Introduction: Navigating the Global Market for starter motor replacement cost

In an increasingly interconnected world, navigating the global market for starter motor replacement cost poses significant challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the various factors influencing starter motor replacement costs—from the type of vehicle to labor rates and part quality—can make a substantial difference in procurement decisions. This guide is designed to equip international buyers with the knowledge needed to source reliable starter motors, ensuring that they can make informed choices that align with their operational needs.

Throughout this comprehensive resource, we will explore the different types of starter motors available, their applications across various vehicle makes and models, and the implications of choosing between new and remanufactured options. Additionally, we will delve into effective supplier vetting processes, providing insights on how to identify trustworthy partners in the starter motor supply chain. By breaking down the cost components and highlighting common pitfalls, this guide empowers buyers to approach their sourcing strategies with confidence.

For businesses in regions like Saudi Arabia and Nigeria, where access to quality automotive parts can be inconsistent, understanding the intricacies of starter motor replacement costs is not merely advantageous but essential. Armed with this information, B2B buyers can optimize their purchasing processes, minimize downtime, and ultimately enhance their operational efficiency.

Table Of Contents

- Top 4 Starter Motor Replacement Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor replacement cost

- Understanding starter motor replacement cost Types and Variations

- Key Industrial Applications of starter motor replacement cost

- 3 Common User Pain Points for ‘starter motor replacement cost’ & Their Solutions

- Strategic Material Selection Guide for starter motor replacement cost

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor replacement cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor replacement cost’

- Comprehensive Cost and Pricing Analysis for starter motor replacement cost Sourcing

- Alternatives Analysis: Comparing starter motor replacement cost With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor replacement cost

- Navigating Market Dynamics and Sourcing Trends in the starter motor replacement cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor replacement cost

- Strategic Sourcing Conclusion and Outlook for starter motor replacement cost

- Important Disclaimer & Terms of Use

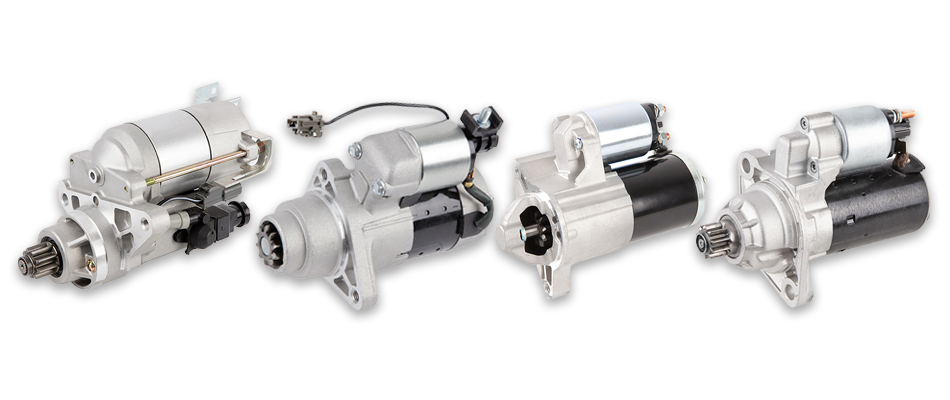

Understanding starter motor replacement cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Economy Starters | Budget-friendly options, typically aftermarket, lower lifespan | Fleet vehicles, cost-sensitive repairs | Pros: Lower initial cost. Cons: Shorter lifespan, potential reliability issues. |

| OEM Starters | Original Equipment Manufacturer parts, higher quality and reliability | Luxury and performance vehicles | Pros: Guaranteed compatibility and quality. Cons: Higher cost compared to aftermarket. |

| High-Performance Starters | Enhanced power output, designed for performance vehicles | Racing teams, high-performance fleets | Pros: Superior performance and durability. Cons: Significantly higher cost. |

| Remanufactured Starters | Rebuilt using used components, lower cost than new starters | Budget-conscious repairs, older vehicles | Pros: Cost-effective solution. Cons: Potentially shorter lifespan than new starters. |

| Specialty Starters | Custom-built for unique applications, often high-end or niche markets | Specialty vehicles, custom builds | Pros: Tailored solutions for specific needs. Cons: Higher investment and longer lead times. |

What Are the Characteristics of Economy Starters?

Economy starters are a cost-effective solution for businesses looking to minimize repair expenses. Typically aftermarket parts, they are designed for budget-conscious buyers, such as fleet managers or small repair shops. However, while they offer a lower upfront cost, their lifespan is often shorter, which can lead to repeated replacements. B2B buyers must weigh the initial savings against potential long-term costs and reliability issues.

How Do OEM Starters Compare to Other Options?

OEM starters are manufactured by the original vehicle manufacturer and provide a high level of reliability and compatibility. They are particularly suited for luxury or performance vehicles where quality is paramount. B2B buyers in sectors that prioritize vehicle performance, such as transportation or logistics, benefit from the assurance that OEM parts will maintain vehicle integrity. However, the higher cost may be a consideration for those operating on tighter budgets.

What Makes High-Performance Starters Unique?

High-performance starters are tailored for vehicles that require enhanced power output, such as racing cars or performance fleets. These starters are designed to withstand extreme conditions and provide reliable performance under stress. B2B applications often include racing teams or companies that operate high-performance vehicles. While they offer significant benefits in terms of durability and efficiency, the investment is considerably higher, making them suitable for specialized markets.

Why Choose Remanufactured Starters?

Remanufactured starters present a viable alternative for businesses looking to save costs without compromising too much on quality. These starters are rebuilt from used components, offering a lower price point. They are particularly appealing for older vehicles or budget-conscious repairs. However, B2B buyers should consider the potential for a shorter lifespan and ensure that they source remanufactured parts from reputable suppliers to avoid reliability issues.

What Are the Advantages of Specialty Starters?

