Introducción: Navegar por el mercado mundial de piezas de un alternador de automóvil

En el competitivo panorama de la industria automovilística, abastecerse de piezas de alta calidad de un alternador de automóvil es un reto crítico para los compradores B2B internacionales. Con la creciente demanda de sistemas eléctricos fiables en los vehículos, la comprensión de los matices de los componentes del alternador, como rotores, estatores y rectificadores, se convierte en esencial para garantizar un rendimiento óptimo del vehículo. El objetivo de esta completa guía es proporcionar a los compradores de África, Sudamérica, Oriente Medio y Europa, incluidos mercados clave como Arabia Saudí y Alemania, los conocimientos necesarios para tomar decisiones de compra con conocimiento de causa.

Navegar por el mercado mundial de piezas de alternador implica un enfoque polifacético, que abarca diversos aspectos, como los tipos de componentes, sus aplicaciones en diferentes modelos de vehículos y las complejidades de los procesos de investigación de proveedores. Además, profundizaremos en las consideraciones de coste y las evaluaciones de valor, lo que permitirá a los compradores identificar las mejores opciones que se ajusten a sus necesidades operativas y a sus limitaciones presupuestarias.

Al proporcionar un conocimiento profundo de la funcionalidad de cada componente y su impacto en la eficiencia del vehículo, esta guía capacita a los compradores B2B para seleccionar a los proveedores adecuados y negociar con eficacia. En última instancia, nuestro objetivo es agilizar el proceso de aprovisionamiento, ayudando a las empresas no sólo a ahorrar costes, sino también a mejorar la fiabilidad y el rendimiento de su oferta de automoción en un mercado cada vez más globalizado.

Índice

- Lista de fabricantes y proveedores de las 4 piezas principales del alternador de un coche

- Introducción: Navegar por el mercado mundial de piezas de un alternador de automóvil

- Comprender las partes de un alternador de coche Tipos y variaciones

- Principales aplicaciones industriales de las piezas de un alternador de automóvil

- 3 puntos débiles habituales de los usuarios de ‘piezas de un alternador de coche’ y sus soluciones

- Guía estratégica de selección de materiales para piezas de un alternador de automóvil

- Mirada en profundidad: Procesos de fabricación y garantía de calidad de las piezas de un alternador de automóvil

- Guía práctica de búsqueda: Una lista de comprobación paso a paso para ‘partes de un alternador de coche’

- Análisis exhaustivo de costes y precios de las piezas de un alternador de automóvil Sourcing

- Análisis de alternativas: Comparación de piezas de un alternador de automóvil con otras soluciones

- Propiedades técnicas esenciales y terminología comercial de las piezas de un alternador de automóvil

- Dinámica del mercado y tendencias de aprovisionamiento en el sector de los componentes del alternador del automóvil

- Preguntas más frecuentes (FAQ) para compradores B2B de piezas de un alternador de automóvil

- Conclusiones y perspectivas de la contratación estratégica de piezas de un alternador de automóvil

- Aviso legal importante y condiciones de uso

Comprender las partes de un alternador de coche Tipos y variaciones

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Alternador estándar | Comúnmente utilizado en vehículos de pasajeros, carcasa de aluminio ligero | Fabricación de automóviles, talleres de reparación | Ventajas: Económico y ampliamente disponible. Contras: Rendimiento limitado para sistemas de alta demanda. |

| Alternador de alto rendimiento | Mayor amperaje para vehículos de altas prestaciones | Carreras, aplicaciones pesadas | Ventajas: Soporta altas demandas eléctricas. Contras: Coste más elevado y puede requerir instalaciones específicas. |

| Alternador marino | Diseñado para entornos marinos, materiales resistentes a la corrosión | Fabricación de embarcaciones, reparaciones navales | Ventajas: Resistente a las condiciones más duras. Contras: Suelen ser más caros debido a su diseño especializado. |

| Alternador diesel | Fabricado para motores diésel de gran potencia, construcción robusta | Vehículos comerciales, maquinaria industrial | Ventajas: Fiable con cargas pesadas. Contras: Más pesado y voluminoso que los modelos estándar. |

| Alternador inteligente | Integrado con electrónica avanzada para eficiencia y diagnóstico | Vehículos eléctricos, gestión de flotas | Ventajas: Mejora de la eficiencia del combustible y el diagnóstico. Contras: Mayor inversión inicial, complejidad en la instalación. |

¿Qué características tienen los alternadores estándar?

Los alternadores estándar son los más comunes en los turismos. Suelen tener una carcasa de aluminio ligero que ayuda a disipar el calor y evita la magnetización. Estos alternadores son adecuados para aplicaciones generales de automoción, incluidos los coches de uso diario y los camiones ligeros. Al comprar alternadores estándar, los compradores deben considerar la compatibilidad con los modelos de vehículos y la rentabilidad, ya que están ampliamente disponibles en el mercado.

¿En qué se diferencian los alternadores de alto rendimiento de los estándar?

Los alternadores de alto rendimiento están diseñados específicamente para proporcionar un mayor amperaje, lo que los hace ideales para vehículos de alto rendimiento que requieren potencia eléctrica adicional, como los coches de carreras y los vehículos con amplios sistemas eléctricos posventa. Estos alternadores pueden soportar grandes demandas eléctricas, pero tienen un precio más elevado. Los compradores deben evaluar sus necesidades específicas de potencia y asegurarse de que los requisitos de instalación se ajustan al diseño de su vehículo.

¿Qué hace únicos a los alternadores marinos?

Los alternadores marinos están diseñados para soportar los duros entornos marinos, con materiales resistentes a la corrosión y diseños que evitan la entrada de agua. Estas unidades son esenciales para embarcaciones y otras aplicaciones marinas en las que la fiabilidad es fundamental. Al comprar alternadores marinos, los compradores deben tener en cuenta las condiciones ambientales y asegurarse de que el producto cumple las normas marinas, a pesar de su mayor coste debido a su construcción especializada.

¿Por qué elegir alternadores diésel para aplicaciones pesadas?

Los alternadores diésel están fabricados para soportar los rigores de los motores diésel de gran potencia, proporcionando una salida eléctrica robusta adecuada para vehículos comerciales y maquinaria industrial. Su diseño se centra en la fiabilidad bajo cargas pesadas, lo que los hace indispensables en los sectores del transporte y la logística. Los compradores deben evaluar los requisitos específicos de potencia de sus aplicaciones, ya que estos alternadores tienden a ser más voluminosos y pesados que los modelos estándar.

¿Cuáles son las ventajas de los alternadores inteligentes?

Los alternadores inteligentes incorporan componentes electrónicos avanzados que mejoran la eficiencia y ofrecen capacidades de diagnóstico. Se utilizan cada vez más en vehículos eléctricos y sistemas de gestión de flotas, lo que permite una mejor supervisión de los sistemas eléctricos. Aunque ofrecen una mayor eficiencia en el consumo de combustible y más información operativa, la complejidad de la instalación y los costes iniciales más elevados pueden ser un factor a tener en cuenta por los compradores. Evaluar los beneficios a largo plazo frente a los costes iniciales es crucial para tomar decisiones de compra informadas.

Principales aplicaciones industriales de las piezas de un alternador de automóvil

| Industria/Sector | Aplicación específica de las piezas de un alternador de automóvil | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Fabricación de automóviles | Uso de reguladores de tensión en líneas de montaje para el control de calidad | Garantiza la calidad y fiabilidad constantes de los vehículos | Fiabilidad de los proveedores, cumplimiento de las normas del sector |

| Energía renovable | Componentes del alternador en vehículos híbridos y eléctricos | Apoya la transición al transporte sostenible | Compatibilidad con los sistemas existentes, opciones de garantía |

| Maquinaria pesada | Alternadores en maquinaria agrícola y de construcción | Mejora el tiempo de actividad de los equipos y la eficacia operativa | Durabilidad en condiciones duras, apoyo al mantenimiento |

| Logística del transporte | Piezas de alternadores en vehículos de flota para sistemas de gestión de la energía | Reduce los costes operativos y mejora el rendimiento del vehículo | Rentabilidad, disponibilidad de piezas de repuesto |

¿Cómo se utilizan las piezas de un alternador de automóvil en la fabricación de automóviles?

