Introduction: Navigating the Global Market for how much is a new starter

In today’s global market, understanding how much a new starter costs can significantly impact your operational efficiency and budget management. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, sourcing reliable and cost-effective starter replacements is often a complex challenge. This guide aims to demystify the costs associated with new starters, providing valuable insights into various types, applications, and factors that influence pricing.

By exploring the intricacies of starter components, potential costs for different vehicle makes and models, and the nuances of supplier vetting, this comprehensive resource empowers you to make informed purchasing decisions. Whether you’re managing a fleet in Nigeria, running a logistics company in Brazil, or overseeing vehicle maintenance in the Middle East, understanding these dynamics can lead to smarter investments and improved operational reliability.

This guide will equip you with essential knowledge about the starter replacement process, including DIY options, labor costs, and the importance of quality assurance when selecting suppliers. With the right information at your fingertips, you can navigate the complexities of the starter market, ensuring that your vehicles remain operational without overspending.

Índice

- Top 2 How Much Is A New Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much is a new starter

- Understanding how much is a new starter Types and Variations

- Key Industrial Applications of how much is a new starter

- 3 Common User Pain Points for ‘how much is a new starter’ & Their Solutions

- Strategic Material Selection Guide for how much is a new starter

- In-depth Look: Manufacturing Processes and Quality Assurance for how much is a new starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is a new starter’

- Comprehensive Cost and Pricing Analysis for how much is a new starter Sourcing

- Alternatives Analysis: Comparing how much is a new starter With Other Solutions

- Essential Technical Properties and Trade Terminology for how much is a new starter

- Navigating Market Dynamics and Sourcing Trends in the how much is a new starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much is a new starter

- Strategic Sourcing Conclusion and Outlook for how much is a new starter

- Aviso legal importante y condiciones de uso

Understanding how much is a new starter Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Nuevos entrantes | Brand new components, factory specifications | Gestión de flotas, talleres de reparación de automóviles | Ventajas: Reliable performance, warranty included. Contras: Mayor coste inicial. |

| Motores de arranque reconstruidos | Refurbished parts, often tested for quality | Pequeños talleres, mecánicos independientes | Ventajas: Rentable y respetuoso con el medio ambiente. Contras: May have shorter lifespan than new starters. |

| Arrancadores posventa | Non-OEM parts, varying quality and price | Budget-conscious buyers, DIY mechanics | Ventajas: Wide range of prices, availability. Contras: Quality can be inconsistent. |

| Arrancadores OEM | Original Equipment Manufacturer parts, exact fit | Concesionarios, servicios de flota | Ventajas: Compatibilidad garantizada, alta calidad. Contras: Often the most expensive option. |

| Motores de arranque de alto rendimiento | Enhanced power output, designed for specific applications | Racing teams, performance vehicles | Ventajas: Improved starting power, tailored for specific needs. Contras: Mayor coste, puede requerir modificaciones. |

¿Cuáles son las características de los recién llegados?

New starters are brand-new components manufactured to meet original specifications. They are ideal for businesses that prioritize reliability and longevity, particularly in fleet management and automotive repair sectors. When purchasing new starters, B2B buyers should consider the warranty offered, as this can provide peace of mind regarding performance and durability. However, the higher upfront costs may be a concern for budget-sensitive operations.

How Do Rebuilt Starters Compare?

Rebuilt starters are refurbished units that have been cleaned, tested, and repaired to meet performance standards. They are suitable for small garages and independent mechanics looking for cost-effective solutions. While they are generally more affordable than new starters and have a lesser environmental impact, buyers should be aware that they may not last as long as new units. Ensuring quality through reputable suppliers is crucial when opting for rebuilt starters.

What Should Buyers Know About Aftermarket Starters?

Aftermarket starters are non-OEM components that can vary significantly in quality and price. They are often sought by budget-conscious buyers and DIY mechanics. The main advantage is the wide selection available, which allows for competitive pricing. However, buyers must be cautious as the quality can be inconsistent, potentially leading to premature failures. Conducting thorough research and selecting reputable brands can mitigate risks associated with aftermarket options.

¿Por qué elegir arrancadores OEM?

OEM starters are manufactured by the original equipment manufacturer, ensuring a perfect fit and compatibility with specific vehicle models. They are commonly purchased by dealerships and fleet services that prioritize reliability and adherence to manufacturer specifications. While OEM starters guarantee high quality, they are typically the most expensive option available. Buyers should weigh the importance of compatibility and performance against budget constraints when considering OEM products.

What Are High-Performance Starters Used For?

High-performance starters are designed to provide enhanced power output and are often tailored for specific applications, such as racing or performance vehicles. These starters are crucial for businesses involved in motorsports or high-performance automotive modifications. While they offer significant advantages in terms of starting power, they usually come at a higher price point and may require modifications to fit certain vehicles. Understanding the specific needs of the application is essential for B2B buyers considering high-performance starters.

Key Industrial Applications of how much is a new starter

| Industria/Sector | Specific Application of how much is a new starter | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Replacement of starters in vehicles for repair shops | Increased customer satisfaction and repeat business | Quality of parts, warranty terms, and supplier reliability |

| Transporte público | Ensuring operational efficiency of buses and commercial vehicles | Reducción del tiempo de inactividad y de los costes de mantenimiento | Availability of parts, compatibility with various vehicle models |

| Agricultura | Starting heavy machinery like tractors and harvesters | Enhanced productivity and reduced operational delays | Durability of starters for harsh environments and local sourcing |

| Minería | Replacement in mining vehicles and equipment | Minimizing equipment failure and maintaining safety standards | Cost-effectiveness, ease of installation, and local support services |

| Construcción | Garantizar el funcionamiento fiable de los equipos de construcción | Improved project timelines and reduced equipment rental costs | Specifications for heavy-duty starters and after-sales support |

How is ‘how much is a new starter’ Relevant in Automotive Repair?