Specialty starters are custom-built to meet specific needs, making them ideal for niche markets or unique vehicle applications. Businesses involved in custom vehicle builds or those operating specialized equipment can benefit greatly from these tailored solutions. Although they typically require a higher investment and longer lead times, the advantages of having a starter designed for particular requirements can outweigh the drawbacks, particularly in competitive industries where performance is critical.

Key Industrial Applications of starter motor replacement cost

| Industry/Sector | Specific Application of starter motor replacement cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Cost analysis for starter replacements in workshops | Helps in budgeting and pricing services effectively | Availability of quality parts, local labor rates, and warranty options |

| Transportation | Fleet management for commercial vehicles | Reduces downtime and ensures operational efficiency | Bulk purchasing options, reliable suppliers, and quick delivery times |

| Agriculture | Starter motor replacements for farm machinery | Enhances productivity and reduces maintenance costs | Compatibility with various machinery models and regional support |

| Construction | Heavy equipment starter motor replacements | Minimizes project delays and operational disruptions | Access to OEM parts and service support for diverse equipment types |

| Mining | Cost management for starter replacements in mining rigs | Ensures safety and reliability of operations | Consideration of harsh operating conditions and part durability |

How is ‘starter motor replacement cost’ utilized in the Automotive Repair Sector?

In the automotive repair industry, understanding the cost of starter motor replacements is crucial for workshops. It allows them to provide accurate estimates to customers, ensuring transparency and trust. Repair shops can analyze costs based on vehicle types, labor rates, and part quality, which aids in setting competitive pricing. For international buyers, sourcing reliable suppliers who offer both new and remanufactured starters is essential to meet varying customer needs while managing operational costs effectively.

What is the importance of starter motor replacement cost in Transportation?

For businesses in the transportation sector, particularly those managing fleets, the cost of starter motor replacement plays a vital role in maintaining vehicle reliability. By budgeting for these replacements, fleet managers can minimize vehicle downtime, which directly impacts service delivery and profitability. When sourcing, it’s important to consider suppliers who can provide bulk purchasing options and rapid delivery services, especially in regions with limited access to parts.

Why is starter motor replacement cost critical for Agriculture?

In agriculture, starter motors are essential for the operation of various machinery, such as tractors and harvesters. The cost of replacement impacts farmers’ operational budgets and productivity. By investing in reliable starters, they can avoid costly delays during critical planting and harvesting seasons. Buyers should focus on sourcing parts that are compatible with a range of machinery and ensure that suppliers offer support and service specific to agricultural needs in their region.

How does starter motor replacement cost affect the Construction Industry?

In the construction sector, heavy equipment relies heavily on functional starter motors for operation. Understanding replacement costs allows construction firms to plan maintenance schedules effectively, preventing project delays. Businesses must consider the availability of OEM parts and service support for diverse equipment types, ensuring that replacements can be conducted swiftly to avoid costly downtime. This is particularly important in international markets where logistical challenges can arise.

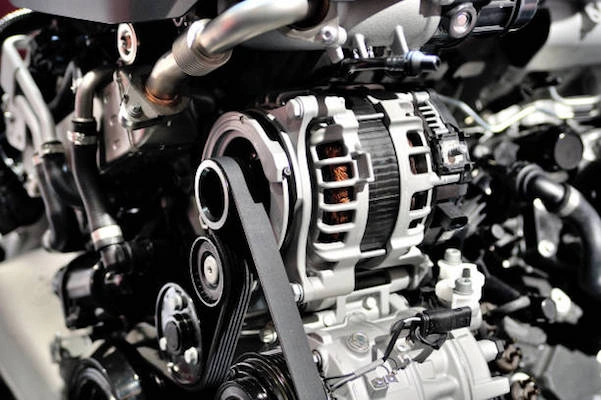

Illustrative image related to starter motor replacement cost

What role does starter motor replacement cost play in Mining Operations?

Mining operations depend on reliable machinery, where starter motors are critical for safety and efficiency. The cost of replacements must be managed carefully to prevent disruptions in production. Companies should prioritize sourcing durable parts that can withstand harsh conditions typical in mining environments. Additionally, having access to local suppliers who understand the specific challenges faced in mining can greatly enhance operational reliability and safety.

3 Common User Pain Points for ‘starter motor replacement cost’ & Their Solutions

Scenario 1: Unpredictable Costs Affecting Budgeting for Fleet Maintenance

The Problem: B2B buyers managing fleets often face the unpredictable nature of starter motor replacement costs, which can significantly impact their maintenance budgets. When a fleet vehicle suddenly fails to start, it can lead to unexpected downtime and replacement expenses that were not accounted for in the budget. This unpredictability creates challenges in financial planning and can affect operational efficiency, especially in regions with limited access to parts and skilled labor.

The Solution: To mitigate these unpredictable costs, fleet managers should implement a proactive maintenance strategy that includes regular diagnostic checks on starter systems. Establishing relationships with reputable suppliers who can provide consistent pricing for both new and remanufactured starter motors is essential. Additionally, using fleet management software can help track vehicle performance and identify patterns of starter failures, allowing for timely replacements before they lead to breakdowns. Consider negotiating bulk purchasing agreements with suppliers to secure better rates, and always keep a few critical parts, like starter motors, in stock for the most commonly used vehicle types in your fleet.

Scenario 2: Quality vs. Cost Dilemma in Starter Motor Selection

The Problem: When sourcing starter motors, B2B buyers often face a dilemma between opting for cheaper aftermarket parts or investing in higher-quality OEM parts. This decision is crucial, as selecting lower-quality components can lead to frequent failures and increased long-term costs due to repeated replacements. Buyers in regions with varying part availability may find it challenging to balance cost-effectiveness with reliability, especially when operating under strict budget constraints.

