Introduction: Navigating the Global Market for 3 types of starter motor

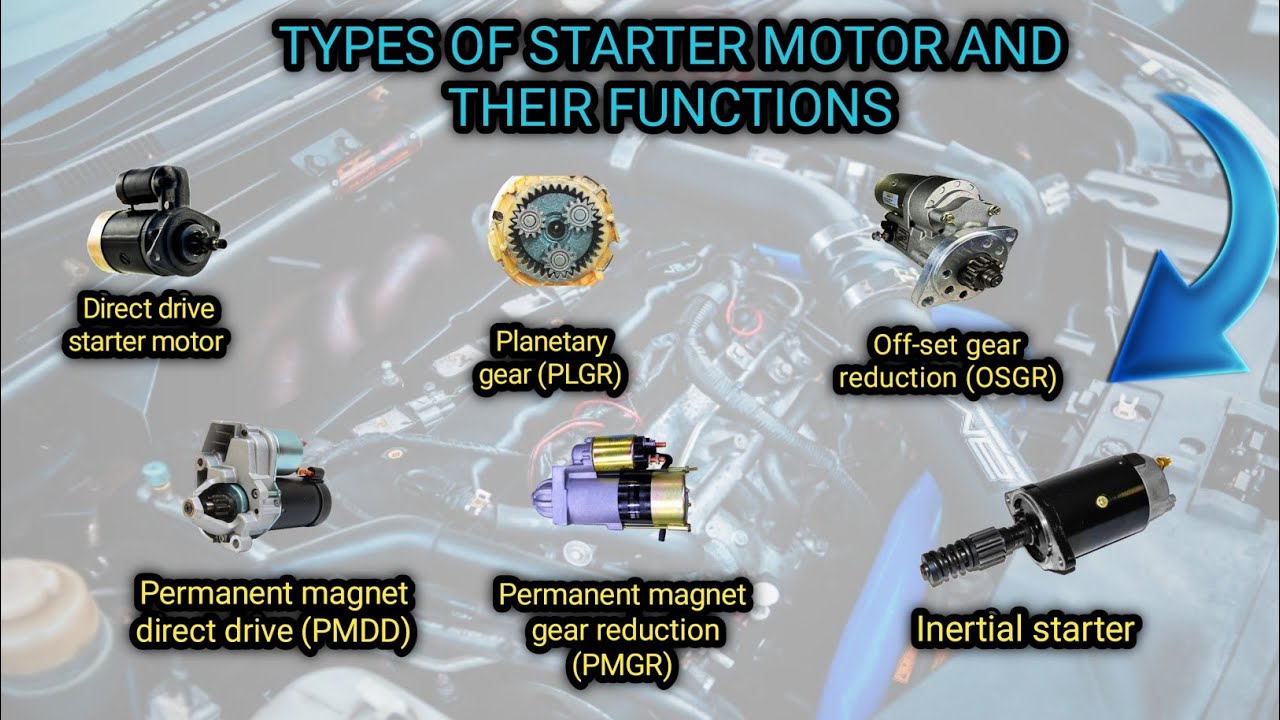

In today’s rapidly evolving industrial landscape, sourcing the right types of starter motors is crucial for ensuring the efficiency and longevity of electric motors. As global markets expand, B2B buyers face the challenge of navigating a diverse array of starter motor options, each with its unique specifications and applications. This comprehensive guide explores three primary types of starter motors—Direct-On-Line, Star-Delta, and Soft Starters—providing insights into their functionalities, advantages, and ideal use cases.

Understanding these starter motor types is essential for optimizing motor performance and ensuring operational safety, particularly for businesses in regions like Africa, South America, the Middle East, and Europe, including countries such as Vietnam and Germany. With a focus on practical applications, this guide also delves into critical considerations such as supplier vetting, cost analysis, and maintenance requirements. By equipping buyers with the necessary knowledge to make informed purchasing decisions, this resource empowers businesses to enhance their operational efficiency, reduce downtime, and ultimately drive profitability.

Whether you are looking to upgrade existing systems or invest in new technologies, this guide serves as a valuable tool in your journey towards sourcing the most suitable starter motors for your industrial needs.

Índice

- Top 2 3 Types Of Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 3 types of starter motor

- Understanding 3 types of starter motor Types and Variations

- Key Industrial Applications of 3 types of starter motor

- 3 Common User Pain Points for ‘3 types of starter motor’ & Their Solutions

- Strategic Material Selection Guide for 3 types of starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for 3 types of starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 types of starter motor’

- Comprehensive Cost and Pricing Analysis for 3 types of starter motor Sourcing

- Alternatives Analysis: Comparing 3 types of starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for 3 types of starter motor

- Navigating Market Dynamics and Sourcing Trends in the 3 types of starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 3 types of starter motor

- Strategic Sourcing Conclusion and Outlook for 3 types of starter motor

- Aviso legal importante y condiciones de uso

Understanding 3 types of starter motor Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