En la fabricación de automóviles, los reguladores de tensión son cruciales para mantener la calidad de los sistemas eléctricos de los vehículos. Estos componentes garantizan que la salida de tensión se mantenga estable, evitando así fallos eléctricos durante el montaje. Para los compradores B2B de este sector, es esencial abastecerse de reguladores de tensión de alta calidad que cumplan las normas del sector. La fiabilidad en las cadenas de suministro es una consideración crítica, ya que cualquier interrupción puede provocar retrasos en la producción y un aumento de los costes.

¿Qué papel desempeñan los componentes del alternador en las aplicaciones de energías renovables?

Las piezas de un alternador de automóvil se integran cada vez más en vehículos híbridos y eléctricos, donde convierten la energía mecánica en energía eléctrica de forma eficiente. Esta transición apoya el cambio de la industria automovilística hacia soluciones de transporte sostenibles. Los compradores de este sector deben tener en cuenta la compatibilidad de los componentes del alternador con los sistemas existentes, así como las opciones de garantía para asegurar el rendimiento a largo plazo. La capacidad de abastecerse de piezas innovadoras y de alta eficiencia puede proporcionar una ventaja competitiva en un mercado en rápida evolución.

¿Cuáles son las ventajas de los alternadores en la maquinaria pesada?

En el sector de la maquinaria pesada, los alternadores son vitales para equipos como excavadoras y tractores, a los que proporcionan energía fiable para diversas operaciones. Al garantizar un suministro de energía constante, las piezas de alternador mejoran el tiempo de actividad de la maquinaria y la eficiencia operativa. Los compradores deben centrarse en el suministro de componentes duraderos que puedan soportar condiciones de trabajo duras, así como contar con un soporte de mantenimiento adecuado para minimizar el tiempo de inactividad. Esto es especialmente importante en regiones donde la maquinaria está sometida a factores medioambientales extremos.

¿Qué ventajas ofrecen las piezas de alternador en la logística del transporte?

En la logística del transporte, las piezas de los alternadores de automóvil forman parte integral de los vehículos de flota equipados con sistemas avanzados de gestión de la energía. Estos sistemas optimizan la eficiencia del combustible y el rendimiento general del vehículo, lo que supone un importante ahorro de costes. Los compradores B2B de este sector deben dar prioridad al abastecimiento de componentes de alternador rentables que ofrezcan alta fiabilidad y fácil disponibilidad de piezas de repuesto. Esto garantiza que las flotas permanezcan operativas con interrupciones mínimas, lo que repercute directamente en la rentabilidad.

3 puntos débiles habituales de los usuarios de ‘piezas de un alternador de coche’ y sus soluciones

Situación 1: Dificultad para obtener piezas de calidad para el alternador

El problema:

Los compradores B2B se encuentran a menudo con importantes dificultades a la hora de abastecerse de piezas de alternador de alta calidad. Esto es especialmente cierto en regiones como África y Sudamérica, donde los proveedores locales pueden ofrecer componentes de calidad inferior que no cumplen las normas de calidad internacionales. Las piezas de mala calidad pueden provocar averías frecuentes, aumentar los costes de mantenimiento y, en última instancia, afectar a la fiabilidad de sus servicios de automoción. Los compradores también pueden tener que lidiar con cadenas de suministro incoherentes, lo que dificulta la obtención de los componentes necesarios en el momento oportuno.

La solución:

Para hacer frente a este problema, los compradores B2B deben dar prioridad al establecimiento de relaciones con fabricantes o proveedores de buena reputación que tengan un historial probado en la producción de piezas de alternador de alta calidad. Es esencial llevar a cabo una diligencia debida exhaustiva; esto incluye comprobar las certificaciones, las opiniones de los clientes y las garantías de los productos. Aprovechar las plataformas especializadas en transacciones B2B también puede ayudar a los compradores a encontrar proveedores fiables. Además, mantener una base de proveedores diversificada puede mitigar los riesgos asociados a las interrupciones de la cadena de suministro. Los compradores también deben considerar la posibilidad de invertir en asociaciones directas con los fabricantes para garantizar una calidad constante de piezas adaptadas a sus necesidades específicas.

Escenario 2: Comprender las especificaciones técnicas de los componentes del alternador

El problema:

Otro problema común para los compradores B2B es la complejidad que supone comprender las especificaciones técnicas de los componentes del alternador, como el rotor, el estator y el regulador de tensión. Muchos compradores pueden no tener los conocimientos técnicos necesarios para diferenciar entre los distintos componentes y sus especificaciones, lo que lleva a la adquisición de piezas incorrectas o incompatibles. Esto puede dar lugar a ineficiencias operativas y a un aumento de los costes debido a las devoluciones o a esfuerzos adicionales de aprovisionamiento.

La solución:

Para superar este reto, los compradores B2B deben invertir en sesiones de formación para sus equipos de compras, centradas en los aspectos fundamentales de los componentes de los alternadores y sus funciones. Utilizar catálogos de productos detallados y fichas técnicas puede proporcionar a los compradores las especificaciones necesarias para tomar decisiones informadas. Colaborar con ingenieros o consultores técnicos expertos también puede ayudar a comprender especificaciones complejas. Además, la aplicación de un proceso de adquisición estandarizado que incluya una lista de comprobación de compatibilidad y especificaciones puede agilizar el aprovisionamiento y reducir los errores.

Escenario 3: Gestión de los niveles de inventario de piezas de alternador

El problema:

Gestionar los niveles de inventario de piezas de alternador puede ser una tarea desalentadora para los compradores B2B, especialmente en regiones con una demanda fluctuante. Un exceso de existencias puede provocar un aumento de los costes de mantenimiento y una posible obsolescencia, mientras que un déficit de existencias puede provocar una pérdida de ventas y la insatisfacción de los clientes. Este equilibrio se hace aún más difícil cuando se trata de múltiples tipos de vehículos y sus respectivas necesidades de alternadores.

La solución:

Para gestionar eficazmente los niveles de inventario, los compradores B2B deben implantar un software de gestión de inventario que utilice análisis de datos para prever la demanda con precisión. Esta tecnología puede ayudar a realizar un seguimiento de las tendencias de ventas, las variaciones estacionales y las demandas del mercado, lo que permite a los compradores ajustar sus niveles de existencias de forma proactiva. Además, establecer un sistema de inventario justo a tiempo (JIT) puede minimizar los costes de mantenimiento y garantizar que las piezas esenciales estén disponibles cuando se necesiten. La comunicación regular con los proveedores para discutir los plazos de entrega y la frecuencia de los pedidos también puede mejorar la gestión del inventario. Adoptando estas estrategias, los compradores pueden optimizar sus niveles de inventario, garantizando que satisfacen las demandas de los clientes sin incurrir en costes innecesarios.

Guía estratégica de selección de materiales para piezas de un alternador de automóvil

¿Cuáles son los principales materiales utilizados en los alternadores de automóvil?

A la hora de seleccionar los materiales para los distintos componentes de un alternador de automóvil, es esencial tener en cuenta propiedades como la durabilidad, el peso, el coste y la compatibilidad con las normas de automoción. A continuación, analizamos cuatro materiales comunes utilizados en los componentes de los alternadores, centrándonos en sus propiedades, ventajas, desventajas e implicaciones para los compradores B2B internacionales.

Aluminio: el campeón del peso ligero

Propiedades clave: El aluminio es conocido por su excelente resistencia a la corrosión y su ligereza. Puede soportar fluctuaciones moderadas de temperatura, lo que lo hace adecuado para el entorno generador de calor de un alternador.

Ventajas y desventajas: La característica de ligereza del aluminio contribuye a la eficiencia global del vehículo, ya que reduce el peso del alternador. Sin embargo, el aluminio puede ser menos duradero que otros metales, sobre todo en condiciones de gran tensión. Sus procesos de fabricación suelen ser sencillos, pero su coste puede ser superior al del acero.

Impacto en la aplicación: La resistencia a la corrosión del aluminio lo hace ideal para aplicaciones en las que la exposición a la humedad es habitual, sobre todo en regiones con climas húmedos. Sin embargo, su menor resistencia a la tracción en comparación con el acero puede requerir consideraciones de diseño cuidadosas para evitar fallos estructurales.

Consideraciones para compradores internacionales: Los compradores de regiones como Europa y Oriente Medio deben garantizar el cumplimiento de normas como ASTM y DIN para las aleaciones de aluminio. La preferencia por los materiales ligeros en el diseño de automóviles es cada vez mayor, lo que convierte al aluminio en una opción favorable.

