Introduction: Navigating the Global Market for signs of a failed starter

Are you struggling to identify the signs of a failed starter in your vehicles? For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these indicators is crucial for maintaining operational efficiency and minimizing downtime. A faulty starter can lead to unexpected vehicle failures, impacting productivity and logistics. This comprehensive guide delves into the critical signs of a failing starter, including uncharacteristic sounds, dashboard indicators, and performance issues, enabling you to make informed decisions when sourcing replacement parts.

Throughout this guide, we will explore various types of starters, their applications in different vehicle models, and effective strategies for vetting suppliers. Additionally, we will cover the cost implications of starter replacements and repairs, ensuring you have a holistic view of the marketplace. By equipping yourself with this knowledge, you can confidently navigate the complexities of the global starter market, ensuring your fleet remains reliable and efficient.

Ultimately, this resource is designed to empower you as a B2B buyer, enabling you to make strategic purchasing decisions that enhance the longevity and performance of your vehicles. With the right insights, you can mitigate risks associated with starter failures, streamline your operations, and foster partnerships with reputable suppliers that meet your specific needs.

Índice

- Top 3 Signs Of A Failed Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for signs of a failed starter

- Understanding signs of a failed starter Types and Variations

- Key Industrial Applications of signs of a failed starter

- 3 Common User Pain Points for ‘signs of a failed starter’ & Their Solutions

- Strategic Material Selection Guide for signs of a failed starter

- In-depth Look: Manufacturing Processes and Quality Assurance for signs of a failed starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘signs of a failed starter’

- Comprehensive Cost and Pricing Analysis for signs of a failed starter Sourcing

- Alternatives Analysis: Comparing signs of a failed starter With Other Solutions

- Essential Technical Properties and Trade Terminology for signs of a failed starter

- Navigating Market Dynamics and Sourcing Trends in the signs of a failed starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of signs of a failed starter

- Strategic Sourcing Conclusion and Outlook for signs of a failed starter

- Aviso legal importante y condiciones de uso

Understanding signs of a failed starter Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Sonido de clic | A distinct clicking noise when attempting to start the engine | Talleres de reparación de automóviles, servicios de flotas | Ventajas: Easy to diagnose; often indicates a relay issue. Contras: May not represent the full extent of starter problems. |

| Luces del salpicadero encendidas | Dashboard lights illuminate, but the engine fails to crank | Vehicle maintenance, logistics companies | Ventajas: Quick visual check; indicates potential electrical issues. Contras: Requires further inspection to pinpoint the starter as the cause. |

| Engine Won’t Start After Jump | Engine remains unresponsive despite jumpstarting attempts | Transportation services, car rentals | Ventajas: Suggests deeper starter issues; prompts professional intervention. Contras: Can lead to costly repairs if not addressed early. |

| Smoke or Burning Odor | Smoke or burning smell during starting attempts | Heavy machinery, construction equipment | Ventajas: Alerts to severe electrical faults; immediate action required. Contras: Indicates potential for significant damage if ignored. |

| Oil Leakage on Starter | Presence of oil around the starter area | Proveedores de piezas de automóviles, talleres de reparación | Ventajas: Indicates maintenance needs; can prevent further damage. Contras: Requires comprehensive inspection and potential repairs to both starter and engine. |

What Are the Key Signs of a Failed Starter and Their Characteristics?

Clicking Sound: This symptom is characterized by a repeated clicking noise when the ignition is engaged. It often indicates that the starter motor is not receiving enough power, possibly due to a faulty relay or weak battery. For B2B buyers, this symptom is easily diagnosable and can guide fleet services or automotive repair shops to quickly address potential issues, saving time and reducing downtime for vehicles.

Dashboard Lights On: When the dashboard lights illuminate but the engine does not respond, it suggests that the electrical system is functioning, yet the starter may be failing. This symptom is crucial for logistics companies and vehicle maintenance providers, as it allows them to conduct quick visual checks that can lead to timely interventions, thereby avoiding more severe mechanical failures.

Engine Won’t Start After Jump: If the engine fails to start even after multiple jumpstart attempts, it indicates deeper issues with the starter system. This symptom is particularly relevant for transportation services and car rental businesses, where reliability is paramount. Recognizing this sign can prompt immediate professional assessment, potentially saving significant repair costs and ensuring operational efficiency.

Smoke or Burning Odor: The presence of smoke or a burning smell during starting attempts is a critical warning sign of electrical failure within the starter system. For heavy machinery operators and construction equipment managers, this symptom necessitates immediate attention to prevent catastrophic failures and extensive repairs. Understanding this sign is vital for maintaining safety and operational integrity.

Oil Leakage on Starter: Finding oil around the starter area indicates potential oil leaks that can impair starter functionality. For automotive parts suppliers and repair shops, this sign highlights the need for preventive maintenance. Addressing oil leaks promptly can mitigate further damage, ensuring that vehicles operate smoothly and efficiently, ultimately enhancing customer satisfaction and retention.