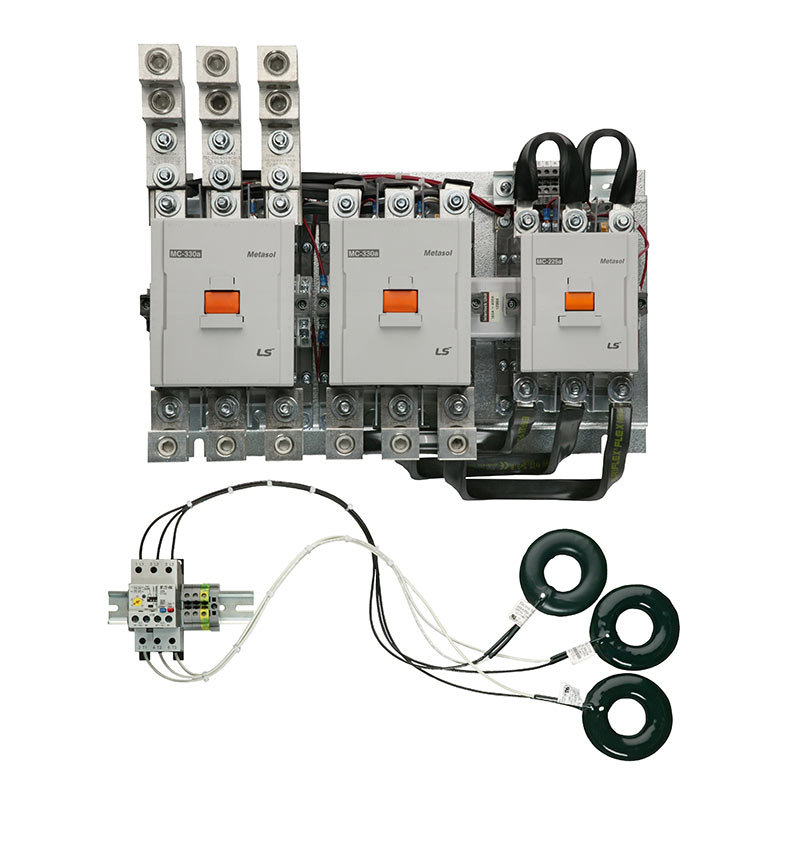

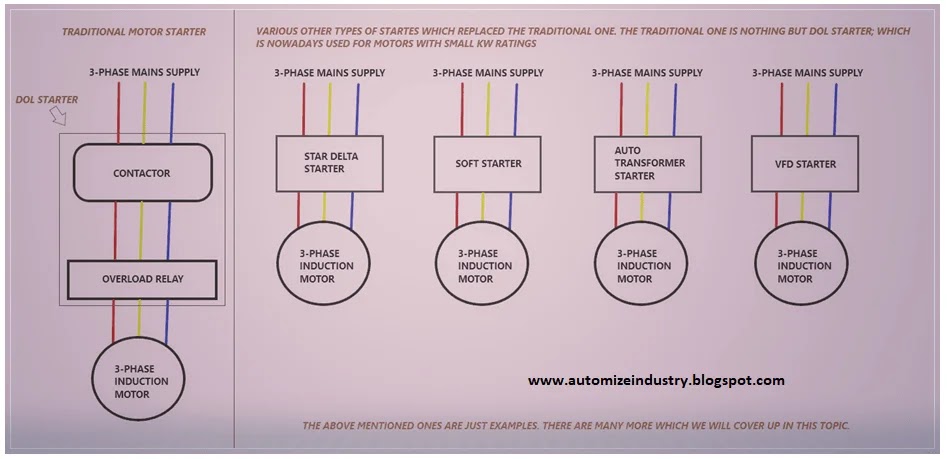

| Arranque directo en línea (DOL) | Connects motor directly to power supply; simple design | Water pumps, fans, conveyors | Ventajas: Simple, low cost; Contras: Una corriente de irrupción elevada puede dañar el motor. |

| Arrancador Star-Delta | Reduces starting current by switching configurations | Large industrial motors | Ventajas: Low starting current; Contras: Requires complex wiring. |

| Arrancador suave | Gradually increases voltage to motor for smooth start | HVAC systems, crushers, mixers | Ventajas: Reduces mechanical stress, prolongs motor life; Contras: More expensive than DOL. |

| Unidad de frecuencia variable (VFD) | Controls motor speed and torque via frequency adjustment | CNC machines, pumps, fans | Ventajas: Energy efficient, precise speed control; Contras: Mayor inversión inicial. |

| Arrancador de tensión reducida | Lowers voltage during startup to reduce inrush current | Heavy machinery, large compressors | Ventajas: Protects against voltage spikes; Contras: Can be complex to install. |

What are the Key Characteristics of Direct On-Line (DOL) Starters?

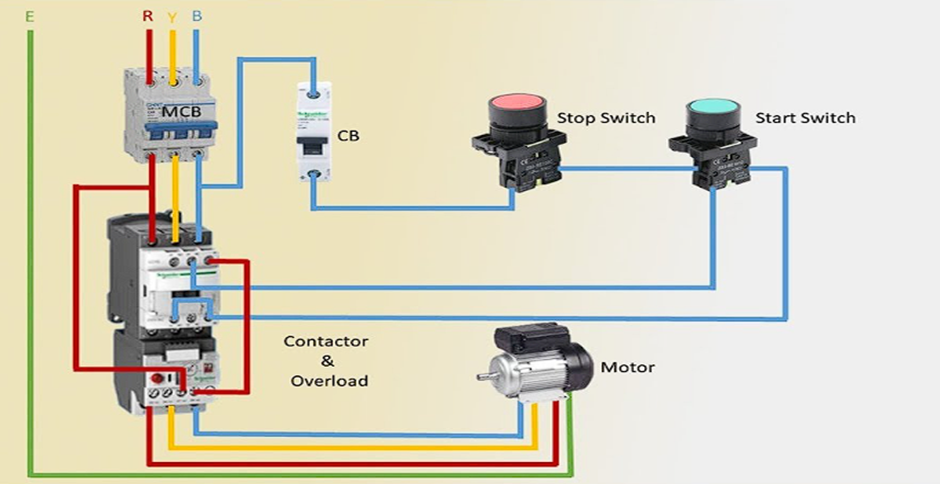

Direct On-Line (DOL) starters are characterized by their straightforward design that connects the motor directly to the power supply. This simplicity makes them a popular choice for applications with lower horsepower requirements, such as water pumps and small fans. However, buyers should be cautious of the high inrush current associated with DOL starters, which can lead to motor damage if not properly managed. When considering a DOL starter, it’s essential to evaluate the motor’s specifications and the operational environment to ensure compatibility.

How Does the Star-Delta Starter Function and Where is it Best Used?

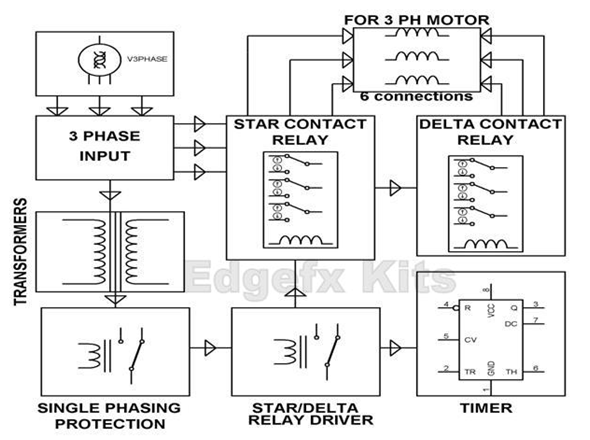

Star-Delta starters are unique in that they initially connect the motor in a star configuration to reduce the starting current, then switch to a delta configuration for normal operation. This makes them particularly suitable for large industrial motors where high starting torque is required, such as in manufacturing plants. While they offer significant benefits in terms of reduced starting current, the complexity of installation and wiring can be a drawback for some buyers. It’s crucial to assess the specific operational demands and installation capabilities before opting for this type.

Why Choose a Soft Starter for Your Applications?

Soft starters are designed to gradually increase the voltage supplied to the motor, allowing for a smooth and controlled start. This feature significantly reduces mechanical stress on the motor and extends its lifespan, making soft starters ideal for applications like HVAC systems and industrial mixers. While they tend to be more expensive than traditional starters, the long-term benefits in terms of reduced maintenance and replacement costs can justify the investment. Buyers should consider their operational needs and budget when evaluating soft starters.