El acero: El caballo de batalla duradero

Propiedades clave: El acero ofrece una gran resistencia a la tracción y durabilidad, capaz de soportar altas temperaturas y presiones. Es menos propenso a deformarse bajo carga que el aluminio.

Ventajas y desventajas: La principal ventaja del acero es su resistencia y longevidad, lo que lo hace adecuado para aplicaciones de alto rendimiento. Sin embargo, el acero es más pesado que el aluminio, lo que puede afectar negativamente a la eficiencia del combustible. Además, es susceptible a la corrosión a menos que se trate o recubra.

Imagen ilustrativa relacionada con las partes de un alternador de automóvil

Impacto en la aplicación: El acero es especialmente eficaz en componentes que requieren gran resistencia, como los núcleos del rotor y el estator. Su compatibilidad con diversos medios lo hace versátil, pero su peso puede ser un inconveniente en los diseños de vehículos ligeros.

Consideraciones para compradores internacionales: Los compradores deben considerar las opciones de revestimiento para mejorar la resistencia a la corrosión, especialmente en regiones húmedas como África y Sudamérica. El cumplimiento de normas internacionales como JIS y ASTM es crucial para garantizar la calidad del producto.

Cobre: el conductor eléctrico

Propiedades clave: El cobre es un excelente conductor de la electricidad, con una elevada conductividad térmica y resistencia a la corrosión. Puede funcionar eficazmente a temperaturas elevadas.

Ventajas y desventajas: La principal ventaja del cobre son sus propiedades eléctricas superiores, que lo hacen ideal para bobinados y conexiones. Sin embargo, el cobre es relativamente caro en comparación con el aluminio y el acero, lo que puede aumentar los costes generales de producción.

Impacto en la aplicación: La excelente conductividad del cobre es esencial para la eficacia del alternador, especialmente en el rectificador y los componentes del cableado. Su compatibilidad con diversos sistemas eléctricos mejora el rendimiento general.

Consideraciones para compradores internacionales: Los compradores de regiones con normas eléctricas estrictas, como Alemania, deben asegurarse de que los componentes de cobre cumplen los requisitos pertinentes. La demanda mundial de cobre también puede provocar fluctuaciones en los precios, lo que repercute en las consideraciones presupuestarias.

Los compuestos plásticos: El material aislante

Propiedades clave: Los compuestos plásticos son ligeros y ofrecen un excelente aislamiento eléctrico. Soportan diversas temperaturas y son resistentes a muchos productos químicos.

Ventajas y desventajas: La principal ventaja de los compuestos plásticos son sus propiedades aislantes, cruciales para componentes como el regulador de tensión. Sin embargo, pueden no ofrecer la misma durabilidad que los metales y ser más susceptibles al desgaste con el paso del tiempo.

Imagen ilustrativa relacionada con las partes de un alternador de automóvil

Impacto en la aplicación: Los compuestos plásticos son ideales para componentes que no soportan carga, ya que proporcionan el aislamiento necesario sin añadir peso. Sin embargo, su rendimiento a largo plazo puede verse afectado por factores medioambientales, como la exposición a los rayos UV.

Consideraciones para compradores internacionales: Los compradores deben asegurarse de que los materiales plásticos cumplen las normas internacionales para aplicaciones de automoción. En regiones con altas temperaturas, debe evaluarse la estabilidad térmica de los compuestos plásticos para evitar su degradación.

Tabla resumen

| Material | Caso típico de uso de piezas de un alternador de automóvil | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Aluminio | Carcasa exterior y componentes | Ligero y resistente a la corrosión. | Menos duradero bajo condiciones de gran estrés. | Medio |

| Acero | Núcleos de rotor y estator | Alta resistencia a la tracción | Más pesado, susceptible a la corrosión | Bajo |

| Cobre | Bobinados eléctricos y conexiones | Conductividad eléctrica superior | Mayor coste en comparación con otras alternativas | Alto |

| Compuestos plásticos | Componentes aislantes (por ejemplo, regulador de tensión) | Excelente aislamiento eléctrico | Menos duraderos que los metales | Medio |

Esta guía estratégica de selección de materiales proporciona información práctica a los compradores B2B del sector de la automoción, garantizando la toma de decisiones informadas que se ajusten a los requisitos de rendimiento y a las normas regionales.

Mirada en profundidad: Procesos de fabricación y garantía de calidad de las piezas de un alternador de automóvil

¿Cuáles son las principales etapas de la fabricación de piezas para un alternador de automóvil?

El proceso de fabricación de las piezas del alternador de automóvil consta de varias etapas críticas, cada una de ellas diseñada para garantizar la máxima calidad y rendimiento.

Imagen ilustrativa relacionada con las partes de un alternador de automóvil

¿Cómo se prepara el material para los componentes del alternador?

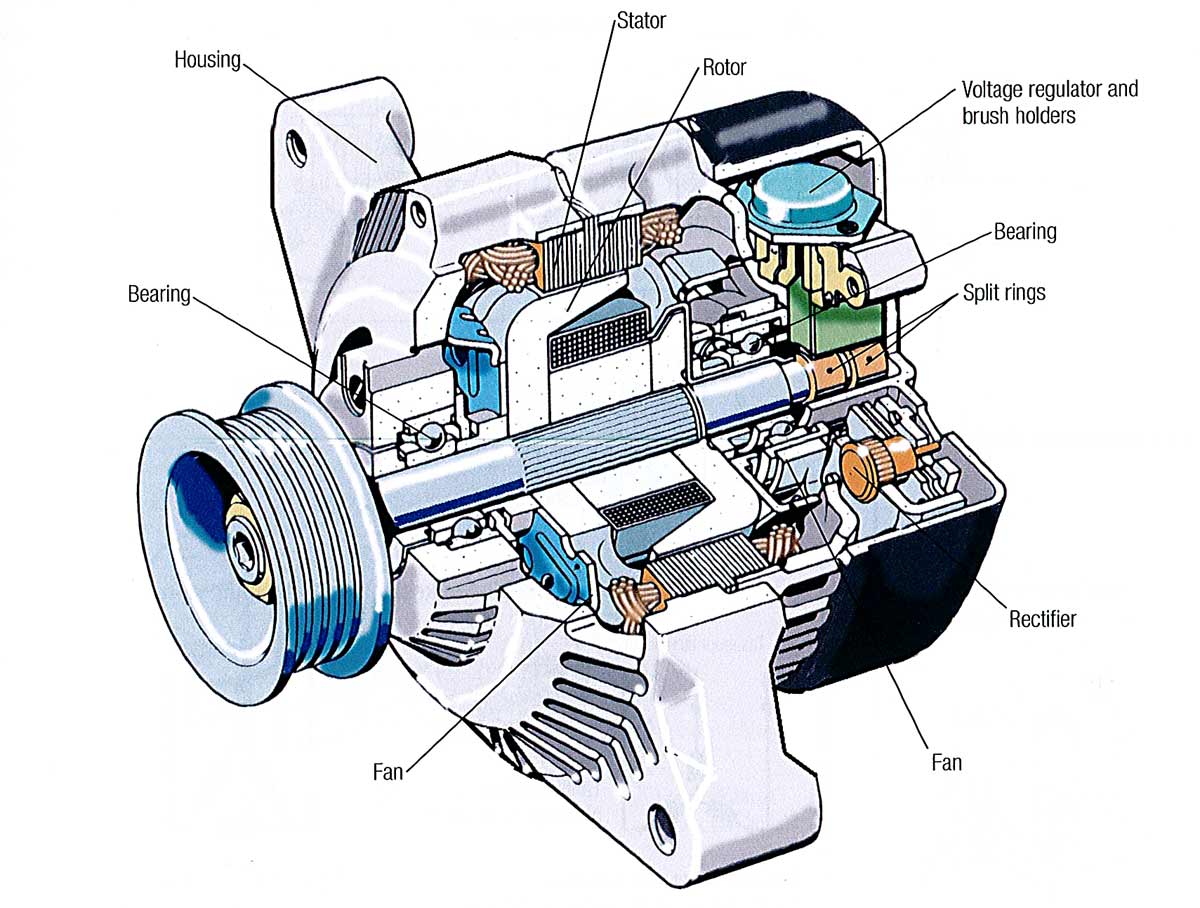

El primer paso en el proceso de fabricación es la preparación de las materias primas. Para las piezas de los alternadores, se suelen utilizar materiales como el aluminio para las carcasas, el cobre para los bobinados y el acero de alta calidad para los cojinetes. Cada material debe cumplir unas normas específicas de resistencia, conductividad y resistencia térmica. Los proveedores suelen realizar inspecciones de los materiales para verificar el cumplimiento de normas internacionales como la ISO 9001, lo que garantiza que los materiales utilizados son adecuados para aplicaciones de automoción.

