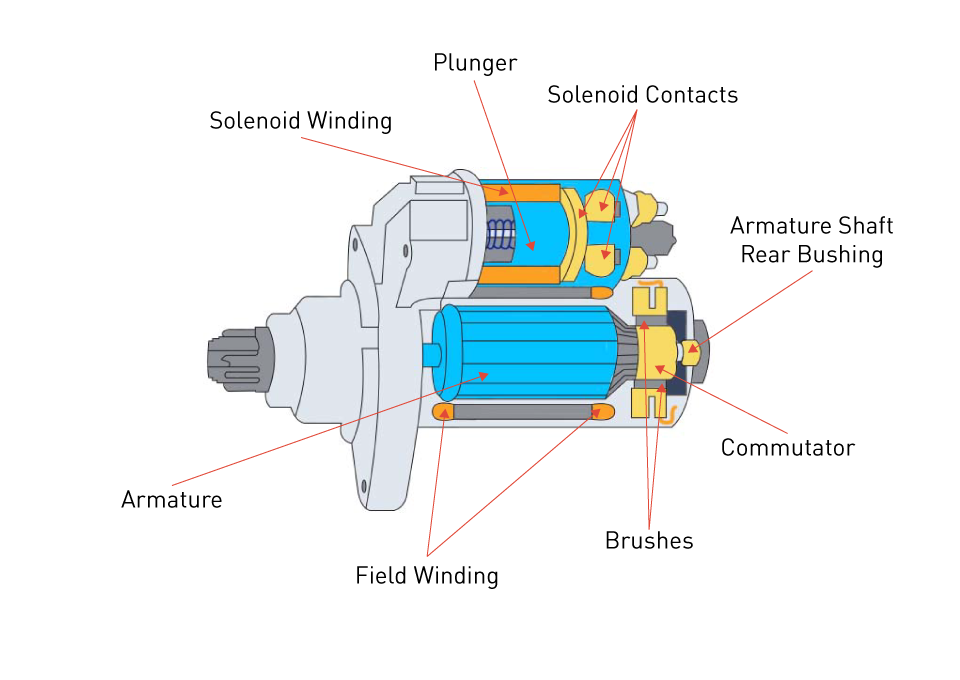

La solución: Para comunicar eficazmente cómo funciona un motor de arranque, los compradores B2B deben invertir en recursos educativos detallados, como manuales técnicos o vídeos instructivos que desglosen los componentes y el funcionamiento del motor de arranque. Proporcionar ayudas visuales, como diagramas que muestren la interacción entre el motor de arranque, el solenoide y el volante, puede mejorar la comprensión. Además, ofrecer sesiones de formación práctica o talleres puede ayudar a los clientes a comprender mejor los aspectos técnicos. Este enfoque no sólo genera confianza, sino que también posiciona su marca como un socio experto en el sector de la automoción.

Escenario 2: Identificación de los síntomas de fallo del motor de arranque

El problema: Muchos compradores B2B se enfrentan a dificultades a la hora de diagnosticar problemas en el motor de arranque de los vehículos. Los clientes a menudo informan de problemas de arranque, pero sin una comprensión clara de los síntomas o las causas subyacentes, los compradores pueden tener dificultades para proporcionar soluciones adecuadas. Esta situación se agrava cuando los clientes atribuyen erróneamente los fallos del motor de arranque a otros componentes, lo que conduce a compras y reparaciones equivocadas.

La solución: La aplicación de un enfoque sistemático para diagnosticar las averías del motor de arranque puede mejorar significativamente la satisfacción del cliente. Los compradores deben elaborar una guía detallada de localización de averías en la que se describan los síntomas más comunes -como chasquidos o un arranque lento- y sus posibles causas, como problemas con la batería o fallos en el solenoide. Además, anime a los clientes a realizar comprobaciones iniciales como inspeccionar la carga de la batería y las conexiones antes de concluir que el motor de arranque está averiado. Proporcionar acceso a herramientas de diagnóstico y formación sobre su uso también puede ayudar a los clientes a identificar los problemas con precisión, lo que lleva a decisiones más informadas y reparaciones eficaces.

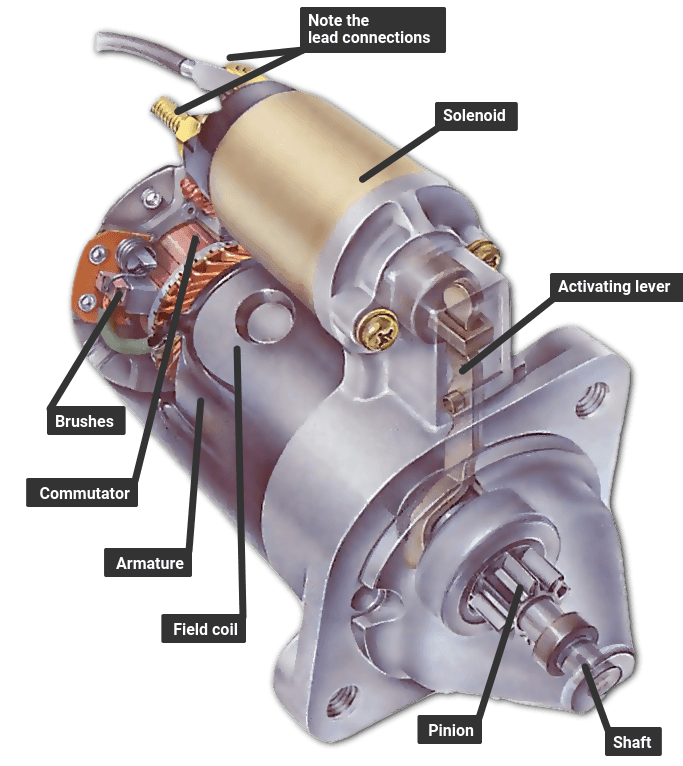

Imagen ilustrativa relacionada con cómo funciona un motor de arranque en un coche

Escenario 3: Abastecimiento de motores de arranque de calidad

El problema: Abastecerse de motores de arranque fiables puede suponer un importante quebradero de cabeza para los compradores B2B, especialmente en regiones con normas de calidad y fiabilidad de los proveedores variables. Las complicaciones surgen cuando los compradores no son capaces de diferenciar entre productos de alta calidad y productos de calidad inferior, lo que puede provocar fallos frecuentes, reclamaciones de garantía y, en última instancia, dañar su reputación en el mercado.

La solución: Para mitigar los problemas de abastecimiento, los compradores B2B deben establecer relaciones sólidas con fabricantes y proveedores reputados y conocidos por sus normas de control de calidad. Es esencial llevar a cabo la diligencia debida, como revisar las certificaciones del proveedor y su historial de rendimiento. Además, elaborar una lista de comprobación estandarizada para evaluar los motores de arranque -teniendo en cuenta factores como las especificaciones de par, las condiciones de garantía y las opiniones de los clientes- puede agilizar el proceso de aprovisionamiento. Entablar una comunicación regular con los proveedores para debatir las mejoras de los productos y las tendencias del sector también puede garantizar que los compradores se mantengan informados y sean competitivos en sus ofertas. Al dar prioridad a la calidad y la fiabilidad, los compradores B2B pueden fomentar relaciones a largo plazo con los clientes, mejorando su posición en el mercado.