Key Industrial Applications of signs of a failed starter

| Industria/Sector | Specific Application of signs of a failed starter | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Talleres de reparación de automóviles | Diagnosing starter issues in vehicles for clients | Enhances service reliability and customer satisfaction | Quality of diagnostic tools and starter components |

| Gestión de flotas | Regular monitoring of starter conditions across multiple vehicles | Reduce el tiempo de inactividad y los costes de mantenimiento. | Bulk purchasing options and warranty considerations |

| Transporte y logística | Ensuring operational readiness of delivery and freight vehicles | Improves efficiency and timely deliveries | Availability of replacement parts and technical support |

| Equipos de construcción | Assessing starter performance in heavy machinery | Minimizes project delays and equipment failures | Compatibilidad con varias marcas de maquinaria |

| Sector agrícola | Monitoring starters in tractors and farm equipment | Ensures timely farming operations and productivity | Access to specialized parts and service expertise |

How Do Automotive Repair Shops Utilize Signs of a Failed Starter?

Automotive repair shops rely heavily on the ability to diagnose starter issues effectively. Recognizing signs such as unusual sounds, dashboard indicators, or engine unresponsiveness allows technicians to quickly identify and resolve starter problems. This capability enhances service reliability, leading to increased customer satisfaction and repeat business. For international buyers, sourcing high-quality diagnostic tools and starter components is crucial to maintain service standards and ensure accurate troubleshooting.

What Role Does Fleet Management Play in Monitoring Starter Conditions?

In fleet management, regular monitoring of starter conditions is vital to ensure that vehicles are operational and minimize downtime. Fleet managers can leverage signs of a failed starter to implement preventive maintenance strategies, thereby reducing unexpected breakdowns and maintenance costs. For businesses operating in regions like Africa and South America, bulk purchasing options for starter components can lead to significant cost savings, while warranty considerations ensure that they are protected against defects.

How Is the Transportation and Logistics Sector Impacted by Starter Issues?

The transportation and logistics industry heavily depends on the operational readiness of delivery vehicles. Monitoring starter performance helps prevent delays caused by vehicle failures, ensuring timely deliveries. For B2B buyers in the Middle East and Europe, access to reliable replacement parts and robust technical support is essential for maintaining fleet performance and reducing operational disruptions.

Why Is It Important for Construction Equipment to Have Functional Starters?

In the construction industry, heavy machinery relies on functional starters to operate efficiently. Recognizing signs of a failing starter can help prevent project delays caused by equipment failures. Buyers in this sector should focus on sourcing compatible starter parts for various machinery brands, as well as ensuring access to expert service support to facilitate timely repairs.

How Does the Agricultural Sector Benefit from Monitoring Starters?

The agricultural sector benefits greatly from monitoring starters in tractors and other farm equipment. Identifying signs of a failed starter ensures that farmers can maintain productivity and adhere to tight planting and harvesting schedules. For international buyers, access to specialized parts and service expertise is vital, as it enables them to manage equipment effectively and reduce the risk of operational downtime.

3 Common User Pain Points for ‘signs of a failed starter’ & Their Solutions

Scenario 1: Difficulty Diagnosing Starter Issues in Fleet Vehicles

El problema: Fleet managers often face the challenge of diagnosing starter failures in a timely manner, which can lead to unexpected downtimes and operational delays. When a vehicle in the fleet refuses to start, it can disrupt scheduled deliveries or services, impacting customer satisfaction and profitability. The lack of immediate access to diagnostic tools or expertise can exacerbate this issue, leaving fleet operators unsure of whether the starter is at fault or if other components, like the battery or ignition system, are involved.

La solución: To effectively address this pain point, fleet managers should invest in comprehensive training for their maintenance staff on recognizing signs of a failing starter. This includes identifying abnormal sounds, dashboard light indicators, and the vehicle’s overall responsiveness when attempting to start. Additionally, creating a standardized checklist for routine inspections can help in early detection. Implementing a preventative maintenance schedule that includes battery checks, starter assessments, and wiring inspections will not only minimize unexpected failures but also enhance the overall reliability of the fleet.

Scenario 2: Managing Inventory of Replacement Starters

El problema: B2B buyers, particularly those operating automotive repair shops or dealerships, often struggle with managing inventory levels of replacement starters. Too much inventory can lead to increased holding costs, while too little can result in lost sales opportunities when customers need immediate service. The challenge is compounded by the diversity of vehicle models and starter types, making it difficult to predict which starters will be in demand.

La solución: To streamline inventory management, businesses can leverage data analytics and customer history to better forecast starter replacement needs. Implementing an inventory management system that tracks sales trends and vehicle maintenance patterns can provide valuable insights into which starter models are most frequently required. Collaborating with reliable suppliers to establish a just-in-time inventory system can also help ensure that the necessary parts are on hand without overstocking. Additionally, offering customers the option to pre-order specific starter models can enhance service efficiency and customer satisfaction.

Scenario 3: Navigating Warranty Claims for Starter Failures

El problema: B2B buyers, such as automotive parts distributors, often encounter challenges when navigating warranty claims for faulty starters. Issues arise when customers report starter failures shortly after purchase, leading to disputes about coverage and the conditions under which the starter was used. This can create friction between the distributor and their clients, affecting long-term relationships and trust.

La solución: To mitigate these challenges, distributors should establish clear communication protocols regarding warranty terms and conditions at the point of sale. Providing detailed product documentation that outlines proper installation procedures, usage guidelines, and maintenance recommendations can help reduce the incidence of claims. Additionally, training customer service representatives to handle warranty inquiries effectively will ensure that claims are processed smoothly and efficiently. Implementing a robust tracking system for warranty claims can also help identify recurring issues, allowing for proactive measures to be taken with manufacturers to address quality control concerns.

Strategic Material Selection Guide for signs of a failed starter

What Materials Are Commonly Used in Starter Systems?