In the automotive repair sector, understanding the cost of a new starter is critical for repair shops. A reliable starter ensures that vehicles can be quickly serviced, minimizing downtime for customers. Shops must consider sourcing quality parts that fit a variety of vehicle models, which can lead to higher customer satisfaction and repeat business. Additionally, offering transparent pricing on starter replacements can enhance trust and loyalty among clients, especially in competitive markets.

What is the Importance of Starter Replacement in Public Transportation?

For public transportation systems, the cost of a new starter directly impacts operational efficiency. Buses and commercial vehicles must be in optimal condition to avoid service interruptions that can frustrate passengers. By investing in reliable starters, transit authorities can reduce maintenance costs and enhance service reliability. Sourcing parts that are compatible with multiple vehicle models is essential, as it allows for streamlined inventory management and quicker repairs.

Why Do Farmers Need to Consider Starter Costs in Agriculture?

In agriculture, the ability to start heavy machinery like tractors and harvesters is vital for productivity. The cost of a new starter can influence farmers’ decisions on equipment maintenance and replacement. A reliable starter minimizes delays during critical planting and harvesting seasons, directly impacting yield and profitability. Buyers should focus on the durability of starters, particularly in harsh environments, and consider local sourcing to reduce shipping costs and support regional economies.

How Does Starter Replacement Impact Mining Operations?

In the mining industry, the reliability of vehicles and equipment is paramount, making the cost of a new starter a significant factor. Mining operations depend on heavy machinery that must perform under extreme conditions. By ensuring that starters are readily available and cost-effective, mining companies can prevent equipment failures that lead to safety hazards and financial losses. Key considerations include the ease of installation and the availability of local support services to minimize downtime.

What Role Does Starter Cost Play in Construction Equipment?

Construction projects often rely on heavy machinery that requires dependable starters to maintain timelines and operational efficiency. The cost of a new starter can affect project budgets and equipment rental decisions. By investing in high-quality starters, construction firms can reduce the risk of equipment failure, thus enhancing project delivery. Buyers should prioritize specifications for heavy-duty starters and ensure robust after-sales support to address any issues that may arise during usage.

3 Common User Pain Points for ‘how much is a new starter’ & Their Solutions

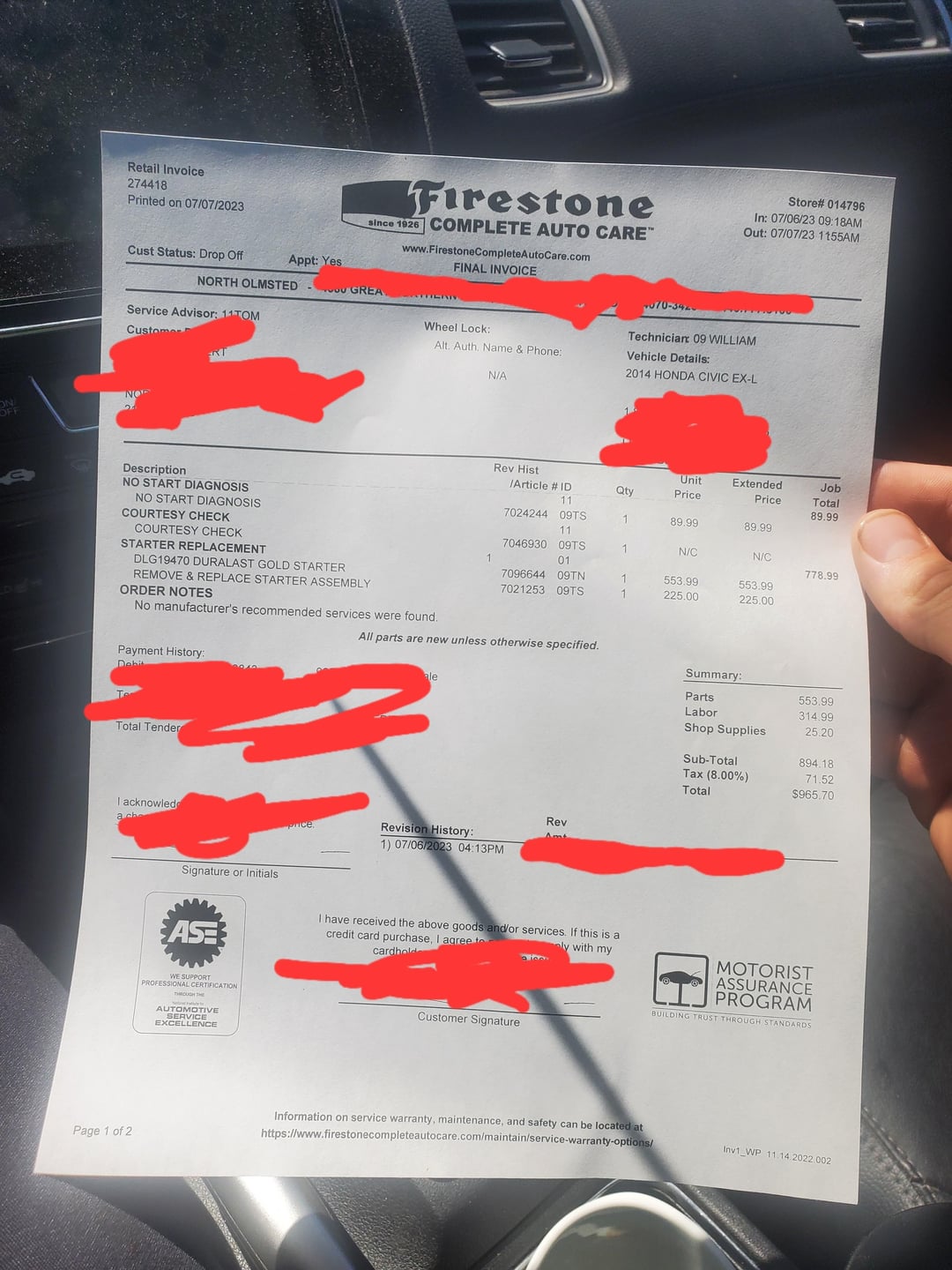

Scenario 1: Navigating Unpredictable Replacement Costs

El problema: B2B buyers often struggle with the unpredictability of starter replacement costs, which can vary significantly based on the vehicle’s make, model, and year. This inconsistency can lead to budgeting challenges, particularly for fleet managers or businesses relying on multiple vehicles. For instance, a fleet manager may face a situation where the starter of a common sedan is relatively inexpensive to replace, while a specialized luxury vehicle incurs exorbitant costs. This lack of clarity can hinder effective financial planning and resource allocation.

