Introduction: Navigating the Global Market for alternator manufacturers

In the complex world of global commerce, sourcing reliable alternator manufacturers can pose significant challenges for B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. With the increasing demand for high-quality power solutions across various industries, navigating the myriad options available can be daunting. This guide is designed to empower international buyers by providing an in-depth analysis of the alternator manufacturing landscape, encompassing various types, applications, and essential supplier vetting criteria.

Throughout this comprehensive resource, we will explore the different categories of alternators, from light-duty to heavy-duty industrial models, and highlight the leading manufacturers known for their durability and performance. Additionally, we will address critical aspects such as cost considerations, warranty offerings, and sustainable manufacturing practices that are becoming increasingly important to today’s conscientious buyers. By arming yourself with this knowledge, you can make informed purchasing decisions that align with your operational needs and budget constraints.

This guide serves as a vital tool for B2B buyers seeking to enhance their procurement strategies, ensuring that they choose the right alternator suppliers who meet rigorous quality and reliability standards. With insights tailored to the unique challenges faced by diverse markets, you will be well-equipped to navigate the global alternator market with confidence.

Índice

- Top 7 Alternator Manufacturers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator manufacturers

- Understanding alternator manufacturers Types and Variations

- Key Industrial Applications of alternator manufacturers

- 3 Common User Pain Points for ‘alternator manufacturers’ & Their Solutions

- Strategic Material Selection Guide for alternator manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator manufacturers’

- Comprehensive Cost and Pricing Analysis for alternator manufacturers Sourcing

- Alternatives Analysis: Comparing alternator manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator manufacturers

- Navigating Market Dynamics and Sourcing Trends in the alternator manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator manufacturers

- Strategic Sourcing Conclusion and Outlook for alternator manufacturers

- Aviso legal importante y condiciones de uso

Understanding alternator manufacturers Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Alternadores industriales | High power output, robust construction, designed for heavy-duty use | Construction, mining, agriculture, manufacturing | Ventajas: Durable, high efficiency; Contras: Mayor inversión inicial. |

| Alternadores de gran potencia | Built for extreme conditions, often with advanced cooling systems | Commercial vehicles, trucks, buses | Ventajas: Reliable performance; Contras: May require specialized maintenance. |

| Light-Duty Alternators | Compact design, optimized for energy efficiency, quick installation | Vehículos de pasajeros, camiones ligeros | Ventajas: Cost-effective, easy to install; Contras: Limited power output for heavy applications. |

| Alternadores reacondicionados | Recycled components, environmentally friendly, cost-effective | Various applications, suitable for budget-conscious buyers | Ventajas: Eco-friendly, lower cost; Contras: Variabilidad potencial de la calidad. |

| Sustainable Alternators | Manufactured with a focus on reducing carbon footprint, often using recycled materials | Green initiatives, eco-conscious businesses | Ventajas: Environmentally responsible; Contras: May have higher price points. |

What Are the Key Characteristics of Industrial Alternators?

Industrial alternators are characterized by their ability to deliver high power outputs, often exceeding 440 KW, making them ideal for demanding applications such as construction, mining, and large-scale manufacturing. Their robust construction ensures longevity and reliability under extreme conditions. When purchasing, B2B buyers should consider the specific power requirements of their machinery and the operational environment, as these factors significantly influence performance and durability.

How Do Heavy-Duty Alternators Stand Out in Performance?

Heavy-duty alternators are engineered to withstand rigorous operating conditions, making them perfect for commercial vehicles like trucks and buses. They typically feature advanced cooling systems and high-quality materials that enhance reliability and efficiency. B2B buyers should evaluate the alternator’s compatibility with their fleet and consider factors such as warranty and service support to ensure optimal performance and reduced downtime.

Why Choose Light-Duty Alternators for Passenger Vehicles?

Light-duty alternators are designed for smaller vehicles, focusing on energy efficiency and ease of installation. They are compact and cost-effective, making them a popular choice among automotive manufacturers and repair shops. Buyers should assess the alternator’s compatibility with specific vehicle models and consider the balance between cost and performance, especially for high-demand applications.

What Are the Benefits of Opting for Remanufactured Alternators?

Remanufactured alternators offer a sustainable and cost-effective alternative to new units. These products are created from recycled components, ensuring they meet or exceed original equipment (OE) specifications. While they provide significant savings, buyers should ensure the remanufactured alternators come with quality assurances and warranties to mitigate risks associated with variability in quality.

How Do Sustainable Alternators Contribute to Environmental Goals?

Sustainable alternators are manufactured with a focus on minimizing environmental impact, often utilizing recycled materials and eco-friendly processes. They appeal to businesses aiming for green initiatives and corporate social responsibility goals. However, buyers should be prepared for potentially higher price points and assess the long-term benefits of sustainability against immediate costs.

Key Industrial Applications of alternator manufacturers

| Industria/Sector | Specific Application of alternator manufacturers | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Construcción | Powering heavy machinery such as excavators and cranes | Ensures continuous operation and reduces downtime in projects | Look for rugged alternators with high power output and durability |

| Agricultura | Supporting equipment like tractors and irrigation systems | Enhances productivity and operational efficiency in farming | Seek alternators with adaptability to varying voltage requirements |

| Minería | Operating mining vehicles and equipment | Provides reliable power in harsh environments | Consider suppliers with proven performance in extreme conditions |

| Transporte | Powering heavy-duty trucks and commercial vehicles | Improves reliability and reduces maintenance costs | Evaluate options for remanufactured units for cost-effectiveness |

| Energía renovable | Integrating with wind and solar power systems | Supports sustainable energy solutions and grid stability | Focus on manufacturers offering sustainable and efficient designs |

How Are Alternator Manufacturers Utilized in Construction?

In the construction industry, alternators are critical for powering heavy machinery such as excavators, cranes, and generators. These machines require a consistent power supply to operate effectively, minimizing downtime and maximizing productivity on job sites. B2B buyers in this sector should prioritize rugged alternators that can withstand harsh conditions and provide high power output. Reliability and durability are essential, as any failure can result in costly project delays.

