Introduction: Navigating the Global Market for que hace el alternador de un carro

In today’s competitive automotive landscape, understanding the role of the alternator in a vehicle is crucial for B2B buyers looking to source reliable components. The alternator is not just a mechanical part; it is the backbone of a vehicle’s electrical system, converting mechanical energy from the engine into electrical energy that powers various automotive components. This guide aims to provide international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, with a comprehensive understanding of what the alternator does, its types, applications, and how to effectively vet suppliers.

As you navigate the global market, this guide will delve into critical aspects such as the different types of alternators, their specific applications in various vehicle models, and the factors influencing their costs. Additionally, we will provide insights on how to assess supplier reliability, ensuring you make informed purchasing decisions that align with your operational needs. Whether you are sourcing components for assembly or replacement parts for maintenance, our detailed analysis equips you with the knowledge to select high-quality alternators that meet industry standards. By leveraging this guide, you can enhance your procurement strategy and foster long-term partnerships with trustworthy suppliers in the automotive sector.

Table Of Contents

- Top 3 Que Hace El Alternador De Un Carro Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for que hace el alternador de un carro

- Understanding que hace el alternador de un carro Types and Variations

- Key Industrial Applications of que hace el alternador de un carro

- 3 Common User Pain Points for ‘que hace el alternador de un carro’ & Their Solutions

- Strategic Material Selection Guide for que hace el alternador de un carro

- In-depth Look: Manufacturing Processes and Quality Assurance for que hace el alternador de un carro

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘que hace el alternador de un carro’

- Comprehensive Cost and Pricing Analysis for que hace el alternador de un carro Sourcing

- Alternatives Analysis: Comparing que hace el alternador de un carro With Other Solutions

- Essential Technical Properties and Trade Terminology for que hace el alternador de un carro

- Navigating Market Dynamics and Sourcing Trends in the que hace el alternador de un carro Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of que hace el alternador de un carro

- Strategic Sourcing Conclusion and Outlook for que hace el alternador de un carro

- Important Disclaimer & Terms of Use

Understanding que hace el alternador de un carro Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Alternator | Utilizes a belt-driven system, generating AC power | Automotive manufacturing, repair shops | Pros: Widely available, cost-effective. Cons: Less efficient at low RPMs. |

| Smart Alternator | Features advanced electronics for optimized performance | High-end vehicle production, fleet management | Pros: Increased fuel efficiency, better battery management. Cons: Higher initial cost. |

| High-Output Alternator | Designed for vehicles with high electrical demands | Performance vehicles, heavy machinery | Pros: Supports additional electrical accessories. Cons: May require modifications. |

| Diesel Alternator | Specifically designed for diesel engines | Commercial trucking, heavy equipment | Pros: Durable, suited for high-load applications. Cons: Heavier and more expensive. |

| Hybrid/Electric Vehicle Alternator | Integrates with electric systems for energy recovery | EV manufacturers, renewable energy sectors | Pros: Enhances energy efficiency, reduces emissions. Cons: Complex installation and maintenance. |

What Are the Characteristics of Conventional Alternators?

Conventional alternators are the most common type found in vehicles today. They operate using a belt-driven system connected to the engine, generating alternating current (AC) that is converted to direct current (DC) for use in the vehicle’s electrical systems. They are typically cost-effective and widely available, making them a popular choice for automotive manufacturers and repair shops. However, they may not perform efficiently at low engine RPMs, which can be a concern for businesses dealing with vehicles that frequently operate in stop-and-go conditions.

How Do Smart Alternators Enhance Vehicle Performance?

Smart alternators incorporate advanced electronics and sensors to optimize charging and energy use. They can adjust their output based on the vehicle’s electrical demand, which improves fuel efficiency and battery lifespan. These alternators are increasingly favored in high-end vehicle production and fleet management due to their performance benefits. While they come with a higher initial cost, the long-term savings on fuel and battery replacements can justify the investment for B2B buyers.

Why Choose High-Output Alternators for Performance Vehicles?

High-output alternators are designed to meet the demands of vehicles equipped with multiple electrical accessories, such as high-powered audio systems or additional lighting. They generate more electricity than standard alternators, making them ideal for performance vehicles and heavy machinery that require reliable power supply. Buyers should consider the potential need for modifications to accommodate these alternators, as they can be bulkier and require different mounting solutions.

What Makes Diesel Alternators Suitable for Heavy Equipment?