La solución: To mitigate these challenges, it is crucial for B2B buyers to conduct thorough research before making a purchase decision. Start by creating a detailed inventory of all vehicles in your fleet, noting their specific models and years. Utilize online resources, such as manufacturer websites or automotive forums, to gather average replacement costs tailored to each vehicle. Additionally, consider building relationships with multiple auto parts suppliers to gain insights on bulk purchasing options or discounts that may lower overall costs. Establish a budget that factors in the highest possible replacement cost for the most expensive vehicle, ensuring your company is prepared for any financial surprises. Implementing a proactive maintenance schedule can also help identify potential starter issues before they necessitate replacement, further controlling costs.

Scenario 2: Understanding the Signs of Starter Failure

El problema: For many B2B buyers, especially those managing fleets, the challenge lies in accurately diagnosing starter problems before they escalate. Symptoms like erratic cranking or unusual noises can often be misattributed to other vehicle issues, resulting in unnecessary repairs or replacements. This misdiagnosis can lead to increased downtime for vehicles, which ultimately affects productivity and operational efficiency.

La solución: To effectively address this issue, B2B buyers should invest in diagnostic tools or training for their maintenance teams. A multimeter can help assess the battery’s voltage and ensure that the starting system is functioning properly. Implementing a checklist for troubleshooting starter issues can streamline the process—encouraging technicians to check battery connections, fuses, and relays before concluding that the starter itself is at fault. Additionally, educating the team on the common signs of starter failure will empower them to make informed decisions about repairs. This proactive approach not only reduces the risk of misdiagnosis but also minimizes vehicle downtime and maximizes operational efficiency.

Escenario 3: Equilibrar las reparaciones de bricolaje con los servicios profesionales

El problema: B2B buyers often grapple with the decision of whether to undertake starter replacements in-house or to seek professional mechanic services. While DIY repairs can save money, they require the right tools, knowledge, and time, which can be scarce in a busy business environment. Conversely, relying solely on professional services can lead to higher costs, particularly if maintenance budgets are tight.

La solución: A strategic approach is to create a hybrid model that leverages both DIY capabilities and professional assistance. Begin by assessing your team’s skill levels and the complexity of the starter replacement process for your vehicles. For simpler replacements, provide your team with comprehensive guides and necessary tools, enabling them to handle these tasks efficiently. For more complex starters, particularly in luxury or larger vehicles, consider establishing partnerships with trusted local mechanics who can offer favorable rates for bulk repairs. This dual approach not only helps manage costs but also fosters a culture of learning and skill development within your team. Regularly review and adjust your maintenance strategy based on vehicle performance and emerging challenges, ensuring your fleet remains operational without incurring unnecessary expenses.

Strategic Material Selection Guide for how much is a new starter

When selecting materials for automotive starters, particularly in the context of international B2B markets, it is crucial to understand the properties, advantages, and limitations of common materials used in starter production. The choice of material can significantly affect performance, cost, and compliance with regional standards. Below are analyses of four common materials used in starter manufacturing.

What are the Key Properties of Copper in Starter Manufacturing?

Copper is widely used in the electrical components of starters due to its excellent electrical conductivity. It can handle high temperatures and pressures, making it suitable for automotive applications. Additionally, copper exhibits good corrosion resistance, especially when treated with protective coatings.

Ventajas y desventajas: The primary advantage of copper is its superior conductivity, which ensures efficient starting performance. However, copper is relatively expensive compared to other materials, and its weight can contribute to the overall weight of the starter, potentially affecting vehicle performance.

Impacto en la aplicación: Copper is particularly compatible with electrical systems that require reliable conductivity and minimal voltage drop. However, in regions with high humidity or corrosive environments, additional protective measures may be necessary to prevent oxidation.

Consideraciones para compradores internacionales: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local standards regarding electrical components. Copper wiring and connectors should meet ASTM or DIN standards to ensure reliability and safety.

How Does Aluminum Perform as a Material for Starters?

Aluminum is another common material used in starter housings and components. It is lightweight, which can improve fuel efficiency and vehicle performance. Aluminum also has good thermal conductivity and corrosion resistance.

Ventajas y desventajas: The lightweight nature of aluminum is a significant advantage, particularly for performance vehicles. However, aluminum can be less durable than steel, especially under high-stress conditions, which may lead to premature failure in some applications.

Impacto en la aplicación: Aluminum is suitable for applications where weight reduction is critical. However, it may not perform as well in high-stress environments, such as heavy-duty trucks or off-road vehicles.

Consideraciones para compradores internacionales: Buyers should be aware of the specific aluminum grades that meet local standards. Compliance with JIS or ASTM standards is essential to ensure quality and performance.

What Role Does Steel Play in Starter Production?

Steel is commonly used in the structural components of starters due to its strength and durability. It can withstand high mechanical stresses and is often treated to enhance corrosion resistance.

Ventajas y desventajas: The main advantage of steel is its robustness, making it suitable for heavy-duty applications. However, steel is heavier than aluminum, which can negatively impact vehicle weight and fuel efficiency.

Impacto en la aplicación: Steel is ideal for applications requiring high durability, such as in trucks and SUVs. However, its weight may not be suitable for performance-oriented vehicles.

Consideraciones para compradores internacionales: Steel components must adhere to local standards, and buyers should consider the availability of specific grades that comply with ASTM or DIN standards.

How Does Plastic Composite Material Affect Starter Design?

Plastic composites are increasingly being used in starter production, particularly for non-structural components. They offer excellent resistance to corrosion and can be molded into complex shapes, reducing manufacturing complexity.