What Role Do Alternator Manufacturers Play in Agriculture?

In agriculture, alternators are vital for supporting equipment like tractors, irrigation systems, and harvesters. They ensure that these machines operate efficiently, which directly influences productivity and yield. International buyers, especially from regions with diverse agricultural practices, should look for alternators that can adapt to varying voltage requirements and environmental conditions. The ability to provide stable power in remote locations can significantly enhance operational efficiency.

How Do Alternator Manufacturers Support Mining Operations?

Mining operations depend heavily on alternators to power vehicles and machinery in often extreme environments. These alternators must deliver reliable performance under high stress and harsh conditions, ensuring that equipment remains operational. Buyers from the mining sector need to consider suppliers with a track record of performance in challenging environments. Emphasizing durability and high output capacity is crucial for maintaining productivity in this sector.

Why Are Alternator Manufacturers Important for Transportation?

In the transportation sector, particularly for heavy-duty trucks and commercial vehicles, alternators play a crucial role in powering electrical systems and ensuring reliable vehicle performance. A dependable alternator reduces maintenance costs and enhances the overall reliability of the fleet. B2B buyers should evaluate options that include remanufactured units, which can offer significant cost savings while still meeting original equipment specifications. The focus should be on quality and performance to minimize downtime.

How Are Alternator Manufacturers Integrated into Renewable Energy Solutions?

In the renewable energy sector, alternators are integrated into wind and solar power systems to convert mechanical energy into electrical power. This application supports sustainable energy solutions and helps maintain grid stability. Buyers in this market should seek manufacturers that provide efficient and sustainable designs, as the demand for green technology continues to rise. Ensuring compatibility with existing systems and understanding the specific power requirements are key considerations for successful integration.

3 Common User Pain Points for ‘alternator manufacturers’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality and Reliability of Alternators

El problema: B2B buyers often struggle with ensuring that the alternators they source meet high-quality standards and can reliably perform under demanding conditions. This is particularly crucial for industries like construction and agriculture, where equipment downtime can lead to significant financial losses. Buyers may encounter issues with poorly manufactured alternators that fail prematurely, leading to costly repairs and replacements.

La solución: To mitigate this risk, buyers should prioritize sourcing alternators from reputable manufacturers known for their commitment to quality and reliability. Conduct thorough research on manufacturers by reviewing their certifications, industry reputation, and customer feedback. Consider opting for brands that have a proven track record in the specific industry, such as Leroy Somer or DENSO, which are recognized for their durable and high-performing products. Additionally, establishing a clear communication channel with suppliers can help clarify warranty terms and product specifications, ensuring that the alternators will perform as expected in challenging environments.

Scenario 2: Challenges with Compatibility and Specifications

El problema: Another common issue faced by B2B buyers is the compatibility of alternators with existing equipment. Many buyers find themselves purchasing alternators that do not fit the specifications of their machinery, leading to installation challenges and operational inefficiencies. This is particularly prevalent in industries with diverse machinery and vehicle types, where specifications can vary widely.

La solución: To avoid compatibility issues, buyers should conduct a comprehensive analysis of their equipment’s specifications before making a purchase. This includes checking voltage requirements, power ratings, and physical dimensions. Engaging with manufacturers or distributors who offer expert consultation can also be beneficial. They can provide insights into the best alternator options for specific equipment needs. Utilizing detailed catalogs and technical datasheets provided by manufacturers can further assist in making informed decisions. Additionally, consider investing in alternators that come with adjustable features to enhance compatibility across different machinery.

Scenario 3: Sustainability Concerns in Alternator Manufacturing

El problema: As sustainability becomes a more pressing concern, many B2B buyers are increasingly aware of the environmental impact of their purchasing decisions. However, they may find it challenging to identify manufacturers that prioritize sustainable practices in their production processes. This can lead to frustration among buyers who wish to align their procurement strategies with their corporate social responsibility goals.

La solución: To address sustainability concerns, buyers should actively seek out manufacturers that demonstrate a commitment to sustainable practices. This includes those who offer sustainably manufactured alternators, which can provide the same or better quality compared to traditional options while reducing environmental impact. Companies like TERREPOWER highlight their sustainable manufacturing processes, which extend the life of components while minimizing waste. Buyers should inquire about the materials used, recycling programs, and the overall carbon footprint of the products. Participating in industry forums and sustainability initiatives can also provide insights into the best practices and manufacturers leading the way in sustainable alternator production. By prioritizing these manufacturers, buyers can contribute to a more sustainable future while meeting their operational needs.

Strategic Material Selection Guide for alternator manufacturers

¿Cuáles son los principales materiales utilizados en la fabricación de alternadores?

When selecting materials for alternator manufacturing, manufacturers must consider various factors, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in alternator production: aluminum, copper, steel, and composite materials. Each material has distinct properties that can significantly impact the performance and suitability of alternators for different applications.

How Does Aluminum Benefit Alternator Manufacturers?

Aluminum is a popular choice for alternator housings and components due to its lightweight nature and excellent corrosion resistance. Key properties include a temperature rating of up to 150°C and a low density, which contributes to reduced overall weight.

Ventajas: Aluminum’s lightweight characteristic enhances fuel efficiency in automotive applications, while its corrosion resistance ensures longevity, especially in humid or coastal environments. Additionally, aluminum can be easily machined and formed, simplifying manufacturing processes.

Contras: The primary limitation of aluminum is its lower tensile strength compared to other metals, which may affect performance under high-stress conditions. It can also be more expensive than steel, depending on the market.

Impacto en la aplicación: Aluminum is particularly suitable for light-duty and automotive alternators where weight reduction is crucial. However, it may not be the best choice for heavy-duty applications requiring high strength.

Consideraciones para compradores internacionales: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN and ASTM, which may dictate specific aluminum grades for durability and performance.

Why Is Copper Essential for Alternator Performance?

Copper is widely used in alternator windings due to its excellent electrical conductivity, which is critical for efficient power generation. It can handle high temperatures, with a melting point of approximately 1,085°C, making it suitable for high-performance applications.