¿Qué técnicas se utilizan en el proceso de conformado?

Una vez preparados los materiales, comienza el proceso de conformado. Las técnicas clave incluyen:

- Fundición a presión: Este método se utiliza habitualmente para crear carcasas de aluminio. Consiste en verter aluminio fundido en un molde para producir formas intrincadas con gran precisión.

- Estampado: Para piezas como el estator y el rotor, se emplea el estampado para cortar chapas metálicas con las formas requeridas. Esta técnica garantiza la uniformidad y reduce los residuos.

- Sinusoide: En el estator, el hilo de cobre se enrolla alrededor de núcleos laminados. Este proceso es crítico, ya que afecta directamente a la eficiencia del alternador.

Estas técnicas de conformado no sólo dan forma a los componentes, sino que también mejoran su integridad estructural, que es vital para el rendimiento del alternador.

¿Cómo se ensamblan las piezas del alternador?

La fase de montaje consiste en reunir los distintos componentes fabricados en las etapas anteriores. Los elementos clave son:

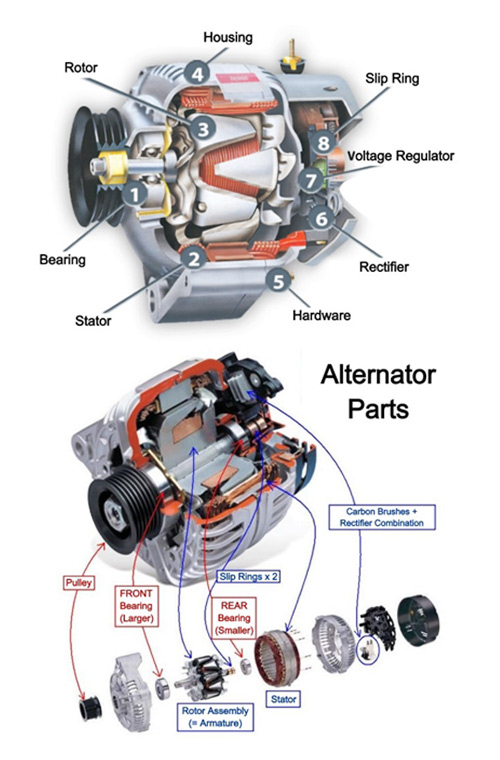

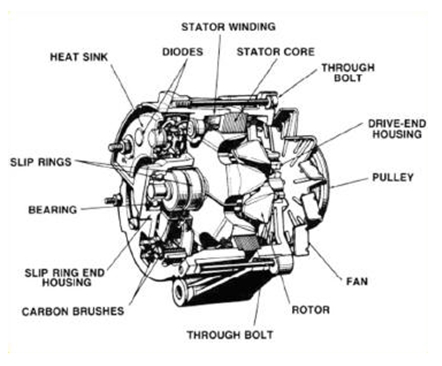

- Conjunto del rotor: El rotor, formado por un eje, anillos rozantes y bobinados de campo, se ensambla cuidadosamente. La precisión es crucial para garantizar que el rotor gire libremente dentro del estator.

- Conjunto estator: Se conectan los bobinados del estator y se monta el núcleo laminado. Este conjunto debe aislarse correctamente para evitar cortocircuitos eléctricos.

- Integración de diodos y reguladores de tensión: Estos componentes están integrados en el alternador para gestionar la salida y la conversión eléctricas.

El montaje suele realizarse en entornos controlados para minimizar la contaminación y garantizar un ajuste y un funcionamiento adecuados.

Imagen ilustrativa relacionada con las partes de un alternador de automóvil

¿Qué procesos de acabado se emplean?

Los procesos de acabado mejoran la durabilidad y el atractivo estético de las piezas del alternador. Las técnicas incluyen:

- Anodizado: Los componentes de aluminio suelen anodizarse para mejorar la resistencia a la corrosión y la dureza de la superficie.

- Pintura o revestimiento: Se aplican revestimientos protectores para evitar el desgaste y los daños ambientales.

- Inspección de calidad: Antes del embalaje, cada componente se somete a rigurosas inspecciones para garantizar que cumple las tolerancias y normas de calidad especificadas.

¿Cuáles son las normas de control de calidad de las piezas del alternador?

La garantía de calidad es primordial en la fabricación de piezas de alternador, ya que estos componentes son fundamentales para el rendimiento y la seguridad del vehículo.

¿Qué normas internacionales deben tener en cuenta los compradores B2B?

Los compradores B2B deben buscar proveedores que cumplan normas de calidad internacionales reconocidas, como:

- ISO 9001: Esta norma se centra en los sistemas de gestión de la calidad y garantiza que los fabricantes cumplan sistemáticamente los requisitos reglamentarios y de los clientes.

- ISO/TS 16949: Específicamente adaptada a la industria del automóvil, esta norma hace hincapié en la prevención de defectos y la reducción de la variación y los residuos en la cadena de suministro.

- Marcado CE: Para los mercados europeos, el marcado CE indica que los productos cumplen las normas de salud, seguridad y protección del medio ambiente.

El cumplimiento de estas normas no sólo garantiza la calidad, sino que también facilita el comercio internacional.

¿Cuáles son los puntos clave del control de calidad?

Los puntos de control de calidad (CC) son esenciales a lo largo de todo el proceso de fabricación. Los puntos de control clave son:

- Control de calidad de entrada (IQC): Las materias primas se inspeccionan a su llegada para garantizar que cumplen las especificaciones.

- Control de calidad durante el proceso (IPQC): Durante la fabricación, se establecen varios puntos de control para supervisar los procesos y detectar los defectos a tiempo.

- Control de calidad final (FQC): Los alternadores terminados se someten a pruebas de rendimiento, potencia eléctrica e integridad física antes de ser enviados.

Estos puntos de control ayudan a identificar y rectificar los problemas antes de que los productos lleguen a los clientes.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

Los compradores B2B disponen de varias vías para verificar los procesos de control de calidad de sus proveedores:

¿Qué medidas pueden tomar los compradores para auditar a los proveedores?

- Auditorías de proveedores: La realización de auditorías in situ permite a los compradores evaluar de primera mano los procesos de fabricación y las medidas de control de calidad del proveedor. Esto puede incluir la revisión de la documentación relacionada con los sistemas de gestión de la calidad y los controles de los procesos.

- Solicitud de informes de calidad: Los proveedores deben facilitar documentación sobre sus procedimientos de control de calidad, incluidos los resultados de las pruebas y los certificados de conformidad. Esta transparencia contribuye a generar confianza y seguridad.

- Inspecciones por terceros: La contratación de agencias de inspección externas puede proporcionar una evaluación imparcial de las prácticas de garantía de calidad del proveedor. Estas agencias pueden realizar inspecciones y pruebas aleatorias para garantizar el cumplimiento de las normas internacionales.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

Al tratar con proveedores internacionales, sobre todo de regiones como África, Sudamérica, Oriente Medio y Europa, los compradores B2B deben conocer matices específicos:

- Cumplimiento normativo: Las normativas sobre componentes de automoción pueden variar de una región a otra. Los compradores deben familiarizarse con los requisitos locales de sus mercados de destino.

- Diferencias culturales: Los estilos de comunicación y las prácticas empresariales pueden variar considerablemente. Establecer líneas claras de comunicación y expectativas es crucial para el éxito de las asociaciones.

- Consideraciones logísticas: Comprender la logística de los envíos y las aduanas puede afectar a los plazos y costes de entrega. Los compradores deben colaborar estrechamente con los proveedores para garantizar envíos puntuales y conformes.

Al centrarse en estos procesos de fabricación y en las normas de garantía de calidad, los compradores B2B pueden tomar decisiones informadas a la hora de abastecerse de piezas para alternadores de automóvil, asegurándose de recibir productos de alta calidad que satisfagan sus necesidades.

