Introduction: Navigating the Global Market for signs of a bad starter solenoid

In the competitive landscape of automotive parts procurement, understanding the signs of a bad starter solenoid is crucial for B2B buyers seeking to minimize downtime and enhance operational efficiency. The solenoid serves as a pivotal component in the ignition system, and recognizing its failure can prevent costly delays in vehicle operations across various sectors, including transportation and logistics. This comprehensive guide will delve into the various signs indicating a faulty starter solenoid, explore its applications in different vehicle types, and provide insights into effective supplier vetting processes.

As international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—navigate the complexities of sourcing automotive components, this guide aims to empower decision-makers with actionable insights. It will cover critical aspects such as identifying potential issues, understanding the implications of solenoid failure, and evaluating the costs associated with repair or replacement. By equipping buyers with the knowledge to recognize the early warning signs of a malfunctioning starter solenoid, this resource ensures informed purchasing decisions that align with both operational needs and budget considerations. With a focus on quality and reliability, this guide is an essential tool for B2B buyers dedicated to maintaining their fleet’s performance and reliability in a dynamic market.

Table Of Contents

- Top 5 Signs Of A Bad Starter Solenoid Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for signs of a bad starter solenoid

- Understanding signs of a bad starter solenoid Types and Variations

- Key Industrial Applications of signs of a bad starter solenoid

- 3 Common User Pain Points for ‘signs of a bad starter solenoid’ & Their Solutions

- Strategic Material Selection Guide for signs of a bad starter solenoid

- In-depth Look: Manufacturing Processes and Quality Assurance for signs of a bad starter solenoid

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘signs of a bad starter solenoid’

- Comprehensive Cost and Pricing Analysis for signs of a bad starter solenoid Sourcing

- Alternatives Analysis: Comparing signs of a bad starter solenoid With Other Solutions

- Essential Technical Properties and Trade Terminology for signs of a bad starter solenoid

- Navigating Market Dynamics and Sourcing Trends in the signs of a bad starter solenoid Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of signs of a bad starter solenoid

- Strategic Sourcing Conclusion and Outlook for signs of a bad starter solenoid

- Important Disclaimer & Terms of Use

Understanding signs of a bad starter solenoid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| No Response | Engine does not turn over; no sounds or lights | Automotive repair shops, fleet management | Pros: Clear indication of failure. Cons: May require comprehensive diagnostics. |

| Single Click | A single click sound when the ignition is engaged | Automotive parts suppliers, repair services | Pros: Easy to diagnose. Cons: Could be misdiagnosed as battery issues. |

| Intermittent Starting | Engine starts sometimes and fails at other times | Fleet operations, vehicle maintenance | Pros: Potentially less urgent. Cons: Can lead to unexpected failures. |

| Continuous Engagement | Starter engages but does not disengage when key is released | Automotive repair, heavy machinery | Pros: Immediate identification of solenoid issues. Cons: Risk of starter damage. |

| Unintentional Start | Engine starts without key being turned | Security systems, automotive diagnostics | Pros: Critical safety concern. Cons: Requires urgent attention to prevent hazards. |

What are the Characteristics of a No Response Sign?

The “No Response” sign occurs when the engine fails to turn over entirely, often indicating a complete failure of the starter solenoid or related electrical components. This situation is common in automotive repair shops where technicians must diagnose the root cause of the issue. For B2B buyers, understanding this sign is crucial as it can represent a significant downtime for vehicles, impacting fleet operations and repair timelines. Purchasing high-quality replacement parts and ensuring proper diagnostics can mitigate these risks.

How to Identify a Single Click Sound?

A single click sound when attempting to start the engine often suggests that the solenoid is attempting to engage but is unable to complete the circuit. This symptom is frequently encountered in automotive parts suppliers and repair services. B2B buyers should consider investing in reliable solenoid brands that offer warranties and proven performance to minimize future issues. While this sign can be easy to diagnose, it can also be misattributed to battery problems, leading to unnecessary part replacements.

Why is Intermittent Starting a Concern?

Intermittent starting, where the engine occasionally fails to start, is a significant concern for fleet operations and vehicle maintenance services. This symptom can indicate a failing starter solenoid, which may lead to unpredictable vehicle behavior. For B2B buyers, this inconsistency can lead to increased operational costs and potential safety hazards. It’s essential to select solenoids from reputable manufacturers that provide consistent performance to ensure reliability across the fleet.

What Does Continuous Engagement Mean?

Continuous engagement occurs when the starter engages but does not disengage after the key is released, often leading to potential damage to the starter motor. This issue is particularly relevant for automotive repair shops and heavy machinery operations where equipment reliability is paramount. B2B buyers should consider the implications of this sign, as it can lead to costly repairs and downtime. Investing in quality solenoids with robust operational specifications can help prevent such failures.

How Serious is an Unintentional Start?

An unintentional start, where the engine starts without the key being turned, poses a serious safety risk and is typically an indication of a malfunctioning solenoid. This symptom is critical for security systems and automotive diagnostics, as it can lead to accidents or unauthorized vehicle use. B2B buyers should prioritize sourcing high-quality solenoids that meet safety standards to mitigate these risks. Addressing this issue promptly is essential to maintain operational safety and protect assets.