Ventajas: The high conductivity of copper leads to lower energy losses and improved efficiency in alternators. Its durability also ensures reliable performance over time.

Contras: Copper can be more expensive than aluminum and is prone to corrosion if not properly insulated or coated. Additionally, its weight can be a disadvantage in applications where minimizing weight is a priority.

Impacto en la aplicación: Copper is ideal for heavy-duty and industrial alternators where performance and reliability are paramount. However, its cost may be a barrier for budget-sensitive projects.

Consideraciones para compradores internacionales: Compliance with international standards for electrical components is critical. Buyers should verify that copper wiring meets the necessary specifications to ensure safety and performance.

¿Cómo contribuye el acero a la durabilidad del alternador?

Steel is commonly used in alternator frames and structural components due to its high tensile strength and durability. It can withstand harsh environmental conditions and mechanical stress, making it suitable for heavy-duty applications.

Ventajas: Steel’s strength provides excellent protection for internal components, and its cost-effectiveness makes it a popular choice among manufacturers. It also has good machining properties, allowing for precise manufacturing.

Contras: Steel is heavier than aluminum and can be susceptible to corrosion if not adequately treated or coated. This can lead to increased maintenance requirements over time.

Impacto en la aplicación: Steel is best suited for industrial and heavy-duty alternators where strength and durability are critical. However, its weight may be a disadvantage in applications where weight savings are essential.

Consideraciones para compradores internacionales: Buyers in Africa and South America should be aware of local standards for steel quality and corrosion resistance, which can vary significantly across regions.

What Role Do Composite Materials Play in Alternator Manufacturing?

Composite materials, including plastics and reinforced polymers, are increasingly being used in alternator manufacturing for non-structural components. They offer unique properties such as lightweight, corrosion resistance, and design flexibility.

Ventajas: Composites can significantly reduce weight and provide excellent resistance to environmental factors. They also allow for innovative designs that can improve airflow and cooling within the alternator.

Contras: The primary limitation of composites is their lower mechanical strength compared to metals, which may restrict their use in high-stress applications. Additionally, they can be more expensive to produce.

Impacto en la aplicación: Composites are particularly useful in automotive and light-duty applications where weight reduction is a priority, but their use in heavy-duty applications may be limited.

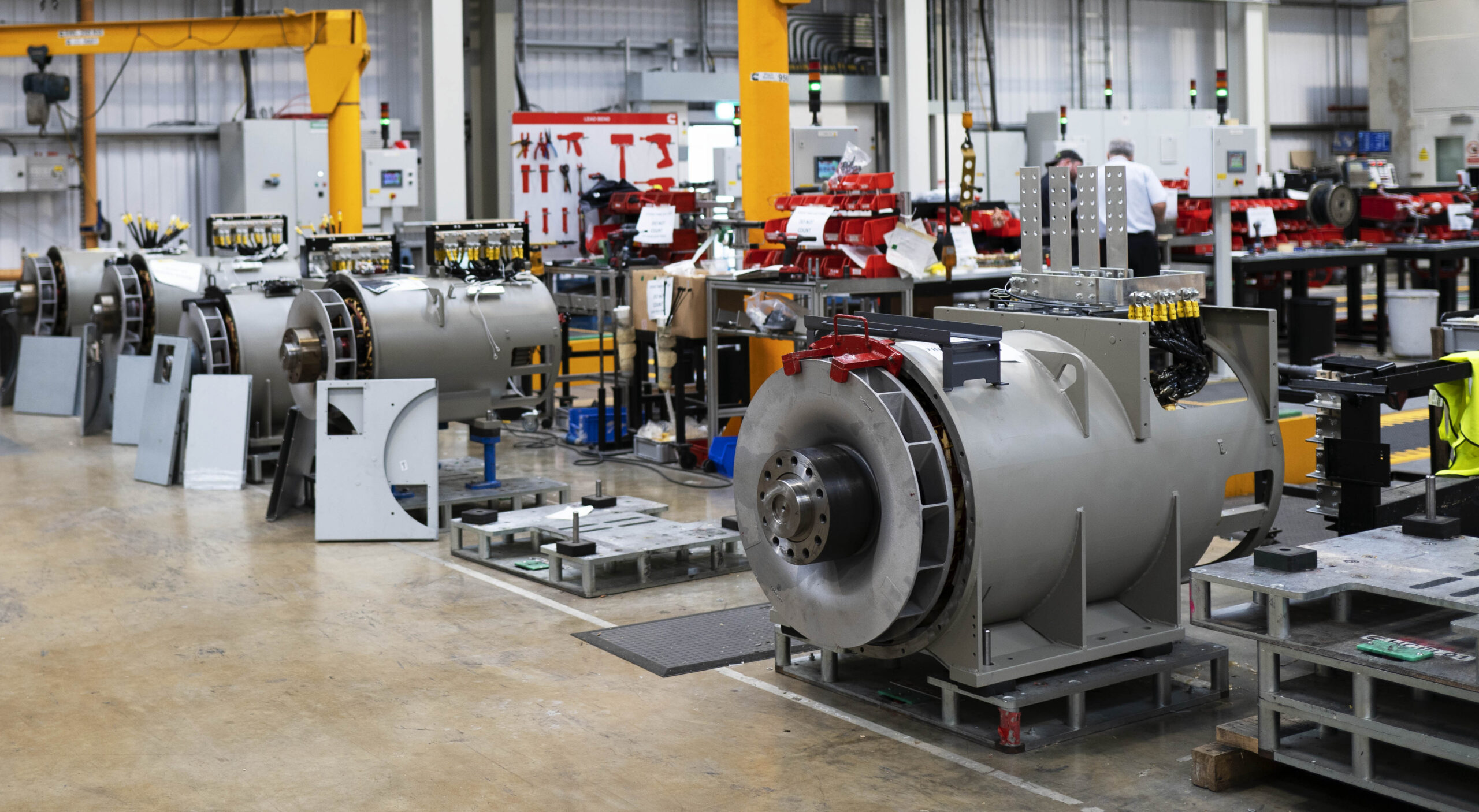

Illustrative image related to alternator manufacturers

Consideraciones para compradores internacionales: Buyers should ensure that composite materials meet relevant standards for mechanical performance and environmental resistance, especially in regions with extreme weather conditions.

