Introduction: Navigating the Global Market for how to know if a starter is bad

In the intricate world of automotive parts procurement, understanding how to know if a starter is bad is crucial for international B2B buyers. A faulty starter can lead to significant downtime and unexpected costs, particularly for businesses relying on a fleet of vehicles. This guide comprehensively addresses the key indicators of starter failure, enabling you to swiftly identify issues before they escalate.

We will explore various types of starters, their applications across different vehicle models, and the common signs of malfunction, including unusual noises and dashboard warnings. Additionally, we will provide insights into the best practices for supplier vetting to ensure you source high-quality components that meet stringent international standards. Cost considerations and potential impacts on your operations will also be analyzed, giving you a holistic understanding of the market landscape.

By equipping yourself with this knowledge, you will empower your purchasing decisions, ensuring you select reliable starters that enhance vehicle performance and minimize operational disruptions. This guide is particularly tailored for B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including Brazil and Nigeria, where understanding local supplier dynamics and regional market trends is essential for effective sourcing.

Índice

- Top 1 How To Know If A Starter Is Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to know if a starter is bad

- Understanding how to know if a starter is bad Types and Variations

- Key Industrial Applications of how to know if a starter is bad

- 3 Common User Pain Points for ‘how to know if a starter is bad’ & Their Solutions

- Strategic Material Selection Guide for how to know if a starter is bad

- In-depth Look: Manufacturing Processes and Quality Assurance for how to know if a starter is bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if a starter is bad’

- Comprehensive Cost and Pricing Analysis for how to know if a starter is bad Sourcing

- Alternatives Analysis: Comparing how to know if a starter is bad With Other Solutions

- Essential Technical Properties and Trade Terminology for how to know if a starter is bad

- Navigating Market Dynamics and Sourcing Trends in the how to know if a starter is bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to know if a starter is bad

- Strategic Sourcing Conclusion and Outlook for how to know if a starter is bad

- Aviso legal importante y condiciones de uso

Understanding how to know if a starter is bad Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Indicadores auditivos | Clicking, grinding, or whirring sounds when starting | Talleres de reparación de automóviles, servicios de flotas | Ventajas: Diagnóstico rápido; Contras: May require further testing to confirm. |

| Electrical Symptoms | Dashboard lights up, but no engine response | Vehicle diagnostics, maintenance services | Ventajas: Indicates potential starter issues; Contras: Could be battery or alternator related. |

| Inspección visual | Oil-soaked starter or corroded connections | Auto parts suppliers, mechanics | Ventajas: Direct visual clues; Contras: Requires access to starter location. |

| Jump-Start Testing | Vehicle starts with jump, but not on its own | Centros de servicio de automoción | Ventajas: Simple test to isolate issues; Contras: Temporary solution, further diagnosis needed. |

| Performance Degradation | Gradual starting difficulties, slow cranking | Fleet management, transportation firms | Ventajas: Early detection of issues; Contras: May lead to unexpected downtime if not addressed. |

What Are the Key Characteristics of Auditory Indicators for Starters?

Auditory indicators are often the first signs of starter failure. Common sounds include clicking, grinding, or whirring when attempting to start the vehicle. These sounds typically suggest mechanical failure within the starter or an issue with electrical connections. For B2B buyers, recognizing these sounds can lead to timely repairs, minimizing vehicle downtime and operational disruptions.

How Do Electrical Symptoms Indicate Starter Issues?

Electrical symptoms manifest when the dashboard lights illuminate but the engine fails to respond. This situation may indicate a malfunctioning starter or could also be related to the battery or alternator. For businesses managing vehicle fleets, understanding these symptoms allows for efficient diagnostics, ensuring that technicians can quickly identify the root cause and implement necessary repairs.

Why Is Visual Inspection Important for Starters?

Visual inspection involves checking for oil-soaked starters or corroded connections, which can significantly impact starter performance. This method is particularly useful for mechanics and auto parts suppliers who need to assess components quickly. While it offers direct evidence of potential issues, accessibility to the starter can be a challenge, requiring skilled technicians for thorough inspections.

What Is the Significance of Jump-Start Testing?

Jump-start testing is a straightforward method to determine if the starter is functioning correctly. If a vehicle starts with a jump but fails to run independently, it often points to starter issues. This testing method is valuable for automotive service centers, providing a quick diagnostic tool to isolate problems. However, it is essential to follow up with comprehensive diagnostics to prevent future complications.

How Does Performance Degradation Indicate Starter Failure?

Performance degradation, such as slow cranking or difficulty starting, can be a precursor to starter failure. This gradual decline in performance is particularly critical for businesses in transportation and logistics. Early detection allows for proactive maintenance, reducing the risk of unexpected breakdowns and ensuring that vehicles remain operational. Addressing these issues promptly can save businesses from costly repairs and downtime.

Key Industrial Applications of how to know if a starter is bad

| Industria/Sector | Specific Application of how to know if a starter is bad | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Diagnostic services for starter issues in vehicles | Reduces downtime and repair costs for fleet operations | Access to quality diagnostic tools and skilled technicians |

| Equipos agrícolas | Maintenance checks on agricultural machinery starters | Ensures continuous operation during critical seasons | Availability of specialized starter components for diverse machinery |

| Equipos de construcción | Troubleshooting starter failures in heavy machinery | Minimizes project delays and enhances productivity | Reliable sourcing of starters and parts for various equipment types |

| Transporte y logística | Evaluating starters in commercial vehicles | Increases fleet reliability and reduces breakdowns | Partnerships with suppliers for bulk purchasing and warranties |

| Explotaciones mineras | Regular checks on starters of mining equipment | Mejora la seguridad y la eficacia operativa | Access to robust, durable starters suitable for harsh environments |

How Is ‘How to Know If a Starter Is Bad’ Applied in the Automotive Repair Sector?