Key Industrial Applications of signs of a bad starter solenoid

| Industry/Sector | Specific Application of signs of a bad starter solenoid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnosing vehicle starting issues | Reduces downtime and repair costs for fleet vehicles | Quality of solenoid components, supplier reliability |

| Heavy Machinery | Ensuring operational readiness of construction equipment | Prevents project delays and enhances productivity | Availability of replacement parts, service support |

| Transportation Logistics | Maintenance of delivery vehicles | Ensures timely deliveries and minimizes disruptions | Compatibility with various vehicle models, warranty terms |

| Agricultural Equipment | Managing farm machinery starting systems | Maximizes operational efficiency during critical seasons | Durability of components in harsh environments, pricing |

| Mining Operations | Monitoring starter systems in mining vehicles | Enhances safety and operational efficiency | Compliance with local regulations, sourcing from trusted brands |

How Can Automotive Repair Shops Utilize Signs of a Bad Starter Solenoid?

Automotive repair shops frequently encounter issues related to starter solenoids, particularly in diagnosing vehicle starting problems. Recognizing signs such as a single click or intermittent starting can lead to faster repairs, reducing vehicle downtime and repair costs for fleet operators. For international buyers, sourcing high-quality solenoid components is crucial to ensure reliable repairs. Factors such as supplier reliability, part compatibility, and warranty offerings should be prioritized.

What Role Does a Bad Starter Solenoid Play in Heavy Machinery Operations?

In the heavy machinery sector, the functionality of starter solenoids is vital for ensuring that construction equipment is operational and ready for use. A malfunctioning solenoid can lead to project delays, impacting productivity and profitability. Buyers in this industry should focus on the availability of replacement parts and robust service support, especially in remote areas where equipment reliability is critical. Ensuring that sourced components can withstand demanding environments is also essential.

How Do Transportation Logistics Companies Address Starter Solenoid Issues?

Transportation logistics companies depend heavily on the reliability of their delivery vehicles. Signs of a bad starter solenoid can lead to unexpected vehicle failures, disrupting schedules and incurring additional costs. By proactively monitoring and maintaining starter systems, businesses can ensure timely deliveries. When sourcing solenoids, compatibility with various vehicle models and favorable warranty terms are essential considerations for international buyers, particularly in regions with diverse vehicle fleets.

Why Is Monitoring Starter Systems Important in Agricultural Equipment?

In agriculture, the ability to start machinery reliably is crucial during planting and harvesting seasons. Signs of a failing starter solenoid can hinder operations, affecting yield and efficiency. Agricultural businesses must prioritize sourcing durable components that can withstand harsh conditions. Additionally, pricing and availability are key factors for international buyers, who may face logistical challenges in accessing replacement parts.

How Can Mining Operations Benefit from Understanding Starter Solenoid Issues?

Mining operations rely on heavy vehicles that must function reliably in challenging environments. A bad starter solenoid can compromise safety and efficiency, leading to potential hazards and operational delays. By recognizing the signs of a failing solenoid, mining companies can implement timely maintenance strategies. Compliance with local regulations and sourcing from trusted brands are crucial for international buyers to ensure both safety and reliability in their operations.

3 Common User Pain Points for ‘signs of a bad starter solenoid’ & Their Solutions

Scenario 1: Unexpected Downtime Due to Starter Solenoid Issues

The Problem:

For fleet managers in industries such as logistics and transportation, the sudden failure of a vehicle’s starter solenoid can lead to unexpected downtime. This not only disrupts daily operations but also incurs additional costs related to repairs, towing, and lost productivity. When a driver turns the key and hears a solitary click with no engine response, the immediate concern is the potential for a cascading effect on delivery schedules and customer commitments. This situation becomes particularly challenging in regions where reliable repair services may not be readily available.

The Solution:

To mitigate the risks associated with starter solenoid failures, fleet managers should implement a proactive maintenance program. Regular inspections of the starter solenoid and associated wiring can help identify early signs of wear or damage. Additionally, sourcing high-quality solenoids from reputable manufacturers ensures reliability. When a vehicle shows symptoms such as intermittent starting issues or clicking sounds, it’s crucial to address these concerns immediately. Establish partnerships with local mechanics who specialize in electrical systems to ensure prompt service. Providing training for drivers to recognize early signs of solenoid problems can also facilitate timely interventions, thus minimizing downtime and maintaining operational efficiency.

Scenario 2: Challenges in Sourcing Quality Replacement Parts

The Problem:

B2B buyers in the automotive repair sector often face significant challenges in sourcing quality replacement parts for starter solenoids. With the proliferation of counterfeit and low-quality components in the market, repair shops risk installing parts that may fail prematurely, leading to dissatisfied customers and increased warranty claims. This is particularly acute in regions with less stringent regulatory oversight, where the temptation to cut costs with cheaper parts can lead to long-term issues.

The Solution:

To navigate the complexities of sourcing quality starter solenoid replacements, buyers should develop a comprehensive supplier vetting process. Prioritize suppliers who provide detailed product specifications, warranties, and have a transparent quality assurance process. It is also beneficial to build relationships with manufacturers directly, as this can lead to more reliable sourcing and potential bulk purchasing discounts. Regularly attending industry trade shows and forums can keep buyers informed about reputable suppliers and emerging technologies in starter solenoid design. Additionally, establishing a feedback loop with customers can help identify any recurring issues with specific parts, enabling buyers to make informed decisions.