The Solution: To navigate this dilemma, buyers should conduct thorough research on the reliability and warranty terms of aftermarket starters versus OEM options. Engaging with industry peers through forums or trade shows can provide insights into long-term performance and user experiences with various brands. Additionally, consider utilizing a tiered purchasing approach where you invest in OEM parts for critical vehicles that experience higher usage and use aftermarket parts for less critical ones. This strategy ensures that you maintain reliability where it matters most while still managing costs effectively.

Illustrative image related to starter motor replacement cost

Scenario 3: Labor Costs Complicating Starter Replacement Decisions

The Problem: In many cases, B2B buyers underestimate the labor costs associated with starter motor replacement, particularly for complex vehicle models. This oversight can lead to significant budget overruns and delays in vehicle readiness. In regions with high labor rates or limited skilled technicians, the cost of installation can be a substantial part of the total replacement expense, causing frustration and logistical challenges for fleet operations.

The Solution: To address this issue, buyers should prioritize working with auto service providers who offer transparent labor pricing and provide detailed estimates before commencing work. Building partnerships with local mechanics or service centers that understand the specific needs of your fleet can lead to more accurate labor assessments. Additionally, investing in training for in-house technicians can reduce reliance on external services, allowing for quicker turnaround times and lower labor costs. Leveraging technology, such as diagnostic tools, can help identify starter issues before they escalate, enabling more strategic planning for repairs and replacements.

Strategic Material Selection Guide for starter motor replacement cost

What Are the Common Materials Used in Starter Motor Replacement?

When considering starter motor replacements, the choice of materials is critical for ensuring durability, performance, and cost-effectiveness. Below, we analyze four common materials used in starter motors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to starter motor replacement cost

What Are the Key Properties of Copper in Starter Motors?

Copper is widely used in electrical components due to its excellent conductivity and thermal properties. Its high melting point (approximately 1,984°F or 1,085°C) and resistance to corrosion make it suitable for various automotive applications. Copper’s ability to handle high temperatures and pressures ensures reliable performance in starter motors.

Pros & Cons of Copper:

The primary advantage of copper is its superior electrical conductivity, which enhances the efficiency of the starter motor. However, copper can be more expensive than alternatives like aluminum, and its weight can be a drawback in applications where reducing weight is critical.

Impact on Application:

Copper’s compatibility with various automotive fluids and its resistance to oxidation make it ideal for starter motors. However, in regions with high humidity or corrosive environments, additional protective coatings may be necessary.

Illustrative image related to starter motor replacement cost

Considerations for International Buyers:

B2B buyers from regions such as Africa and South America should ensure compliance with local standards for electrical components. Common standards like ASTM and DIN may apply, and buyers should consider the availability of copper in their local markets.

How Does Aluminum Compare for Starter Motor Components?

Aluminum is another popular material in starter motor construction, particularly for housings and casings. It has a lower density than copper, making it lightweight and easier to handle. Aluminum also exhibits good corrosion resistance, particularly when anodized.

Pros & Cons of Aluminum:

The key advantage of aluminum is its lightweight nature, which can enhance fuel efficiency in vehicles. However, it has lower electrical conductivity than copper, which can impact performance in high-demand applications.

Impact on Application:

Aluminum’s compatibility with various automotive environments makes it suitable for starter motor applications. However, its lower strength compared to steel can be a limitation in high-stress scenarios.

Considerations for International Buyers:

Buyers in the Middle East and Europe should be aware of the varying quality standards for aluminum. Compliance with local manufacturing standards is crucial to ensure product reliability.

Illustrative image related to starter motor replacement cost

What Role Does Steel Play in Starter Motor Construction?

Steel is often used in starter motor components that require high strength and durability, such as the casing and internal gears. Steel can withstand high pressures and temperatures, making it suitable for heavy-duty applications.

Pros & Cons of Steel:

The primary advantage of steel is its strength and durability, which ensures long-lasting performance. However, steel is heavier than aluminum and can be susceptible to corrosion if not properly treated.

Impact on Application:

Steel’s robustness makes it ideal for starter motors in heavy-duty vehicles, such as trucks and construction equipment. However, its weight can be a disadvantage in applications where weight reduction is essential.

Illustrative image related to starter motor replacement cost

Considerations for International Buyers:

B2B buyers should ensure that the steel used meets international standards such as JIS or ASTM. Additionally, buyers in regions like Nigeria should consider local sourcing options to reduce costs.

How Does Plastic Factor into Starter Motor Design?

Plastic is increasingly used in starter motor applications, particularly for insulation and housing components. It offers good electrical insulation properties and is lightweight.

Pros & Cons of Plastic:

The main advantage of plastic is its low cost and ease of manufacturing. However, it is less durable than metals and can degrade over time, especially under high temperatures.

Impact on Application:

Plastic components are suitable for non-load-bearing parts of the starter motor, where insulation is critical. However, they may not be suitable for high-stress components.

Considerations for International Buyers:

Buyers should be aware of the specific grades of plastic used and their compliance with local regulations. In regions with high temperatures, selecting heat-resistant plastics is essential.

Summary Table of Material Selection for Starter Motors

| Material | Typical Use Case for starter motor replacement cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections and windings | Superior electrical conductivity | Higher cost and weight | High |

| Aluminum | Housings and casings | Lightweight and corrosion-resistant | Lower electrical conductivity | Medium |

| Steel | Gears and structural components | High strength and durability | Heavier and potential corrosion | Medium |

| Plastic | Insulation and non-load-bearing components | Low cost and easy to manufacture | Less durable and heat-sensitive | Low |

This analysis provides valuable insights for international B2B buyers considering starter motor replacements, highlighting the importance of material selection in terms of performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor replacement cost

The production of starter motors is a complex process that requires precision engineering and stringent quality control measures. For B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe, understanding these manufacturing processes and quality assurance protocols is crucial for ensuring they source reliable components at competitive prices.