In the automotive repair industry, understanding how to identify a faulty starter is crucial for efficient diagnostics. Repair shops often face challenges with vehicles that exhibit starting issues, which can stem from a bad starter. By implementing diagnostic services, technicians can quickly determine whether the starter or associated components (like the battery or alternator) are at fault, thus reducing vehicle downtime. For B2B buyers, sourcing high-quality diagnostic tools and ensuring technicians are well-trained are essential for maintaining service standards.

What Role Does Starter Diagnosis Play in Agricultural Equipment Maintenance?

In agriculture, machinery reliability is paramount, especially during peak seasons. Operators must frequently assess the health of starters in tractors and other equipment to avoid costly delays. By recognizing the signs of a failing starter, such as unusual noises or failure to engage, farmers can schedule timely repairs or replacements. Buyers in this sector should prioritize sourcing specialized starter components that cater to a variety of agricultural machinery, ensuring they can maintain operational continuity.

How Does Starter Troubleshooting Benefit Construction Equipment Management?

The construction industry relies heavily on heavy machinery, where starter failures can lead to significant project delays. By understanding how to identify starter issues, construction managers can implement proactive maintenance checks. This not only minimizes downtime but also enhances overall productivity on job sites. For B2B buyers, it’s important to establish reliable sourcing channels for robust starters that can withstand the demanding conditions typical in construction environments.

Why Is Starter Evaluation Important for Transportation and Logistics Fleets?

In the transportation and logistics sector, the reliability of commercial vehicles is critical. Regular evaluations of starters can prevent unexpected breakdowns, ensuring that deliveries are made on time. Companies benefit from implementing systematic checks and diagnostics to identify starter issues early. B2B buyers should focus on developing partnerships with suppliers that offer bulk purchasing options and extended warranties, which can enhance fleet management efficiency.

How Can Mining Operations Enhance Safety with Starter Inspections?

Mining operations often involve the use of heavy machinery in challenging conditions, making the reliability of starters essential for safety and efficiency. Regular inspections to determine the health of starters can help prevent equipment failures that could pose safety risks. By understanding the signs of a bad starter, mining companies can implement maintenance protocols that enhance operational efficiency. Buyers in this sector should seek durable starters designed to perform reliably in harsh environments, ensuring both safety and productivity.

3 Common User Pain Points for ‘how to know if a starter is bad’ & Their Solutions

Scenario 1: Difficulty Diagnosing the Root Cause of Starting Issues

El problema: For B2B buyers managing fleets or vehicle maintenance in sectors like logistics or transportation, accurately diagnosing starting issues can be a daunting task. When a vehicle fails to start, it can lead to significant downtime, impacting productivity and increasing operational costs. Buyers may struggle to determine whether the problem lies with the starter, battery, or alternator due to their interconnected nature. This uncertainty can cause frustration and delay in getting vehicles back on the road.

La solución: Implement a systematic troubleshooting process to isolate the issue. Start by conducting a visual inspection of the battery and connections for signs of corrosion or loose wires. Use a multimeter to check the battery voltage; a reading below 12.4 volts indicates a weak battery. Next, perform the “jump-start test” to see if the vehicle starts with external power. If it does, the battery may need replacement. Conversely, if the vehicle fails to start even after a jump, further investigate the starter and alternator. Engaging with a certified technician can also expedite the diagnosis, ensuring a quicker resolution and minimizing downtime.

Scenario 2: Understanding the Signs of a Failing Starter

El problema: B2B buyers often face the challenge of recognizing the subtle signs of a failing starter, particularly when dealing with multiple vehicles. Symptoms like grinding noises or intermittent starting issues can be misattributed to other components, leading to unnecessary repairs and costs. Buyers may find themselves questioning when to take action, risking further damage to the starter or related components.

La solución: Educate your team on the key indicators of a bad starter to enhance awareness and response time. Train staff to listen for distinct sounds such as clicking, grinding, or whirring when starting the vehicle. Encourage them to monitor dashboard indicators; if the engine fails to crank while lights and accessories function, this is a strong indicator of starter failure. Implement a scheduled inspection routine for starters, especially in older vehicles. Documenting symptoms and repair history can help identify patterns, allowing for proactive maintenance before a complete failure occurs.

Scenario 3: Sourcing Quality Starter Components for Replacement

El problema: Sourcing reliable starter components can be a significant concern for B2B buyers, especially in regions with fluctuating market conditions. Buyers may encounter counterfeit or substandard parts that not only fail to resolve the issue but can also exacerbate the problem, leading to increased repair costs and vehicle downtime. The challenge lies in identifying reputable suppliers and ensuring the quality of replacement starters.