Ventajas y desventajas: The primary advantage of plastic composites is their lightweight nature and resistance to environmental factors. However, they may not withstand high temperatures or mechanical stresses as effectively as metals.

Illustrative image related to how much is a new starter

Impacto en la aplicación: Plastic composites are suitable for applications where weight reduction and corrosion resistance are priorities. However, they may not be ideal for high-performance or heavy-duty starters.

Consideraciones para compradores internacionales: Buyers should ensure that plastic components meet relevant international standards for automotive parts. Compliance with ISO standards can help ensure the reliability of plastic materials in automotive applications.

Tabla resumen de selección de materiales para principiantes

| Material | Typical Use Case for how much is a new starter | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Cobre | Componentes eléctricos de los arrancadores | Excelente conductividad eléctrica | Alto coste y peso | Alto |

| Aluminio | Lightweight housings for starters | Reduces overall vehicle weight | Less durable under stress | Medio |

| Acero | Structural components for heavy-duty starters | Alta resistencia y durabilidad | Increases overall weight | Medio |

| Plastic Composite | Non-structural parts in starters | Ligero y resistente a la corrosión. | Rendimiento limitado a altas temperaturas | Bajo |

This guide provides a comprehensive overview of material selection for automotive starters, emphasizing the importance of understanding each material’s properties and implications for international B2B buyers.

Illustrative image related to how much is a new starter

In-depth Look: Manufacturing Processes and Quality Assurance for how much is a new starter

¿Cuáles son las principales etapas de la fabricación de un nuevo arrancador?

The manufacturing process for automotive starters involves several key stages, each critical to producing a reliable and efficient product. These stages include material preparation, forming, assembly, and finishing.

¿Cómo se prepara el material para la fabricación de masas madre?

The initial step in manufacturing starters begins with material preparation. High-quality metals, such as steel and aluminum, are typically used due to their durability and resistance to corrosion. Suppliers must ensure that the materials meet specific mechanical and chemical properties required for automotive applications. This often involves sourcing from certified vendors and conducting preliminary tests on material samples.

¿Qué técnicas de conformado se utilizan habitualmente en la producción de arrancadores?

Once materials are prepared, they undergo various forming processes. Techniques such as casting, forging, and machining are commonly employed. For instance, the starter housing might be cast to create a lightweight yet robust structure, while components like the armature are often machined to precise specifications to ensure optimal performance.

Advanced forming techniques, such as die-casting or injection molding for smaller components, can also be utilized. These processes allow for high-volume production with minimal waste, which is essential for maintaining cost-effectiveness in a competitive market.

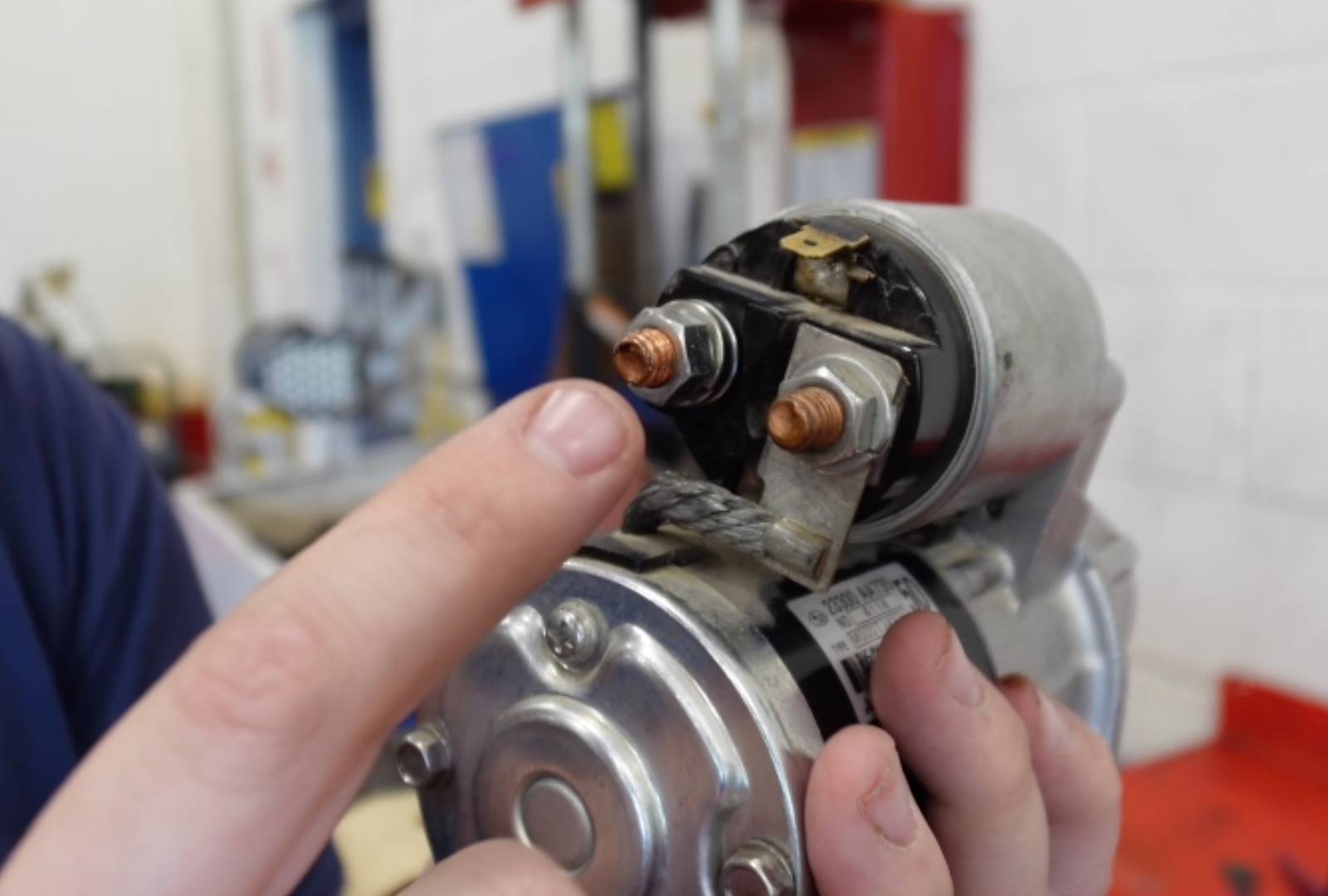

How Are Starters Assembled During Manufacturing?

