Introduction: Navigating the Global Market for changing a headlight

Navigating the global market for changing a headlight can pose significant challenges for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With varying vehicle models and headlight technologies, sourcing the right replacement bulbs and ensuring compatibility can be daunting. This guide aims to demystify the process by providing a comprehensive overview of headlight types, applications, and key considerations for sourcing from reliable suppliers.

From incandescent to LED options, understanding the nuances of each bulb type is crucial for making informed purchasing decisions. Buyers will also gain insights into the vetting process for suppliers, helping them identify quality products that meet regional standards and regulations. Furthermore, this guide addresses cost factors, including bulk purchasing strategies and potential savings, ensuring that businesses can maintain both safety and budget efficiency.

By equipping B2B buyers with essential knowledge and practical tips, this resource empowers them to navigate the complexities of headlight sourcing effectively. Whether you’re in Vietnam or Saudi Arabia, our guide will help you make strategic decisions that enhance your product offerings and ensure customer satisfaction. Embrace the opportunity to elevate your procurement strategy with confidence and clarity.

Índice

- Top 3 Changing A Headlight Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for changing a headlight

- Understanding changing a headlight Types and Variations

- Key Industrial Applications of changing a headlight

- 3 Common User Pain Points for ‘changing a headlight’ & Their Solutions

- Strategic Material Selection Guide for changing a headlight

- In-depth Look: Manufacturing Processes and Quality Assurance for changing a headlight

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘changing a headlight’

- Comprehensive Cost and Pricing Analysis for changing a headlight Sourcing

- Alternatives Analysis: Comparing changing a headlight With Other Solutions

- Essential Technical Properties and Trade Terminology for changing a headlight

- Navigating Market Dynamics and Sourcing Trends in the changing a headlight Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of changing a headlight

- Strategic Sourcing Conclusion and Outlook for changing a headlight

- Aviso legal importante y condiciones de uso

Understanding changing a headlight Types and Variations

| Nombre del tipo | Características distintivas clave | Aplicaciones B2B principales | Breves ventajas y desventajas para los compradores |

|---|---|---|---|

| Bombillas halógenas | Traditional incandescent design, widely used, lower cost. | Talleres de reparación de automóviles, servicios de flotas | Ventajas: Cost-effective, easy to replace. Contras: Shorter lifespan, less brightness. |

| HID (descarga de alta intensidad) | Produces bright light with less energy, longer lifespan. | Luxury vehicle manufacturers, high-end repair shops | Ventajas: Superior brightness, energy-efficient. Contras: Higher initial cost, complex installation. |

| LED (diodo emisor de luz) | Long lifespan, energy-efficient, available in various colors. | Electric vehicle manufacturers, aftermarket suppliers | Ventajas: Long-lasting, low power consumption. Contras: Higher upfront costs, may require complete assembly replacement. |

| Bombillas de xenón | A type of HID bulb known for its bright, white light output. | High-performance automotive sectors | Ventajas: Excelente visibilidad, aspecto elegante. Contras: Expensive, requires special fixtures. |

| Composite Headlight Assemblies | Integrated units that include the lens and bulb together. | Auto manufacturers, collision repair shops | Ventajas: All-in-one solution, ensures compatibility. Contras: More costly, complete assembly replacement needed. |

What Are the Characteristics of Halogen Bulbs?

Halogen bulbs are the most common type of headlights found in vehicles today. They are characterized by their incandescent design, which uses a tungsten filament encased in a halogen gas-filled envelope. This design allows for a brighter light output compared to standard incandescent bulbs, making them a popular choice for many automotive applications. B2B buyers should consider their lower initial cost and ease of replacement, particularly for automotive repair shops that require bulk purchases. However, halogen bulbs have a shorter lifespan and may not provide the best visibility compared to newer technologies.

How Do HID Bulbs Stand Out in Performance?

High-Intensity Discharge (HID) bulbs are known for their exceptional brightness and energy efficiency. They operate by creating an electric arc between two electrodes in a gas-filled chamber, producing a white light that is significantly brighter than halogen bulbs. This makes HID bulbs suitable for luxury vehicles and high-performance applications where visibility is crucial. B2B buyers should weigh the initial investment against the long lifespan and reduced energy consumption, although installation can be more complex and may require specialized equipment.

What Are the Advantages of LED Headlights?

LED headlights are becoming increasingly popular due to their longevity and energy efficiency. These bulbs emit light through a semiconductor, which allows for a range of color temperatures and styles. They are particularly suitable for electric vehicle manufacturers and aftermarket suppliers looking to offer modern lighting solutions. While the initial cost can be higher, the long lifespan and low power consumption make LED headlights a cost-effective choice in the long run. However, B2B buyers should note that some LED systems may require complete assembly replacements, which can add to the overall cost.

Why Choose Xenon Bulbs for Automotive Applications?

Xenon bulbs, a specific type of HID bulb, are recognized for their bright, white light output that enhances road visibility significantly. This makes them a preferred option for high-performance automotive sectors where style and safety are paramount. B2B buyers should consider the stylish appearance and excellent visibility offered by xenon bulbs, but they should also be aware of the higher costs and the need for specialized fixtures, which can impact the overall budget.

What Are Composite Headlight Assemblies and Their Benefits?

Composite headlight assemblies are integrated units that combine the lens and bulb into a single component. This design ensures compatibility and simplifies the replacement process, making them ideal for auto manufacturers and collision repair shops. While they provide an all-in-one solution, B2B buyers should consider the higher costs associated with these assemblies, as they often require complete replacements rather than just bulb changes. This factor can influence purchasing decisions, especially for businesses focused on cost efficiency.

