Introduction: Navigating the Global Market for replacing starter

In the ever-evolving landscape of the automotive industry, sourcing reliable replacement starters is a critical concern for international B2B buyers. The challenge lies not only in identifying the right components but also in navigating the complexities of varying market conditions, regulations, and supplier capabilities across regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide delves into the multifaceted world of starter replacement, offering insights into types of starters, their applications, and essential factors for supplier vetting.

Understanding the cost implications is equally vital, as prices can fluctuate dramatically based on vehicle make, model, and regional availability. With estimates ranging from $50 for rebuild parts to over $1,100 for professional installations, informed decision-making is paramount. This guide empowers B2B buyers by providing actionable strategies for assessing quality, negotiating prices, and ensuring compliance with local standards.

By equipping international buyers with the knowledge needed to evaluate options and suppliers effectively, this resource fosters confidence in the purchasing process. Whether you are in Brazil, Nigeria, or any other market, you’ll find the insights necessary to make strategic decisions that enhance your operations and ensure customer satisfaction.

Table Of Contents

- Top 2 Replacing Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for replacing starter

- Understanding replacing starter Types and Variations

- Key Industrial Applications of replacing starter

- 3 Common User Pain Points for ‘replacing starter’ & Their Solutions

- Strategic Material Selection Guide for replacing starter

- In-depth Look: Manufacturing Processes and Quality Assurance for replacing starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘replacing starter’

- Comprehensive Cost and Pricing Analysis for replacing starter Sourcing

- Alternatives Analysis: Comparing replacing starter With Other Solutions

- Essential Technical Properties and Trade Terminology for replacing starter

- Navigating Market Dynamics and Sourcing Trends in the replacing starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of replacing starter

- Strategic Sourcing Conclusion and Outlook for replacing starter

- Important Disclaimer & Terms of Use

Understanding replacing starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Replacement | Direct swap with OEM parts; typically straightforward. | Fleet maintenance, automotive repair shops | Pros: Cost-effective, easy installation. Cons: Limited warranty. |

| Remanufactured Starter | Rebuilt to OEM specifications; often includes new parts. | Automotive parts suppliers, dealerships | Pros: More sustainable, often cheaper than new. Cons: Potential variability in quality. |

| High-Performance Starter | Enhanced power output; designed for performance vehicles. | Racing teams, performance car shops | Pros: Improved starting power, reliability. Cons: Higher cost, may require modifications. |

| Mini Starter | Compact design; suitable for space-restricted applications. | Custom vehicle builders, compact cars | Pros: Space-saving, lightweight. Cons: May have lower torque output. |

| Gear Reduction Starter | Uses gear reduction to increase torque; efficient operation. | Heavy machinery, commercial vehicles | Pros: High torque, efficient energy use. Cons: More complex installation. |

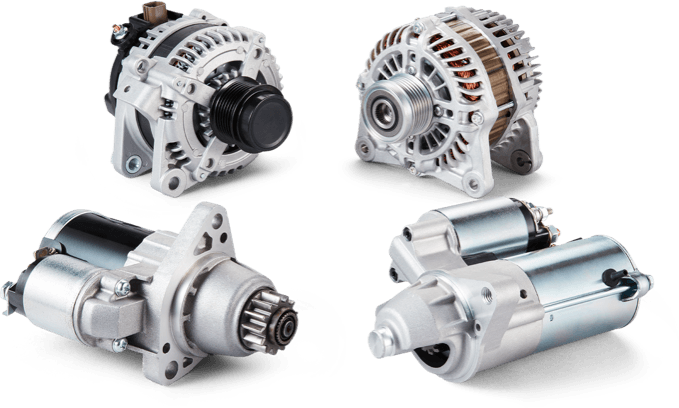

What Are the Characteristics of Standard Replacement Starters?

Standard replacement starters are the most common type used in automotive repair. They involve directly replacing a faulty starter with an original equipment manufacturer (OEM) part. This type is ideal for fleet maintenance and general automotive repair shops, as it typically offers straightforward installation and cost-effectiveness. Buyers should consider the warranty terms and compatibility with their specific vehicle models, as these factors can influence long-term satisfaction and performance.

How Do Remanufactured Starters Differ from New Starters?

Remanufactured starters are rebuilt to meet OEM specifications, often incorporating new components where necessary. This type appeals to automotive parts suppliers and dealerships looking for a balance between cost and quality. B2B buyers should consider the sustainability aspect, as remanufactured starters reduce waste. However, variability in quality can be a concern, so sourcing from reputable suppliers is crucial for maintaining reliability.

When Should You Consider High-Performance Starters?

High-performance starters are designed to deliver enhanced power output, making them suitable for racing teams and performance vehicle shops. These starters provide improved reliability and starting power, especially in demanding conditions. While they can be a worthwhile investment for businesses focused on performance, buyers should be aware of the higher costs and potential modifications required to fit specific vehicles.

What Advantages Do Mini Starters Offer?

Mini starters are compact and lightweight, making them ideal for applications where space is limited, such as in custom vehicle builds or compact cars. Their design allows for easier installation in tight spaces, but buyers should consider the torque output, as mini starters may not provide the same performance as standard-sized options. This type is particularly appealing for businesses focused on innovative automotive solutions.

Why Choose Gear Reduction Starters for Heavy Machinery?

Gear reduction starters are engineered to use a gear system to increase torque, making them suitable for heavy machinery and commercial vehicles that require substantial starting power. These starters are known for their efficiency and reliability. However, their installation can be more complex, which may lead to higher labor costs. B2B buyers should assess the specific requirements of their machinery to determine if the benefits outweigh the installation challenges.