Diesel alternators are engineered specifically for diesel engines, which often operate under heavy loads. They are built to withstand the rigors of commercial trucking and heavy equipment applications. Their durability and efficiency in high-load scenarios make them a preferred choice for businesses in the transportation and construction sectors. However, the trade-off is that they tend to be heavier and more expensive than standard alternators, which can affect overall vehicle weight and cost.

How Do Hybrid/Electric Vehicle Alternators Contribute to Sustainability?

Hybrid and electric vehicle alternators play a crucial role in energy recovery and management systems. They are designed to work seamlessly with electric drivetrains, capturing energy during braking and converting it into usable power. This technology is increasingly relevant as the automotive industry shifts towards sustainability. B2B buyers in the EV manufacturing and renewable energy sectors should consider the complexity of installation and maintenance associated with these advanced systems, as they require specialized knowledge and components.

Key Industrial Applications of que hace el alternador de un carro

| Industry/Sector | Specific Application of que hace el alternador de un carro | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Integration of alternators in vehicle assembly lines | Ensures reliable power supply for vehicle systems | Quality assurance, compatibility with vehicle models |

| Transportation and Logistics | Use in fleet vehicles for efficient energy management | Reduces operational costs through improved energy efficiency | Durability, maintenance support, and warranty terms |

| Renewable Energy Sector | Alternators in hybrid and electric vehicles for energy generation | Enhances sustainability and reduces carbon footprint | Regulatory compliance, efficiency ratings, and sourcing of eco-friendly materials |

| Heavy Machinery and Equipment | Application in construction and mining vehicles for reliable power supply | Increases operational uptime and reduces downtime costs | Robust design, resistance to harsh environments, and service availability |

| Emergency Services | Use in ambulances and emergency response vehicles for critical power supply | Ensures reliability in life-saving situations | Reliability under extreme conditions, rapid response capabilities, and maintenance accessibility |

How is ‘que hace el alternador de un carro’ utilized in Automotive Manufacturing?

In automotive manufacturing, alternators are integrated into the assembly of vehicles to provide the necessary electrical power for various systems. This ensures that all components, including lighting, infotainment, and safety systems, operate efficiently. For B2B buyers in this sector, sourcing high-quality alternators that are compatible with specific vehicle models is essential. Quality assurance processes and adherence to industry standards are crucial to maintain operational efficiency and ensure customer satisfaction.

What role does the alternator play in Transportation and Logistics?

In the transportation and logistics industry, fleet vehicles rely heavily on alternators to manage energy consumption effectively. A well-functioning alternator reduces the frequency of battery replacements and enhances overall vehicle performance, leading to lower operational costs. Buyers in this sector should consider the durability and maintenance support of alternators, as these factors directly impact the total cost of ownership and fleet reliability.

How does the Renewable Energy Sector benefit from alternators?

The renewable energy sector utilizes alternators in hybrid and electric vehicles to convert mechanical energy into electrical energy efficiently. This application is crucial for enhancing the sustainability of these vehicles, as it contributes to reduced carbon emissions. B2B buyers must ensure that the alternators meet regulatory compliance and efficiency ratings, as these factors are vital in the competitive market focused on eco-friendly solutions.

Why are alternators essential in Heavy Machinery and Equipment?

In heavy machinery and equipment, such as construction and mining vehicles, alternators are vital for providing a reliable power supply. These machines often operate in challenging environments, where electrical reliability is crucial for performance and safety. Buyers in this sector should prioritize sourcing alternators with robust designs that can withstand harsh conditions, along with ensuring that service and maintenance support are readily available to minimize downtime.

How do alternators support Emergency Services?

Emergency services vehicles, including ambulances and fire trucks, depend on alternators for critical power supply to life-saving equipment. The reliability of these systems is paramount, as any failure can have dire consequences. B2B buyers in this field should focus on sourcing alternators that exhibit high reliability under extreme conditions, ensuring that emergency services can respond effectively when it matters most.

3 Common User Pain Points for ‘que hace el alternador de un carro’ & Their Solutions

Scenario 1: Understanding Alternator Failures in Fleet Vehicles

The Problem: B2B buyers managing fleets often encounter unexpected downtime due to alternator failures, which can significantly impact operations. For instance, a logistics company may experience delays if multiple vehicles fail to start because their alternators are not functioning correctly. This not only disrupts delivery schedules but also incurs additional costs for repairs and lost business opportunities. Fleet managers may struggle to diagnose these issues promptly and efficiently, leading to increased operational inefficiencies.