Guía práctica de búsqueda: Una lista de comprobación paso a paso para ‘partes de un alternador de coche’

En el competitivo panorama del aprovisionamiento de piezas de automoción, especialmente de componentes de alternador, es esencial que los compradores B2B naveguen por el proceso de aprovisionamiento con precisión. Esta guía proporciona una lista de comprobación paso a paso adaptada a los compradores internacionales de regiones como África, Sudamérica, Oriente Medio y Europa. Siguiendo estos pasos, podrá asegurarse de abastecerse de piezas de alternador de alta calidad que satisfagan sus requisitos técnicos y sus necesidades comerciales.

Paso 1: Defina sus especificaciones técnicas

Antes de iniciar el proceso de aprovisionamiento, defina claramente las especificaciones técnicas de las piezas de alternador que necesita. Esto incluye conocer el tipo de vehículo, el modelo específico de alternador y los componentes individuales, como rotores, estatores, rectificadores y reguladores de tensión. Disponer de especificaciones precisas ayuda a comunicar eficazmente sus requisitos a los proveedores, minimizando los malentendidos y garantizando la compatibilidad.

Paso 2: Investigar posibles proveedores

Investigue a fondo para identificar posibles proveedores especializados en piezas de alternadores de automoción. Utilice directorios en línea, foros del sector y ferias comerciales para encontrar fabricantes de renombre. Busque proveedores con un historial probado en su mercado objetivo y asegúrese de que tienen experiencia en el trato con compradores internacionales.

Paso 3: Evaluar las certificaciones de los proveedores

Verifique las certificaciones y normas de calidad de los posibles proveedores. Busque certificaciones ISO u otras acreditaciones relevantes para el sector que demuestren la adhesión a sistemas de gestión de la calidad. Asegurarse de que sus proveedores cumplen las normas internacionales es crucial para mantener la integridad de sus productos y cumplir la normativa regional.

Paso 4: Solicitud de muestras para la evaluación de la calidad

Antes de realizar compras al por mayor, solicite muestras de las piezas del alternador para evaluar su calidad. Evalúe los materiales, la fabricación y la compatibilidad con sus sistemas actuales. Probar las muestras puede ayudar a identificar cualquier problema potencial al principio del proceso, ahorrando tiempo y recursos a largo plazo.

Paso 5: Comprender la estructura de precios

Hable de precios con los proveedores preseleccionados. Es fundamental conocer toda la estructura de precios, incluidos los costes unitarios, los gastos de envío y los posibles aranceles o impuestos. Comparar presupuestos de varios proveedores puede ayudarle a negociar mejores condiciones y a asegurarse de que recibe precios competitivos.

Paso 6: Revisar las condiciones generales

Revise a fondo las condiciones propuestas por el proveedor. Preste atención a las condiciones de pago, los plazos de entrega, las políticas de devolución y la información sobre la garantía. Unas condiciones claras protegerán tus intereses y establecerán un marco para una transacción fluida.

Paso 7: Establecer un plan de comunicación

La comunicación eficaz es clave para el éxito del aprovisionamiento. Establezca un plan de comunicación claro con el proveedor elegido, que incluya actualizaciones periódicas sobre el estado del pedido y cualquier problema que pueda surgir. Las líneas de comunicación abiertas ayudan a construir relaciones sólidas y garantizan que ambas partes estén alineadas a lo largo del proceso de aprovisionamiento.

Siguiendo esta lista de comprobación, los compradores B2B pueden navegar por las complejidades del aprovisionamiento de piezas de alternador con confianza, asegurándose de adquirir componentes de alta calidad que satisfagan sus necesidades operativas.

Imagen ilustrativa relacionada con las partes de un alternador de automóvil

Análisis exhaustivo de costes y precios de las piezas de un alternador de automóvil Sourcing

¿Cuáles son los principales componentes de coste en el suministro de piezas de alternador para automóviles?

A la hora de adquirir piezas de un alternador de automóvil, comprender la estructura de costes es crucial para los compradores B2B internacionales. Los principales componentes del coste son:

-

Materiales: La selección de materiales influye significativamente en el coste. Los materiales habituales son el aluminio para la carcasa, el cobre para los bobinados y diversos plásticos para el aislamiento. Los materiales de alta calidad pueden aumentar los costes iniciales, pero pueden mejorar la durabilidad y el rendimiento, afectando en última instancia al Coste Total de Propiedad (CTP).

-

Trabajo: Los costes laborales varían mucho según la región. Por ejemplo, los países con salarios más bajos pueden ofrecer precios competitivos, pero es esencial evaluar el nivel de cualificación de la mano de obra y su experiencia en la fabricación de componentes de precisión.

-

Gastos generales de fabricación: Incluye los costes asociados a las instalaciones, los servicios públicos, la depreciación de los equipos y la mano de obra indirecta. Unos procesos de fabricación eficientes pueden reducir los gastos generales, lo que beneficia tanto al proveedor como al comprador.

-

Herramientas: Los costes iniciales de utillaje pueden ser considerables, especialmente en el caso de piezas personalizadas. Los compradores deben tener en cuenta estos costes a la hora de evaluar los presupuestos, ya que pueden influir significativamente en el precio total, sobre todo en el caso de pedidos de bajo volumen.

-

Control de calidad (QC): La aplicación de procesos rigurosos de control de calidad garantiza que los componentes cumplan las especificaciones, lo que puede aumentar los costes pero reducir la probabilidad de defectos y devoluciones. Certificaciones como la ISO también pueden aumentar los costes, pero pueden ser necesarias para cumplir la normativa en determinados mercados.

-

Logística: Los gastos de envío, incluidos flete, seguro y aranceles, pueden variar en función de la distancia y el modo de transporte. Los compradores deben tener en cuenta los Incoterms a la hora de negociar los precios, ya que dictan quién asume estos costes.

-

Margen: Los proveedores aplicarán un margen basado en su estructura de costes, las condiciones del mercado y el panorama competitivo. Conocer el margen típico del sector puede ayudar a los compradores en las negociaciones.

¿Cómo influyen los precios en las decisiones de aprovisionamiento?

Hay varios factores que pueden influir en el precio de las piezas de alternador de automóvil:

-

Volumen/Cantidad mínima de pedido: Las cantidades mínimas de pedido (MOQ) pueden afectar a los precios. Los pedidos más grandes suelen recibir descuentos, por lo que los compradores deben evaluar cuidadosamente sus necesidades para aprovechar los precios por volumen.

-

Especificaciones y personalización: Los diseños o especificaciones personalizados pueden conllevar un aumento de los costes debido a la necesidad de herramientas y procesos especializados. Una comunicación clara de los requisitos puede ayudar a gestionar estos costes.

-

Calidad de los materiales y certificaciones: Los materiales de mayor calidad y el cumplimiento de certificaciones específicas pueden conllevar un aumento del precio, pero pueden ofrecer mejores prestaciones y fiabilidad.

-

Factores relacionados con los proveedores: La reputación, fiabilidad y ubicación del proveedor pueden influir en el precio. Los proveedores consolidados con un historial probado pueden cobrar precios más altos, pero ofrecen mayores garantías de calidad y fiabilidad en las entregas.

-

Incoterms: La elección de los Incoterms puede afectar significativamente al coste total en destino. Los distintos términos trasladan las responsabilidades del envío, el seguro y los aranceles, lo que influye en el precio final que paga el comprador.

¿Cuáles son los consejos más eficaces para ahorrar costes?

Para optimizar las estrategias de aprovisionamiento y lograr rentabilidad, los compradores B2B internacionales deben tener en cuenta los siguientes consejos:

-

Negocia con prudencia: Aprovechar el conocimiento de los componentes del coste y las condiciones del mercado para negociar mejores precios. Establecer relaciones sólidas con los proveedores también puede facilitar condiciones más favorables.

-

Evaluar el coste total de propiedad (TCO): En lugar de centrarse únicamente en el precio de compra, tenga en cuenta el coste total de propiedad, que incluye los costes de mantenimiento, garantía y posibles averías. Invertir en componentes de mayor calidad puede suponer un ahorro a largo plazo.

-

Comprender los matices de los precios en las distintas regiones: Los compradores de África, Sudamérica, Oriente Medio y Europa deben ser conscientes de las variaciones regionales de precios debidas a factores como los costes laborales, los aranceles de importación y la demanda del mercado. Investigar las condiciones del mercado local puede aportar información para una negociación eficaz.

-

Manténgase informado sobre las tendencias del mercado: Mantenerse al corriente de las tendencias del mercado de piezas de automoción, incluidos los cambios en los costes de los materiales y los avances tecnológicos, puede ayudar a los compradores a anticiparse a las fluctuaciones de los precios y a tomar decisiones de compra con conocimiento de causa.