Key Industrial Applications of changing a headlight

| Industria/Sector | Specific Application of changing a headlight | Valor/beneficio para la empresa | Consideraciones clave sobre el abastecimiento para esta aplicación |

|---|---|---|---|

| Talleres de reparación de automóviles | Routine maintenance for vehicle lighting systems | Enhances customer safety and satisfaction | Availability of a wide range of compatible bulbs and tools |

| Gestión de flotas | Regular headlight replacements for commercial vehicle fleets | Reduces downtime and enhances operational safety | Bulk purchasing options and reliable supply chains |

| Transporte y logística | Ensuring compliance with safety regulations for transport vehicles | Minimizes legal liabilities and improves safety | Cumplimiento de la normativa local y las certificaciones de calidad |

| Transporte público | Upgrading headlight systems for buses and public transport | Increases visibility and passenger safety | Durable products suitable for heavy usage and adverse conditions |

| Construction & Mining | Replacing headlights in heavy machinery and vehicles | Improves safety in low-visibility environments | Robust bulbs that withstand harsh conditions and vibrations |

How Do Automotive Repair Shops Benefit from Changing Headlights?

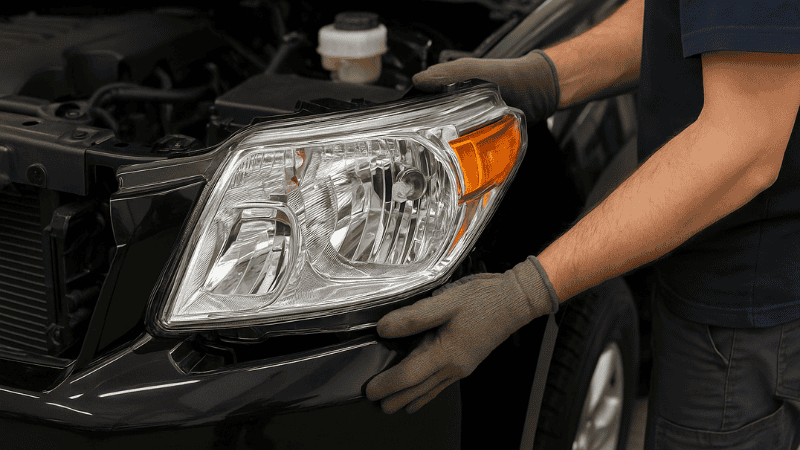

Automotive repair shops frequently perform headlight replacements as part of routine vehicle maintenance. A well-functioning headlight system is crucial for ensuring driver visibility and safety, especially during nighttime or adverse weather conditions. By providing reliable headlight replacement services, repair shops can enhance customer satisfaction and loyalty. B2B buyers in this sector should focus on sourcing high-quality bulbs that fit a variety of vehicle models and ensure they have the necessary tools to perform installations efficiently.

Illustrative image related to changing a headlight

Why is Regular Headlight Replacement Important for Fleet Management?

In fleet management, regular headlight replacements are vital to maintaining operational safety and efficiency. Commercial vehicles often operate in diverse and challenging environments, making visibility crucial for avoiding accidents. By ensuring that all vehicles in a fleet have functioning headlights, managers can reduce downtime caused by repairs and enhance overall safety compliance. Buyers in this space should consider bulk purchasing agreements for headlights to ensure consistent quality and availability across their fleet.

What Role Does Changing Headlights Play in Transportation & Logistics?

Transportation and logistics companies must adhere to strict safety regulations, which include maintaining functional vehicle lighting systems. Regular headlight replacements not only ensure compliance with these regulations but also minimize the risk of accidents that could lead to legal liabilities. For international B2B buyers, understanding local regulations regarding vehicle lighting is essential. This includes sourcing headlights that meet specific compliance standards in different regions.

How Do Public Transportation Services Benefit from Upgrading Headlights?

Public transportation systems, such as buses, greatly benefit from upgraded headlight systems. Enhanced visibility is crucial for the safety of both passengers and drivers, especially in urban areas with frequent stops and varying light conditions. By investing in high-quality headlight replacements, public transport authorities can improve safety and reliability. B2B buyers in this sector should prioritize sourcing durable and efficient lighting solutions that can withstand frequent use and environmental challenges.

Why is Headlight Replacement Critical in Construction & Mining?

In construction and mining, vehicles often operate in low-visibility environments, making functional headlights essential for safety. Regular headlight replacements in heavy machinery and transport vehicles help mitigate risks associated with poor visibility, thereby protecting workers and equipment. Buyers in these industries should seek robust headlight solutions designed to withstand harsh conditions, including dust, moisture, and vibrations, ensuring longevity and reliability in demanding environments.

3 Common User Pain Points for ‘changing a headlight’ & Their Solutions

Escenario 1: Dificultad para identificar la bombilla adecuada para el faro delantero

El problema: B2B buyers, particularly those managing fleets or automotive repair shops, often face confusion when it comes to selecting the appropriate headlight bulb for different vehicle models. With an extensive array of bulb types and specifications, including halogen, HID, and LED options, it can be challenging to determine the correct fit. Misidentifying the bulb not only leads to wasted time and resources but also affects vehicle safety and compliance with local regulations.

La solución: To mitigate this issue, B2B buyers should invest in comprehensive bulb catalogs or databases that provide vehicle-specific recommendations. Suppliers can offer an online tool or mobile app where users can input vehicle make, model, and year to quickly find the correct bulb type. Furthermore, establishing a relationship with a reliable parts distributor can ensure that the latest product information is readily available. Conducting regular training sessions for mechanics and staff on the importance of proper bulb selection can also enhance operational efficiency and safety compliance.

