Introducción: Navegando por el mercado mundial de cuánto cuesta cambiar un motor de arranque

In the complex landscape of automotive maintenance, understanding the costs associated with changing a starter is crucial for B2B buyers across diverse regions. Whether you are sourcing parts for a fleet in Africa, managing vehicle services in South America, or overseeing automotive repairs in Europe, the challenge remains the same: obtaining reliable information on starter replacement costs and procedures. This guide aims to demystify the expenses involved in changing a starter by providing a comprehensive overview of various factors, including types of starters, applications across different vehicle models, and supplier vetting processes.

B2B buyers will benefit from detailed insights into the cost ranges for starter parts and labor, which can significantly vary based on vehicle make, model, and geographic location. Additionally, this guide addresses the intricacies of sourcing quality components and services, empowering decision-makers to make informed purchasing choices that align with their operational needs. With a focus on international markets, including Germany and Brazil, this resource equips businesses with the necessary tools to navigate the global market effectively. By leveraging the information provided, companies can optimize their maintenance budgets, enhance service reliability, and ultimately improve their bottom line.

Índice

- Top 6 fabricantes & proveedores de Cuánto cuesta cambiar un motor de arranque Lista

- Introducción: Navegando por el mercado mundial de cuánto cuesta cambiar un motor de arranque

- Saber cuánto cuesta cambiar un motor de arranque Tipos y variaciones

- Aplicaciones industriales clave de cuánto cuesta cambiar un motor de arranque

- 3 puntos de fricción habituales entre los usuarios sobre ‘cuánto cuesta cambiar un motor de arranque’ y sus soluciones

- Guía estratégica de selección de materiales para cuánto cuesta cambiar un motor de arranque

- En profundidad: Procesos de fabricación y garantía de calidad para cuánto cuesta cambiar un motor de arranque

- Guía práctica de contratación: Una lista de comprobación paso a paso para ‘cuánto cuesta cambiar un motor de arranque’

- Análisis exhaustivo de costes y precios de cuánto cuesta cambiar un motor de arranque Sourcing

- Análisis de Alternativas: Comparación de cuánto cuesta cambiar un motor de arranque con otras soluciones

- Propiedades técnicas esenciales y terminología comercial para cuánto cuesta cambiar un motor de arranque

- Navegar por la dinámica del mercado y las tendencias de aprovisionamiento en el sector ¿Cuánto cuesta cambiar un motor de arranque?

- Preguntas frecuentes para compradores B2B sobre cuánto cuesta cambiar un motor de arranque

- Strategic Sourcing Conclusion and Outlook for cuánto cuesta cambiar un motor de arranque

- Aviso legal importante y condiciones de uso

Saber cuánto cuesta cambiar un motor de arranque Tipos y variaciones

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Reemplazo del motor de arranque OEM | Original parts from the vehicle manufacturer | Concesionarios de automóviles, servicios de flotas | Ventajas: Guaranteed fit and performance; warranty. Contras: Mayor coste en comparación con las opciones de posventa. |

| Motor de arranque aftermarket | Third-party parts that meet or exceed OEM specifications | Independent repair shops, wholesalers | Ventajas: Cost-effective; wide variety of options. Contras: Variable quality; may not always match OEM specifications. |

| Motor de arranque reconstruido | Refurbished original starters with replaced components | Auto parts retailers, repair shops | Ventajas: Eco-friendly; lower cost than new starters. Contras: Limited warranty; potential for inconsistent quality. |

| Performance Starter | High-performance starters designed for specific applications | Equipos de carreras, tiendas de alto rendimiento | Ventajas: Enhanced starting power; designed for high-stress conditions. Contras: Higher price; may not be suitable for everyday vehicles. |

| Kits de inicio para bricolaje | Kits that include all necessary parts for self-installation | DIY enthusiasts, small repair shops | Ventajas: Cost savings; empowers buyers to learn. Contras: Requires mechanical skills; potential for errors if not installed correctly. |

What are the Key Features of OEM Starter Replacements?

OEM (Original Equipment Manufacturer) starters are specifically designed to match the exact specifications of the vehicle manufacturer. They are often more reliable due to rigorous testing and quality standards. For B2B buyers, particularly those in automotive dealerships or fleet services, OEM starters provide peace of mind with warranties and guaranteed compatibility. However, the higher cost may deter budget-conscious buyers who are looking for more economical solutions.

How Do Aftermarket Starters Compare in Terms of Cost and Quality?

Aftermarket starters are produced by third-party manufacturers and can often be more affordable than OEM options. They cater to a wide range of vehicles and are particularly popular among independent repair shops and wholesalers. While many aftermarket starters meet or exceed OEM specifications, buyers should be cautious about quality variations. Performing due diligence on suppliers and understanding warranty policies is essential for B2B buyers considering these options.

What Should You Know About Rebuilt Starters?

Rebuilt starters are original starters that have been refurbished and had worn components replaced. They offer a more sustainable option for buyers looking to save costs while minimizing waste. Auto parts retailers and repair shops often stock these products. While they are generally cheaper than new starters, buyers should consider the limited warranties and potential quality inconsistencies that can come with rebuilt parts.