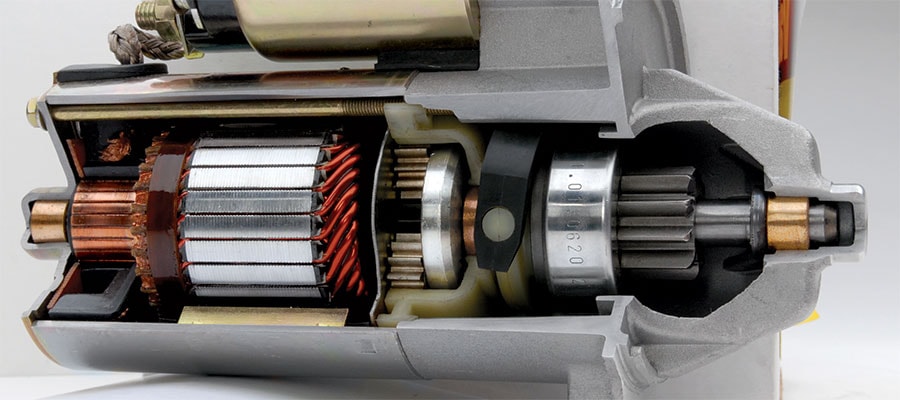

What Are the Main Stages of Starter Motor Manufacturing?

The manufacturing process of starter motors typically involves several key stages: material preparation, forming, assembly, and finishing. Each of these stages plays a vital role in ensuring the performance and durability of the final product.

How Is Material Prepared for Starter Motor Production?

The first step in manufacturing starter motors is material preparation. Manufacturers select high-quality materials such as copper for windings, high-grade steel for the housing, and specialized alloys for components like the armature. The materials undergo a series of treatments to enhance their properties, such as heat treatment to improve strength and corrosion resistance. This preparation ensures that the components can withstand the demanding conditions they will face in various vehicle types.

Illustrative image related to starter motor replacement cost

What Techniques Are Used in Forming Starter Motor Components?

After material preparation, the forming stage begins. This involves several techniques, including:

- Stamping: Used for creating metal parts such as the housing and end plates. High-precision stamping ensures uniformity in size and shape.

- Machining: This process involves cutting, drilling, and milling components to achieve the precise dimensions required for optimal functionality.

- Winding: The copper wire is wound around the armature in a specific pattern to create the magnetic field necessary for the starter’s operation.

These forming techniques are critical for producing components that not only fit together perfectly but also function efficiently.

How Are Starter Motors Assembled?

The assembly stage is where the previously formed components come together. This process typically follows these steps:

- Component Inspection: Each part is inspected for defects before assembly, ensuring only high-quality components are used.

- Assembly: Skilled technicians assemble the motor, ensuring that each component is placed correctly and securely. This process may involve the use of automated machines for precision.

- Electrical Connections: Proper electrical connections are established, often involving soldering or crimping techniques to ensure long-lasting durability.

Quality during assembly is paramount, as any misalignment or improper connection can lead to failures in the field.

What Finishing Techniques Are Applied to Starter Motors?

The finishing stage enhances the motor’s aesthetic appeal and protects it from environmental factors. Typical finishing processes include:

Illustrative image related to starter motor replacement cost

- Painting or Coating: Protective coatings are applied to prevent rust and corrosion, particularly for motors that will be exposed to harsh conditions.

- Testing and Calibration: Before the final product leaves the factory, it undergoes rigorous testing to ensure it meets performance standards.

What Quality Control Measures Are Essential for Starter Motor Manufacturing?

Quality control (QC) is a critical aspect of the starter motor manufacturing process. It ensures that products meet international standards and customer expectations.

Which International Standards Apply to Starter Motor Manufacturing?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with such standards ensures that the manufacturing processes are well-documented, consistently monitored, and continually improved.

Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for automotive components are crucial. These certifications indicate that products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Starter Motor Production?

Quality control checkpoints are strategically placed throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Inspection of raw materials and components before they enter the production line to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify issues as they arise.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify performance, durability, and compliance with specifications.

By implementing these checkpoints, manufacturers can significantly reduce the risk of defects and ensure a high-quality end product.

What Testing Methods Are Commonly Used in Starter Motor Quality Control?

Common testing methods for starter motors include:

- Electrical Testing: Ensures the motor operates correctly under various conditions, checking for issues like short circuits or improper voltage.

- Performance Testing: Simulates real-world conditions to evaluate how the starter motor performs under load.

- Durability Testing: Assesses the motor’s ability to withstand extreme temperatures, vibrations, and other environmental factors.

These tests are essential for verifying the reliability and longevity of starter motors, making them suitable for diverse applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, and the Middle East, verifying a supplier’s quality control measures is vital for mitigating risks. Buyers can take several steps to ensure they are engaging with reputable manufacturers:

- Supplier Audits: Conducting audits of potential suppliers allows buyers to assess their manufacturing processes, quality control measures, and adherence to international standards.

- Quality Reports: Requesting detailed quality control reports provides insights into the manufacturer’s testing protocols and defect rates.

- Third-party Inspections: Engaging independent inspection agencies can offer unbiased evaluations of the supplier’s quality control practices and product reliability.

By employing these strategies, buyers can build confidence in their suppliers and ensure that they are procuring high-quality starter motors that meet their operational needs.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers must be aware of various nuances related to quality control and certifications, especially when dealing with international suppliers. Different regions may have specific regulations and standards that affect product quality, performance, and safety.

For instance, products exported to Europe must comply with CE marking requirements, while those in the Middle East may need to adhere to GSO standards. Understanding these regional requirements is essential for ensuring compliance and avoiding costly delays.