Scenario 2: Challenges in the Replacement Process

El problema: Many B2B buyers encounter difficulties during the headlight replacement process, particularly when dealing with various vehicle designs that may require different approaches for bulb access. Complicated assemblies, tight spaces, and the need for specialized tools can lead to increased labor time and costs. This complexity can result in frustration for technicians and potentially lead to errors during installation, impacting the service quality.

La solución: To address these challenges, businesses should consider investing in specialized tools and equipment designed for quick and efficient headlight replacement. Additionally, creating a standardized protocol or checklist for headlight replacement can streamline the process. This protocol should include step-by-step guides tailored for different vehicle models, easily accessible through digital platforms. Moreover, offering hands-on training workshops can empower technicians with the skills to handle various headlight configurations confidently, thereby reducing installation times and enhancing service quality.

Illustrative image related to changing a headlight

Scenario 3: Ensuring Compliance with Local Regulations

El problema: B2B buyers operating in diverse regions must navigate varying regulations regarding vehicle lighting standards. Failure to comply can lead to legal repercussions, fines, and increased liability in case of accidents. Understanding the nuances of these regulations, especially in markets like Africa and South America, where standards may differ significantly, poses a significant challenge for businesses.

La solución: To ensure compliance, B2B buyers should stay informed about local and international automotive lighting regulations by subscribing to industry newsletters and participating in relevant associations. Collaborating with legal experts or automotive consultants can provide insights into compliance requirements. Additionally, sourcing headlight products from manufacturers that clearly label compliance with regional standards can simplify the selection process. Implementing a compliance checklist that is regularly updated can help teams verify that all products meet necessary regulations before installation, thereby minimizing risks and enhancing operational integrity.

Strategic Material Selection Guide for changing a headlight

What Materials Are Commonly Used for Changing a Headlight?

When considering the materials involved in changing a headlight, it’s essential to focus on the bulb types and their respective housings. The most common materials include glass, polycarbonate, halogen, and LED components. Each material has unique properties that affect performance, durability, and suitability for various applications.

How Does Glass Perform as a Material in Headlight Bulbs?

Glass is traditionally used in incandescent and halogen bulbs. It has excellent optical clarity and can withstand high temperatures, making it suitable for the heat generated by these bulbs. However, glass is relatively fragile and can shatter upon impact, which is a significant downside in rugged environments.

Ventajas:

– High optical clarity enhances visibility.

– Good temperature resistance ensures longevity.

Contras:

– Prone to breakage, especially in rough conditions.

– Heavier than alternative materials, which can impact installation.

For international buyers, particularly in regions like Africa and the Middle East, compliance with safety standards is crucial, as broken glass can pose significant risks. Buyers should ensure that the glass used meets local regulations and standards such as ASTM or ISO.

What Advantages Do Polycarbonate Materials Offer for Headlight Housings?

Polycarbonate is increasingly popular for headlight housings due to its lightweight and impact-resistant properties. This thermoplastic material can withstand extreme temperatures and is less likely to shatter than glass, making it ideal for automotive applications.

Ventajas:

– Lightweight, which aids in fuel efficiency.

– High impact resistance reduces the risk of damage.

Contras:

– Susceptible to scratching, which can affect visibility over time.

– May require UV protection to prevent yellowing.

For B2B buyers in South America and Europe, the preference for polycarbonate can be attributed to its balance of performance and cost. However, buyers should be aware of the need for UV protection to ensure long-term clarity and compliance with local automotive standards.

How Do Halogen Bulbs Compare in Terms of Performance and Cost?

Halogen bulbs are a type of incandescent bulb that incorporates a halogen gas to increase brightness and lifespan. They are widely used due to their affordability and ease of replacement. Halogen bulbs offer good visibility and are compatible with most headlight assemblies.

Ventajas:

– Inexpensive and readily available.

– Good light output and color temperature.

Contras:

– Shorter lifespan compared to LED options.

– Generates significant heat, which can affect surrounding components.

For international buyers, especially in regions with variable climates like Vietnam, understanding the heat generation and its impact on vehicle components is essential. Buyers should also consider local regulations regarding light output and energy consumption.

What Are the Benefits of Using LED Technology in Headlights?

LED (Light Emitting Diode) technology has revolutionized automotive lighting with its energy efficiency and longevity. LEDs consume less power and have a much longer lifespan than traditional bulbs, making them a cost-effective choice in the long run.

Ventajas:

– Extremely long lifespan reduces replacement frequency.

– Low energy consumption enhances overall vehicle efficiency.

Contras:

– Higher initial cost compared to halogen or incandescent bulbs.

– May require specific housing or heat management solutions.

For B2B buyers in Europe and the Middle East, the adoption of LED technology aligns with sustainability goals and energy regulations. Compliance with standards such as ECE R112 for automotive lighting is critical for market acceptance.

Summary Table of Material Selection for Changing a Headlight

| Material | Typical Use Case for changing a headlight | Ventaja clave | Desventaja/limitación clave | Coste relativo (bajo/medio/alto) |

|---|---|---|---|---|

| Vidrio | Bulbs for halogen and incandescent headlights | High optical clarity | Fragile and prone to shattering | Medio |

| Policarbonato | Headlight housings | Ligero y resistente a los impactos. | Sensible a los arañazos | Medio |

| Halogen | Standard automotive headlights | Inexpensive and widely available | Shorter lifespan than LEDs | Bajo |

| LED | Modern automotive headlights | Extremely long lifespan and energy-efficient | Mayor coste inicial | Alto |

This material selection guide provides insights into the properties and performance of various materials used in headlight applications, aiding B2B buyers in making informed purchasing decisions.