Key Industrial Applications of replacing starter

| Industry/Sector | Specific Application of replacing starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacing starters in various vehicle models | Reduces downtime for customers, enhancing service reputation | Need for quality, OEM or compatible parts; availability of technical support |

| Transportation & Logistics | Starter replacement in fleet vehicles | Ensures fleet reliability and minimizes operational disruptions | Bulk purchasing options; warranty terms; compatibility with multiple vehicle types |

| Agriculture | Replacing starters in agricultural machinery | Enhances machinery uptime, crucial during planting and harvest | Sourcing durable parts that can withstand harsh environments; local availability |

| Construction | Starter replacement in heavy construction equipment | Maintains productivity by reducing equipment failures | Consideration for part availability in remote locations; understanding of machinery specifications |

| Mining | Replacing starters in mining equipment | Ensures continuous operation in demanding environments | Need for rugged components; reliable supply chains for critical repairs |

How is ‘Replacing Starter’ Used in Automotive Repair Shops?

In automotive repair shops, replacing starters is a common service due to the high frequency of starter failures across various vehicle models. When customers experience starting issues, timely replacement of the starter can significantly reduce vehicle downtime, enhancing customer satisfaction and loyalty. Repair shops must source high-quality, OEM, or compatible starter parts, ensuring they have access to technical support for specific vehicle makes and models. This is particularly important in regions like Africa or South America, where parts availability may vary.

What are the Benefits of Starter Replacement in Transportation & Logistics?

In the transportation and logistics sector, fleet vehicles rely heavily on functional starters for reliable operations. Regular replacement of faulty starters ensures that vehicles remain operational, minimizing delays and disruptions in service. Businesses benefit from increased efficiency and reduced maintenance costs. Key sourcing considerations include bulk purchasing options to lower costs, favorable warranty terms, and ensuring compatibility with a diverse range of vehicle types, especially in regions with varied fleets, such as the Middle East and Europe.

Why is Starter Replacement Critical for Agricultural Machinery?

Agricultural machinery, such as tractors and harvesters, often requires starter replacements to maintain operational efficiency during critical planting and harvesting seasons. A malfunctioning starter can lead to significant downtime, impacting productivity and yield. Buyers in the agriculture sector need to consider sourcing durable starter parts that can withstand harsh environmental conditions, as well as ensuring local availability to facilitate quick repairs. This is especially crucial in rural areas of countries like Brazil and Nigeria, where agricultural activities are vital to the economy.

How Does Replacing Starters Impact Construction Equipment?

In the construction industry, heavy equipment like excavators and bulldozers frequently requires starter replacements to ensure continuous operation on job sites. A reliable starter is essential for minimizing equipment failures, which can lead to costly project delays. When sourcing starters for construction machinery, businesses must consider the availability of parts in remote locations and the specific machinery specifications to avoid compatibility issues. This is particularly important in developing regions where construction projects are booming.

What Role Does Starter Replacement Play in Mining Operations?

In mining operations, starters are critical components for heavy machinery used in extracting resources. The harsh conditions often lead to increased wear and tear on starters, necessitating regular replacements to ensure machinery operates without interruption. Ensuring a reliable supply chain for rugged components is essential to avoid operational downtime. International buyers in the mining sector should prioritize sourcing from suppliers that understand the demands of mining environments, ensuring that the starters are built to last under extreme conditions.

3 Common User Pain Points for ‘replacing starter’ & Their Solutions

Scenario 1: Understanding the True Cost of Starter Replacement

The Problem: Many B2B buyers, particularly those managing fleets or automotive repair shops, often face uncertainty regarding the total cost associated with starter replacement. This confusion can stem from a lack of clarity on labor costs, part prices, and the variability based on vehicle type. Buyers may find themselves over-budgeting or underestimating costs, leading to potential cash flow issues or surprise expenses that disrupt their financial planning.