Additionally, buyers should consider the implications of language barriers and cultural differences in business practices. Clear communication about quality expectations and standards is crucial for successful partnerships.

By gaining a thorough understanding of manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions when sourcing starter motors, ensuring they receive high-quality products that meet their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor replacement cost’

Introduction

Navigating the costs associated with starter motor replacement is crucial for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. This step-by-step checklist will help you systematically evaluate the key factors influencing starter motor replacement costs, enabling informed purchasing decisions that align with your operational needs.

Illustrative image related to starter motor replacement cost

Step 1: Assess Your Vehicle Requirements

Understanding the specific vehicle models and types that your company operates is vital. Different vehicles can have vastly different starter motor requirements, which affects both the part’s cost and installation complexity. Gather information on your fleet to ensure compatibility when sourcing replacement starters.

Step 2: Define Your Budget Parameters

Establishing a clear budget for starter motor replacement is essential. Consider not only the cost of the starter motors themselves but also labor costs associated with installation. Typical ranges can vary significantly based on vehicle type and location, so factor in potential additional repairs that may arise during replacement.

Step 3: Research Supplier Options

A thorough evaluation of potential suppliers can lead to better pricing and service quality. Look for suppliers with a strong track record in your specific region and industry. Pay attention to their offerings of both new and remanufactured starters, as well as their warranty policies on parts and labor.

Illustrative image related to starter motor replacement cost

- Tip: Request case studies or testimonials from similar companies to gauge supplier reliability.

Step 4: Verify Quality Standards

Quality assurance is crucial when sourcing automotive parts. Ensure that the starter motors meet international standards, such as ISO certification or OEM specifications. High-quality parts can reduce the likelihood of premature failure, ultimately lowering your long-term costs.

Step 5: Compare Labor Costs

Labor charges can vary widely depending on the complexity of the installation. Some vehicles may require extensive disassembly, while others allow for easier access to the starter. Request detailed quotes from service providers to compare labor costs effectively, and inquire about the estimated time required for installation.

Step 6: Evaluate After-Sales Support

Consider the level of after-sales support offered by potential suppliers. Reliable customer service and support can be invaluable, especially if issues arise post-installation. Look for suppliers who provide comprehensive installation guidance and are responsive to inquiries.

Step 7: Plan for Future Needs

Finally, consider your long-term requirements for starter motor replacements. Establishing a relationship with a reliable supplier can lead to better pricing and service terms for future purchases. Discuss bulk order discounts or service agreements that can further optimize costs over time.

By following these steps, B2B buyers can streamline the process of sourcing starter motor replacements, ensuring both cost-effectiveness and quality assurance in their procurement strategies.

Comprehensive Cost and Pricing Analysis for starter motor replacement cost Sourcing

What Are the Key Cost Components of Starter Motor Replacement?

The cost structure for starter motor replacement involves several critical components that B2B buyers must consider.

-

Materials: The primary cost factor is the starter motor itself. Prices can range from $75 for economy starters to over $1,000 for high-performance models. The choice between new and remanufactured units significantly impacts costs. New starters generally offer a longer lifespan but come at a higher price point, while remanufactured options can be more budget-friendly but might have a reduced operational life.

-

Labor: Labor costs vary depending on the complexity of the installation. Basic vehicle replacements may incur costs of $100 to $250, whereas complex models, particularly luxury or performance vehicles, can lead to labor fees ranging from $300 to $600. Understanding the make and model of the vehicle is crucial for estimating labor expenses accurately.

-

Manufacturing Overhead: This encompasses costs related to production facilities, equipment maintenance, and administrative expenses. These overheads can add a significant percentage to the overall cost, especially for manufacturers with stringent quality control processes.

-

Tooling and Quality Control (QC): Specialized tools are often required for starter motor replacement, contributing to the labor cost. Additionally, manufacturers may incur QC expenses to ensure reliability and performance standards, which can be reflected in the final pricing.

-

Logistics: Shipping and handling costs can vary based on the location of the supplier and the destination. International logistics may introduce additional complexities, such as customs duties and tariffs, which can significantly affect the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on competitive market dynamics and the supplier’s pricing strategy.

What Price Influencers Should Buyers Consider When Sourcing?

Several factors can influence pricing in the starter motor replacement market:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often results in lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for businesses to consolidate their purchases.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized manufacturing processes. Buyers should balance their requirements with the associated costs to ensure a cost-effective solution.

-

Materials and Quality Certifications: The choice of materials affects both performance and cost. Components with industry-standard certifications may command higher prices, but they often provide better reliability and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The delivery terms agreed upon (e.g., FOB, CIF) can impact total costs. Understanding these terms is essential for calculating landed costs accurately, especially for international transactions.

What Tips Can Buyers Use to Optimize Costs in Starter Motor Sourcing?

-

Negotiation: Engaging in negotiations with suppliers can yield better pricing. Understanding the cost structure allows buyers to discuss specific components that can be adjusted without compromising quality.

-

Total Cost of Ownership (TCO): Buyers should evaluate not just the initial purchase price but also the long-term costs associated with the starter motor, including installation, maintenance, and potential replacements. This approach can help in making informed decisions that lead to overall cost savings.

-

Pricing Nuances for International Buyers: B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local market conditions that may affect pricing. Building relationships with local distributors can also help mitigate some of these costs.

-

Quality Assessment: Prioritize suppliers who adhere to strict quality standards. Investing in high-quality starters may result in lower replacement rates and maintenance costs, ultimately enhancing the value proposition.

Disclaimer

The prices mentioned are indicative and can vary widely based on geographic location, market dynamics, and specific supplier agreements. Always conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing starter motor replacement cost With Other Solutions

Understanding Alternatives to Starter Motor Replacement

When faced with starter motor issues, B2B buyers must consider not just the cost of replacement but also viable alternatives that can address the problem effectively. Understanding these alternatives can lead to better decision-making regarding budget allocation, operational efficiency, and long-term vehicle maintenance strategies.