Illustrative image related to changing a headlight

In-depth Look: Manufacturing Processes and Quality Assurance for changing a headlight

What Are the Key Manufacturing Processes for Headlight Production?

The manufacturing of automotive headlights involves several critical stages, each crucial to ensuring the final product meets safety and performance standards. Understanding these stages can empower B2B buyers to make informed decisions when sourcing headlights from suppliers.

How Are Materials Prepared for Headlight Manufacturing?

The first step in the manufacturing process is material preparation. Headlight components primarily consist of glass or polycarbonate for lenses, metal for reflectors, and various plastics for housing and mounting.

-

Selección de materiales: High-quality materials are selected based on durability, weight, and optical clarity. For instance, polycarbonate is favored for its impact resistance, while glass offers better optical quality.

-

Component Sourcing: Suppliers must ensure that all materials comply with international standards, such as ISO 9001 for quality management systems. Buyers should inquire about the origin and certifications of these materials to ensure compliance.

What Techniques Are Used in the Forming and Assembly of Headlights?

Once materials are prepared, they undergo forming and assembly processes that define their functionality and performance.

Illustrative image related to changing a headlight

-

Técnicas de conformado:

– Moldeo por inyección: This technique is widely used for producing plastic components, allowing for complex shapes and designs that meet specific automotive requirements.

– Blow Molding: Often used for creating hollow parts, such as the headlight housing, ensuring lightness without compromising strength. -

Proceso de montaje:

– Components are assembled in a cleanroom environment to prevent contamination, which is crucial for maintaining optical clarity.

– Assembly often involves automated processes for precision, followed by manual checks for quality assurance.

How Is the Finishing of Headlights Conducted?

The finishing stage is vital for ensuring that the headlights meet aesthetic and functional requirements.

- Tratamiento superficial: Lenses may undergo anti-fogging and anti-scratch treatments, enhancing durability and performance.

- Recubrimiento: Reflectors are often coated with reflective materials to maximize light output. This process must meet specific industry standards to ensure effectiveness.

- Montaje final: This includes the installation of bulbs, wiring, and connectors, followed by a comprehensive inspection to ensure proper functionality.

What Quality Control Measures Are Essential in Headlight Manufacturing?

Quality assurance is a critical component of headlight manufacturing. It ensures that the end product meets safety standards and performs reliably under various conditions.

¿Qué normas internacionales deben conocer los compradores B2B?

For B2B buyers, understanding relevant international standards is essential when evaluating suppliers.

- ISO 9001: This standard focuses on quality management systems, emphasizing consistent quality in products and services.

- Marcado CE: In Europe, headlights must comply with CE marking, signifying conformity with health, safety, and environmental protection standards.

- SAE Standards: In the U.S., the Society of Automotive Engineers (SAE) provides guidelines on headlight performance, including photometric requirements.

What Are the Common Quality Control Checkpoints in Headlight Production?

Quality control is implemented at various stages of the manufacturing process to identify defects early.

- Control de calidad de entrada (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- Control de calidad durante el proceso (IPQC): During the manufacturing stages, random samples are tested for defects, ensuring that production remains within tolerances.

- Control de calidad final (FQC): Before shipment, finished products undergo rigorous testing, including visual inspections and performance tests to verify compliance with standards.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

- Auditorías de proveedores: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control measures, and adherence to standards.

- Informes de calidad: Requesting quality assurance reports can provide insight into the supplier’s testing methods and results.

- Inspecciones por terceros: Engaging independent inspection services can offer an unbiased evaluation of the supplier’s manufacturing processes and product quality.

¿Qué consideraciones de control de calidad deben tener en cuenta los compradores internacionales?

B2B buyers from Africa, South America, the Middle East, and Europe should consider specific nuances in quality control when sourcing headlights.

- Cumplimiento normativo: Different regions may have varying regulations regarding automotive parts. Understanding local laws is essential to ensure compliance.

- Logística y transporte: Buyers should be aware of how shipping conditions may affect product quality. For instance, extreme temperatures during transport can impact bulb performance.

- Diferencias culturales: Communication styles and business practices vary across regions, which can influence quality control processes. Establishing clear expectations and standards can help bridge these gaps.

Conclusión

The manufacturing processes and quality assurance measures for headlights are intricate and crucial for ensuring safety and performance in automotive lighting. For B2B buyers, understanding these processes not only aids in selecting reliable suppliers but also ensures compliance with international standards, ultimately leading to better product outcomes. By focusing on quality control checkpoints and verifying supplier practices, buyers can mitigate risks associated with sourcing headlights in a global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘changing a headlight’

Introducción

Changing a headlight is a straightforward yet essential maintenance task for vehicle safety and compliance. For B2B buyers in diverse regions, including Africa, South America, the Middle East, and Europe, understanding the procurement process for headlight replacement is crucial. This guide provides a structured checklist to streamline your sourcing efforts, ensuring you select the right products and suppliers effectively.

Illustrative image related to changing a headlight

Paso 1: Identify the Headlight Specifications

Begin by determining the specific headlight bulb requirements for the vehicles in your fleet. Check the vehicle’s manual or the existing bulbs for part numbers and specifications. Understanding these details is vital to ensure compatibility and performance, preventing costly mistakes in ordering.

- Consider bulb types: Halogen, HID, and LED options may vary in performance and longevity.