Summary of Material Properties for Alternator Manufacturing

| Material | Typical Use Case for alternator manufacturers | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Aluminio | Light-duty automotive alternators | Ligero y resistente a la corrosión. | Menor resistencia a la tracción | Medio |

| Cobre | Heavy-duty and industrial alternators | Excelente conductividad eléctrica | Mayor coste y peso | Alto |

| Acero | Industrial and heavy-duty alternators | Alta resistencia y durabilidad | Más pesado y susceptible a la corrosión | Bajo |

| Compuesto | Non-structural components in automotive | Ligereza y flexibilidad de diseño | Menor resistencia mecánica | Medio |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions about the materials used in alternator manufacturing, ensuring compliance with standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator manufacturers

What Are the Key Stages in the Manufacturing Process for Alternator Manufacturers?

The manufacturing process for alternators is a multi-step procedure that ensures high-quality and reliable products. It typically involves several main stages: material preparation, forming, assembly, and finishing.

-

Preparación del material: The first stage involves sourcing high-grade materials such as copper, aluminum, and steel. These materials are crucial for ensuring durability and performance. Manufacturers often use advanced technologies to test material properties, ensuring they meet industry standards before moving forward.

-

Formación: This stage includes processes like stamping, winding, and machining. Stamping is used to create the casing and other components, while winding involves coiling copper wire to create the stator and rotor. Precision is essential here, as the efficiency of the alternator hinges on the accuracy of these components.

-

Ensamblaje: During assembly, the formed parts are brought together. This includes inserting the rotor into the stator, attaching the voltage regulator, and integrating other components like bearings and cooling fans. Automated assembly lines are often employed for speed and consistency, but skilled technicians also perform critical tasks to ensure quality.

-

Acabado: The final stage involves painting, coating, and sometimes remanufacturing units. This not only enhances appearance but also protects against environmental factors such as moisture and corrosion. Quality control checks are implemented throughout this stage to catch any defects.

¿Qué medidas de control de calidad son esenciales para la fabricación de alternadores?

Quality control (QC) is a critical aspect of alternator manufacturing, ensuring that products meet both international and industry-specific standards. Key QC measures include:

Illustrative image related to alternator manufacturers

-

Normas internacionales: Adhering to standards such as ISO 9001 is vital for demonstrating a commitment to quality management systems. ISO 9001 certification indicates that the manufacturer meets international quality benchmarks, which can be particularly important for B2B buyers seeking reliable partners.

-

Normas específicas del sector: Certifications like CE (European Conformity) and API (American Petroleum Institute) are also significant. CE certification ensures products meet EU safety and health requirements, while API standards are crucial for products used in the oil and gas industries.

-

Puntos de control de calidad: Quality control checkpoints are established at various stages of the manufacturing process:

– Control de calidad de entrada (IQC): This is the first checkpoint, where raw materials are inspected upon arrival to ensure they meet specified standards.

– Control de calidad durante el proceso (IPQC): Conducted during the manufacturing process, IPQC involves continuous monitoring of production to identify and rectify defects in real-time.

– Control de calidad final (FQC): The final inspection stage where completed alternators undergo rigorous testing to ensure they meet all functional and performance specifications.

How Do Alternator Manufacturers Conduct Testing to Ensure Quality?

Testing is an integral part of the quality assurance process for alternators. Common testing methods include:

-

Pruebas eléctricas: This involves checking the alternator’s voltage output, current capacity, and overall electrical performance. Tests are conducted under various load conditions to simulate real-world usage.

-

Pruebas mecánicas: Mechanical integrity tests assess the structural strength of components, including stress tests and vibration tests. These ensure that the alternator can withstand operational stresses without failure.

-

Pruebas medioambientales: Alternators are subjected to extreme conditions, such as high and low temperatures, humidity, and exposure to corrosive elements. This testing helps predict how products will perform in diverse environments, particularly important for international markets.

-

Pruebas de durabilidad: Manufacturers often conduct lifecycle testing to determine the longevity of their products. This involves simulating years of use in a compressed timeframe to identify potential points of failure.

¿Cómo pueden los compradores B2B verificar las prácticas de control de calidad de los proveedores?

B2B buyers, especially those in Africa, South America, the Middle East, and Europe, must have robust strategies to verify the quality control practices of alternator manufacturers. Key approaches include:

-

Auditorías de proveedores: Conducting audits allows buyers to review the manufacturer’s facilities, processes, and quality control measures firsthand. This is particularly effective in identifying compliance with international standards and industry-specific certifications.

-

Informes de calidad: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including historical data on product performance and defect rates. This information is crucial for understanding the reliability of the supplier.

-

Inspecciones por terceros: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing practices. These agencies can perform inspections at various stages, ensuring compliance with standards and specifications.

-

Certificaciones y documentos de conformidad: Buyers should always request copies of certifications, such as ISO 9001 or CE compliance. Validating these documents ensures that the manufacturer adheres to recognized quality standards.

¿Cuáles son los matices del control de calidad para los compradores internacionales?

International B2B buyers must navigate specific nuances in quality control when sourcing alternators from manufacturers across different regions. Key considerations include:

-

Diferencias culturales: Understanding cultural attitudes towards quality and compliance is crucial. Some regions may prioritize cost over quality, leading to potential risks for buyers.

-

Cumplimiento normativo: Different countries have varying regulations regarding product standards. Buyers must ensure that the alternators they purchase comply with local laws and regulations, which can vary significantly between regions like Europe and Africa.

-

Communication Barriers: Effective communication is essential for verifying quality control practices. Language barriers can complicate discussions about quality standards and expectations, making it imperative for buyers to work with suppliers that have a strong understanding of their needs.

-

Consideraciones sobre logística y cadena de suministro: Quality control does not end with manufacturing; logistics play a significant role in maintaining product integrity. Buyers should inquire about the supplier’s logistics practices, including packaging, shipping conditions, and handling procedures to minimize damage during transit.