En conclusión, un conocimiento exhaustivo de la estructura de costes y de los factores que influyen en la fijación de precios en el aprovisionamiento de piezas de alternador de automóvil puede beneficiar significativamente a los compradores B2B internacionales. Aplicando técnicas de negociación estratégica y teniendo en cuenta el coste total de propiedad, los compradores pueden conseguir un precio y una calidad del producto óptimos mientras navegan por las complejidades del aprovisionamiento global.

Análisis de alternativas: Comparación de piezas de un alternador de automóvil con otras soluciones

Explorar alternativas a las piezas de un alternador de coche

Al evaluar los componentes de un alternador de automóvil, es esencial considerar soluciones alternativas que puedan alcanzar objetivos similares en la generación de energía eléctrica para sistemas de automoción. Existen varias tecnologías que complementan o compiten con las piezas tradicionales del alternador. Comprender estas alternativas puede ayudar a los compradores B2B a tomar decisiones informadas que se ajusten a sus necesidades operativas específicas y a las condiciones del mercado.

| Aspecto comparativo | Partes del alternador de un coche | Alternativa 1 Nombre: Generador | Alternativa 2 Nombre: Sistema de gestión de baterías (BMS) |

|---|---|---|---|

| Rendimiento | Eficaz en la conversión de energía mecánica en eléctrica | Alto rendimiento para vehículos grandes, menos eficiente para coches pequeños | Optimiza el uso de la batería y prolonga su vida útil |

| Coste | Inversión inicial moderada; durabilidad a largo plazo | Mayores costes iniciales de instalación y mantenimiento | Costes variables en función del tipo de batería y la tecnología de gestión |

| Facilidad de implementación | Instalación de serie en la mayoría de los vehículos | Requiere conocimientos especializados de instalación | Puede integrarse en los sistemas eléctricos existentes |

| Mantenimiento | Comprobación periódica de cepillos y anillos rozantes | Requiere mucho mantenimiento y revisiones periódicas | Mantenimiento mínimo; requiere actualizaciones de software |

| Mejor caso de uso | Ideal para turismos estándar | Ideal para vehículos pesados y aplicaciones industriales | Perfecto para vehículos eléctricos e híbridos que requieren un uso eficiente de la batería |

¿Cuáles son los pros y los contras de utilizar un generador como alternativa?

Los generadores son dispositivos que convierten la energía mecánica en energía eléctrica, de forma similar a los alternadores. Son especialmente ventajosos en vehículos pesados y aplicaciones industriales, donde es esencial un alto rendimiento. Sin embargo, aunque proporcionan un fuerte suministro de energía, pueden ser menos eficientes en vehículos más pequeños, lo que supone un desperdicio de combustible y un aumento de los costes operativos. Además, los generadores suelen requerir un mantenimiento más frecuente y su instalación puede resultar más compleja.

Imagen ilustrativa relacionada con las partes de un alternador de automóvil

¿En qué se diferencia un sistema de gestión de baterías (BMS)?

Un sistema de gestión de baterías (BMS) está diseñado para controlar y gestionar el rendimiento de las baterías, garantizando ciclos óptimos de carga y descarga. Esta tecnología es especialmente útil en vehículos eléctricos e híbridos, donde la vida útil y la eficiencia de la batería son fundamentales. El BMS puede prolongar la vida útil de la batería y mejorar el rendimiento general del vehículo, pero conlleva costes variables según el tipo de baterías utilizadas y la complejidad del sistema de gestión. Además, un BMS requiere la integración con los sistemas existentes del vehículo, lo que puede complicar la instalación.

Conclusión: ¿Cómo pueden los compradores B2B elegir la solución adecuada a sus necesidades?

A la hora de elegir entre piezas de un alternador de automóvil y soluciones alternativas como generadores o sistemas de gestión de baterías, los compradores B2B deben evaluar sus requisitos operativos específicos. Factores como el tipo de vehículo, las limitaciones presupuestarias y las capacidades de mantenimiento deben guiar el proceso de toma de decisiones. Comprender los puntos fuertes y débiles de cada opción puede conducir a elecciones más informadas, garantizando que la tecnología seleccionada se alinea con los objetivos estratégicos de la empresa al tiempo que satisface las demandas de su base de clientes.

Propiedades técnicas esenciales y terminología comercial de las piezas de un alternador de automóvil

¿Cuáles son las principales características técnicas de las piezas del alternador?

Comprender las especificaciones técnicas de los componentes del alternador de automóvil es crucial para los compradores B2B, especialmente a la hora de seleccionar piezas para fabricación o reparación. He aquí varias especificaciones críticas:

-

Grado del material

La carcasa exterior de la mayoría de los alternadores suele ser de aluminio debido a su ligereza y a sus propiedades no magnéticas. El grado del material afecta a la durabilidad, la disipación del calor y el rendimiento general. Por ejemplo, un aluminio de grado superior puede soportar temperaturas más altas y resistir la corrosión, lo que es esencial para la longevidad en diversos entornos, especialmente en regiones con condiciones climáticas extremas. -

Niveles de tolerancia

La tolerancia se refiere a la variación admisible en las dimensiones de las piezas, como el rotor y el estator. Unas tolerancias precisas garantizan que los componentes encajen correctamente, evitando fallos mecánicos. En aplicaciones de automoción, las tolerancias típicas pueden oscilar entre ±0,01 mm y ±0,05 mm. Para los fabricantes, conocer los niveles de tolerancia es vital para mantener el control de calidad y garantizar la compatibilidad entre distintos modelos de vehículos. -

Tensión nominal de salida

Los alternadores están diseñados para generar una tensión de salida específica, normalmente entre 12 V y 14,5 V para aplicaciones de automoción. Este valor es crucial para garantizar que los sistemas eléctricos de los vehículos reciban la potencia adecuada. Los compradores B2B deben tener en cuenta la tensión de salida al comprar alternadores para asegurarse de que cumplen los requisitos específicos de los distintos vehículos, especialmente en mercados con normas eléctricas diferentes. -

Eficiencia de refrigeración

El diseño de los ventiladores de refrigeración dentro del alternador afecta significativamente a su eficiencia. Los alternadores modernos suelen incorporar sistemas de refrigeración interna que optimizan la disipación del calor. Comprender la eficiencia de la refrigeración puede ayudar a los compradores a seleccionar alternadores que funcionen de forma fiable en entornos de altas temperaturas, lo que es especialmente importante en regiones con temperaturas ambiente elevadas como algunas zonas de África y Oriente Medio. -

Clasificación actual

La corriente nominal, que suele medirse en amperios (A), indica la corriente eléctrica máxima que puede suministrar el alternador. Esta especificación es esencial para garantizar que el alternador pueda hacer frente a las demandas de potencia de los vehículos modernos, que a menudo incluyen numerosos accesorios electrónicos. Los compradores B2B deben asegurarse de que el valor nominal de la corriente coincide con las especificaciones de los vehículos que están revisando o fabricando.

¿Qué terminología comercial común deben conocer los compradores B2B?

Familiarizarse con la jerga del sector es vital para comunicarse y negociar con eficacia en el sector de los recambios de automoción. He aquí varios términos clave:

-

OEM (fabricante de equipos originales)

OEM hace referencia a las piezas fabricadas por el fabricante de los componentes originales del vehículo. Estas piezas suelen ser de mayor calidad y están diseñadas específicamente para determinados modelos de vehículos. Los compradores B2B suelen preferir las piezas OEM para garantizar la compatibilidad y la fiabilidad, sobre todo en mercados que priorizan la calidad. -

MOQ (cantidad mínima de pedido)

MOQ es la cantidad más pequeña de un producto que un proveedor está dispuesto a vender. Comprender las MOQ es esencial para que los compradores B2B gestionen el inventario de forma eficaz y se aseguren de que cumplen los requisitos de su cadena de suministro sin comprometer recursos en exceso. -

RFQ (Solicitud de presupuesto)

Una petición de oferta es un documento que se envía a los proveedores solicitando un presupuesto para productos o servicios específicos. Es un paso fundamental en el proceso de adquisición, ya que permite a los compradores comparar precios y condiciones de distintos proveedores, lo que facilita la toma de decisiones con conocimiento de causa. -

Incoterms (Términos comerciales internacionales)

Los Incoterms son un conjunto de normas internacionales que definen las responsabilidades de compradores y vendedores en las transacciones internacionales. Aclaran quién es responsable del envío, el seguro y los aranceles. Los compradores B2B deben conocer los Incoterms para negociar mejores condiciones y gestionar la logística con eficacia. -

Piezas de recambio

Las piezas de recambio son componentes fabricados por terceros en lugar de por el fabricante original. Aunque suelen ser más asequibles, su calidad puede variar. Comprender la diferencia entre piezas OEM y piezas de recambio ayuda a los compradores a tomar decisiones informadas basadas en el coste, la calidad y la compatibilidad.