The assembly stage is where various components come together to form the final starter unit. Components such as the solenoid, armature, and electromagnetic coils are meticulously assembled, often using automated machinery to ensure precision. Manual assembly may be necessary for complex parts, where skilled technicians ensure that each component is correctly aligned and securely fastened.

During this phase, manufacturers often implement standardized assembly procedures to maintain consistency across production batches. This is crucial, as even minor deviations can lead to significant performance issues in automotive applications.

¿Qué procesos de acabado se aplican a los iniciadores?

After assembly, starters undergo finishing processes that enhance their durability and performance. These may include surface treatments like powder coating or plating to prevent corrosion. Additionally, components might be tested for proper alignment and functionality before moving to the final inspection stage.

What Quality Assurance Standards Are Relevant in Starter Manufacturing?

Quality assurance is paramount in the production of automotive starters. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system. This standard emphasizes continuous improvement, which is crucial for meeting the evolving demands of the automotive market.

How Do Industry-Specific Certifications Impact Quality Assurance?

In addition to general ISO standards, specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the intended market for the starter. These certifications indicate compliance with safety and performance standards, providing B2B buyers with confidence in the reliability of their purchases.

¿Cuáles son los principales puntos de control de calidad en la fabricación de iniciadores?

Quality control (QC) checkpoints are integral to ensuring that starters meet both performance and safety standards. Common QC checkpoints include:

-

Control de calidad de entrada (IQC): This involves inspecting raw materials and components upon delivery to ensure they meet required specifications.

-

Control de calidad durante el proceso (IPQC): During production, manufacturers perform checks at various stages to identify any issues early in the process, minimizing waste and rework.

-

Control de calidad final (FQC): Before dispatch, each completed starter undergoes a thorough inspection to verify that it meets all performance criteria and specifications.

What Common Testing Methods Are Employed to Ensure Starter Quality?

To verify the functionality and reliability of starters, several testing methods are commonly employed:

-

Pruebas eléctricas: This includes checking the starter’s electrical resistance, current draw, and voltage output to ensure it functions correctly under load conditions.

-

Pruebas de durabilidad: Starters may undergo various stress tests to simulate prolonged use, ensuring they can withstand the rigors of daily automotive operations.

-

Pruebas de vibración y ruido: These tests assess the starter’s performance under different conditions, ensuring that it operates smoothly and quietly, which is particularly important for high-end vehicles.

¿Cómo pueden los compradores B2B verificar las medidas de control de calidad de los proveedores?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are actionable steps:

-

Realización de auditorías: Regular audits of suppliers can help ensure they adhere to quality standards and manufacturing processes. Buyers should inquire about the frequency and scope of these audits.

-

Solicitar informes de calidad: Suppliers should provide documented evidence of their quality control processes, including IQC, IPQC, and FQC reports, along with any relevant certifications.

-

Contrate a inspectores externos: Employing third-party inspectors can provide an unbiased assessment of the supplier’s quality control practices. This is especially useful for buyers unfamiliar with local manufacturing standards.

-

Evaluate Compliance with International Standards: Buyers should ensure that suppliers comply with relevant international quality standards. This not only ensures product reliability but also aligns with global best practices.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

When sourcing starters internationally, buyers must consider regional standards and regulations. For example, products exported to Europe must comply with CE marking, while those intended for the U.S. market may require adherence to specific automotive standards like SAE (Society of Automotive Engineers). Understanding these nuances can help buyers navigate the complexities of international trade and quality assurance.

Illustrative image related to how much is a new starter

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices in starter production empowers B2B buyers to make informed decisions. By prioritizing suppliers who adhere to rigorous quality standards and implementing robust verification practices, businesses can ensure they procure reliable and high-performance automotive starters.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is a new starter’

Introducción

Navigating the procurement process for a new starter is critical for ensuring your vehicles or machinery operate efficiently. This guide provides a step-by-step checklist to assist B2B buyers in sourcing the right starter at a competitive price while ensuring quality and reliability. By following these steps, you can make informed decisions that align with your operational needs.

Paso 1: Assess Your Requirements

Begin by defining the specific needs for the starter you wish to procure. This includes understanding the type of vehicle or machinery it will be used for, as different models may require distinct starter specifications.

- Consideraciones clave:

- Engine size and type.

- Compatibility with existing systems.

- Performance requirements, such as cranking power and durability.

Paso 2: Investigar los precios del mercado

Conduct thorough research to understand the price range for starters in your market. Prices can vary significantly based on brand, quality, and supplier location.

- What to Do:

- Compare prices from multiple suppliers.

- Look for bulk purchase discounts if you plan to buy in larger quantities.

- Consider the total cost of ownership, including potential installation or shipping fees.

Paso 3: Evaluar las certificaciones de los proveedores

Before proceeding with a purchase, ensure that potential suppliers hold the necessary certifications and comply with industry standards. This helps mitigate risks associated with quality and safety.

Illustrative image related to how much is a new starter

- Certification Types:

- ISO certifications.

- Compliance with local regulations in your region.

- Quality assurance certifications that guarantee product reliability.

Paso 4: Request Technical Documentation

Ask suppliers for detailed technical documentation related to the starter. This information is vital for assessing compatibility and performance.

- Documents to Request:

- Product specifications and technical drawings.

- Installation manuals and warranty information.

- Testing and quality control reports.

Paso 5: Review Supplier Reputation

Investigate the reputation of potential suppliers through customer reviews, industry references, and case studies. A supplier’s history can provide insights into their reliability and service quality.

- Dónde buscar:

- Online platforms that aggregate supplier reviews.

