Introducción: Navegar por el mercado mundial de ¿cuánto cuesta un faro?

En el panorama en constante evolución de los recambios de automoción, entender cuánto cuesta un faro puede ser un reto desalentador para los compradores B2B internacionales. Con una miríada de opciones que van desde las bombillas halógenas básicas hasta los avanzados sistemas LED y HID, la búsqueda de los faros adecuados para su vehículo o flota requiere una cuidadosa consideración de la calidad, el precio y la compatibilidad. Esta completa guía profundizará en los distintos tipos de faros, sus aplicaciones y los factores que influyen en su coste, permitiéndole tomar decisiones de compra con conocimiento de causa.

Navegar por el mercado mundial de faros no sólo significa evaluar los precios -desde $10 para las bombillas halógenas hasta varios miles de dólares para los conjuntos de gama alta-, sino también comprender los matices de la investigación de proveedores, las consideraciones de garantía y los costes de instalación. Para los compradores de regiones tan diversas como África, Sudamérica, Oriente Medio y Europa, incluidos países como Alemania y Brasil, esta guía constituye un recurso esencial. Le proporciona información práctica para asegurarse de que adquiere faros que cumplen las normas de seguridad al tiempo que optimiza su presupuesto.

Si conoce los tipos, los costes y las mejores prácticas para el mantenimiento y la sustitución de los faros, podrá aumentar la seguridad de los vehículos, mejorar la eficacia operativa y, en última instancia, aumentar el valor de su empresa.

Índice

- Lista de los 3 mejores fabricantes y proveedores de Cuánto cuesta un faro delantero

- Introducción: Navegar por el mercado mundial de ¿cuánto cuesta un faro?

- Comprender cuánto cuesta un faro Tipos y variaciones

- Aplicaciones industriales clave de ¿cuánto cuesta un faro?

- 3 puntos débiles habituales de los usuarios de ‘cuánto cuesta un faro’ y sus soluciones

- Guía estratégica de selección de materiales para ¿Cuánto cuesta un faro?

- Una mirada en profundidad: Procesos de fabricación y garantía de calidad de ¿Cuánto cuesta un faro?

- Guía práctica de búsqueda: Una lista de comprobación paso a paso para ‘cuánto cuesta un faro’

- Análisis exhaustivo de costes y precios de cuánto cuesta un faro Sourcing

- Análisis de alternativas: Comparación de cuánto cuesta un faro con otras soluciones

- Propiedades técnicas esenciales y terminología comercial de ¿cuánto cuesta un faro?

- Dinámicas de mercado y tendencias de aprovisionamiento en el sector ¿Cuánto cuesta un faro?

- Preguntas frecuentes para compradores B2B sobre cuánto cuesta un faro delantero

- Conclusión y perspectivas de Strategic Sourcing sobre cuánto cuesta un faro delantero

- Aviso legal importante y condiciones de uso

Comprender cuánto cuesta un faro Tipos y variaciones

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Faros halógenos | Rentable, vida útil corta (500-1.000 horas), fácil de sustituir | Vehículos de flota, compradores con presupuesto ajustado | Ventajas: Bajo coste inicial; Contras: Necesidad de sustituciones frecuentes debido a su corta vida útil. |

| Descarga de alta intensidad (HID) | Iluminación más brillante, mayor vida útil (2.000-3.000 horas), requiere un balasto | Vehículos de lujo, aplicaciones centradas en el rendimiento | Ventajas: Mayor visibilidad; Contras: Mayor coste e instalación compleja. |

| Diodo emisor de luz (LED) | Larga duración (hasta 30.000 horas), eficiencia energética, coste inicial elevado | Flotas modernas, vehículos eléctricos e híbridos | Ventajas: Bajo consumo de energía; Contras: Piezas de recambio caras y posibles problemas de garantía. |

| Conjuntos de faros sellados | Diseño integrado, a menudo no reparable, elevado coste de sustitución | Vehículos de gama alta, sistemas avanzados de iluminación | Ventajas: Estética y rendimiento mejorados; Contras: Coste significativo para la sustitución del conjunto completo. |

| Faros láser | Alcance de visibilidad extremadamente alto, tecnología punta, muy caro | Vehículos de lujo y de altas prestaciones | Ventajas: Visibilidad superior; Contras: Costes de sustitución extremadamente elevados, no muy disponibles. |

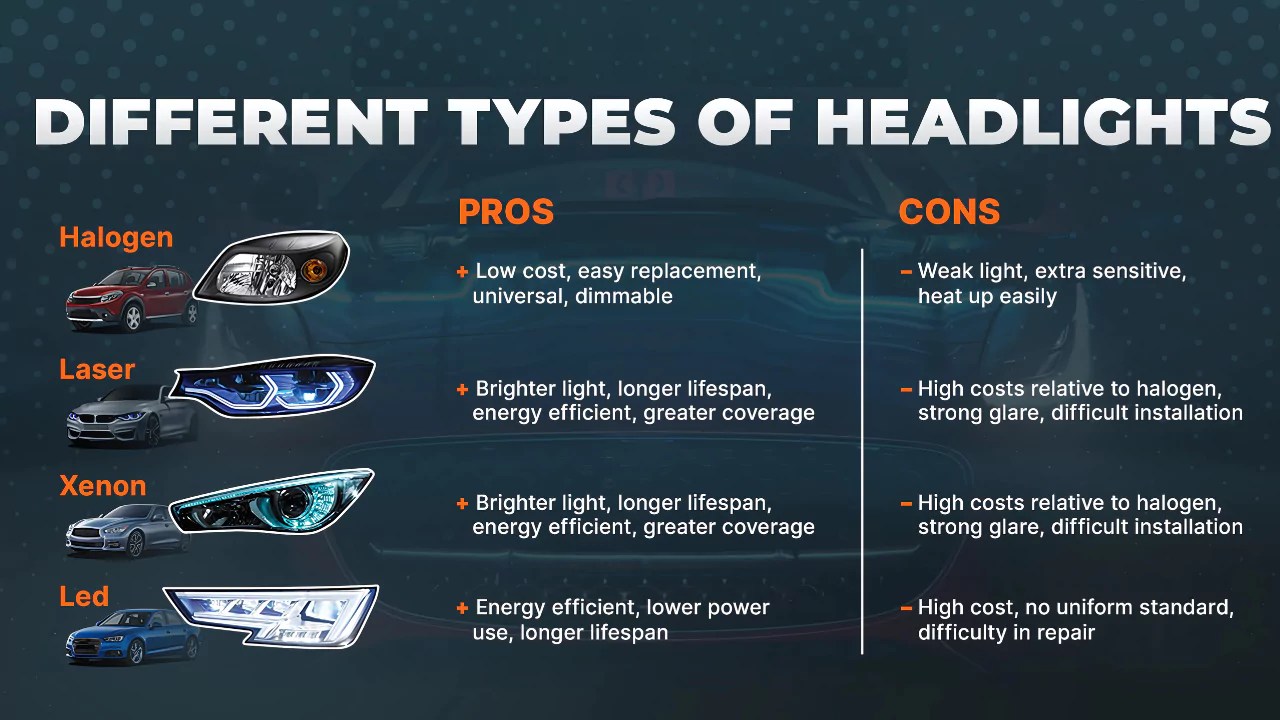

¿Qué características tienen los faros halógenos?

Los faros halógenos son la opción más tradicional disponible, conocida por su asequibilidad y facilidad de sustitución. Suelen costar entre $10 y $40 por bombilla y son adecuados para flotas o vehículos con un presupuesto ajustado en los que la rentabilidad es primordial. Sin embargo, su vida útil más corta, de 500 a 1.000 horas, hace que las empresas tengan que hacer frente a costes de sustitución frecuentes, que pueden acumularse con el tiempo. Cuando compre bombillas halógenas, asegúrese de que cumplen las normas de seguridad para mantener la fiabilidad del vehículo.

¿En qué se diferencian los faros de descarga de alta intensidad (HID)?

Los faros HID ofrecen una iluminación mucho más brillante que las opciones halógenas y tienen una vida útil de aproximadamente 2.000 a 3.000 horas. Son ideales para los vehículos de lujo y los que requieren una mayor visibilidad. Sin embargo, el coste de las bombillas HID puede rondar los $150 cada una, y su instalación suele requerir asistencia profesional debido a la complejidad del sistema de balastos. Los compradores B2B deben sopesar la inversión inicial frente a las ventajas de una mayor seguridad y visibilidad.

¿Por qué elegir faros de diodos emisores de luz (LED)?

Los faros LED representan la última tecnología en iluminación para automóviles, ya que ofrecen una impresionante vida útil de hasta 30.000 horas y un menor consumo de energía. Aunque tienen un precio más elevado, que suele oscilar entre $50 y $200 por par, su longevidad puede reducir con el tiempo los costes totales de propiedad. Las empresas que operan con flotas modernas, especialmente vehículos eléctricos e híbridos, pueden encontrar los faros LED particularmente atractivos debido a su eficiencia y reducido impacto ambiental. Sin embargo, la posible necesidad de sustituir el conjunto completo debe tenerse en cuenta en las decisiones de compra.