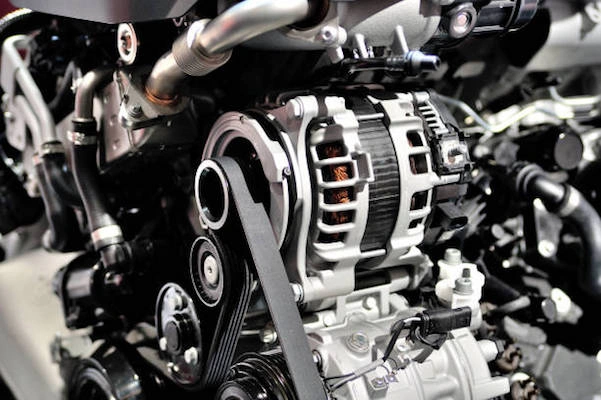

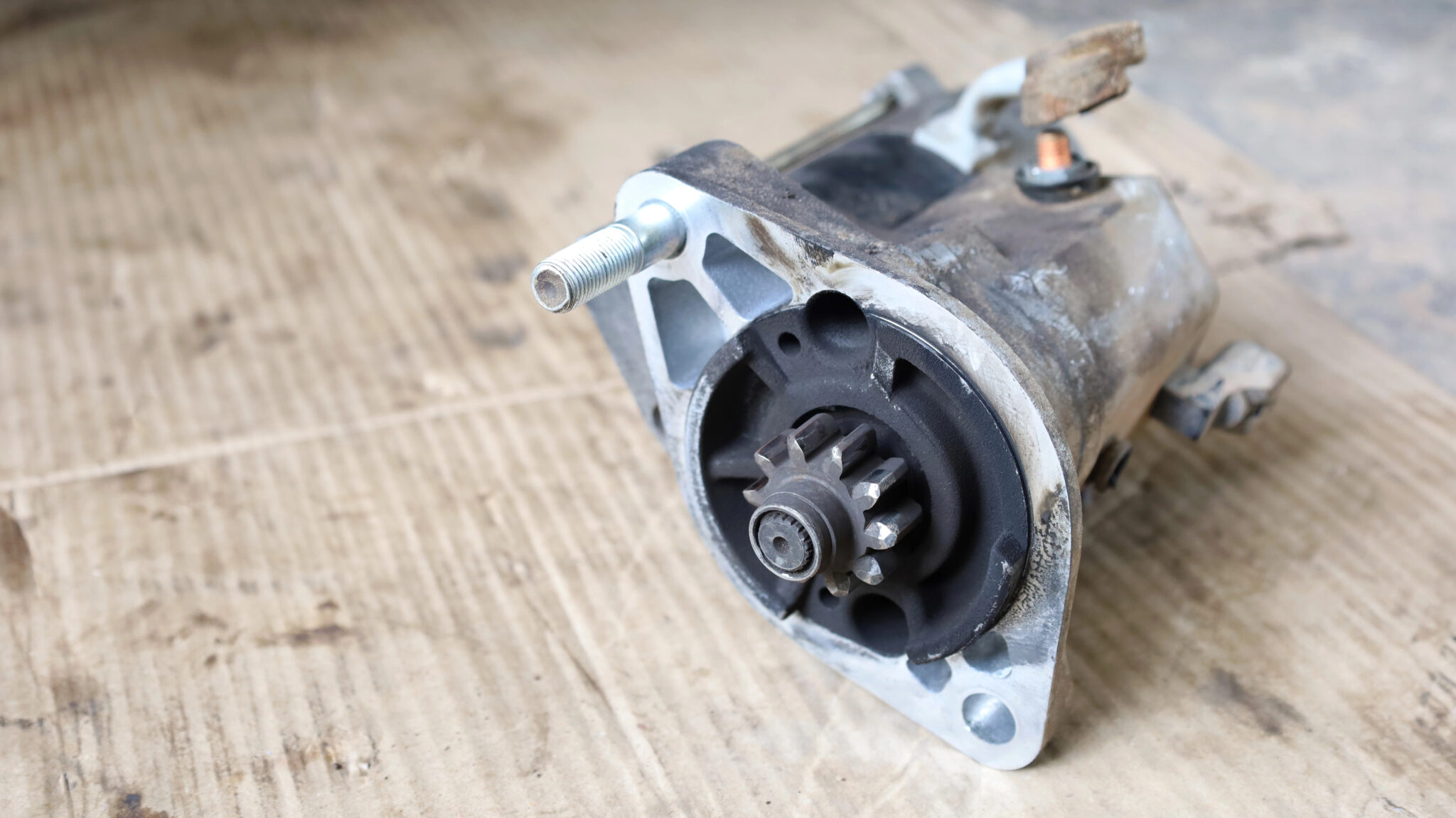

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

When to Consider Performance Starters for Specific Applications?

Performance starters are engineered for high-performance vehicles and racing applications. They offer superior starting power and are designed to withstand extreme conditions. B2B buyers in the racing industry or performance shops may find these starters essential for their operations. However, the higher price point and specialized nature mean they are not suitable for everyday vehicles, making them a niche investment.

What Advantages Do DIY Starter Kits Offer?

DIY starter kits provide all the necessary components for individuals or small repair shops to replace starters without professional help. This option appeals to budget-conscious buyers who possess the mechanical skills required for installation. However, the risk of installation errors and the need for proper tools can pose challenges. B2B buyers should assess their workforce’s skill level before opting for this cost-saving solution.

Aplicaciones industriales clave de cuánto cuesta cambiar un motor de arranque

| Industria/Sector | Aplicación específica de cuánto cuesta cambiar un motor de arranque | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Talleres de reparación de automóviles | Cost estimation for starter replacement in various vehicles | Accurate pricing helps in customer satisfaction and trust | Availability of OEM vs. aftermarket parts, labor costs |

| Gestión de flotas | Budgeting for maintenance of vehicle starters | Reduces downtime and improves fleet reliability | Bulk purchasing options, warranty on parts |

| Equipos de construcción | Evaluación de los costes de sustitución de los arrancadores de maquinaria pesada | Ensures operational efficiency and reduces project delays | Compatibility with specific machinery models |

| Servicios de transporte | Planning for starter maintenance in commercial vehicles | Enhances vehicle uptime and service delivery | Access to reliable suppliers for parts and service |

| Maquinaria agrícola | Assessing starter replacement costs for tractors and harvesters | Optimizes performance during critical planting/harvesting | Local sourcing for parts, understanding regional pricing |

How Do Automotive Repair Shops Use Starter Replacement Cost Estimates?

Automotive repair shops frequently encounter starter issues in various vehicles. Understanding how much it costs to change a starter helps these businesses provide accurate estimates to customers, fostering trust and transparency. Repair shops must consider the balance between OEM and aftermarket parts to ensure quality while managing costs. Additionally, the complexity of the vehicle model can impact labor costs, making it essential for shops to have a clear understanding of their pricing structure to remain competitive.

Why is Starter Maintenance Critical for Fleet Management?

In fleet management, maintaining the reliability of vehicles is paramount. By evaluating the costs associated with starter replacements, fleet managers can effectively budget for routine maintenance, reducing unexpected breakdowns. This proactive approach enhances fleet reliability and minimizes downtime, which is crucial for meeting service delivery commitments. Key considerations include sourcing parts in bulk for cost savings and ensuring that replacements meet the specific requirements of diverse vehicle models within the fleet.

How Do Construction Companies Evaluate Starter Replacement for Heavy Machinery?

Construction companies rely heavily on machinery that often requires starter replacements due to wear and tear. Understanding the costs associated with changing starters allows these businesses to budget effectively and avoid project delays. Compatibility with specific machinery models is critical, as is the sourcing of reliable parts to ensure that operations remain efficient. Companies must also consider the availability of local suppliers to minimize lead times and transportation costs.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

What Are the Benefits of Starter Maintenance in Transportation Services?

For transportation services, the operational efficiency of commercial vehicles is crucial. Evaluating starter replacement costs enables these businesses to plan maintenance schedules that enhance vehicle uptime. This is particularly important for companies that rely on timely deliveries to maintain customer satisfaction. Access to reliable suppliers for parts and service is vital, as is the ability to quickly address any starter-related issues to keep vehicles in optimal working condition.