- Industry-specific forums or groups.

- Direct testimonials from past clients.

Paso 6: Negociar los términos y condiciones

Once you have identified a suitable supplier, negotiate terms and conditions to ensure favorable procurement. This includes payment terms, delivery schedules, and return policies.

- Negotiation Points:

- Minimum order quantities.

- Lead times for delivery.

- Warranty and support services offered post-purchase.

Paso 7: Finalización del pedido y seguimiento de la entrega

After agreeing on terms, finalize your order and keep track of the delivery process. Effective communication with your supplier during this phase is crucial to ensure timely receipt and compliance with your specifications.

Illustrative image related to how much is a new starter

- Monitoring Tips:

- Confirm shipping details and expected delivery dates.

- Stay in contact with the supplier for updates.

- Prepare for inspection upon arrival to ensure quality standards are met.

By following this comprehensive checklist, B2B buyers can streamline the procurement process for starters, ensuring they select the right product from a reliable supplier while optimizing costs and operational efficiency.

Comprehensive Cost and Pricing Analysis for how much is a new starter Sourcing

What Are the Key Cost Components of Sourcing a New Starter?

When sourcing a new starter, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materiales: The materials used in starter production, such as electromagnetic coils, armatures, and solenoids, significantly influence costs. High-quality materials may increase upfront costs but can enhance durability and performance.

-

Trabajo: Labor costs encompass both manufacturing and assembly processes. Regions with higher labor costs, such as parts of Europe, may see elevated prices compared to regions like South America or Africa, where labor may be more affordable.

-

Gastos generales de fabricación: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help keep these costs lower.

-

Herramientas: Initial costs for specialized tools and dies used in starter production can be substantial. These costs are typically amortized over production volume, making them less significant per unit when larger quantities are ordered.

-

Control de calidad (QC): Ensuring that starters meet safety and performance standards necessitates rigorous QC processes. This can add to the overall cost but is vital for maintaining product reliability.

-

Logística: Shipping costs, influenced by distance, shipping method, and import/export regulations, can significantly impact the total cost. Buyers should consider the efficiency of logistics partners to optimize these expenses.

-

Margen: Suppliers will include their profit margins in the pricing structure. The margin can vary based on market competition and the supplier’s business model.

What Influences the Price of New Starters in B2B Transactions?

Several factors can influence the price of new starters:

-

Volumen/MOQ (cantidad mínima de pedido): Larger orders typically lead to reduced per-unit costs. Buyers should consider their consumption rates to negotiate better pricing.

-

Especificaciones/Personalización: Customized starters designed for specific vehicle models can incur additional costs. Standardized components are generally more cost-effective.

-

Materiales y certificaciones de calidad: Higher-grade materials and certifications (e.g., ISO, TS16949) can lead to increased prices but often provide better reliability and longevity.

-

Factores relacionados con los proveedores: Supplier reputation, reliability, and geographic location can affect pricing. Local suppliers may offer cost advantages in logistics.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects the total landed cost of the product. Buyers should ensure clarity on who bears responsibility for freight and insurance.

What Tips Can Help Buyers Optimize Costs When Sourcing Starters?

B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can take several steps to optimize their sourcing costs:

-

Negociación: Establish strong relationships with suppliers and leverage volume purchases to negotiate favorable terms. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Rentabilidad: Assess the total cost of ownership (TCO), including maintenance and replacement costs, rather than just the initial purchase price. Choosing a more reliable starter may yield long-term savings.

-

Matices en la fijación de precios: Be aware of fluctuations in currency exchange rates and local economic conditions, as they can impact pricing. Additionally, consider seasonal demand variations that may affect availability and pricing.

-

Auditorías de proveedores: Conducting supplier audits can ensure that partners adhere to quality and cost standards. This transparency can foster trust and improve negotiations.

Descargo de responsabilidad sobre precios indicativos

The prices for new starters can vary widely based on the factors outlined above. It’s crucial for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions. Always consult with suppliers for the most accurate and current pricing based on specific requirements and conditions.

Alternatives Analysis: Comparing how much is a new starter With Other Solutions

Exploring Alternatives to Purchasing a New Starter

When faced with the decision of how to address starter issues in vehicles, B2B buyers have several options beyond simply purchasing a new starter. It’s essential to weigh the costs, performance, and ease of implementation of each alternative to determine the best course of action for your specific needs. Below, we’ll compare the costs and benefits of buying a new starter against two viable alternatives: starter rebuilding and using a jump starter or battery charger.

| Aspecto comparativo | How Much Is A New Starter | Starter Rebuilding | Jump Starter or Battery Charger |

|---|---|---|---|

| Rendimiento | High reliability with new parts | Variable reliability; depends on quality of parts used | Temporary solution; depends on battery condition |

| Coste | $80 – $350 (part only); $150 – $1,100 (installation) | $50 – $200 (parts and labor) | $50 – $150 (initial investment) |

| Facilidad de implementación | Moderate; requires professional installation for some vehicles | Requires technical skills; can be DIY or professional | Very easy; plug and play with minimal setup |

| Mantenimiento | Minimal; generally lasts several years | Ongoing; may need future repairs | Low; requires periodic charging and maintenance |

| Mejor caso de uso | Long-term reliability for frequent use | Cost-effective for older vehicles or specific parts | Ideal for emergency starts or infrequent use |

What Are the Pros and Cons of Starter Rebuilding?

Rebuilding a starter is a cost-effective alternative that can extend the life of an existing component. The process typically involves replacing worn-out parts and can be done either DIY or by a professional mechanic. The primary advantage is the lower cost compared to purchasing a new starter, which can be particularly beneficial for businesses operating older vehicle fleets. However, the reliability of a rebuilt starter can vary based on the quality of the replacement parts used. Additionally, while rebuilding may be less expensive, it may not provide the same long-term reliability as a new starter, leading to potential future repairs.

How Do Jump Starters or Battery Chargers Work as an Alternative?