Scenario 3: Training Technicians on Starter Solenoid Diagnosis

The Problem:

Automotive repair businesses, especially those operating in diverse geographical markets, often struggle with ensuring their technicians are adequately trained to diagnose issues related to starter solenoids. Misdiagnosis can lead to unnecessary repairs, customer dissatisfaction, and financial losses. Furthermore, the technical complexity of newer vehicles, which may use integrated starter solenoids, complicates the training process.

The Solution:

Investing in comprehensive training programs for technicians is essential. This can include workshops, online courses, and hands-on training sessions focusing on the specific symptoms and diagnosis of bad starter solenoids. Collaborating with manufacturers to provide training on their products can also enhance technicians’ understanding and skills. Encouraging a culture of continuous learning and skill development will empower technicians to accurately diagnose issues, thus improving service quality and customer satisfaction. Additionally, utilizing diagnostic tools and software can streamline the troubleshooting process, allowing technicians to quickly identify solenoid problems and recommend appropriate solutions to customers.

Strategic Material Selection Guide for signs of a bad starter solenoid

What Materials Are Commonly Used for Starter Solenoids?

When considering the materials used in starter solenoids, it’s crucial to analyze their properties, advantages, and limitations. This analysis can guide B2B buyers in making informed decisions based on their specific operational environments and compliance requirements.

How Does Copper Perform in Starter Solenoid Applications?

Copper is a prevalent choice for electrical contacts within starter solenoids due to its excellent electrical conductivity. It typically operates efficiently in a temperature range of -40°C to 150°C, making it suitable for various climates.

Pros: Copper’s high conductivity ensures minimal energy loss, which is vital for the efficient operation of solenoids. It is also relatively easy to manufacture and can be formed into complex shapes, enhancing design flexibility.

Cons: However, copper is prone to corrosion, especially in humid or saline environments, which can lead to electrical failures. Additionally, its cost is higher than some alternatives, which may not be ideal for budget-sensitive projects.

Impact on Application: In regions with high humidity or exposure to corrosive elements, protective coatings or alternative materials may be necessary to ensure longevity.

What Role Does Aluminum Play in Starter Solenoid Design?

Aluminum is increasingly used in starter solenoids due to its lightweight and good conductivity, albeit lower than copper. It has a temperature rating of up to 120°C, making it suitable for moderate thermal environments.

Pros: The primary advantage of aluminum is its lightweight nature, which can reduce the overall weight of the starter assembly. It is also more resistant to corrosion than copper, especially when anodized.

Cons: The downside is that aluminum’s lower conductivity can lead to higher energy losses, and it may require larger cross-sectional areas for the same performance level compared to copper. Additionally, the manufacturing process can be more complex, impacting production timelines.

Impact on Application: In regions where weight is a critical factor, such as in automotive applications, aluminum can be beneficial. However, buyers must consider the trade-off with conductivity.

Why Is Steel Considered for Structural Components in Solenoids?

Steel is often used for the structural components of starter solenoids due to its strength and durability. It can withstand significant mechanical stress and has a temperature rating of up to 200°C.

Pros: The robustness of steel makes it ideal for applications where mechanical integrity is paramount. It is also cost-effective, making it a popular choice for mass production.

Cons: However, steel is susceptible to rust and corrosion, particularly in humid or marine environments. This necessitates protective coatings, which can add to manufacturing complexity and cost.

Impact on Application: Buyers in regions with high moisture levels, such as coastal areas, should prioritize corrosion-resistant steel grades or coatings to ensure performance longevity.

How Does Plastic Contribute to Starter Solenoid Functionality?

Plastics, particularly high-performance polymers, are often used for insulating components in starter solenoids. They can withstand temperatures ranging from -40°C to 120°C, depending on the type.

Pros: The primary advantage of plastics is their excellent electrical insulation properties, which prevent short circuits and enhance safety. They are also lightweight and can be molded into complex shapes, facilitating design innovation.

Cons: On the downside, plastics may not withstand high temperatures as well as metals, which can limit their use in high-heat environments. Additionally, they can be more expensive than traditional materials.

Impact on Application: In regions with varying temperatures, selecting the right type of plastic is crucial to ensure reliability and performance.

Summary Table of Material Selection for Starter Solenoids

| Material | Typical Use Case for signs of a bad starter solenoid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical contacts in solenoids | Excellent electrical conductivity | Prone to corrosion | High |

| Aluminum | Structural components and housings | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Structural elements and enclosures | High strength and durability | Susceptible to rust and corrosion | Low |

| Plastic | Insulating components | Excellent electrical insulation | Limited high-temperature resistance | Medium |

This strategic analysis of materials used in starter solenoids provides B2B buyers with essential insights to make informed purchasing decisions tailored to their operational needs and environmental conditions.

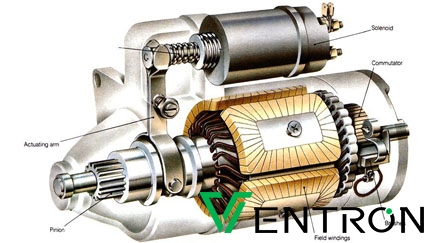

Illustrative image related to signs of a bad starter solenoid

In-depth Look: Manufacturing Processes and Quality Assurance for signs of a bad starter solenoid

What Are the Key Manufacturing Processes for a Starter Solenoid?

The manufacturing of starter solenoids involves several critical stages that ensure the final product meets performance and durability requirements. Understanding these processes can help B2B buyers evaluate potential suppliers more effectively.