When addressing the signs of a failed starter, understanding the materials involved in the starter system is crucial for B2B buyers. The starter motor and its components are typically made from a selection of materials that each offer distinct properties and performance characteristics. Here, we analyze four common materials used in starter systems: aluminum, steel, copper, and plastic.

How Does Aluminum Contribute to Starter Performance?

Aluminum is widely used in starter housings and components due to its lightweight and excellent thermal conductivity. Key properties include a temperature rating of up to 150°C and good corrosion resistance, which is vital in various environments, especially in regions with high humidity or salt exposure.

Ventajas: Aluminum is durable and lightweight, making it suitable for automotive applications where weight reduction is essential for fuel efficiency. Its resistance to corrosion extends the lifespan of starter components.

Contras: While aluminum is cost-effective, it can be more expensive than some steel options. Additionally, it may not withstand high-pressure environments as well as some alternatives.

Impacto en la aplicación: Aluminum’s compatibility with various automotive fluids makes it a versatile choice. However, international buyers should ensure compliance with local standards, such as ASTM or DIN, particularly in regions like Europe and the Middle East, where stringent regulations apply.

¿Qué papel desempeña el acero en los sistemas de arranque?

Steel is often used for internal components of the starter motor due to its strength and durability. It typically has a higher temperature rating than aluminum, often exceeding 200°C, and is resistant to wear and tear.

Ventajas: Steel’s robustness makes it ideal for high-stress applications, ensuring reliability and longevity. Its cost-effectiveness is another significant advantage, especially for bulk purchases.

Contras: Steel is heavier than aluminum, which can negatively impact vehicle performance. Additionally, it is prone to corrosion if not properly treated or coated.

Illustrative image related to signs of a failed starter

Impacto en la aplicación: Steel’s strength is beneficial in regions with rough terrains, such as parts of Africa and South America. However, international buyers must consider corrosion resistance, especially in coastal areas, and ensure compliance with relevant standards.

How Does Copper Enhance Electrical Performance in Starters?

Copper is primarily used in the electrical connections and windings of starter motors due to its exceptional electrical conductivity. It can handle high currents and has a temperature rating of approximately 200°C.

Ventajas: Copper’s excellent conductivity ensures efficient power transfer, which is critical for starter performance. Its durability also contributes to the longevity of electrical components.

Contras: The primary drawback of copper is its cost, which can be significantly higher than aluminum and steel. Additionally, copper is susceptible to corrosion, necessitating protective coatings.

Impacto en la aplicación: In regions with high humidity or exposure to corrosive environments, such as the Middle East, buyers should prioritize copper components with protective coatings. Compliance with international electrical standards is also essential.

What Is the Role of Plastic in Starter Systems?

Plastic is often used for insulating components and housings in starter systems. It is lightweight and can withstand temperatures up to 100°C, making it suitable for low-stress applications.

Illustrative image related to signs of a failed starter

Ventajas: The lightweight nature of plastic contributes to overall vehicle efficiency. It is also cost-effective and can be molded into complex shapes, allowing for versatile designs.

Contras: Plastic’s lower temperature and pressure ratings limit its application in high-stress environments. It is also less durable than metals, which may lead to premature failure.

Impacto en la aplicación: In regions with milder climates, such as parts of Europe, plastic components can be advantageous. However, buyers should be cautious about using plastic in high-temperature or high-stress applications and ensure compliance with relevant standards.

Summary Table of Material Properties for Starter Systems

| Material | Typical Use Case for signs of a failed starter | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Aluminio | Carcasas y componentes de arranque | Ligero y resistente a la corrosión. | Higher cost compared to steel | Medio |

| Acero | Internal components of starter motors | Resistente y duradero | Prone to corrosion if untreated | Bajo |

| Cobre | Conexiones eléctricas y bobinados | Excelente conductividad eléctrica | Alto coste y susceptibilidad a la corrosión | Alto |

| Plástico | Componentes y carcasas aislantes | Ligero y rentable | Limited temperature and pressure ratings | Bajo |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in starter systems, allowing for informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for signs of a failed starter

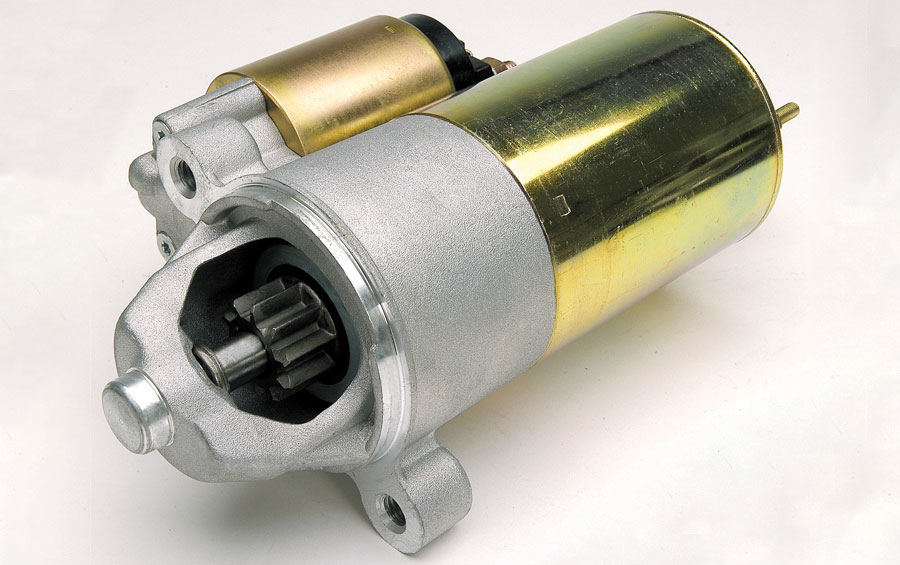

¿Cuáles son las principales etapas de la fabricación de un motor de arranque?