The Solution: To mitigate the risks associated with alternator failures, fleet managers should implement a proactive maintenance strategy that includes regular inspections of the alternators and related electrical systems. Investing in diagnostic tools that assess the health of the alternator can help identify issues before they result in failures. Additionally, establishing a partnership with a reliable supplier of high-quality alternators can ensure that replacement parts are readily available when needed. Educating the maintenance team on the signs of alternator wear, such as unusual noises or fluctuating electrical outputs, can empower them to act swiftly, reducing vehicle downtime and maintaining operational efficiency.

Scenario 2: Sourcing Quality Alternators for International Markets

The Problem: B2B buyers in regions like Africa and South America often face challenges in sourcing quality alternators that meet international standards. Counterfeit parts or low-quality components can lead to premature failures, safety hazards, and increased maintenance costs. This is particularly problematic for companies that rely heavily on vehicles for their operations, as subpar alternators can compromise vehicle performance and reliability.

The Solution: To successfully source quality alternators, buyers should prioritize working with reputable manufacturers who provide clear certifications and warranties for their products. Conducting thorough research on suppliers, including checking their industry reputation and customer reviews, can help avoid issues with counterfeit parts. Additionally, utilizing platforms that connect businesses with verified suppliers can streamline the procurement process. Buyers should also consider establishing long-term relationships with manufacturers who can provide consistent quality and support, ensuring that they receive reliable alternators that contribute to the longevity and performance of their fleet.

Scenario 3: Training Staff on Alternator Maintenance and Troubleshooting

The Problem: Many companies lack the necessary training for their maintenance staff regarding alternator care and troubleshooting. This knowledge gap can lead to improper handling of alternators during routine checks, resulting in avoidable damage or inefficiencies in the vehicle’s electrical system. For instance, without proper training, technicians may overlook early signs of alternator wear, leading to costly repairs or replacements that could have been avoided.

The Solution: To address this issue, businesses should invest in comprehensive training programs focused on alternator maintenance and diagnostics. This can include workshops led by industry experts or partnerships with technical schools that offer automotive training. Incorporating hands-on training sessions allows staff to gain practical experience in identifying and resolving alternator-related issues. Additionally, creating a maintenance manual that outlines best practices for alternator care can serve as a valuable reference for technicians. By equipping staff with the right knowledge and skills, companies can enhance their operational efficiency and prolong the lifespan of their vehicle fleet.

Strategic Material Selection Guide for que hace el alternador de un carro

What Materials Are Commonly Used in Alternators and Their Performance Characteristics?

When selecting materials for the components of an alternator, it’s essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Below, we analyze four common materials used in alternator manufacturing, focusing on their performance and implications for international B2B buyers.

What Are the Key Properties of Copper in Alternator Applications?

Copper is widely used in alternators, particularly for windings and electrical connections due to its excellent electrical conductivity. Key properties include:

- Temperature Rating: Typically withstands temperatures up to 200°C.

- Corrosion Resistance: Moderate; copper can oxidize, leading to reduced conductivity if not properly treated.

Pros & Cons: Copper is highly durable and provides superior electrical performance, making it ideal for efficient energy transfer. However, it is relatively expensive compared to other conductive materials like aluminum, and its susceptibility to corrosion necessitates protective coatings.

Impact on Application: Copper’s high conductivity ensures efficient energy conversion in alternators, crucial for maintaining battery charge and powering electrical systems.

Considerations for International Buyers: Compliance with standards like ASTM B170 for copper wire is essential. Buyers should also consider local sourcing to mitigate costs associated with import tariffs.

How Does Aluminum Compare as a Material for Alternators?

Aluminum is often used in alternator housings and some winding applications due to its lightweight and cost-effectiveness. Key properties include:

- Temperature Rating: Can handle temperatures up to 150°C.

- Corrosion Resistance: Excellent; aluminum naturally forms a protective oxide layer.

Pros & Cons: The lightweight nature of aluminum reduces overall vehicle weight, improving fuel efficiency. However, its lower electrical conductivity compared to copper can lead to increased resistance and energy loss in electrical applications.

Impact on Application: While aluminum is suitable for structural components, it may not be the best choice for high-performance electrical windings.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions and consider the recycling capabilities of aluminum in their regions.

What Role Does Steel Play in Alternator Manufacturing?

Steel is primarily used for structural components and supports within the alternator. Key properties include:

- Temperature Rating: Can withstand temperatures up to 300°C.

