Introduction: Navigating the Global Market for alternator assembly

In an increasingly interconnected world, sourcing high-quality alternator assemblies presents a significant challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. As industries evolve and the demand for reliable automotive components surges, understanding the complexities of alternator assembly becomes essential for decision-makers. This comprehensive guide delves into the various types of alternators, their applications across different vehicles, and the critical factors influencing supplier selection and cost.

Navigating the global market for alternator assemblies requires a keen understanding of regional specifications, compliance standards, and supplier capabilities. Buyers will benefit from insights into the latest technological advancements and performance metrics that can affect product quality and longevity. Additionally, this guide provides actionable strategies for vetting suppliers, ensuring that buyers can make informed decisions that align with their operational needs and budget constraints.

By equipping B2B purchasers with the knowledge necessary to evaluate options effectively, this guide empowers them to forge partnerships that enhance their supply chains and drive business success. Whether you’re sourcing for the automotive industry in Germany or exploring alternatives in Saudi Arabia, understanding the nuances of alternator assembly is crucial for maintaining competitive advantage in the global market.

Índice

- Top 4 Alternator Assembly Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator assembly

- Understanding alternator assembly Types and Variations

- Key Industrial Applications of alternator assembly

- 3 Common User Pain Points for ‘alternator assembly’ & Their Solutions

- Strategic Material Selection Guide for alternator assembly

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator assembly

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator assembly’

- Comprehensive Cost and Pricing Analysis for alternator assembly Sourcing

- Alternatives Analysis: Comparing alternator assembly With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator assembly

- Navigating Market Dynamics and Sourcing Trends in the alternator assembly Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator assembly

- Strategic Sourcing Conclusion and Outlook for alternator assembly

- Aviso legal importante y condiciones de uso

Understanding alternator assembly Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Alternador estándar | Lightweight aluminum housing, efficient cooling system | Vehículos de pasajeros, camiones ligeros | Ventajas: Económico y ampliamente disponible. Contras: Limited power output for high-demand applications. |

| Alternador de alto rendimiento | Enhanced winding design, larger rotor, and improved cooling | Vehículos de alto rendimiento, maquinaria pesada | Ventajas: Greater power output, suitable for high-demand electrical systems. Contras: Higher cost, may require modifications for installation. |

| Alternador sin escobillas | No brushes, reduced wear, and maintenance | Industrial equipment, renewable energy systems | Ventajas: Mayor vida útil, menor mantenimiento. Contras: Higher initial investment, more complex design. |

| Alternador marino | Corrosion-resistant materials, specialized cooling features | Embarcaciones, vehículos marítimos | Ventajas: Durable in harsh environments, reliable performance. Contras: Generally more expensive than standard models. |

| Alternador inteligente | Integrated electronics for real-time monitoring and efficiency | Vehículos híbridos, vehículos eléctricos | Ventajas: Optimizes energy use, enhances battery life. Contras: Requires advanced knowledge for installation and integration. |

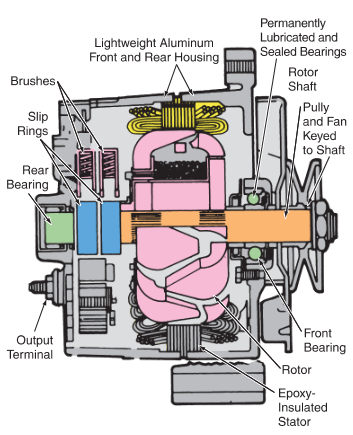

¿Qué características tienen los alternadores estándar?

Standard alternators are the most commonly used type in passenger vehicles and light trucks. Characterized by their lightweight aluminum housing and efficient internal cooling systems, these units convert mechanical energy into electrical energy effectively. They are designed to meet the electrical demands of typical automotive applications. For B2B buyers, the key considerations include price and compatibility with existing vehicle systems, making them a go-to choice for general automotive needs.

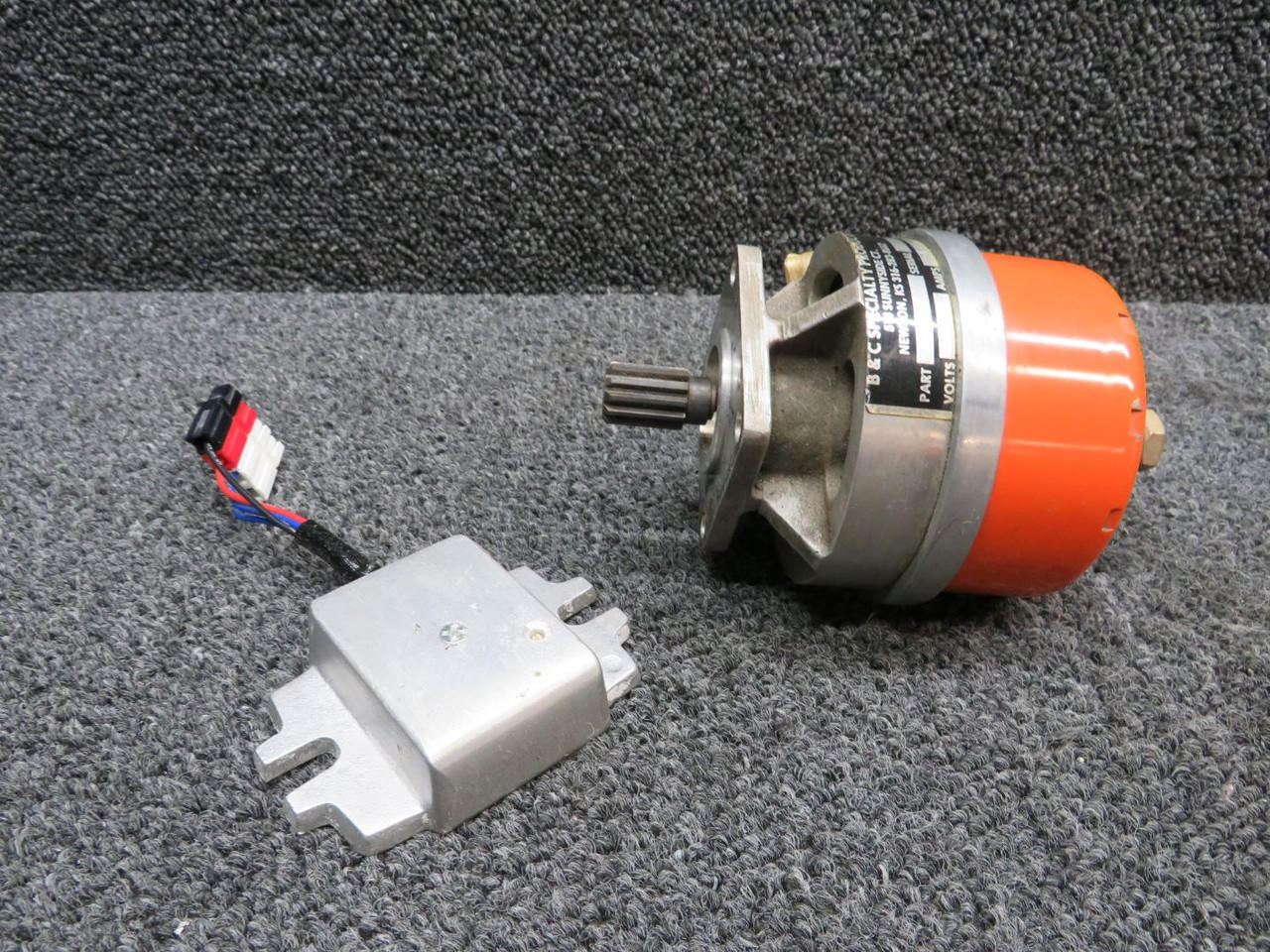

Illustrative image related to alternator assembly

How do High-Output Alternators Differ from Standard Ones?