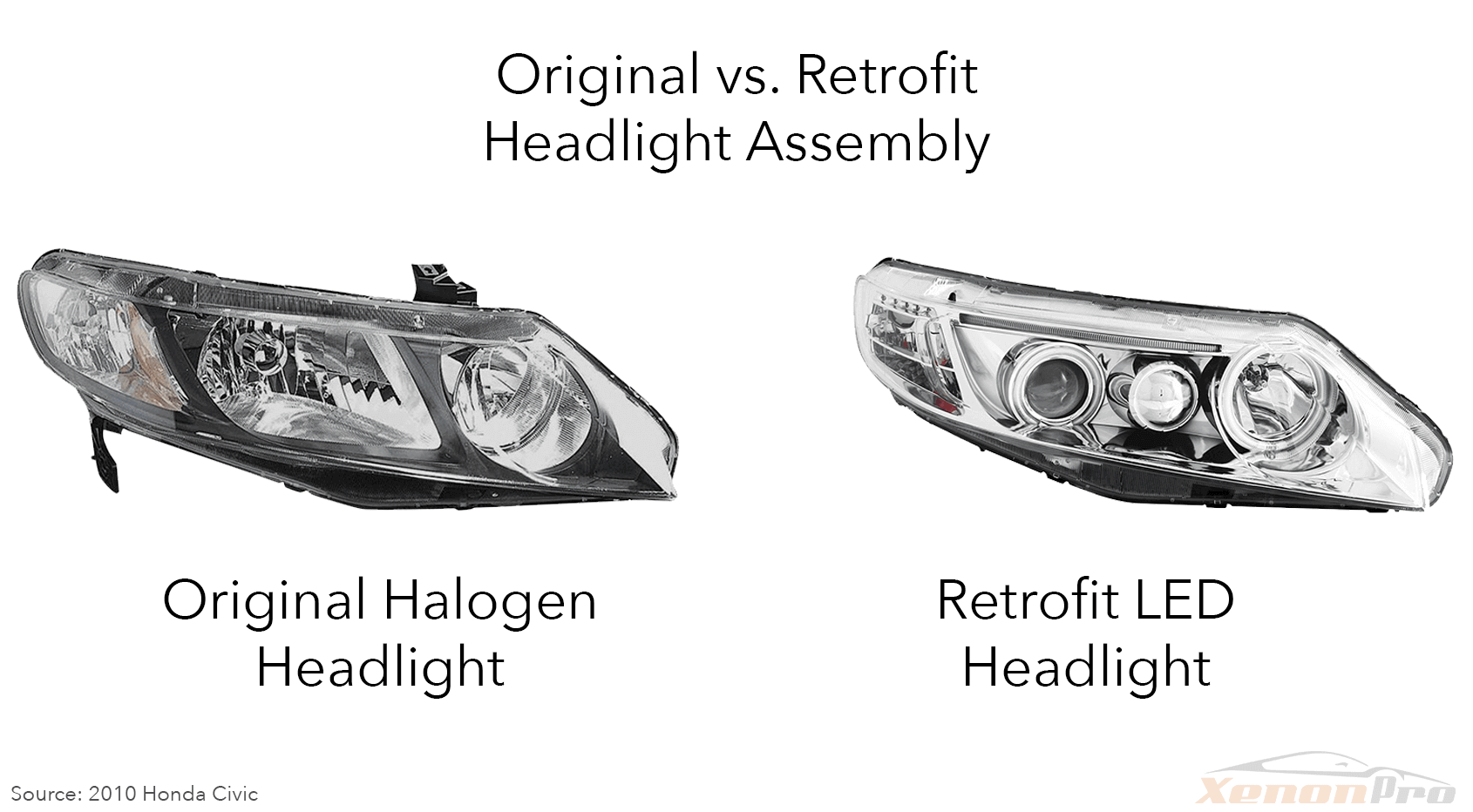

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

¿Qué son los faros sellados y cuáles son sus aplicaciones?

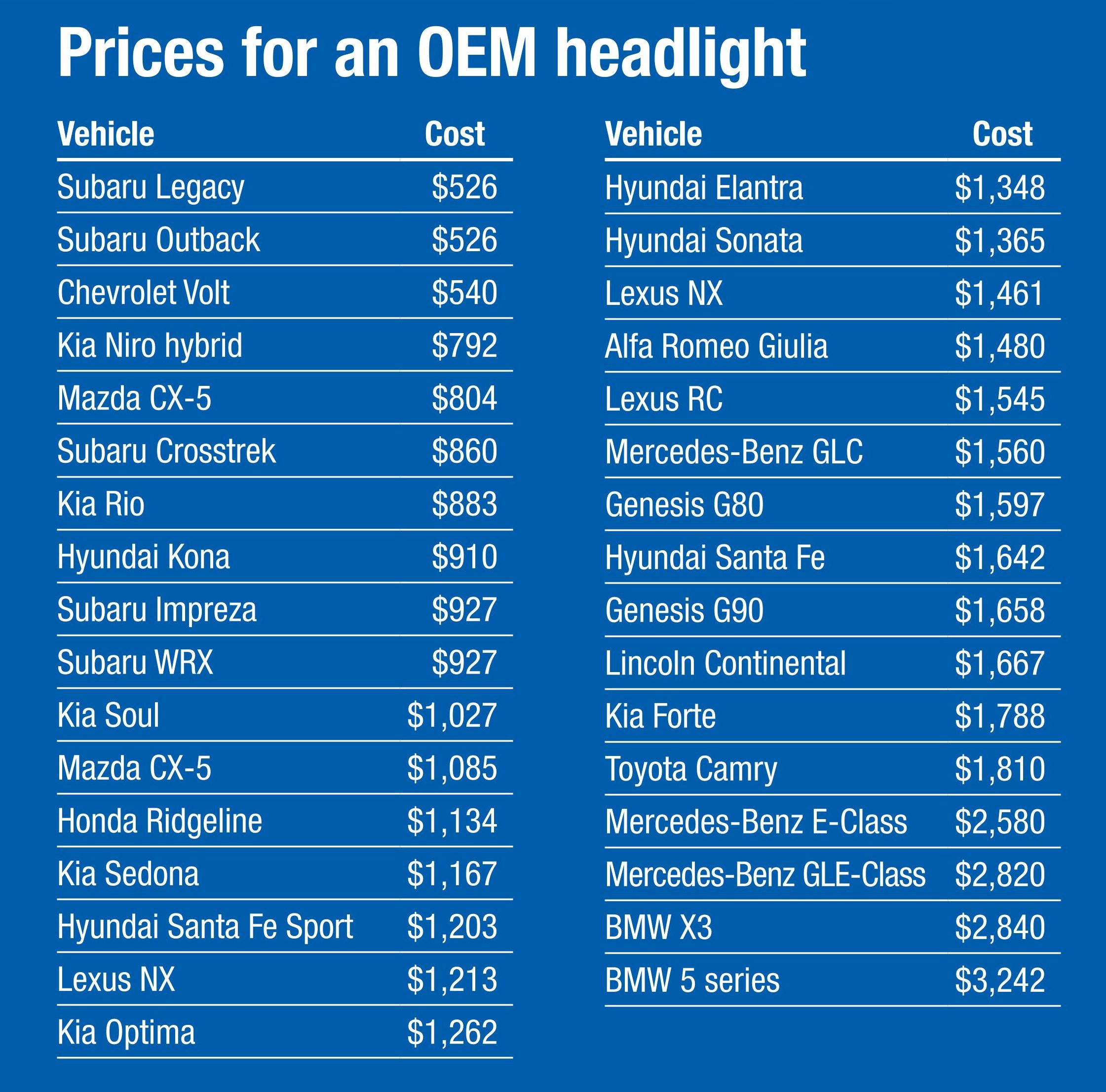

Los conjuntos de faros sellados están diseñados para los vehículos modernos y ofrecen un aspecto elegante e integrado. Sin embargo, su sustitución puede resultar costosa, superando a menudo los $1.000 en los modelos de gama alta. Estos conjuntos suelen encontrarse en vehículos de lujo con sistemas de iluminación avanzados, que atraen a compradores B2B centrados en la estética y el rendimiento. Aunque ofrecen una funcionalidad superior, su naturaleza no reparable puede dar lugar a elevados costes de sustitución, por lo que es esencial que las empresas tengan en cuenta las implicaciones a largo plazo a la hora de seleccionar este tipo de faros.

¿Cómo encajan los faros láser en el mercado?