Comparison Table

| Comparison Aspect | Starter Motor Replacement Cost | Battery Replacement | Jump Start Solutions |

|---|---|---|---|

| Performance | Restores full functionality | Limited to battery issues | Temporary fix, may not resolve underlying issues |

| Cost | $250 – $1,000+ | $100 – $300 | $20 – $50 (cables) |

| Ease of Implementation | Requires professional service | Relatively easy, can be DIY | Quick and easy with no tools required |

| Maintenance | Minimal post-replacement | Regular checks needed | No maintenance needed |

| Best Use Case | Long-term solution for starting issues | When battery is dead or weak | Immediate, short-term solution for starting issues |

Detailed Breakdown of Alternatives

Battery Replacement

Replacing the battery can be a cost-effective alternative when the vehicle fails to start due to a depleted or faulty battery. This option is typically less expensive than replacing the starter motor, ranging from $100 to $300. The ease of implementation is also a significant advantage, as many businesses can perform this task in-house or with minimal technical expertise. However, it is crucial to note that a battery replacement only resolves issues related to battery failure and will not fix problems stemming from the starter motor itself. Regular maintenance checks are necessary to ensure the battery remains in optimal condition, adding to the overall lifecycle cost.

Jump Start Solutions

Jump starting a vehicle is the most immediate solution when faced with starting issues. This method involves using jumper cables to connect a working battery to the dead one, allowing the vehicle to start temporarily. With a minimal cost of around $20 to $50 for cables, this solution is highly accessible and can be executed quickly without professional assistance. However, it is important to recognize that jump starting does not address the root cause of the starting issue; it merely provides a temporary fix. If the starter or battery is faulty, the vehicle may not start again without further intervention.

Conclusion: How to Choose the Right Solution

When selecting the right solution for starter motor issues, B2B buyers should assess the specific circumstances of their vehicles. If the problem is identified as a failing starter motor, investing in a replacement may be the best long-term strategy, despite the higher upfront costs. Conversely, if the issue is solely related to the battery, a replacement or jump start may suffice. Ultimately, understanding the nuances of each alternative allows businesses to make informed decisions that align with their operational needs and budget constraints, ensuring reliable vehicle performance in the long run.

Essential Technical Properties and Trade Terminology for starter motor replacement cost

What Are the Key Technical Properties of Starter Motors That Affect Replacement Costs?

When considering starter motor replacement costs, several critical specifications are vital for B2B decision-makers. Understanding these technical properties not only aids in cost estimation but also ensures quality and compatibility with vehicles.