High-output alternators feature enhanced winding designs and larger rotors, allowing them to generate significantly more electrical power. This makes them ideal for performance vehicles and heavy machinery that require robust electrical systems, such as high-powered audio systems or additional lighting. B2B buyers should consider the specific power requirements of their applications, as these alternators often come at a higher price point and may necessitate modifications for installation.

¿Qué ventajas ofrecen los alternadores sin escobillas?

Brushless alternators eliminate the need for brushes, which reduces wear and maintenance over time. They are particularly well-suited for industrial equipment and renewable energy systems, where reliability and longevity are paramount. B2B buyers should weigh the higher initial investment against the long-term savings in maintenance and replacement costs, especially in applications where downtime is costly.

Why Choose Marine Alternators for Watercraft?

Marine alternators are designed with corrosion-resistant materials and specialized cooling features to withstand harsh marine environments. They are crucial for boats and other marine vehicles, ensuring reliable performance even in challenging conditions. For B2B buyers in the marine sector, the durability and reliability of these alternators justify their higher price, especially when considering the potential costs of equipment failure at sea.

What Makes Smart Alternators Innovative?

Smart alternators incorporate integrated electronics that allow for real-time monitoring and optimization of energy use. These units are particularly beneficial for hybrid and electric vehicles, where efficient energy management is critical for performance and battery life. B2B buyers should consider the complexity of installation and integration with existing systems, as these advanced units may require specialized knowledge to implement effectively.

Key Industrial Applications of alternator assembly

| Industria/Sector | Specific Application of alternator assembly | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Automoción | Sistemas eléctricos de vehículos | Ensures reliable power supply for vehicle components | Certificaciones de calidad, compatibilidad con modelos de vehículos |

| Energía renovable | Sistemas de aerogeneradores | Converts mechanical energy to electrical power | Durabilidad en entornos difíciles, índices de eficiencia |

| Marina | Ship propulsion and electrical systems | Provides stable electrical output for navigation | Corrosion resistance, size and weight specifications |

| Equipos de construcción | Heavy machinery power generation | Supports operations of hydraulic systems and tools | Resistance to vibration, thermal management capabilities |

| Telecomunicaciones | Backup power systems for cell towers | Maintains operational continuity during outages | Reliability, maintenance support, global sourcing capabilities |

How is ‘Alternator Assembly’ Used in the Automotive Industry?

In the automotive sector, alternator assemblies are integral to vehicle electrical systems, converting mechanical energy from the engine into electrical energy. This electricity is crucial for powering lights, infotainment systems, and other electronic components. For international buyers, particularly in regions like Africa and South America, sourcing high-quality alternators that meet specific vehicle compatibility and durability standards is essential. Additionally, understanding local regulations on emissions and energy efficiency can impact procurement decisions.

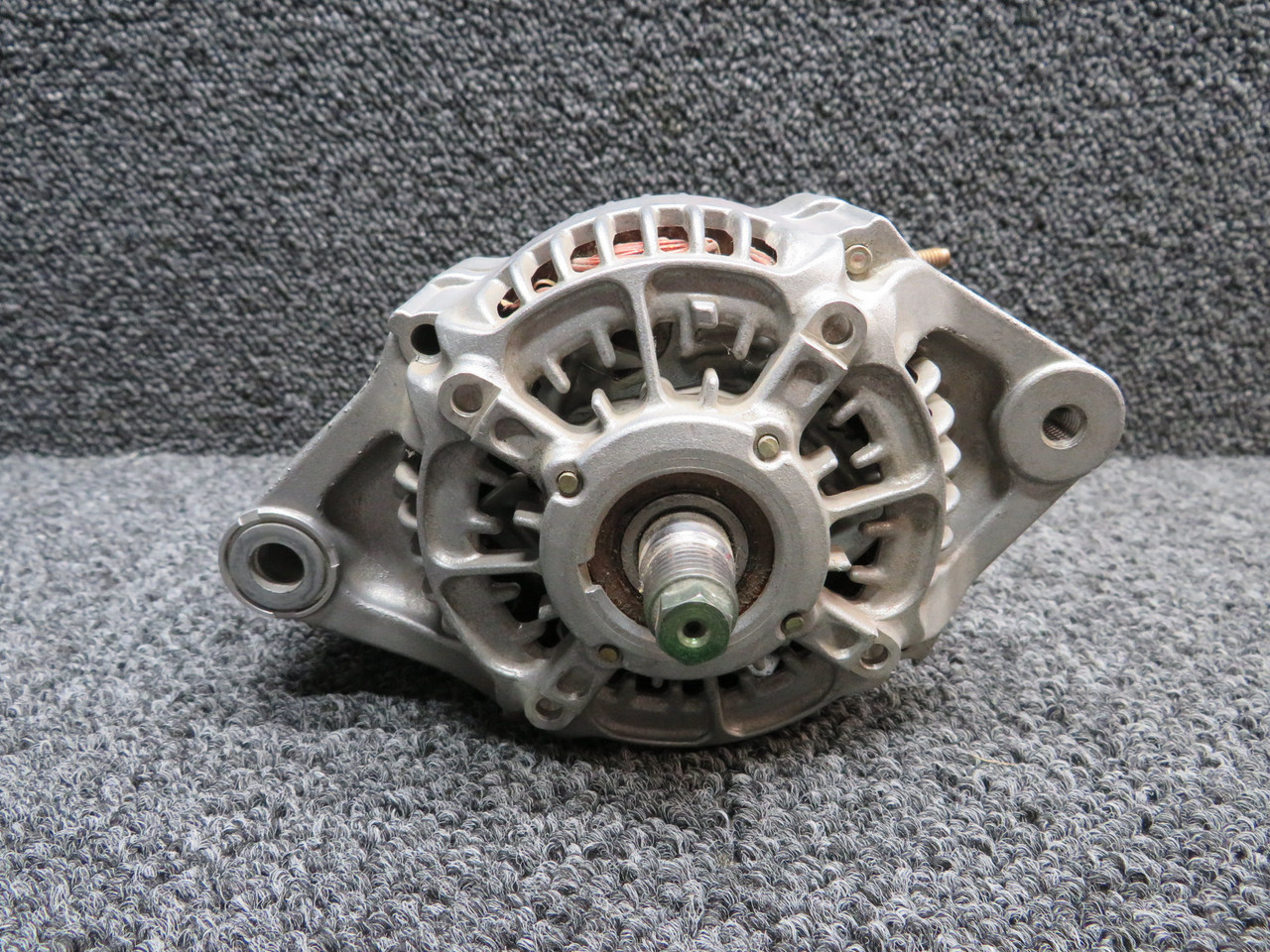

Illustrative image related to alternator assembly

What Role Does ‘Alternator Assembly’ Play in Renewable Energy Applications?