What Advantages Do Variable Frequency Drives (VFDs) Offer?

Variable Frequency Drives (VFDs) are advanced motor starters that allow for precise control over motor speed and torque by varying the frequency of the power supply. This capability is especially beneficial in applications like CNC machines and variable-speed pumps, where efficiency and performance are critical. Although VFDs come with a higher initial cost, the energy savings and enhanced operational flexibility they provide can lead to significant long-term savings. B2B buyers should weigh the upfront investment against potential operational efficiencies when considering VFDs.

What is the Role of Reduced Voltage Starters in Heavy Machinery?

Reduced Voltage Starters are designed to lower the voltage supplied to the motor during startup, effectively managing inrush currents and protecting the motor from potential damage. They are commonly used in heavy machinery and large compressors, where the risk of voltage spikes can be significant. While they offer essential protection, the complexity of installation and potential need for additional components can be a consideration for buyers. Evaluating the specific requirements of the machinery and the electrical system is crucial for making an informed decision.

Key Industrial Applications of 3 types of starter motor

| Industria/Sector | Specific Application of 3 types of starter motor | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Fabricación | Full Voltage or Across-the-Line Starter for conveyor systems | Ensures immediate motor response for efficient production flow | Compatibility with existing systems and voltage specifications |

| Minería | Reduced Voltage Starter for heavy machinery | Minimizes inrush current, prolonging equipment life | Durability and resistance to harsh environmental conditions |

| Agricultura | Soft Starter for irrigation pumps | Smooth start reduces mechanical stress, increasing longevity | Sizing for pump capacity and efficiency ratings |

| Construcción | Full Voltage Reversing Starter for cranes | Allows for precise control of load movement | Safety certifications and compliance with local regulations |

| Tratamiento del agua | Variable Frequency Drive (VFD) for water pumps | Energy savings through optimized speed control | Energy efficiency ratings and maintenance support availability |

How is the Full Voltage or Across-the-Line Starter Used in Manufacturing?

In manufacturing environments, Full Voltage or Across-the-Line Starters are commonly employed to control conveyor systems. These starters connect directly to the power supply, facilitating immediate motor response, which is crucial for maintaining production flow. By ensuring that motors start without delay, they help in reducing downtime and increasing overall operational efficiency. For international buyers, especially from regions like Africa and South America, it is essential to ensure compatibility with existing electrical systems and to verify voltage specifications to avoid operational disruptions.

What Role Does a Reduced Voltage Starter Play in Mining?

In the mining industry, Reduced Voltage Starters are vital for managing the inrush current associated with heavy machinery such as excavators and drills. By limiting the initial current, these starters prevent damage to the equipment and electrical systems, thereby prolonging their operational lifespan. This is particularly important in rugged environments where equipment durability is critical. Buyers in the Middle East and Europe should focus on sourcing starters that meet high durability standards and can withstand extreme conditions.

How Do Soft Starters Benefit Agricultural Applications?

Soft Starters are increasingly used in agricultural settings, particularly for irrigation pumps. They provide a gradual increase in voltage, allowing pumps to start smoothly and reducing mechanical stress. This not only enhances the longevity of the pumps but also improves energy efficiency during operation. For buyers in regions like Africa, where energy costs can be significant, selecting appropriately sized soft starters that match the pump capacity is crucial for maximizing operational efficiency and reducing costs.

What Advantages Do Full Voltage Reversing Starters Offer in Construction?

Full Voltage Reversing Starters are essential in construction applications, particularly for cranes that require precise load control. These starters enable the motor to reverse direction by interchanging phases, which is critical for lifting and lowering heavy materials safely. International buyers must ensure that these starters comply with safety certifications and local regulations to avoid legal and operational issues. Additionally, they should consider the specific load requirements to select the right starter for their equipment.

Why Are Variable Frequency Drives Important in Water Treatment?

Variable Frequency Drives (VFDs) are increasingly utilized in water treatment facilities to optimize the operation of water pumps. By allowing for precise control of motor speed, VFDs can lead to significant energy savings and improved system efficiency. This is particularly relevant for international buyers, as energy costs can vary widely by region. When sourcing VFDs, it is essential to consider energy efficiency ratings and the availability of maintenance support to ensure long-term operational reliability.

3 Common User Pain Points for ‘3 types of starter motor’ & Their Solutions

Scenario 1: Inrush Current Damage During Startup

El problema: Many B2B buyers encounter issues with excessive inrush currents when starting motors, particularly with Full Voltage or Direct-On-Line (DOL) starters. This surge can damage the motor windings and related electrical components, leading to costly downtime and repairs. Industries that rely heavily on electric motors, such as manufacturing and construction, are especially vulnerable to this problem, as unexpected motor failures can halt operations and lead to significant financial losses.

La solución: To mitigate inrush current issues, it is essential to consider implementing a Reduced Voltage Starter or a Soft Starter. These alternatives gradually ramp up the voltage supplied to the motor, significantly reducing the initial current spike. When selecting a starter, ensure it is rated for the specific motor application and the load it will handle. Additionally, invest in high-quality overload relays to provide further protection against overheating. Training staff on the proper operation and monitoring of these devices can also enhance their effectiveness, ensuring that motors start smoothly and operate efficiently.

Scenario 2: Need for Direction Control in Operations

El problema: In sectors like logistics or manufacturing, businesses often require motors that can reverse direction for various tasks, such as conveyors or cranes. B2B buyers frequently face challenges when selecting a suitable motor starter that can facilitate this functionality. Full Voltage Reversing Starters can be complex and may lead to confusion among operators, resulting in operational delays and potential safety risks.

La solución: To address this challenge, buyers should opt for Full Voltage Reversing Starters that are specifically designed for applications requiring directional control. When sourcing these starters, ensure they have intuitive controls and robust safety features, such as mechanical interlocks to prevent accidental switching. Moreover, providing comprehensive training for operators on the correct use of these starters can minimize the risk of operational errors. Regular maintenance and checks on the starter and motor systems will also enhance reliability and performance.

Scenario 3: Operating Multiple Speed Requirements

El problema: Companies in industries like textile manufacturing or food processing often require motors that can operate at multiple speeds to handle various tasks efficiently. However, sourcing the right motor starter can be daunting, especially when trying to meet precise speed requirements without compromising performance. This can lead to inefficient operations and increased energy costs if the wrong starter is chosen.

La solución: For applications that demand variable speeds, consider utilizing a Multi-Speed Starter or a Variable Frequency Drive (VFD). VFDs are particularly advantageous as they allow for fine-tuning of motor speed and torque by adjusting the frequency of the power supply. When selecting a VFD, ensure it is compatible with the motor’s specifications, and consider factors such as load characteristics and application requirements. Additionally, implementing a control system that allows for easy adjustments and monitoring can help optimize performance. Regularly reviewing operational data will also enable businesses to make informed decisions about when to adjust speeds, ultimately improving efficiency and reducing energy consumption.