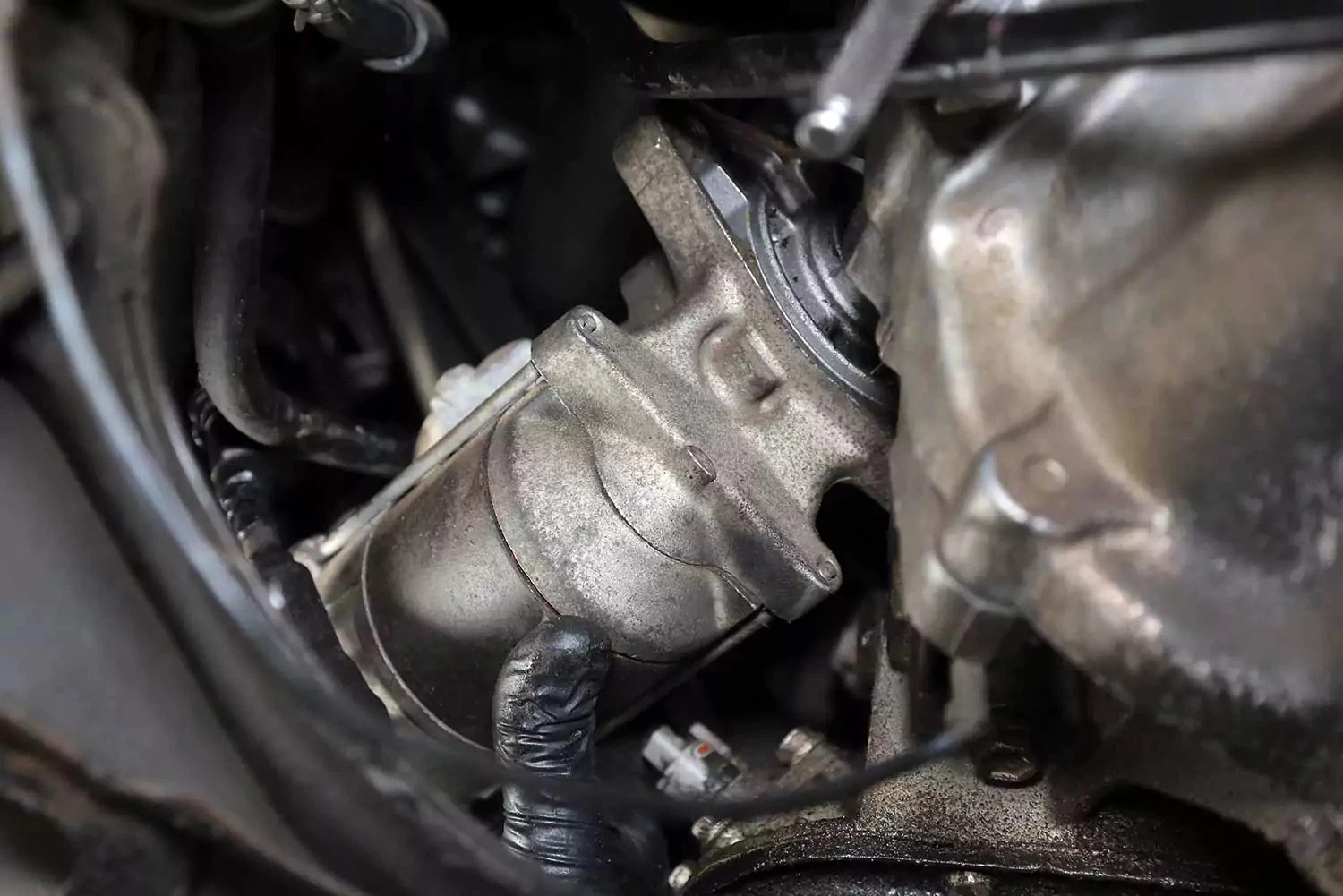

Illustrative image related to replacing starter

The Solution: To effectively manage costs, B2B buyers should develop a comprehensive pricing strategy that considers both parts and labor. Start by establishing relationships with multiple suppliers to obtain quotes for starter parts and labor estimates based on vehicle make and model. Investing in a robust inventory management system can help track parts pricing trends over time, allowing buyers to make informed purchasing decisions. Additionally, consider creating a standardized service package for common vehicles in your fleet, which can streamline the replacement process and reduce labor costs. Implementing a regular maintenance schedule can also help identify starter issues early, potentially reducing the need for costly replacements.

Scenario 2: Diagnosing Starter Issues Accurately

The Problem: B2B buyers often encounter difficulties in diagnosing whether the starter is indeed the source of starting issues. Misdiagnosis can lead to unnecessary expenses if a starter is replaced when the actual problem lies elsewhere, such as in the battery or ignition system. This not only impacts operational efficiency but can also lead to distrust among customers seeking reliable service.

The Solution: To combat misdiagnosis, buyers should invest in diagnostic tools that can accurately identify starter-related problems. Utilizing a multimeter can help assess battery voltage and check for proper electrical connections, while OBD-II scanners can provide insights into error codes that indicate potential issues with the starter or related components. Training staff on systematic troubleshooting techniques can also enhance diagnostic accuracy. Documenting common symptoms of starter failure, such as erratic cranking or unusual noises, can serve as a quick reference for technicians, ensuring they can efficiently pinpoint the problem and recommend appropriate solutions.

Scenario 3: Sourcing Quality Replacement Starters

The Problem: Sourcing quality replacement starters can be a significant challenge for B2B buyers, especially in regions with fluctuating supply chains and varying market standards. Buyers may struggle to differentiate between reliable and subpar products, leading to potential issues with performance and longevity. This challenge is particularly pronounced in international markets where counterfeit parts may be prevalent.

The Solution: To ensure the procurement of quality starters, buyers should establish partnerships with reputable manufacturers or authorized distributors known for their quality control standards. Conducting thorough research and requesting certifications or warranties can help verify the authenticity of the products. Additionally, implementing a vendor rating system based on quality, delivery times, and service can aid in making informed decisions. Leveraging technology, such as blockchain for traceability, can further secure the supply chain, ensuring that buyers receive genuine parts. Regularly reviewing supplier performance can also help maintain a high standard of quality in replacements, ultimately leading to improved customer satisfaction and reduced warranty claims.

Strategic Material Selection Guide for replacing starter

What Are the Key Materials for Replacing Starters?

When it comes to replacing starters, the material selection significantly influences performance, durability, and cost-effectiveness. Below, we analyze four common materials used in starter manufacturing, focusing on their properties, advantages, and considerations for international B2B buyers.

How Does Copper Impact Starter Performance?

Copper is a widely used material in starter motors, particularly for its excellent electrical conductivity. With a high melting point of approximately 1,984°F (1,085°C) and resistance to corrosion, copper is ideal for components like windings and terminals.

Pros: Copper’s superior conductivity ensures efficient energy transfer, enhancing the starter’s performance. Additionally, it is relatively easy to work with, allowing for intricate designs and manufacturing processes.

Illustrative image related to replacing starter

Cons: However, copper is more expensive than alternatives like aluminum, which may affect the overall cost of the starter. It is also heavier, which could be a consideration in applications where weight is a critical factor.

Impact on Application: Copper starters are suitable for high-performance vehicles and applications requiring robust electrical systems. However, buyers must consider the local availability and price fluctuations of copper, especially in regions like Africa and South America, where market conditions can vary.

What Role Does Aluminum Play in Starter Manufacturing?

Aluminum is another popular choice for starter components, particularly for housings and casings. With a melting point of around 1,221°F (660°C) and good corrosion resistance, aluminum is lightweight and durable.

Pros: The lightweight nature of aluminum contributes to overall vehicle efficiency, making it an attractive option for manufacturers looking to reduce weight. Additionally, it is generally less expensive than copper, which can lower production costs.

Cons: Despite its advantages, aluminum has lower electrical conductivity compared to copper, which can impact performance in high-demand applications. It may also require additional coatings or treatments to enhance corrosion resistance in harsh environments.

Impact on Application: Aluminum starters are often used in everyday vehicles and applications where weight savings are crucial. International buyers should ensure compliance with local standards such as ASTM or DIN, as aluminum quality can vary significantly.