Guía estratégica de selección de materiales para cómo funciona un motor de arranque en un coche

A la hora de seleccionar materiales para motores de arranque, es esencial tener en cuenta sus propiedades, ventajas y limitaciones. La elección del material puede influir significativamente en el rendimiento, la durabilidad y la rentabilidad general del motor de arranque, sobre todo para los compradores B2B internacionales de mercados tan diversos como África, Sudamérica, Oriente Medio y Europa. A continuación, analizamos cuatro materiales comunes utilizados en los motores de arranque.

¿Cuáles son las propiedades clave del cobre en los motores de arranque?

El cobre se utiliza ampliamente en motores de arranque principalmente por su excelente conductividad eléctrica. Esta propiedad permite una transmisión eficaz de la corriente eléctrica, que es vital para el funcionamiento del motor. El cobre también ofrece una buena conductividad térmica, que ayuda a disipar el calor generado durante el funcionamiento, mejorando así la fiabilidad del rendimiento.

Ventajas: El cobre es duradero y resistente a la corrosión, por lo que resulta adecuado para diversos entornos. Su alta conductividad garantiza que los motores de arranque puedan proporcionar el par necesario para arrancar el motor con eficacia.

Contras: El principal inconveniente del cobre es su coste, que puede ser superior al de alternativas como el aluminio. Además, el cobre es relativamente pesado, lo que puede no ser ideal para aplicaciones en las que la reducción de peso es fundamental.

Impacto en la aplicación: El cobre es compatible con diversos fluidos de automoción, y su resistencia a la corrosión garantiza la longevidad en entornos difíciles.

Consideraciones para compradores internacionales: Los compradores deben garantizar el cumplimiento de normas internacionales como la ASTM B170 para el alambre de cobre y considerar las implicaciones de la fluctuación de los precios del cobre en los costes globales.

¿Cómo mejora el aluminio el rendimiento del motor de arranque?

El aluminio es otro material habitual en los motores de arranque, sobre todo en componentes como la carcasa y los soportes. Se valora por su ligereza, que contribuye a la eficiencia general del vehículo.

Ventajas: El aluminio es rentable y ofrece una buena resistencia a la corrosión, lo que lo hace adecuado para diversos climas. Su ligereza ayuda a reducir el peso total del motor de arranque, mejorando la eficiencia del combustible.

Contras: Aunque el aluminio es duradero, no es tan resistente como el cobre o el acero, lo que puede limitar su uso en aplicaciones sometidas a grandes esfuerzos. Además, su conductividad térmica es inferior a la del cobre, lo que puede provocar retención de calor.

Impacto en la aplicación: La compatibilidad del aluminio con los fluidos de automoción suele ser buena, pero hay que tener cuidado en entornos de altas temperaturas.

Consideraciones para compradores internacionales: El cumplimiento de normas como la DIN 1725 para las aleaciones de aluminio es esencial. Los compradores también deben tener en cuenta la disponibilidad de aluminio en su región, ya que puede variar.

¿Por qué el acero es una elección común para los componentes del motor de arranque?

El acero, en particular el acero al carbono, suele utilizarse para componentes como el inducido y el piñón debido a su resistencia y durabilidad.

Ventajas: El acero ofrece una gran resistencia a la tracción, por lo que es ideal para componentes que soportan grandes esfuerzos mecánicos. Además, es relativamente barato en comparación con otros materiales.

Contras: El acero es más pesado que el aluminio y el cobre, lo que puede ser una desventaja en aplicaciones en las que la reducción de peso es fundamental. Además, es susceptible a la corrosión si no se trata adecuadamente.

Impacto en la aplicación: La compatibilidad del acero con los fluidos de automoción suele ser buena, pero la resistencia a la corrosión debe mejorarse mediante revestimientos o tratamientos.

Imagen ilustrativa relacionada con cómo funciona un motor de arranque en un coche

Consideraciones para compradores internacionales: Los compradores deben asegurarse del cumplimiento de normas como la ASTM A36 para el acero al carbono. Los tratamientos anticorrosivos pueden ser necesarios en regiones húmedas o costeras.

¿Qué papel desempeña el plástico en el diseño de motores de arranque?

Los materiales plásticos, en particular los polímeros de alto rendimiento, se utilizan cada vez más en los motores de arranque para componentes no estructurales como aisladores y carcasas.

Ventajas: Los plásticos son ligeros y pueden moldearse en formas complejas, lo que permite flexibilidad en el diseño. También ofrecen excelentes propiedades de aislamiento eléctrico.

Contras: Los plásticos no resisten las altas temperaturas tan bien como los metales y pueden degradarse con el tiempo en determinadas condiciones ambientales. Su resistencia mecánica también es inferior a la de los metales.

Impacto en la aplicación: En general, los plásticos son compatibles con los fluidos de automoción, pero su rendimiento puede variar en función del polímero específico utilizado.

Consideraciones para compradores internacionales: Los compradores deben buscar el cumplimiento de normas internacionales como ISO 9001 para la gestión de la calidad. La elección del plástico debe tener en cuenta la temperatura local y las condiciones ambientales.

Tabla resumen de selección de materiales para motores de arranque

| Material | Caso práctico típico de cómo funciona un motor de arranque en un coche | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Cobre | Conexiones eléctricas y bobinados | Excelente conductividad eléctrica | Mayor coste, mayor peso | Alto |

| Aluminio | Carcasa y soportes | Ligero y rentable | Resistencia inferior a la del cobre/acero | Medio |

| Acero | Armadura y piñón | Alta resistencia a la tracción | Más pesado, propenso a la corrosión | Bajo |

| Plástico | Aisladores y componentes no estructurales | Flexibilidad de diseño, ligereza | Menor resistencia a la temperatura | Medio |

Este análisis proporciona una visión global de las opciones de materiales para motores de arranque, ayudando a los compradores B2B a tomar decisiones informadas adaptadas a sus necesidades específicas y consideraciones regionales.

En profundidad: Procesos de fabricación y garantía de calidad para ¿Cómo funciona un motor de arranque en un coche?

¿Cuáles son las principales etapas de la fabricación de un motor de arranque?

La fabricación de motores de arranque implica una serie de intrincadas etapas diseñadas para garantizar tanto la calidad como la funcionalidad. Cada etapa desempeña un papel fundamental en la fabricación de un producto fiable que satisfaga las exigencias de las aplicaciones de automoción.

¿Cómo se prepara el material para la producción de motores de arranque?

La fase inicial de la fabricación de motores de arranque comienza con la preparación del material. Se obtienen materias primas de alta calidad, como cobre para los bobinados, acero para la carcasa y diversos polímeros para los componentes aislantes. Estos materiales se someten a inspecciones exhaustivas para garantizar que cumplen las normas especificadas de conductividad, resistencia y durabilidad.