La solución: Develop a robust supplier evaluation process to ensure quality and reliability in sourcing starter components. Look for suppliers with a proven track record in the automotive industry, particularly those that specialize in your vehicle types. Request certifications and warranties on parts to guarantee their authenticity and durability. Consider forming partnerships with local distributors who understand the regional market, ensuring timely access to quality components. Additionally, utilize performance data from your fleet to guide purchasing decisions, focusing on brands that have demonstrated longevity and reliability in similar conditions. This proactive approach will help mitigate risks and improve fleet performance over time.

Strategic Material Selection Guide for how to know if a starter is bad

What Materials Should Be Considered for Diagnosing a Bad Starter?

When assessing the performance of a starter, the materials used in its construction and the tools for diagnosis play a crucial role. Here, we analyze four common materials relevant to diagnosing a bad starter, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Copper in Starter Components?

Copper is widely used in electrical components due to its excellent conductivity. It has a high melting point of about 1,984°F (1,085°C), making it suitable for applications that experience significant heat. Additionally, copper exhibits good corrosion resistance, particularly when coated.

Ventajas: Copper’s high conductivity ensures efficient power transfer, which is essential for starter performance. It also has a relatively low cost compared to other conductive materials.

Contras: While copper is durable, it can be prone to corrosion if not properly treated, especially in humid or saline environments. This can lead to electrical failures over time.

Impacto en la aplicación: Copper’s compatibility with various electrical media makes it ideal for wiring and connections in starter systems. However, international buyers must consider local environmental conditions that may affect copper’s longevity.

Consideraciones internacionales: Compliance with standards such as ASTM B170 for copper wire is vital. Buyers in regions like Africa and South America should also be aware of local regulations regarding copper sourcing and recycling.

How Does Aluminum Compare as a Material for Starter Components?

Aluminum is another common material, particularly in starter housings and components due to its lightweight and corrosion-resistant properties. It has a melting point of about 1,221°F (660°C) and can withstand moderate temperatures.

Ventajas: Aluminum’s lightweight nature contributes to overall vehicle efficiency, and its corrosion resistance is beneficial in diverse environmental conditions.

Contras: While aluminum is less expensive than some metals, it is not as conductive as copper, which may lead to efficiency losses in electrical applications.

Impacto en la aplicación: Aluminum is suitable for non-load-bearing components, but its use in high-stress areas should be evaluated carefully.

Consideraciones internacionales: Compliance with standards like ASTM B221 for aluminum extrusions is essential. Buyers should also consider the availability of aluminum and its recycling processes in their regions.

¿Qué papel desempeña el acero en los sistemas de arranque?

Steel is often used in starter gears and casing due to its exceptional strength and durability. With a melting point of approximately 2,500°F (1,370°C), steel can withstand high temperatures and mechanical stress.

Ventajas: The high tensile strength of steel makes it ideal for components that require durability and resistance to wear and tear.

Contras: Steel is heavier than aluminum and copper, which can negatively impact vehicle weight and efficiency. It is also susceptible to rust if not properly coated.

Impacto en la aplicación: Steel’s robustness makes it suitable for critical components, but its weight must be managed in overall vehicle design.

Consideraciones internacionales: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers should also be aware of local regulations regarding steel sourcing and environmental impact.

How Effective is Plastic in Starter Diagnostics?

Plastic materials, particularly those designed for electrical insulation, are often used in starter relays and covers. They can withstand moderate temperatures and offer excellent electrical insulation properties.

Ventajas: Plastics are lightweight, cost-effective, and resistant to corrosion, making them a practical choice for non-load-bearing components.

Contras: Plastics may degrade over time under extreme temperatures or exposure to certain chemicals, which can compromise their effectiveness.

Impacto en la aplicación: Plastic is suitable for housing and insulation but should be evaluated for specific applications where heat and chemical exposure are concerns.

Consideraciones internacionales: Compliance with standards like ASTM D638 for plastic materials is essential. Buyers should also consider local regulations regarding plastic waste and recycling.

Summary Table of Material Selection for Starter Diagnostics

| Material | Typical Use Case for how to know if a starter is bad | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Cobre | Electrical connections and wiring in starters | Excelente conductividad | Susceptible a la corrosión | Medio |

| Aluminio | Carcasas de arranque y componentes ligeros | Ligero y resistente a la corrosión. | Conductividad inferior a la del cobre. | Medio |

| Acero | Gears and structural components in starters | Alta resistencia y durabilidad | Más pesado y propenso a oxidarse. | Medio |

| Plástico | Insulation and relay covers | Ligero y rentable | May degrade under extreme conditions | Bajo |

This analysis provides a comprehensive overview of materials relevant to diagnosing a bad starter, offering actionable insights for international B2B buyers in diverse markets. Understanding these materials will help buyers make informed decisions that align with their operational needs and local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for how to know if a starter is bad

¿Cuáles son las principales etapas del proceso de fabricación de los iniciadores?

Manufacturing starters involves several critical stages, each crucial for ensuring the final product’s reliability and performance. The main stages include material preparation, forming, assembly, and finishing.

-

Preparación del material: This initial stage involves selecting high-quality raw materials, such as copper for windings and durable metals for housing and gears. Suppliers often provide materials with certifications to verify their quality. The materials undergo inspection to ensure they meet specified standards, such as tensile strength and corrosion resistance.

-

Formación: In this stage, the prepared materials are shaped into components using various techniques like stamping, machining, and casting. Advanced machinery ensures precise dimensions, which is essential for the proper fit and function of the starter. Techniques like CNC machining may be employed for intricate parts to achieve high tolerances.