In renewable energy, particularly in wind turbine systems, alternator assemblies convert the mechanical energy produced by the turbine blades into electrical energy. This energy can then be used to supply power to the grid or charge batteries. Buyers from the Middle East and Europe should prioritize alternators that offer high efficiency and durability, especially in challenging weather conditions. Sourcing components that comply with international renewable energy standards can also enhance project viability and sustainability.

How Do ‘Alternator Assemblies’ Benefit the Marine Industry?

In the marine industry, alternator assemblies are essential for powering ships’ electrical systems, including navigation and communication tools. They provide a reliable electrical output necessary for safe maritime operations. Buyers in Europe and the Middle East should consider sourcing alternators that are resistant to corrosion and designed to function in high-vibration environments typical of marine applications. Compliance with maritime safety standards is also a critical factor in the sourcing process.

What is the Importance of ‘Alternator Assembly’ in Construction Equipment?

Heavy machinery in the construction industry relies on alternator assemblies to generate power for hydraulic systems and tools. This reliable power supply is crucial for maintaining productivity on job sites. International buyers, especially in developing regions, need to focus on sourcing alternators that are robust and capable of withstanding the rigors of heavy-duty operations. Factors such as thermal management capabilities and resistance to environmental conditions should be prioritized to ensure optimal performance.

How is ‘Alternator Assembly’ Utilized in Telecommunications?

In telecommunications, alternator assemblies are vital for backup power systems in cell towers, ensuring that communication services remain operational during power outages. This reliability is crucial for maintaining network integrity, particularly in remote areas. B2B buyers should focus on sourcing alternators that offer high reliability and low maintenance needs. Additionally, understanding the local power infrastructure and potential sourcing challenges in regions like Africa can help in selecting the most suitable alternator assemblies for these applications.

3 Common User Pain Points for ‘alternator assembly’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Alternator Assemblies

El problema: For B2B buyers, especially in regions like Africa and South America, sourcing high-quality alternator assemblies can be a daunting challenge. The market is flooded with low-cost alternatives that may not meet international quality standards. Buyers often face issues such as subpar performance, increased failure rates, and a lack of warranty support. This situation can lead to operational delays and increased maintenance costs, ultimately affecting the bottom line.

La solución: To effectively source quality alternator assemblies, buyers should prioritize partnerships with reputable manufacturers who adhere to international quality standards like ISO 9001. Conducting thorough due diligence, including factory visits and requesting product samples, can help assess the quality of the alternators. Additionally, leveraging industry trade shows and exhibitions can provide insights into reliable suppliers and innovative products. Establishing long-term relationships with trusted manufacturers can lead to better pricing and more reliable support, ensuring that the products meet the necessary performance criteria for various applications.

Scenario 2: Challenges with Technical Specifications and Compatibility

El problema: Another common pain point is the confusion surrounding technical specifications and compatibility of alternator assemblies with various vehicle models. Many buyers struggle to understand the specific requirements for their applications, leading to incorrect orders that can disrupt operations. The complexity increases when dealing with various international standards and specifications, particularly in regions with diverse vehicle types and models.

La solución: To overcome this challenge, B2B buyers should invest in comprehensive training for their procurement teams regarding technical specifications and compatibility issues. Working closely with engineers during the selection process can ensure that the right alternator assemblies are chosen based on the specific needs of the vehicles or equipment. Implementing a robust inventory management system that includes detailed specifications for each part can streamline the ordering process and reduce errors. Additionally, collaborating with suppliers who offer technical support can provide valuable insights and help clarify any compatibility concerns.