Al comprender estas propiedades técnicas y terminologías comerciales, los compradores B2B pueden tomar decisiones informadas a la hora de abastecerse de piezas de alternadores de automóvil, asegurándose de que satisfacen las necesidades específicas de sus mercados.

Dinámica del mercado y tendencias de aprovisionamiento en el sector de los componentes del alternador del automóvil

¿Cuáles son las tendencias clave que determinan el mercado de recambios de alternadores para automóviles?

El mercado mundial de recambios de automoción, en particular el de alternadores, está experimentando una importante transformación impulsada por los avances tecnológicos y las cambiantes demandas de los consumidores. Uno de los principales motores es la creciente adopción de vehículos eléctricos e híbridos, que requieren sistemas de alternadores más sofisticados para gestionar la energía de forma eficiente. Este cambio es especialmente evidente en regiones como Europa y Oriente Medio, donde las estrictas normativas medioambientales están impulsando a los fabricantes a innovar. Además, el auge de la tecnología inteligente en los vehículos, incluidos los sistemas avanzados de gestión de baterías, está configurando el diseño y la funcionalidad de los componentes de los alternadores.

Entre las tendencias emergentes en el aprovisionamiento B2B se incluye la integración de materiales avanzados, como los compuestos ligeros, que mejoran la eficiencia y la durabilidad de los alternadores. También se están imponiendo las plataformas digitales, que permiten a los compradores internacionales abastecerse de piezas de forma más eficiente. La tecnología Blockchain está mejorando la transparencia en las cadenas de suministro, garantizando que los compradores puedan verificar la autenticidad y el origen de las piezas. En mercados como África y Sudamérica, donde la fabricación local va en aumento, las asociaciones con proveedores locales se están volviendo cruciales para reducir los plazos de entrega y los costes.

¿Cómo influye la sostenibilidad en las decisiones de aprovisionamiento de piezas de alternador?

La sostenibilidad es cada vez más un tema central en el aprovisionamiento de piezas de automoción, incluidas las de alternadores. El impacto medioambiental de los procesos de fabricación ha llevado a muchas empresas a reevaluar sus cadenas de suministro. Los compradores internacionales dan prioridad a los proveedores que demuestran su compromiso con la reducción de la huella de carbono y la utilización de materiales ecológicos. Esto incluye el abastecimiento de componentes reciclables o fabricados con materiales reciclados, que no sólo cumplen las normas reglamentarias, sino que también atraen a los consumidores concienciados con el medio ambiente.

El abastecimiento ético es igualmente importante, y los compradores buscan proveedores que respeten las prácticas laborales justas y el abastecimiento responsable de materias primas. Certificaciones como la ISO 14001 para sistemas de gestión medioambiental y otras certificaciones ecológicas pueden servir de indicadores del compromiso de un proveedor con la sostenibilidad. Esta tendencia es especialmente relevante para los compradores internacionales de regiones como Europa, donde los consumidores exigen cada vez más transparencia y prácticas éticas a las marcas que apoyan.

¿Cómo ha evolucionado el mercado de recambios de alternadores de automóvil?

La evolución del mercado de recambios para alternadores de automóvil ha estado marcada por importantes avances tecnológicos desde la introducción de los primeros alternadores a principios del siglo XX. Inicialmente diseñados para una funcionalidad básica, los alternadores modernos incorporan ahora componentes sofisticados como reguladores de tensión y rectificadores de diodos que optimizan el rendimiento y la eficacia. La transición de los sistemas mecánicos a los electrónicos ha mejorado aún más la fiabilidad y el rendimiento de los alternadores.

En las últimas décadas, la industria ha experimentado un cambio hacia diseños más compactos y ligeros, impulsada por la necesidad de eficiencia de combustible y rendimiento en los vehículos contemporáneos. Esta evolución no se limita a la mejora de la funcionalidad, sino que también refleja las expectativas cambiantes de los consumidores y la tendencia general de la industria automovilística hacia la electrificación. A medida que estas tendencias siguen desarrollándose, a los compradores internacionales B2B se les presentan oportunidades para aprovechar las tecnologías innovadoras y las prácticas sostenibles en sus estrategias de abastecimiento.

Preguntas más frecuentes (FAQ) para compradores B2B de piezas de un alternador de automóvil

-

¿Cómo puedo elegir las piezas de alternador adecuadas para mi vehículo?

Al seleccionar las piezas del alternador, tenga en cuenta la marca y el modelo específicos del vehículo para garantizar la compatibilidad. Investigue las especificaciones del alternador, incluidos el rotor, el estator, el regulador de tensión y el rectificador. También es esencial comprobar los estándares de calidad de las piezas y la reputación del proveedor. Solicite siempre descripciones y especificaciones detalladas del producto para asegurarse de que está adquiriendo los componentes correctos que satisfacen sus requisitos de rendimiento. -

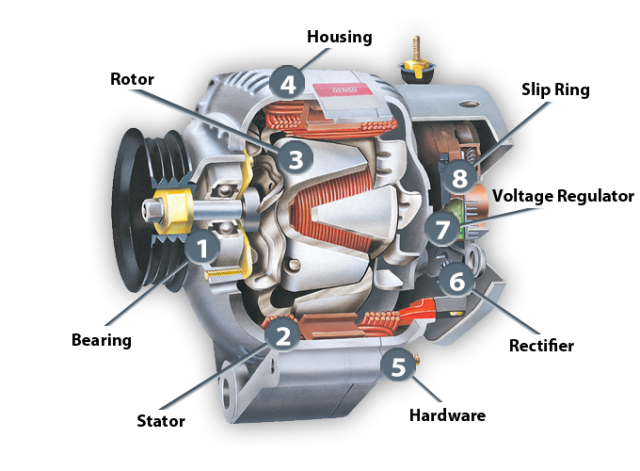

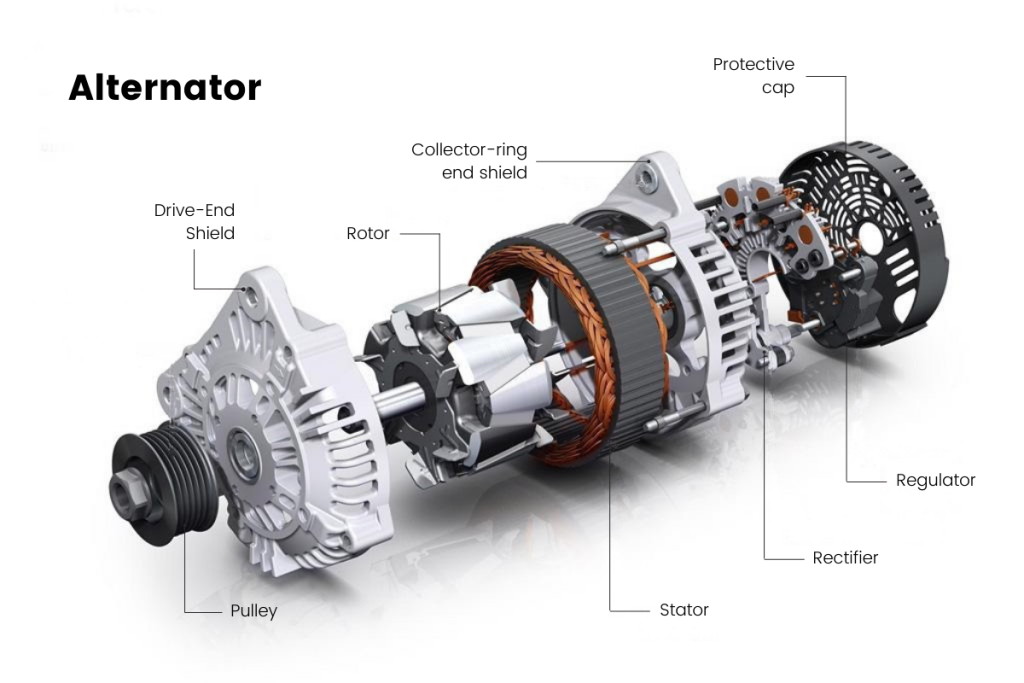

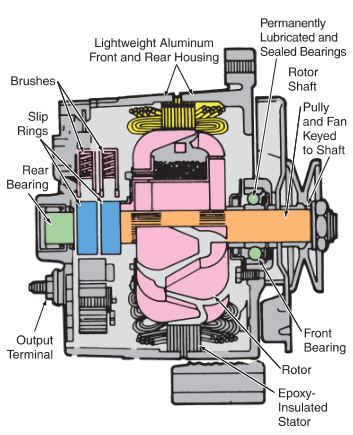

¿Cuáles son los componentes más importantes del alternador de un coche?