Manufacturing a starter motor involves several critical stages to ensure that the final product meets performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Starter Motors?

The first stage involves sourcing high-quality materials, which typically include copper for windings, steel for the housing, and various metals for internal components. Suppliers must adhere to international standards, such as ISO 9001, to ensure the materials are durable and reliable.

Illustrative image related to signs of a failed starter

Once sourced, materials undergo rigorous inspections to verify their quality. This initial quality check is crucial as it sets the foundation for the entire manufacturing process. Common tests include tensile strength assessments and electrical conductivity evaluations.

¿Qué técnicas se emplean para formar componentes de arranque?

In the forming stage, the prepared materials are shaped into the necessary components of the starter motor. Techniques such as stamping, machining, and die-casting are commonly employed.

- Estampado: This method is used to create metal parts by using dies to cut and shape the materials. It is efficient for producing large quantities of components like end plates and housings.

- Mecanizado: Precision machining is often utilized for components that require tight tolerances, such as the armature and rotor. This process ensures that all moving parts fit together seamlessly.

- Die-Casting: For parts that require complex shapes, die-casting offers a reliable method for producing intricate designs quickly and accurately.

Each of these techniques requires skilled labor and advanced machinery to maintain quality throughout the forming process.

¿Cómo se ensamblan los motores de arranque?

The assembly stage is where the various components come together to form the complete starter motor. This process typically involves several steps, including the installation of the armature, the attachment of the solenoid, and the integration of electrical connections.

- Automated Assembly: Many manufacturers employ automated assembly lines to enhance efficiency and reduce human error. Robotics and conveyor systems allow for precise and consistent assembly.

- Montaje manual: Certain delicate operations may still require skilled technicians. These workers ensure that each component is correctly positioned and secured, particularly in critical areas like electrical connections.

Quality control checkpoints are integrated throughout the assembly process to catch any defects early, minimizing waste and ensuring a reliable end product.

Illustrative image related to signs of a failed starter

¿Qué procesos de acabado se aplican a los motores de arranque?

Finishing processes enhance the durability and aesthetic appeal of the starter motor. Common techniques include painting, coating, and final inspections.

- Recubrimiento: To protect against corrosion, many components undergo coating processes, such as powder coating or electroplating. This not only extends the life of the starter but also ensures it meets industry standards for environmental resistance.

- Inspección final: After assembly, each starter motor undergoes a final inspection. This may include functional testing, where the motor is activated to ensure it operates correctly under simulated conditions.

The finishing stage is critical, as it determines the motor’s readiness for market and its ability to withstand the rigors of use.

What Are the Key Quality Assurance Standards for Starter Motors?

Quality assurance in starter motor manufacturing is critical for ensuring reliability and performance. Various international standards guide this process, with ISO 9001 being one of the most recognized. This standard outlines a framework for quality management systems, emphasizing continuous improvement and customer satisfaction.

How Do International Standards Impact Quality Control?

In addition to ISO 9001, industry-specific standards like CE marking and API specifications may apply, depending on the market and application of the starter motor. These standards ensure compliance with safety and performance criteria.

Quality control checkpoints are integrated into the manufacturing process, typically including:

- Control de calidad de entrada (IQC): This involves the inspection of raw materials upon delivery to ensure they meet specified standards.

- Control de calidad durante el proceso (IPQC): Continuous monitoring during manufacturing helps catch defects early in the process.

- Control de calidad final (FQC): A thorough inspection of the finished product ensures it meets all performance and safety requirements.

¿Qué métodos de prueba comunes se utilizan para los motores de arranque?

Several testing methods are employed to verify the functionality and reliability of starter motors. These may include:

- Pruebas eléctricas: This assesses the motor’s electrical performance, including current draw and voltage output.

- Pruebas mecánicas: This evaluates the physical integrity of components, ensuring they can withstand operational stresses.

- Pruebas térmicas: Overheating can be a concern, so thermal tests assess how well the starter motor dissipates heat during operation.

These tests are crucial for identifying potential failures before the product reaches the market.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies:

- Auditorías de proveedores: Conducting on-site audits allows buyers to evaluate the manufacturing facilities, processes, and quality control measures firsthand. This can include reviewing documentation related to ISO certifications and production methodologies.

- Quality Control Reports: Requesting regular quality reports can provide insights into a supplier’s adherence to quality standards. These reports should detail testing outcomes and any corrective actions taken in response to failures.

- Inspecciones por terceros: Engaging independent inspection agencies can offer unbiased assessments of the manufacturer’s processes and products. This step is particularly valuable for buyers who may not have the capacity to perform their own audits.

¿Cuáles son los matices del control de calidad para los compradores internacionales?

International buyers must also be aware of the nuances that may affect quality control in different regions. Factors such as local regulations, cultural differences in manufacturing practices, and varying levels of technological advancement can all impact the quality of the final product.

For instance, buyers from Africa may face challenges related to supply chain reliability and availability of quality materials. In contrast, European buyers may prioritize compliance with stringent environmental regulations. Understanding these regional differences can help B2B buyers make informed decisions and choose suppliers that align with their quality expectations.