- Assess wattage and voltage: Ensure that the specifications align with your vehicle’s electrical system to avoid damage.

Paso 2: Buscar proveedores fiables

Conduct thorough research to identify suppliers that specialize in automotive lighting. Look for companies with a solid reputation and positive reviews from other B2B customers. This step is essential to ensure you are sourcing from reputable entities that can meet your quality and service expectations.

- Utilize industry networks: Leverage trade associations or online forums to gather insights and recommendations.

- Evaluate supplier history: Look for suppliers with a track record of timely delivery and reliable customer service.

Paso 3: Evaluate Product Quality and Standards

Quality assurance is paramount when selecting headlight bulbs. Ensure that the products comply with international safety standards and regulations applicable in your region. This not only enhances vehicle safety but also reduces liability risks.

- Look for certifications: Check for compliance with standards such as ISO or equivalent.

- Request samples: If possible, obtain samples to assess the product quality firsthand.

Paso 4: Verify Pricing and Terms

Before making a purchase, compare pricing across different suppliers. Understand the pricing structure, including bulk purchase discounts, shipping costs, and payment terms. This step is crucial for budget management and ensuring you get the best value for your investment.

- Negocia las condiciones: Don’t hesitate to discuss payment plans or discounts for larger orders.

- Considere el coste total de propiedad: Factor in long-term performance and warranty options alongside the initial purchase price.

Paso 5: Evaluar el servicio posventa y la garantía

Evaluate the after-sales support and warranty terms offered by potential suppliers. A solid warranty and responsive customer service can save significant costs and time in case of product failures or defects.

Illustrative image related to changing a headlight

- Comprender la cobertura de la garantía: Determine what is covered and for how long.

- Inquire about return policies: Ensure there are clear procedures for returns or exchanges in case of issues.

Paso 6: Make a Trial Purchase

Once you have selected a supplier, consider making a smaller trial purchase before committing to a larger order. This allows you to assess the supplier’s reliability and the product’s performance in real-world conditions.

- Monitor delivery times: Ensure that the supplier meets promised timelines.

- Evaluate product performance: Test the bulbs under various conditions to confirm they meet your expectations.

Paso 7: Establecer una relación a largo plazo

Building a long-term relationship with a supplier can lead to better pricing, priority service, and a deeper understanding of your specific needs. Regular communication can also help you stay informed about new products and advancements in headlight technology.

- Schedule regular reviews: Periodically assess the supplier relationship to ensure continued alignment with your business goals.

- Provide feedback: Share your experiences to help the supplier improve their offerings and services.

By following these steps, B2B buyers can effectively navigate the sourcing process for headlight replacement, ensuring safety, compliance, and cost-effectiveness in their vehicle maintenance efforts.

Comprehensive Cost and Pricing Analysis for changing a headlight Sourcing

What Are the Key Cost Components in Headlight Replacement Sourcing?

When sourcing headlight replacements, understanding the cost components is crucial for B2B buyers. The primary cost elements include:

-

Materiales: The cost of headlight bulbs varies widely based on technology (halogen, HID, LED) and quality. High-performance bulbs typically have a higher price point due to advanced features such as improved brightness and longevity.

-

Trabajo: Labor costs can vary significantly depending on the complexity of the installation process. While changing a headlight can be a DIY task, professional installation may be required for certain vehicle models, impacting the overall cost.

-

Gastos generales de fabricación: This encompasses the indirect costs of producing headlight bulbs, including utilities, salaries of non-production staff, and depreciation of manufacturing equipment.

-

Herramientas: Initial costs for specialized tools and molds needed for bulb production can be substantial. However, these costs are amortized over the production volume, influencing the unit cost.

-

Control de calidad (QC): Maintaining quality standards incurs additional costs. Ensuring that bulbs meet safety and performance certifications is critical, particularly for international markets where regulations may differ.

-

Logística: Transportation and storage costs can add to the overall expense, particularly for international shipments. Efficient logistics can mitigate these costs, making sourcing more competitive.

-

Margen: Suppliers typically include a margin to cover risks and ensure profitability. This margin can fluctuate based on market demand and competitive pressures.

How Do Price Influencers Affect Headlight Sourcing?

Several factors can influence the pricing of headlight replacements, particularly for international B2B buyers:

-

Volumen y cantidad mínima de pedido (MOQ): Larger orders often qualify for volume discounts, significantly reducing per-unit costs. Establishing a consistent purchasing pattern can also help negotiate better terms.

-

Especificaciones y personalización: Customized headlight solutions tailored to specific vehicle models may incur higher costs. Standardized products are usually more cost-effective, so consider balancing customization needs with budget constraints.

-

Calidad de los materiales y certificaciones: Higher quality bulbs with certifications (e.g., ISO, CE) typically command higher prices. However, investing in certified products can lead to lower failure rates and longer lifespan, improving overall value.

-

Factores relacionados con los proveedores: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium but often provide more assurance in quality and service.

-

Incoterms: Understanding shipping terms is vital for managing total costs. Different Incoterms can shift responsibilities and costs between buyers and sellers, affecting the overall financial outlay.

What Are the Best Practices for Negotiating Headlight Pricing?

For international buyers, especially those in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

Illustrative image related to changing a headlight

-

Comprender el coste total de propiedad (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and performance. A higher upfront cost may be justified by lower TCO.

-

Leverage Market Knowledge: Familiarize yourself with local market conditions, competitor pricing, and supplier capabilities. This knowledge can empower you during negotiations.