Los componentes esenciales de un alternador de automóvil son el rotor, el estator, el rectificador, el regulador de tensión, los anillos colectores y los cojinetes. El rotor genera un campo magnético y el estator lo transforma en energía eléctrica. El rectificador transforma la corriente alterna (CA) producida en corriente continua (CC) para los sistemas eléctricos del vehículo. Conocer estos componentes le ayudará a evaluar la calidad y funcionalidad de las piezas que adquiera. -

¿Qué debo tener en cuenta al buscar proveedores de piezas de alternador?

Al examinar a los proveedores, tenga en cuenta su experiencia en el sector, certificaciones y procesos de control de calidad. Pida referencias o estudios de casos a clientes anteriores para calibrar su fiabilidad y nivel de servicio. También es útil comprobar si cumplen las normas y reglamentos internacionales aplicables en su región. Un proveedor con un proceso de comunicación transparente y políticas de devolución claras también puede mitigar los riesgos en su proceso de compra. -

¿Cuáles son las cantidades mínimas de pedido (CMP) habituales para las piezas de alternador?

Las cantidades mínimas de pedido de piezas de alternador pueden variar mucho en función del proveedor y de los componentes específicos. En general, las cantidades mínimas de pedido pueden oscilar entre 50 y varios cientos de unidades. Es fundamental hablar de sus necesidades con los posibles proveedores para encontrar un equilibrio entre la rentabilidad y sus necesidades de inventario. Algunos proveedores pueden ofrecer flexibilidad en las cantidades mínimas de compra para los primeros compradores o los pedidos más grandes. -

¿Qué condiciones de pago debo esperar cuando compro piezas de alternador a nivel internacional?

Las condiciones de pago pueden variar considerablemente en función de la política del proveedor y la naturaleza de la transacción. Los acuerdos más habituales incluyen el pago por adelantado, a 30 o 60 días netos, o cartas de crédito para pedidos grandes. Es esencial negociar unas condiciones que se ajusten a sus necesidades de tesorería, asegurándose al mismo tiempo de que el proveedor se siente cómodo con el acuerdo. Documente siempre las condiciones de pago en el contrato para evitar malentendidos. -

¿Cómo puedo asegurarme de la calidad de las piezas de alternador que compro?

Para garantizar la calidad, solicite a los proveedores certificaciones y documentos de conformidad, como normas ISO o equivalentes. Realice controles de calidad al recibir los productos, incluidas inspecciones visuales y pruebas de funcionalidad. Si es posible, establezca una relación a largo plazo con proveedores que ofrezcan garantías sobre sus productos, lo que puede proporcionar una garantía adicional de calidad. -

¿Qué consideraciones logísticas debo tener en cuenta al importar piezas de alternador?

Al importar piezas de alternador, tenga en cuenta los métodos de envío, la normativa aduanera y los plazos de entrega. Elija un socio logístico con experiencia en la manipulación de componentes de automoción para agilizar el proceso. También es fundamental conocer los aranceles de importación, los impuestos y las tasas adicionales que puedan aplicarse. Una comunicación clara con su proveedor sobre las preferencias de envío y los requisitos de documentación puede evitar retrasos. -

¿Puedo personalizar las piezas del alternador para satisfacer requisitos específicos?

Muchos proveedores ofrecen opciones de personalización para las piezas del alternador, que pueden incluir tamaños específicos, materiales o especificaciones de rendimiento. Hable de sus necesidades con el proveedor para ver si puede atender pedidos personalizados. Esté preparado para proporcionar especificaciones detalladas y, posiblemente, participar en un proceso de creación de prototipos. La personalización puede afectar a los plazos de entrega y a los costes, así que téngalos en cuenta en su planificación.

Lista de fabricantes y proveedores de las 4 piezas principales del alternador de un coche

1. HowStuffWorks - Alternadores

Dominio: auto.cómofuncionanlascosas.com

Registrado: 1998 (27 años)

Introducción: Los alternadores son pequeños y ligeros, aproximadamente del tamaño de un coco, y están fabricados con una carcasa exterior de aluminio para la disipación del calor. Los componentes clave incluyen:

– Polea motriz acoplada al eje del rotor, que convierte la energía mecánica en energía eléctrica.

– Terminales: Terminal S (detecta el voltaje de la batería), terminal IG (interruptor de encendido), terminal L (circuito de la luz de advertencia), terminal B (salida principal a ba...

2. AutoElectro - Alternadores

Dominio: autoelectro.es

Registrado: 1999 (26 años)

Introducción: Alternador: Genera energía para alimentar el sistema eléctrico y cargar la batería. Salida: Corriente continua (CC). Componentes: 1. Regulador: controla la distribución de energía a la batería. 2. Rectificador - convierte la CA en CC. 3. Rotor - masa giratoria que actúa como un electroimán. 4. Anillos colectores - proporcionan corriente continua al rotor. 5. Cojinete del extremo del anillo colector - soporta la rotación del eje del rotor. 6. Estator - bobinas de...

3. Electude - Fundamentos del alternador

Dominio: electude.com

Registrado: 2005 (20 años)

Introducción: El alternador es un componente fundamental del automóvil que convierte la energía mecánica en energía eléctrica, generando energía para los consumidores eléctricos y la batería del vehículo. Entre sus componentes principales se incluyen:

– Polea: Transfiere la energía mecánica del motor.

- Rotor: Crea el campo magnético para la generación de corriente alterna.

– Estator: La parte estática donde se genera el voltaje.

– Rectificador: …

4. Scribd - Componentes del alternador de automoción

Dominio: scribd.com

Registrado: 2006 (19 años)

Introducción: En este documento se describen las principales piezas y funciones de un alternador de automoción y se describen 8 piezas clave: 1) Polea: hace girar el conjunto del rotor a través de la correa del motor, 2) Carcasa: protege los componentes internos, 3) Cojinetes: permiten que el rotor gire libremente, 4) Conjunto del rotor: genera un campo magnético, 5) Conjunto del estator: utiliza el campo magnético para generar electricidad, 6) Rectificador: convierte...

Conclusiones y perspectivas de la contratación estratégica de piezas de un alternador de automóvil

En conclusión, el aprovisionamiento estratégico de piezas de alternador de automóvil es crucial para los compradores B2B internacionales que buscan mejorar la resistencia de su cadena de suministro y la eficiencia operativa. Los componentes clave, como el rotor, el estator, el regulador de tensión y el rectificador, no sólo desempeñan un papel importante en la funcionalidad del alternador, sino que también ofrecen oportunidades para ahorrar costes y mejorar la calidad. Al aprovechar las prácticas de aprovisionamiento estratégico, las empresas pueden garantizar la adquisición de piezas de alta calidad que cumplan rigurosas normas de rendimiento, lo que en última instancia conduce a una mayor satisfacción y lealtad de los clientes.

A medida que la industria del automóvil siga evolucionando, especialmente en los mercados emergentes de África, Sudamérica, Oriente Medio y Europa, la demanda de componentes de alternador fiables y eficientes no hará sino aumentar. Se anima a los compradores a que se pongan en contacto con proveedores de confianza que den prioridad a la innovación y la sostenibilidad en sus ofertas.

Imagen ilustrativa relacionada con las partes de un alternador de automóvil

De cara al futuro, considere el potencial de colaboración con fabricantes que puedan proporcionarle no sólo piezas, sino también conocimientos sobre tecnologías emergentes que podrían redefinir la eficiencia en el rendimiento de los vehículos. Al abastecerse de forma proactiva de componentes de alternador de alta calidad, su empresa se posiciona para prosperar en un entorno competitivo, al tiempo que contribuye al crecimiento del sector de la automoción en su región.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.