In conclusion, understanding the manufacturing processes and quality assurance practices of alternator manufacturers is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they partner with manufacturers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator manufacturers’

Introducción

Sourcing high-quality alternators is essential for businesses looking to ensure reliability and efficiency in their power systems. This step-by-step checklist is designed to guide B2B buyers through the procurement process, helping them identify reputable alternator manufacturers that meet their specific needs. By following these steps, you can make informed decisions that enhance your operational capabilities.

Paso 1: Defina sus especificaciones técnicas

Understanding your technical requirements is the foundation of successful sourcing. Clearly outline the power ratings, sizes, and compatibility of alternators with your existing systems. This will help you narrow down manufacturers that specialize in the specific types of alternators you need, whether for light-duty, heavy-duty, or industrial applications.

Paso 2: Research and Identify Reputable Manufacturers

Conduct thorough research to identify established manufacturers known for their quality and reliability. Look for brands with positive reviews and long-standing industry presence, such as Leroy Somer, John Deere, Marelli, and Stamford. This step is critical as it sets the stage for ensuring that the alternators you purchase will meet high performance and durability standards.

Paso 3: Evaluar las certificaciones de los proveedores

Before proceeding, verify that potential suppliers hold relevant certifications and comply with international quality standards. Certifications like ISO 9001 or CE mark indicate a commitment to quality and safety. This ensures that the products you source are not only compliant but also manufactured under stringent quality control processes.

Paso 4: Assess Product Range and Customization Options

Examine the range of alternators offered by each manufacturer. A diverse product portfolio indicates the manufacturer’s capability to meet various application needs. Additionally, inquire about customization options, as some projects may require specific configurations or features tailored to your operational requirements.

Paso 5: Solicitar muestras y documentación técnica

Before finalizing your order, request samples and technical documentation from shortlisted manufacturers. Testing samples in your operational environment will allow you to evaluate performance firsthand. Technical documentation should include installation guides, warranty information, and maintenance requirements, ensuring you are fully informed about the product’s lifecycle.

Paso 6: Review Warranty and Support Services

A strong warranty and customer support framework are essential for long-term satisfaction. Inquire about warranty terms, including duration and coverage, as well as the availability of technical support and after-sales services. This will help you gauge the manufacturer’s commitment to customer satisfaction and product reliability.

Paso 7: Negocie las condiciones y haga su pedido

Once you are satisfied with your evaluation, negotiate terms that align with your budget and timelines. Ensure clarity on pricing, delivery schedules, and payment terms to avoid any misunderstandings. A well-structured agreement sets the stage for a smooth transaction and establishes a positive working relationship with your selected manufacturer.

By following these steps, B2B buyers can confidently navigate the complexities of sourcing alternators, ensuring they partner with manufacturers that align with their quality standards and operational needs.

Comprehensive Cost and Pricing Analysis for alternator manufacturers Sourcing

Understanding the intricate cost structure and pricing dynamics of alternator manufacturing is essential for B2B buyers looking to optimize their procurement strategies. This analysis provides insight into the various components that contribute to the overall pricing of alternators, while also highlighting critical factors that influence these costs.

¿Cuáles son los principales componentes de coste en la fabricación de alternadores?

The cost structure of alternator manufacturing can be broken down into several key components:

-

Materiales: The raw materials used in alternator production, such as copper, steel, and specialized plastics, significantly impact the overall cost. Prices for these materials can fluctuate based on global market conditions, supply chain disruptions, and geopolitical factors.

-

Trabajo: Labor costs vary by region and can be influenced by local wage standards, skill levels, and the complexity of the manufacturing process. In regions with higher labor costs, manufacturers may leverage automation to maintain competitive pricing.

-

Gastos generales de fabricación: This includes costs associated with facility maintenance, utilities, and indirect labor. Efficient manufacturing processes and lean production techniques can help minimize overhead expenses.

-

Herramientas: Custom tooling for specific alternator designs can represent a substantial upfront investment. Buyers should consider the amortization of these costs when evaluating price quotes.

-

Control de calidad (QC): Ensuring high-quality standards through rigorous testing and inspection processes incurs additional costs. Certifications such as ISO or CE can enhance product value but may also increase pricing.

-

Logística: Shipping costs, including freight and handling, can vary based on distance, mode of transport, and volume of the order. Efficient logistics management can significantly reduce these costs.

-

Margen: Manufacturers typically apply a margin to cover their operational risks and profit expectations. This margin can vary widely based on competition and brand positioning.

What Factors Influence Pricing in Alternator Sourcing?

Several factors can significantly influence the pricing of alternators, particularly for international buyers:

-

Volumen/Cantidad mínima de pedido: Larger orders often qualify for bulk discounts, which can lead to substantial cost savings. Minimum order quantities (MOQs) set by manufacturers can impact pricing flexibility.

-

Especificaciones y personalización: Custom alternators designed to meet specific requirements (e.g., higher power output or unique dimensions) typically come with a higher price tag due to the additional engineering and tooling costs involved.

-

Calidad y certificaciones: Alternators that meet higher quality standards or have industry certifications tend to command premium prices. Buyers should weigh the benefits of such certifications against their budget constraints.

-

Factores relacionados con los proveedores: The reputation and reliability of the supplier can influence pricing. Established manufacturers with proven track records may charge more for their products but often provide better after-sales support and warranty options.

-

Incoterms: Understanding Incoterms is vital for international transactions. The chosen terms (e.g., FOB, CIF) will affect the total landed cost of the alternators, impacting overall pricing strategies.

¿Qué consejos de negociación pueden ayudar a los compradores internacionales?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation is key to achieving cost-efficient purchasing:

-

Aprovechar el coste total de propiedad (TCO): Rather than focusing solely on initial purchase prices, consider the TCO, which includes maintenance, operational efficiency, and potential downtime costs. This broader perspective can justify a higher upfront investment for superior quality products.

-

Realizar estudios de mercado: Understand the market landscape, including competitor pricing and product offerings. This information can empower buyers during negotiations and help secure better deals.