Imagen ilustrativa relacionada con cómo funciona un motor de arranque en un coche

Una vez confirmados los materiales, se cortan, moldean o procesan según especificaciones predeterminadas. Por ejemplo, los hilos de cobre se trefilan hasta alcanzar el calibre requerido, y los componentes de acero se estampan o mecanizan para crear piezas de precisión como el inducido y la carcasa.

¿Qué técnicas se utilizan en el proceso de conformado de motores de arranque?

Tras la preparación del material, comienza el proceso de conformado. Para crear los componentes del motor de arranque suelen emplearse técnicas como la fundición a presión, el estampado y la forja. Por ejemplo, el inducido suele fabricarse mediante una combinación de procesos de estampación y bobinado, en los que el hilo de cobre aislado se enrolla alrededor de un núcleo de hierro laminado para mejorar las propiedades magnéticas.

Además, componentes como el solenoide y el piñón se fabrican mediante mecanizado de alta precisión para garantizar que encajan perfectamente en el conjunto. La fase de conformado es fundamental, ya que establece las dimensiones y formas fundamentales que afectarán al rendimiento general del motor.

¿Cómo se realiza el montaje en la fabricación de motores de arranque?

La fase de montaje consiste en integrar cuidadosamente todos los componentes individuales en un motor de arranque completo. En este proceso se utilizan a menudo líneas de montaje automatizadas equipadas con sistemas robóticos para mayor precisión y eficacia. Los componentes clave, como el inducido, las bobinas de campo, el conmutador y el solenoide, se juntan para garantizar que las conexiones eléctricas sean seguras y estén alineadas correctamente.

Durante el montaje, los fabricantes suelen emplear especificaciones de par de apriete para apretar tornillos y elementos de fijación, garantizando que cada conexión sea lo bastante robusta para soportar la tensión de funcionamiento. Esta fase también puede incluir la instalación de puntos de control de calidad para detectar cualquier defecto antes de que el producto pase a la fase de acabado.

¿Qué técnicas de acabado se aplican a los motores de arranque?

Los procesos de acabado son vitales para mejorar la durabilidad y el rendimiento de los motores de arranque. Entre las técnicas de acabado más comunes se encuentran el tratamiento de superficies, la pintura y el revestimiento. Los componentes pueden recubrirse con materiales anticorrosivos para protegerlos de factores ambientales, sobre todo en regiones propensas a la humedad o a temperaturas extremas.

Además, se realiza una inspección final para comprobar si hay defectos superficiales o errores de montaje. Este paso garantiza que el motor de arranque cumple las normas del sector antes de ser embalado y enviado a los clientes.

¿Cuáles son los procesos de garantía de calidad para los motores de arranque?

La garantía de calidad (GC) es esencial en la fabricación de motores de arranque para garantizar la fiabilidad y la seguridad. El cumplimiento de las normas internacionales ayuda a los fabricantes a mantener la calidad del producto y satisfacer las expectativas de los clientes.

¿Qué normas internacionales son relevantes para la garantía de calidad de los motores de arranque?

En el ámbito de los componentes de automoción, ISO 9001 es una norma fundamental que describe los requisitos de un sistema de gestión de la calidad. El cumplimiento de la norma ISO 9001 demuestra el compromiso del fabricante con la calidad y la mejora continua.

Además de las normas ISO, también pueden aplicarse certificaciones industriales específicas, como la CE (Conformité Européenne) para los productos vendidos en Europa y las normas API (American Petroleum Institute) para el rendimiento. Estas certificaciones garantizan que los motores de arranque cumplen la normativa de seguridad y medio ambiente.

¿Qué puntos de control de calidad se suelen aplicar?

Los puntos de control de calidad (CC) se colocan estratégicamente a lo largo del proceso de fabricación para supervisar la calidad en las distintas fases.

Imagen ilustrativa relacionada con cómo funciona un motor de arranque en un coche

-

Control de calidad de entrada (IQC): Este punto de control consiste en inspeccionar las materias primas a su recepción para garantizar que cumplen las especificaciones de calidad antes de iniciar la producción.

-

Control de calidad durante el proceso (IPQC): Durante las fases de fabricación, se realizan inspecciones periódicas para verificar que los componentes se fabrican dentro de las tolerancias. Esto puede incluir la medición de dimensiones y la comprobación de las conexiones eléctricas.

-

Control de calidad final (FQC): Antes de embalar los productos, se realiza una inspección exhaustiva para comprobar la funcionalidad y fiabilidad de los motores de arranque. Los métodos de prueba habituales incluyen pruebas eléctricas, pruebas de par y simulaciones de funcionamiento para garantizar que los motores funcionan correctamente en condiciones reales.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

Para los compradores B2B internacionales, verificar los procesos de control de calidad de un proveedor es crucial para garantizar la fiabilidad del producto y el cumplimiento de la normativa local. He aquí varias estrategias para evaluar eficazmente la calidad del proveedor:

-

Auditorías: La realización de auditorías in situ permite a los compradores evaluar de primera mano el entorno de fabricación y los procesos de control de calidad. Esto incluye la revisión de la documentación relacionada con los sistemas de gestión de la calidad y los registros de inspección.

-

Informes: Solicitar informes de calidad periódicos puede proporcionar información sobre el rendimiento del proveedor a lo largo del tiempo. Puede incluir índices de defectos, resultados de inspecciones y medidas correctivas adoptadas en respuesta a problemas de calidad.

-

Inspecciones por terceros: Contratar servicios de inspección de terceros puede proporcionar una evaluación imparcial de los procesos de control de calidad del proveedor y de la calidad del producto. Estas inspecciones pueden ser especialmente valiosas para los compradores que operan en regiones con requisitos normativos estrictos.

¿Cuáles son los matices del control de calidad y la certificación para los compradores B2B internacionales?

Al tratar con proveedores internacionales, los compradores B2B deben sortear diversos matices de control de calidad y certificación. Es esencial comprender los requisitos específicos de los distintos mercados.

-

Normativa regional: Cada región puede tener sus propias normas de seguridad y medio ambiente. Por ejemplo, los componentes de automoción vendidos en Europa deben cumplir la marca CE, mientras que los productos de Estados Unidos pueden tener que cumplir normas específicas de la EPA.

-

Consideraciones culturales: Las distintas regiones pueden tener enfoques diferentes sobre la calidad y las prácticas de fabricación. Para los compradores de África o Sudamérica, es esencial tener en cuenta las normas y prácticas de la industria local a la hora de evaluar a los proveedores.

-

Barreras lingüísticas y de comunicación: La comunicación eficaz es vital para garantizar que se entienden y cumplen las expectativas de calidad. Los compradores deben considerar la posibilidad de trabajar con proveedores que puedan facilitar documentación y asistencia en varios idiomas.