Los faros láser están a la vanguardia de la tecnología de iluminación del automóvil, ya que ofrecen una visibilidad inigualable y un alcance que puede superar los 800 metros. Sin embargo, su elevado coste -a menudo varios miles de dólares para sustituirlos- limita su aplicación principalmente a los vehículos de lujo y de altas prestaciones. Los compradores B2B deben considerar si la inversión se ajusta a sus necesidades operativas, ya que las ventajas de una mayor seguridad y visibilidad se ven contrarrestadas por el importante desembolso económico que requieren su mantenimiento y sustitución.

Aplicaciones industriales clave de ¿cuánto cuesta un faro?

| Industria/Sector | Aplicación específica de cuánto cuesta un faro delantero | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Fabricación de automóviles | Análisis de costes de producción de faros | Optimiza los presupuestos de fabricación y las estrategias de precios | Calidad de los materiales, cumplimiento de las normas de seguridad |

| Servicios de reparación de vehículos | Estimación de los costes de sustitución para los clientes | Aumenta la satisfacción del cliente gracias a la transparencia de los precios | Acceso a proveedores fiables, consideraciones sobre la garantía |

| Gestión de flotas | Presupuesto de mantenimiento y sustitución de faros | Reduce el tiempo de inactividad y aumenta la seguridad del vehículo | Opciones de compra a granel, fiabilidad de los proveedores |

| Concesionarios | Fijación de precios competitivos para vehículos con conjuntos de faros | Maximiza la rentabilidad y atrae a los compradores | Comprensión de las tendencias del mercado, suministro de piezas OEM frente a piezas de recambio |

| Compañías de seguros | Evaluación de los costes relacionados con las reclamaciones por daños en los faros | Agiliza la tramitación de siniestros y la evaluación de riesgos | Estimación precisa de costes, asociaciones con talleres de reparación |

¿Qué importancia tiene ‘cuánto cuesta un faro’ en la fabricación de automóviles?

En el sector de la fabricación de automóviles, comprender el coste de los faros es crucial para las estrategias de presupuestación y fijación de precios. Los fabricantes deben evaluar los costes asociados a los distintos tipos de faros (halógenos, HID o LED) teniendo en cuenta la complejidad de su montaje. Esta información permite a las empresas optimizar los costes de producción, garantizando su competitividad en el mercado. Para los compradores internacionales, sobre todo de África y Sudamérica, es esencial abastecerse de materiales de alta calidad que cumplan las normas de seguridad para evitar costosas retiradas y mejorar la reputación de la marca.

¿Por qué es importante conocer los costes de sustitución de faros para los Servicios de Reparación de Vehículos?

Los servicios de reparación de vehículos se benefician significativamente de tener un conocimiento claro de los costes de sustitución de faros. Este conocimiento les permite ofrecer estimaciones precisas a los clientes, mejorando la transparencia y la satisfacción del cliente. Los talleres de reparación deben tener en cuenta la variedad de tecnologías de faros y sus costes de mano de obra asociados, especialmente cuando sustituyen conjuntos complejos en vehículos modernos. Para los compradores B2B de Europa y Oriente Medio, establecer relaciones con proveedores fiables que puedan suministrar piezas OEM con rapidez es fundamental para mantener la eficacia del servicio.

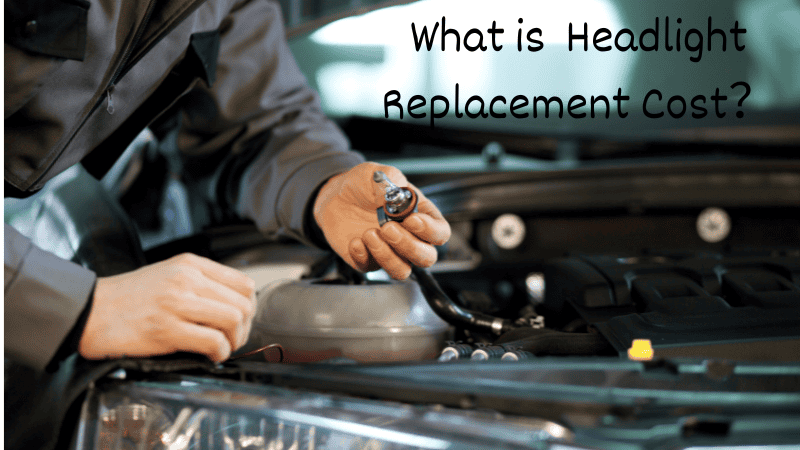

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

¿Cómo influye el coste de los faros en la gestión de flotas?

Para las empresas de gestión de flotas, presupuestar el mantenimiento y la sustitución de los faros es un aspecto vital de la eficacia operativa. Conocer los costes asociados a los distintos tipos de faros permite a los gestores de flotas planificar programas de mantenimiento periódicos y garantizar la seguridad de los vehículos. Este enfoque proactivo minimiza el tiempo de inactividad, lo que en última instancia se traduce en un ahorro de costes. Los compradores internacionales deben considerar acuerdos de compra al por mayor con los proveedores para asegurar precios favorables y garantizar la disponibilidad de piezas en diversos mercados.

¿Qué papel desempeñan los precios de los faros en los concesionarios de automóviles?

Los concesionarios aprovechan el conocimiento de los costes de los faros para fijar precios competitivos para los vehículos, especialmente los equipados con sistemas de iluminación avanzados. Al conocer las implicaciones de los costes de los faros, los concesionarios pueden posicionar eficazmente su inventario para atraer a los compradores, maximizando la rentabilidad. Los compradores internacionales, sobre todo en regiones con distintas normativas, deben mantenerse informados sobre las tendencias del mercado y las diferencias entre piezas OEM y de recambio para tomar decisiones de compra con conocimiento de causa.

¿Cómo afecta el coste de los faros a las compañías de seguros?

Las compañías de seguros deben evaluar los costes de sustitución de los faros cuando tramitan siniestros relacionados con daños en vehículos. Un conocimiento exhaustivo de estos costes permite a las aseguradoras agilizar la tramitación de los siniestros y evaluar con precisión el riesgo. Este conocimiento es especialmente beneficioso en regiones en las que las tecnologías de faros evolucionan rápidamente. Para los compradores B2B del sector asegurador, asociarse con talleres de reparación puede mejorar la precisión de las estimaciones de costes, lo que beneficia tanto a la aseguradora como al asegurado.

3 puntos débiles habituales de los usuarios de ‘cuánto cuesta un faro’ y sus soluciones

Hipótesis 1: Costes inesperados de la sustitución de faros en vehículos de lujo

El problema: Los compradores B2B que gestionan flotas o compran para fabricantes de vehículos de gama alta a menudo se encuentran con costes inesperados asociados a la sustitución de faros. Los vehículos de lujo utilizan con frecuencia sistemas de iluminación avanzados que incluyen conjuntos de faros sellados, cuya sustitución puede superar los $1.000. Esta complejidad no sólo aumenta el coste, sino que también puede provocar tiempos de inactividad inesperados en los vehículos, lo que afecta a la eficiencia operativa. Los compradores pueden no estar preparados para estos gastos, lo que afecta a su presupuesto y a sus previsiones financieras.

La solución: Para gestionar y anticipar eficazmente los costes de sustitución de faros, los compradores deben realizar un análisis exhaustivo de su flota o inventario para identificar qué vehículos cuentan con sistemas de iluminación avanzados. Al compilar una lista de las piezas de recambio previstas y los costes asociados, las empresas pueden presupuestar adecuadamente. Para ello, es fundamental contar con proveedores fiables que puedan proporcionar datos completos sobre precios y disponibilidad. Además, establecer relaciones con proveedores de servicios de automoción puede ayudar a agilizar el proceso de sustitución, garantizando que cualquier instalación necesaria se realice de forma eficiente. También es aconsejable considerar alternativas de posventa que mantengan la calidad pero ofrezcan ahorros de costes, garantizando el cumplimiento de las normas de seguridad.

Situación 2: Confusión sobre los tipos de faros y sus especificaciones

El problema: Muchos compradores B2B se enfrentan a la confusión cuando intentan determinar el tipo correcto de faro para modelos de vehículo específicos. Con la evolución de la tecnología de iluminación del automóvil, que incluye opciones halógenas, HID y LED, la variedad puede ser abrumadora. Los compradores pueden equivocarse al pedir las piezas equivocadas, lo que provoca retrasos en las reparaciones y costes añadidos, ya que las devoluciones y los nuevos pedidos pueden llevar mucho tiempo y ser costosos.

La solución: Para mitigar esta confusión, los compradores B2B deben invertir tiempo en conocer las especificaciones de los vehículos para los que compran o cuyo mantenimiento realizan. Las bases de datos en línea o los recursos de los fabricantes pueden proporcionar información crucial sobre los tipos de faros adecuados para los distintos modelos. Además, establecer asociaciones con proveedores de confianza que puedan ofrecer orientación sobre las últimas tecnologías en faros mejorará los procesos de compra. La aplicación de un protocolo de compras estandarizado, que incluya una lista de comprobación en la que se indiquen las marcas y modelos de vehículos y los tipos de faros compatibles, puede agilizar los pedidos y minimizar los errores.