-

Establecer relaciones a largo plazo: Building strong relationships with suppliers can lead to more favorable pricing terms and enhanced service. Long-term partnerships often yield better deals and priority support.

-

Tenga en cuenta los matices de los precios: Pricing strategies can vary significantly across regions. Buyers should be cognizant of local economic conditions, currency fluctuations, and import tariffs that may affect overall costs.

Conclusión

In the competitive landscape of alternator sourcing, understanding the comprehensive cost structure and the various factors influencing pricing is essential for B2B buyers. By leveraging this knowledge, buyers can make informed decisions that align with their operational needs and budgetary constraints. Always remember that prices may vary widely and can be subject to negotiation, so it’s essential to approach the procurement process with a strategic mindset.

Alternatives Analysis: Comparing alternator manufacturers With Other Solutions

Exploring Alternatives to Alternator Manufacturers in Power Generation Solutions

In the quest for reliable power generation, businesses often consider various solutions, including traditional alternators from reputable manufacturers. However, understanding alternatives can help B2B buyers make informed decisions that align with their operational needs and budget constraints. This analysis compares traditional alternator manufacturers with two viable alternatives: Battery Energy Storage Systems (BESS) y Sistemas de energía solar.

| Aspecto comparativo | Alternator Manufacturers | Battery Energy Storage Systems (BESS) | Sistemas de energía solar |

|---|---|---|---|

| Rendimiento | High reliability, designed for various loads | Variable; depends on battery technology and size | Effective for daytime use; energy production varies with sunlight |

| Coste | High initial investment; long-term durability | Moderate to high upfront costs; lowers energy bills over time | High initial investment; potential for long-term savings and incentives |

| Facilidad de implementación | Requiere instalación e integración profesionales | Moderate; may require integration with existing systems | Installation can be complex; permits often needed |

| Mantenimiento | Regular checks required; generally low maintenance | Moderate; batteries may need replacement every 5-10 years | Low maintenance; occasional cleaning required |

| Mejor caso de uso | Heavy-duty applications in industrial settings | Ideal for renewable energy integration, peak shaving | Best for off-grid applications or reducing reliance on the grid |

What Are the Advantages and Disadvantages of Battery Energy Storage Systems (BESS)?

Battery Energy Storage Systems (BESS) offer a modern alternative to traditional alternators, particularly in integrating renewable energy sources. The primary advantage of BESS is its ability to store excess energy generated from renewable sources, allowing businesses to use this stored energy during peak demand or outages. This flexibility can lead to significant cost savings on energy bills over time.

However, the initial investment can be substantial, and the longevity of batteries often requires replacement every few years, which can lead to increased lifecycle costs. BESS also depend on the efficiency of the charging and discharging cycles, which can be affected by temperature and usage patterns.

¿Cómo se comparan los sistemas de energía solar con los alternadores tradicionales?

Solar Power Systems harness energy from the sun to generate electricity, making them an eco-friendly alternative to traditional alternators. The primary benefit of solar power is its potential for energy independence and long-term cost savings, as sunlight is free and abundant. Additionally, many governments offer incentives for solar installations, further reducing the financial burden.

The downsides include high upfront installation costs and the variability of energy production, which depends on weather and geographic location. Solar systems often require a backup solution, such as an alternator or BESS, to ensure power supply during cloudy days or at night.

How Should B2B Buyers Choose the Right Power Generation Solution?

When selecting between traditional alternator manufacturers and alternative solutions like BESS and solar power systems, B2B buyers should assess their specific operational requirements, budget constraints, and long-term goals. Evaluating factors such as energy consumption patterns, the importance of sustainability, and available incentives will guide decision-making. Ultimately, the right solution should align with both current needs and future growth, ensuring reliability and efficiency in power generation.

Essential Technical Properties and Trade Terminology for alternator manufacturers

What Are the Key Technical Properties of Alternators Important for Manufacturers?

When selecting alternators, understanding critical specifications is vital for ensuring compatibility and performance. Here are some essential technical properties that alternator manufacturers and buyers should consider:

-

Power Output Rating (KW)

The power output rating indicates the maximum electrical power the alternator can generate, typically measured in kilowatts (KW). This specification is crucial as it determines whether the alternator can adequately support the electrical load of the application, whether in industrial machinery, commercial vehicles, or residential generators. Higher power ratings typically correlate with increased production costs, making it essential for buyers to evaluate their specific needs. -

Regulación de voltaje

Voltage regulation refers to the alternator’s ability to maintain a consistent output voltage despite variations in load conditions. This property is critical for preventing damage to electrical components connected to the alternator, ensuring optimal performance and longevity. Buyers should seek alternators with advanced voltage regulation systems, such as automatic voltage regulators (AVR), to enhance reliability. -

Índice de eficiencia

The efficiency rating measures how effectively an alternator converts mechanical energy into electrical energy. Higher efficiency means less energy waste, which is especially important for industries aiming to reduce operational costs and environmental impact. Manufacturers that prioritize high-efficiency designs can offer significant long-term savings for end-users. -

Mecanismo de enfriamiento

The cooling mechanism is vital for managing the temperature of the alternator during operation. Overheating can lead to premature failure and decreased performance. Alternators may feature air-cooled or water-cooled systems, and understanding these options can help buyers select the right product for their operating environment. -

Grado del material

The material grade of components like windings, casings, and bearings significantly impacts durability and performance. High-quality materials, such as copper for windings or corrosion-resistant alloys for casings, can enhance the lifespan of the alternator. Buyers should inquire about the material specifications to ensure they are investing in a reliable product. -

Noise and Vibration Levels

Alternators can produce noise and vibrations during operation, which may affect surrounding equipment and work environments. Specifications related to noise and vibration levels help buyers assess whether an alternator is suitable for their application, particularly in sensitive environments like hospitals or laboratories.

What Are Common Trade Terms Used in the Alternator Manufacturing Industry?