How Does Steel Contribute to Starter Durability?

Steel is commonly used in starter components like the housing and drive gears due to its strength and durability. With a melting point of around 2,500°F (1,370°C), steel can withstand high temperatures and pressures.

Pros: Steel’s high tensile strength makes it ideal for components subjected to significant mechanical stress. It is also cost-effective, making it a popular choice for mass-produced starters.

Cons: On the downside, steel is heavier than aluminum and can be prone to corrosion if not properly coated. This could lead to premature failure in environments with high humidity or exposure to corrosive substances.

Illustrative image related to replacing starter

Impact on Application: Steel starters are suitable for heavy-duty vehicles and applications where durability is paramount. Buyers in regions like the Middle East, where environmental conditions can be harsh, should prioritize corrosion-resistant coatings to enhance longevity.

What Advantages Does Plastic Offer in Starter Components?

Plastic is increasingly being used in starter components, particularly for insulation and housing parts. With a melting point varying widely depending on the type of plastic, it can offer unique advantages in specific applications.

Pros: Plastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for innovative designs. They also provide excellent electrical insulation, which is crucial in starter applications.

Cons: However, plastics may not withstand high temperatures as effectively as metals and can degrade over time when exposed to UV light or extreme temperatures. This could limit their application in high-performance or heavy-duty starters.

Impact on Application: Plastic components are often used in low to mid-range vehicles where cost savings are essential. International buyers should consider the specific type of plastic used and its compliance with local automotive standards.

Summary Table of Material Selection for Replacing Starters

| Material | Typical Use Case for replacing starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical windings and terminals | Excellent conductivity | Higher cost and weight | High |

| Aluminum | Casings and housings | Lightweight and cost-effective | Lower conductivity compared to copper | Medium |

| Steel | Housing and drive gears | High strength and durability | Heavier and prone to corrosion | Low |

| Plastic | Insulation and housing parts | Lightweight and versatile | Limited temperature resistance | Low |

This analysis provides a comprehensive overview of material options for replacing starters, enabling international B2B buyers to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for replacing starter

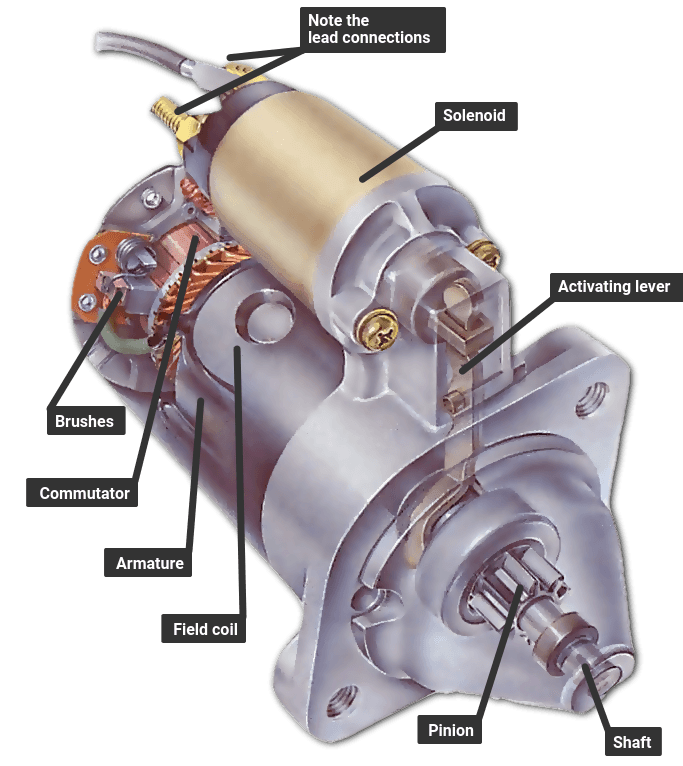

What Are the Key Stages in the Manufacturing Process of Starters?

Manufacturing an automotive starter involves several critical stages that ensure the end product meets industry standards for performance and reliability. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Starter Manufacturing?

The process begins with the selection of high-quality materials. Common materials include steel for the housing and aluminum for components like the armature, due to their lightweight and durability. Manufacturers often source these materials from certified suppliers to ensure compliance with international standards.

Illustrative image related to replacing starter

Once the materials are selected, they undergo preparation, which includes cutting, machining, and treating to achieve the desired specifications. This step is crucial as the mechanical properties of the materials directly influence the starter’s performance and longevity.

What Forming Techniques Are Used in Starter Production?

Forming techniques vary depending on the component being manufactured. For instance, the electromagnetic field coils are typically wound using precision machinery to ensure consistent quality. The armature is formed through a combination of stamping and winding processes, which require high precision to maintain electrical efficiency.

Injection molding may also be used for plastic components, such as the solenoid housing. These techniques ensure that components fit perfectly and function as intended, reducing the likelihood of failures during operation.

How Are Starters Assembled for Optimal Performance?

Assembly is a critical stage where all components are brought together. Workers or automated systems meticulously assemble parts such as the solenoid, armature, and starter drive gear. During this process, it’s vital to adhere to torque specifications to prevent future issues.

Quality checks are integrated into the assembly line, where components are tested for fit and function before moving to the next stage. This proactive approach minimizes the risk of defects and ensures that the starter meets performance expectations.

Illustrative image related to replacing starter

What Finishing Processes Are Essential for Starters?

After assembly, starters undergo various finishing processes. These may include surface treatments like painting or coating to prevent corrosion, as well as electrical testing to ensure optimal functionality. Finishing processes also encompass the application of labels and markings that comply with regulatory standards.

The finishing phase is not just aesthetic; it serves to enhance the durability and reliability of the starter, which is crucial for vehicle performance.

What Quality Assurance Standards Are Relevant for Starters?