Escenario 3: El impacto del deterioro del rendimiento de los faros en la seguridad

El problema: Para las empresas de sectores en los que la seguridad es primordial, como el transporte y la logística, el deterioro del rendimiento de los faros puede suponer riesgos importantes. Unos faros oscuros o nublados pueden reducir la visibilidad y aumentar la probabilidad de accidentes. Los compradores B2B pueden tener dificultades para comprender las implicaciones económicas de no solucionar los problemas de los faros con prontitud, ya que esto podría dar lugar a primas de seguro más elevadas y a posibles reclamaciones por responsabilidad civil.

La solución: Para dar prioridad a la seguridad y mitigar los riesgos, los compradores B2B deben aplicar un programa de mantenimiento periódico que incluya inspecciones de los faros. Es esencial formar al personal para que reconozca los signos de deterioro de los faros, como la disminución del brillo o la nubosidad. Cuando se detectan problemas, los compradores deben tener un protocolo preestablecido para la sustitución oportuna, utilizando acuerdos de compra al por mayor con los proveedores para reducir costes. Además, invertir en kits de restauración de faros para reparaciones menores puede prolongar la vida útil de los faros existentes, ahorrando costes y mejorando la seguridad. Al fomentar una cultura de mantenimiento proactivo de los vehículos, las empresas pueden reducir significativamente los gastos relacionados con la seguridad y mejorar la eficiencia operativa general.

Guía estratégica de selección de materiales para ¿Cuánto cuesta un faro?

¿Qué materiales se utilizan habitualmente en la fabricación de faros?

Al considerar el coste de los faros, los materiales utilizados en su construcción desempeñan un papel crucial a la hora de determinar su rendimiento, longevidad y coste global. Aquí analizamos cuatro materiales habituales en la fabricación de faros: policarbonato, vidrio, aluminio y materiales compuestos. Cada material tiene propiedades distintas que influyen en el rendimiento del producto final y en su idoneidad para diversas aplicaciones.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

¿Cómo afecta el policarbonato al coste y el rendimiento de los faros?

El policarbonato es una opción popular para las lentes de los faros debido a su ligereza y su alta resistencia a los impactos. Puede soportar importantes variaciones de temperatura, lo que lo hace idóneo para aplicaciones de automoción. Las lentes de policarbonato pueden moldearse con formas complejas, lo que permite diseños innovadores que mejoran la estética del vehículo.

Ventajas: El policarbonato es relativamente barato, ofrece buena resistencia a los rayos UV y es menos propenso a romperse que el vidrio. También permite flexibilidad de diseño, lo que puede ser ventajoso para los fabricantes que buscan diferenciar sus productos.

Contras: Aunque duradero, el policarbonato puede rayarse con facilidad y amarillear con el tiempo si se expone a la luz ultravioleta. Esta degradación puede afectar a la claridad del faro, reduciendo la visibilidad y la seguridad.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Impacto en la aplicación: El policarbonato es compatible con diversas tecnologías de iluminación para automóviles, como las halógenas, HID y LED. Sin embargo, su susceptibilidad al rayado exige una manipulación cuidadosa durante la fabricación y la instalación.

Consideraciones para compradores internacionales: Los compradores de regiones como África y Sudamérica deben asegurarse de que los materiales de policarbonato cumplen las normas locales de seguridad automovilística. El cumplimiento de las normas ASTM o ISO puede ser esencial para la aceptación en el mercado.

¿Qué papel desempeña el cristal en la construcción de faros?

El cristal se ha utilizado tradicionalmente en la fabricación de faros por su excelente claridad óptica y su resistencia a los arañazos. Soporta altas temperaturas y es menos propenso a amarillear en comparación con el policarbonato.

Ventajas: El vidrio proporciona un rendimiento óptico superior, garantizando que los faros emitan una luz clara y brillante. También es más resistente a factores ambientales, como la radiación UV y los productos químicos.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Contras: El principal inconveniente del cristal es su peso, que puede aumentar el peso total del vehículo y afectar a la eficiencia del combustible. Además, el cristal es más propenso a romperse en caso de impacto, lo que puede elevar los costes de sustitución.

Impacto en la aplicación: El vidrio es especialmente adecuado para vehículos de altas prestaciones en los que la claridad óptica es primordial. Sin embargo, su fragilidad puede limitar su uso en aplicaciones todoterreno o resistentes.

Consideraciones para compradores internacionales: Los compradores europeos, sobre todo los alemanes, pueden decantarse por el vidrio por sus características de rendimiento, pero también deben tener en cuenta la logística del transporte de materiales más pesados.

¿Cómo influye el aluminio en el coste del montaje de faros?

El aluminio se utiliza a menudo en los componentes estructurales de los conjuntos de faros, como carcasas y soportes. Su ligereza y resistencia a la corrosión lo convierten en una opción atractiva para los vehículos modernos.

Ventajas: El aluminio es duradero y ligero, lo que reduce el peso total del vehículo al tiempo que proporciona una excelente resistencia a la corrosión. Esto puede reducir los costes de mantenimiento a lo largo de la vida útil del vehículo.

Contras: El proceso de fabricación del aluminio puede ser más complejo y costoso que el de otros materiales, lo que puede incrementar el coste global de los conjuntos de faros.

Impacto en la aplicación: El aluminio es especialmente beneficioso en regiones con alta humedad o exposición a la sal, ya que resiste eficazmente la corrosión. Sin embargo, su elevado coste puede disuadir a los compradores con poco presupuesto.

Consideraciones para compradores internacionales: Los compradores de las regiones costeras de Oriente Próximo pueden dar prioridad al aluminio por su resistencia a la corrosión, mientras que los de climas más templados pueden optar por materiales menos caros.

¿Cuáles son las ventajas de los materiales compuestos en el diseño de faros?

Los materiales compuestos, que combinan distintos materiales para optimizar el rendimiento, se utilizan cada vez más en la fabricación de faros. Estos materiales pueden ofrecer un equilibrio entre peso, coste y durabilidad.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Ventajas: Los materiales compuestos pueden diseñarse para ofrecer propiedades específicas, como una mayor resistencia a los impactos o estabilidad térmica. También pueden ser más ligeros que los materiales tradicionales, lo que contribuye a la eficiencia general del vehículo.

Contras: La complejidad de la fabricación de materiales compuestos puede elevar los costes. Además, garantizar una calidad uniforme en todos los lotes puede resultar complicado.

Impacto en la aplicación: Los materiales compuestos son adecuados para una serie de aplicaciones de automoción, especialmente en vehículos diseñados para ofrecer rendimiento y eficiencia. Sin embargo, su aceptación en el mercado puede variar en función de las preferencias regionales.

Consideraciones para compradores internacionales: Los compradores de Sudamérica pueden encontrar atractivos los materiales compuestos por sus propiedades de ahorro de peso, pero deben verificar el cumplimiento de la normativa local en materia de seguridad y rendimiento de los materiales.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Cuadro sinóptico de selección de materiales para faros

| Material | Caso típico de uso de cuánto cuesta un faro | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Policarbonato | Lentes de los faros de los vehículos de masas | Ligero y resistente a los impactos. | Se raya fácilmente y puede amarillear | Bajo |

| Vidrio | Faros de alto rendimiento para vehículos | Claridad óptica superior | Pesado y propenso a romperse | Medio |

| Aluminio | Componentes estructurales de los faros | Resistente a la corrosión y ligero | Mayor complejidad de fabricación | Alto |

| Compuesto | Diseños avanzados de faros para vehículos de altas prestaciones | Propiedades personalizables | Mayores costes de producción | Medio |

Una mirada en profundidad: Procesos de fabricación y garantía de calidad de ¿Cuánto cuesta un faro?

¿Cuáles son las principales etapas del proceso de fabricación de faros?

El proceso de fabricación de faros es un viaje complejo que incluye varias etapas críticas: preparación del material, conformado, montaje y acabado. Cada etapa desempeña un papel vital para garantizar que el producto final cumpla las normas de seguridad y rendimiento.

-

Preparación del material: El primer paso consiste en abastecerse de materias primas de alta calidad. Los componentes de los faros suelen ser de plástico, vidrio y metal. Por ejemplo, el policarbonato se utiliza habitualmente para la fabricación de lentes por su durabilidad y claridad óptica. Los proveedores deben asegurarse de que estos materiales cumplen normas internacionales, como la ISO 9001, que rige los sistemas de gestión de calidad. Garantizar que los materiales no tienen defectos y cumplen las especificaciones es crucial.

-

Formación: Una vez preparados los materiales, el siguiente paso es el conformado. Esto incluye el moldeado de componentes de plástico y la conformación de lentes de cristal. A menudo se utilizan técnicas avanzadas como el moldeo por inyección y el moldeo por soplado. La elección de la técnica de conformado puede influir significativamente en el rendimiento y el coste del faro. Por ejemplo, el moldeo por inyección a alta presión puede crear formas complejas que mejoran la aerodinámica y la estética, pero puede ser más caro que los métodos tradicionales.