How Do Agricultural Businesses Assess Starter Replacement Costs?

Agricultural equipment, such as tractors and harvesters, often experiences starter issues, especially during peak seasons. Understanding the costs associated with changing starters allows agricultural businesses to optimize performance during critical planting and harvesting periods. Local sourcing for parts can significantly affect pricing and availability, making it essential for buyers to understand regional market dynamics. Additionally, agricultural businesses should assess the warranty and reliability of parts to ensure they are investing wisely in their equipment’s longevity.

3 puntos de fricción habituales entre los usuarios sobre ‘cuánto cuesta cambiar un motor de arranque’ y sus soluciones

Scenario 1: Unexpected Costs During Starter Replacement

El problema: B2B buyers often face the challenge of unpredictable costs associated with starter replacement. This unpredictability can be particularly frustrating when managing a fleet of vehicles or machinery where downtime equates to lost revenue. A buyer might receive a quote for a starter replacement, but once the mechanic begins the work, they discover additional issues, such as the need for specialized parts or extra labor time, which can escalate the costs significantly. This lack of clarity can lead to budget overruns and financial strain.

La solución: To mitigate unexpected costs, it is essential for buyers to conduct thorough pre-repair diagnostics. Before agreeing to a starter replacement, buyers should invest in a comprehensive inspection that evaluates not only the starter but also related components like the battery, wiring, and relays. Establishing a relationship with a trusted mechanic who understands the specific vehicles or equipment used in your operation can help in obtaining accurate estimates. Additionally, buyers should inquire about potential hidden costs in advance, such as labor rates for complex starter placements or the availability of parts. This proactive approach can lead to more predictable expenses and better budget management.

Scenario 2: Variability in Labor Costs by Vehicle Type

El problema: Another common pain point for B2B buyers is the variability in labor costs associated with starter replacement, which can differ dramatically based on the vehicle type. For example, replacing a starter in a standard sedan may take less time and skill than in a luxury vehicle or heavy-duty truck, leading to differing labor rates. This can create confusion and frustration for fleet managers who are trying to estimate costs across a diverse range of vehicles, making it difficult to standardize budgeting.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

La solución: To address this challenge, buyers should categorize their fleet into different segments based on vehicle types and understand the average labor costs associated with each category. Creating a cost matrix that includes estimated parts and labor for various vehicle classes can streamline budgeting and decision-making. Furthermore, engaging with multiple service providers to compare quotes can provide insights into market rates for specific vehicle types. Leveraging online platforms to access vehicle repair databases can also assist in anticipating labor costs based on vehicle specifications, thus enabling more informed financial planning.

Scenario 3: Sourcing Quality Parts for Diverse Vehicle Makes

El problema: B2B buyers frequently struggle with sourcing quality starter parts, especially when managing a fleet that includes a variety of makes and models. The challenge lies in ensuring that the parts not only fit the vehicles but also meet quality standards. Poor-quality parts can lead to repeated failures and additional costs, resulting in operational downtime and dissatisfaction among clients or end-users.

La solución: To overcome the sourcing challenge, buyers should establish relationships with reputable suppliers who specialize in automotive parts. Conducting research on suppliers’ reputations, including reading reviews and seeking recommendations from other businesses, can help identify reliable sources. Additionally, utilizing advanced inventory management systems can assist buyers in tracking parts for different vehicles, ensuring that the right components are always on hand. Consider implementing a procurement strategy that focuses on OEM (Original Equipment Manufacturer) parts for critical components like starters, as they tend to offer better longevity and reliability. By prioritizing quality over cost, buyers can minimize the risk of future issues and enhance overall fleet performance.

Guía estratégica de selección de materiales para cuánto cuesta cambiar un motor de arranque

¿Qué materiales se utilizan habitualmente en la sustitución de motores de arranque?

When considering the replacement of a vehicle starter, the choice of materials can significantly impact performance, durability, and overall cost. Here, we analyze several common materials used in starter construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

Steel: A Durable and Cost-Effective Choice

Propiedades clave: Steel is known for its high tensile strength and excellent wear resistance. It can withstand high temperatures and pressures, making it suitable for automotive applications.

Ventajas y desventajas: Steel is relatively inexpensive and widely available, which makes it a popular choice for starter components. However, it is prone to corrosion if not properly treated, which can affect longevity in harsh environments. Additionally, the manufacturing complexity is moderate, as steel can be easily machined and welded.

Impacto en la aplicación: Steel starters are compatible with a variety of vehicle types, but their performance may degrade in environments with high humidity or salt exposure.

Consideraciones para compradores internacionales: Buyers in regions like Africa and South America should consider corrosion-resistant coatings for steel starters. Compliance with local standards, such as ASTM or DIN, is also crucial for ensuring quality and safety.

Aluminio: Ligero y resistente a la corrosión

Propiedades clave: Aluminum is lightweight and exhibits excellent corrosion resistance, making it ideal for components exposed to moisture and chemicals.

Ventajas y desventajas: The primary advantage of aluminum is its weight, which can improve vehicle efficiency. However, it is generally more expensive than steel and may not offer the same level of durability under extreme conditions. Manufacturing processes for aluminum can be more complex, requiring specialized techniques.

Impacto en la aplicación: Aluminum starters are particularly suitable for high-performance vehicles where weight reduction is critical. However, they may not be as robust as steel starters in heavy-duty applications.

Consideraciones para compradores internacionales: In Europe, buyers may prefer aluminum starters for their lightweight properties, especially in the automotive racing sector. Compliance with EU regulations on materials is essential for market entry.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

Plastic Composites: Innovative and Versatile

Propiedades clave: Plastic composites are lightweight and can be engineered for specific thermal and mechanical properties. They often exhibit good electrical insulation and resistance to chemicals.

Ventajas y desventajas: The use of plastic composites can significantly reduce weight and manufacturing costs. However, they may not withstand high temperatures as well as metals, limiting their application in certain environments. Additionally, the long-term durability of plastic components can be a concern.

Impacto en la aplicación: Plastic composites are suitable for non-structural components of starters, such as housings or covers. They can help improve fuel efficiency but may require careful selection based on temperature and chemical exposure.

Consideraciones para compradores internacionales: Buyers in the Middle East and Africa should be aware of the varying standards for plastic components in automotive applications. Ensuring compliance with local regulations and testing for temperature resistance is vital.

El cobre: Esencial para la conductividad eléctrica

Propiedades clave: Copper is renowned for its excellent electrical conductivity and thermal properties, making it a critical material for starter wiring and connections.

Ventajas y desventajas: Copper components facilitate efficient electrical flow, which is essential for starter operation. However, copper is more expensive than other materials, and it can be prone to corrosion if not properly insulated.