-

Establecer relaciones a largo plazo: Building a strong partnership with suppliers can facilitate better pricing and terms over time. Consistent orders can lead to loyalty discounts.

-

Esté abierto a alternativas: If a specific product exceeds budget constraints, explore alternative brands or technologies that meet your needs without compromising quality.

-

Consider Group Purchasing: Collaborating with other businesses to make bulk purchases can enhance negotiating power and reduce costs.

Conclusión

Navigating the cost and pricing landscape for headlight replacements requires a thorough understanding of the various components and influencing factors. By employing strategic sourcing and negotiation tactics, B2B buyers can optimize their purchasing decisions, ensuring both quality and cost-effectiveness in their headlight sourcing processes. Always remember that prices can fluctuate based on market conditions, so it’s advisable to seek multiple quotes and stay informed about industry trends.

Alternatives Analysis: Comparing changing a headlight With Other Solutions

Exploring Alternatives to Changing a Headlight

In the automotive industry, ensuring optimal visibility is crucial for safety and compliance. While changing a headlight is a common solution for addressing lighting issues, there are alternative methods that may offer varying benefits depending on specific circumstances. This analysis compares the traditional headlight replacement with two alternative solutions: upgrading to LED headlights and utilizing headlight restoration kits.

Tabla comparativa

| Aspecto comparativo | Changing A Headlight | Actualización a faros LED | Using Headlight Restoration Kits |

|---|---|---|---|

| Rendimiento | Restores original brightness | Higher brightness, longer lifespan | Improves clarity but less effective if bulbs are burnt out |

| Coste | Moderate cost for bulbs | Mayor inversión inicial | Lower cost for restoration kits |

| Facilidad de implementación | Relatively simple DIY task | Instalación más compleja | Simple DIY process |

| Mantenimiento | Requiere revisiones periódicas. | Minimal upkeep | Needs reapplication over time |

| Mejor caso de uso | Quick fix for burnt-out bulbs | Long-term investment for better visibility | Cost-effective solution for foggy headlights |

Desglose detallado de las alternativas

Actualización a faros LED

LED headlights are increasingly popular due to their superior performance and efficiency. They provide brighter illumination and have a significantly longer lifespan than traditional halogen bulbs, often lasting up to 25,000 hours. However, the initial investment is higher, and installation can be more complex, sometimes requiring professional assistance or additional components for compatibility. For businesses looking to enhance vehicle safety and reduce long-term costs, LED headlights can be an excellent choice.

Illustrative image related to changing a headlight

Using Headlight Restoration Kits

Headlight restoration kits offer a cost-effective solution for improving the clarity and functionality of existing headlights. These kits typically include polishing compounds and tools designed to remove oxidation and yellowing from headlight lenses. While they can restore visibility to a degree, they do not replace burnt-out bulbs and may require reapplication over time. This method is best suited for businesses looking to extend the life of their existing headlights without the need for immediate replacement, making it a budget-friendly alternative.

Conclusión: Cómo elegir la solución adecuada para sus necesidades

When deciding on the best approach for headlight issues, B2B buyers should consider their specific needs, including budget constraints, desired performance, and the longevity of the solution. Changing a headlight is a straightforward option for immediate repairs, while upgrading to LED headlights can provide long-term benefits despite higher initial costs. On the other hand, restoration kits serve as a practical interim solution for maintaining clarity in headlights. By evaluating these factors, businesses can make informed decisions that align with their operational goals and enhance vehicle safety.

Essential Technical Properties and Trade Terminology for changing a headlight

¿Cuáles son las propiedades técnicas clave para la sustitución de los faros?

Understanding the technical specifications of headlight bulbs is crucial for B2B buyers involved in automotive parts procurement. The right specifications not only ensure compliance with safety standards but also enhance vehicle performance and customer satisfaction.

1. Tipo de bombilla

Headlight bulbs come in various types, including Halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode). Each type has distinct performance characteristics, such as brightness, lifespan, and energy efficiency. For instance, LED bulbs typically have a longer lifespan and consume less energy compared to halogen bulbs, making them a preferred choice for modern vehicles. B2B buyers should consider the specific requirements of their customer base when selecting bulb types.

2. Salida de lúmenes

Lumen output measures the brightness of the bulb. A higher lumen rating indicates a brighter light, which is essential for night driving and adverse weather conditions. For example, a standard halogen bulb may produce around 1,000 lumens, while high-performance LED options can exceed 3,000 lumens. Understanding lumen output helps buyers ensure that they provide adequate visibility and safety features for their customers.

3. Temperatura de color

Color temperature, measured in Kelvin (K), affects how light appears to the human eye. For headlights, a range of 3,000K to 6,000K is common, with lower values producing a warm yellow light and higher values yielding a cooler, bluish light. Cooler temperatures can enhance road visibility and contrast, which is particularly beneficial in urban environments. B2B buyers should align their product offerings with regional preferences and regulations regarding color temperature.

4. Tipo de base

The base type of a headlight bulb determines how it fits into the headlight assembly. Common types include H1, H4, and H7 bases. Each vehicle model requires specific base types for proper installation. Ensuring compatibility with a wide range of vehicle models can enhance sales potential and customer satisfaction.

Illustrative image related to changing a headlight

5. Voltaje de funcionamiento

Most headlight bulbs operate at standard automotive voltages (typically 12V). However, some high-performance options may have different voltage requirements. B2B buyers need to be aware of these specifications to avoid compatibility issues and ensure that the bulbs operate efficiently within their designated systems.