-

Ensamblaje: Once the components are formed, they are assembled into the starter unit. This process often involves automated assembly lines to enhance efficiency and reduce human error. Key components such as the solenoid, armature, and field windings are meticulously assembled, ensuring all electrical connections are secure and free of contaminants.

-

Acabado: The finishing stage involves applying protective coatings, such as galvanization or powder coating, to prevent corrosion and enhance durability. Final inspections are conducted to ensure that the starter meets all operational specifications and that no defects are present.

¿Cómo se implementa el control de calidad en la fabricación de arrancadores?

Quality assurance (QA) is paramount in the manufacturing of starters, ensuring that each unit meets industry standards and customer expectations. Various international and industry-specific standards guide the QA processes.

-

Normas internacionales pertinentes: Compliance with ISO 9001 is essential for manufacturers aiming to deliver consistent quality. This standard emphasizes a process-oriented approach to quality management, focusing on continual improvement and customer satisfaction. Other certifications like CE mark (for compliance with European health, safety, and environmental protection standards) may also be relevant depending on the market.

-

Normas específicas del sector: Depending on the application, specific standards like API (American Petroleum Institute) or SAE (Society of Automotive Engineers) may apply. These standards often dictate performance and safety requirements for automotive components, ensuring that starters are suitable for their intended use.

¿Cuáles son los principales puntos de control de calidad en la producción de arrancadores?

Quality control (QC) checkpoints are integral to the manufacturing process, helping to identify and rectify issues before products reach the market. Key checkpoints include:

-

Control de calidad de entrada (IQC): This initial checkpoint involves inspecting raw materials and components upon receipt. Suppliers must provide documentation and certifications for the materials, which undergo tests for conformity to specifications.

-

Control de calidad durante el proceso (IPQC): Throughout the manufacturing process, various inspections are performed to ensure that components are being manufactured correctly. This may involve monitoring tolerances during machining and checking assembly techniques to prevent defects.

-

Control de calidad final (FQC): Before dispatch, each starter undergoes a final inspection. This includes testing electrical performance, verifying fit and finish, and conducting functional tests to ensure the starter operates as intended under specified conditions.

Which Testing Methods Are Commonly Used to Assess Starter Quality?

Manufacturers employ a range of testing methods to verify the quality and functionality of starters. These methods can vary based on the application and intended use of the starter.

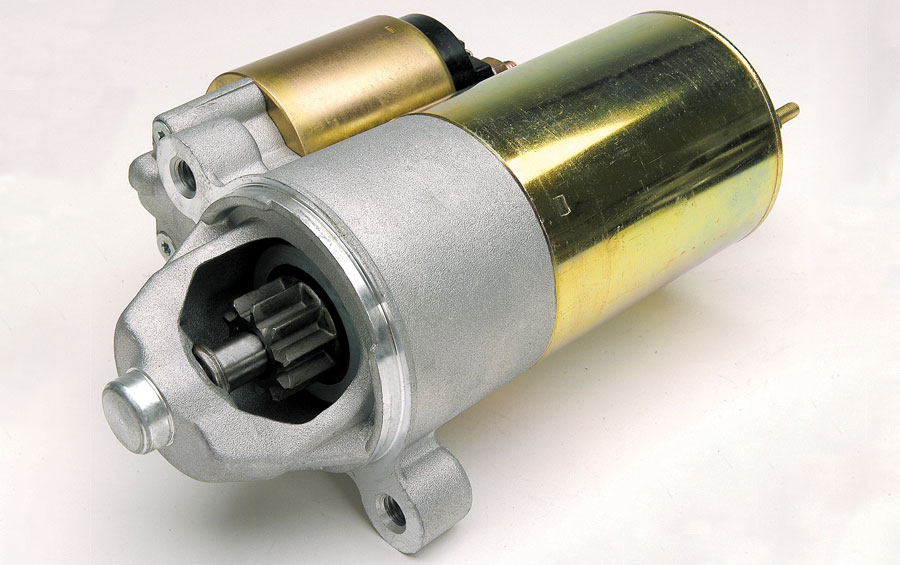

Illustrative image related to how to know if a starter is bad

-

Pruebas eléctricas: This includes checking the starter’s voltage draw, current draw, and resistance to ensure it operates within the specified limits. Functional tests simulate starting conditions to verify performance under load.

-

Pruebas mecánicas: Mechanical integrity tests assess the durability of components under stress. This may include torque tests to evaluate the starter’s ability to withstand operational forces without failure.

-

Pruebas medioambientales: Starters may undergo environmental testing to assess performance in extreme conditions, such as high temperatures or humidity. This ensures reliability in various climates, which is particularly relevant for B2B buyers in regions like Africa and South America.

¿Cómo pueden los compradores B2B verificar las prácticas de control de calidad de los proveedores?

When sourcing starters, B2B buyers should take proactive steps to verify their suppliers’ quality control practices. Here are some strategies to ensure supplier reliability:

-

Auditorías de proveedores: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. Auditors can evaluate the supplier’s facilities, equipment, and workforce practices.

-

Solicitud de informes de calidad: Buyers can request documentation that outlines the supplier’s quality control processes, including inspection reports, testing results, and certifications. This documentation should demonstrate compliance with relevant standards.