-

Ensamblaje: Tras el conformado, se ensamblan los distintos componentes. Esta etapa puede incluir la integración del casquillo de la bombilla, el cableado y los componentes electrónicos de los faros más avanzados, como los LED o los sistemas de iluminación adaptativa. Las líneas de montaje automatizadas se emplean habitualmente para mejorar la eficiencia y reducir los errores humanos. Sin embargo, el montaje manual puede seguir siendo necesario para los productos más complejos o de mayor calidad, lo que garantiza que cada unidad se fabrique con los más altos estándares.

-

Acabado: La etapa final consiste en aplicar revestimientos protectores y realizar los tratamientos de superficie necesarios. Esto puede incluir protección UV para evitar el amarilleamiento y mejorar la durabilidad. El proceso de acabado también implica controles de calidad para garantizar que el producto sea visualmente atractivo y funcionalmente sólido. Cualquier defecto en esta fase puede acarrear costes significativos para los fabricantes e insatisfacción entre los compradores B2B.

¿Cómo se aplica la garantía de calidad en la fabricación de faros?

El control de calidad es una parte integral del proceso de fabricación, que garantiza que los faros cumplen los criterios de seguridad y rendimiento. Estos procesos se rigen por varias normas internacionales y específicas del sector.

-

Normas internacionales pertinentes: El cumplimiento de la norma ISO 9001 es esencial para mantener los sistemas de gestión de la calidad. Esta norma garantiza que los fabricantes produzcan sistemáticamente productos que cumplan los requisitos reglamentarios y de los clientes. Además, certificaciones como la marca CE (Conformité Européenne) indican el cumplimiento de las normas de seguridad europeas, aunque también pueden aplicarse normas específicas de la industria del automóvil.

-

Puntos de control de calidad: Varios puntos de control a lo largo del proceso de fabricación ayudan a mantener la calidad:

– Control de calidad de entrada (IQC): Se trata de inspeccionar las materias primas y los componentes a su llegada para garantizar que cumplen las especificaciones antes de que comience el procesamiento.

– Control de calidad durante el proceso (IPQC): Los controles de calidad durante el proceso de fabricación ayudan a detectar cualquier defecto en una fase temprana. Por ejemplo, midiendo las dimensiones o comprobando las propiedades de los materiales en distintas fases.

– Control de calidad final (FQC): Tras el montaje, se realiza una inspección minuciosa para garantizar que el producto final cumple todas las especificaciones. Esto puede incluir pruebas de funcionalidad, mediciones de salida de luz e inspecciones visuales. -

Métodos de prueba comunes: Los fabricantes suelen emplear diversos métodos de ensayo para garantizar la calidad del producto. Estos pueden incluir:

– Pruebas fotométricas: Evaluación de la potencia luminosa, la distribución y la intensidad.

– Pruebas térmicas: Evaluar el comportamiento del faro en condiciones de temperatura variables.

– Pruebas de durabilidad: Someter los faros a vibraciones, impactos y exposición a factores ambientales para simular las condiciones del mundo real.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

Para los compradores B2B, especialmente los de regiones como África, Sudamérica, Oriente Medio y Europa, verificar los procesos de control de calidad de un proveedor es crucial para garantizar la fiabilidad y la seguridad.

-

Realización de auditorías: Las auditorías periódicas de las instalaciones de fabricación pueden proporcionar información sobre las prácticas de gestión de la calidad del proveedor. Los compradores deben informarse sobre la frecuencia de estas auditorías y si las llevan a cabo organizaciones externas.

-

Solicitud de informes de calidad: Los proveedores deben facilitar documentación sobre sus medidas de control de calidad, incluidos los resultados de las pruebas y las certificaciones. Los compradores pueden solicitar estos informes para evaluar el cumplimiento de las normas del sector.

-

Servicios de inspección por terceros: La contratación de servicios de inspección por terceros puede proporcionar una evaluación imparcial de los procesos de fabricación y las medidas de control de calidad del proveedor. Estas inspecciones pueden ser cruciales para garantizar que los productos cumplen las normas internacionales de seguridad y calidad.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

Los compradores B2B internacionales deben sortear varios matices en el control de calidad cuando se abastecen de faros de fabricantes de distintas regiones.

-

Comprender las normas regionales: Las normas sobre productos de automoción pueden variar de una región a otra. Los compradores deben familiarizarse con la normativa de sus mercados de destino. Por ejemplo, las normas europeas pueden ser más estrictas que las de otras regiones, lo que influye en los tipos de productos que pueden venderse.

-

Diferencias culturales en la percepción de la calidad: Las actitudes culturales hacia la calidad pueden variar, lo que influye en el modo en que los fabricantes enfocan la garantía de calidad. En algunas regiones se da más importancia a la estética visual, mientras que en otras priman las prestaciones.

-

Comunicación y documentación: Una comunicación clara es vital para garantizar que las expectativas de calidad se entienden y se cumplen. Los compradores B2B deben asegurarse de que todos los acuerdos estén documentados y en ellos se indiquen los requisitos específicos de calidad, los métodos de ensayo y los plazos de entrega.

Al conocer los procesos de fabricación y las medidas de garantía de calidad del sector de los faros, los compradores B2B pueden tomar decisiones de compra informadas que se ajusten a sus objetivos de seguridad, rendimiento y costes. Este conocimiento no solo ayuda a seleccionar proveedores fiables, sino también a fomentar asociaciones a largo plazo que beneficien a todas las partes implicadas.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Guía práctica de búsqueda: Una lista de comprobación paso a paso para ‘cuánto cuesta un faro’

En esta guía esbozaremos una lista de comprobación práctica para compradores B2B que deseen comprender y adquirir faros. Con la gran variedad de opciones disponibles en el mercado, es esencial navegar por el proceso de compra de manera eficaz para garantizar la seguridad, el cumplimiento y la relación calidad-precio.

Paso 1: Identifique los requisitos de su vehículo

Es fundamental conocer los requisitos específicos de los faros de su modelo de vehículo. Cada tipo de vehículo puede requerir diferentes tipos de bombillas y conjuntos, como halógenas, HID o LED. Consulte el manual del propietario del vehículo o una tienda de repuestos de confianza para obtener las especificaciones correctas, incluidos los números de pieza y la compatibilidad.

Paso 2: Tecnologías de faros de investigación

Familiarícese con los distintos tipos de tecnologías de faros disponibles. Las opciones incluyen:

– Halógeno: Rentable pero de vida útil más corta.

– HID (Xenón): Ofrece una luz más brillante, pero su instalación puede resultar compleja.

– LED: De larga duración y alta eficiencia, aunque pueden ser costosas.

Comprender estas tecnologías ayuda a tomar una decisión informada basada en los requisitos de presupuesto y rendimiento.

Paso 3: Evaluar las certificaciones de los proveedores

Antes de comprometerte con un proveedor, verifica sus certificaciones y el cumplimiento de las normas de seguridad pertinentes. Busque la marca “DOT” en las bombillas, que indica que cumplen las normas del Departamento de Transporte de Estados Unidos. Este paso es crucial, ya que garantiza que los productos que adquiera sean seguros y fiables, minimizando posibles responsabilidades.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Paso 4: Comparar precios y calidad

Realice un análisis exhaustivo del mercado para comparar precios entre varios proveedores. Tenga en cuenta factores como:

– Precios por volumen: Los descuentos por pedidos grandes pueden reducir considerablemente los costes.

– Garantía de calidad: Asegúrese de que los proveedores ofrecen garantías sobre sus productos.

Equilibrar el coste con la calidad es esencial para asegurarse de hacer una buena inversión.

Paso 5: Evaluar la fiabilidad y reputación del proveedor

Investigue a los posibles proveedores examinando su reputación en el mercado. Busque testimonios de clientes, estudios de casos y referencias del sector. Un proveedor fiable debe tener un historial de entregas puntuales y productos de calidad, lo que puede ser crucial para mantener su inventario y la satisfacción del cliente.

Paso 6: Prever los costes de instalación y mantenimiento

Considere el coste total de propiedad, incluida la instalación y el mantenimiento. Algunos faros pueden requerir una instalación profesional, lo que puede aumentar el gasto total. Además, planifica posibles sustituciones futuras conociendo la vida útil media de los faros que elijas, ya que esto puede afectar al presupuesto a largo plazo.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Paso 7: Solicitar muestras y realizar pruebas

Antes de finalizar su pedido, solicite muestras para comprobar el rendimiento de los faros. Esto le permitirá evaluar factores como la luminosidad, la longevidad y la calidad general. Probar muestras le garantiza que está satisfecho con el producto antes de realizar una gran inversión, lo que le ayuda a mitigar el riesgo de adquirir artículos insatisfactorios.

Siguiendo esta lista de comprobación, los compradores B2B pueden navegar eficazmente por las complejidades del aprovisionamiento de faros, asegurándose de que cumplen las normas de seguridad sin dejar de ser rentables.