Strategic Material Selection Guide for 3 types of starter motor

What Are the Key Materials for Starter Motors?

When selecting materials for starter motors, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: copper, aluminum, steel, and thermoplastics. Each material plays a significant role in the performance and durability of starter motors, influencing their suitability for various applications.

How Does Copper Benefit Starter Motors?

Copper is widely used in electrical components due to its excellent conductivity and thermal properties. It has a high melting point (approximately 1,984°F or 1,085°C) and offers good corrosion resistance, making it ideal for environments with fluctuating temperatures.

Ventajas: Copper’s superior electrical conductivity ensures efficient power transfer, reducing energy losses. Additionally, its malleability allows for easy fabrication into complex shapes, which is beneficial for intricate starter motor designs.

Contras: The primary drawback of copper is its cost, which is significantly higher than aluminum. Furthermore, while copper has good corrosion resistance, it can still tarnish over time, requiring protective coatings in harsh environments.

Impacto en la aplicación: Copper is particularly suitable for applications requiring high efficiency and reliability, such as automotive and industrial machinery. Its compatibility with various media makes it a preferred choice in diverse operating conditions.

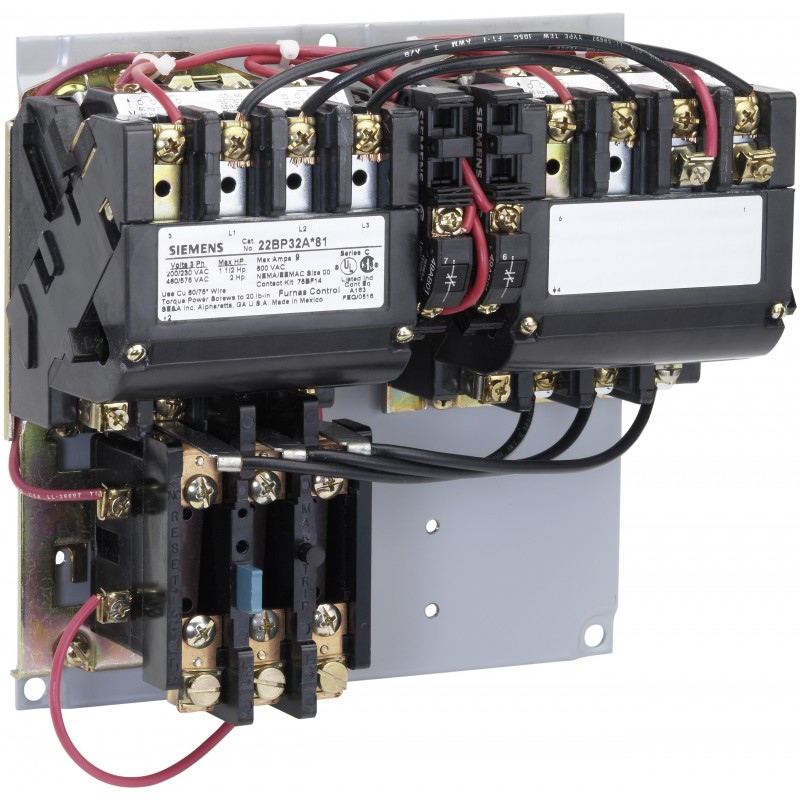

Illustrative image related to 3 types of starter motor

Consideraciones para compradores internacionales: Buyers from regions like Africa and the Middle East should ensure compliance with international standards such as ASTM B187 for copper alloys. In Europe, adherence to DIN standards is crucial for quality assurance.

What Role Does Aluminum Play in Starter Motor Construction?

Aluminum is another common material used in starter motors, known for its lightweight and corrosion-resistant properties. With a melting point of about 1,221°F (660°C), aluminum can withstand moderate temperature variations.

Ventajas: The lightweight nature of aluminum reduces overall motor weight, improving fuel efficiency in automotive applications. It also has a lower cost compared to copper, making it an attractive option for manufacturers.

Contras: While aluminum has decent conductivity, it is not as effective as copper, which may lead to slightly higher energy losses. Additionally, aluminum’s mechanical strength is lower than that of steel, which may limit its use in high-stress applications.

Impacto en la aplicación: Aluminum is ideal for applications where weight reduction is critical, such as in electric vehicles. Its corrosion resistance makes it suitable for outdoor and marine environments.

Consideraciones para compradores internacionales: Buyers should verify compliance with JIS H 4000 standards for aluminum alloys, especially in regions like Japan and South America, where specific grades are preferred.

How Does Steel Contribute to Starter Motor Durability?

Steel is often used in the structural components of starter motors due to its strength and durability. Depending on the alloy, steel can withstand high temperatures (up to 2,500°F or 1,370°C) and offers excellent mechanical properties.

Ventajas: The high tensile strength of steel makes it suitable for heavy-duty applications, providing robustness and longevity. Steel components can also be easily machined, allowing for precise manufacturing.

Illustrative image related to 3 types of starter motor

Contras: Steel is heavier than both copper and aluminum, which can negatively impact the overall weight of the motor. Additionally, it is prone to corrosion unless properly coated or treated.

Impacto en la aplicación: Steel is commonly used in starter motor housings and frames, where strength is essential. Its ability to withstand harsh conditions makes it suitable for industrial and agricultural machinery.

Consideraciones para compradores internacionales: Compliance with ASTM A36 standards is critical for buyers in the U.S. and Europe, ensuring that the steel used meets necessary quality and safety requirements.

Illustrative image related to 3 types of starter motor

What Advantages Do Thermoplastics Offer in Starter Motors?

Thermoplastics are increasingly being utilized in starter motor applications for components such as housings and insulation. With a wide range of temperature tolerances depending on the specific type, thermoplastics can be engineered for various applications.

Ventajas: Thermoplastics are lightweight, cost-effective, and offer excellent electrical insulation properties. They are also resistant to many chemicals and can be molded into complex shapes, making them versatile for various designs.

Contras: While thermoplastics can handle moderate temperatures, they may not be suitable for high-heat applications compared to metals. Their mechanical strength is also generally lower than that of metals, which may limit their use in structural applications.

Impacto en la aplicación: Thermoplastics are ideal for non-structural components where insulation and weight savings are critical, such as in automotive applications.

Consideraciones para compradores internacionales: Buyers should ensure compliance with international standards such as ISO 9001 for quality management systems, particularly in regions like Europe and South America.