Quality assurance is vital in the manufacturing of starters, ensuring that products meet both safety and performance standards. Various international and industry-specific standards guide this process.

Which International Standards Should B2B Buyers Look For?

ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system. Manufacturers that adhere to this standard demonstrate their commitment to continuous improvement and customer satisfaction. Additionally, compliance with CE marking indicates conformity with health, safety, and environmental protection standards within the European market.

For buyers in regions like Africa and South America, understanding local compliance requirements, such as those set by the Brazilian National Institute of Metrology, Quality and Technology (INMETRO), is also crucial.

What Industry-Specific Standards Are Important?

In addition to ISO standards, certain industry-specific certifications can enhance a manufacturer’s credibility. For example, the American Petroleum Institute (API) sets quality standards for equipment used in the oil and gas industry. Although not directly related to automotive starters, suppliers with API certification may demonstrate a higher level of manufacturing rigor that can be beneficial for B2B buyers.

What Are the Key Quality Control Checkpoints in Starter Manufacturing?

Quality control (QC) checkpoints play a pivotal role in ensuring that starters meet established standards throughout the manufacturing process.

How Do Incoming Quality Control (IQC) Measures Work?

Incoming Quality Control (IQC) involves inspecting raw materials and components as they arrive at the manufacturing facility. This step ensures that all materials meet specified standards before being used in production. Suppliers should provide documentation to verify material quality, including certificates of conformity.

What Is the Role of In-Process Quality Control (IPQC)?

In-Process Quality Control (IPQC) monitors production processes at various stages. This may involve regular testing of components for dimensional accuracy and performance. For instance, during the assembly phase, torque tests may be conducted to ensure that components are correctly fitted.

IPQC helps catch defects early, reducing the risk of faulty products reaching the market.

How Does Final Quality Control (FQC) Ensure Product Integrity?

Final Quality Control (FQC) occurs once the starters are fully assembled. This step includes comprehensive testing to assess the performance of the starter under simulated operating conditions. Common tests include electrical continuity checks, load testing, and functional tests to ensure that each starter meets operational specifications.

FQC is critical for identifying any last-minute defects that may have been overlooked during earlier checkpoints.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability and compliance with regulations.

Illustrative image related to replacing starter

What Are Effective Methods for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality assurance practices. Buyers can develop a checklist based on international standards and industry-specific requirements to evaluate the supplier’s processes. On-site audits allow buyers to observe manufacturing practices firsthand and assess adherence to quality standards.

How Can Buyers Utilize Quality Reports and Documentation?

Requesting quality reports and documentation is another method for verifying supplier quality. Manufacturers should be able to provide detailed records of their QC processes, including inspection reports, compliance certificates, and test results. Scrutinizing these documents helps buyers ensure that the supplier maintains rigorous quality standards.

What Is the Importance of Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and quality control processes. These inspections can be particularly valuable for buyers unfamiliar with local manufacturing practices or regulations in regions such as Africa or South America.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers face unique challenges regarding quality control. Understanding local regulations and standards in the supplier’s country can be complex but is essential for ensuring compliance.

Illustrative image related to replacing starter

How Can Cultural and Regional Differences Impact Quality Assurance?

Cultural differences may affect manufacturing practices and attitudes toward quality. Buyers should consider these factors when evaluating suppliers. Establishing clear communication channels and setting expectations upfront can help mitigate misunderstandings.

Why Is It Essential to Build Strong Relationships with Suppliers?

Building strong relationships with suppliers can facilitate better quality assurance. Open communication about quality expectations and regular feedback can lead to improvements in manufacturing processes and product quality. This partnership approach can be particularly effective in regions like Africa and South America, where establishing trust and reliability is crucial.

In conclusion, understanding the manufacturing processes and quality assurance measures for automotive starters is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing processes, and rigorous quality control checkpoints, buyers can ensure they source reliable and high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘replacing starter’

In the competitive landscape of automotive parts procurement, sourcing a reliable starter replacement is crucial for ensuring vehicle performance and customer satisfaction. This guide outlines a practical checklist for B2B buyers, providing actionable steps to facilitate the sourcing process effectively.

Illustrative image related to replacing starter

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the starter is essential to ensure compatibility with your vehicle models. Consider factors such as the make, model, year, and engine type of the vehicles that will utilize the starters. This information will guide you in selecting the right product that meets your operational requirements.

Step 2: Research Supplier Capabilities

Conduct thorough research to identify suppliers with proven capabilities in automotive starter manufacturing. Look for suppliers who specialize in the specific types of starters you need, as their expertise can significantly impact the quality and reliability of the product. Evaluate their production capacity and whether they can meet your volume requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, certifications, and references from buyers in similar industries or regions. Pay attention to customer reviews and case studies to assess their track record in delivering quality products and services.

- Quality Assurance: Ensure that the supplier has a robust quality assurance process in place to minimize defects and ensure compliance with industry standards.

Step 4: Verify Certifications and Compliance

Confirm that the suppliers adhere to relevant industry standards and regulations. Look for certifications such as ISO 9001 or other applicable quality management standards, which indicate a commitment to quality. Compliance with local regulations in your target markets, such as those in Africa or Europe, is also vital to avoid legal complications.

Illustrative image related to replacing starter

Step 5: Assess Pricing and Payment Terms

Evaluate the pricing structures offered by potential suppliers. Compare costs not only for the starters themselves but also for shipping, handling, and any additional fees. Understanding the payment terms is equally important; look for options that align with your cash flow needs.

- Negotiation Flexibility: Consider negotiating bulk purchase discounts or favorable payment terms to enhance your procurement strategy.

Step 6: Request Samples and Conduct Testing

Before making a large order, request samples of the starters for testing. This step is critical to ensure that the products meet your quality standards and performance expectations. Conduct tests under real-world conditions to assess durability and compatibility with your vehicles.