Análisis exhaustivo de costes y precios de cuánto cuesta un faro Sourcing

¿Cuáles son los principales componentes de coste en el aprovisionamiento de faros?

Cuando se adquieren faros con fines B2B, es fundamental comprender la estructura de costes. Los principales componentes son:

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

-

Materiales: El coste de los materiales varía significativamente en función del tipo de faro. Las bombillas halógenas suelen ser más baratas que los sistemas HID o LED, que requieren materiales avanzados para un mejor rendimiento y longevidad. La calidad de los materiales utilizados repercute directamente en el precio final.

-

Trabajo: Los costes de mano de obra abarcan tanto la fabricación como la instalación. Dependiendo de la complejidad del diseño del faro, los costes de mano de obra pueden variar. Por ejemplo, montar una simple bombilla halógena requiere menos mano de obra que fabricar un complejo módulo LED con electrónica integrada.

-

Gastos generales de fabricación: Incluye los costes relacionados con las instalaciones de producción, el mantenimiento de los equipos y los servicios públicos. Los fabricantes también pueden incurrir en costes adicionales relacionados con el cumplimiento de las normas de seguridad y calidad, especialmente en el caso de los envíos internacionales.

-

Herramientas: El utillaje personalizado puede suponer una importante inversión inicial, sobre todo si se trata de diseños o especificaciones únicos. Este coste suele amortizarse en grandes series de producción, por lo que es importante tener en cuenta las cantidades mínimas de pedido (MOQ).

-

Control de calidad (QC): Garantizar la fiabilidad de los productos para faros implica rigurosos procesos de control de calidad, que pueden aumentar el coste total. Esto es especialmente relevante para los compradores B2B que requieren productos certificados que cumplan las normas internacionales.

-

Logística: Los gastos de envío, incluidos los fletes y derechos de aduana, dependen del origen de los faros, el destino y el método de envío. Los incoterms pueden afectar significativamente a los costes y responsabilidades logísticas.

-

Margen: Los proveedores suelen añadir un margen para cubrir sus costes y beneficios. Conocer el margen puede ayudar a los compradores a negociar mejores precios.

¿Qué factores influyen en el precio?

Varios factores pueden influir en el precio de los faros en el mercado B2B:

-

Volumen/Cantidad mínima de pedido: La compra de grandes cantidades suele conllevar una reducción de los precios por unidad. Los compradores deben negociar cantidades máximas que se ajusten a sus necesidades y garanticen la rentabilidad.

-

Especificaciones/Personalización: Los faros personalizados o con funciones avanzadas (como la iluminación adaptativa) tendrán precios más elevados. Los compradores deben comunicar claramente sus especificaciones para evitar costes inesperados.

-

Calidad de los materiales y certificaciones: Los materiales y certificaciones de mayor calidad (como ISO o DOT) pueden aumentar los costes, pero son esenciales para la seguridad y el cumplimiento de la normativa en muchos mercados. Los compradores deben equilibrar la calidad con las limitaciones presupuestarias.

-

Factores relacionados con los proveedores: La elección del proveedor puede influir significativamente en el precio. Los proveedores establecidos y con buena reputación pueden cobrar más, pero a menudo ofrecen mejor calidad y servicio. Los compradores deben evaluar a los proveedores en función de su fiabilidad, plazos de entrega y resultados anteriores.

-

Incoterms: Las condiciones de envío definidas por los Incoterms pueden afectar al coste total. Los compradores deben ser conscientes de sus responsabilidades con respecto al envío, el seguro y los aranceles.

¿Cuáles son los mejores consejos de negociación y rentabilidad para compradores B2B?

A la hora de negociar los precios de los faros, tenga en cuenta las siguientes estrategias para mejorar la rentabilidad:

-

Aprovecha los descuentos por volumen: Utilice las compras al por mayor para negociar precios más bajos. Si es posible, consolide pedidos de varios productos para aumentar el volumen de pedidos.

-

Explorar los proveedores locales: Especialmente para los compradores de África, Sudamérica y Oriente Medio, abastecerse de fabricantes locales puede reducir los costes de envío y los plazos de entrega.

-

Evaluar el coste total de propiedad (TCO): Tenga en cuenta no sólo el precio de compra, sino también los costes de instalación, mantenimiento y posible sustitución. Elegir faros de mayor calidad puede suponer un menor coste total de propiedad a largo plazo.

-

Manténgase informado sobre las tendencias del mercado: Conocer las fluctuaciones del mercado y los avances tecnológicos puede ayudar a los compradores a planificar mejor sus compras y negociar con eficacia.

-

Solicitar varias cotizaciones: Solicite siempre presupuestos a varios proveedores para comparar precios y condiciones. Esto puede servir de ventaja en las negociaciones y ayudar a identificar el mejor valor global.

Conclusión

Aunque los precios indicativos de los faros pueden variar mucho, entender los componentes del coste y los factores que influyen en el precio es esencial para los compradores B2B que buscan tomar decisiones de compra informadas. Aplicando técnicas de negociación estratégica y centrándose en la eficiencia de los costes totales, los compradores internacionales pueden gestionar eficazmente sus necesidades de abastecimiento de faros, garantizando al mismo tiempo el cumplimiento de las normas de seguridad.

Análisis de alternativas: Comparación de cuánto cuesta un faro con otras soluciones

Exploración de alternativas a los costes de los faros: Un análisis comparativo

A medida que los compradores B2B buscan soluciones eficaces de iluminación para los vehículos, resulta crucial comprender el coste y la eficacia de los faros tradicionales en comparación con las tecnologías alternativas. Este análisis examina los costes asociados a las sustituciones de faros estándar frente a tecnologías de iluminación innovadoras como las luces de descarga de alta intensidad (HID) y los sistemas de diodos emisores de luz (LED). Cada alternativa presenta ventajas y retos únicos que pueden afectar significativamente a los costes operativos a largo plazo y a la seguridad del vehículo.

| Aspecto comparativo | ¿Cuánto cuesta un faro? | Faros HID | Faros LED |

|---|---|---|---|

| Rendimiento | Iluminación estándar | Hasta 3-5 veces más luminoso | Gran luminosidad y eficiencia energética |

| Coste | $20 - $1.000+ | $150 - $300 por bombilla | $50 - $200 por bombilla (el conjunto puede superar $600) |

| Facilidad de implementación | Sustitución sencilla de bombillas | Instalación profesional recomendada | Complejo, a menudo requiere la sustitución del montaje |

| Mantenimiento | Sustitución periódica de bombillas | Requiere la sustitución del balasto | Larga vida útil pero costosas sustituciones |

| Mejor caso de uso | Uso general para vehículos antiguos | Vehículos de altas prestaciones que necesitan mayor visibilidad | Vehículos modernos que requieren eficiencia energética y longevidad |

¿Cuáles son los pros y los contras de los faros HID?

Los faros de descarga de alta intensidad (HID) ofrecen una iluminación mucho más brillante que las bombillas halógenas estándar, por lo que son ideales para vehículos orientados al rendimiento. El coste de las bombillas HID oscila entre $150 y $300, y su vida útil puede alcanzar entre 2.000 y 3.000 horas, lo que las convierte en una opción viable para un uso a largo plazo. Sin embargo, la complejidad de la instalación suele requerir ayuda profesional, lo que aumenta el coste total. Además, las luces HID pueden oscurecerse con el tiempo, por lo que es necesario sustituirlas a tiempo para mantener una visibilidad óptima.

¿Cómo se comparan los faros LED?

Los faros de diodos emisores de luz (LED) son la opción más avanzada disponible actualmente. Proporcionan una luminosidad y una eficiencia energética excepcionales, con una vida útil de unas 30.000 horas. Los costes de sustitución de las bombillas LED suelen oscilar entre $50 y $200, pero si es necesario sustituir todo el conjunto del faro, los costes pueden dispararse hasta superar los $600. Aunque los LED duran mucho más, la complejidad de su tecnología puede dar lugar a costosas reparaciones si fallan los componentes. Además, el reequipamiento de vehículos antiguos con sistemas LED no siempre es factible, lo que limita su uso a los modelos más recientes.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Conclusión: ¿Cómo pueden los compradores B2B tomar la decisión correcta?

A la hora de elegir entre faros tradicionales y soluciones de iluminación alternativas, los compradores B2B deben tener en cuenta sus necesidades operativas específicas, los tipos de vehículos y las limitaciones presupuestarias. Los faros estándar pueden ser suficientes para el uso general en vehículos antiguos, mientras que las opciones HID y LED ofrecen un mayor rendimiento y eficiencia para las flotas modernas. En última instancia, la decisión debe alinearse con las prioridades de la organización, ya sea la rentabilidad, la seguridad o el avance tecnológico. Comprender el coste total de propiedad, incluidos los ciclos de mantenimiento y sustitución, permitirá a los compradores tomar decisiones informadas que sirvan mejor a sus objetivos operativos.