Al conocer estos procesos de fabricación y prácticas de garantía de calidad, los compradores B2B pueden tomar decisiones informadas a la hora de abastecerse de motores de arranque, garantizando en última instancia que seleccionan proveedores fiables que suministran productos de alta calidad.

Guía práctica de búsqueda: Una lista de comprobación paso a paso para ‘cómo funciona un motor de arranque en un coche’

A fin de garantizar el éxito del proceso de adquisición para entender cómo funciona un motor de arranque en los vehículos, esta guía proporciona una lista de comprobación detallada que ayudará a los compradores B2B a tomar decisiones informadas. Con la creciente demanda de componentes de automoción fiables en diversos mercados, como África, Sudamérica, Oriente Medio y Europa, es esencial seguir un enfoque estructurado.

Paso 1: Defina sus especificaciones técnicas

Establecer unas especificaciones técnicas claras es crucial para abastecerse de motores de arranque. Esto incluye conocer el voltaje requerido, los valores nominales de par y la compatibilidad con modelos de vehículos específicos. Documentar estas especificaciones le ayudará a agilizar la comunicación con los proveedores y le garantizará que recibe productos que satisfacen sus necesidades operativas.

Paso 2: Investigar posibles proveedores

Investigue a fondo para identificar posibles proveedores especializados en motores de arranque. Busque fabricantes con una sólida reputación en el sector de la automoción y un historial probado. Utiliza directorios online, ferias y publicaciones del sector para elaborar una lista de candidatos.

Paso 3: Evaluar las certificaciones de los proveedores

Antes de seguir adelante, compruebe que los proveedores disponen de las certificaciones pertinentes que cumplen las normas internacionales de automoción. Busque certificaciones ISO, sistemas de gestión de la calidad y cumplimiento de la normativa regional. Este paso es crucial para asegurarse de que los componentes que adquiere se fabrican bajo estrictos controles de calidad.

Paso 4: Evaluar la calidad y fiabilidad del producto

La garantía de calidad no es negociable cuando se trata de abastecerse de motores de arranque. Solicite muestras o especificaciones detalladas del producto para evaluar los materiales y los procesos de fabricación utilizados. Hable de las políticas de garantía y los índices de avería para calibrar la fiabilidad de los productos.

- Subbala: Solicite los resultados de las pruebas de rendimiento para verificar la durabilidad del motor en diversas condiciones.

Paso 5: Solicitar asistencia técnica y documentación

Asegúrese de que sus proveedores le proporcionan una asistencia técnica y una documentación completas. Esto incluye guías de instalación, manuales de resolución de problemas e instrucciones de mantenimiento. Tener acceso a estos recursos facilitará una integración más fluida de los motores de arranque en sus operaciones.

Paso 6: Negociar los términos y condiciones

Una vez identificado un proveedor adecuado, negocie los términos y condiciones de la compra. Discuta los precios, las condiciones de pago, los plazos de entrega y las políticas de devolución. Unos acuerdos claros en esta fase pueden ayudar a evitar malentendidos y garantizar un proceso de compra fluido.

Paso 7: Establecer canales de comunicación

Por último, establezca canales de comunicación eficaces con el proveedor elegido. Las actualizaciones periódicas y las líneas de comunicación abiertas ayudarán a abordar cualquier problema que pueda surgir durante el proceso de contratación. Establecer una relación sólida con el proveedor puede mejorar el servicio y la asistencia a largo plazo.

Siguiendo esta lista de comprobación estructurada, los compradores B2B pueden navegar eficazmente por las complejidades del aprovisionamiento de motores de arranque, asegurándose de adquirir componentes de alta calidad que cumplan sus requisitos específicos.

Análisis exhaustivo de costes y precios de Cómo funciona un motor de arranque en un coche Sourcing

¿Cuáles son los principales componentes del coste de adquisición de motores de arranque?

A la hora de adquirir motores de arranque, es fundamental conocer la estructura de costes. Los principales componentes que contribuyen al coste total son los materiales, la mano de obra, los gastos generales de fabricación, las herramientas, el control de calidad, la logística y el margen de beneficio.

-

Materiales: El coste de materias primas como el cobre para los bobinados, el acero para la carcasa y diversas aleaciones para componentes como el inducido y el colector puede variar significativamente. Los materiales de alta calidad son esenciales para la durabilidad y el rendimiento, pero pueden aumentar los costes.

-

Trabajo: Los costes laborales dependerán de la complejidad del proceso de fabricación y del nivel de cualificación de los trabajadores. Las regiones con costes laborales más bajos, como algunas zonas de África y Sudamérica, pueden ofrecer precios competitivos, pero hay que tener en cuenta la garantía de calidad.

-

Gastos generales de fabricación: Aquí se incluyen los costes relacionados con los servicios públicos, el alquiler y el mantenimiento de los equipos. Unos procesos de fabricación eficientes pueden ayudar a minimizar los gastos generales, lo que es especialmente relevante para la producción de grandes volúmenes.

-

Herramientas: Los costes iniciales de utillaje pueden ser significativos, especialmente en el caso de los motores de arranque personalizados. Estos costes se amortizan a lo largo de las series de producción, por lo que es esencial evaluar el volumen previsto a la hora de valorar el coste total.

-

Control de calidad (QC): La aplicación de rigurosos procesos de control de calidad garantiza que los motores de arranque cumplan las normas del sector y las especificaciones del cliente. Aunque esto supone un coste añadido, puede evitar costosas devoluciones y mejorar la satisfacción del cliente.

-

Logística: Los costes de envío, incluidos el transporte, los derechos de aduana y el almacenamiento, deben tenerse en cuenta en el coste total. Los diferentes Incoterms pueden afectar a los costes y responsabilidades logísticas, por lo que es importante elegir los términos adecuados a sus necesidades.

-

Margen: Los proveedores suelen incluir un margen de beneficio en sus precios. Conocer las referencias del sector puede ayudar a los compradores a negociar mejores acuerdos.

¿Cómo influyen los precios en la compra de motores de arranque?

Varios factores influyen en el precio de los motores de arranque más allá de los componentes básicos del coste:

-

Volumen/Cantidad mínima de pedido: Los pedidos más grandes suelen dar lugar a costes unitarios más bajos debido a las economías de escala. Establecer una cantidad mínima de pedido (MOQ) también puede ayudar a los proveedores a gestionar los costes de producción.

-

Especificaciones y personalización: Los motores de arranque personalizados que cumplen requisitos específicos del vehículo pueden suponer costes adicionales. Los compradores deben considerar si el gasto añadido se ajusta a sus necesidades operativas.

-

Materiales y certificaciones de calidad: Los motores fabricados con materiales de calidad superior y certificados conforme a las normas de calidad internacionales pueden tener un precio superior. Sin embargo, esto suele traducirse en un mayor rendimiento y longevidad.

-

Factores relacionados con los proveedores: La reputación y fiabilidad de los proveedores puede influir en el precio. Los proveedores establecidos pueden ofrecer mejor asistencia y garantías, lo que puede justificar costes más elevados.