By prioritizing quality assurance throughout the manufacturing process, B2B buyers can ensure they are sourcing reliable starter motors that meet their operational needs, ultimately enhancing their business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘signs of a failed starter’

In this guide, we will provide a practical checklist for B2B buyers focused on identifying and sourcing components related to the signs of a failed starter. Understanding these signs is crucial for ensuring vehicle reliability and minimizing downtime, especially for businesses reliant on transportation.

Paso 1: Identify Key Symptoms of a Failing Starter

Begin by familiarizing yourself with the core symptoms that indicate a starter issue. Look for uncharacteristic sounds like clicking or grinding, a non-responsive engine despite dashboard lights illuminating, or smoke emissions during failed start attempts. Recognizing these signs early can help prevent more significant mechanical failures and costly repairs.

Paso 2: Defina sus especificaciones técnicas

Clearly outline the technical specifications required for the starter components you are sourcing. This may include voltage ratings, physical dimensions, and compatibility with specific vehicle models. Having precise specifications ensures that you receive components that meet your operational needs and avoid compatibility issues.

Paso 3: Evaluar posibles proveedores

It’s essential to vet potential suppliers thoroughly. Request company profiles, product catalogs, and references from other buyers within your industry or region. Look for suppliers who specialize in automotive components and have a proven track record of quality and reliability, as this will help ensure that you receive durable and efficient products.

- Evaluar las certificaciones de calidad: Verify if the supplier holds relevant quality certifications (e.g., ISO 9001) to ensure adherence to industry standards.

- Revisar los comentarios de los clientes: Look for testimonials and case studies that can provide insight into their customer service and product performance.

Paso 4: Solicitar muestras para pruebas

Once you have shortlisted suppliers, request samples of the starter components for testing. Conducting physical tests will help you assess the quality, compatibility, and performance of the products before making bulk purchases. This step is vital in preventing future issues that could arise from substandard parts.

Paso 5: Analizar las estructuras de precios

Investigate the pricing models offered by different suppliers. Compare costs not just on the unit price but also consider shipping, handling, and potential bulk order discounts. Understanding the total cost of ownership will help you make informed purchasing decisions that align with your budget constraints.

Paso 6: Inquire About Warranty and Support Policies

Before finalizing your purchase, ensure you understand the warranty and support policies provided by the supplier. A robust warranty can protect your investment and provide peace of mind, while responsive customer support is crucial for resolving any post-purchase issues swiftly.

Paso 7: Establish a Relationship for Future Needs

Building a strong relationship with your supplier can offer long-term benefits. Regular communication can provide insights into new products, potential upgrades, and timely support for any issues you encounter. A reliable supplier can become a valuable partner as your business needs evolve.

By following this checklist, B2B buyers can effectively source components related to signs of a failed starter, ensuring operational efficiency and vehicle reliability.

Illustrative image related to signs of a failed starter

Comprehensive Cost and Pricing Analysis for signs of a failed starter Sourcing

Understanding the cost structure and pricing dynamics of sourcing components related to the signs of a failed starter is crucial for B2B buyers. This analysis will guide international purchasers, particularly from regions like Africa, South America, the Middle East, and Europe, in making informed decisions.

What are the Key Cost Components in Sourcing Starter Components?

Materiales: The primary materials involved in starter production include metals, plastics, and electrical components. Costs can fluctuate based on the quality of these materials, with higher-grade materials often yielding better performance and longevity.

Trabajo: Labor costs vary significantly depending on the region of manufacturing. In countries with lower labor costs, such as those in parts of Africa and South America, the overall pricing may be more competitive. Conversely, labor in Europe tends to be higher, impacting the final cost structure.

Gastos generales de fabricación: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs, allowing for more competitive pricing.

Illustrative image related to signs of a failed starter

Herramientas: The initial investment in tooling for starter production can be substantial, particularly for customized or high-volume orders. The amortization of these costs over larger production runs can reduce the per-unit price.

Control de calidad (QC): Implementing stringent QC measures ensures that the products meet required standards, which can influence both the cost and reliability of the starters. Buyers should consider suppliers with robust QC processes, as this can reduce long-term costs associated with warranty claims or replacements.

Logística: Shipping costs, tariffs, and import duties can significantly affect the total cost of ownership. Understanding the Incoterms associated with the shipment can clarify responsibilities for freight charges and insurance, impacting overall pricing.

Margen: Suppliers will typically apply a margin on top of their costs, which can vary based on market conditions, competition, and the perceived value of their products. Negotiating this margin can be beneficial for buyers looking to optimize costs.

¿Cómo influyen los precios en las decisiones de aprovisionamiento?

Volumen/Cantidad mínima de pedido: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often lead to discounts, making it essential for businesses to assess their inventory needs and negotiate favorable terms.

Especificaciones y personalización: Custom specifications can increase costs due to the need for specialized materials or tooling. Buyers should weigh the benefits of customization against the potential for higher expenses.

Calidad y certificaciones: Products that meet international quality standards or possess specific certifications may command higher prices. However, investing in certified products can lead to lower failure rates and reduced maintenance costs over time.

Factores relacionados con los proveedores: The reliability and reputation of the supplier can influence pricing. Established suppliers with a track record of quality and service may charge premium prices, but they can also offer peace of mind regarding product performance and availability.