Illustrative image related to starter motor replacement cost

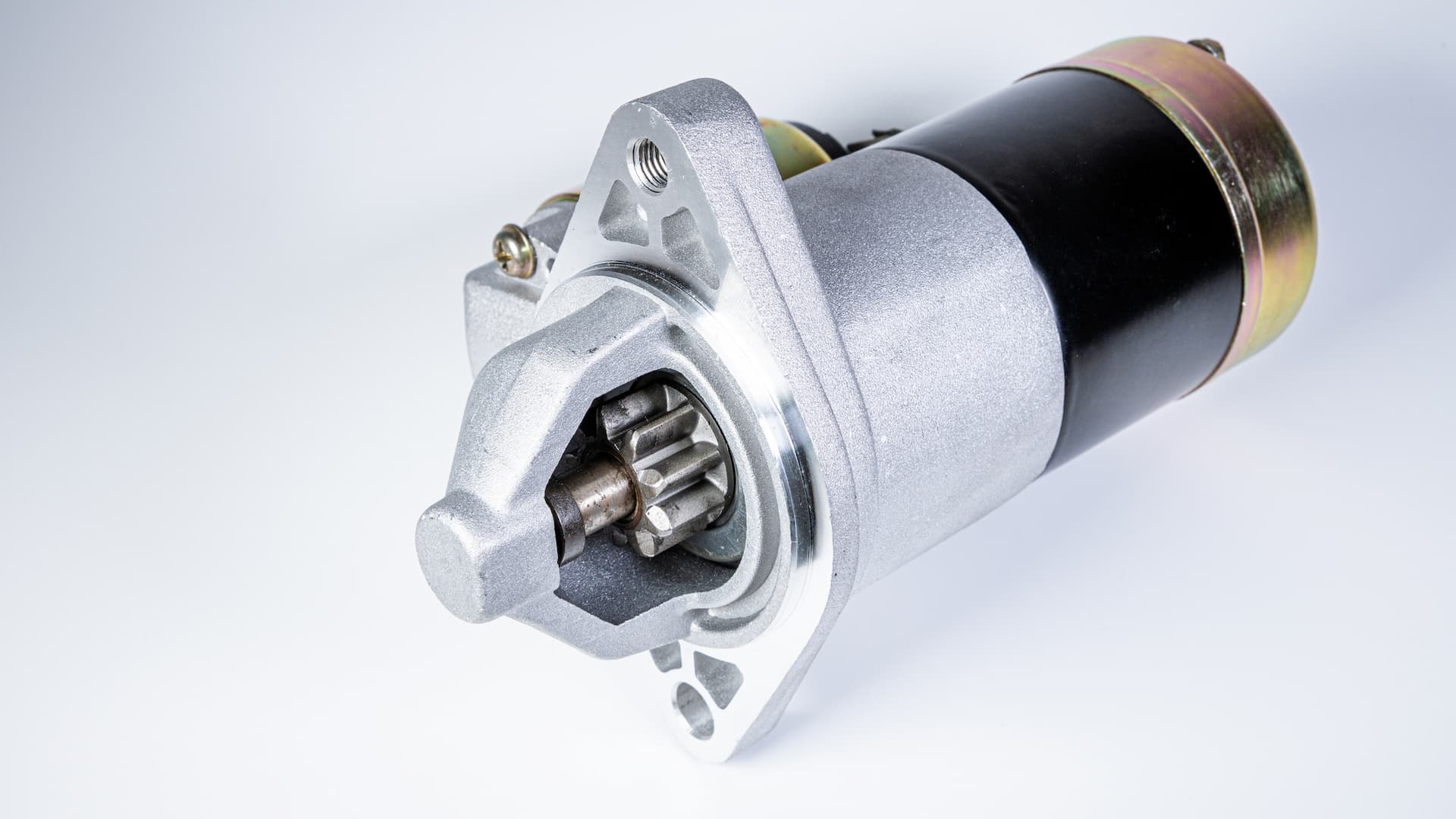

1. Material Grade

The material grade of a starter motor often dictates its durability and performance. Most starter motors are made from high-grade steel or aluminum, which provide strength and resistance to wear. For B2B buyers, selecting the right material grade is essential; higher-grade materials typically enhance longevity, which can reduce the frequency of replacements and associated costs.

2. Torque Rating

Torque rating is a measure of the rotational force the starter motor can produce to crank the engine. This specification is crucial, especially for larger vehicles like trucks and SUVs that require higher torque to start. B2B buyers must consider torque ratings to ensure the selected starter motor meets the specific demands of the vehicle, preventing potential failures and additional costs.

3. Voltage and Amperage

Most starter motors operate on a 12-volt system, but the amperage can vary significantly. A higher amperage rating indicates a more powerful starter, which is necessary for larger engines. For businesses, understanding these electrical specifications is vital in ensuring compatibility with existing vehicle systems and avoiding operational inefficiencies.

4. Thermal Resistance

Starter motors generate heat during operation, and thermal resistance indicates the motor’s ability to withstand high temperatures without failing. This specification is particularly relevant in hot climates or for vehicles that undergo heavy use. B2B buyers should prioritize thermal resistance to ensure the longevity and reliability of the starter motor, minimizing unexpected replacements.

5. OEM vs. Aftermarket Quality

Original Equipment Manufacturer (OEM) parts are made by the vehicle’s manufacturer, while aftermarket parts are produced by third parties. OEM parts generally offer better reliability and warranty coverage, but at a higher cost. B2B buyers need to weigh the cost-effectiveness of aftermarket options against the long-term benefits of OEM parts, considering factors such as warranty and performance.

What Common Trade Terms Should You Know When Discussing Starter Motor Replacement Costs?

Familiarizing yourself with industry jargon can facilitate smoother negotiations and clearer communications in the B2B environment. Here are essential terms related to starter motor replacements.

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original vehicle manufacturer. These parts are designed to meet the specific standards and specifications of the vehicle, ensuring compatibility and reliability. For B2B buyers, opting for OEM parts can reduce the risk of operational issues and improve customer satisfaction.

Illustrative image related to starter motor replacement cost

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for businesses looking to manage inventory costs effectively. Understanding the MOQ helps B2B buyers plan their purchases and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the context of starter motors, an RFQ allows buyers to compare costs, specifications, and delivery terms from multiple suppliers, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for B2B buyers involved in cross-border purchases of starter motors, as they define who bears the costs and risks during shipping.

Illustrative image related to starter motor replacement cost

5. Warranty Period

The warranty period is the time frame during which the manufacturer guarantees the part against defects. For businesses, understanding warranty terms is crucial as it affects the long-term cost of ownership and the decision to choose between OEM and aftermarket parts.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions regarding starter motor replacements, optimizing both cost and performance for their fleet or inventory.

Navigating Market Dynamics and Sourcing Trends in the starter motor replacement cost Sector

What Are the Current Market Trends Impacting Starter Motor Replacement Costs?

The global market for starter motor replacements is influenced by several factors, including the rising demand for electric vehicles (EVs), the expansion of automotive manufacturing in emerging markets, and an increasing focus on aftermarket services. In regions like Africa and South America, the growth of the automotive sector is fueled by a burgeoning middle class and urbanization, leading to higher vehicle ownership. This trend presents opportunities for B2B buyers to source components more competitively, especially as local manufacturing capabilities improve.

Additionally, technological advancements are shaping the sourcing landscape. The integration of digital platforms for procurement and inventory management allows international buyers to streamline their sourcing processes, enhancing efficiency and reducing costs. For instance, platforms that offer real-time data on starter motor pricing and availability empower buyers to make informed decisions quickly. Furthermore, the trend toward remanufactured parts is gaining traction, driven by cost considerations and a growing preference for sustainable practices among consumers.

How Are Sustainability and Ethical Sourcing Influencing Starter Motor Replacement Costs?

Environmental considerations are increasingly influencing the starter motor replacement sector, particularly for international B2B buyers. The automotive industry faces pressure to adopt sustainable practices, leading to a rising demand for ethically sourced components. Buyers are now prioritizing suppliers that demonstrate a commitment to environmental stewardship, such as those utilizing recycled materials or certified green production processes.

Illustrative image related to starter motor replacement cost

Certifications like ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to compete in global markets. These credentials not only enhance brand reputation but also appeal to eco-conscious buyers. Moreover, as regulations around emissions and waste management tighten, investing in sustainable sourcing can mitigate risks associated with compliance and enhance long-term profitability.

What Is the Historical Context Behind the Starter Motor Replacement Sector?

Historically, the starter motor replacement industry has evolved significantly alongside the automotive sector. Initially dominated by mechanical systems, advancements in electrical engineering during the late 20th century introduced more reliable and efficient starter motors, leading to a decrease in failure rates. The rise of electronic vehicles in recent years has further transformed the landscape, as new technologies require different starter systems altogether.