-

Inspecciones por terceros: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspectors can evaluate the manufacturing process and final products to ensure they meet specified requirements.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

International B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control:

-

Diferencias culturales: Different regions may have varying standards for quality and compliance. Understanding these differences is crucial for effective communication and setting expectations with suppliers.

-

Cumplimiento normativo: Buyers should ensure that their suppliers comply with local regulations in their respective markets. For example, automotive parts may need to meet specific safety and environmental regulations in Europe versus South America.

-

Consideraciones logísticas: Quality control processes may be influenced by shipping and logistics. Buyers should evaluate how delays or damage during transportation could affect product quality and what measures suppliers have in place to mitigate these risks.

By understanding the manufacturing processes and quality assurance protocols for starters, B2B buyers can make informed decisions, ensuring they source reliable and high-quality components for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if a starter is bad’

To assist B2B buyers in identifying a faulty starter, this guide provides a practical checklist. A well-functioning starter is crucial for vehicle reliability, and knowing how to diagnose issues can save time and resources. Follow these steps to ensure effective sourcing and evaluation of starters.

Illustrative image related to how to know if a starter is bad

Paso 1: Understand Starter Functionality

Before assessing a starter’s condition, familiarize yourself with its role in the vehicle’s electrical system. The starter engages the engine by drawing power from the battery, making it essential for vehicle operation. Understanding this mechanism helps in identifying symptoms of failure accurately.

Paso 2: Identify Common Symptoms of a Bad Starter

Recognizing the signs of a failing starter is crucial for timely intervention. Key symptoms include:

– Sonidos de clics when turning the key, indicating a lack of engagement.

– No engine response despite dashboard lights illuminating, which suggests a potential starter malfunction.

Documenting these symptoms can guide discussions with suppliers regarding potential replacements.

Paso 3: Conduct Preliminary Troubleshooting

Before sourcing a new starter, perform basic troubleshooting to rule out other issues. Check the battery and connections for corrosion or loose cables, as these can mimic starter problems. If possible, conduct a jump-start test; if the vehicle starts, the issue may lie with the battery or alternator rather than the starter.

Paso 4: Defina sus especificaciones técnicas

Clearly outline the specifications needed for your starter, including voltage, size, and compatibility with specific vehicle models. This helps in narrowing down supplier options and ensures that the components you source will meet operational requirements. Accurate specifications prevent costly mispurchases and downtime.

Illustrative image related to how to know if a starter is bad

Paso 5: Evaluar posibles proveedores

Thoroughly vet potential suppliers to ensure reliability and quality. Request documentation such as:

– Company profiles detailing their history and experience.

– Casos prácticos o testimonios from other B2B buyers, especially in your region.

This due diligence is essential for building a trustworthy supplier relationship and ensuring you receive quality parts.

Paso 6: Revisar las políticas de garantía y devolución

Before finalizing any purchase, examine the warranty and return policies offered by the supplier. A robust warranty indicates the supplier’s confidence in their product quality and provides you with peace of mind regarding potential defects. Understanding return policies also aids in managing any unexpected issues post-purchase.

Paso 7: Plan for Installation and Maintenance

Consider how the starter will be installed and maintained. Proper installation is critical for performance and longevity; therefore, ensure that you have access to qualified technicians. Additionally, inquire about maintenance recommendations from suppliers to ensure the starter’s optimal performance over time.

By following this checklist, B2B buyers can effectively evaluate and source starters, ensuring reliability and performance in their vehicle operations.

Comprehensive Cost and Pricing Analysis for how to know if a starter is bad Sourcing

What Are the Key Cost Components in Starter Sourcing?

When sourcing components like starters, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to how to know if a starter is bad

-

Materiales: This encompasses the raw materials used to manufacture starters, such as copper for wiring, steel for housing, and various electronic components. The quality of these materials can significantly impact both performance and durability.

-

Trabajo: Labor costs are tied to the workforce involved in the manufacturing process. Skilled labor may demand higher wages, which can influence the final pricing of the starter.

-

Gastos generales de fabricación: This includes costs associated with the production facilities, utilities, and equipment necessary for manufacturing starters. Efficient manufacturing processes can help reduce these costs.

-

Herramientas: Specialized tools and machinery required for starter production represent a fixed cost that must be amortized over the production volume.

-

Control de calidad (QC): To ensure that the starters meet industry standards, companies must invest in quality control measures. This may involve testing each component and ensuring compliance with relevant certifications.

-

Logística: Transporting starters from the manufacturing site to the buyer involves logistics costs, which can vary based on distance and shipping methods.

-

Margen: Finally, suppliers will add a profit margin to cover their costs and ensure profitability. Understanding this margin can be crucial for negotiating better pricing.

¿Cómo influyen los precios en los costes de arranque?

Several factors can influence the pricing of starters, particularly for international B2B buyers:

-

Volumen/Cantidad mínima de pedido: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often result in discounts, while smaller orders may incur higher per-unit costs.

-

Especificaciones/Personalización: Custom starters designed to meet specific operational requirements can lead to increased costs due to additional engineering and production processes.

-

Materiales: The choice of materials, such as high-quality copper versus standard alternatives, can affect the performance and longevity of the starter, thus influencing the price.

-

Calidad/Certificaciones: Products that meet international quality standards or possess certifications (e.g., ISO, CE) may command higher prices due to the assurance of reliability and performance.