Jump starters and battery chargers serve as practical solutions for addressing starting issues, especially in emergency situations. These devices can temporarily boost a weak battery to get a vehicle running without needing to replace the starter. Their ease of use makes them accessible to anyone, requiring minimal technical knowledge. However, this approach is not a substitute for a faulty starter. If the starter itself is damaged, a jump starter will only provide a short-term fix. Moreover, if the battery is consistently failing, investing in a new starter or rebuilding may be necessary for long-term reliability.

Conclusión: ¿Cómo deben elegir los compradores B2B la solución adecuada?

When deciding between purchasing a new starter, opting for a rebuild, or utilizing jump starters, B2B buyers should consider several factors, including vehicle age, frequency of use, and budget constraints. For businesses that rely heavily on their vehicles, investing in a new starter may be the best long-term solution. Conversely, for older vehicles or those used less frequently, rebuilding or using jump starters can offer significant cost savings. Ultimately, understanding the specific requirements of your fleet and the operational context will guide you toward the most effective solution.

Essential Technical Properties and Trade Terminology for how much is a new starter

What Are the Key Technical Properties of Starters in Automotive Applications?

Understanding the technical properties of automotive starters is essential for B2B buyers, especially when evaluating replacement options. Here are some critical specifications to consider:

1. Grado del material

The materials used in starter construction, such as steel or aluminum alloys, significantly impact durability and performance. High-grade materials can withstand extreme temperatures and vibrations, ensuring a longer lifespan and reliability. For B2B buyers, investing in starters made from higher-grade materials often translates to reduced long-term costs and increased customer satisfaction.

2. Especificaciones de par

Torque specifications indicate the amount of rotational force that a starter motor can deliver. This is crucial for ensuring that the engine cranks efficiently. Starters with the correct torque ratings are vital for compatibility with specific vehicle models. For businesses, understanding torque requirements helps in selecting the right starter for their fleet, preventing performance issues and unnecessary replacements.

3. Resistencia eléctrica

Electrical resistance measures how much a starter resists the flow of electrical current. A lower resistance typically leads to better performance and quicker engine starts. High resistance can result in power loss and inefficiencies. B2B buyers should prioritize starters with optimal electrical resistance to ensure efficient operation and minimize energy waste.

4. Cranking Amperage

Cranking amperage is the amount of current a starter draws to initiate engine turnover. This specification is critical for understanding the starter’s power requirements and compatibility with the vehicle’s battery. For fleet operators, selecting starters with appropriate cranking amperage helps ensure that all vehicles start reliably, especially in colder climates.

5. Size and Dimensions

The physical dimensions of a starter affect its compatibility with different engine layouts. Starters must fit precisely within the engine compartment without causing interference with other components. B2B buyers need to consider size specifications to avoid installation issues and ensure a seamless fit in their vehicles.

¿Cuáles son los términos comerciales habituales relacionados con los arrancadores para automóviles?

Familiarity with industry terminology can enhance communication and negotiation processes in B2B transactions. Here are some common terms:

1. OEM (fabricante de equipos originales)

OEM refers to parts made by the original manufacturer of the vehicle. These parts typically meet strict quality standards and are often preferred for replacements. B2B buyers should consider OEM options for reliability, although they may come at a higher cost compared to aftermarket alternatives.

2. MOQ (cantidad mínima de pedido)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and avoid overstocking. This term often affects pricing; larger orders may lead to discounts, making it crucial for budget-conscious buyers.

3. RFQ (Solicitud de presupuesto)

An RFQ is a formal request sent to suppliers to obtain price quotes for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process, ensuring that they receive competitive pricing and detailed information about the products they are interested in.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers during the shipping process. Understanding these terms helps B2B buyers clarify costs, risks, and responsibilities associated with the transportation of automotive starters. This knowledge is vital for managing logistics and avoiding disputes.

5. Periodo de garantía

The warranty period refers to the time frame during which the manufacturer guarantees the performance of the starter. A longer warranty often indicates higher confidence in the product’s quality. B2B buyers should evaluate warranty options as they can significantly impact long-term operational costs and customer trust.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing automotive starters, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the how much is a new starter Sector

What Are the Current Market Dynamics for New Starters?

The automotive starter market is influenced by several global drivers, including the rise in vehicle production, increasing consumer demand for electric vehicles (EVs), and advancements in automotive technology. In regions such as Africa, South America, the Middle East, and Europe, buyers are navigating a complex landscape characterized by varying economic conditions and regulatory frameworks. For instance, the push for greener technologies has led to a surge in demand for EV starters, which are typically more complex and costly than traditional starters.

Emerging trends in B2B sourcing are also shaping the market. Digital platforms for procurement are becoming increasingly popular, enabling buyers to compare prices and specifications more efficiently. Additionally, just-in-time (JIT) inventory systems are being adopted to minimize costs and enhance supply chain efficiency. This is particularly relevant in regions like Brazil and Nigeria, where logistics and supply chain challenges can significantly impact the availability and pricing of automotive components. Buyers are encouraged to leverage these technologies to optimize their sourcing strategies and reduce costs.

Furthermore, understanding local regulations concerning automotive components is vital. Compliance with safety and environmental standards can influence sourcing decisions and costs. International buyers must stay informed about these regulations to ensure that they source compliant products, thereby avoiding potential penalties and delays in operations.

How Can Sustainability and Ethical Sourcing Impact New Starter Purchases?

Sustainability is becoming a cornerstone of B2B procurement strategies, particularly in the automotive sector. The environmental impact of starter production, including resource extraction and waste generation, is prompting buyers to consider ethical sourcing practices. This includes the use of recycled materials and components that adhere to ‘green’ certifications, which can enhance brand reputation and customer loyalty.

Illustrative image related to how much is a new starter

Ethical supply chains are increasingly important, as consumers and businesses alike are prioritizing sustainability. For international B2B buyers, this means seeking suppliers who demonstrate transparency in their sourcing practices and who are committed to reducing their carbon footprint. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are indicators of a supplier’s commitment to sustainability and can be significant factors in the decision-making process.