Propiedades técnicas esenciales y terminología comercial de ¿cuánto cuesta un faro?

A la hora de evaluar los costes asociados a los faros, comprender las especificaciones técnicas y la terminología del sector es crucial para los compradores B2B internacionales. Este conocimiento ayuda a tomar decisiones de compra informadas y a negociar eficazmente con los proveedores.

¿Cuáles son las principales características técnicas que influyen en el coste de los faros?

-

Tipo de bombilla y tecnología

– Halógeno: La opción más común y rentable, que suele oscilar entre $10 y $40. Son fáciles de sustituir, pero tienen una vida útil más corta (500-1.000 horas).

– Descarga de alta intensidad (HID): Ofrece una luminosidad y longevidad superiores (2.000-3.000 horas), pero cuesta bastante más, alrededor de $150 por bombilla. Los sistemas HID requieren una instalación especializada debido al alto voltaje.

– Diodo emisor de luz (LED): La última tecnología con mayor vida útil (hasta 30.000 horas) y menor consumo de energía. Sin embargo, los costes de sustitución pueden oscilar entre $50 y más de $200, y los conjuntos completos cuestan bastante más. -

Tipo de montaje

– Sellado frente a no sellado: Los conjuntos de faros sellados suelen requerir la sustitución completa si falla una bombilla, lo que conlleva costes más elevados (hasta $1.000). Las opciones no selladas permiten sustituir solo la bombilla, lo que puede resultar más económico. -

Grado del material

- Los materiales utilizados en la lente y la carcasa del faro pueden afectar a la durabilidad y el rendimiento. Los materiales de mayor calidad pueden ofrecer una mejor resistencia a los rayos UV y a los impactos, que son esenciales para la longevidad en diversas condiciones ambientales. -

Compatibilidad eléctrica

- La compatibilidad del sistema de faros con la arquitectura eléctrica del vehículo es fundamental. La incompatibilidad puede provocar fallos y mayores costes de reparación o sustitución, sobre todo en vehículos modernos con sistemas de iluminación avanzados. -

Potencia luminosa (lúmenes)

- La luminosidad del faro, medida en lúmenes, es una especificación vital. Un mayor número de lúmenes suele ir asociado a una mayor visibilidad y seguridad, por lo que es un factor clave para los compradores.

¿Qué condiciones comerciales deben conocer los compradores B2B al adquirir faros?

-

OEM (fabricante de equipos originales)

- Se refiere a las piezas fabricadas por el fabricante original del vehículo. Los faros OEM suelen ser más caros, pero garantizan la compatibilidad y la calidad. -

MOQ (cantidad mínima de pedido)

- La cantidad más pequeña que un proveedor está dispuesto a vender. Conocer el MOQ es esencial para presupuestar y gestionar el inventario, sobre todo en las compras al por mayor. -

RFQ (Solicitud de presupuesto)

- Proceso formal en el que un comprador solicita precios y condiciones a los proveedores. Una petición de oferta puede ayudar a los compradores a evaluar los precios del mercado y la fiabilidad del proveedor. -

Incoterms (Términos comerciales internacionales)

- Términos comerciales estándar que definen las responsabilidades entre compradores y vendedores en las transacciones internacionales. Familiarizarse con incoterms como FOB (franco a bordo) o CIF (coste, seguro y flete) es crucial para entender los costes y responsabilidades del envío. -

Garantía y política de devoluciones

- Condiciones asociadas a la sustitución o reparación de productos defectuosos. Conocer la duración y las condiciones de la garantía puede repercutir significativamente en los costes a largo plazo y en las relaciones con los proveedores. -

Recambios originales y recambios de repuesto

- Las piezas de recambio son producidas por terceros fabricantes y pueden ofrecer precios más bajos, pero su calidad puede variar. Entender esta distinción ayuda a los compradores a evaluar el valor frente al coste.

Conclusión

Navegar por las complejidades de los costes de los faros requiere un sólido conocimiento tanto de las propiedades técnicas como de la terminología del sector. Al familiarizarse con estos aspectos, los compradores B2B pueden optimizar sus estrategias de adquisición, asegurándose de que obtienen productos de calidad que satisfacen sus necesidades operativas al tiempo que gestionan eficazmente los costes.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Dinámicas de mercado y tendencias de aprovisionamiento en el sector ¿Cuánto cuesta un faro?

¿Cuáles son los principales factores que influyen en el coste de los faros?

El mercado mundial de faros está experimentando cambios significativos impulsados por los avances tecnológicos y la evolución de las preferencias de los consumidores. Uno de los principales motores es la transición de las bombillas halógenas tradicionales a tecnologías de iluminación más avanzadas, como los sistemas LED y HID. Estas nuevas opciones ofrecen mayor luminosidad, eficiencia energética y una vida útil más larga, lo que resulta especialmente atractivo para los compradores B2B internacionales de regiones como África, Sudamérica, Oriente Medio y Europa.

En cuanto a las tendencias de abastecimiento, cada vez se hace más hincapié en los diseños modulares que facilitan las sustituciones y actualizaciones, atendiendo a la creciente demanda de soluciones de automoción personalizables. Además, a medida que los vehículos se vuelven más complejos con sistemas de iluminación integrados que incluyen funciones como la iluminación adaptativa y la nivelación automática, el coste de los componentes de recambio puede variar mucho. Por ejemplo, los compradores B2B deben ser conscientes de que, mientras que las bombillas halógenas básicas pueden adquirirse por un precio tan bajo como $10, los conjuntos LED de alta calidad pueden superar los $1.000, lo que repercute significativamente en los presupuestos generales de mantenimiento de los vehículos.

Los mercados emergentes de África y Sudamérica también están experimentando un aumento de la demanda de piezas de recambio asequibles, lo que ha provocado una mayor competencia entre los proveedores. Este cambio está impulsando a los fabricantes a invertir en métodos de producción rentables, garantizando al mismo tiempo el cumplimiento de las normas de seguridad internacionales, como las establecidas por el Departamento de Transporte de Estados Unidos. Comprender esta dinámica del mercado ayudará a los compradores internacionales a tomar decisiones informadas a la hora de abastecerse de componentes para faros.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

¿Cómo afecta la sostenibilidad al aprovisionamiento de faros en el sector B2B?

La sostenibilidad se está convirtiendo en un factor esencial en el abastecimiento de componentes de automoción, incluidos los faros. A medida que aumentan las preocupaciones medioambientales en todo el mundo, los compradores B2B dan cada vez más prioridad a los proveedores que se adhieren a prácticas de abastecimiento éticas y ofrecen productos con un menor impacto medioambiental. Esto incluye el uso de materiales reciclables y la garantía de que los procesos de fabricación minimizan los residuos y el consumo de energía.

Los fabricantes de faros también se están centrando en obtener certificaciones ‘verdes’, como la ISO 14001, que indica un compromiso con las prácticas responsables con el medio ambiente. Los compradores de regiones como Europa, donde la normativa es más estricta, suelen exigir a los proveedores que demuestren el cumplimiento de estas normas de sostenibilidad. Esto no sólo ayuda a reducir la huella de carbono, sino que también mejora la reputación de marca de las empresas comprometidas con las prácticas sostenibles.

Además, la creciente popularidad de los vehículos eléctricos está influyendo en el mercado de los faros a medida que los fabricantes exploran soluciones de iluminación innovadoras que se ajusten a las iniciativas ecológicas. Por ejemplo, los faros LED son más eficientes energéticamente que las opciones tradicionales, lo que se traduce en una disminución del consumo total de energía del vehículo. Los compradores B2B deben tener en cuenta no sólo los costes inmediatos, sino también los beneficios a largo plazo del abastecimiento sostenible, incluido el ahorro potencial de energía y el cumplimiento de futuras normativas.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

¿Cuál es la evolución de la tecnología de faros y su relevancia para los compradores B2B?

La evolución de la tecnología de los faros ha influido significativamente en la industria del automóvil y sigue siendo relevante para los compradores B2B. Históricamente, los vehículos estaban equipados con simples bombillas incandescentes de haz sellado, que eran baratas y fáciles de sustituir. Sin embargo, a medida que evolucionaron las normas de seguridad y cambiaron las expectativas de los consumidores, los fabricantes empezaron a adoptar tecnologías de iluminación más avanzadas.

La introducción de las bombillas halógenas supuso una notable mejora de la luminosidad y la longevidad, lo que generalizó su uso en las décadas de 1980 y 1990. Con la llegada de las tecnologías HID y LED a principios de la década de 2000, la atención pasó a centrarse en la mejora de la visibilidad y la eficiencia energética. Hoy en día, los faros LED se están convirtiendo en estándar en muchos modelos de vehículos nuevos debido a su longevidad y menor consumo de energía, mientras que las luces HID siguen estando destinadas a los vehículos de alto rendimiento.