- Corrosion Resistance: Varies; stainless steel offers good resistance, while carbon steel may require coatings.

Pros & Cons: Steel is robust and cost-effective, providing excellent strength and durability. However, it is heavier than aluminum, which could affect vehicle weight and efficiency.

Impact on Application: Steel’s strength is vital for maintaining the structural integrity of the alternator under operational stresses.

Considerations for International Buyers: Buyers should be aware of the relevant standards such as ASTM A36 for carbon steel and consider local regulations regarding the use of certain steel grades.

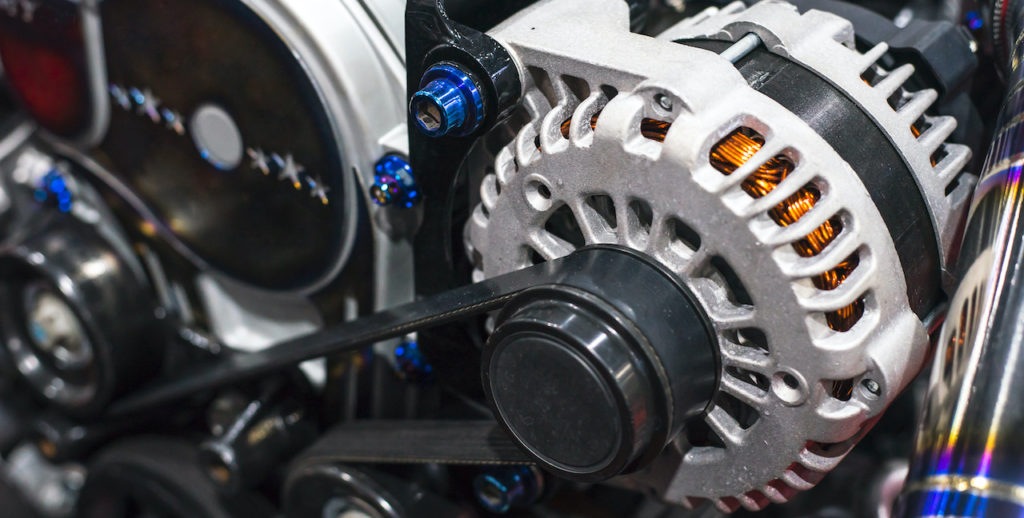

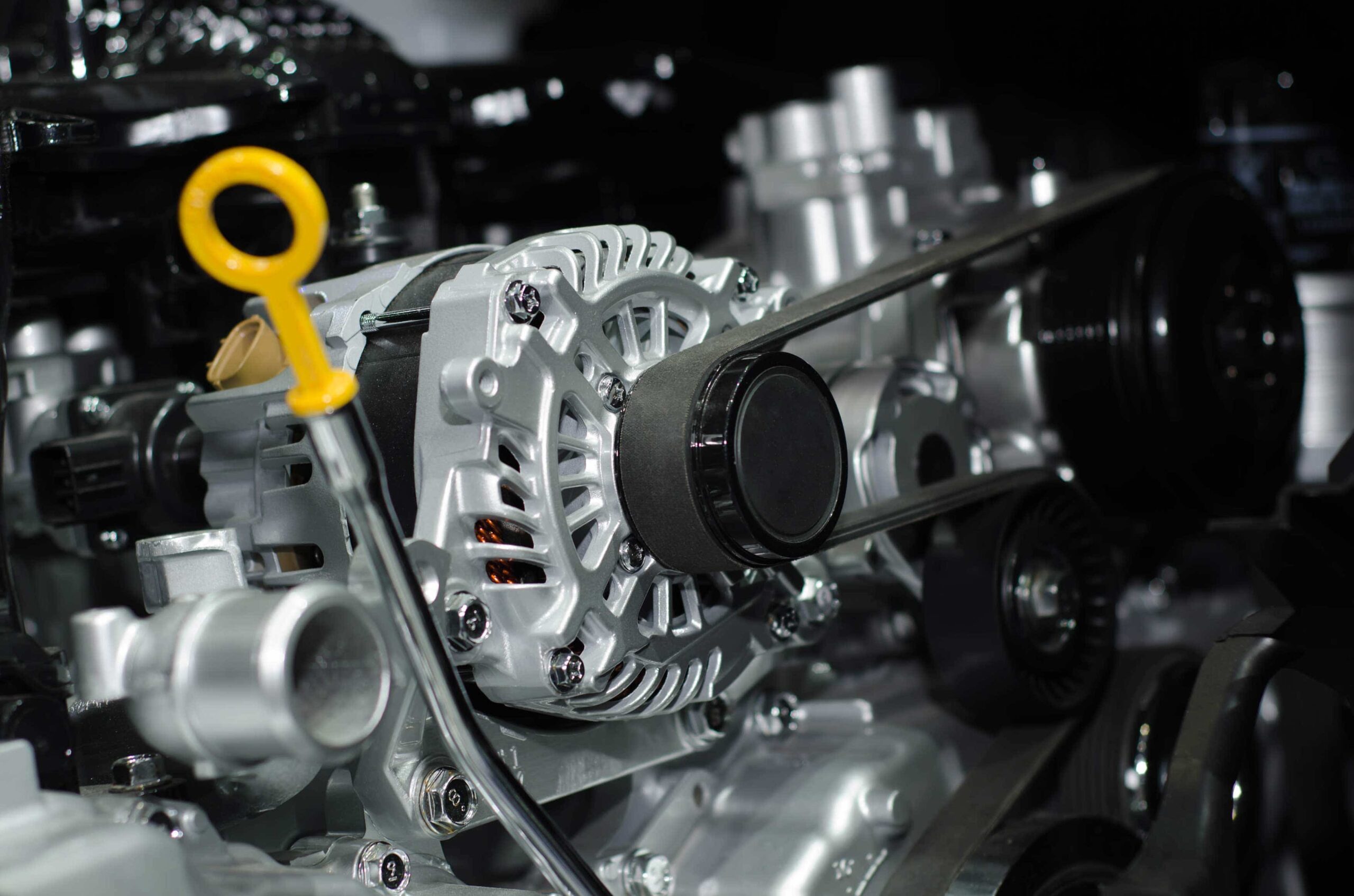

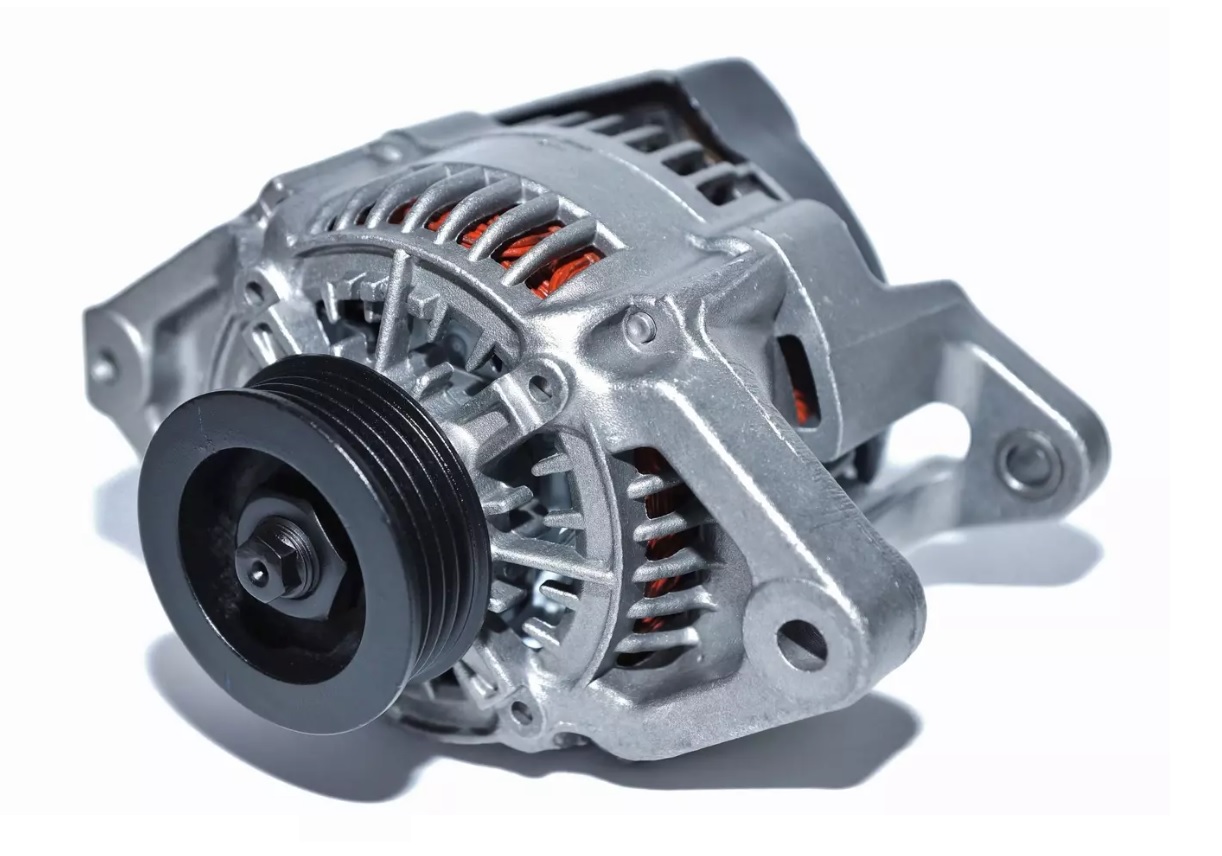

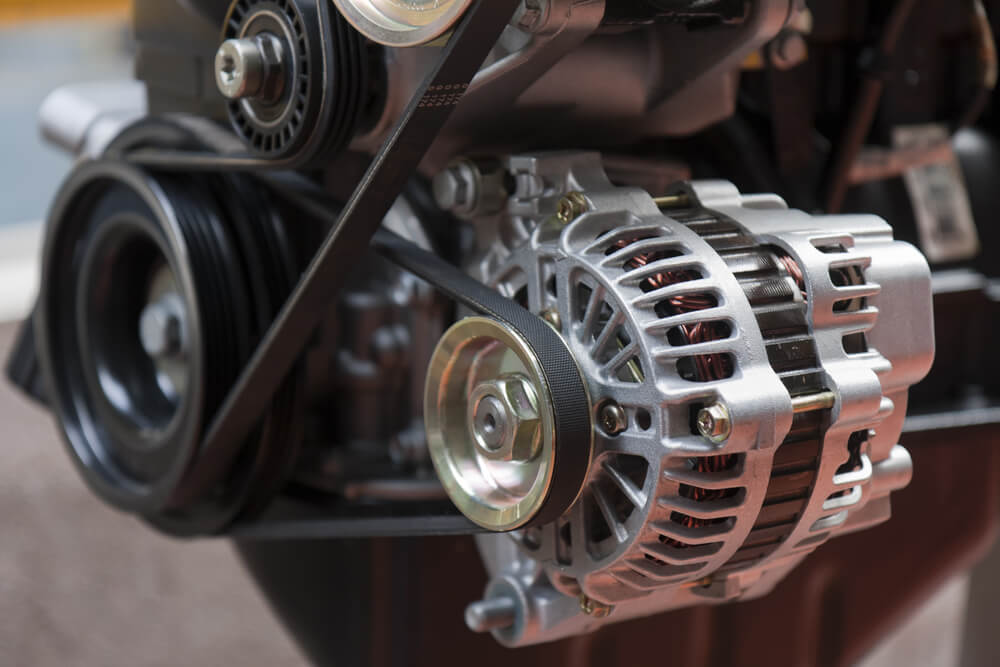

Illustrative image related to que hace el alternador de un carro

Why Is Plastic Used in Alternators?

Plastic is commonly used for insulation and housing components within alternators. Key properties include:

- Temperature Rating: Generally withstands temperatures up to 120°C.

- Corrosion Resistance: Excellent; plastics do not corrode and are resistant to many chemicals.

Pros & Cons: Plastic is lightweight and offers good electrical insulation properties, making it suitable for various applications. However, it may not withstand high temperatures as effectively as metals.

Impact on Application: Plastic components help reduce weight and improve insulation, contributing to the overall efficiency of the alternator.

Considerations for International Buyers: Compliance with standards like ISO 9001 for quality management in plastic manufacturing is crucial for ensuring product reliability.

Summary of Material Selection for Alternators

| Material | Typical Use Case for que hace el alternador de un carro | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings and electrical connections | Superior electrical conductivity | Higher cost and corrosion susceptibility | High |

| Aluminum | Housings and some windings | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Steel | Structural components and supports | High strength and durability | Heavier than aluminum | Low |

| Plastic | Insulation and housing components | Excellent insulation and corrosion resistance | Limited temperature tolerance | Low |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in alternators, their properties, and considerations for international B2B buyers. Understanding these factors will enable buyers to make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for que hace el alternador de un carro

What Are the Typical Manufacturing Processes for Car Alternators?