Step 7: Establish a Communication Plan

Set up a clear communication plan with your chosen supplier. Effective communication is vital for addressing any issues that may arise during the procurement process. Establish regular check-ins to discuss order status, delivery schedules, and any potential challenges.

By following this comprehensive sourcing checklist, B2B buyers can make informed decisions when procuring starter replacements, ultimately enhancing their operational efficiency and customer satisfaction.

Comprehensive Cost and Pricing Analysis for replacing starter Sourcing

When considering the replacement of starters in a B2B context, understanding the detailed cost structure and pricing dynamics is critical for international buyers. A comprehensive analysis of the components involved can lead to better decision-making and cost efficiencies.

What Are the Key Cost Components in Starter Replacement?

The primary cost components associated with replacing starters include:

-

Materials: The cost of starter units can vary widely based on the type, brand, and specifications. Prices for starter parts can range from $50 to over $350 for rebuilds and new units alike. The quality of materials—such as the type of magnets, coils, and casing—will influence the overall cost.

-

Labor: Labor costs for installation or replacement can add significantly to the total expense. Depending on the complexity of the job, labor rates can range from $150 to over $1,100. Accessibility of the starter in the vehicle and the mechanic’s expertise will also impact labor costs.

-

Manufacturing Overhead: This includes the costs associated with production facilities, equipment maintenance, and other indirect costs that manufacturers incur. Efficient manufacturing processes can help reduce these costs, which can be passed on to buyers.

-

Tooling: For custom or specialized starters, tooling costs can be significant. Manufacturers may need to invest in specific molds or machinery, which can increase the price of the final product.

-

Quality Control (QC): Ensuring that starters meet safety and performance standards involves costs related to testing and quality assurance. Certifications and compliance with international standards can also add to the overall price.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as shipping routes, customs duties, and local taxes can significantly affect the final cost.

-

Margin: Supplier margins can vary based on market competition and the exclusivity of the product. Understanding the margin structure can help in negotiations.

How Do Price Influencers Affect Starter Replacement Costs?

Several factors influence pricing and should be considered by B2B buyers:

-

Volume/MOQ: Larger orders typically qualify for bulk discounts, which can reduce the per-unit cost. Establishing a minimum order quantity (MOQ) can also help negotiate better pricing.

-

Specifications and Customization: Custom starters designed for specific vehicle models or unique applications will generally command higher prices due to the additional engineering and material costs involved.

-

Quality and Certifications: High-quality starters with certifications (like ISO or OEM standards) are often priced higher due to the assurance of reliability and performance. Buyers should assess whether the added cost aligns with their operational needs.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers with a history of quality may charge more but could offer better warranties and support.

-

Incoterms: Understanding the terms of trade can influence the total landed cost. Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect pricing.

What Tips Can Help Buyers Negotiate Better Prices for Starters?

-

Research and Compare: Conduct thorough market research to understand the average costs of starters in different regions. This knowledge can empower buyers during negotiations.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront costs. Consider factors such as longevity, warranty, and potential downtime costs related to starter failures.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to more favorable pricing and terms. Regular communication and trust can lead to better deals.

-

Be Open to Alternatives: Sometimes, alternative brands or refurbished options can provide the same functionality at a lower cost. However, ensure that they meet quality standards.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow and allow for better budgeting, which is crucial for international transactions.

Conclusion

Understanding the cost components and pricing influencers in starter replacement can empower international B2B buyers to make informed purchasing decisions. By leveraging the tips provided, buyers can enhance their negotiation strategies and ultimately achieve cost efficiencies. Keep in mind that the prices mentioned are indicative and can vary significantly based on specific circumstances and market conditions.

Illustrative image related to replacing starter

Alternatives Analysis: Comparing replacing starter With Other Solutions

Exploring Alternative Solutions to Replacing a Starter

When faced with starter issues in vehicles, B2B buyers must evaluate various solutions to determine the most effective approach. While replacing the starter is a common method, several alternatives exist that may better suit specific operational needs, budgets, or maintenance capabilities. This analysis compares replacing a starter with two viable alternatives: starter repair and utilizing a jump-start or battery replacement.

Comparison Table

| Comparison Aspect | Replacing Starter | Starter Repair | Jump-Start / Battery Replacement |

|---|---|---|---|

| Performance | High reliability; new parts ensure optimal function. | Variable; depends on quality of repairs. | Temporary; may not resolve underlying issues. |

| Cost | $150 – $1,100 (labor included) | $50 – $300 (if parts are reusable) | $20 – $100 (cables/battery cost) |

| Ease of Implementation | Moderate; requires tools and mechanical knowledge. | Moderate; requires diagnostic skills and tools. | Easy; often requires minimal tools and knowledge. |

| Maintenance | Low; new starters generally require little upkeep. | Moderate; may need future repairs if not done correctly. | Low; battery maintenance is needed for longevity. |

| Best Use Case | Long-term solution for vehicles with severe starter issues. | Cost-effective for minor problems or older vehicles. | Quick fix for immediate starting issues; not a long-term solution. |

Detailed Breakdown of Alternatives

1. Starter Repair

Starter repair involves diagnosing the specific issue with the existing starter and replacing or fixing only the damaged components. This option can be significantly more cost-effective than a complete replacement, especially if the starter is relatively new and only minor repairs are needed. However, the downside is that the reliability of the repaired starter can be inconsistent. If the repair is not executed correctly, or if the starter is nearing the end of its lifespan, buyers may face recurring issues.

2. Jump-Start / Battery Replacement

Jump-starting a vehicle or replacing the battery is a common quick fix when dealing with starting issues. This method is particularly useful if the problem is identified as a battery failure rather than a starter malfunction. The initial cost is relatively low, especially if the jump-start can be performed using cables. However, this solution is merely a stopgap and does not address underlying issues with the starter or other components. If the starter is indeed faulty, relying on jump-starts may lead to further complications and ultimately more significant repair costs.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution for starter issues involves assessing the specific circumstances surrounding the vehicle’s performance and the financial implications of each option. For businesses operating fleets or managing vehicle maintenance, understanding the long-term impacts of each alternative is essential. If reliability and performance are paramount, replacing the starter may be the best route. However, for older vehicles or those on a tight budget, starter repair can offer a valuable compromise. Meanwhile, jump-starting or battery replacement serves as a temporary measure that can provide immediate relief but should not be relied upon as a permanent fix. Ultimately, evaluating the unique needs of the vehicle and the operational context will guide B2B buyers to the most appropriate solution.