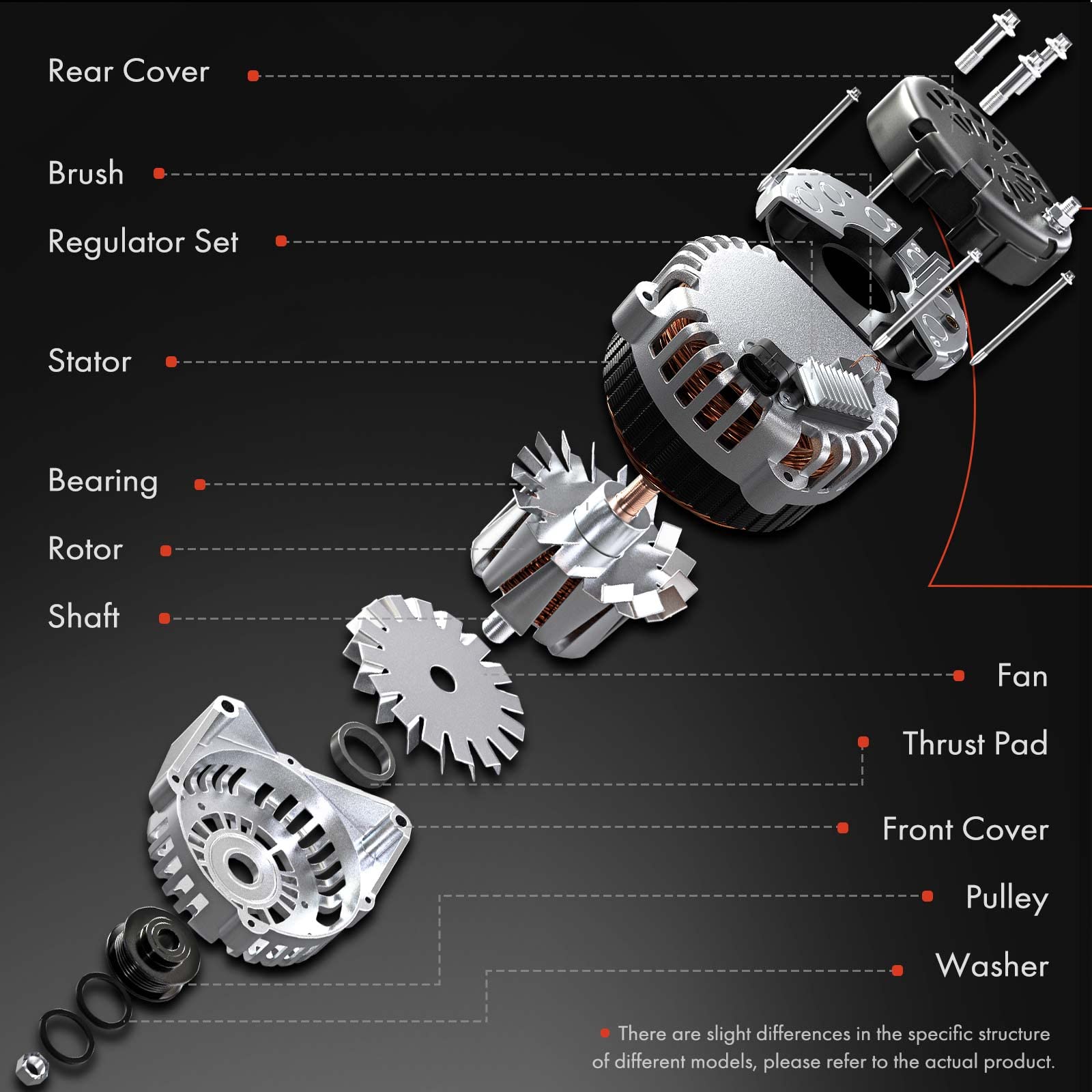

Illustrative image related to alternator assembly

Scenario 3: High Failure Rates and Performance Issues in Alternator Assemblies

El problema: B2B buyers often experience high failure rates and performance issues with alternator assemblies, which can lead to significant downtime and increased repair costs. This problem is exacerbated in regions with harsh environmental conditions, such as extreme heat or humidity, where lower-quality components are more likely to fail. Buyers may find themselves replacing alternators more frequently than anticipated, impacting overall operational efficiency.

La solución: To mitigate performance issues, buyers should focus on selecting alternator assemblies that are designed for durability and resilience in specific environmental conditions. This includes looking for products with enhanced cooling features, such as built-in fans or superior heat dissipation capabilities. Buyers should also consider investing in advanced diagnostics tools to monitor the health of the alternators in real-time, allowing for proactive maintenance before failures occur. Establishing a comprehensive maintenance schedule and training staff on best practices for installation and handling can further enhance the longevity and performance of alternator assemblies. Additionally, seeking out suppliers that offer warranties and service agreements can provide peace of mind and support in case of performance-related issues.

Strategic Material Selection Guide for alternator assembly

What Are the Key Materials Used in Alternator Assembly?

When selecting materials for alternator assembly, it’s crucial to consider not just the performance characteristics but also the economic and regulatory implications, especially for international B2B buyers. This analysis focuses on four common materials: aluminum, copper, steel, and plastic composites, each with unique properties and implications for performance and cost.

How Does Aluminum Benefit Alternator Assemblies?

Aluminum is a primary choice for the outer housing of alternators due to its lightweight nature and excellent thermal conductivity. Key properties include a high strength-to-weight ratio, good corrosion resistance, and the ability to dissipate heat effectively, which is vital for maintaining performance under high operational temperatures.

Illustrative image related to alternator assembly

Ventajas: Aluminum is durable and lightweight, which enhances fuel efficiency in vehicles. Its manufacturing process is relatively straightforward, allowing for cost-effective mass production.

Contras: While aluminum is resistant to corrosion, it can be susceptible to wear over time, especially in harsh environments. Additionally, it may not provide the same structural integrity as heavier metals under extreme stress.

Impacto en la aplicación: Aluminum’s thermal properties make it suitable for environments with high temperatures, ensuring efficient operation. However, buyers in regions with high humidity or saline conditions should consider additional protective coatings.

Consideraciones para compradores internacionales: Compliance with standards such as ASTM and DIN is essential. Buyers in Europe, particularly Germany, may favor aluminum due to its lightweight benefits, while those in the Middle East might require additional corrosion resistance.

Illustrative image related to alternator assembly

¿Qué papel desempeña el cobre en el rendimiento del alternador?

Copper is extensively used in the windings of both the rotor and stator due to its superior electrical conductivity. Key properties include high thermal and electrical conductivity, which are essential for efficient power generation.

Ventajas: Copper’s excellent conductivity ensures minimal energy loss, enhancing the alternator’s efficiency. It is also highly durable and resistant to corrosion when properly treated.

Contras: The primary downside of copper is its cost, which can be significantly higher than alternatives like aluminum. Moreover, it is heavier, which may not be ideal for all vehicle designs.

Impacto en la aplicación: Copper’s conductivity makes it suitable for high-performance applications where efficiency is paramount. However, in regions with high temperatures, it may require careful thermal management.

Illustrative image related to alternator assembly

Consideraciones para compradores internacionales: Buyers in South America and Africa should be aware of the fluctuating copper prices and consider sourcing strategies that mitigate costs. Compliance with international standards for electrical components is also crucial.

¿Cómo contribuye el acero a la integridad estructural de los alternadores?

Steel is often used for components that require high strength, such as the rotor shaft and internal supports. Key properties include high tensile strength and resistance to deformation under load.

Ventajas: Steel’s durability ensures that alternator components can withstand significant mechanical stress, making it ideal for heavy-duty applications.

Contras: Steel is heavier than aluminum and can be prone to corrosion if not treated properly. Manufacturing complexity can also increase costs due to the need for additional processing.

Impacto en la aplicación: Steel is suitable for applications requiring high strength and durability, particularly in commercial vehicles. However, its weight may impact overall vehicle efficiency.

Illustrative image related to alternator assembly

Consideraciones para compradores internacionales: Buyers in Europe may prefer steel components that meet stringent safety standards, while those in Africa and the Middle East may focus on cost-effectiveness and availability.

What Advantages Do Plastic Composites Offer in Alternator Assemblies?

Plastic composites are increasingly used for non-structural components, such as housings and insulation. Key properties include lightweight, corrosion resistance, and the ability to be molded into complex shapes.

Ventajas: Plastic composites reduce weight, which can enhance fuel efficiency. They also offer excellent resistance to environmental factors, such as moisture and chemicals.

Contras: While durable, plastic composites may not withstand high temperatures as well as metals. They can also be less effective in terms of mechanical strength compared to metals.

Impacto en la aplicación: Suitable for components that do not bear heavy loads, plastic composites can improve the overall efficiency of the alternator. However, their performance in extreme heat must be considered.

Consideraciones para compradores internacionales: Buyers in regions with high humidity or corrosive environments, like the Middle East, may find plastic composites particularly advantageous. Compliance with local and international standards is essential for quality assurance.

Summary Table of Material Selection for Alternator Assembly

| Material | Typical Use Case for alternator assembly | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Aluminio | Carcasa exterior | Lightweight and good heat dissipation | Susceptible to wear over time | Medio |

| Cobre | Rotor and stator windings | Excelente conductividad eléctrica | Alto coste y peso | Alto |

| Acero | Rotor shaft and internal supports | Alta resistencia y durabilidad | Más pesado y propenso a la corrosión. | Medio |

| Compuestos plásticos | Componentes no estructurales | Lightweight and corrosion resistant | Rendimiento limitado a altas temperaturas | Bajo |

This material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions that align with performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator assembly

¿Cuáles son las principales etapas de la fabricación de un alternador?