What Are the Main Stages of Starter Solenoid Manufacturing?

-

Material Preparation: The first step involves sourcing high-quality materials, typically including copper for electrical components, steel for the solenoid casing, and various insulating materials. Suppliers must ensure that these materials meet specified standards to guarantee conductivity, strength, and resistance to environmental factors.

-

Forming: This stage includes the shaping of components through methods such as stamping, machining, and die-casting. For instance, copper coils are wound to create the electromagnetic field necessary for the solenoid’s operation. Precision in this step is crucial as it affects the solenoid’s performance.

-

Assembly: During assembly, individual components such as the coil, casing, and plunger are brought together. This may involve manual labor or automated machinery, depending on the scale of production. Proper alignment and secure connections are essential to ensure reliable operation.

-

Finishing: This final stage includes surface treatments such as coating or painting to enhance corrosion resistance and aesthetics. Quality checks are also conducted during this phase to detect any defects before the product is packaged for distribution.

How Is Quality Assurance Implemented in Starter Solenoid Manufacturing?

Quality assurance is vital in the production of starter solenoids, as even minor defects can lead to significant failures. International and industry-specific standards play a crucial role in maintaining quality.

What International Standards Should B2B Buyers Consider?

-

ISO 9001: This standard outlines criteria for a quality management system, emphasizing customer satisfaction and continuous improvement. Suppliers adhering to ISO 9001 demonstrate a commitment to quality and reliability.

-

CE Marking: For companies operating in the European market, CE marking signifies that the product complies with EU safety, health, and environmental requirements. This is particularly relevant for automotive components.

-

API Standards: For solenoids used in specific industries, such as oil and gas, adherence to API standards ensures that products can withstand demanding operational conditions.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to ensuring that each stage of production meets required specifications.

-

Incoming Quality Control (IQC): Before production begins, all raw materials are inspected for quality and compliance with specifications. This step helps prevent defects from entering the manufacturing process.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor production processes and equipment. This involves checking dimensions, electrical resistance, and the integrity of solder joints.

-

Final Quality Control (FQC): After assembly, the completed solenoids undergo rigorous testing to ensure functionality. This may include electrical testing, thermal cycling, and stress testing to simulate real-world conditions.

What Common Testing Methods Are Used for Quality Assurance?

B2B buyers should be aware of various testing methods that suppliers employ to verify the quality of starter solenoids.

- Electrical Testing: This involves measuring resistance, inductance, and current draw to ensure the solenoid operates within specified parameters.

- Mechanical Testing: Tests such as tensile strength and fatigue testing evaluate the durability of the solenoid’s components.

- Environmental Testing: Products are subjected to temperature extremes, humidity, and corrosion tests to ensure they can withstand harsh conditions.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers meet quality standards, B2B buyers can take several steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and compliance with international standards.

-

Requesting Quality Reports: Buyers can ask suppliers for detailed quality assurance reports, including test results and compliance certificates for relevant standards.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased evaluation of the supplier’s manufacturing and quality control processes, giving buyers added confidence.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing starter solenoids from international suppliers, particularly from regions such as Africa, South America, and the Middle East, there are specific considerations to keep in mind:

-

Cultural Differences: Understanding local business practices and communication styles can facilitate smoother negotiations and ensure clarity in quality expectations.

-

Regulatory Compliance: Different regions may have varying regulations regarding automotive components. Buyers must ensure that suppliers meet local compliance requirements, which may differ from international standards.

-

Logistical Challenges: International shipping can introduce risks such as damage during transit. Buyers should verify that suppliers have robust packaging and shipping protocols to mitigate these risks.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance measures associated with starter solenoids is essential for B2B buyers. By focusing on critical manufacturing stages, relevant standards, and effective quality control techniques, buyers can make informed decisions when selecting suppliers. This approach not only enhances the reliability of the components they procure but also contributes to overall operational efficiency and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘signs of a bad starter solenoid’

Introduction

Understanding the signs of a bad starter solenoid is crucial for businesses involved in automotive maintenance and repair. This guide provides a practical checklist to help B2B buyers identify and source reliable components related to starter solenoids. By following these steps, you can ensure that you procure high-quality parts that meet your operational needs and maintain vehicle reliability.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the starter solenoids you need. This includes voltage ratings, compatibility with vehicle models, and any unique features required for your operations. Knowing these specifications helps narrow down your supplier options and ensures you acquire the correct parts without unnecessary delays.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers who specialize in starter solenoids. Look for companies with a proven track record in the automotive parts industry and positive reviews from other B2B customers. Reliable suppliers often provide detailed information about their products, including datasheets and installation guides.

Step 3: Verify Supplier Certifications

Before finalizing your supplier choice, verify their certifications and quality assurance processes. Ensure they comply with international standards such as ISO or equivalent local certifications. This step is essential to confirm that the parts you are sourcing are reliable and manufactured under stringent quality controls.

Step 4: Request Samples for Testing

Request samples of the starter solenoids you are considering for procurement. Testing samples before making a bulk purchase allows you to assess the product’s quality and functionality. Evaluate the solenoids for performance indicators, such as response time and durability under varying conditions.

Step 5: Assess Warranty and Support Options

Examine the warranty and support options provided by the supplier. A robust warranty reflects the supplier’s confidence in their product quality. Additionally, ensure that they offer responsive customer support for troubleshooting and after-sales inquiries, which can be invaluable in maintaining operational efficiency.