Para los compradores B2B, comprender esta evolución es crucial para tomar decisiones de aprovisionamiento. Conocer el contexto histórico puede ayudar a los compradores a anticipar tendencias futuras y prepararse para posibles cambios tecnológicos. Además, a medida que los diseños de los vehículos se vuelven más sofisticados, aumenta la complejidad de los conjuntos de faros, por lo que es esencial que los compradores se mantengan informados sobre los últimos avances y sus implicaciones para los costes de mantenimiento y sustitución.

Preguntas frecuentes para compradores B2B sobre cuánto cuesta un faro delantero

-

¿Cómo puedo determinar el coste de la sustitución de los faros de los distintos modelos de vehículo?

El coste de la sustitución de los faros varía significativamente en función de la marca, el modelo y el tipo de faro del vehículo. Para las bombillas halógenas básicas, los precios pueden oscilar entre $10 y $40, mientras que las opciones avanzadas como los conjuntos HID o LED pueden superar los $1.000. Para calcular con exactitud los costes, consulta el manual de instrucciones de tu vehículo para conocer el tipo de bombilla específico, o consulta a proveedores que puedan ofrecerte precios basados en las especificaciones de tu vehículo. Además, ten en cuenta los costes de mano de obra si es necesaria una instalación profesional, que puede añadir entre $30 y $300 al gasto total. -

¿Cuál es el mejor tipo de faro para las distintas condiciones de conducción?

Elegir el mejor faro depende de las condiciones de conducción y de los requisitos del vehículo. Las bombillas halógenas son económicas pero pueden no ofrecer la mejor visibilidad. Las bombillas HID proporcionan una iluminación más brillante y son adecuadas para la conducción nocturna, mientras que los LED son eficientes energéticamente y duran más, por lo que son ideales para condiciones variadas. En zonas urbanas con mucho tráfico, los LED pueden ser preferibles por su longevidad y bajo consumo. A la hora de elegir los faros, tenga siempre en cuenta las normas y reglamentos locales sobre iluminación de vehículos. -

¿Qué debo tener en cuenta a la hora de comprar faros en el extranjero?

A la hora de comprar faros en el extranjero, tenga en cuenta factores como el cumplimiento de la normativa local, las certificaciones de calidad y la fiabilidad del proveedor. Compruebe que los productos cumplen las normas de seguridad del mercado de destino, como DOT para EE.UU. o ECE para Europa. Lleve a cabo una investigación exhaustiva del proveedor, que incluya la comprobación de referencias y revisiones, y asegúrese de que puede proporcionar la documentación necesaria para el despacho de aduanas. Además, evalúe la logística de envío y los posibles aranceles que puedan afectar a sus costes totales. -

¿Cuáles son las cantidades mínimas de pedido (CMP) para la compra de faros?

Las cantidades mínimas de pedido de faros pueden variar mucho de un proveedor a otro. Algunos fabricantes pueden fijar cantidades mínimas de 50 unidades para modelos básicos, mientras que otros, especialmente para faros especializados o de gama alta, pueden exigir pedidos de 100 a 500 unidades. Cuando negocie con los proveedores, pregunte por la flexibilidad de las cantidades máximas de producción, especialmente si es un comprador nuevo o está probando la demanda del mercado. Esto puede ayudarle a gestionar los costes de inventario y reducir el riesgo asociado al exceso de existencias. -

¿Cómo puedo asegurarme de la calidad de los faros cuando compro al por mayor?

Para garantizar la calidad al comprar faros al por mayor, solicite muestras antes de comprometerse a realizar un pedido grande. Evalúe la compatibilidad, luminosidad y durabilidad de las muestras. Además, compruebe si el proveedor ofrece garantías sobre sus productos, lo que puede indicar confianza en su calidad. Implementar un proceso de garantía de calidad, como inspecciones o certificaciones de terceros, puede mitigar aún más los riesgos asociados a las compras al por mayor. -

¿Qué condiciones de pago debo esperar para comprar faros?

Las condiciones de pago de los faros pueden variar según el proveedor y la región. Las condiciones habituales incluyen un depósito en el momento de confirmar el pedido y el pago del saldo restante antes del envío. Algunos proveedores pueden ofrecer condiciones de pago neto, que permiten el pago entre 30 y 90 días después de la entrega. Es crucial establecer acuerdos de pago claros por adelantado para evitar malentendidos. Considere la posibilidad de utilizar métodos de pago seguros, como cartas de crédito o servicios de custodia, para proteger su inversión. -

¿Cómo puedo gestionar la logística de los envíos internacionales de faros?

Gestionar la logística de los envíos internacionales de faros implica seleccionar transitarios fiables y conocer la normativa aduanera tanto del país exportador como del importador. Asegúrese de que toda la documentación de envío, como facturas y certificados de origen, sea precisa y esté completa para evitar retrasos. Además, considere el método de envío (aéreo o marítimo) en función de la urgencia y el coste. Colaborar con un socio logístico familiarizado con las piezas de automoción puede agilizar el proceso y ayudar a mitigar los posibles problemas. -

¿Cuáles son las mejores prácticas para restaurar las lentes de los faros opacas?

Restaurar las lentes de los faros opacas puede mejorar la visibilidad y la seguridad. Las mejores prácticas incluyen el uso de un kit de restauración de faros que contenga papel de lija, pulimento y sellador UV. Empieza limpiando bien las lentes y luego líjalas con papel de lija de grano progresivamente más fino. Tras el pulido, aplique un sellador UV para protegerlas de futuros daños. Para pedidos grandes, considere la posibilidad de ofrecer servicios de restauración como parte de su línea de productos, ya que muchos consumidores pueden pasar por alto este aspecto del mantenimiento, lo que supone una oportunidad de negocio adicional.

Lista de los 3 mejores fabricantes y proveedores de Cuánto cuesta un faro delantero

1. Ford - Opciones de sustitución de las bombillas de los faros

Dominio: reddit.com

Registrado: 2005 (20 años)

Introducción: Ford Fusion 2014; bombilla del faro delantero izquierdo; coste de mano de obra $300; mano de obra extensa que implica levantar y retirar varios paneles de la carrocería; consulta sobre opciones para sustituir la bombilla.

2. CarParts - Conjunto de faros

Dominio: recambios.es

Registrado: 1999 (26 años)

Introducción: Faros delanteros - Halógeno, HID, Xenon, LED de $61 | Disponible para el conductor y el pasajero | Amplia selección de faros delanteros de repuesto | Fabricado por nombres respetados en la industria | Diferentes tecnologías de iluminación: Halógeno, HID/Xenon, LED | Envío rápido y devoluciones sin problemas | Garantizado para varias marcas y modelos.

3. Xenon Pro - Guía de costes de sustitución de faros

Dominio: xenonpro.com

Inscrito: 2013 (12 años)

Introducción: Guía de costes de sustitución de faros: 1. Bombillas halógenas de fábrica: Coste $30 - $50 por par, Vida útil 1.000+ horas. 2. Bombillas Xenon HID de fábrica: Coste $50 - $150 por bombilla, vida útil 10.000+ horas. 3. Bombillas LED de fábrica: Coste N/A (todo el conjunto debe ser reemplazado), Vida útil 30.000+ horas. 4. Kit de conversión a LED: Coste $60 - $200, Vida útil 5.000+ horas. 5. Kit de conversión Xenon HID: Coste $50 - $200, vida útil 5.000...

Conclusión y perspectivas de Strategic Sourcing sobre cuánto cuesta un faro delantero

En el competitivo mercado automovilístico actual, comprender los diversos costes asociados a la sustitución de faros es crucial para los compradores B2B internacionales. El rango de precios puede variar significativamente en función del tipo de faro - halógeno, HID o LED - y de la marca y modelo del vehículo. Por ejemplo, mientras que las bombillas halógenas básicas pueden costar entre $10 y $40, los conjuntos LED avanzados pueden alcanzar más de $1.000. Esta variabilidad subraya la importancia del aprovisionamiento estratégico, que garantiza que las empresas no sólo encuentren soluciones rentables, sino que también den prioridad a la calidad y al cumplimiento de las normas de seguridad.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Invertir en componentes de alta calidad y conocer el coste total de propiedad, incluida la instalación y las posibles sustituciones futuras, puede aumentar la satisfacción y la seguridad de los clientes. Además, a medida que los vehículos utilizan cada vez más tecnologías de iluminación avanzadas, mantenerse informado sobre las tendencias del mercado y las capacidades de los proveedores se convierte en un imperativo para fomentar las asociaciones a largo plazo.

De cara al futuro, los compradores B2B de regiones como África, Sudamérica, Oriente Medio y Europa deberían aprovechar la oportunidad para optimizar sus estrategias de adquisición. Al alinearse con proveedores de renombre y adoptar soluciones innovadoras, las empresas pueden asegurar su posición en un panorama automovilístico en rápida evolución. Comprométase hoy con su cadena de suministro para asegurarse de que está equipado para satisfacer las demandas del mercado del mañana.

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Imagen ilustrativa relacionada con cuánto cuesta un faro delantero

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.