-

Incoterms: La elección de los Incoterms puede afectar significativamente a los costes totales en destino. Comprender términos como CIF (coste, seguro y flete) o FOB (franco a bordo) puede ayudar a presupuestar y negociar.

¿Qué consejos de compra pueden mejorar la rentabilidad en el aprovisionamiento de motores de arranque?

Los compradores B2B pueden aprovechar diversas estrategias para mejorar la rentabilidad a la hora de adquirir motores de arranque:

-

Negociación: Establecer relaciones con los proveedores puede conducir a condiciones más favorables. Ser transparente sobre sus necesidades y volumen puede animar a los proveedores a ofrecer descuentos o mejores condiciones de pago.

-

Coste total de propiedad (TCO): Evalúe los costes a largo plazo asociados al motor de arranque, incluido el mantenimiento, las garantías y los posibles tiempos de inactividad. Un precio inicial más bajo no siempre supone un ahorro de costes.

-

Matices en los precios para compradores internacionales: Para los compradores de África, Sudamérica, Oriente Medio y Europa, es esencial tener en cuenta las condiciones del mercado regional, los aranceles y las fluctuaciones monetarias. Trabajar con proveedores locales puede mitigar algunos de estos costes.

-

Evaluación de la calidad: Antes de realizar una compra, asegúrese de que los motores de arranque cumplen sus normas de calidad. La diligencia debida con los proveedores y la solicitud de muestras pueden ayudar a tomar decisiones con conocimiento de causa.

Descargo de responsabilidad sobre los precios indicativos

Los precios de los motores de arranque pueden variar mucho en función de los factores mencionados. La información facilitada es indicativa y debe verificarse con los proveedores para conocer los precios más exactos y actuales en función de las necesidades específicas de abastecimiento.

Análisis de alternativas: Comparación de cómo funciona el motor de arranque de un coche con otras soluciones

Introducción: Explorando alternativas a los motores de arranque en aplicaciones de automoción

En el ámbito de la ingeniería de automoción, el motor de arranque ha sido un componente fundamental para iniciar el funcionamiento del motor. Sin embargo, a medida que la tecnología evoluciona, han surgido soluciones alternativas que pueden proporcionar funcionalidades similares o mejoradas. Este análisis presenta una comparación entre el motor de arranque tradicional y dos alternativas viables: el sistema integrado de motor de arranque-generador y el arranque manual por manivela. Al examinar estas tecnologías, los compradores B2B pueden tomar decisiones informadas en función de sus necesidades operativas y consideraciones presupuestarias.

Tabla comparativa

| Aspecto comparativo | Cómo funciona el motor de arranque de un coche | Sistema de arranque-generador integrado | Arranque manual |

|---|---|---|---|

| Rendimiento | Alto par para un arranque rápido del motor | Arranque y parada del motor sin interrupciones | Limitado al esfuerzo manual; menos fiable |

| Coste | Coste inicial moderado, requiere mantenimiento | Mayor inversión inicial pero menor mantenimiento | Bajo coste, sin componentes eléctricos |

| Facilidad de implementación | Instalación de serie en la mayoría de los vehículos | Requiere integración y diseño avanzados | Instalación sencilla; no requiere herramientas especiales |

| Mantenimiento | Necesidad de revisiones periódicas, tendencia al desgaste | Menor mantenimiento gracias al menor número de piezas móviles | Mínimo; depende de la capacidad del usuario |

| Mejor caso de uso | Vehículos convencionales de gasolina y diésel | Vehículos híbridos y eléctricos | Coches antiguos o de emergencia |

Desglose detallado de las alternativas

Sistema de arranque-generador integrado

El sistema integrado de motor de arranque y generador (ISG) combina las funciones de un motor de arranque y un alternador en una sola unidad. Proporciona un par elevado para el arranque del motor y permite el frenado regenerativo, que mejora la eficiencia del combustible. El sistema ISG es especialmente beneficioso para los vehículos híbridos y eléctricos, en los que el uso eficiente de la energía es primordial. Sin embargo, requiere una instalación más compleja y suele ser más caro de entrada que los motores de arranque tradicionales. La reducción de las necesidades de mantenimiento y el aumento de las prestaciones lo convierten en una opción convincente para los diseños de automóviles modernos, sobre todo en los mercados centrados en la sostenibilidad.

Arranque manual

El arranque manual por manivela es un método tradicional de arranque de motores, utilizado principalmente en vehículos antiguos. Este sistema implica girar físicamente una manivela para arrancar el motor, ofreciendo una solución de bajo coste con un mínimo de piezas. Aunque elimina la dependencia de componentes eléctricos, requiere un esfuerzo físico considerable y puede ser poco fiable, especialmente en condiciones adversas. Este método es el más adecuado para coches antiguos o situaciones en las que pueden fallar los sistemas eléctricos, pero en general es poco práctico para los vehículos modernos. Es más un recuerdo nostálgico de la ingeniería automovilística de los primeros tiempos que una solución viable para las demandas actuales del mercado.

Conclusión: Cómo elegir la solución de arranque adecuada a sus necesidades

Para los compradores B2B que evalúan soluciones de arranque, la decisión entre un motor de arranque, un sistema integrado de arranque-generador o un arranque manual con manivela dependerá de varios factores, como el tipo de vehículo, el presupuesto y la aplicación prevista. Las empresas centradas en vehículos convencionales pueden considerar que los motores de arranque son la opción más fiable y rentable. En cambio, las que invierten en tecnología híbrida o eléctrica deberían considerar el motor de arranque-generador integrado por su eficiencia y ventajas de rendimiento. Mientras tanto, los arranques manuales con manivela es mejor reservarlos para nichos de mercado. Alineando la elección de la tecnología con las necesidades operativas, los compradores pueden mejorar su oferta de automoción al tiempo que mantienen su competitividad en el mercado global.

Propiedades técnicas esenciales y terminología comercial de cómo funciona un motor de arranque en un coche

¿Cuáles son las propiedades técnicas clave de un motor de arranque?

Comprender las especificaciones técnicas de los motores de arranque es crucial para los compradores B2B, especialmente cuando se abastecen de componentes para aplicaciones de automoción. Estas son algunas propiedades esenciales que hay que tener en cuenta:

Imagen ilustrativa relacionada con cómo funciona un motor de arranque en un coche

-

Grado del material

Los motores de arranque suelen fabricarse con materiales de alta calidad, como el aluminio y el acero, que garantizan su durabilidad y resistencia a la corrosión. La elección del material afecta al peso, la conductividad térmica y el rendimiento general del motor. Seleccionar el material adecuado puede aumentar la longevidad y la fiabilidad, algo crucial para los clientes que operan en distintos entornos. -

Par nominal

El par nominal es una especificación crítica que indica la capacidad del motor para hacer girar el motor. Medido en Newton-metros (Nm), un par más alto es esencial para arrancar motores más grandes. Conocer los requisitos de par para cada tipo de vehículo ayuda a los compradores a asegurarse de que el motor de arranque puede engranar y arrancar el motor con eficacia, especialmente en regiones con temperaturas extremas o aplicaciones de uso intensivo. -