Step 6: Evaluate Pricing and Payment Terms

Compare pricing structures among different suppliers while considering the overall value offered. Look for transparent pricing that includes shipping, handling, and any potential duties. Assess payment terms to ensure they align with your financial processes and cash flow management.

Step 7: Check for Local Availability and Shipping Options

Finally, confirm the availability of starter solenoids in your region and the shipping options provided by the supplier. Local availability can significantly reduce lead times and shipping costs. Additionally, inquire about the supplier’s logistics capabilities to ensure timely delivery.

By following this checklist, B2B buyers can effectively source quality starter solenoids while minimizing risks associated with procurement. Prioritizing technical specifications, supplier reliability, and post-purchase support will lead to better decision-making and enhanced operational performance.

Comprehensive Cost and Pricing Analysis for signs of a bad starter solenoid Sourcing

What Are the Key Cost Components in Sourcing Starter Solenoids?

When sourcing starter solenoids, several cost components come into play that significantly impact the overall pricing structure. Understanding these elements can help B2B buyers make informed decisions.

Materials: The primary materials used in the manufacture of starter solenoids include copper for electrical connections, steel for housing, and various plastics for insulation. Prices for these raw materials can fluctuate based on market conditions, supply chain stability, and geopolitical factors, particularly for international buyers.

Labor: Labor costs vary by region and can be influenced by local wage rates, skill levels, and labor laws. For example, labor costs in Europe might be higher compared to Africa or South America, affecting the overall pricing strategy.

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, which can be passed on to buyers as lower prices.

Tooling: The initial cost of tooling for production can be significant, especially for customized solenoids. Buyers looking for unique specifications may incur higher tooling expenses, which can affect the final price.

Quality Control (QC): Ensuring that solenoids meet quality standards is crucial. The costs associated with quality control processes can vary based on the complexity of the solenoid and the certification requirements in different markets.

Logistics: Shipping costs, including freight, insurance, and customs duties, play a vital role in the pricing structure. International buyers should be aware of Incoterms, which define the responsibilities of buyers and sellers in shipping arrangements.

Margin: Suppliers typically apply a margin to cover their operational costs and profit. This margin can vary based on market demand, competition, and the supplier’s reputation for quality and service.

How Do Price Influencers Affect Starter Solenoid Sourcing?

Several factors influence the pricing of starter solenoids, particularly in international markets.

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Buyers should negotiate MOQs with suppliers to maximize cost-efficiency while ensuring they do not overstock.

Specifications and Customization: Custom-built solenoids tailored to specific applications can significantly increase costs. Buyers should weigh the necessity of customization against budget constraints.

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO or CE) can enhance reliability but also increase costs. Buyers should assess whether the added expense aligns with their operational needs.

Supplier Factors: The supplier’s reputation, reliability, and service quality can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

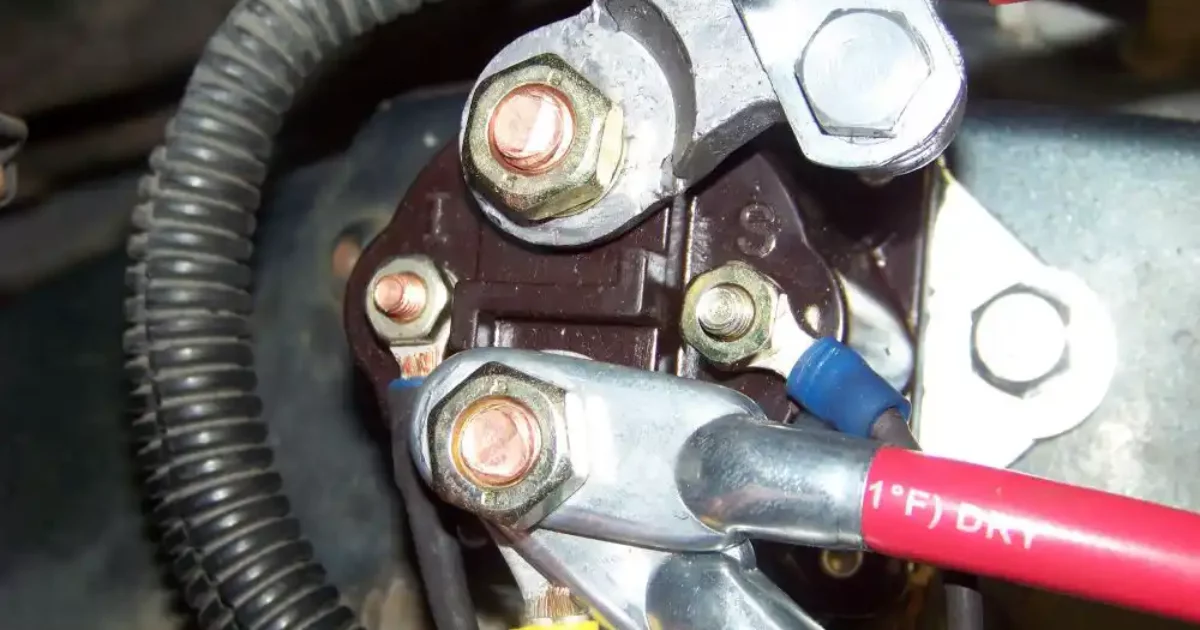

Illustrative image related to signs of a bad starter solenoid

What Buyer Tips Can Help Optimize Costs in Sourcing Starter Solenoids?