Tabla resumen de selección de materiales para motores de arranque

| Material | Typical Use Case for 3 types of starter motor | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Cobre | Conexiones eléctricas y bobinados | Excellent conductivity and thermal properties | High cost, potential tarnishing | Alto |

| Aluminio | Carcasas y componentes ligeros | Ligero y resistente a la corrosión. | Lower conductivity than copper, less strength | Medio |

| Acero | Structural components and frames | Alta resistencia y durabilidad | Más pesado, propenso a la corrosión | Medio |

| Thermoplastics | Aislamiento y componentes no estructurales | Lightweight, cost-effective, and versatile | Lower heat tolerance and mechanical strength | Bajo |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their specific applications and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 types of starter motor

¿Cuáles son las principales etapas del proceso de fabricación de los motores de arranque?

Manufacturing starter motors involves a series of meticulously structured stages, each critical to ensuring the final product meets both performance and quality standards. The typical stages include material preparation, forming, assembly, and finishing.

¿Cómo se prepara el material para la producción de motores de arranque?

The first step in the manufacturing process is material preparation. High-quality raw materials such as copper for windings, silicon steel for laminations, and durable plastics for housings are sourced from reputable suppliers. These materials undergo rigorous quality checks to ensure they meet specifications. For instance, copper must have a minimum conductivity level, while steel must exhibit the right magnetic properties.

¿Qué técnicas de conformado se utilizan en la fabricación de motores de arranque?

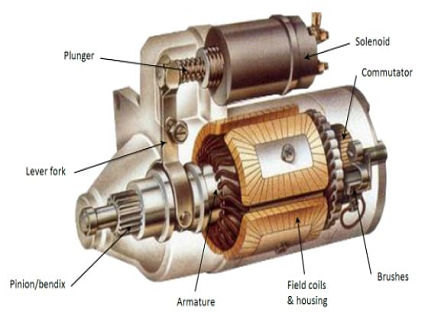

Once the materials are prepared, forming techniques come into play. Key processes include stamping, machining, and winding. Stamping is used for creating the motor’s core and housing components, where precision is vital to ensure proper fit and function. Machining involves cutting the components to exact dimensions, often using CNC machines for high accuracy. Winding the copper wire around the stator and rotor is a delicate task, requiring skilled operators to ensure the coils are uniform, which directly affects performance.

Illustrative image related to 3 types of starter motor

¿Cómo se lleva a cabo el proceso de montaje de los motores de arranque?

The assembly stage involves integrating all the components into a cohesive unit. This includes the installation of the rotor, stator, and any necessary electrical connections. Quality control during assembly is paramount; operators must verify that each part is correctly positioned and secured. Automated systems may assist in this process, reducing the risk of human error.

¿Qué procesos de acabado son esenciales para los motores de arranque?

Finishing processes are the final step in manufacturing and include painting, coating, and testing. Painting not only provides aesthetic appeal but also protects against corrosion. Coatings may be applied to enhance durability. Comprehensive testing follows to ensure the motors meet performance specifications. Each starter motor undergoes electrical testing to check for shorts and insulation integrity, as well as functional testing to confirm operational capabilities.

What Are the Key Quality Control Measures in Starter Motor Production?

Quality assurance is crucial in the manufacturing of starter motors to ensure reliability and performance. International standards such as ISO 9001 provide a framework for quality management systems that manufacturers should adhere to. Compliance with industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) is also critical, especially for motors used in various industrial applications.

What Are the Common Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process, typically categorized into Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Illustrative image related to 3 types of starter motor

-

Control de calidad de entrada (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility. Tests may include dimensional checks, material composition analysis, and visual inspections for defects.

-

Control de calidad durante el proceso (IPQC): During production, various checks are performed at different stages to ensure that processes are in control. This includes monitoring machine settings and parameters, conducting spot checks on assemblies, and verifying that manufacturing tolerances are maintained.

-

Control de calidad final (FQC): At the end of the production line, each starter motor undergoes comprehensive testing. This may include functional tests, load tests, and environmental tests to simulate operating conditions. Any unit failing to meet specified criteria is rejected and either repaired or discarded.

¿Cómo pueden los compradores B2B verificar las prácticas de control de calidad de los proveedores?

B2B buyers must ensure that their suppliers maintain high-quality standards. One effective method is to conduct supplier audits, which involve visiting the manufacturing facility to assess processes, quality control measures, and overall compliance with international standards.

Additionally, obtaining quality assurance reports from suppliers can provide insight into their manufacturing practices. These reports should detail test results, compliance with standards, and any corrective actions taken for non-conformance.

For further assurance, buyers may consider third-party inspections. Engaging independent inspection services can help verify that the supplier adheres to quality standards and provides unbiased feedback on production quality.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. Different regions may have varying standards and expectations regarding quality. For instance, European buyers may place a strong emphasis on CE certification, while buyers in the Middle East may prioritize compliance with local regulatory standards.

Furthermore, cultural differences can influence quality expectations and communication styles. Establishing clear communication channels and understanding regional compliance requirements is essential for smooth transactions.

Conclusion: The Importance of Quality Assurance in Starter Motor Manufacturing

In conclusion, the manufacturing processes and quality assurance measures for starter motors are critical to ensuring the reliability and performance of these essential components. By understanding the stages of manufacturing and the importance of quality control, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only aids in the procurement of high-quality starter motors but also enhances the overall efficiency and reliability of their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 types of starter motor’

Introducción

This practical sourcing guide aims to assist B2B buyers in procuring three types of starter motors: Full Voltage Starters, Reduced Voltage Starters, and Soft Starters. Each type serves specific applications and understanding their features, benefits, and procurement considerations is essential for making informed purchasing decisions.

Paso 1: Defina sus especificaciones técnicas

Before initiating the procurement process, clearly outline your technical requirements for the starter motors. This includes voltage ratings, power capacity, and operational features such as reversing capabilities or speed control.

– Consider the application: Understand the specific industrial or commercial context in which the starter motor will be used.

– Compliance standards: Ensure specifications align with local and international safety and efficiency standards.

Step 2: Assess Application Needs

Identify the operational requirements and challenges faced in your environment. This will help determine the most suitable starter motor type.

– Inrush current considerations: If your application involves high starting torque, a Reduced Voltage Starter may be more appropriate to minimize inrush currents.

– Operational flexibility: For applications requiring directional control, a Full Voltage Reversing Starter can offer significant advantages.

Paso 3: Evaluar posibles proveedores

Thoroughly vet potential suppliers to ensure they can meet your technical and operational requirements. This step is crucial for establishing a reliable supply chain.

– Solicite documentación: Ask for company profiles, product catalogs, and certifications that demonstrate compliance with industry standards.

– Check references: Reach out to previous customers, particularly those in your industry or region, to gauge supplier reliability and service quality.