Tensión nominal

La mayoría de los motores de arranque funcionan a 12 voltios, pero existen variaciones para aplicaciones específicas. La tensión nominal influye en la eficiencia del motor y su compatibilidad con el sistema eléctrico del vehículo. Los compradores B2B deben asegurarse de que la tensión nominal coincide con las especificaciones del vehículo para evitar fallos eléctricos o ineficiencias. -

Consumo de corriente

El consumo de corriente, medido en amperios (A), indica cuánta corriente eléctrica necesita el motor de arranque durante su funcionamiento. Un mayor consumo de corriente significa un motor de arranque más potente, pero también puede provocar el agotamiento de la batería si no se gestiona correctamente. Comprender el consumo de corriente es vital para que los compradores evalúen la compatibilidad de la batería y garanticen un rendimiento fiable en diferentes climas. -

Temperatura de funcionamiento

El rango de temperatura de funcionamiento indica las condiciones ambientales en las que el motor de arranque puede funcionar eficazmente. Los motores diseñados para temperaturas extremas son esenciales para regiones con climas duros, ya que garantizan un arranque fiable del motor. Los compradores B2B deben tener en cuenta los valores nominales de temperatura para evitar fallos en condiciones extremas, que pueden provocar costosos tiempos de inactividad. -

Ciclos de vida

Esta especificación refleja el número esperado de ciclos de arranque que un motor de arranque puede realizar antes de fallar. Un ciclo de vida mayor indica un producto más robusto y fiable. Los compradores de sectores en los que se utilizan vehículos pesados deberían dar prioridad a los motores de arranque con ciclos de vida útil ampliados para reducir los costes de mantenimiento y mejorar la eficiencia operativa.

¿Cuáles son los términos comerciales más comunes relacionados con los motores de arranque?

Navegar por el mercado de recambios de automoción requiere familiarizarse con una terminología comercial específica. Estos son algunos términos comunes que los compradores B2B deben entender:

-

OEM (fabricante de equipos originales)

Las piezas OEM son componentes fabricados por el fabricante del vehículo o un proveedor certificado. Estas piezas cumplen normas específicas de calidad y rendimiento. Los compradores suelen preferir las piezas OEM por su fiabilidad y compatibilidad con los sistemas existentes, lo que garantiza que las reparaciones mantengan la integridad del vehículo. -

MOQ (cantidad mínima de pedido)

MOQ se refiere al menor número de unidades que un proveedor está dispuesto a vender en un solo pedido. Comprender las MOQ es crucial para que los compradores gestionen el inventario con eficacia y eviten el exceso de existencias. Ayuda a presupuestar y planificar futuras compras, sobre todo en empresas con una demanda fluctuante. -

RFQ (Solicitud de presupuesto)

Una petición de oferta es un documento que los compradores envían a los proveedores para solicitar precios y condiciones de productos o servicios específicos. Es un paso fundamental en el proceso de compra, que permite a las empresas comparar ofertas y negociar mejores acuerdos. Una petición de oferta puede ayudar a agilizar las decisiones de compra y garantizar precios competitivos. -

Incoterms (Términos comerciales internacionales)

Los Incoterms definen las responsabilidades de compradores y vendedores en las transacciones internacionales, especificando quién es responsable de los gastos de envío, el seguro y los riesgos durante el transporte. Familiarizarse con los Incoterms es esencial para los compradores B2B que participan en el comercio transfronterizo, ya que garantizan la claridad de los términos contractuales y reducen los posibles conflictos. -

Plazo de entrega

El plazo de entrega es el periodo que transcurre entre la realización de un pedido y la recepción de la mercancía. Comprender los plazos de entrega es crucial para la gestión y planificación del inventario, ya que permite a las empresas alinear su cadena de suministro con las necesidades operativas. Esto es especialmente importante en regiones con una dinámica variable de la cadena de suministro.

Al conocer estas propiedades técnicas y términos comerciales, los compradores B2B pueden tomar decisiones informadas a la hora de adquirir motores de arranque, garantizando la compatibilidad, fiabilidad y valor de sus inversiones.

Cómo navegar por la dinámica del mercado y las tendencias de abastecimiento en el sector de cómo funciona un motor de arranque en un coche

¿Cuáles son las tendencias actuales del mercado de motores de arranque?

El mercado de motores de arranque experimenta actualmente un crecimiento significativo impulsado por varios factores globales. La creciente demanda de vehículos de automoción, sobre todo en los mercados emergentes de África y Sudamérica, es uno de los principales impulsores. A medida que se acelera la urbanización en estas regiones, más consumidores buscan opciones de transporte fiables. Al mismo tiempo, el auge de los vehículos eléctricos (VE) en Europa y Oriente Medio está reconfigurando el panorama de los motores de arranque, ya que los motores de arranque tradicionales se están integrando en sistemas híbridos que combinan las funciones de arranque y generador.

Los compradores B2B también deben ser conscientes de los avances tecnológicos que están influyendo en las tendencias de abastecimiento. La llegada de las tecnologías inteligentes y el IoT (Internet de las cosas) está conduciendo al desarrollo de motores de arranque más eficientes y duraderos. Los fabricantes se centran ahora en integrar funciones de diagnóstico y mantenimiento predictivo en los motores de arranque, lo que puede ayudar a reducir el tiempo de inactividad y mejorar la fiabilidad general del vehículo. Además, la dinámica de la cadena de suministro está cambiando, con un énfasis cada vez mayor en el abastecimiento localizado para mitigar los riesgos asociados a las interrupciones de la cadena de suministro global. Esta tendencia es especialmente relevante para los compradores de Europa y otras regiones en las que los factores geopolíticos pueden afectar a la importación.

¿Cómo afecta la sostenibilidad a la cadena de suministro de motores de arranque?

La sostenibilidad se está convirtiendo en un tema central en el sector de los motores de arranque, lo que lleva a los compradores B2B internacionales a dar prioridad al abastecimiento ético y a las prácticas respetuosas con el medio ambiente. El impacto medioambiental de los componentes de automoción está bajo escrutinio, con normativas cada vez más estrictas en materia de emisiones y gestión de residuos. Los compradores buscan cada vez más proveedores que se adhieran a prácticas sostenibles, como el uso de materiales reciclables y la reducción al mínimo del consumo de energía en los procesos de fabricación.

El abastecimiento ético no es solo una medida de cumplimiento; se ha convertido en un diferenciador competitivo. Los compradores buscan ahora proveedores que puedan aportar certificaciones relacionadas con la sostenibilidad, como la ISO 14001 (gestión medioambiental) o que demuestren su adhesión a los principios de la economía circular. Además, el uso de materiales ‘verdes’ en la producción de motores de arranque está ganando adeptos, y los fabricantes exploran alternativas a los metales y plásticos tradicionales que sean menos perjudiciales para el medio ambiente. Este cambio no sólo reduce la huella ecológica, sino que también atrae a los consumidores concienciados con el medio ambiente, mejorando la reputación de la marca en el mercado.