International B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, can implement several strategies to optimize their sourcing costs.

Negotiation: Engage suppliers in negotiations to secure better pricing, especially when placing large orders. Building long-term relationships can also yield better terms over time.

Focus on Total Cost of Ownership (TCO): Consider not only the purchase price but also the costs associated with logistics, installation, maintenance, and potential downtime. A lower upfront cost may not always result in savings in the long run.

Understand Pricing Nuances: Different regions may have varying pricing structures based on local market dynamics. For example, prices in Germany may reflect higher labor and material costs than in Nigeria. Buyers should conduct thorough market research to understand these differences.

Leverage Incoterms: Familiarity with Incoterms can help buyers understand their responsibilities concerning shipping costs and risks. This knowledge can lead to more favorable terms and potentially lower overall costs.

Conclusion

Sourcing starter solenoids involves a multifaceted cost structure influenced by various factors ranging from materials to logistics. By understanding these components and implementing strategic buying practices, international B2B buyers can effectively manage their costs and make informed purchasing decisions. Always remember that prices can vary significantly based on regional factors, and it is crucial to conduct thorough market research before finalizing any agreements.

Alternatives Analysis: Comparing signs of a bad starter solenoid With Other Solutions

Exploring Alternatives to Signs of a Bad Starter Solenoid

In the automotive sector, identifying issues related to the starter solenoid is crucial for efficient vehicle operation. However, there are alternative approaches and technologies that can also address starting issues, offering various advantages. This analysis compares the signs of a bad starter solenoid with alternative solutions such as advanced diagnostic tools and starter relay systems.

| Comparison Aspect | Signs of a Bad Starter Solenoid | Advanced Diagnostic Tools | Starter Relay Systems |

|---|---|---|---|

| Performance | Identifies specific solenoid issues through symptoms | Provides comprehensive system analysis for multiple components | Controls high-power circuits effectively |

| Cost | Generally low (visual inspection and testing) | Higher upfront cost for tools | Moderate cost, depends on vehicle type |

| Ease of Implementation | Simple troubleshooting process | Requires training and expertise | Installation may require professional help |

| Maintenance | Minimal, mostly observational | Regular updates and calibration needed | Low, but may require periodic checks |

| Best Use Case | Quick identification of solenoid problems | Comprehensive diagnostics for complex issues | Reliable operation in high-power applications |

What Are Advanced Diagnostic Tools and How Do They Compare?

Advanced diagnostic tools encompass a range of electronic devices that analyze vehicle systems, including the starter solenoid. These tools can provide insights into various electrical components, allowing technicians to diagnose issues beyond just the starter solenoid.

Pros: They offer a thorough understanding of vehicle health, can identify multiple issues simultaneously, and often include features like data logging for future reference.

Illustrative image related to signs of a bad starter solenoid

Cons: The initial investment can be significant, and they may require specialized training to use effectively. For companies in emerging markets, such as those in Africa or South America, the cost and expertise required may be barriers.

How Do Starter Relay Systems Function as an Alternative?

Starter relay systems serve as an intermediary between the ignition switch and the starter motor, ensuring that high power is delivered only when needed. They can also protect the starter solenoid from excessive wear.

Pros: They enhance the reliability of starting mechanisms, can handle higher currents than solenoids, and often have built-in safety features to prevent system failures.

Cons: While they improve performance, installation may require professional services, which can add to labor costs. Furthermore, if the relay fails, it may lead to similar symptoms as a bad solenoid, complicating the diagnosis.

Conclusion: Choosing the Right Solution for Your Needs

When determining the best approach to address starting issues, B2B buyers should consider their specific operational requirements, budget constraints, and available expertise. While recognizing the signs of a bad starter solenoid is a practical and often cost-effective first step, investing in advanced diagnostic tools or starter relay systems may provide longer-term benefits. An informed decision will depend on whether immediate troubleshooting or comprehensive vehicle diagnostics aligns more closely with your business’s operational strategy and goals.

Essential Technical Properties and Trade Terminology for signs of a bad starter solenoid

What Are the Key Technical Properties of a Bad Starter Solenoid?

Understanding the technical specifications of a starter solenoid is crucial for B2B buyers looking to source reliable automotive components. Here are some essential properties to consider:

-

Material Grade

The material used in the construction of the starter solenoid significantly affects its durability and performance. Common materials include copper for electrical connections and high-grade steel for the housing. Selecting solenoids made from high-quality materials ensures better resistance to corrosion and wear, which is particularly important in regions with harsh environmental conditions. -

Current Rating (Amperage)

The current rating indicates the maximum electrical current the solenoid can handle without failure. Typically, starter solenoids are rated between 100 to 300 amps. Understanding this rating is vital for ensuring compatibility with the vehicle’s electrical system, which can prevent overheating and potential damage to both the solenoid and the starter motor. -

Operating Voltage

Most starter solenoids operate at standard voltages such as 12V or 24V. Knowing the correct operating voltage is essential for B2B buyers to ensure compatibility with the vehicles they service or manufacture. An incorrect voltage can lead to solenoid failure or inadequate performance. -

Response Time

The response time refers to how quickly the solenoid activates once the ignition signal is received. A fast response time (typically milliseconds) is crucial for reliable engine starts. Buyers should prioritize solenoids with a low response time to enhance vehicle reliability, particularly in commercial fleets where downtime is costly. -

Mounting Configuration

The mounting configuration defines how the solenoid is installed in the vehicle. Common configurations include direct mounting on the starter or remote mounting within the engine compartment. Understanding the mounting requirements helps in selecting the right solenoid that fits seamlessly into existing vehicle designs, thereby reducing installation time and costs. -

Temperature Range

The operational temperature range indicates the conditions under which the solenoid can function effectively. Many starter solenoids can operate within a range of -40°C to 85°C. For B2B buyers, selecting solenoids that can withstand extreme temperatures is essential, especially in regions with fluctuating climates.