Illustrative image related to 3 types of starter motor

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications and comply with international quality standards, such as ISO 9001. This guarantees the quality and safety of the starter motors.

– Busque certificaciones específicas del sector: Depending on your region, certifications from recognized bodies may be required for motor starters.

– Assess warranty and support: Understand the warranty terms and after-sales support offered by suppliers, as these can significantly impact long-term satisfaction.

Step 5: Compare Pricing and Value

Once you have shortlisted suppliers, compare pricing structures while considering the overall value each supplier offers, not just the upfront cost.

– Evaluate total cost of ownership: Consider factors such as maintenance, energy efficiency, and potential downtime that may affect overall costs.

– Request quotes: Obtain detailed quotes that specify all included components, shipping costs, and delivery timelines.

Step 6: Conduct a Pilot Test

Before finalizing a large order, consider conducting a pilot test with a small batch of starter motors. This allows you to evaluate performance in real-world conditions.

– Monitor performance metrics: Assess how well the motors perform under typical operating conditions.

– Gather user feedback: Involve your operational team in the evaluation process to gain insights into usability and reliability.

Step 7: Finalize the Purchase Agreement

After successfully evaluating suppliers and conducting tests, finalize the purchase agreement with your chosen supplier. Ensure all terms are clearly defined.

– Include service agreements: Specify maintenance and support services in the contract to safeguard against future issues.

– Negotiate payment terms: Discuss payment schedules that align with your budget and cash flow requirements.

By following this checklist, B2B buyers can streamline the procurement process for starter motors, ensuring they select the right type and supplier to meet their operational needs effectively.

Comprehensive Cost and Pricing Analysis for 3 types of starter motor Sourcing

What Are the Key Cost Components in Starter Motor Sourcing?

When sourcing starter motors, understanding the cost structure is essential for B2B buyers, especially those operating in diverse international markets. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materiales: The type of materials used in starter motors significantly influences costs. Components such as copper, steel, and specialized alloys can vary based on market fluctuations. Higher-quality materials may be required for specific applications, which can increase costs but also enhance durability and efficiency.

-

Trabajo: Labor costs can vary widely depending on the manufacturing location. For instance, countries with lower labor costs may offer competitive pricing, but this can sometimes compromise quality. Understanding the labor market in the supplier’s region can help buyers gauge the overall cost-effectiveness of sourcing from that area.

-

Gastos generales de fabricación: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Manufacturers with advanced technology may incur higher overhead but can produce motors with greater precision and efficiency.

-

Herramientas: Custom tooling for specific motor designs can be a significant upfront cost. Buyers should consider whether they require standard models or customized solutions, as this will impact the overall tooling investment.

-

Control de calidad (QC): Implementing rigorous QC processes ensures that starter motors meet safety and performance standards. This adds to the cost but is crucial for long-term reliability and compliance with international regulations.

-

Logística: Shipping costs can vary significantly based on the Incoterms agreed upon. International buyers should factor in shipping methods, tariffs, and potential delays, which can affect the total cost and delivery timeline.

-

Margen: Supplier margins can vary based on market competition and the supplier’s business model. Understanding the pricing strategy of suppliers can aid in negotiations.

How Do Price Influencers Affect Starter Motor Costs?

Several factors influence the pricing of starter motors, which B2B buyers must consider:

-

Volumen y cantidad mínima de pedido (MOQ): Larger orders often lead to better pricing, as suppliers can reduce production costs through economies of scale. Buyers should negotiate MOQs that align with their needs while seeking volume discounts.

-

Especificaciones y personalización: Custom specifications typically incur higher costs due to the need for specialized materials or manufacturing processes. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Calidad de los materiales y certificaciones: Motors that require specific certifications (e.g., ISO, CE) may cost more due to the additional compliance measures involved. High-quality materials often correlate with enhanced performance and longevity.

-

Factores relacionados con los proveedores: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge a premium, but the assurance of reliability can justify the cost.

-

Incoterms: The chosen Incoterms affect shipping responsibilities and costs. Buyers should understand the implications of terms like FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) to manage total costs effectively.

What Are the Best Negotiation Tips for B2B Buyers in Starter Motor Sourcing?

To achieve favorable pricing in starter motor sourcing, B2B buyers should employ several strategies:

-

Investigación y evaluación comparativa: Conduct thorough market research to understand prevailing prices and competitor offerings. This information can empower buyers during negotiations.

-

Coste total de propiedad (TCO): Assess not just the purchase price but the overall cost of ownership, including installation, maintenance, and energy consumption over the motor’s lifecycle. This approach helps in justifying higher initial costs for more efficient motors.

-

Construir relaciones: Establishing long-term relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster trust and collaboration.

-

Flexibility in Specifications: Being open to alternative materials or designs can allow for cost reductions. Discussing options with suppliers may yield unexpected savings.

-

Cultural Awareness: Understanding cultural differences in negotiation styles, particularly when dealing with international suppliers, can enhance communication and lead to better outcomes.

By considering these cost components, price influencers, and negotiation strategies, B2B buyers can make informed decisions that optimize their sourcing of starter motors, ensuring they achieve both quality and cost-efficiency.

Alternatives Analysis: Comparing 3 types of starter motor With Other Solutions

Introduction: Exploring Alternative Solutions to Starter Motors

In the landscape of industrial automation, the choice of motor starting solutions is critical for operational efficiency and equipment longevity. While the three types of starter motors—Direct-On-Line (DOL), Star-Delta, and Soft Starters—are widely used, there are alternative technologies that can also effectively start motors and provide similar functionalities. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and application needs.

Tabla comparativa

| Aspecto comparativo | 3 Types Of Starter Motor | Unidad de frecuencia variable (VFD) | Arrancador suave |

|---|---|---|---|

| Rendimiento | Reliable for low to medium loads, effective in controlling starting current. | Offers precise speed control and energy efficiency for varying load conditions. | Gradual increase in voltage reduces mechanical stress, enhancing motor lifespan. |

| Coste | Generally lower initial investment, but may incur higher operational costs due to energy loss. | Higher upfront cost but can lead to significant energy savings over time. | Moderate cost with potential savings on maintenance and wear. |

| Facilidad de implementación | Simple installation and operation; minimal training required. | Requires more complex setup and programming; technical expertise needed. | Straightforward installation, similar to traditional starters. |

| Mantenimiento | Low maintenance; components are robust and long-lasting. | Requires regular software updates and occasional recalibrations. | Low maintenance; fewer components at risk of failure. |

| Mejor caso de uso | Suitable for straightforward applications with consistent load requirements. | Ideal for applications requiring variable speed and torque control. | Best for applications where soft starts are necessary to prevent mechanical shock. |

Desglose detallado de las alternativas

Unidad de frecuencia variable (VFD)

VFDs are advanced electronic devices that control the speed and torque of electric motors by varying the frequency and voltage of the power supplied. They excel in applications where load conditions fluctuate, providing precise control over motor performance. The advantages of VFDs include energy efficiency and reduced wear on equipment. However, they come with a higher initial investment and require a certain level of technical expertise for proper installation and programming. For businesses looking to optimize energy consumption and performance in variable load environments, VFDs present a compelling option.