The manufacturing process for alternators involves several critical stages that ensure the final product meets the stringent demands of quality and performance. These stages include material preparation, forming, assembly, and finishing.

¿Cómo se prepara el material para la producción de alternadores?

Material preparation is the first step in alternator manufacturing. Key materials include aluminum for the housing, copper for the windings, and iron for the rotor core. Suppliers must ensure that materials meet specific standards, such as ASTM or ISO certifications, to guarantee their quality.

The aluminum is often pre-treated to enhance its corrosion resistance and improve its thermal conductivity, which is vital for heat dissipation during alternator operation. The copper windings are typically drawn to a precise gauge to ensure optimal electrical conductivity. Quality checks during this stage include verifying the material’s chemical composition and mechanical properties.

Illustrative image related to alternator assembly

¿Qué técnicas de conformado se utilizan en la fabricación de alternadores?

Once the materials are prepared, they undergo various forming techniques. Aluminum housings are typically produced through die casting or extrusion processes, which allow for precise shapes and tolerances. The rotor core is fabricated using stamping techniques to create the finger pole shapes necessary for effective magnetic field generation.

Copper windings are formed into coils using automated winding machines, ensuring consistent tension and alignment. This stage also involves the creation of the stator, which is assembled from multiple segments of copper wire. Quality assurance during forming includes dimensional inspections and non-destructive testing (NDT) methods to detect any material defects.

¿Cómo se lleva a cabo el proceso de montaje de los alternadores?

The assembly process is where all components come together. This stage typically follows a systematic workflow that begins with the rotor assembly. The rotor is installed onto the shaft, followed by the installation of brushes and slip rings, which are critical for electrical conduction.

Next, the stator is positioned around the rotor, ensuring the necessary clearance for high-speed operation. The diode rectifier and voltage regulator are then integrated into the assembly. Each connection is checked for continuity, and torque specifications are adhered to during the assembly of various components to prevent future failures.

What Finishing Techniques Are Applied in Alternator Manufacturing?

Finishing techniques are essential for enhancing the durability and functionality of the alternator. This stage often includes surface treatments such as anodizing or powder coating to protect the aluminum housing from corrosion and wear.

The finished alternators undergo a series of electrical tests to ensure they meet performance specifications. These tests can include load testing and output voltage verification to confirm that the alternators can provide the required electrical output under different operating conditions. Visual inspections are also conducted to check for any cosmetic defects.

What Quality Assurance Standards Are Relevant for Alternator Manufacturers?

Quality assurance in alternator manufacturing is critical to ensure the reliability and performance of the final product. International standards such as ISO 9001 provide a framework for quality management systems, emphasizing continuous improvement and customer satisfaction.

In addition to general quality standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the application of the alternator. For example, automotive alternators must comply with specific automotive industry standards to ensure they can withstand the rigorous conditions of vehicle operation.

¿Cuáles son los principales puntos de control de calidad en la fabricación de alternadores?

Quality control (QC) is embedded throughout the manufacturing process. Key checkpoints include:

-

Control de calidad de entrada (IQC): This initial inspection verifies that all incoming materials meet specified quality standards before they enter the production line.

-

Control de calidad durante el proceso (IPQC): During the manufacturing process, various checks are performed to ensure that components are being produced correctly. This includes dimensional checks, visual inspections, and functional testing of subassemblies.

-

Control de calidad final (FQC): Before shipment, the completed alternators undergo a final inspection and testing phase. This includes electrical testing to ensure they meet performance criteria and visual inspections to check for any manufacturing defects.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

B2B buyers have several options to ensure that their alternator suppliers maintain high-quality standards. One effective method is to conduct supplier audits, which can reveal the supplier’s adherence to quality management systems and production processes. These audits may include reviewing quality documentation, inspecting production facilities, and evaluating employee training programs.

Illustrative image related to alternator assembly

Buyers should also request quality control reports that detail inspection results and testing outcomes. Third-party inspections can provide an additional layer of assurance, as independent auditors can verify that suppliers meet international standards and specifications.

¿Qué matices deben tener en cuenta los compradores internacionales en relación con el control de calidad?

For international buyers, understanding the nuances of quality control can be crucial, especially when sourcing from different regions. Different countries may have varying regulations and standards, which can affect product quality and compliance.

Buyers from Africa, South America, the Middle East, and Europe should be particularly aware of regional certifications that may be required. For instance, in Europe, CE marking is mandatory for many electrical products, while in the Middle East, compliance with GCC standards might be necessary.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. It’s essential for buyers to establish clear specifications and maintain open lines of communication with suppliers to ensure mutual understanding of quality standards.

Conclusión

In conclusion, the manufacturing processes and quality assurance protocols for alternator assembly are complex and multifaceted. By understanding these processes and standards, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality alternators that meet their operational needs. Effective quality control not only safeguards product performance but also builds trust in supplier relationships, which is vital for long-term success in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator assembly’

To streamline your procurement process for alternator assemblies, this guide provides a step-by-step checklist tailored for B2B buyers. Whether you’re sourcing for automotive manufacturing or aftermarket supply, these actionable steps will ensure you make informed decisions.

Paso 1: Defina sus especificaciones técnicas

Before engaging with suppliers, it’s crucial to outline your technical requirements. This includes understanding the specific types of alternators you need, such as power output, size, and design features. Detailed specifications help in aligning your needs with supplier capabilities, minimizing the risk of mismatches.

- Potencia de salida: Determine the voltage and amperage required for your applications.

- Design Features: Consider factors like cooling mechanisms and housing materials.

Paso 2: Investigar e identificar posibles proveedores

Conduct thorough research to identify suppliers with a proven track record in alternator assembly. Look for companies that specialize in automotive components and have experience in your target markets.

- Reputación del sector: Check industry forums, reviews, and ratings to gauge supplier reliability.

- Geographic Presence: Consider suppliers with local presence or distribution capabilities in your target regions, such as Africa, South America, the Middle East, and Europe.

Paso 3: Evaluar las certificaciones de los proveedores

Verification of certifications is essential to ensure compliance with industry standards. Suppliers should possess relevant certifications such as ISO 9001 for quality management and any specific automotive industry standards.

- Garantía de calidad: Certifications indicate a commitment to quality, which is crucial for performance and safety.

- Cumplimiento normativo: Ensure suppliers meet local regulations in your target markets to avoid legal complications.

Paso 4: Request Samples and Prototypes

Before finalizing any supplier, request samples or prototypes of the alternator assemblies. This allows you to assess the quality and performance of the products firsthand.

- Pruebas de rendimiento: Evaluate the samples under real-world conditions to ensure they meet your specifications.