What Are the Common Trade Terms Related to Starter Solenoids?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common trade terms relevant to starter solenoids:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are generally preferred for their guaranteed compatibility and quality. B2B buyers often seek OEM solenoids to ensure that their products meet manufacturer specifications. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. Understanding MOQ helps buyers manage inventory and financial commitments effectively. It is particularly important in international transactions where bulk purchasing may lead to better pricing. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. B2B buyers use RFQs to compare offers from multiple vendors, helping them secure the best deal for starter solenoids and other components. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), helps B2B buyers understand shipping responsibilities, costs, and risks associated with transporting starter solenoids. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is critical for planning inventory and ensuring that they can meet customer demands without delays. -

Warranty Period

The warranty period specifies the duration for which the manufacturer guarantees the solenoid against defects. This is a key consideration for B2B buyers as it reflects the product’s reliability and the manufacturer’s confidence in their components.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right starter solenoids that meet their operational needs and standards.

Navigating Market Dynamics and Sourcing Trends in the signs of a bad starter solenoid Sector

What Are the Key Trends Influencing the Signs of a Bad Starter Solenoid Market?

The global market for automotive components, including starter solenoids, is influenced by several key drivers. The rise in vehicle production and the increasing demand for both personal and commercial transportation are significant factors pushing market growth. Notably, regions such as Africa and South America are experiencing a surge in vehicle ownership, resulting in higher demand for automotive parts and components. In Europe, particularly in countries like Germany, the emphasis on electric and hybrid vehicles is reshaping the landscape for automotive parts, including starter solenoids, which are vital for both conventional and electric vehicle systems.

Emerging B2B technology trends, such as the integration of IoT (Internet of Things) in automotive systems, are enhancing diagnostics capabilities for identifying signs of a bad starter solenoid. This technology allows for real-time monitoring of vehicle health, which can alert users to potential issues before they lead to failure. Additionally, the trend toward digitalization in procurement processes is enabling international buyers to source components more efficiently, facilitating smoother transactions across borders.

The market dynamics for international B2B buyers are characterized by the need for reliable suppliers who can offer competitive pricing without compromising on quality. In regions like the Middle East and Africa, where supply chain challenges can be more pronounced, establishing strong relationships with manufacturers is crucial. Buyers should also be aware of fluctuating raw material costs, which can impact pricing and availability, urging them to stay informed about market conditions.

How Important Is Sustainability and Ethical Sourcing in the Signs of a Bad Starter Solenoid Sector?

Sustainability and ethical sourcing are becoming increasingly important in the automotive parts industry, including for starter solenoids. As environmental regulations tighten globally, manufacturers are under pressure to minimize their carbon footprint and adopt greener production practices. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainability, which can include using recycled materials, reducing waste, and implementing energy-efficient manufacturing processes.

The environmental impact of automotive components is significant, especially given the lifecycle of vehicles and their parts. Buyers should look for manufacturers that hold certifications such as ISO 14001 for environmental management systems, which indicate a commitment to reducing ecological impact. Additionally, “green” materials, such as those derived from sustainable sources or that are recyclable at the end of their life cycle, are gaining traction. This focus not only aligns with corporate social responsibility goals but also appeals to environmentally-conscious consumers.

Furthermore, ethical supply chains are vital in ensuring that materials are sourced responsibly, without exploitation of labor or adverse environmental impact. Buyers should assess their suppliers’ practices and consider the transparency of their supply chains to mitigate risks associated with unethical sourcing. By prioritizing sustainability, B2B buyers can enhance their brand reputation and appeal to a growing market segment that values environmental stewardship.

What Is the Evolution of the Signs of a Bad Starter Solenoid Market?

The evolution of the starter solenoid market reflects broader changes in automotive technology and consumer behavior. Initially, starter solenoids were simple electromagnetic devices designed to engage the starter motor. Over the years, advancements in automotive engineering have led to more sophisticated designs that can handle higher currents and integrate seamlessly with electronic control units in modern vehicles.

The shift from traditional combustion engines to electric and hybrid vehicles has also transformed the role of starter solenoids. In electric vehicles, solenoids may serve different functions, such as engaging auxiliary systems or supporting regenerative braking mechanisms. This evolution highlights the need for manufacturers to innovate continuously, adapting their products to meet the demands of new vehicle technologies.

As the market continues to grow, B2B buyers should remain vigilant about these trends, understanding how technological advancements can influence product performance and sourcing decisions. By staying informed about the evolution of starter solenoids, businesses can position themselves strategically within the automotive supply chain, ensuring they meet the needs of their customers effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of signs of a bad starter solenoid

1. How do I identify signs of a bad starter solenoid in vehicles?

To identify signs of a bad starter solenoid, observe the vehicle’s starting behavior. Common indicators include a complete lack of response when turning the ignition key, a single click sound, or repeated clicking noises. If the engine starts intermittently or continues to run after releasing the key, these are further signs of solenoid malfunction. Regular maintenance checks and diagnostics can help detect these issues early, preventing more significant problems and costs.