Arrancador suave

Soft starters control the voltage supplied to the motor during startup, allowing for a gradual increase in power. This feature reduces mechanical stress on both the motor and connected equipment, prolonging their lifespan. Soft starters are particularly beneficial in applications where sudden starts could cause damage or where equipment is sensitive to mechanical shock. They are generally easy to install and require minimal maintenance. While they may not provide the same level of speed control as VFDs, their ability to manage inrush current makes them a suitable alternative for many industrial applications.

Conclusión: Cómo elegir la solución adecuada para sus necesidades

When selecting a motor starting solution, B2B buyers must consider specific operational requirements, including the nature of the load, energy efficiency goals, and budget constraints. The three types of starter motors provide reliable options for straightforward applications, while alternatives like VFDs and soft starters offer enhanced control and protection for more complex scenarios. Ultimately, the right choice will depend on balancing initial costs with long-term operational efficiency, maintenance needs, and application-specific requirements. By thoroughly evaluating these factors, businesses can ensure they invest in the most suitable motor starting solution for their unique operational landscape.

Essential Technical Properties and Trade Terminology for 3 types of starter motor

What Are the Key Technical Properties of Different Types of Starter Motors?

When selecting a starter motor for industrial applications, several technical properties must be considered to ensure optimal performance and reliability. Here are some critical specifications:

Illustrative image related to 3 types of starter motor

-

Tensión nominal

Voltage rating is essential as it indicates the maximum voltage the motor starter can handle safely. For instance, common ratings include 230V, 400V, and 690V. In a B2B context, aligning the voltage rating with the specific requirements of machinery helps prevent equipment failure and ensures compliance with regional electrical standards. -

Clasificación actual

This specification defines the maximum current the starter can manage without overheating. Typically measured in amperes (A), selecting the appropriate current rating is crucial for avoiding overloads that could damage both the motor and the starter. B2B buyers must ensure that the current rating matches the motor’s requirements to optimize performance and longevity. -

Enclosure Type

The enclosure type refers to the protective casing of the starter motor, which can be rated for various environmental conditions, such as NEMA or IP ratings. These ratings indicate resistance to dust, water, and other environmental factors. For international buyers, understanding enclosure specifications is vital to ensure the starter motor will perform reliably in diverse climates, from humid regions in South America to arid environments in the Middle East. -

Control Method

Different starter motors use various control methods, including Direct-On-Line (DOL), Star-Delta, and Variable Frequency Drives (VFD). Each method has distinct advantages in terms of starting torque, energy efficiency, and application suitability. B2B decision-makers should evaluate which control method aligns best with their operational needs to enhance efficiency and reduce energy consumption. -

Protección contra sobrecargas

This feature helps prevent motor damage due to excessive current. Overload relays are often integrated into motor starters to trip the circuit when current exceeds a set threshold. For buyers, understanding the overload protection mechanisms can ensure that their investment in starter motors translates into reduced maintenance costs and longer equipment life.

Which Trade Terminology Should B2B Buyers Understand for Starter Motors?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms relevant to starter motors:

-

OEM (fabricante de equipos originales)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, sourcing from reputable OEMs ensures quality and compatibility, which can significantly reduce operational risks. -

MOQ (cantidad mínima de pedido)

MOQ specifies the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for buyers in managing inventory and cash flow, especially in regions with fluctuating demand. -

RFQ (Solicitud de presupuesto)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. This term is vital for B2B transactions, as it helps buyers compare offers and negotiate better terms based on competitive pricing. -

Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers in international shipping, including who pays for shipping, insurance, and tariffs. For international B2B buyers, understanding these terms can facilitate smoother logistics and compliance with trade regulations. -

Plazo de entrega

Lead time indicates the time between placing an order and receiving it. Awareness of lead times is essential for B2B buyers to plan their operations and minimize downtime, especially in industries where machinery reliability is critical. -

Technical Datasheet

This document provides detailed specifications and performance characteristics of a product, including starter motors. Reviewing technical datasheets is crucial for B2B buyers to make informed decisions based on their specific application needs.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions when selecting starter motors, ensuring they meet their operational requirements while optimizing cost and performance.

Navigating Market Dynamics and Sourcing Trends in the 3 types of starter motor Sector

What Are the Current Market Dynamics and Key Trends for Starter Motors?

The global market for starter motors is experiencing robust growth, driven by increasing industrialization and the rising demand for efficient electrical systems. Key trends include the adoption of advanced technologies such as Variable Frequency Drives (VFDs) and soft starters, which enhance energy efficiency and reduce operational costs. Furthermore, the shift towards automation in manufacturing processes is pushing the need for sophisticated motor starters that can handle varying load conditions and provide precise control over motor functions.

Illustrative image related to 3 types of starter motor

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should be aware of the localization of supply chains as a response to geopolitical tensions and trade policies. This shift is prompting manufacturers to seek local partnerships to mitigate risks and enhance supply chain resilience. Additionally, the demand for customization in starter motors is rising, as companies seek solutions that cater specifically to their operational needs. Buyers should also consider suppliers who can offer a diverse range of starter types, including full voltage starters and reduced voltage starters, tailored to specific applications.

Emerging technologies, such as IoT-enabled starter motors, are also gaining traction, allowing for real-time monitoring and predictive maintenance. This evolution is crucial for industries with high uptime requirements, as it helps in preemptively addressing potential motor failures. For B2B buyers, investing in these technologies can lead to significant cost savings and improved operational efficiency.

How Can Sustainability and Ethical Sourcing Be Integrated into the Starter Motor Supply Chain?

Sustainability is becoming a pivotal factor in the sourcing of starter motors, as environmental concerns gain prominence globally. The production of starter motors often involves materials and processes that can have significant environmental impacts, such as the extraction of metals and the energy-intensive manufacturing processes. Buyers are encouraged to prioritize suppliers who adopt environmentally friendly practices, such as reducing waste and utilizing renewable energy sources in their production lines.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should seek out suppliers who are transparent about their sourcing practices and who adhere to ethical labor standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can provide assurance that suppliers are committed to sustainable practices.