Impacto en la aplicación: Copper is indispensable for electrical connections in starters, ensuring reliable performance. Its use is crucial in high-performance and luxury vehicles where electrical efficiency is paramount.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

Consideraciones para compradores internacionales: In regions like Germany, where automotive standards are stringent, ensuring that copper components meet specific conductivity and corrosion resistance standards is essential. Buyers should also consider the implications of fluctuating copper prices on overall costs.

Cuadro recapitulativo de la selección de materiales para la sustitución de arrancadores

| Material | Caso práctico típico de cuánto cuesta cambiar un motor de arranque | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Acero | Componentes estructurales en los arrancadores | Alta resistencia y durabilidad | Propenso a la corrosión | Bajo |

| Aluminio | Motores de arranque ligeros para vehículos de altas prestaciones | Excelente resistencia a la corrosión | Higher cost and less durability | Med |

| Compuestos plásticos | Componentes no estructurales, como carcasas. | Ligero y rentable | Resistencia limitada a la temperatura | Bajo |

| Cobre | Electrical connections and wiring in starters | Excelente conductividad eléctrica | High cost and corrosion potential | Alto |

This strategic material selection guide provides valuable insights for B2B buyers, helping them make informed decisions when sourcing components for starter replacements in various global markets.

En profundidad: Procesos de fabricación y garantía de calidad para cuánto cuesta cambiar un motor de arranque

What Are the Key Stages in the Manufacturing Process for Automotive Starters?

Understanding the manufacturing process of automotive starters is crucial for B2B buyers looking to source reliable components. The production of a starter involves several key stages, ensuring that the final product meets the necessary performance and quality standards.

What Is the Material Preparation Process for Starters?

The initial phase of manufacturing involves material preparation, where raw materials such as metals (steel, aluminum, copper) and plastics are sourced. These materials must meet specific industry standards to ensure durability and performance. Suppliers typically conduct thorough checks to verify the quality of these raw materials, which may include chemical composition analysis and tensile strength testing.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

How Are Starters Formed During Manufacturing?

The forming stage includes several techniques tailored to create the necessary components of the starter. Common methods include:

- Fundición: Metal components, such as the starter housing, are often produced through casting processes. This allows for intricate designs and strong structural integrity.

- Mecanizado: Precision machining is used to create components like the armature and solenoid. This process ensures that parts fit together correctly and function effectively.

- Estampado: For components like the starter drive gear, stamping is utilized to produce parts quickly and efficiently with high tolerances.

These forming techniques are critical in ensuring that each part can withstand the operational stresses it will face in the vehicle.

What Are the Assembly Procedures for Automotive Starters?

Once the components are prepared, they move into the assembly phase. This stage involves:

- Integración de componentes: Each part, from the solenoid to the electromagnetic field coils, is carefully integrated. Automated assembly lines are often used to enhance efficiency and reduce human error.

- Cableado y conexiones: Electrical connections are made to ensure that the starter can receive power effectively. This is a crucial stage where incorrect wiring can lead to significant performance issues.

Quality control checks are often implemented during assembly to ensure that components are correctly fitted and functional.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

How Is the Finishing Stage Important in Starter Manufacturing?

The finishing process includes surface treatments and protective coatings that enhance the durability of the starter. Techniques such as electroplating or powder coating are commonly used to prevent corrosion and wear. This stage may also involve final inspections to ensure that the starter meets aesthetic and functional standards before being packaged for distribution.

What Quality Assurance Measures Are in Place for Starters?

Quality assurance is paramount in the manufacturing process of automotive starters. International and industry-specific standards guide manufacturers in maintaining consistent quality throughout production.

¿Qué normas internacionales son pertinentes para la fabricación de arrancadores?

ISO 9001 is one of the most recognized quality management systems globally. Compliance with ISO 9001 helps manufacturers ensure that they consistently provide products that meet customer and regulatory requirements. For automotive components, adherence to standards set by the International Automotive Task Force (IATF) can also be critical.

In addition, certifications like CE mark in Europe and API standards in the U.S. ensure that the products meet specific safety and performance requirements. These certifications can provide B2B buyers with confidence in the reliability and safety of the starters they source.

¿Cuáles son los principales puntos de control de calidad en la producción de arrancadores?

Quality control checkpoints are critical in the manufacturing process and include:

- Control de calidad de entrada (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility to ensure they meet specified standards.

- Control de calidad durante el proceso (IPQC): During the manufacturing process, various inspections are conducted to monitor the production stages. This can include checking dimensions and electrical performance.

- Control de calidad final (FQC): Before the product leaves the facility, it undergoes thorough testing, including functional tests and performance evaluations to ensure it meets all specifications.

¿Qué métodos de prueba se utilizan habitualmente para los arrancadores?

Manufacturers utilize various testing methods to verify the performance and reliability of starters, including:

- Pruebas eléctricas: Ensuring that the starter can handle the required voltage and current.

- Pruebas de durabilidad: Simulating operational conditions to assess the starter’s lifespan and reliability under stress.

- Pruebas de vibración y ruido: Checking for any abnormal sounds or vibrations during operation, which could indicate potential failure points.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

B2B buyers should implement a robust verification process to ensure that their suppliers maintain high-quality standards.

¿Cuáles son las mejores prácticas para realizar auditorías a proveedores?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. During an audit, buyers should focus on:

- Documentation Review: Ensuring that the supplier has the necessary certifications and quality management documentation.

- Facility Inspection: Visiting the manufacturing site to observe processes and quality control measures in action.

- Process Evaluation: Assessing the techniques and technologies used in production to ensure they align with industry standards.

How Can Buyers Access Quality Reports and Third-Party Inspections?

Requesting quality reports from suppliers can provide insights into their performance metrics and quality history. Additionally, third-party inspections can be a valuable resource for verifying the integrity of the manufacturing process. Engaging independent testing agencies to evaluate components before shipment can further ensure that the products meet specified standards.

¿Cuáles son los matices del control de calidad y la certificación para los compradores B2B internacionales?

International buyers must be aware of the nuances in quality control and certification processes across different regions. For example, in Europe, compliance with CE standards is critical, while in the U.S., adherence to API standards may be necessary. Buyers from Africa and South America should also consider local regulations and standards that may impact product quality and safety.

Understanding these regional differences can help buyers make informed decisions and ensure that the starters they source meet the necessary quality benchmarks. By prioritizing quality assurance in the sourcing process, B2B buyers can mitigate risks and enhance the reliability of their automotive components.

Guía práctica de contratación: Una lista de comprobación paso a paso para ‘cuánto cuesta cambiar un motor de arranque’

Introducción

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in understanding the costs and processes associated with changing a vehicle starter. Given the complexity of automotive parts and services, having a structured approach will help streamline procurement, ensuring you make informed decisions that align with your operational needs.