Manufacturing a car alternator involves several critical stages, each requiring precise execution to ensure a high-quality final product. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to que hace el alternador de un carro

How Is Material Prepared for Alternator Production?

The manufacturing process begins with material preparation, where raw materials such as aluminum for the housing, copper for the windings, and steel for various components are sourced. Quality control in this stage is vital; suppliers must provide materials that meet specific standards for conductivity and durability. B2B buyers should verify the material specifications and certifications from suppliers to ensure compliance with international standards.

What Forming Techniques Are Used in Alternator Manufacturing?

After material preparation, the next step is forming. This involves shaping the components through various methods such as die casting for the aluminum housing and stamping for metal parts. The rotor and stator are produced using winding machines that coil copper wire into precise configurations. Advanced techniques like CNC machining may be employed for high-precision components. Manufacturers often utilize simulations to optimize designs before physical production, enhancing efficiency and reducing waste.

How Is Assembly Conducted for Car Alternators?

The assembly stage is where all components come together. Key techniques include:

- Automated Assembly Lines: These lines use robotics for placing components, ensuring speed and precision.

- Manual Assembly: Skilled technicians perform delicate tasks, such as installing the rectifier and connecting wiring, which require careful handling.

- Torque Specifications: Each bolt and screw must be tightened to specific torque values to ensure structural integrity.

Quality assurance is critical during assembly; manufacturers often conduct real-time inspections to catch defects early in the process.

What Finishing Processes Are Essential for Car Alternators?

Finishing processes are the final steps in manufacturing an alternator. This includes painting or coating components to prevent corrosion and enhance aesthetics. A key technique is electrostatic painting, which ensures an even coat and better adhesion. Manufacturers also perform electrical testing to verify that the alternator meets performance specifications.

How Is Quality Assurance Implemented in Alternator Manufacturing?

Quality assurance (QA) plays a fundamental role in the production of car alternators. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain consistent quality management systems. This is particularly important for B2B buyers, as compliance with these standards indicates a commitment to quality.

Illustrative image related to que hace el alternador de un carro

What International Standards Are Relevant for Alternator Manufacturing?

- ISO 9001: Focuses on quality management systems.

- CE Marking: Indicates compliance with EU safety and environmental standards.

- API Standards: Relevant for automotive components, ensuring performance and safety.

Understanding these standards helps B2B buyers assess the reliability of potential suppliers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to ensuring that each alternator meets quality standards. Key checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitors production processes in real-time to identify defects as they occur.

- Final Quality Control (FQC): Conducts comprehensive testing on finished alternators, including electrical performance tests and visual inspections.

These checkpoints help identify defects early, reducing the likelihood of faulty products reaching the market.

What Testing Methods Are Commonly Used in Alternator Quality Assurance?

Several testing methods are utilized to ensure the functionality and durability of car alternators:

- Electrical Testing: Measures output voltage and current to ensure the alternator operates within specified parameters.

- Vibration Testing: Assesses the alternator’s resistance to vibrations, simulating real-world operating conditions.

- Thermal Testing: Evaluates performance under temperature extremes to ensure reliability in various environments.

B2B buyers should inquire about the specific testing methods employed by suppliers to understand the robustness of their quality assurance processes.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain rigorous quality control, B2B buyers can take several steps:

- Conduct Audits: Regular audits of suppliers can reveal their adherence to quality standards and practices.

- Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including any certifications obtained.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality control measures.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Considerations: Different regions may have varying standards and practices. Understanding local manufacturing norms is essential for effective communication and collaboration.

- Regulatory Compliance: Buyers must ensure that suppliers comply with both local and international regulations, which may differ significantly.

- Supply Chain Transparency: A transparent supply chain is crucial for verifying the quality and origin of materials used in alternator manufacturing.

By understanding these aspects, B2B buyers can make informed decisions, ensuring that they partner with reliable suppliers capable of delivering high-quality alternators.

In conclusion, the manufacturing processes and quality assurance measures for car alternators are critical elements that B2B buyers must consider. By understanding these processes and implementing thorough verification methods, buyers can secure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘que hace el alternador de un carro’

To assist B2B buyers in procuring components related to the alternator of a vehicle, this practical sourcing guide provides a comprehensive checklist. Understanding the critical role of the alternator and its functionality can significantly influence purchasing decisions and supplier relationships.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital to ensure that the alternator meets your vehicle’s requirements. Consider factors such as power output, compatibility with existing systems, and size constraints. This clarity will help you communicate effectively with suppliers and avoid costly mismatches.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in alternator technology. This includes developments in efficiency, durability, and materials used. Understanding these trends will help you make informed purchasing decisions and enable you to ask suppliers the right questions regarding their products.