In terms of materials, the use of recyclable components and eco-friendly packaging is increasingly important. B2B buyers should evaluate the environmental certifications of materials used in starter motors, such as those indicating low carbon footprints or sustainable sourcing practices. By integrating sustainability into the sourcing strategy, companies can not only meet regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious customers.

What Is the Brief Evolution of Starter Motors and Their Impact on B2B Buyers?

The evolution of starter motors has significantly shaped their applications in various industries. Initially, starter motors were designed for simplicity and efficiency, primarily employing direct-on-line (DOL) methods. However, as industrial needs grew more complex, the demand for advanced motor starters that could manage inrush current and provide overload protection led to innovations such as soft starters and VFDs.

This evolution reflects a broader trend toward automation and efficiency in industrial processes. For B2B buyers, understanding the historical context of starter motors can provide insights into the technological advancements that have led to current offerings. Buyers can leverage this knowledge to make informed decisions about which starter motor technologies best align with their operational goals, ensuring they are investing in solutions that not only meet current demands but also anticipate future challenges in an ever-evolving marketplace.

By recognizing these trends, integrating sustainable practices, and understanding the historical context of starter motors, international B2B buyers can navigate the complexities of sourcing in this sector more effectively, ultimately leading to enhanced operational efficiency and competitive advantage.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 types of starter motor

-

How do I solve compatibility issues when sourcing starter motors?

To solve compatibility issues, first, ensure that the starter motor specifications match your application requirements, including voltage, phase, and horsepower ratings. Consult with manufacturers or suppliers to confirm compatibility with your existing systems. Additionally, consider the motor starter type that suits your operational needs—whether it’s a Direct On-Line, Star-Delta, or Soft Starter. Conducting a thorough review of your motor’s operational environment and application can help in selecting the correct starter motor to avoid any performance issues. -

What is the best starter motor for high-load applications?

For high-load applications, the best choice is often a Reduced Voltage Starter or a Soft Starter. These types effectively manage inrush currents, minimizing mechanical stress on the motor during startup. The Soft Starter gradually ramps up voltage, ensuring a smooth acceleration which is ideal for large motors. Depending on your application, a Variable Frequency Drive (VFD) can also be advantageous as it offers precise speed control and energy efficiency, making it suitable for high-demand scenarios. -

What factors should I consider when vetting suppliers for starter motors?

When vetting suppliers, consider their industry experience, reputation, and product quality certifications. Look for suppliers who provide detailed product specifications and offer technical support. It’s also essential to assess their responsiveness and customer service. Request references or case studies from previous clients, particularly those in your region, to gauge their reliability. Finally, inquire about their supply chain stability and delivery timelines to ensure they can meet your demands consistently. -

What are typical minimum order quantities (MOQs) for starter motors?

Minimum order quantities (MOQs) for starter motors can vary widely depending on the supplier and the type of motor. Generally, MOQs can range from 10 to 100 units for standard models. Custom or specialized motors may have higher MOQs due to the unique manufacturing processes involved. It’s advisable to discuss your specific needs with suppliers to find flexibility in MOQs, especially if you are just starting or testing new markets. -

What payment terms should I expect when purchasing starter motors internationally?

Payment terms for international purchases typically include options such as advance payment, letter of credit, or net payment terms (e.g., 30, 60, or 90 days). Many suppliers may require a deposit upfront, especially for large orders or customized products. It’s crucial to clarify these terms before finalizing the order. Additionally, ensure you understand any potential currency exchange implications and transaction fees that may apply, as these can affect your overall costs. -

How can I ensure quality assurance (QA) for the starter motors I purchase?

To ensure quality assurance, request certifications such as ISO or IEC standards from your suppliers, indicating that their products meet international quality benchmarks. Establish a clear QA process that includes pre-shipment inspections and testing of the starter motors. Engaging third-party inspection services can provide an unbiased assessment of product quality. Additionally, consider setting up a warranty or return policy to address any potential defects or issues post-purchase. -

What logistics considerations should I be aware of when importing starter motors?

Logistics considerations include shipping methods, customs clearance, and potential tariffs or duties applicable in your country. Evaluate the best shipping options based on delivery time and cost-effectiveness, whether by air or sea. Ensure that your supplier provides all necessary documentation for customs, such as invoices and certificates of origin. It’s also wise to work with a freight forwarder familiar with importing electrical components to navigate the complexities of international shipping. -

What is the expected lifespan of a starter motor and how can I extend it?

The expected lifespan of a starter motor typically ranges from 5 to 15 years, depending on usage and maintenance. To extend its lifespan, ensure regular maintenance, including lubrication and inspections for wear and tear. Implementing proper installation practices and using the correct motor starter type can also significantly affect longevity. Additionally, monitoring operational conditions and addressing any issues promptly will help prevent premature failure and ensure reliable performance over time.

Top 2 3 Types Of Starter Motor Manufacturers & Suppliers List

1. Vocal – Motor Starters Overview

Dominio: vocal.media

Introducción: Types of Motor Starters: 1. Direct-On-Line (DOL) Starters: – Key Components: Contactor, Overload Relay, Push Buttons – Applications: Small motors (<5 kW) like pumps, fans, conveyors – Advantages: Simple, cost-effective, compact design, reliable maintenance – Disadvantages: High inrush current, not suitable for larger motors. 2. Star-Delta Starters: – Key Components: Three Contactors, Timer, Overlo…

2. Campus Component – Motor Starter

Dominio: campuscomponent.com

Registrado: 2009 (16 años)

Introducción: Motor starter is an electrical device used to safely start, stop, and protect electric motors from damage caused by overcurrent, short circuits, or other faults. It regulates the flow of electrical power to the motor, ensuring smooth operation. Key features include: 1. Starting the Motor Safely – regulates high inrush current during startup. 2. Stopping the Motor – provides reliable methods to cut…

Strategic Sourcing Conclusion and Outlook for 3 types of starter motor

In conclusion, understanding the three main types of starter motors—Full Voltage, Reduced Voltage, and Soft Starters—is essential for optimizing operational efficiency and ensuring the longevity of electrical systems. Each type offers unique benefits tailored to specific applications, from managing inrush currents to providing overload protection. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, strategic sourcing of these motor starters can significantly impact not only the performance of machinery but also the overall energy efficiency of operations.

Illustrative image related to 3 types of starter motor

Investing in the right starter motor can enhance reliability, reduce maintenance costs, and improve safety standards within your operations. As industries increasingly focus on sustainability and energy efficiency, the demand for advanced motor starters will continue to grow. Buyers should prioritize suppliers that offer high-quality products and comprehensive support to ensure optimal integration into their systems.

Looking ahead, now is the time to leverage strategic sourcing initiatives to secure the best motor starters for your specific needs. By making informed decisions, you can position your business for success in a competitive landscape, driving innovation and efficiency in your operations.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.