-

Factores relacionados con los proveedores: The supplier’s reputation, location, and production capabilities can also affect pricing. Established suppliers with a track record of quality may charge more than newer or less reliable manufacturers.

-

Incoterms: The terms of trade (Incoterms) dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these can help avoid unexpected costs.

What Buyer Tips Can Enhance Cost Efficiency?

To navigate the complexities of sourcing starters effectively, consider the following tips:

-

Negociar con eficacia: Don’t hesitate to negotiate prices, especially if you’re placing a large order. Leverage your volume to secure better terms.

-

Evaluar el coste total de propiedad (TCO): Assess not just the initial purchase price but also the long-term costs associated with maintenance and potential failures. A higher upfront cost might be justified by lower maintenance costs.

-

Comprender los matices de los precios para los compradores internacionales: International buyers must be aware of currency fluctuations, import duties, and shipping costs that can impact the total cost. Researching local market conditions can also provide insight into fair pricing.

-

Considera a los proveedores locales: Sourcing from local manufacturers in regions like Africa or South America can reduce logistics costs and lead times, although it may require a trade-off in terms of quality or specifications.

-

Solicitud de muestras: Before committing to a large order, request samples to evaluate the quality and performance of the starters. This can prevent costly mistakes later on.

Conclusión

Understanding the cost structure and pricing influencers for starters is vital for international B2B buyers looking to make informed purchasing decisions. By taking into account the various cost components, engaging in effective negotiation, and considering the total cost of ownership, businesses can optimize their sourcing strategy. Remember to stay informed about market dynamics and supplier capabilities to ensure successful procurement.

Alternatives Analysis: Comparing how to know if a starter is bad With Other Solutions

Exploring Alternatives to ‘How to Know If a Starter Is Bad’

In the automotive sector, diagnosing a faulty starter is crucial for vehicle maintenance and operational efficiency. While traditional methods provide valuable insights, alternative solutions may offer enhanced diagnostics or preventative measures. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their operational needs.

| Aspecto comparativo | How To Know If A Starter Is Bad | Alternative 1: Battery Tester | Alternative 2: Diagnostic Scanner |

|---|---|---|---|

| Rendimiento | Effective in identifying starter issues through sound and behavior analysis. | Primarily identifies battery health; may indirectly indicate starter problems. | Comprehensive diagnostics for multiple vehicle systems, including starters. |

| Coste | Generally low cost, primarily requiring basic tools or service fees. | Affordable battery testers range from $20 to $100. | Diagnostic scanners can range from $50 to $500 depending on features. |

| Facilidad de implementación | Requires basic knowledge of vehicle systems; relatively straightforward. | User-friendly; can be used by non-professionals. | May require training to interpret results accurately. |

| Mantenimiento | Low; occasional inspection needed. | Low; battery testers require minimal upkeep. | Moderate; software updates and familiarity with new diagnostic features needed. |

| Mejor caso de uso | Ideal for quick checks and immediate troubleshooting when a vehicle won’t start. | Best for assessing battery health before diagnosing starter issues. | Optimal for comprehensive vehicle health checks, especially in fleet management. |

What Are the Benefits and Drawbacks of Using a Battery Tester?

Battery testers are a practical alternative for diagnosing electrical issues in vehicles. These devices are designed to assess battery health by measuring voltage and load capacity. A significant advantage is their cost-effectiveness and ease of use, making them accessible for both professional and amateur mechanics. However, their primary limitation is that they do not directly diagnose starter issues. Instead, they may only indicate a battery problem, which can lead to misdiagnosis if the starter is indeed at fault.

How Does a Diagnostic Scanner Compare to Traditional Methods?

Diagnostic scanners provide a more sophisticated alternative, offering comprehensive analysis across multiple vehicle systems, including the starter. These tools can read error codes and monitor real-time data, giving a clearer picture of potential issues. Their versatility makes them invaluable for fleet management or for businesses that service a variety of vehicles. However, the cost and complexity of these devices can be prohibitive for smaller operations, and users may need training to effectively interpret the data.

Conclusión: ¿Cómo pueden los compradores B2B elegir la solución adecuada a sus necesidades?

Selecting the appropriate diagnostic method hinges on the specific needs of the buyer. For businesses focused on quick diagnostics and minimal investment, traditional methods for identifying starter issues remain effective. In contrast, those seeking a more comprehensive approach may find value in investing in battery testers or diagnostic scanners. Ultimately, understanding the operational context and potential challenges will guide B2B buyers in choosing the right solution that not only addresses immediate needs but also enhances overall vehicle maintenance efficiency.

Essential Technical Properties and Trade Terminology for how to know if a starter is bad

What Key Technical Properties Should You Consider for Assessing a Starter’s Condition?

Understanding the technical properties of starters is crucial for B2B buyers to ensure they are making informed purchasing decisions. Below are essential specifications that can help in identifying a faulty starter.

1. Grado del material

The materials used in the construction of a starter significantly impact its durability and performance. High-grade materials, such as reinforced steel or composite plastics, resist wear and corrosion, which is vital in harsh environments. For international buyers, especially in regions with extreme weather conditions, selecting starters made from superior materials can enhance longevity and reliability.

2. Par nominal

The torque rating of a starter indicates its ability to turn the engine over. A higher torque rating is often necessary for larger engines or those in heavy-duty applications. Understanding the torque requirements for different vehicle models allows buyers to select the appropriate starter, thereby avoiding potential engine starting issues.