Paso 1: Assess Your Vehicle’s Specifications

Understanding your vehicle’s make, model, and year is crucial. Different vehicles have varying starter types, and prices can fluctuate significantly based on these specifications. Ensure you have the correct technical details to avoid procurement errors and ensure compatibility with your vehicle’s electrical system.

Paso 2: Determine the Scope of Work

Clarify whether you require a replacement starter or a rebuild. A complete replacement may be more cost-effective if the starter is severely damaged, while a rebuild could save money if only minor repairs are needed. Understanding the extent of the work will assist in budgeting accurately and negotiating with suppliers.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

Paso 3: Buscar opciones de proveedores

Conduct thorough research to identify potential suppliers for starters. Look for reputable distributors or manufacturers known for quality and reliability in your region. Be mindful of their track record in sourcing parts for your specific vehicle type, as this will influence both price and availability.

- Consider geographical proximity: Suppliers closer to your operational base may reduce shipping costs and delivery times.

- Evaluate their product range: Ensure they offer a variety of starters that meet different specifications.

Paso 4: Solicitar presupuestos detallados

Reach out to multiple suppliers for detailed quotations. A comprehensive quote should include the cost of the starter, shipping fees, and any potential installation charges. This step is vital to compare offers effectively and assess which suppliers provide the best value.

- Inquire about bulk pricing: If you plan to procure multiple starters, ask about discounts for bulk orders.

- Check for warranty information: A good warranty can provide peace of mind and reflect the supplier’s confidence in their product.

Paso 5: Verificar las certificaciones y normas de calidad de los proveedores

Ensure that your chosen suppliers comply with relevant automotive standards and certifications. Certifications can indicate a supplier’s commitment to quality and safety, which is essential for critical components like starters.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

- Look for ISO certifications or equivalent: These standards can enhance trust in the product quality.

- Request performance data: Suppliers should provide information on their starters’ performance metrics to validate quality claims.

Paso 6: Considerar la asistencia y el servicio posventa

Evaluate the level of after-sales support offered by the supplier. Reliable customer service can be crucial if issues arise post-purchase. Ensure the supplier has a responsive team to handle inquiries, returns, or warranty claims.

- Check for technical support: Having access to technical assistance can be invaluable, especially if you encounter installation challenges.

- Assess the return policy: A clear and fair return policy protects your investment should the starter not meet your expectations.

Paso 7: Finalice su pedido y controle la entrega

Once you’ve selected a supplier based on your assessments, finalize your order. Monitor the delivery process to ensure timely receipt of the starter. Keeping track of your order helps you manage inventory and plan for any necessary installation work.

- Confirm shipping timelines: Understanding delivery expectations can aid in scheduling maintenance or repairs.

- Inspect upon delivery: Verify that the starter matches the specifications and is free from damage before accepting the shipment.

By following this checklist, B2B buyers can navigate the complexities of sourcing vehicle starters effectively, ensuring they secure the best products at competitive prices while minimizing operational disruptions.

Análisis exhaustivo de costes y precios de cuánto cuesta cambiar un motor de arranque Sourcing

When analyzing the costs associated with changing a starter, several critical components contribute to the overall pricing structure. Understanding these elements can help international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

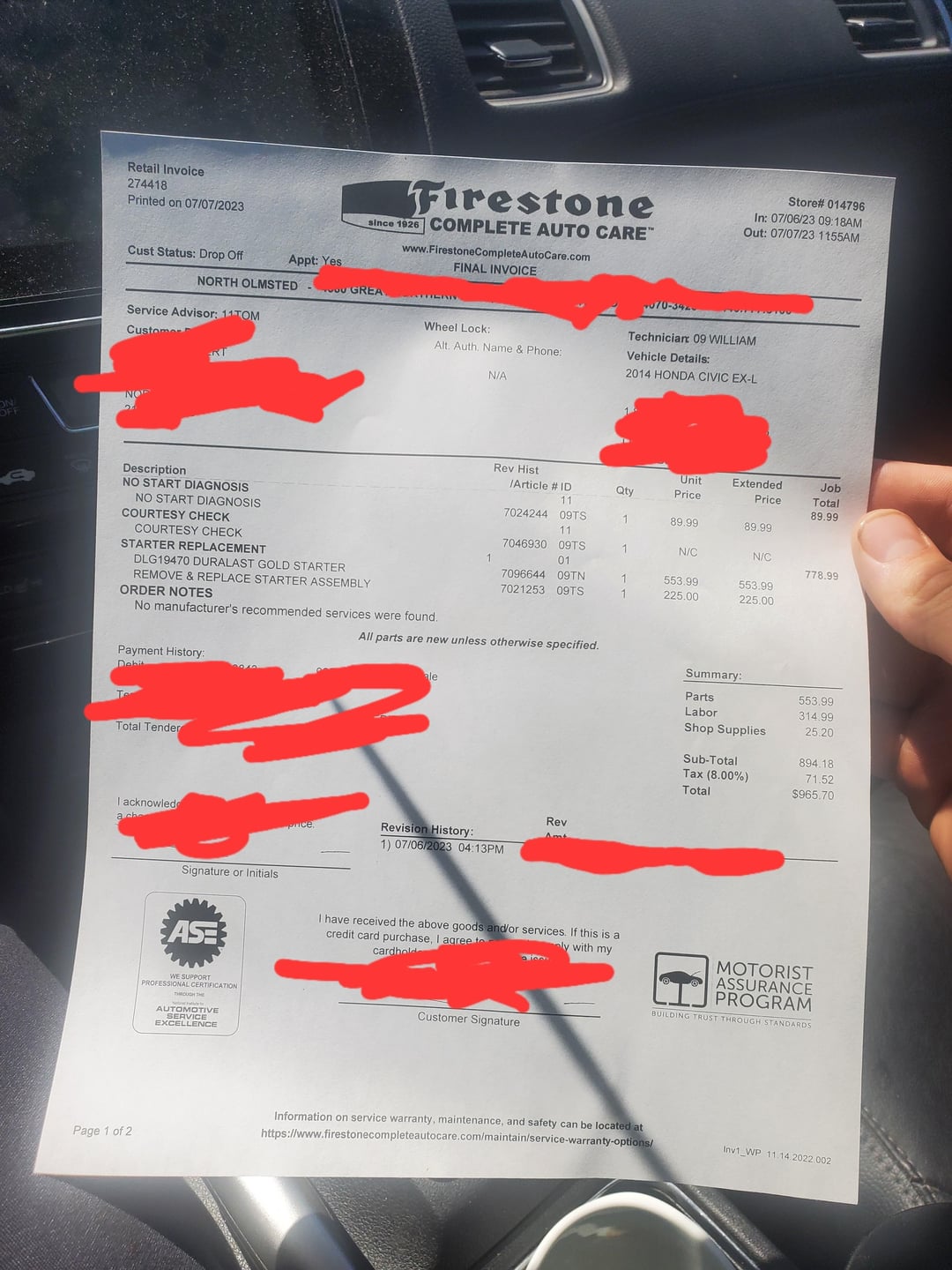

¿Cuáles son los principales componentes del coste de cambiar un motor de arranque?