¿Qué desarrollos históricos han influido en la tecnología actual de los motores de arranque?

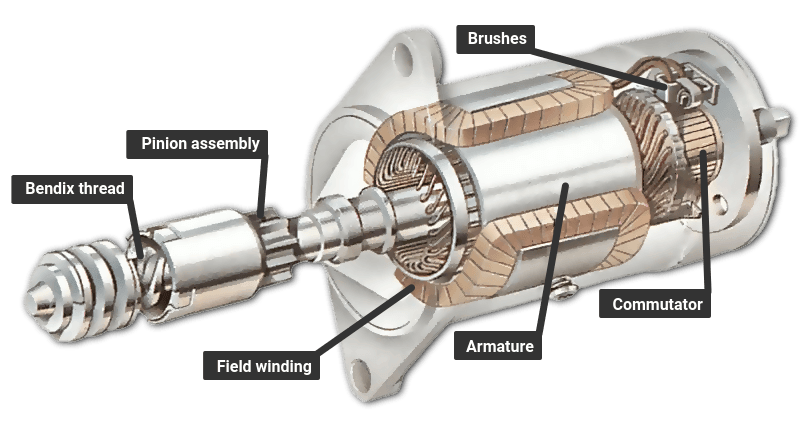

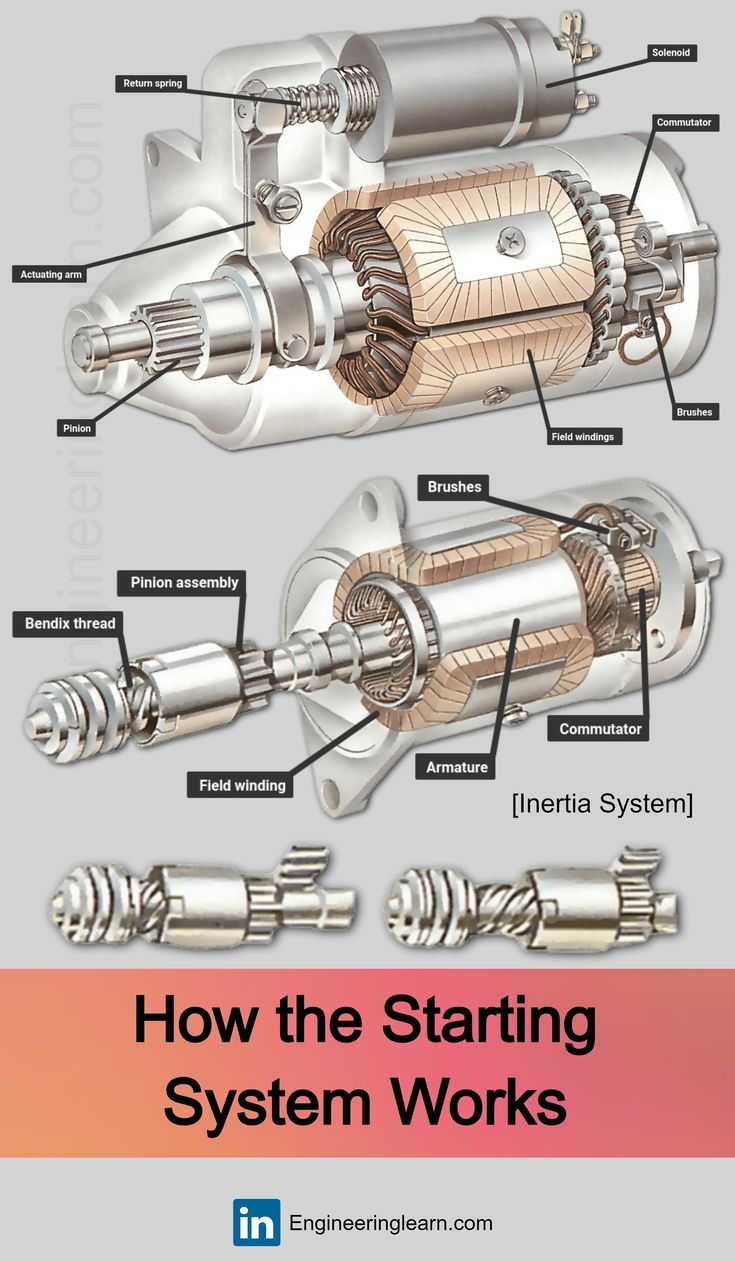

La evolución de los motores de arranque ha desempeñado un papel fundamental en la configuración de la industria del automóvil. Inventado inicialmente por Charles Kettering en 1911, el motor de arranque eléctrico revolucionó el funcionamiento de los vehículos, sustituyendo al método de manivela manual, que requería mucha mano de obra. El diseño de Kettering integraba un motor eléctrico con un sistema de engranajes que permitía acoplarlo y desacoplarlo fácilmente, lo que sentó las bases de la tecnología moderna de motores de arranque.

Imagen ilustrativa relacionada con cómo funciona un motor de arranque en un coche

A lo largo de las décadas, los avances han continuado, con mejoras en los materiales y el diseño que han dado lugar a motores de arranque más eficientes y fiables. La introducción de solenoides y electroimanes mejoró aún más la funcionalidad, permitiendo un acoplamiento y desacoplamiento rápidos para evitar daños mecánicos. A medida que los vehículos han evolucionado, también lo han hecho los motores de arranque, adaptándose a las tecnologías de los vehículos híbridos y eléctricos. Este contexto histórico es crucial para los compradores B2B, ya que comprender las innovaciones del pasado puede proporcionar información sobre las tendencias futuras y las áreas potenciales de inversión en tecnología de motores de arranque.

Preguntas frecuentes (FAQ) para compradores B2B de cómo funciona un motor de arranque en un coche

-

¿Cómo se solucionan los problemas de un motor de arranque que no engrana?

Para solucionar el problema de un motor de arranque que no engrana, compruebe primero la batería del vehículo. Asegúrese de que está completamente cargada y de que las conexiones están limpias y apretadas. Si la batería está en buen estado, inspeccione el solenoide y el motor de arranque en busca de signos de desgaste o mal funcionamiento. Además, compruebe la continuidad del interruptor de encendido y del cableado. Si el motor de arranque sigue sin engranar después de estas comprobaciones, es posible que necesite ser sustituido o reparado por un profesional. -

¿Cuál es el mejor motor de arranque para vehículos de altas prestaciones?

Para vehículos de alto rendimiento, se recomienda un motor de arranque de alto par. Estos motores están diseñados para ofrecer una mayor potencia para arrancar motores más grandes de manera eficiente. Busque modelos con componentes robustos, como solenoides mejorados y engranajes de piñón duraderos, para garantizar la fiabilidad bajo tensión. También es esencial tener en cuenta la compatibilidad con los requisitos específicos de su vehículo y consultar a los fabricantes para obtener opciones a medida. -

¿Qué factores debo tener en cuenta a la hora de comprar motores de arranque en el extranjero?