2. What is the best method to source high-quality starter solenoids for my business?

To source high-quality starter solenoids, start by researching reputable manufacturers and suppliers with proven track records. Utilize trade platforms and industry-specific directories to find suppliers. Consider requesting samples to assess quality before committing to larger orders. Additionally, check for certifications and compliance with international standards to ensure reliability and performance. Engaging with suppliers that offer customization options can also help meet specific market needs.

3. What should I consider when vetting suppliers for starter solenoids?

When vetting suppliers for starter solenoids, evaluate their production capabilities, quality assurance processes, and experience in the automotive sector. Request references or case studies from previous clients, and verify their compliance with relevant international standards. It’s also crucial to assess their communication responsiveness and willingness to provide support during and after the purchase. Conducting a factory visit, if feasible, can further assure you of their operational standards.

4. Are there minimum order quantities (MOQs) for starter solenoids?

Minimum order quantities (MOQs) for starter solenoids can vary significantly between suppliers, often depending on the type of product and the supplier’s capacity. Some manufacturers may have MOQs as low as 50 units, while others might require orders of several hundred. When negotiating, clarify the MOQ and discuss potential flexibility, especially if you are a new buyer or looking to test a product line before larger commitments.

5. What payment terms are typically offered by international suppliers of starter solenoids?

International suppliers of starter solenoids may offer various payment terms, including advance payment, letter of credit, or payment upon delivery. Commonly, a 30% deposit is required upfront with the balance due before shipment. It’s essential to negotiate favorable terms that align with your cash flow and risk management strategies. Always ensure that payment methods are secure and that contracts clearly outline payment schedules and conditions.

6. How can I ensure quality assurance when purchasing starter solenoids?

To ensure quality assurance when purchasing starter solenoids, request detailed specifications and quality control documentation from the supplier. Implement a pre-shipment inspection process to verify product compliance with agreed standards. Establish a clear returns policy for defective items and consider third-party quality audits. Building a strong relationship with the supplier can also facilitate better communication regarding quality expectations and improvements.

7. What logistics considerations should I keep in mind when importing starter solenoids?

When importing starter solenoids, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose reliable freight forwarders experienced in handling automotive parts to ensure timely delivery. Understand the import duties and taxes applicable in your country to budget appropriately. Additionally, develop a robust inventory management system to monitor stock levels and streamline the supply chain.

8. How do I handle potential delays or issues with my starter solenoid orders?

To handle potential delays or issues with starter solenoid orders, maintain open communication with your supplier to receive timely updates. Have contingency plans in place, such as alternative suppliers or expedited shipping options. Document all agreements and timelines in your contracts to hold parties accountable. If disputes arise, approach them professionally, seeking amicable resolutions through negotiation or mediation to maintain a positive supplier relationship.

Top 5 Signs Of A Bad Starter Solenoid Manufacturers & Suppliers List

1. LinkedIn – Starter Solenoid

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: Starter solenoid is an electromagnetic switch that engages the starter motor when the ignition key is turned to the “start” position. It controls the high current needed to operate the starter motor safely, ensuring clean engagement and disengagement to reduce wear. Symptoms of a bad starter solenoid include clicking noises, failure to crank, difficulty starting, decreased acceleration performance…

2. Reddit – Solenoid Jump Start Cable

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: solenoid jump start cable, multimeter, battery, starter solenoid

3. Can-Am – Renegade & Outlander

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Can-Am Renegade and Outlander (United States)

4. Johnson – 1978 55EL78 Outboard Motor Parts

Domain: marineengine.com

Registered: 1999 (26 years)

Introduction: 1978 Johnson 55, 55EL78 outboard motor; ARCO rebuilt starter; new starter solenoid; rectifier; battery cables; electrical connections; troubleshooting symptoms include slow cranking, starter dragging, and overheating.

5. Eric’s Car Care – Starter Solenoid Solutions

Domain: ericscarcare.com

Registered: 2021 (4 years)

Introduction: This company, Eric’s Car Care – Starter Solenoid Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for signs of a bad starter solenoid

In evaluating the signs of a bad starter solenoid, it is essential for international B2B buyers to recognize the implications of quality sourcing on their operational efficiency. Understanding symptoms such as intermittent starting, clicking sounds, or complete failure to engage can prevent costly downtime and enhance the reliability of fleet operations. The value of strategic sourcing cannot be overstated; selecting high-quality components from reputable suppliers ensures not only compliance with international standards but also longevity and performance in diverse environments.

As businesses in Africa, South America, the Middle East, and Europe navigate the complexities of automotive supply chains, prioritizing partnerships with manufacturers who emphasize quality control and customer support is crucial. By doing so, companies can mitigate risks associated with faulty components and maintain a competitive edge in their markets.

Looking ahead, it is vital for B2B buyers to stay informed about advancements in starter solenoid technology and sourcing strategies. Engage with trusted suppliers and leverage industry insights to optimize your procurement processes. Your proactive approach today can lead to enhanced operational resilience tomorrow, ensuring that your vehicles are always ready to perform when needed.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to signs of a bad starter solenoid

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.