3. Especificaciones eléctricas

Key electrical properties include voltage ratings and current draw. Most starters operate at 12 volts, but it is essential to confirm compatibility with the specific vehicle’s electrical system. Additionally, the current draw during operation should be within the acceptable range to prevent overheating and ensure efficient performance.

4. Niveles de tolerancia

Tolerance refers to the allowable deviation in the dimensions of starter components. Precise tolerances are crucial for optimal fit and function, especially in systems where multiple parts interact closely. Inadequate tolerances can lead to premature wear or failure, making it vital for buyers to understand the specifications provided by manufacturers.

5. Test Standards Compliance

Look for starters that comply with industry test standards, such as ISO or SAE certifications. These standards ensure that the products meet specific performance and safety criteria. Compliance can serve as a quality assurance indicator, particularly important for international buyers looking for reliable products.

6. Periodo de garantía

The warranty period offered by manufacturers reflects the confidence they have in their products. A longer warranty can be indicative of superior quality and durability. For B2B buyers, understanding the warranty terms can help mitigate risks associated with purchasing faulty components.

What Common Trade Terms Should You Know When Dealing with Starters?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to starters.

1. OEM (fabricante de equipos originales)

OEM refers to parts made by the original manufacturer of the vehicle. Buying OEM starters ensures compatibility and quality, which is crucial for maintaining vehicle performance. B2B buyers often prefer OEM parts for their reliability and warranty support.

Illustrative image related to how to know if a starter is bad

2. MOQ (cantidad mínima de pedido)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for inventory management, as it helps buyers plan their purchases effectively. For international buyers, MOQs can also influence shipping costs and overall procurement strategies.

3. RFQ (Solicitud de presupuesto)

An RFQ is a document used to solicit price quotes from suppliers. It typically outlines the specifications and quantities needed. For B2B buyers, issuing RFQs can streamline the procurement process and ensure competitive pricing.

4. Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly concerning shipping and delivery. Familiarity with these terms helps buyers understand their obligations and rights, which is critical for smooth transactions across borders.

5. Plazo de entrega

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory planning and ensuring that operations remain uninterrupted. For global buyers, lead times can vary significantly based on shipping routes and customs processes.

6. Mercado de repuestos

Aftermarket refers to parts and accessories made by companies other than the original manufacturer. While these can offer cost savings, they may vary in quality and compatibility. B2B buyers should carefully evaluate aftermarket options to ensure they meet performance standards.

In summary, understanding these technical properties and trade terms is essential for B2B buyers to make informed decisions regarding starter purchases. By focusing on quality, specifications, and industry jargon, businesses can enhance their procurement strategies and ensure reliable vehicle performance.

Navigating Market Dynamics and Sourcing Trends in the how to know if a starter is bad Sector

What Are the Key Market Dynamics Influencing the Starter Industry?

The global automotive starter market is experiencing a transformative phase driven by several key factors. The increasing demand for electric vehicles (EVs) is reshaping the starter’s role, as manufacturers pivot towards integrating advanced technology to accommodate hybrid and fully electric systems. Furthermore, the rise in vehicle electrification necessitates a deeper understanding of how starters function in conjunction with batteries and alternators. This trend is particularly pronounced in emerging markets like Nigeria and Brazil, where the automotive sector is rapidly evolving.

International B2B buyers must also navigate the complexities of sourcing components across different regions. Supply chain disruptions, exacerbated by geopolitical tensions and the COVID-19 pandemic, have highlighted the need for diversified sourcing strategies. Companies are increasingly seeking reliable suppliers who can provide high-quality starters that meet stringent performance standards. Additionally, digital transformation in procurement processes, such as the adoption of e-sourcing platforms and AI-driven analytics, is becoming essential for buyers to make informed decisions quickly.

The growth of the aftermarket for starters is another critical trend. As vehicles age, the demand for replacement starters is expected to rise, especially in regions with older fleets. B2B buyers should remain vigilant about the latest diagnostic tools and technologies that facilitate the identification of starter issues, enabling them to offer superior service to their customers.

Illustrative image related to how to know if a starter is bad

How Can Sustainability and Ethical Sourcing Impact the Starter Supply Chain?

Sustainability is increasingly becoming a priority in the B2B landscape, particularly in the automotive sector. Buyers are now more aware of the environmental impacts associated with traditional manufacturing processes, prompting a shift towards sustainable practices. This includes sourcing starters made from recycled materials or those produced through environmentally friendly processes.

Ethical sourcing is equally important, as consumers and businesses alike demand transparency in supply chains. B2B buyers should consider suppliers who adhere to sustainable practices, such as reducing carbon footprints and ensuring fair labor practices. Certifications like ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability.

Additionally, the focus on “green” materials is gaining traction. Buyers should prioritize starters that utilize eco-friendly components or materials that have minimal environmental impact throughout their lifecycle. This not only aligns with global sustainability goals but also enhances brand reputation, making companies more attractive to environmentally conscious consumers.

What Is the Historical Context of Starters in the Automotive Industry?

The automotive starter has evolved significantly since its inception in the early 20th century. Originally powered by hand-crank mechanisms, starters transitioned to electric systems in the 1910s, revolutionizing vehicle operation. This shift allowed for greater convenience and efficiency, setting the foundation for modern automotive technology.