- Inspección de calidad: Look for signs of craftsmanship, such as the integrity of components and assembly precision.

Paso 5: Negociar los términos y condiciones

Once you’ve identified a suitable supplier, engage in negotiations to establish favorable terms. This includes pricing, payment terms, delivery schedules, and warranties.

Illustrative image related to alternator assembly

- Cost Structure: Understand the pricing model and negotiate for bulk discounts if applicable.

- Plazos de entrega: Ensure that the supplier can meet your production schedules to avoid delays.

Paso 6: Establish Communication Protocols

Effective communication with your supplier is key to a successful partnership. Set clear protocols for regular updates, feedback, and issue resolution.

- Point of Contact: Designate a representative from both sides for streamlined communication.

- Mecanismo de retroalimentación: Create a system for providing and receiving feedback on product quality and service.

Paso 7: Supervisar el rendimiento de los proveedores

After procurement, continuously monitor supplier performance against agreed-upon metrics. This includes quality control, delivery times, and responsiveness.

- Performance Reviews: Schedule regular assessments to ensure suppliers maintain their standards.

- Adapt and Improve: Be open to making adjustments in your procurement strategy based on performance insights.

By following this checklist, B2B buyers can effectively navigate the sourcing process for alternator assemblies, ensuring they partner with suppliers that meet their specific needs while maintaining quality and compliance.

Illustrative image related to alternator assembly

Comprehensive Cost and Pricing Analysis for alternator assembly Sourcing

Understanding the cost structure of alternator assembly sourcing is crucial for international B2B buyers aiming to make informed purchasing decisions. This analysis will delve into various cost components, price influencers, and provide actionable buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Alternator Assembly?

-

Materiales: The primary materials used in alternator assembly include aluminum for the housing, copper for the windings, and various plastics and metals for internal components like the rotor, stator, and rectifier. The quality and sourcing of these materials significantly affect the overall cost. For instance, high-grade aluminum and copper may raise the price but enhance durability and performance.

-

Trabajo: Labor costs can vary widely based on the location of the manufacturing facility. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the expertise and skill level of the workforce, as this can impact the quality of the alternators produced.

-

Gastos generales de fabricación: This includes expenses related to factory maintenance, utilities, and administrative costs. Efficient production processes can help mitigate overhead, thereby reducing overall costs.

-

Herramientas: The initial investment in tooling, such as molds and dies for manufacturing parts, can be substantial. However, these costs are often amortized over large production runs, which can lower the per-unit cost for high-volume orders.

-

Control de calidad (QC): Implementing stringent quality control measures is essential to ensure product reliability. While this adds to the upfront costs, it can reduce warranty claims and increase customer satisfaction, ultimately providing cost savings.

-

Logística: Shipping costs can fluctuate based on the distance to the buyer, shipping method, and current fuel prices. International buyers should factor in customs duties and taxes, which can significantly impact total costs.

-

Margen: Suppliers will typically add a margin to cover profit and risk. Understanding the industry standards for margins can help buyers assess whether a quoted price is fair.

¿Cómo influyen los precios en la compra de alternadores?

-

Volumen/MOQ (cantidad mínima de pedido): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider their current and future needs to negotiate the best pricing.

-

Especificaciones y personalización: Custom alternators designed to meet specific requirements (e.g., voltage, size) can incur additional costs. Clear communication about specifications can help avoid surprises in pricing.

-

Materiales y certificaciones de calidad: The choice of materials and the presence of quality certifications (ISO, TS16949) can influence costs. Buyers should weigh the benefits of higher quality against their budget constraints.

-

Factores relacionados con los proveedores: The supplier’s reputation, reliability, and production capacity can impact pricing. Established suppliers may charge more due to their proven track record, but they often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They define responsibilities regarding shipping, insurance, and tariffs, which can significantly influence the total landed cost.

¿Cuáles son los mejores consejos de negociación para compradores internacionales?

-

Volumen de apalancamiento: Use the potential for larger orders to negotiate better pricing. Suppliers are often willing to offer discounts for significant commitments.

-

Evaluar el coste total de propiedad (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, warranty claims, and potential downtime. This holistic view can justify a higher upfront investment in quality.

-

Comprender los matices de los precios: Be aware of regional pricing differences. For instance, European manufacturers may have higher costs due to labor and regulatory standards, while suppliers in Africa or South America might offer competitive pricing but variable quality.

-

Cultivate Relationships: Building strong relationships with suppliers can lead to better terms and pricing flexibility. Regular communication and trust can result in favorable negotiations.

-

Descargo de responsabilidad sobre los precios indicativos: Prices in the alternator assembly market can fluctuate based on various factors, including material costs and geopolitical events. It’s crucial to obtain current quotations and be prepared for adjustments.

By understanding these cost components and price influencers, international B2B buyers can make strategic sourcing decisions that align with their operational needs and budgetary constraints.

Alternatives Analysis: Comparing alternator assembly With Other Solutions

Exploring Alternatives to Alternator Assembly

In today’s evolving automotive landscape, B2B buyers must evaluate various power generation technologies to meet their specific requirements. While the alternator assembly has long been the industry standard for converting mechanical energy from the engine into electrical power, several alternative solutions are gaining traction. Understanding the strengths and weaknesses of each option can help businesses make informed decisions that align with their operational needs.

| Aspecto comparativo | Alternator Assembly | Regenerative Braking System | Battery Electric Systems |

|---|---|---|---|

| Rendimiento | High efficiency in energy conversion, consistent output. | Captures kinetic energy during braking, improving overall efficiency. | Provides instant power but depends on battery capacity and charging cycles. |

| Coste | Moderate initial investment; long lifespan reduces total cost of ownership. | Higher upfront costs due to complex integration with vehicle systems. | High initial costs for battery production and installation. |

| Facilidad de implementación | Relatively straightforward installation in most vehicles. | Requires specialized design and integration, which may complicate retrofitting. | Installation can be complex and requires infrastructure for charging. |

| Mantenimiento | Low maintenance with standard checks; durable components. | Requires periodic checks on braking systems and energy recovery mechanisms. | High maintenance costs associated with battery replacement and management systems. |

| Mejor caso de uso | Ideal for conventional internal combustion engine vehicles. | Best for hybrid and electric vehicles focused on energy efficiency. | Optimal for fully electric vehicles or applications where charging infrastructure is available. |

What Are the Benefits and Drawbacks of Regenerative Braking Systems?

Regenerative braking systems harness the kinetic energy produced during braking to recharge the vehicle’s battery. This technology is particularly beneficial in hybrid and electric vehicles, as it enhances overall energy efficiency. However, the complexity of integrating regenerative braking into existing systems can pose challenges for manufacturers. Additionally, the upfront costs associated with this technology are typically higher than those of traditional alternator assemblies, potentially making it a less attractive option for budget-conscious buyers.

How Do Battery Electric Systems Compare?