This evolution has also influenced the aftermarket, with a growing emphasis on high-performance and remanufactured starters that cater to diverse customer needs. As the market continues to expand, understanding these historical trends is vital for B2B buyers, enabling them to navigate the complexities of sourcing and pricing effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor replacement cost

-

How do I determine the cost of starter motor replacement for my fleet?

To accurately assess the cost of starter motor replacement for your fleet, consider multiple factors including the type of vehicles you operate, the specific starter motor models required, and prevailing labor rates in your region. Additionally, factor in potential additional repairs that may be necessary if a starter failure has impacted other components. Request quotes from multiple suppliers and ensure to specify the make and model of your vehicles for precise pricing. -

What factors influence the price of starter motors in international markets?

The price of starter motors can vary significantly based on factors such as the country of origin, local demand, tariffs, and shipping costs. In international markets, the availability of OEM versus aftermarket parts also plays a critical role; OEM parts typically command higher prices due to their guaranteed compatibility and warranty coverage. Understanding regional market conditions and supplier reliability is essential for effective pricing strategies. -

What is the best way to vet suppliers for starter motors?

To vet suppliers for starter motors, start by checking their industry reputation, certifications, and customer reviews. Request references from previous clients to gauge satisfaction levels. Additionally, evaluate their quality assurance processes and warranty offerings. Engaging in a trial order can also help assess their reliability before committing to larger orders, ensuring they can meet your quality and delivery expectations. -

Can I customize starter motors for specific applications?

Yes, many suppliers offer customization options for starter motors to meet specific application requirements. This may include modifications for higher performance, alterations for unique vehicle models, or adjustments for environmental conditions. When discussing customization, clearly outline your specifications and quality standards to ensure that the final product meets your operational needs. -

What are typical minimum order quantities (MOQs) for starter motors?

Minimum order quantities (MOQs) for starter motors can vary widely among suppliers, often ranging from 10 to 100 units or more, depending on the manufacturer and type of starter motor. Larger MOQs may be associated with lower per-unit costs, making it beneficial for bulk buyers. When negotiating with suppliers, clarify MOQs and explore potential discounts for larger orders to optimize your procurement strategy. -

What payment terms should I expect when sourcing starter motors internationally?

Payment terms for international purchases of starter motors can vary. Common practices include upfront payments, partial payments upon order confirmation, and balance due upon delivery. Some suppliers may offer letters of credit or payment through escrow services for larger transactions to mitigate risk. Always negotiate terms that align with your cash flow needs and ensure clarity in the agreement to avoid misunderstandings. -

How can I ensure quality assurance (QA) for starter motors sourced overseas?

To ensure quality assurance for starter motors sourced overseas, implement a robust QA process that includes pre-shipment inspections, certifications of compliance, and adherence to international quality standards. Engage third-party inspection services if necessary, and request samples prior to bulk orders to verify product quality. Establishing clear communication with suppliers regarding your quality expectations is also crucial for maintaining standards. -

What logistics considerations should I keep in mind when importing starter motors?

When importing starter motors, consider logistics factors such as shipping methods, customs regulations, and lead times. Choosing the right shipping option (air freight versus sea freight) can significantly impact delivery times and costs. Additionally, familiarize yourself with import tariffs and potential duties to budget effectively. Collaborating with experienced logistics providers can help streamline the process and ensure compliance with local regulations.

Top 4 Starter Motor Replacement Cost Manufacturers & Suppliers List

1. Reddit – Cost Overview

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Cost Overview, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Last Chance Auto Repairs – Starter Replacement Costs

Domain: lastchanceautorepairs.com

Registered: 2009 (16 years)

Introduction: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Factors affecting cost: Vehicle type & model, New vs Re-Manufactured starters, Additional repairs (battery replacement, wiring repairs, etc.). DIY costs: Parts only: $100 – $400…

3. Starter Motor Replacement Costs – Key Insights

Domain: carbuzz.com

Registered: 2003 (22 years)

Introduction: Starter motor replacement cost ranges from $450 to $600 on average. Specific models like the Toyota Tundra (2000-2005) V8 can cost between $650 and $900 due to complex installation, while a Honda Civic’s replacement cost is estimated between $490 and $760. Factors affecting costs include labor time (1.5 to 2.5 hours for most starters, up to 4 hours for valley-mounted starters), and the type of sta…

4. Starter Replacement – Cost & Tips

Domain: forum.ih8mud.com

Registered: 2000 (25 years)

Introduction: Labor cost for starter replacement ranges from $200 to $400 depending on the shop and location. A remanufactured OEM starter costs approximately $120. The estimated labor time is around 5 hours, with hourly rates varying by shop. Precautions during installation include cleaning the engine, covering intake ports, and possibly replacing fuel injector damper seals.

Strategic Sourcing Conclusion and Outlook for starter motor replacement cost

In the ever-evolving landscape of automotive maintenance, understanding the costs associated with starter motor replacement is crucial for international B2B buyers. Key factors influencing these costs include the type of vehicle, the choice between new and remanufactured starters, and the complexity of labor involved in the installation. By strategically sourcing quality components and reliable service providers, businesses can optimize their operational efficiency and reduce unexpected expenses.

Investing in high-quality parts not only enhances vehicle longevity but also minimizes the risk of additional repairs that can arise from using inferior products. As the demand for reliable transportation grows across markets in Africa, South America, the Middle East, and Europe, ensuring a seamless supply chain becomes paramount.

Looking ahead, businesses should prioritize partnerships with trusted suppliers who can offer competitive pricing and comprehensive warranties. This proactive approach not only safeguards against fluctuating costs but also empowers companies to maintain their fleets with confidence. Engage with industry experts and explore options that align with your strategic goals—secure your starter motor solutions today to drive your operations forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to starter motor replacement cost

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.