Understanding industry jargon is equally essential for effective communication and decision-making in B2B transactions. Here are several common trade terms that alternator manufacturers and buyers should familiarize themselves with:

-

OEM (fabricante de equipos originales)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of alternators, OEM components are designed to meet the specifications and quality standards of the original manufacturer. Buyers often prefer OEM parts for reliability and compatibility. -

MOQ (cantidad mínima de pedido)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B transactions as it affects inventory management and cost efficiency. Understanding MOQ helps buyers plan their purchases and negotiate better terms. -

RFQ (Solicitud de presupuesto)

An RFQ is a formal request made by a buyer to suppliers to provide pricing and terms for specific products. It is an essential step in the procurement process, enabling buyers to compare offers and make informed decisions based on price and quality. -

Incoterms (Términos comerciales internacionales)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, helping to mitigate risks and misunderstandings. -

Plazo de entrega

Lead time refers to the time required from placing an order to receiving the product. In the alternator manufacturing industry, understanding lead times is vital for supply chain planning, especially for projects with tight deadlines. -

Vatios

Wattage is a measure of electrical power equivalent to one joule per second. In the context of alternators, it indicates the total electrical output. Understanding wattage is critical for buyers to ensure that the alternator meets the power demands of their equipment.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing alternators, ultimately leading to better investments and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the alternator manufacturers Sector

What Are the Key Market Dynamics and Trends Impacting Alternator Manufacturers?

The alternator manufacturing sector is currently experiencing significant shifts driven by global market dynamics. The increasing demand for reliable power sources, particularly in emerging markets like Africa, South America, and the Middle East, is a critical driver. These regions are witnessing rapid industrialization and urbanization, leading to heightened requirements for efficient energy solutions. In Europe, particularly in Germany and Vietnam, there is a growing emphasis on renewable energy integration, which influences alternator design and functionality. Furthermore, the rise of electric vehicles (EVs) is reshaping the landscape, prompting manufacturers to innovate and adapt their products to meet the unique demands of hybrid and fully electric systems.

Illustrative image related to alternator manufacturers

Emerging technologies such as smart manufacturing, IoT, and AI are also influencing sourcing trends. Manufacturers are increasingly leveraging data analytics to optimize production processes and enhance supply chain management. This trend is particularly beneficial for international B2B buyers looking for more efficient and cost-effective sourcing options. Additionally, the rise of e-commerce platforms is simplifying the purchasing process, enabling buyers from diverse geographical regions to access a broader range of products and manufacturers.

How Is Sustainability Shaping Sourcing Decisions in the Alternator Manufacturing Sector?

Sustainability is becoming a pivotal factor for B2B buyers in the alternator manufacturing sector. The environmental impact of production processes is under scrutiny, with a growing preference for manufacturers that prioritize eco-friendly practices. This shift is not just a trend but a response to global calls for more responsible manufacturing that conserves resources and minimizes waste.

Ethical sourcing practices are also gaining traction. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable materials and fair labor practices. Certifications such as ISO 14001 for environmental management and other green certifications are becoming vital in supplier evaluations. This focus on sustainability not only helps in reducing the carbon footprint but also enhances brand reputation among environmentally conscious consumers.

Moreover, the adoption of remanufactured alternators is on the rise, as these products often represent a more sustainable choice. Manufacturers like DENSO have embraced this model, providing high-quality remanufactured units that conserve resources while maintaining performance standards. This trend offers international buyers a compelling option that aligns with their sustainability goals while also addressing budget constraints.

What Is the Historical Context of the Alternator Manufacturing Industry?

The alternator manufacturing industry has evolved significantly since its inception in the early 20th century. Originally designed to convert mechanical energy into electrical energy for automobiles, alternators have undergone transformative advancements in technology and design. The introduction of digital controls and high-efficiency designs in the late 20th century marked a turning point, allowing for more compact and reliable units.

As global energy demands increased, particularly in the late 20th and early 21st centuries, alternators began to find applications beyond automotive uses, including industrial and renewable energy sectors. Today, with the rise of electric vehicles and a focus on sustainability, the industry continues to adapt, fostering innovations that prioritize energy efficiency and environmental responsibility. This rich history of adaptation and innovation positions alternator manufacturers to meet the diverse needs of international B2B buyers in a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator manufacturers

-

How do I choose the right alternator manufacturer for my business needs?

Selecting the right alternator manufacturer involves evaluating several factors such as product quality, reliability, and industry reputation. Look for manufacturers with certifications and compliance to international standards, such as ISO or CE marks. Additionally, consider their experience in your specific industry, as well as customer reviews and testimonials. It’s also wise to assess their product range to ensure they offer models that fit your specific power requirements and applications. -

What is the best alternator brand for industrial applications?

For industrial applications, brands like Leroy Somer, Stamford, and John Deere are highly regarded for their robust and efficient alternators. Leroy Somer is noted for its heavy-duty power supply capabilities, while Stamford offers certified products with high power outputs. John Deere is recognized for its exceptional durability in harsh conditions. Evaluate each brand’s specifications and performance history to determine which best suits your operational demands. -

What customization options should I consider when sourcing alternators?

Many manufacturers offer customization options to meet specific operational needs, such as voltage levels, power output, and mounting configurations. Inquire about available features like integrated cooling systems or compatibility with renewable energy sources. Customization can also include branding options for resale purposes. Be clear about your requirements and discuss them during your initial conversations with potential suppliers. -

What are the minimum order quantities (MOQs) for alternator manufacturers?

Minimum order quantities can vary significantly among manufacturers and depend on factors such as production capacity and product type. Typically, MOQs for industrial alternators range from 50 to 100 units, while some manufacturers may accommodate smaller orders for specific models. Always confirm MOQs with suppliers during negotiations, as this can impact your purchasing strategy and inventory management. -

What payment terms should I expect from alternator suppliers?

Payment terms can vary widely based on the manufacturer and your relationship with them. Common terms include upfront payments, 30% deposits with the balance upon delivery, or net 30/60 days post-invoice. Be sure to clarify these terms before finalizing any agreement to ensure they align with your cash flow capabilities. Establishing a good rapport with suppliers may also lead to more favorable terms in the long run. -

¿Cómo puedo garantizar la calidad de mis alternadores?