Battery electric systems rely solely on batteries to provide power, making them a clean energy solution for fully electric vehicles. These systems offer the advantage of immediate power delivery and zero emissions during operation. However, the reliance on battery capacity and the need for a robust charging infrastructure can limit their practicality, especially in regions with underdeveloped electric grids. Furthermore, the high initial costs for batteries can deter businesses from adopting this technology, despite its long-term cost-effectiveness.

Illustrative image related to alternator assembly

Making the Right Choice: How Should B2B Buyers Decide?

Choosing the right power generation technology depends on a variety of factors, including budget, vehicle type, and long-term operational goals. B2B buyers should consider the total cost of ownership, ease of integration, and the specific performance needs of their fleet. For traditional internal combustion engines, the alternator assembly remains a reliable choice, while hybrid and electric vehicles may benefit more from regenerative braking systems or battery electric solutions. Ultimately, aligning the choice of technology with the operational requirements will ensure optimal performance and cost efficiency.

Essential Technical Properties and Trade Terminology for alternator assembly

What Are the Critical Technical Properties of Alternator Assembly?

Understanding the technical specifications of alternators is crucial for international B2B buyers, especially when sourcing components for automotive applications. Here are some essential properties to consider:

1. Grado del material

Alternators are typically constructed from materials like aluminum and copper. The aluminum housing is lightweight, corrosion-resistant, and efficient at dissipating heat, which is vital for the longevity of the alternator. Copper windings in the stator and rotor enhance electrical conductivity. When sourcing alternators, verifying material grade ensures compliance with industry standards, which is critical for performance and safety.

2. Niveles de tolerancia

Tolerance levels pertain to the allowable deviations in dimensions during manufacturing. For alternator assemblies, precise tolerances are essential for parts like the rotor and stator, as improper fitting can lead to mechanical failures or inefficiencies. Buyers should seek manufacturers that adhere to stringent tolerance specifications to ensure high-quality output and reduce the likelihood of defects in assembly.

3. Eficiencia de refrigeración

Alternators generate significant heat during operation, necessitating effective cooling mechanisms. The design often includes internal cooling fans and venting systems to facilitate airflow. For B2B buyers, understanding cooling efficiency can impact the alternator’s performance in extreme environments, such as those found in hot climates prevalent in parts of Africa and the Middle East.

Illustrative image related to alternator assembly

4. Potencia eléctrica nominal

The electrical output rating indicates the maximum power the alternator can produce, usually measured in amperes (A). This specification is critical for ensuring that the alternator can meet the power demands of various automotive systems. Buyers must assess the electrical output requirements of their applications to avoid underperformance or system failures.

5. Peso

The weight of the alternator affects vehicle performance and fuel efficiency. Lighter alternators contribute to overall vehicle weight reduction, which is particularly beneficial in hybrid and electric vehicles. Buyers should consider weight specifications to align with their design and performance goals.

Which Industry Terms Should B2B Buyers Know for Alternator Assembly?

Familiarity with industry jargon can enhance communication between buyers and suppliers, ensuring that both parties are aligned on expectations and requirements.

1. OEM (fabricante de equipos originales)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of alternators, OEM parts are crucial for ensuring compatibility and reliability. Buyers often prefer OEM parts for quality assurance and warranty coverage.

2. MOQ (cantidad mínima de pedido)

MOQ is the minimum quantity a supplier is willing to sell. Understanding MOQ helps buyers plan their inventory and purchasing strategy. It’s essential to negotiate MOQs that align with production needs without incurring excess inventory costs.

3. RFQ (Solicitud de presupuesto)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. A well-prepared RFQ includes detailed specifications and quantities, allowing suppliers to provide accurate pricing. For B2B buyers, effective RFQs can lead to better pricing and service terms.

4. Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers, especially in regions with complex trade regulations, to avoid misunderstandings and ensure smooth logistics.

5. Plazo de entrega

Lead time refers to the time taken from placing an order to receiving the goods. This term is critical in supply chain management, as longer lead times can disrupt production schedules. Buyers should communicate clearly about lead times to ensure timely delivery of alternator assemblies.

Understanding these technical properties and trade terminologies will empower B2B buyers to make informed decisions when sourcing alternators, enhancing efficiency and reliability in their operations.

Illustrative image related to alternator assembly

Navigating Market Dynamics and Sourcing Trends in the alternator assembly Sector

What Are the Current Market Dynamics and Key Trends in the Alternator Assembly Sector?

The global alternator assembly market is witnessing significant growth, driven by the increasing demand for electric and hybrid vehicles, particularly in regions like Europe, the Middle East, Africa, and South America. As governments push for greener policies and sustainable transport solutions, manufacturers are focusing on producing high-efficiency alternators that meet stringent emissions regulations. This shift is creating new opportunities for B2B buyers to source innovative products that align with these evolving standards.

Emerging technologies such as IoT and smart manufacturing are reshaping the supply chain dynamics in the alternator assembly sector. Buyers are increasingly looking for suppliers who can integrate digital solutions into their manufacturing processes, enhancing operational efficiency and product quality. Additionally, the rise of e-commerce platforms has made it easier for international buyers to connect with manufacturers across different geographies, allowing for more competitive pricing and diverse sourcing options.

Market dynamics are also influenced by fluctuating raw material prices and supply chain disruptions, which have been particularly pronounced post-pandemic. Buyers from regions like Africa and South America should remain vigilant about geopolitical factors that could impact material availability, especially for components like copper and aluminum, which are critical for alternator manufacturing. Establishing robust relationships with suppliers and investing in local sourcing can mitigate risks associated with global supply chain volatility.

How Can Sustainability and Ethical Sourcing Impact the Alternator Assembly Sector?

Sustainability is becoming a non-negotiable factor for B2B buyers in the alternator assembly sector. The environmental impact of manufacturing processes, particularly regarding waste management and energy consumption, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and implementing sustainable practices.

Ethical sourcing is equally critical, as consumers and regulatory bodies demand transparency in supply chains. Buyers should seek suppliers who adhere to ethical standards, ensuring that raw materials are sourced responsibly and that workers are treated fairly. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to ethical practices.

Moreover, utilizing ‘green’ materials in alternator assembly, such as recyclable aluminum and eco-friendly coatings, can enhance product appeal and align with sustainability goals. Buyers should actively inquire about a supplier’s sustainability initiatives and consider long-term partnerships with those who prioritize ethical sourcing, as this can lead to improved brand reputation and customer loyalty.

Illustrative image related to alternator assembly

What Is the Brief Evolution and History of Alternator Technology?

The evolution of alternator technology has been marked by significant advancements since its inception in the early 20th century. Initially, vehicles utilized generators, which produced direct current (DC) electricity. However, as automotive technology progressed, the need for a more efficient and reliable power source led to the development of the alternator, which generates alternating current (AC) and converts it to DC for vehicle use.