Incoterms: Familiarity with Incoterms is vital for international transactions. They dictate the responsibilities of buyers and sellers in shipping arrangements, which can significantly influence the total cost and risk involved in sourcing.

What Tips Can Help Buyers Negotiate Better Pricing?

Negociación: B2B buyers should come prepared with data on market prices, competitor offerings, and potential volume commitments. Building a relationship with suppliers can also facilitate better terms and pricing.

Illustrative image related to signs of a failed starter

Rentabilidad: Conducting a thorough analysis of the total cost of ownership, including potential repairs and maintenance, can help buyers justify higher initial costs for more reliable products.

Matices en los precios para compradores internacionales: Buyers from regions like Nigeria or Brazil should be aware of local economic conditions, currency fluctuations, and import regulations that can impact pricing. Engaging local representatives can aid in navigating these complexities.

Conclusión

Navigating the cost and pricing landscape for starter components requires a deep understanding of the various factors at play. By considering these components and influencers, international B2B buyers can make informed decisions that align with their operational goals while ensuring cost-efficiency and product reliability. Always remember to consult multiple suppliers and consider the long-term implications of your sourcing choices.

Alternatives Analysis: Comparing signs of a failed starter With Other Solutions

Understanding Alternatives for Diagnosing Starter Issues

In the automotive industry, identifying a failing starter system is crucial for maintaining vehicle performance. However, there are alternative methods and technologies that can assist in diagnosing or addressing starting issues. This section compares the traditional approach of recognizing signs of a failed starter with other viable solutions, providing B2B buyers with insights into their options.

Illustrative image related to signs of a failed starter

Tabla comparativa

| Aspecto comparativo | Signs of a Failed Starter | Battery Testing Equipment | Diagnostic Scanners |

|---|---|---|---|

| Rendimiento | Identifies starter issues through symptoms | Tests battery health and output | Provides comprehensive vehicle diagnostics |

| Coste | Low to moderate (DIY inspection) | Moderate (varies by brand) | Higher (initial investment) |

| Facilidad de implementación | Straightforward for individuals with basic knowledge | Fácil de usar, requiere una formación mínima | Requires training for effective use |

| Mantenimiento | Low maintenance; periodic checks needed | Requires calibration and battery maintenance | Software updates needed periodically |

| Mejor caso de uso | Quick symptom identification in a familiar setting | Regular battery health checks in fleet operations | Diagnóstico exhaustivo de problemas complejos |

Desglose detallado de las alternativas

Battery Testing Equipment

Battery testing equipment serves as an essential tool in diagnosing starting problems. It assesses battery voltage, charge capacity, and overall health, providing insights into whether the battery is the root cause of starting failures. The primary advantage of this method is its ability to differentiate between battery and starter issues, ensuring accurate diagnoses. However, the cost can vary significantly depending on the brand and features, making it a moderate investment for businesses. It is user-friendly, requiring minimal training, but regular maintenance and calibration of the equipment are necessary for optimal performance.

Diagnostic Scanners

Diagnostic scanners offer a high-tech approach to vehicle troubleshooting, providing a comprehensive analysis of various systems, including the starter, battery, and electrical components. These devices can pinpoint issues beyond just starting problems, making them invaluable for automotive technicians. The primary downside is the initial cost, which can be substantial, especially for advanced models with extensive features. Furthermore, effective use often requires training to interpret the data accurately. Despite these challenges, the ability to conduct thorough diagnostics makes these scanners a powerful option for businesses looking to maintain a fleet or provide repair services.

Conclusión: elegir la solución adecuada para sus necesidades

When evaluating solutions for diagnosing starter issues, B2B buyers must consider their specific operational needs and budget constraints. While recognizing signs of a failed starter is a cost-effective and straightforward approach, investing in battery testing equipment or diagnostic scanners may offer a more comprehensive understanding of vehicle health. Each method has its strengths and weaknesses, and the best choice will depend on the volume of vehicles being serviced, the technical expertise available, and the desired depth of diagnostics. By carefully weighing these factors, businesses can enhance their service offerings and ensure optimal vehicle performance.

Essential Technical Properties and Trade Terminology for signs of a failed starter

What Are the Key Technical Properties of a Starter System?

Understanding the technical properties of a starter system is crucial for B2B buyers, especially when evaluating the performance and reliability of automotive components. Here are some essential specifications to consider:

1. Grado del material

The materials used in the construction of a starter, including the housing, gears, and electrical contacts, play a vital role in durability and performance. Common materials include aluminum alloys for lightweight strength and copper for efficient electrical conduction. Selecting high-grade materials can enhance the starter’s lifespan and reduce failure rates, which is particularly important for businesses operating in regions with harsh climates.

Illustrative image related to signs of a failed starter

2. Intensidad nominal (amperios)

The current rating indicates the maximum amount of electrical current the starter can draw to initiate the engine. A higher amperage rating can signify a more robust starter capable of handling larger engines or those in extreme conditions. For B2B buyers, understanding the current requirements ensures compatibility with different vehicle models and prevents potential failures due to overload.

3. Torque Specification

Torque specification refers to the rotational force the starter motor can exert to turn the engine over. This is critical for ensuring the engine starts efficiently, particularly in larger vehicles or those with high compression ratios. For businesses, a starter with an adequate torque rating can minimize the risk of failure during startup, leading to reduced maintenance costs and downtime.

4. Tolerancia a la temperatura

The ability of a starter to operate effectively within a specified temperature range is essential, particularly in regions with extreme weather conditions. Starters that can withstand high temperatures without overheating or losing efficiency are vital for maintaining vehicle performance. Buyers should look for starters that meet or exceed the temperature tolerance standards suitable for their operational environment.