To ensure quality assurance, request certifications and test reports from potential suppliers. Reputable manufacturers should provide documentation demonstrating compliance with industry standards and performance metrics. Consider arranging for third-party inspections or audits of the manufacturing process. Establishing clear quality expectations and conducting regular reviews of supplier performance can also help maintain high standards. -

¿Qué consideraciones logísticas debo tener en cuenta al importar alternadores?

When importing alternators, consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Collaborate with logistics partners who have experience in handling industrial components to ensure timely and safe delivery. It’s also wise to factor in lead times, warehousing options, and the total landed cost, which includes shipping and import duties, to avoid unexpected expenses. -

What are the environmental considerations in selecting alternator manufacturers?

Many manufacturers are adopting sustainable practices, such as using recyclable materials and minimizing waste during production. When sourcing alternators, inquire about the manufacturer’s commitment to sustainability, including certifications related to environmental management systems. Choosing suppliers who prioritize eco-friendly practices not only supports corporate social responsibility but may also align with your customers’ values and market demands.

Top 7 Alternator Manufacturers Manufacturers & Suppliers List

1. GenPower USA – Alternators by Leading Manufacturers

Dominio: genpowerusa.com

Registrado: 2001 (24 años)

Introducción: Alternators by Manufacturer: LEROY SOMER, STAMFORD, CUMMINS, MARATHON, KOHLER, MAGNAPLUS, MARELLI, MECC ALTE, NEWAGE, SDMO. Alternators by Power Rating: 10 KW to 40 KW, 45 KW to 95 KW, 100 KW to 175 KW, 200 KW to 350 KW, 400 KW to 600 KW, 650 KW to 2000 KW, 10 KVA to 40 KVA, 45 KVA to 100 KVA, 110 KVA to 200 KVA, 250 KVA to 400 KVA, 440 KVA to 750 KVA, 800 KVA to 2500 KVA. Alternators by Frequency…

2. Delco Remy – Heavy Duty Starters and Alternators

Dominio: delcoremy.com

Registrado: 1998 (27 años)

Introducción: Delco Remy offers Heavy Duty Starters and Alternators designed for commercial trucks, buses, and off-highway applications. Key starter models include 28MT, 31MT, 37MT, 38MT, 39MT, 41MT, 42MT, 50MT, and 150MT, featuring electrical soft-start and overcrank protection. Key alternator models include 22SI, 23SI, 24SI, 28SI, 33SI, 34SI, 35SI, 36SI, 38SI, 40SI, and 55SI, with brushless designs for enhanc…

3. Terrepower – Alternators and Starters

Dominio: terrepower.com

Inscrito: 2021 (4 años)

Introducción: Alternators and starters are essential components in vehicles’ electrical and ignition systems, providing necessary power for smooth operation. Available for light-duty vehicles, heavy-duty commercial trucks, and industrial machinery, these products are engineered for reliable performance in all conditions. They are trusted by mechanics, distributors, and DIYers for quick installation, competitive…

4. Mechman – 48-Volt Elite Alternator

Dominio: mechman.com

Registrado: 1996 (29 años)

Introducción: Mechman Alternators are U.S.A made high output alternators with options for 1-year, 2-year, and lifetime extended warranties. They offer a range of alternators including 24 Volt and 48 Volt models, with outputs ranging from 150a to 370a. Key products include the 48-Volt Elite Alternator (LiFePO4 and AGM) for 2011 – 2024 Cummins 6.7L and Ford T-Mount Housing, priced at $1,799. Additionally, they pr…

5. Bosch – Starters and Alternators

Dominio: boschautoparts.com

Registrado: 2004 (21 años)

Introducción: Bosch offers a wide range of starters and alternators designed for various vehicle applications. Their products are engineered for reliability, performance, and durability, ensuring optimal engine performance. Bosch starters provide high torque and quick starts, while their alternators deliver consistent power output and efficient charging. Both product lines are rigorously tested to meet or excee…

6. Mecc Alte – Industrial Alternators

Dominio: meccalte.com

Introducción: Mecc Alte is the world’s largest independent producer of alternators, offering a range of products from 1 to 5,000 kVA. Their product lineup includes industrial alternators, NPE (Non-Permanent Magnet) models, space saver designs, MV/HV (Medium Voltage/High Voltage) products, portable 400 Hz alternators, and totally enclosed permanent magnets. They also provide Gen-Set controllers and battery charg…

7. J&N – Alternators

Dominio: jnelectric.com

Registrado: 1998 (27 años)

Introducción: Alternators: Various brands including American Power Systems, Arrowhead, Baldor Electric, Balmar, Bosch, C.E. Niehoff, Delco, Denso, Dixie Electric, Electrodyne, Goodall Manufacturing, HD Power Solutions, Hitachi, IMI Hi Torque, J&N, JANNCO, Leece Neville, Lucas Electric, Magneton, Mahle, Marelli, Mitsubishi, Nikko, Penntex, Powerlite, Prestolite, Remy Light Duty, Sawafuji, Tuff Stuff Performance,…

Strategic Sourcing Conclusion and Outlook for alternator manufacturers

As the global demand for reliable power solutions continues to rise, the strategic sourcing of alternators is more crucial than ever for businesses across various sectors. By prioritizing quality brands like Leroy Somer, John Deere, Marelli, and Stamford, international buyers can enhance the performance and longevity of their generators, ultimately leading to significant cost savings. Understanding the diverse offerings—from light-duty to heavy-duty and industrial applications—enables companies to select the right alternators tailored to their specific needs.

The importance of supplier relationships cannot be overstated; partnering with reputable manufacturers ensures access to high-quality products that meet rigorous standards. Furthermore, considering sustainable manufacturing options aligns with the growing emphasis on environmental responsibility, which is increasingly valued in global markets.

Looking ahead, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe should seize the opportunity to leverage strategic sourcing as a means to enhance operational efficiency and competitiveness. Engage with trusted suppliers today to secure the best alternator solutions that will power your business into the future.

Illustrative image related to alternator manufacturers

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.