Essential Technical Properties and Trade Terminology for replacing starter

What Are the Key Technical Properties to Consider When Replacing a Starter?

When evaluating starters for replacement, several technical properties must be considered to ensure compatibility and performance. Here are some critical specifications:

Illustrative image related to replacing starter

-

Material Grade

The material grade of a starter impacts its durability and performance. Common materials include steel and aluminum for the housing, while copper is often used for the windings. For B2B buyers, understanding material grades helps in assessing the longevity and reliability of the starter, which can significantly affect maintenance costs and operational efficiency. -

Electrical Resistance

This property refers to the resistance of the starter’s windings and components to electrical flow. Lower resistance typically indicates higher efficiency, leading to better performance in starting engines. Buyers should evaluate this specification to ensure optimal energy consumption and functionality, particularly in regions with extreme temperatures, where performance may vary. -

Torque Specifications

Torque specifications indicate the amount of force the starter can generate to turn the engine over. This is crucial for ensuring that the starter can handle the engine’s requirements, especially in heavy-duty applications. For international buyers, understanding torque ratings can help in selecting starters suitable for specific vehicle models or types, particularly in commercial fleets. -

Cranking Speed

Measured in revolutions per minute (RPM), cranking speed is a critical specification that determines how quickly the starter can turn the engine. A typical automotive starter operates between 200-300 RPM. Buyers should consider this property to ensure that the starter can meet the demands of different engine sizes and configurations, particularly in diverse markets with various vehicle types. -

Size and Weight

The physical dimensions and weight of the starter can affect installation and vehicle design. Compact and lightweight starters may be preferred in certain applications to reduce overall vehicle weight and improve fuel efficiency. Buyers should ensure that the selected starter fits the vehicle’s specifications without compromising performance. -

Thermal Rating

This property indicates the starter’s ability to operate effectively under high temperatures. Starters with higher thermal ratings are better suited for environments with extreme heat, which is common in many regions, including parts of Africa and South America. Understanding thermal ratings can help buyers prevent premature failures and ensure reliability in challenging conditions.

What Are Common Trade Terminology and Jargon Related to Starter Replacement?

Familiarity with industry terminology is essential for smooth transactions and effective communication. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM parts are manufactured by the same company that produced the original components of the vehicle. These parts are typically preferred for their guaranteed compatibility and performance. Understanding the difference between OEM and aftermarket parts can help buyers make informed decisions regarding quality and warranty considerations. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For buyers, understanding MOQ is vital for budgeting and inventory management, especially when sourcing starters for large fleets or retail operations. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This is an essential step in procurement, allowing buyers to compare prices, terms, and conditions effectively. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers engaged in international transactions, as they help avoid misunderstandings and clarify the logistics involved in starter replacement. -

Warranty Period

This term refers to the duration during which a buyer can claim repairs or replacements for defective products. A thorough understanding of warranty terms is essential for buyers, as it affects long-term costs and product reliability. -

Lead Time

Lead time is the duration from placing an order to receiving the goods. Knowing the lead time is crucial for inventory planning, especially for businesses that rely on just-in-time inventory systems to manage starter replacements.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing starters, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the replacing starter Sector

What Are the Current Market Dynamics and Key Trends in the Replacing Starter Sector?

The global automotive starter replacement market is experiencing significant growth, driven by several key factors. The increasing number of vehicles on the road, particularly in emerging markets like Africa and South America, is a primary driver. For instance, as urbanization accelerates in countries like Nigeria and Brazil, the demand for reliable vehicle maintenance solutions, including starter replacements, has surged. Furthermore, technological advancements in starter design, such as the shift towards more compact and efficient starter motors, are influencing sourcing decisions.

Illustrative image related to replacing starter

B2B buyers are increasingly prioritizing suppliers who utilize digital platforms for streamlined procurement processes. E-commerce solutions and online marketplaces are becoming essential for sourcing starter parts, providing buyers with real-time inventory updates and competitive pricing. Additionally, the integration of advanced analytics and AI in supply chain management is allowing businesses to optimize their purchasing strategies, improving overall efficiency.

Another emerging trend is the focus on aftermarket services. Many suppliers are now offering comprehensive packages that include installation and warranty services, catering to international buyers seeking a one-stop solution. This trend not only enhances customer satisfaction but also builds long-term relationships between suppliers and buyers.

How Is Sustainability and Ethical Sourcing Influencing the Replacing Starter Sector?

Sustainability and ethical sourcing are becoming increasingly important in the automotive industry, including the replacing starter sector. The environmental impact of automotive components is under scrutiny, prompting manufacturers to adopt greener practices. This includes using recyclable materials and reducing waste throughout the production process. For B2B buyers, sourcing from suppliers who prioritize environmental responsibility can enhance their brand’s reputation and appeal to eco-conscious consumers.

Moreover, certifications related to sustainability, such as ISO 14001, are becoming critical in the decision-making process for international buyers. These certifications assure buyers that suppliers adhere to strict environmental management standards. Additionally, there is a growing demand for products made from sustainable materials, such as recycled metals and eco-friendly packaging.

Illustrative image related to replacing starter

Ethical sourcing practices are equally important, as buyers seek to ensure that their suppliers maintain fair labor practices and transparency in their supply chains. This not only mitigates risks associated with unethical labor practices but also aligns with the values of an increasingly socially aware consumer base.

What Is the Brief Evolution of the Replacing Starter Sector?