-

Materiales: The cost of the starter itself can vary widely based on the type and quality of the part. Replacement starters typically range from $80 to over $350, depending on the vehicle’s make and model. For businesses sourcing starters, the quality and brand reputation can significantly influence material costs. Rebuild parts are generally less expensive, ranging from $50 to $350, which may be appealing for budget-conscious buyers.

-

Trabajo: Labor costs can also vary significantly based on the complexity of the starter replacement. Hiring a qualified mechanic might cost between $150 to over $1,100, depending on the vehicle’s accessibility. For businesses with in-house mechanics, the labor cost could be reduced, but it’s essential to account for the time and expertise required for the job.

-

Gastos generales de fabricación: This includes indirect costs associated with producing starters, such as utilities, rent, and salaries of support staff. Buyers should consider suppliers with efficient manufacturing processes to minimize overhead costs, which can be reflected in the final pricing.

-

Herramientas: If custom tooling is required for specific starter designs, this can add to the initial investment. Businesses should evaluate whether the supplier has the necessary tooling in place to avoid additional costs.

-

Control de calidad (QC): Ensuring that starters meet quality standards can add to costs but is essential for reliability. Buyers should consider suppliers with robust QC processes to reduce the risk of defective products, which can lead to additional expenses in replacements and repairs.

-

Logística: Shipping and handling costs can vary based on the location of the supplier and the buyer. Incoterms play a crucial role in defining responsibilities and costs associated with transportation, and understanding these can help buyers negotiate better shipping rates.

-

Margen: Suppliers typically include a profit margin in their pricing. Buyers should seek transparency regarding the margins to ensure they are paying a fair price without compromising on quality.

What Influences the Pricing of Starters?

-

Volumen/MOQ (cantidad mínima de pedido): Larger orders often lead to significant discounts. Buyers should assess their needs and consider bulk purchasing if possible.

-

Especificaciones y personalización: Custom starters tailored to specific vehicle models or performance requirements can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Calidad de los materiales y certificaciones: Higher quality materials and certified parts often come at a premium. Buyers should consider the long-term benefits of investing in quality starters that enhance vehicle reliability.

-

Factores relacionados con los proveedores: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often offer better guarantees and service.

-

Incoterms: Understanding Incoterms is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears the risk and cost at various points during shipping.

What Are the Best Tips for Buyers When Sourcing Starters?

-

Negocia con prudencia: Engage suppliers in negotiation discussions to achieve better pricing, especially for bulk orders. Building a good relationship can lead to favorable terms.

-

Tenga en cuenta el coste total de propiedad (TCO).: Beyond the initial purchase price, consider the long-term costs associated with maintenance, warranty, and potential downtime.

-

Tenga en cuenta los matices de los precios: Different regions may have varying price structures based on local market conditions, import tariffs, and currency fluctuations. Conducting thorough market research can yield significant savings.

-

Solicitud de muestras: Before making large orders, request samples to assess quality and compatibility, ensuring that the products meet your specific requirements.

-

Manténgase informado sobre las tendencias del mercado: Keeping abreast of changes in the automotive parts industry, including technological advancements and shifts in supplier dynamics, can provide leverage in negotiations.

Descargo de responsabilidad

Prices mentioned in this analysis are indicative and can vary based on location, vehicle specifications, and supplier agreements. Always conduct thorough due diligence and seek multiple quotes to ensure competitive pricing.

Análisis de Alternativas: Comparación de cuánto cuesta cambiar un motor de arranque con otras soluciones

Understanding Alternatives to Starter Replacement

When dealing with vehicle starting issues, changing a starter motor is a common solution. However, there are alternative methods and technologies that may achieve similar outcomes. This section will compare the costs, performance, and practicality of replacing a starter with other viable options, providing B2B buyers with a comprehensive understanding to make informed decisions.

Tabla comparativa

| Aspecto comparativo | ¿Cuánto cuesta cambiar un motor de arranque? | Sustitución de la batería | Reparación del motor de arranque |

|---|---|---|---|

| Rendimiento | High (if starter is faulty) | Moderate (if battery is the issue) | Variable (depends on damage) |

| Coste | $150 - $1.100 | $50 - $200 | $75 – $500 |

| Facilidad de implementación | Moderate (requires mechanic) | Easy (DIY possible) | Moderado (requiere experiencia) |

| Mantenimiento | Low (once replaced) | Moderate (battery maintenance needed) | Varies (depends on repairs) |

| Mejor caso de uso | Persistent starting issues | Intermittent starting problems | Minor issues with starter |

Desglose detallado de las alternativas

Sustitución de la batería

Replacing the vehicle’s battery can often resolve starting issues that might initially seem like a starter problem. The cost of battery replacement ranges from $50 to $200, making it a cost-effective option for businesses with a fleet of vehicles. The process can typically be done by the vehicle owner with minimal tools, thereby reducing labor costs. However, it’s essential to ensure that the battery is indeed the source of the issue, as misdiagnosis can lead to unnecessary expenses.

Reparación del motor de arranque

Repairing an existing starter can be a middle-ground solution for businesses looking to minimize costs. The price for starter repairs can range from $75 to $500, depending on the extent of the damage. This option allows companies to retain their current starter, potentially extending its lifespan. However, the effectiveness of repairs can be inconsistent; if the starter has multiple internal failures, a complete replacement might be more practical in the long run. Additionally, the repair process requires skilled technicians, which may not be available in all regions.

Conclusión: elegir la solución adecuada para sus necesidades

For B2B buyers, the decision to change a starter or opt for alternatives such as battery replacement or starter repair should be guided by a thorough analysis of the specific vehicle issues and operational needs. If starting problems are persistent and the starter is confirmed to be faulty, replacement may be the best course of action despite the higher upfront cost. Conversely, if the symptoms suggest a weaker battery or minor starter issues, exploring less expensive alternatives can provide significant savings. Ultimately, understanding the nuances of each option will empower businesses to make informed decisions that align with their operational goals and budgetary constraints.

Propiedades técnicas esenciales y terminología comercial para cuánto cuesta cambiar un motor de arranque

What Are the Critical Technical Specifications for Starter Replacement?