6. Vida útil

The lifespan of headlight bulbs can vary significantly based on the type and quality of the bulb. Halogen bulbs may last around 500-1,000 hours, while LEDs can last over 25,000 hours. Understanding lifespan helps buyers project inventory needs and provides insight into potential customer satisfaction.

What Are Common Trade Terms in Headlight Procurement?

Navigating the B2B automotive parts market requires familiarity with specific trade terminology. Here are some essential terms that buyers should understand:

1. OEM (fabricante de equipos originales)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are designed to meet specific standards and fit perfectly with the vehicle. B2B buyers often prefer OEM parts for their reliability and compatibility, which can enhance customer trust.

2. MOQ (cantidad mínima de pedido)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs effectively and negotiate better pricing with suppliers.

3. RFQ (Solicitud de presupuesto)

An RFQ is a formal process where buyers request pricing from suppliers for specific products. This term is crucial for B2B transactions, allowing buyers to compare offers and select the most competitive options.

4. Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and risk. Familiarity with these terms helps B2B buyers navigate global trade effectively, ensuring clarity in contracts and reducing the risk of disputes.

5. Mercado de repuestos

Aftermarket parts refer to components made by manufacturers other than the original vehicle maker. These parts can vary in quality and pricing. Understanding the aftermarket landscape allows buyers to offer diverse options to their customers.

6. Certificaciones

Certifications, such as DOT (Department of Transportation) or ECE (Economic Commission for Europe), indicate compliance with safety and quality standards. B2B buyers should prioritize certified products to ensure they meet legal requirements and customer expectations.

Illustrative image related to changing a headlight

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, foster strong supplier relationships, and ultimately enhance their product offerings in the automotive lighting sector.

Navigating Market Dynamics and Sourcing Trends in the changing a headlight Sector

What Are the Key Drivers and Trends in the Headlight Replacement Market?

The global headlight replacement market is witnessing significant shifts driven by several factors, including advancements in automotive lighting technology and increasing vehicle ownership in developing regions. The rise of electric and hybrid vehicles is particularly noteworthy, as these vehicles often utilize advanced lighting systems such as LEDs and HIDs, which tend to have different replacement needs compared to traditional halogen bulbs. Furthermore, the expansion of e-commerce has transformed how B2B buyers source automotive parts, allowing for greater accessibility and convenience in acquiring headlight replacements.

In regions such as Africa and South America, where road safety regulations are becoming stricter, the demand for quality headlight replacements is surging. Buyers are increasingly seeking products that offer durability and performance, as well as compliance with local regulations. Moreover, the Middle East and Europe are experiencing a trend toward customization, with buyers looking for headlight options that enhance vehicle aesthetics and visibility. This shift is encouraging suppliers to diversify their offerings, including unique designs and advanced lighting technologies.

Emerging technologies, such as adaptive lighting systems and smart headlights, are also influencing sourcing trends. These innovations not only improve safety but also present new opportunities for B2B collaborations between manufacturers and tech developers. Understanding these dynamics is crucial for international buyers aiming to stay competitive and meet the evolving needs of their markets.

How Does Sustainability Influence Sourcing Decisions in the Headlight Sector?

Sustainability and ethical sourcing are becoming central themes in the automotive sector, including headlight replacements. As environmental concerns gain prominence globally, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials that are recyclable or derived from renewable resources, as well as minimizing the carbon footprint during production.

Illustrative image related to changing a headlight

The environmental impact of traditional headlight materials, such as plastics and metals, is prompting manufacturers to explore alternatives. For instance, using biodegradable materials or recycled components can significantly reduce waste and pollution. Additionally, certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming essential for suppliers aiming to position themselves favorably in the market. Buyers are encouraged to assess their suppliers’ sustainability credentials as part of their procurement strategy.

Furthermore, the shift towards electric vehicles underscores the need for energy-efficient lighting solutions. LED headlights, known for their longevity and lower energy consumption, are increasingly favored, contributing to reduced overall vehicle emissions. By aligning sourcing strategies with sustainability goals, B2B buyers can not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products.

How Has the Headlight Replacement Market Evolved Over Time?

The evolution of the headlight replacement market reflects broader trends in automotive technology and consumer preferences. Initially dominated by incandescent bulbs, the market has transitioned towards halogen and, more recently, LED and HID technologies. This shift is largely driven by advancements in lighting technology that offer improved visibility, energy efficiency, and longer lifespan.

In the early 2000s, halogen bulbs became the standard due to their affordability and enhanced brightness compared to traditional incandescent options. However, as safety regulations tightened and consumer awareness of energy efficiency grew, the adoption of LEDs and HIDs accelerated. These modern lighting solutions not only provide superior performance but also offer greater design flexibility, allowing manufacturers to innovate in both functionality and aesthetics.

Today, the market is characterized by a diverse range of products tailored to meet specific consumer needs, from basic replacements to high-performance options. As automotive technology continues to advance, the headlight replacement sector is poised for further innovation, offering exciting opportunities for B2B buyers to explore and capitalize on emerging trends.

Frequently Asked Questions (FAQs) for B2B Buyers of changing a headlight

-

How do I know when to change a headlight bulb?

To determine when to change a headlight bulb, monitor for signs such as dimming lights or flickering. Regular inspections are essential; if one bulb has failed, the other may soon follow due to simultaneous wear. Additionally, consider environmental factors such as temperature fluctuations and road conditions that may accelerate bulb degradation. Implementing a proactive maintenance schedule can help prevent unexpected failures, ensuring safety and compliance with local regulations. -

What should I consider when purchasing headlight bulbs for my fleet?