As the automotive industry progressed, the design and functionality of starters improved, influenced by advancements in electrical engineering and materials science. In recent years, the focus has shifted towards enhancing the starter’s reliability and efficiency, particularly in light of growing environmental regulations and the push for electrification. This evolution underscores the necessity for B2B buyers to stay informed about technological advancements and emerging trends in starter systems to maintain competitiveness in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of how to know if a starter is bad

-

How do I diagnose a bad starter in a vehicle?

To diagnose a bad starter, start by observing any unusual sounds such as clicking or grinding when turning the key. If the dashboard lights up but the engine doesn’t turn over, this can indicate a starter issue. You can also perform a jump-start test; if the vehicle starts with a jump but won’t run afterward, the starter may be faulty. If the starter appears oil-soaked or overheated, these are further signs of potential failure. Always consult a professional technician for a thorough inspection. -

What are the common symptoms of a failing starter?

Common symptoms of a failing starter include a clicking noise when trying to start the vehicle, the engine not responding at all, or intermittent starting issues. Additionally, if you notice smoke or a burning smell after repeated attempts to start, this indicates serious problems. Dashboard lights may remain illuminated without engine response, further suggesting a starter malfunction. Understanding these symptoms can help you make informed decisions when sourcing replacement starters. -

How can I ensure the quality of starters when sourcing internationally?

To ensure quality when sourcing starters internationally, consider conducting thorough supplier vetting. Request product samples and certifications to assess quality standards. Look for suppliers with a proven track record and customer reviews. Additionally, establish clear quality assurance processes, such as inspections before shipment. Collaborating with local partners who understand regional compliance and quality standards can also enhance your sourcing strategy. -

¿Qué opciones de personalización hay para los principiantes?

Customization options for starters can vary by manufacturer but may include modifications such as voltage adjustments, size specifications, and connector types to fit specific vehicle models. When negotiating with suppliers, clearly outline your requirements and inquire about their capabilities to accommodate these changes. Custom solutions can improve compatibility and performance, ensuring that the starter meets your operational needs. -

What are typical minimum order quantities (MOQ) for starters?

Minimum order quantities (MOQ) for starters can differ significantly between suppliers, often ranging from 100 to 1,000 units. Factors influencing MOQ include the supplier’s production capacity, customization options, and market demand. It’s advisable to discuss MOQs during initial negotiations and explore the possibility of smaller test orders to evaluate product quality before committing to larger quantities. -

What payment terms should I expect when sourcing starters?

Payment terms when sourcing starters can vary widely but typically include options such as advance payment, partial payment before shipment, or net payment terms post-delivery. Establishing clear payment conditions is crucial to mitigate risks. Many suppliers may accept letters of credit or escrow services for larger orders, providing security for both parties. Always negotiate payment terms that align with your cash flow and risk management strategies. -

How do I handle logistics when importing starters?

Handling logistics when importing starters involves coordinating with freight forwarders and understanding customs regulations in your country. Assess shipping options, including air and sea freight, based on budget and urgency. Ensure that all documentation, such as invoices and certificates of origin, is accurate to avoid delays. Additionally, consider warehousing solutions for inventory management once the starters arrive at your destination. -

What should I include in my quality assurance (QA) process for starters?

Your quality assurance (QA) process for starters should include several key components: initial supplier audits, product sampling, and regular inspections during production. Establish clear specifications and performance standards that the starters must meet. Implement testing protocols for electrical performance, durability, and compatibility with intended vehicles. Documenting these processes will help ensure that only high-quality starters reach your customers, enhancing your brand’s reputation.

Top 1 How To Know If A Starter Is Bad Manufacturers & Suppliers List

1. BMW – Starter Replacement Symptoms

Dominio: e90post.com

Registrado: 2005 (20 años)

Introducción: BMW Starter Replacement Symptoms: Weak crank during start, intermittent starting issues, potential battery-related problems. Common models affected include E90, E92, E93 (2006-2013), and other BMW models across various generations. Recommendations include testing the battery first and checking for starter-related symptoms such as distinct struggling noise or failure to start.

Strategic Sourcing Conclusion and Outlook for how to know if a starter is bad

As you navigate the complexities of identifying a bad starter, it’s essential to understand the interconnectedness of your vehicle’s electrical system. Recognizing symptoms such as unusual sounds, dashboard alerts, and non-responsive engines can significantly reduce diagnostic time and costs. Effective troubleshooting, including jump-start tests and visual inspections, empowers B2B buyers to make informed decisions about repairs or replacements.

Strategic sourcing plays a pivotal role in ensuring access to high-quality components. By establishing relationships with reliable suppliers, businesses can secure starters that meet rigorous performance standards, ultimately enhancing vehicle reliability and operational efficiency. This is especially crucial for buyers in regions like Africa, South America, the Middle East, and Europe, where access to dependable automotive parts can impact logistics and service delivery.

Looking ahead, it’s vital to prioritize proactive maintenance and sourcing strategies that will not only mitigate downtime but also optimize fleet performance. Engage with trusted suppliers who understand your market’s unique needs and are committed to delivering quality products. Together, let’s drive toward a future where your fleet operates smoothly, ensuring your business remains competitive and resilient in a rapidly evolving landscape.

Illustrative image related to how to know if a starter is bad

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.