The automotive starter sector has evolved significantly since the introduction of the electric starter motor in the early 20th century. Initially, starters were cumbersome and required manual operation, but advancements in technology have transformed them into compact and efficient devices. The shift from mechanical to electrical starters revolutionized vehicle starting systems, enhancing reliability and ease of use.

In recent decades, the development of high-performance starters, including those designed for hybrid and electric vehicles, has opened new avenues for the market. This evolution has prompted B2B buyers to adapt their sourcing strategies, focusing on suppliers who offer innovative solutions tailored to modern vehicles. As the automotive industry continues to evolve with electrification and automation, the replacing starter sector is poised for further transformation, necessitating ongoing adaptation from buyers and suppliers alike.

Illustrative image related to replacing starter

Frequently Asked Questions (FAQs) for B2B Buyers of replacing starter

-

1. How do I solve starter issues in vehicles?

To address starter issues, first, diagnose the problem accurately. Check the battery condition, as a weak battery can mimic starter failure. Inspect battery connections for corrosion or loose terminals. Test related components such as fuses and relays. If the starter is confirmed to be faulty, determine whether to repair or replace it based on the extent of the damage. Opt for a replacement if significant internal components are damaged, as this can be more cost-effective in the long run. -

2. What is the best starter replacement for heavy-duty vehicles?

The best starter replacement for heavy-duty vehicles, such as trucks or SUVs, should meet OEM specifications and be designed for high-torque applications. Look for starters that are durable, with features like advanced solenoid technology and robust electrical components. Brands with a proven track record in heavy-duty applications, such as Bosch or Denso, are often reliable choices. Always verify compatibility with the specific make and model of the vehicle to ensure optimal performance. -

3. What factors affect the cost of starter replacement?

The cost of starter replacement can vary based on several factors, including the vehicle’s make, model, and year, as well as the complexity of the installation. Labor costs can increase if the starter is hard to access. Additionally, whether you choose a new, rebuilt, or aftermarket starter will influence the price. Shipping and import duties may also affect costs for international buyers, especially when sourcing from different regions. -

4. How can I vet suppliers for starter replacements?

To vet suppliers effectively, conduct thorough research on their reputation, customer reviews, and experience in the automotive parts industry. Request references and check their certifications to ensure compliance with quality standards. It’s beneficial to inquire about their supply chain practices and lead times. Additionally, consider ordering samples to evaluate the quality of their starters before committing to larger orders, ensuring they meet your specifications and performance requirements. -

5. What are the typical minimum order quantities (MOQs) for starter replacements?

Minimum order quantities (MOQs) for starter replacements can vary widely among suppliers. Generally, MOQs may range from 10 to 100 units, depending on the supplier’s production capabilities and inventory management practices. Some manufacturers may offer lower MOQs for specific models or during promotional periods. It’s advisable to discuss MOQs directly with suppliers to negotiate terms that fit your purchasing strategy, particularly if you’re operating in international markets. -

6. What payment terms should I expect when sourcing starters internationally?

Payment terms when sourcing starters internationally typically include options such as advance payment, letter of credit, or open account terms. Most suppliers require a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. Ensure clarity on currency exchange rates, payment methods, and any associated fees. Establishing secure payment methods is crucial to mitigate risks, especially in cross-border transactions. -

7. How can I ensure quality assurance for starter replacements?

To ensure quality assurance for starter replacements, request detailed product specifications and certifications from suppliers. Implement a quality control process that includes inspections during production and pre-shipment checks. Consider third-party inspection services to evaluate the starters before they are shipped. Establishing clear communication regarding quality expectations and warranty terms can also help mitigate issues post-purchase. -

8. What logistics considerations should I keep in mind when sourcing starters?

When sourcing starters, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Choose a supplier with a reliable shipping partner to minimize delays. Be aware of potential import duties and taxes that may affect your overall costs. It’s also wise to have contingency plans for unforeseen shipping disruptions, particularly when dealing with international suppliers to ensure timely delivery of your products.

Top 2 Replacing Starter Manufacturers & Suppliers List

1. eBay – Automotive Tool Setup

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Project Duration: 1 to 2 hours, Skill Level: Intermediate, Starter Weight: 20 pounds or more, Required Tools: Floor jack, jack stands, ramps or wheel cribs, wrenches, sockets, ratchet, backup wrench, extensions, universal extension, combination of extensions, inspection tools for battery cable and flexplate/flywheel.

2. 5th Gen Rams – Starter Systems

Domain: 5thgenrams.com

Registered: 2017 (8 years)

Introduction: The starter is the same between the non-eTorque and eTorque models of the 2019 Ram 1500. The eTorque motor is used to start the engine only when the start/stop feature is activated, while a traditional starter is located under the truck for starting the engine with the push-to-start button. The starter may still be covered under the powertrain warranty.

Strategic Sourcing Conclusion and Outlook for replacing starter

In today’s competitive landscape, strategic sourcing for starter replacements is critical for international B2B buyers. Understanding the nuances of replacement costs, accessibility of parts, and potential for DIY solutions can significantly influence your procurement decisions. Effective sourcing not only streamlines operations but also helps in maintaining vehicle reliability, ultimately reducing downtime and enhancing productivity.

By leveraging local suppliers who understand regional vehicle specifications and service requirements, businesses can optimize their supply chains while ensuring quality. Engaging with manufacturers that offer warranties and robust customer support can further mitigate risks associated with starter failures.

As you navigate the complexities of sourcing replacement starters, consider the evolving market trends and technological advancements that may impact your choices. Staying informed about innovations in starter design and efficiency will empower you to make decisions that align with your operational goals.

Looking ahead, now is the time to assess your sourcing strategies and explore partnerships that can drive value. By investing in quality components and fostering strong supplier relationships, you position your business for success in an ever-evolving marketplace. Embrace the opportunity to enhance your fleet’s performance and reliability today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.