Moreover, the shift towards electric vehicles is prompting manufacturers to rethink their sourcing strategies. Buyers must consider suppliers who are investing in sustainable technologies and practices, which can lead to long-term cost savings and improved market competitiveness. By prioritizing sustainability, companies can mitigate risks associated with regulatory compliance and enhance their appeal in an increasingly eco-conscious market.

What Is the Historical Context of New Starters in the Automotive Industry?

The evolution of automotive starters traces back to the early 20th century when manual cranking was the norm. The introduction of the electric starter in 1912 revolutionized vehicle operation, making it safer and more convenient. Over the decades, advancements in starter technology have led to the development of more efficient and reliable starters, catering to the growing demands of modern vehicles.

In recent years, the focus has shifted towards enhancing starter performance in electric and hybrid vehicles, reflecting broader trends in the automotive industry. This historical context underscores the importance of understanding how technological advancements can influence current sourcing decisions, particularly for international B2B buyers looking to stay competitive in a rapidly evolving market. As the industry continues to innovate, staying informed about these changes will be crucial for making strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of how much is a new starter

-

¿Cómo puedo determinar el coste de un nuevo motor de arranque para mi vehículo?

The cost of a new starter can vary significantly based on factors such as the make, model, and year of the vehicle. Generally, prices range from $80 to over $350 for the starter itself. Additionally, labor costs for installation can range from $150 to over $1,100, depending on the complexity of the job. To get an accurate estimate, consult with local suppliers or mechanics and consider using online resources that provide price comparisons for parts specific to your vehicle. -

What factors should I consider when sourcing a new starter?

When sourcing a new starter, consider the quality and reputation of the supplier, the warranty offered, and the availability of parts for your specific vehicle model. Additionally, check if the supplier provides technical support and documentation for installation. Pricing, shipping costs, and lead times are also critical factors, especially when dealing with international suppliers. Ensure that the supplier can meet your specific requirements, including any certifications needed for your market. -

How can I verify the reliability of a starter supplier?

To verify a supplier’s reliability, check their reputation through reviews and testimonials from previous clients. Look for certifications or memberships in industry associations, as these can indicate a commitment to quality standards. Additionally, request references and conduct background checks on the supplier’s history in the market. Engaging in direct communication to assess their responsiveness and customer service can also provide insights into their reliability. -

What is the minimum order quantity (MOQ) for starters from suppliers?

The minimum order quantity for starters can vary significantly by supplier and region. Many suppliers may have an MOQ ranging from 10 to 100 units, depending on the type of starter and its market demand. It’s essential to discuss your purchasing needs with potential suppliers to negotiate favorable terms. Some suppliers may offer flexibility on MOQ for first-time buyers or bulk orders, so it’s worth exploring these options. -

What payment terms are typically offered for international orders of starters?

Payment terms for international orders can vary, but common practices include upfront payment, partial payment upon order confirmation, and the balance upon shipment. Some suppliers may offer credit terms based on established relationships or purchase history. It’s important to clarify the terms before finalizing the order to avoid misunderstandings. Consider using secure payment methods that provide buyer protection, especially when dealing with new suppliers. -

How can I ensure quality assurance for the starters I purchase?

To ensure quality assurance, request certifications and compliance documents from the supplier that confirm the starters meet industry standards. Consider conducting a pre-shipment inspection or quality audit through third-party services to verify the products before they are shipped. Establishing a clear return policy and warranty terms with the supplier can also protect your investment in case the starters do not meet your quality expectations. -

¿Qué aspectos logísticos debo tener en cuenta al importar iniciadores?

When importing starters, consider shipping options, customs regulations, and import duties that may apply in your country. It’s crucial to work with logistics partners experienced in automotive parts to ensure timely delivery and compliance with regulations. Evaluate the total landed cost, including shipping, insurance, and taxes, to assess the overall expense. Additionally, having a clear understanding of lead times and tracking options can help manage your supply chain effectively. -

Are there options for customizing starters for specific applications?

Yes, many suppliers offer customization options for starters to meet specific application needs. This can include variations in size, performance specifications, or electrical configurations. Discuss your requirements with potential suppliers to explore available customization options and any associated costs. Customization may also affect lead times, so it’s important to factor this into your purchasing timeline.

Top 2 How Much Is A New Starter Manufacturers & Suppliers List

1. Car Talk – Starter Replacement Guide

Dominio: cartalk.com

Registrado: 1995 (30 años)

Introducción: Cost to replace a starter: $600 to $900 for common vehicles; $900 to $1,400 for luxury models. Symptoms of a bad starter include a click sound when starting, screeching noise, and intermittent functionality. Repairing a starter is often not cost-effective; replacement is preferred. New starters are rare; remanufactured starters are commonly used with warranties. Modern vehicles with stop-start sys…

2. CarParts.com – Car Starters

Dominio: recambios.es

Registrado: 1999 (26 años)

Introducción: Car Starters – Standard, Reverse Rotation from $75 | CarParts.com. High-quality replacement starters, new and remanufactured options available. Guaranteed to fit. Fast shipping and hassle-free returns. Ideal for replacing a bad starter that may cause engine issues.

Strategic Sourcing Conclusion and Outlook for how much is a new starter

In summary, understanding the costs associated with replacing a starter is crucial for international B2B buyers. Factors such as vehicle make, model, and accessibility can significantly affect the price, which ranges from $80 to over $1,100, depending on the complexity of the job and the parts required. By prioritizing strategic sourcing, businesses can not only secure competitive pricing but also ensure reliability and quality in their automotive components.

As you navigate the global marketplace, consider partnering with suppliers who offer transparent pricing and comprehensive support. This approach will not only streamline your procurement process but also enhance operational efficiency, ultimately leading to cost savings.

Looking ahead, the automotive industry is expected to evolve with advancements in technology, making it essential to stay informed about emerging trends and innovations. As an international buyer, seize the opportunity to leverage these developments to optimize your sourcing strategies. Engage with trusted suppliers and explore avenues for collaboration that can drive value and growth in your business.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Illustrative image related to how much is a new starter

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.