By the 1960s, alternators began to replace generators in most vehicles, thanks to their ability to produce more power at lower engine speeds. Innovations such as the introduction of integrated voltage regulators and improved cooling systems further enhanced alternator performance. Today, the focus is on optimizing alternator efficiency, reducing weight, and integrating advanced electronic components to meet the demands of modern vehicles, particularly in the context of electric and hybrid models.

Understanding this history is crucial for B2B buyers as it highlights the technological advancements that have shaped the current landscape, enabling them to make informed decisions when sourcing alternator assemblies.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator assembly

-

1. How do I identify a reliable supplier for alternator assemblies?

To identify a reliable supplier for alternator assemblies, start by assessing their experience and reputation in the industry. Look for suppliers with a proven track record, positive reviews, and strong references from previous clients. Utilize platforms such as Alibaba, Global Sources, or trade shows to find potential suppliers. Additionally, verify their certifications (ISO, CE) and request samples to evaluate the quality of their products. Engaging in direct communication and establishing a rapport can further help gauge their reliability and responsiveness. -

2. What are the key specifications to consider when sourcing alternator assemblies?

When sourcing alternator assemblies, consider specifications such as voltage output, amperage rating, and compatibility with specific vehicle models. Additionally, evaluate the materials used (e.g., aluminum housing), cooling mechanisms, and the type of voltage regulator integrated into the assembly. Understanding these specifications will ensure that the alternator meets your operational requirements and enhances the efficiency of your vehicle’s electrical system. -

3. What customization options are available for alternator assemblies?

Many manufacturers offer customization options for alternator assemblies, including variations in size, voltage output, and design features. You can also request specific connectors, terminals, or finishes to match your application needs. When considering customization, communicate your requirements clearly and ask about lead times, costs, and any minimum order quantities (MOQs) that may apply. Customized solutions can enhance compatibility and performance in your specific applications. -

4. What are the typical minimum order quantities (MOQs) for alternator assemblies?

Minimum order quantities (MOQs) for alternator assemblies vary widely among suppliers, typically ranging from 50 to 1,000 units. Smaller manufacturers may accommodate lower MOQs, while larger suppliers might require higher volumes to justify production costs. When negotiating, express your needs and inquire if they can provide flexibility on MOQs, especially for new partnerships or trial orders. -

5. What payment terms should I expect when purchasing alternator assemblies?

Payment terms for purchasing alternator assemblies can differ significantly based on the supplier and your negotiation. Common terms include a deposit (30-50%) upfront with the balance due before shipment, or net payment terms (e.g., 30 days post-delivery). It’s crucial to discuss and agree upon payment methods (e.g., wire transfer, PayPal, letters of credit) early in the negotiation process to avoid any misunderstandings. -

6. How can I ensure quality assurance for alternator assemblies?

To ensure quality assurance for alternator assemblies, request detailed information about the supplier’s quality control processes and certifications. Many reputable manufacturers perform rigorous testing on their products, including electrical performance tests and durability assessments. Additionally, consider requesting batch testing reports or third-party inspection services to verify the quality of the assemblies before shipment. -

7. What logistics considerations should I keep in mind when importing alternator assemblies?

Logistics considerations include shipping methods, transit times, and customs regulations in your destination country. Evaluate whether air freight or sea freight is more suitable for your needs, considering cost and urgency. Additionally, familiarize yourself with import duties, taxes, and documentation required for customs clearance. Working with a freight forwarder can simplify the logistics process and ensure compliance with all regulations. -

8. How do I handle after-sales support and warranty issues for alternator assemblies?

When sourcing alternator assemblies, clarify the supplier’s warranty policy and after-sales support services. A standard warranty period ranges from 1 to 2 years, covering manufacturing defects. Ensure that you understand the process for claiming warranty service, including return procedures and potential shipping costs. Establishing a good relationship with your supplier can facilitate smoother communication and resolution of any issues that arise post-purchase.

Top 4 Alternator Assembly Manufacturers & Suppliers List

1. HowStuffWorks - Alternadores

Dominio: auto.cómofuncionanlascosas.com

Registrado: 1998 (27 años)

Introducción: Los alternadores son pequeños y ligeros, aproximadamente del tamaño de un coco, y están fabricados con una carcasa exterior de aluminio para la disipación del calor y la no magnetización. Los componentes clave incluyen:

– Polea motriz acoplada al eje del rotor, que convierte la energía mecánica en energía eléctrica.

– Several terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (…

2. AutoElectro – Alternator Components

Dominio: autoelectro.es

Registrado: 1999 (26 años)

Introducción: Alternator components and their functions include: 1. Regulator – controls power distribution from the alternator to the battery. 2. Rectifier – converts AC to DC during charging. 3. Rotor – spinning mass that acts as a spinning electromagnet. 4. Slip Rings – provide direct current and power to the rotor. 5. Slip Ring End Bearing – supports rotor shaft rotation. 6. Stator – consists of coils of wi…

3. GenPower USA – Alternator Parts for Generators

Dominio: genpowerusa.com

Registrado: 2001 (24 años)

Introducción: Alternator Parts for Generators including: STAMFORD Alternator Parts (Stators, Bearing Kits, Diodes and Varistors, Droop Kits, Isolation Transformers, PMG, Rectifier Assembly Kits, Space Heaters, Other Parts and Accessories), LEROY SOMER Alternator Parts (Diodes, Modules, PMG), MARELLI Alternator Parts (Rotating Rectifier Assemblies, Space Heaters, Other Parts and Accessories), Voltage Regulators …

4. Electude – Alternator

Dominio: electude.com

Registrado: 2005 (20 años)

Introducción: El alternador es un componente fundamental del automóvil que convierte la energía mecánica en energía eléctrica, generando energía para los consumidores eléctricos y la batería del vehículo. Entre sus componentes principales se incluyen:

– Polea: Transfiere la energía mecánica del motor.

– Rotor: crea el campo magnético para generar corriente alterna.

– Estator: La parte estática donde se genera el voltaje.

– Rectificador: …

Strategic Sourcing Conclusion and Outlook for alternator assembly

In summary, the assembly of alternators is a critical component for the automotive industry, providing essential electrical power for vehicles. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the complexities of alternator assembly can lead to more informed sourcing decisions. The lightweight aluminum construction, advanced cooling mechanisms, and efficient design of modern alternators enhance their performance and longevity, making them a worthwhile investment.

Strategic sourcing plays a pivotal role in optimizing costs while ensuring quality. By aligning with reputable manufacturers and suppliers, businesses can secure high-quality alternators that meet their specific operational needs. This not only enhances vehicle reliability but also fosters long-term partnerships that can adapt to market changes.

Illustrative image related to alternator assembly

Looking ahead, as the automotive sector increasingly embraces electric and hybrid technologies, the demand for innovative alternator solutions will continue to grow. International buyers are encouraged to actively engage with suppliers who offer cutting-edge designs and sustainable practices. By prioritizing strategic sourcing now, companies can position themselves advantageously in a competitive market and drive future success.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.

Illustrative image related to alternator assembly