Cuando compre motores de arranque en el extranjero, tenga en cuenta factores como la calidad del producto, la reputación del proveedor y el cumplimiento de las normas internacionales. Evalúe la experiencia del fabricante en el sector de la automoción y compruebe si cuenta con certificaciones como la ISO. Además, evalúe su capacidad de personalización, las cantidades mínimas de pedido (MOQ) y los plazos de entrega. También es crucial conocer la logística de envío y los aranceles de importación específicos de su región. -

¿Cómo puedo investigar a los proveedores de motores de arranque en África y Sudamérica?

Para investigar a los proveedores de África y Sudamérica, investigue a fondo a los posibles socios. Revise su historial empresarial, los testimonios de sus clientes y las certificaciones de sus productos. Entable una comunicación directa para calibrar su capacidad de respuesta y su disposición a atender sus necesidades específicas. Además, considere la posibilidad de visitar sus instalaciones o solicitar muestras para evaluar la calidad del producto. Los contactos con asociaciones del sector también pueden aportar información valiosa. -

¿Cuáles son las condiciones de pago habituales en las transacciones B2B de motores de arranque?

Las condiciones de pago habituales en las transacciones B2B para motores de arranque suelen incluir opciones como 30 neto, 60 neto o pago por adelantado. Algunos proveedores pueden ofrecer cartas de crédito o servicios de depósito en garantía para pedidos grandes con el fin de mitigar el riesgo. Aclare siempre los métodos de pago aceptados, como transferencias bancarias, tarjetas de crédito o PayPal, y asegúrese de que las condiciones estén documentadas en un contrato para evitar disputas. -

¿Qué medidas de garantía de calidad debo tener en cuenta al comprar motores de arranque?

Cuando compre motores de arranque, busque proveedores que apliquen rigurosas medidas de garantía de calidad (QA). Esto incluye el cumplimiento de normas de calidad internacionales como ISO 9001, pruebas periódicas de los productos y procesos de certificación. Solicite información sobre sus protocolos de pruebas para componentes como inducidos y solenoides. Además, tenga en cuenta a los proveedores que ofrecen garantías sobre sus productos, lo que indica confianza en su calidad. -

¿Cómo influye la logística en el suministro de motores de arranque?

La logística desempeña un papel crucial en el aprovisionamiento de motores de arranque, ya que afecta a los plazos de entrega, los costes de envío y la eficacia general de la cadena de suministro. Conozca las capacidades de envío del proveedor, incluidas sus asociaciones con transitarios y su experiencia con el despacho de aduanas. Evalúe la ubicación del proveedor en relación con su mercado para minimizar los tiempos de envío. Además, tenga en cuenta cualquier posible arancel o normativa de importación que pueda afectar a los costes y los plazos de entrega. -

¿Qué opciones de personalización hay disponibles para los motores de arranque?

Las opciones de personalización de los motores de arranque pueden incluir modificaciones para cumplir normas de rendimiento específicas, ajustes de tamaño o mejoras para determinados modelos de vehículos. Los proveedores pueden ofrecer soluciones a medida en función de sus requisitos, como diferentes valores de par o materiales de la carcasa. Comunique siempre sus necesidades con claridad y solicite prototipos para asegurarse de que las personalizaciones cumplen sus expectativas antes de realizar un pedido en grandes cantidades.

Top 4 fabricantes & proveedores de Cómo funciona el motor de arranque de un coche Lista

1. AutoElectro - Motores de arranque

Dominio: autoelectro.es

Registrado: 1999 (26 años)

Introducción: Los motores de arranque son responsables de hacer girar el motor durante el encendido, permitiendo la entrada de aire y combustible para la combustión. Los componentes clave incluyen:

- Armadura: Un electroimán montado en el eje de transmisión, envuelto con conductores.

- Conmutador: Sección del eje que conduce la electricidad mediante escobillas.

- Escobillas: Conducen la electricidad haciendo contacto con el conmutador.

- Solenoide: Actúa como...

2. Reddit - Arranque del coche

Dominio: reddit.com

Registrado: 2005 (20 años)

Introducción: El motor de arranque del coche se alimenta de la batería y engrana un engranaje más pequeño que gira para arrancar el motor. Cuando se gira la llave, el motor de arranque utiliza la energía de la batería para girar rápidamente y engranar el engranaje principal, de forma similar a como se tira de la cuerda manualmente en un cortacésped de empuje. Una vez que el motor arranca, se vuelve autosuficiente y el motor de arranque se desconecta.

3. Haynes - Guía del sistema de encendido

Dominio: us.haynes.com

Registrado: 1996 (29 años)

Introducción: Esta empresa, Haynes - Ignition System Guide, es una entidad notable en el mercado. Para obtener detalles específicos del producto, se recomienda visitar directamente su sitio web.

4. Cómo funciona un coche - Explicación del sistema de arranque

Dominio: howacarworks.com

Registrado: 2011 (14 años)

Introducción: El sistema de arranque incluye un motor de arranque preacoplado que utiliza un solenoide para mover un piñón, lo que permite un acoplamiento suave con el volante del motor. El motor de arranque requiere una fuerte corriente eléctrica de la batería, activada por un gran interruptor controlado por la llave de contacto. El sistema cuenta con un muelle de retorno para evitar un drenaje excesivo de la batería y posibles daños en el motor de arranque. Dos tipos...

Strategic Sourcing Conclusion and Outlook for ¿cómo funciona un motor de arranque en un coche?

Comprender los entresijos del funcionamiento del motor de arranque es crucial para los compradores B2B internacionales del sector de la automoción. El motor de arranque es el elemento vital del encendido del motor, ya que transforma la energía eléctrica en movimiento mecánico, permitiendo así que los vehículos funcionen con eficacia. Componentes clave como el solenoide, el piñón y las bobinas de campo trabajan conjuntamente para proporcionar el par necesario para el arranque del motor. Reconocer la importancia de estos componentes permite tomar decisiones de compra informadas y refuerza la resistencia de la cadena de suministro.

El aprovisionamiento estratégico de motores de arranque de alta calidad y sus componentes puede reportar importantes beneficios, como la reducción de los índices de avería y la mejora del rendimiento. Dado que la demanda de piezas de automoción fiables sigue creciendo, sobre todo en los mercados emergentes de África, Sudamérica y Oriente Medio, es fundamental establecer relaciones sólidas con proveedores de confianza.

De cara al futuro, los compradores B2B deben dar prioridad a las colaboraciones que hagan hincapié en la innovación y la sostenibilidad de la tecnología de motores de arranque. Aproveche la oportunidad de sacar partido de los avances de vanguardia que pueden optimizar el rendimiento de los vehículos y apoyar el crecimiento empresarial a largo plazo. Al invertir en componentes de calidad y fomentar las asociaciones estratégicas, las empresas pueden navegar por el cambiante panorama de la automoción con confianza y éxito.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Imagen ilustrativa relacionada con cómo funciona un motor de arranque en un coche

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.