When considering the replacement of a starter motor, several technical specifications play a vital role in ensuring compatibility and performance. Understanding these properties can aid B2B buyers in making informed purchasing decisions.

1. Calidad del material

The material grade of a starter motor significantly affects its durability and performance. Most starters are constructed from high-grade steel and aluminum alloys, which provide strength while minimizing weight. For B2B buyers, understanding material grade is essential as it can influence the longevity of the starter and its ability to withstand extreme conditions, particularly in regions with harsh climates.

2. Voltage Rating

Starters typically operate at a voltage of 12V or 24V, depending on the vehicle’s electrical system. Selecting a starter with the appropriate voltage rating is crucial to ensure optimal performance. B2B buyers should verify compatibility with the specific vehicle model to avoid electrical failures that can lead to costly downtime.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

3. Torque Specifications

Torque specifications determine how much force is applied when the starter engages the flywheel. This is critical for proper engine cranking. For buyers, understanding these specifications helps in selecting a starter that will effectively start the engine without causing premature wear or damage to the vehicle’s components.

4. Cranking Amperage

The cranking amperage indicates the maximum current the starter can draw during the initial engine start. This is a vital specification, especially for heavy-duty vehicles that require more power to initiate engine rotation. B2B buyers must ensure that the starter’s cranking amperage aligns with the vehicle’s requirements to avoid underperformance or failure.

5. Mounting Type

Starters come with various mounting configurations, such as side-mounted or top-mounted. This specification is crucial for installation purposes. Buyers should confirm that the starter’s mounting type aligns with the vehicle’s design to facilitate a seamless replacement process.

Imagen ilustrativa relacionada con cuánto cuesta cambiar un motor de arranque

What Common Trade Terms Should B2B Buyers Understand?

Familiarity with industry jargon can enhance communication and negotiation effectiveness for B2B buyers. Here are some essential trade terms related to starter replacement:

1. OEM (fabricante de equipos originales)

OEM refers to parts made by the original manufacturer of the vehicle. Purchasing OEM starters can ensure the highest quality and compatibility, which is particularly important for maintaining warranty coverage. B2B buyers should consider OEM options for their reliability.

2. MOQ (cantidad mínima de pedido)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it affects inventory levels and cash flow. Buyers should negotiate MOQs that align with their business needs to optimize procurement efficiency.

3. RFQ (Solicitud de presupuesto)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ can streamline the procurement process, ensuring that they receive competitive pricing and detailed information on product specifications.

4. Incoterms (Términos comerciales internacionales)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international shipping. Understanding these terms is crucial for B2B transactions, as they clarify issues such as shipping costs, risks, and delivery timelines. Buyers should ensure they are familiar with the applicable Incoterms to avoid misunderstandings.

5. Periodo de garantía

The warranty period indicates the duration for which a manufacturer guarantees the product against defects. B2B buyers should pay attention to warranty terms as they can significantly impact long-term costs and reliability. A comprehensive warranty can provide peace of mind and reduce the risk of future expenditures.

By grasping these technical specifications and industry terms, B2B buyers can make more informed decisions regarding starter replacements, enhancing their operational efficiency and cost-effectiveness.

Navegar por la dinámica del mercado y las tendencias de aprovisionamiento en el sector ¿Cuánto cuesta cambiar un motor de arranque?

What Are the Key Trends Shaping the Market for Starter Replacements?

The global market for automotive starter replacements is influenced by several key dynamics. A significant driver is the increasing vehicle population in emerging markets, particularly in Africa and South America, where the demand for reliable transportation is on the rise. This trend is accompanied by a growing preference for electric and hybrid vehicles, which require specialized starter systems, thus expanding the market for high-quality starters and components. Additionally, the push for digitization in automotive services is facilitating more efficient sourcing channels for B2B buyers. Online platforms and B2B marketplaces are becoming prevalent, allowing international buyers to easily compare prices and availability across regions.

Sourcing trends are also evolving, with a noticeable shift towards direct relationships with manufacturers. This allows for better pricing strategies and shorter lead times, essential for businesses that need to maintain competitive service levels. Moreover, as the automotive sector grapples with the implications of global supply chain disruptions, companies are increasingly looking to diversify their supplier base to mitigate risks. This diversification is particularly vital in regions like the Middle East and Europe, where geopolitical factors can impact supply continuity.

¿Cómo influye la sostenibilidad en el abastecimiento de sustitutos de arranque?

Sustainability and ethical sourcing have become critical considerations in the automotive parts supply chain. The environmental impact of manufacturing processes, including those for starter motors, is under scrutiny. B2B buyers are now expected to prioritize suppliers who demonstrate a commitment to sustainable practices, such as using eco-friendly materials and reducing waste in their production processes.

Furthermore, certifications such as ISO 14001 for environmental management systems are becoming essential in supplier evaluations. These certifications ensure that suppliers adhere to international standards in minimizing their environmental footprint. As consumers increasingly demand transparency in product sourcing, B2B buyers must align their procurement strategies with sustainability goals to enhance brand reputation and customer loyalty. In addition, the use of recycled materials in starter production not only reduces environmental impact but also offers cost savings, making it an attractive option for businesses looking to optimize their sourcing strategies.

What Is the Historical Context Behind Starter Replacement Costs?

The evolution of starter systems can be traced back to the early 20th century when vehicles transitioned from hand-crank systems to electric starters. This innovation significantly improved vehicle accessibility and convenience, establishing the foundation for the modern automotive industry. Over the decades, advancements in technology have led to the development of more efficient starters, which are now integral to vehicle performance.

In recent years, the market has seen a shift towards more complex starter systems, particularly with the rise of hybrid and electric vehicles. These developments have not only increased the cost of components but also the labor involved in repairs and replacements. As a result, understanding the historical context of starter technology is crucial for B2B buyers navigating current pricing trends, as it informs their decisions in terms of cost, technology, and supplier selection.

By staying informed about these market dynamics and sourcing trends, international B2B buyers can make strategic decisions that enhance their operational efficiency and sustainability efforts in the automotive sector.

Preguntas frecuentes para compradores B2B sobre cuánto cuesta cambiar un motor de arranque

-

How do I determine if my vehicle needs a new starter?

To ascertain if your vehicle requires a new starter, start by checking for common symptoms such as erratic cranking, no response when turning the key, or unusual noises during startup. Conduct a thorough inspection of the battery and connections, as these can often be mistaken for starter issues. If the problem persists, consult a qualified mechanic who can accurately diagnose the issue. Understanding these signs can prevent unnecessary costs and help in making informed purchasing decisions. -

What is the average cost to replace a starter in various vehicles?