5. Ciclo de vida

Cycle life indicates how many times a starter can perform its function before failure. A higher cycle life means a longer-lasting component, which is particularly important for fleet operators or businesses that rely heavily on their vehicles. Understanding this property helps buyers choose starters that will reduce replacement frequency and associated costs.

Illustrative image related to signs of a failed starter

6. Tensión nominal

Most automotive starters operate on a 12V system, but understanding the voltage rating is crucial, especially when dealing with heavy-duty vehicles or specialized equipment. A mismatch in voltage can lead to performance issues or component damage. B2B buyers should ensure that the voltage rating of the starter aligns with the specifications of the vehicles in their fleet.

¿Cuáles son los términos comerciales habituales relacionados con los entrantes?

Familiarity with industry jargon is important for effective communication and negotiation in the automotive parts market. Here are some common terms related to starters:

1. OEM (fabricante de equipos originales)

OEM refers to parts made by the same company that manufactured the original components in a vehicle. These parts are often preferred for their guaranteed compatibility and quality, which can be critical for businesses seeking reliable replacements.

2. MOQ (cantidad mínima de pedido)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory levels and budget constraints effectively. It helps in planning purchases to ensure sufficient stock without overcommitting resources.

3. RFQ (Solicitud de presupuesto)

An RFQ is a document sent to suppliers requesting pricing, specifications, and terms for products, such as starters. This process allows businesses to compare options and negotiate better deals, ensuring they get the best value for their purchases.

Illustrative image related to signs of a failed starter

4. Incoterms (Términos comerciales internacionales)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps businesses navigate shipping logistics and costs, particularly when sourcing starters from different regions.

5. Mercado de repuestos

Aftermarket refers to parts made by companies other than the OEM. These parts can offer cost savings and alternative options for businesses but may vary in quality and compatibility. Evaluating aftermarket options requires careful consideration of performance standards and warranty offerings.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing starters, ultimately enhancing their operational efficiency and reducing long-term costs.

Navigating Market Dynamics and Sourcing Trends in the signs of a failed starter Sector

What Are the Current Global Drivers Influencing the Signs of a Failed Starter Market?

The signs of a failed starter market are shaped by several global drivers, primarily the increasing reliance on automotive technology and the growing demand for efficient vehicle maintenance solutions. As the automotive industry evolves with the integration of advanced technologies, international B2B buyers are focusing on sourcing parts that enhance reliability and performance. In regions like Africa and South America, where vehicle reliability is paramount due to varying road conditions, the demand for high-quality starters is surging.

Additionally, the market is witnessing an increase in the use of digital platforms for sourcing automotive parts, allowing buyers from the Middle East and Europe to easily access information and procure components globally. This trend is further accelerated by the rise of e-commerce, where buyers can compare product specifications and prices, leading to more informed purchasing decisions.

Illustrative image related to signs of a failed starter

Emerging technologies such as predictive maintenance tools are also influencing how businesses approach sourcing. By utilizing data analytics, companies can anticipate starter failures before they occur, thus optimizing their supply chain and reducing downtime. This proactive approach not only enhances operational efficiency but also fosters stronger supplier relationships, creating a more resilient market dynamic.

How Is Sustainability and Ethical Sourcing Shaping the Signs of a Failed Starter Sector?

Sustainability and ethical sourcing are becoming crucial considerations for B2B buyers in the signs of a failed starter sector. As environmental concerns grow globally, companies are increasingly held accountable for their supply chain practices. Buyers are now prioritizing suppliers who adopt sustainable practices, such as using eco-friendly materials and reducing carbon footprints.

In terms of automotive components, this translates to sourcing starters made from recycled materials or those that comply with environmental regulations. Certifications such as ISO 14001 for environmental management systems are becoming essential in supplier evaluation, as they demonstrate a commitment to sustainable practices.

Moreover, ethical sourcing is gaining traction, particularly in regions where labor practices may come under scrutiny. Buyers are more inclined to partner with suppliers who ensure fair labor practices and transparency in their operations. This focus not only helps mitigate reputational risks but also aligns with the growing consumer preference for environmentally and socially responsible products.

What Is the Historical Context Behind the Signs of a Failed Starter Market?

Historically, the signs of a failed starter market have evolved alongside advancements in automotive technology. In the early automotive era, starters were mechanical devices reliant on cranking engines manually. The introduction of electrical starters in the early 20th century revolutionized vehicle operation, making it more accessible and efficient.

As vehicles became more sophisticated, so did the components that powered them. The evolution of starter technology, including the transition to high-performance electric starters, has been driven by the need for improved reliability and efficiency. This historical context is significant for B2B buyers, as it underscores the importance of sourcing from suppliers who understand these advancements and can provide innovative solutions to prevent starter failures.

In conclusion, understanding the market dynamics and sourcing trends in the signs of a failed starter sector is essential for international B2B buyers. By being aware of current drivers, sustainability efforts, and historical evolution, buyers can make informed decisions that enhance their operations and align with global standards.

Frequently Asked Questions (FAQs) for B2B Buyers of signs of a failed starter

-

How do I identify the signs of a failed starter in vehicles?