When sourcing headlight bulbs for a fleet, prioritize factors such as bulb type (halogen, HID, or LED), lifespan, brightness, and color temperature. Ensure compatibility with your vehicles by checking the bulb size and specifications. Additionally, consider bulk purchasing options to reduce costs, and evaluate suppliers based on their product quality, warranty offerings, and after-sales support. A reliable supplier should also provide detailed product information to assist in making informed decisions. -

Can I replace one headlight bulb at a time?

While it is technically possible to replace one headlight bulb at a time, it is generally advisable to replace both simultaneously. This ensures uniform brightness and color temperature, enhancing safety and visibility. Furthermore, if one bulb has failed, the other is likely to follow suit soon after. By replacing both, you avoid the inconvenience and additional costs associated with frequent replacements. -

What are the logistics considerations when importing headlight bulbs?

When importing headlight bulbs, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Partnering with a logistics provider familiar with automotive parts can facilitate smoother transactions. Ensure compliance with import/export regulations in your country to avoid delays. Additionally, account for potential tariffs and taxes that may impact your overall costs. Establishing a reliable supply chain is crucial for timely restocking and inventory management. -

How can I vet suppliers for headlight bulbs?

Vetting suppliers for headlight bulbs involves several key steps. Start by researching their reputation within the automotive industry and checking for certifications that demonstrate compliance with safety standards. Request samples to evaluate product quality and performance. Additionally, inquire about their manufacturing processes, lead times, and customer service support. Building relationships with suppliers through transparent communication can also help ensure a successful partnership. -

What are typical minimum order quantities (MOQs) for headlight bulbs?

Minimum order quantities (MOQs) for headlight bulbs can vary significantly based on the supplier and type of bulbs. Typically, MOQs range from 100 to 1,000 units, depending on the manufacturer’s production capabilities and your specific requirements. It’s advisable to discuss MOQs upfront with potential suppliers to negotiate favorable terms that align with your purchasing strategy. Consider ordering in bulk to take advantage of lower prices and ensure a steady supply for your operations. -

What payment terms should I negotiate with suppliers?

Negotiating payment terms with suppliers is crucial for maintaining cash flow. Common terms include net 30, 60, or 90 days, allowing you time to generate revenue before payment is due. Consider options for discounts on early payments or staggered payments based on delivery milestones. It’s also wise to establish a clear agreement on payment methods—whether via bank transfer, letter of credit, or other means—to avoid misunderstandings and ensure smooth transactions. -

How do I ensure quality assurance for imported headlight bulbs?

To ensure quality assurance for imported headlight bulbs, establish clear specifications and standards with your supplier before production. Implement a quality control process that includes inspecting samples upon arrival and conducting tests for performance and durability. Additionally, consider third-party inspections to verify compliance with international safety standards. Building a strong relationship with your supplier can facilitate open communication regarding quality expectations and address any issues promptly.

Top 3 Changing A Headlight Manufacturers & Suppliers List

1. Reddit – Headlight Maintenance Tips

Dominio: reddit.com

Registrado: 2005 (20 años)

Introducción: This company, Reddit – Headlight Maintenance Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. JD Power – Automotive Replacement Parts

Dominio: jdpower.com

Registrado: 1995 (30 años)

Introducción: Headlight bulbs, automotive replacement parts, halogen bulbs, wiring harness, headlight housing, automotive tools (ratchet set), rubber gloves.

3. PEAK® – LED Fog Lamps & Headlights

Dominio: owi.com

Registrado: 1995 (30 años)

Introducción: PEAK® LED Fog Lamps, PEAK® Power Vision Xenon, PEAK® Power Vision Gold Headlights, PEAK® Power Vision Silver Headlights, PEAK® Power Vision Headlights, PEAK® HID Xenon Headlights, PEAK® Halogen Bulbs, PEAK® Power Vision Gold Miniature Exterior Lights, PEAK® LED Miniature Exterior Lights, PEAK® Long Life Miniature Exterior Lights, PEAK® OE Replacement Miniature Exterior Lights, PEAK® Power Vision G…

Strategic Sourcing Conclusion and Outlook for changing a headlight

In the evolving landscape of automotive lighting, strategic sourcing of headlight components is essential for optimizing operational efficiency and customer satisfaction. By understanding the factors that influence headlight performance—such as bulb type, lifespan, and installation processes—B2B buyers can make informed purchasing decisions that enhance safety and visibility for end-users. Engaging with reliable suppliers that provide quality bulbs tailored for specific vehicle models will not only ensure compliance with local regulations but also bolster brand reputation in markets across Africa, South America, the Middle East, and Europe.

Furthermore, as technological advancements continue to shape the automotive industry, staying abreast of innovations in headlight technology—like LED and HID options—can yield significant competitive advantages. These advancements offer longer-lasting, energy-efficient solutions that appeal to a growing environmentally conscious consumer base.

International buyers are encouraged to prioritize partnerships with trusted suppliers who understand the nuances of their regional markets. By leveraging strategic sourcing practices, businesses can enhance their product offerings, streamline operations, and ultimately drive growth in this critical sector. Investing in quality headlight solutions today will illuminate the path toward a safer, more efficient tomorrow.

Illustrative image related to changing a headlight

Aviso legal importante y condiciones de uso

⚠️ Aviso legal importante

La información proporcionada en esta guía, incluido el contenido relativo a los fabricantes, las especificaciones técnicas y el análisis de mercado, tiene fines meramente informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de los errores, omisiones o información desactualizada. Las condiciones del mercado, los datos de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida de forma independiente y exhaustiva. antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en cualquier información contenida en esta guía recae exclusivamente en el lector.