The cost of replacing a starter varies widely based on the vehicle’s make, model, and year. On average, parts can range from $80 to $350 for a new starter, while labor costs can add another $150 to over $1,100. For common vehicles like sedans, costs tend to be lower due to easier access. In contrast, larger trucks or luxury models may incur higher costs due to complex installations. Always obtain quotes from multiple suppliers to ensure competitive pricing. -

What factors should I consider when sourcing starter replacements internationally?

When sourcing starter replacements from international suppliers, consider factors such as product quality, compliance with local regulations, and supplier reliability. Assess the supplier’s production capabilities, lead times, and shipping logistics. Additionally, ensure that they provide warranties and after-sales support. Establishing clear communication regarding specifications and timelines will help mitigate potential issues and enhance your supply chain efficiency. -

How do I vet suppliers for starter components?

To effectively vet suppliers for starter components, start by reviewing their industry reputation and customer feedback. Request samples or detailed product specifications to evaluate quality. It’s beneficial to check certifications and compliance with international standards. Consider visiting the supplier’s facility if possible or utilizing third-party inspection services. Building strong relationships and clear communication channels can also enhance trust and ensure that the supplier meets your requirements consistently. -

What are the minimum order quantities (MOQs) for starter replacements?

Minimum order quantities (MOQs) for starter replacements can vary significantly depending on the supplier and the specific part. Typically, MOQs may range from 50 to several hundred units. Larger orders often result in better pricing and negotiation leverage. It’s essential to discuss MOQs upfront with potential suppliers to align your purchasing capabilities with their production schedules, ensuring a smooth procurement process. -

What payment terms are common for international starter purchases?

Common payment terms for international starter purchases typically include options such as Letter of Credit (LC), telegraphic transfer (TT), or even PayPal for smaller transactions. Payment terms may vary based on the supplier’s policies and the buyer’s creditworthiness. Discussing these terms in advance can help establish mutual trust and ensure that both parties are comfortable with the payment process, thus facilitating smoother transactions. -

How can I ensure quality assurance (QA) for imported starters?

To ensure quality assurance for imported starters, implement a comprehensive inspection process both pre-shipment and upon arrival. Work with suppliers who provide quality certifications and allow for third-party inspections. Establish clear specifications and acceptance criteria before production begins. Regular communication with the supplier during the manufacturing process can also help address potential quality issues early on, reducing the risk of receiving subpar products. -

¿Qué aspectos logísticos debo tener en cuenta al importar iniciadores?

When importing starters, consider logistics factors such as shipping methods, customs clearance processes, and delivery timelines. Assess the total landed cost, including freight, duties, and taxes, to avoid unexpected expenses. Collaborate with experienced freight forwarders who can navigate international shipping regulations and provide insights into the best routes and methods for timely delivery. Proper logistics planning is crucial to maintaining inventory levels and meeting customer demands efficiently.

Top 6 fabricantes & proveedores de Cuánto cuesta cambiar un motor de arranque Lista

1. Facebook – Starter Replacement Cost

Dominio: facebook.com

Registrado: 1997 (28 años)

Introducción: Coste de llevar el coche al taller y sustituir el motor de arranque.

2. Última oportunidad para reparaciones automotrices: costos de reemplazo del motor de arranque

Dominio: últimaoportunidadreparacionesautomóviles.com

Registrado: 2009 (16 años)

Introducción: Coste de sustitución del motor de arranque: Arrancadores económicos: $75 - $200, Arrancadores OEM: $150 - $400, Motores de arranque de alto rendimiento: $300 - $1000+. Costes de mano de obra: Sustitución básica del motor de arranque del vehículo: $100 - $250, Instalaciones complejas: $300 - $600+. Factores que influyen en el coste: Tipo y modelo de vehículo, Motores de arranque nuevos o refabricados, Reparaciones adicionales. Costes de bricolaje: Sólo piezas: $100 - $400, Inversión de tiempo: 2-6 horas. Reparación profesional...

3. Car Talk - Guía de sustitución del motor de arranque

Dominio: cartalk.com

Registrado: 1995 (30 años)

Introducción: Cost to replace a starter: $600 to $900 for common vehicles; $900 to $1,400 for luxury models. Symptoms of a failing starter include clicking sounds, screeching noises, and intermittent functionality. Starters can be new, remanufactured, or rebuilt. Modern vehicles with stop-start systems have starters designed to withstand frequent use.

4. AAA – Car Starter Replacement Cost

Dominio: aaa.com

Matriculado: 1990 (35 años)

Introducción: The average cost to replace a car starter ranges from $700 to $1,200, depending on the make and model of the vehicle and labor hours required. The replacement part itself costs between $100 and $400. Labor rates in the AAA Approved Auto Repair network range from $100 to $250 per hour. Factors influencing cost include the car’s make and model, type of starter (gear reduction starters are more effic…

5. The Truckers Report – Starter Prices and Installation

Dominio: thetruckersreport.com

Inscrito: 2003 (22 años)

Introducción: New starter prices range from $156 to $550. Installation costs can be around $300, with additional road service fees potentially reaching $800 or more. Parts to rebuild a starter can be purchased for under $150.

6. Tundras – Starter Replacement for 2007 Toyota Tundra CrewMax

Dominio: tundras.com

Matriculado: 2000 (25 años)

Introducción: Starter replacement for a 2007 Toyota Tundra CrewMax, quoted cost of $1500 (including $900 labor and $650 part). The part to be replaced is denșo 428000-4640. Discussion indicates that OEM replacement parts can be found around $200, and labor costs may vary. Some members suggest that the issue may not be the starter but possibly the battery, as the vehicle had to be jump-started multiple times bef…

Strategic Sourcing Conclusion and Outlook for cuánto cuesta cambiar un motor de arranque

In conclusion, understanding the costs associated with changing a starter is crucial for international B2B buyers navigating the automotive parts market. Key insights reveal that while starter replacement costs can vary significantly based on the vehicle make, model, and complexity of the job, strategic sourcing can lead to significant savings. By evaluating both new and rebuilt options, as well as considering labor costs, businesses can make informed decisions that enhance their operational efficiency.

Moreover, establishing relationships with reliable suppliers ensures access to quality components and timely service, which is vital for minimizing vehicle downtime. Buyers should also be proactive in troubleshooting starter issues to avoid unnecessary expenditures.

Looking ahead, as the automotive industry continues to evolve, especially in emerging markets across Africa, South America, the Middle East, and Europe, embracing strategic sourcing practices will become increasingly important. By prioritizing quality and cost-effectiveness, international buyers can position themselves for success in a competitive landscape. Engage with reputable suppliers and stay informed about market trends to ensure your sourcing strategies remain effective and future-proof.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.