Identifying a failing starter involves observing several key indicators. Common signs include uncharacteristic sounds, such as a clicking noise or grinding when attempting to start the vehicle. If the dashboard lights illuminate but the engine remains unresponsive, this may also signal starter issues. Additionally, if attempts to jumpstart the vehicle fail or if smoke or burning smells are present, it’s crucial to seek professional help. Regular inspections can help catch these signs early and prevent more significant problems. -

What are the best practices for sourcing starter components internationally?

When sourcing starter components, prioritize suppliers with a strong reputation and proven track record. Research potential vendors, focusing on certifications and industry standards they adhere to. Request samples to assess quality before placing bulk orders. Building relationships with manufacturers in regions known for automotive parts, such as Asia or Europe, can also enhance your sourcing strategy. Ensure clear communication regarding specifications, lead times, and logistics to avoid discrepancies in your orders. -

What is the minimum order quantity (MOQ) for starter parts from suppliers?

Minimum order quantities (MOQ) can vary significantly among suppliers based on their production capabilities and the type of parts. Some manufacturers may set MOQs as low as 50 units for standard items, while others might require orders of 500 or more for custom parts. It is advisable to negotiate MOQs based on your business needs and consider establishing a partnership with suppliers that offer flexibility in order sizes, especially for new buyers. -

How can I ensure quality assurance (QA) for starter parts sourced internationally?

To ensure quality assurance for internationally sourced starter parts, implement a multi-step process. Begin with thorough supplier vetting, checking for certifications like ISO 9001. Request and review product samples before bulk orders, and consider third-party inspections to verify quality standards during production. Establish clear quality expectations in your contracts and maintain open communication with suppliers throughout the manufacturing process to address any potential issues promptly. -

What payment terms should I negotiate with international suppliers for starter parts?

When negotiating payment terms with international suppliers, consider options like letters of credit, wire transfers, or escrow services to mitigate risk. Aim for terms that balance cash flow needs with supplier requirements; common practices include 30% upfront with the balance due upon delivery. Discuss and clarify all conditions, including penalties for late payments and incentives for early payments, to establish a mutually beneficial agreement that fosters trust and reliability. -

How do logistics and shipping impact the procurement of starter parts?

Logistics and shipping are critical components of the procurement process for starter parts. Evaluate shipping methods (air vs. sea) based on cost, speed, and reliability. Factor in customs clearance times and potential tariffs that may affect overall costs. Collaborate with logistics partners experienced in handling automotive components to streamline the process. Proper planning and coordination can help minimize delays and ensure timely delivery, which is essential for maintaining your supply chain. -

What are common root causes of starter failures that I should be aware of?

Common root causes of starter failures include loose or corroded connections, which can impede electrical flow, and worn-out internal components that diminish functionality. Oil leaks may also contribute to starter issues, particularly if they cause contamination or overheating. Regular maintenance checks can identify these problems early, allowing for timely repairs or replacements. Understanding these causes can help inform your purchasing decisions and ensure you source high-quality, durable starter components. -

How can I customize starter parts to meet specific needs?

Customizing starter parts to meet specific requirements involves collaborating closely with your supplier. Discuss your unique specifications, such as size, material, and performance standards. Many manufacturers offer customization options, but this may impact lead times and pricing. Request prototypes to test compatibility and performance before committing to larger orders. Establishing a clear understanding of your customization needs from the outset will facilitate a smoother production process and ensure that the final product meets your expectations.

Top 3 Signs Of A Failed Starter Manufacturers & Suppliers List

1. Subaru – Starter Motor Issues

Dominio: mecánica.stackexchange.com

Registrado: 2009 (16 años)

Introducción: 2004 Subaru WRX, original equipment starter motor, symptoms include grinding screech on cold starts, low amplitude grinding squeal on warm days, concerns about starter failure, battery not new but not original, no current starting problems, potential issues with starter gears and solenoid, recommendation for complete starter replacement due to wear.

2. Facebook – Common Starting Issues

Dominio: facebook.com

Registrado: 1997 (28 años)

Introducción: This company, Facebook – Common Starting Issues, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Northrich Automotive – Starter Repair Services

Dominio: northrichauto.com

Registrado: 2001 (24 años)

Introducción: Northrich Automotive offers automotive repair services, including diagnostics and repairs related to failing car starters. Key signs of a failing starter include slow cranking, refusal to start, intermittent starting issues, dimming interior lights, grinding noises, whirring sounds, continuous running after starting, burning smells, and oil leaks on the starter system. If these issues arise, it is…

Strategic Sourcing Conclusion and Outlook for signs of a failed starter

The insights gathered on the signs of a failed starter underscore the importance of early detection and strategic sourcing in automotive maintenance. By recognizing symptoms such as unusual sounds, dashboard alerts, or engine unresponsiveness, businesses can prevent costly downtime and enhance operational efficiency. Additionally, understanding the root causes of starter failure—ranging from battery issues to oil leaks—empowers international buyers to make informed procurement decisions when sourcing replacement parts and services.

Strategic sourcing not only ensures the acquisition of high-quality components but also fosters relationships with reliable suppliers capable of delivering timely support. This is particularly vital for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, where accessibility to quality automotive parts can vary significantly.

As you look to fortify your supply chain and maintain optimal vehicle performance, consider leveraging these insights to establish robust partnerships with trusted suppliers. By prioritizing quality and reliability in your sourcing strategy, you can mitigate risks associated with starter failures and drive your business forward in an increasingly competitive landscape. Engage with industry experts and suppliers today to ensure your fleet remains operational and ready to meet the demands of your market.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.