Step 3: Identify Reliable Suppliers

Finding trustworthy suppliers is crucial for ensuring quality and reliability. Look for suppliers with a proven track record in the automotive sector. Evaluate their reputation by checking customer reviews, industry certifications, and their history of fulfilling orders on time.

Illustrative image related to que hace el alternador de un carro

Step 4: Request Product Samples and Documentation

Before finalizing a purchase, request product samples and relevant documentation. This includes technical specifications, warranty information, and installation guides. Testing samples ensures that the product meets your standards and helps in assessing the supplier’s quality assurance processes.

Step 5: Verify Supplier Certifications and Compliance

Ensure that potential suppliers have the necessary certifications and comply with industry standards. This is especially important for components like alternators, which are critical to vehicle safety and performance. Certifications such as ISO or specific automotive standards can indicate a supplier’s commitment to quality.

Step 6: Assess Pricing and Payment Terms

Evaluate the pricing structures offered by different suppliers. Compare not just the base price but also consider shipping costs, taxes, and any potential discounts for bulk orders. Additionally, understanding payment terms can help you manage cash flow and budget effectively.

Illustrative image related to que hace el alternador de un carro

Step 7: Establish Clear Communication Channels

Effective communication is essential throughout the procurement process. Ensure that you have established clear channels for discussing specifications, timelines, and any potential issues. This can help mitigate misunderstandings and foster a stronger partnership with your supplier.

By following this structured approach, B2B buyers can navigate the complexities of sourcing alternators more effectively, ensuring that they select the right products from reliable suppliers while maximizing their investment.

Comprehensive Cost and Pricing Analysis for que hace el alternador de un carro Sourcing

What Are the Key Cost Components in Sourcing Alternators?

When sourcing alternators, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of raw materials such as copper for the windings, aluminum for the casing, and various electronic components can vary significantly based on market fluctuations. Buyers should keep an eye on global commodity prices, as these directly impact the final cost of alternators.

-

Labor: Labor costs will depend on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but it’s essential to balance this with the quality of workmanship. Skilled labor is crucial for ensuring that alternators meet performance and safety standards.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs, leading to lower prices for buyers.

-

Tooling: The initial investment in tooling for specific alternator designs can be substantial. Custom or specialized tooling may be necessary for unique specifications, which can increase costs.

-

Quality Control (QC): Ensuring that alternators meet international standards requires a robust QC process. The costs associated with testing and certification can vary, and buyers should prioritize suppliers with proven QC measures to avoid future issues.

-

Logistics: Transportation costs are crucial, particularly for international shipments. Factors such as distance, shipping methods, and customs duties can significantly influence the overall price.

-

Margin: Suppliers will add a margin to cover their operational costs and profit. Understanding typical margins in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect Alternator Sourcing?

Several factors can influence the pricing of alternators in a B2B context:

-

Volume/MOQ: Larger orders often lead to volume discounts. Understanding the minimum order quantities (MOQ) required by suppliers can help buyers optimize their purchases for better pricing.

-

Specifications and Customization: Custom alternators tailored to specific vehicle models or performance requirements can incur additional costs. Buyers should assess whether customization is necessary and how it impacts pricing.

-

Materials and Quality Certifications: Alternators made from higher-grade materials and those certified to meet international standards may carry a premium price. However, investing in quality can reduce the total cost of ownership by minimizing maintenance and replacement needs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality and service may command higher prices but offer better long-term value.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect logistics costs. Buyers should ensure they understand who is responsible for shipping, insurance, and customs duties to avoid unexpected expenses.

What Are Effective Buyer Tips for Sourcing Alternators?

-

Negotiation: Engage in open discussions with suppliers to explore pricing flexibility. Highlighting potential long-term relationships or bulk purchases can create leverage for better terms.

-

Cost-Efficiency: Evaluate total cost of ownership, not just the initial purchase price. Consider factors like durability, warranty, and maintenance costs when making decisions.

-

Pricing Nuances for International Buyers: Understand the local market dynamics in regions like Africa, South America, the Middle East, and Europe. Currency fluctuations, local regulations, and import tariffs can all impact the final cost.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices against competitors. This ensures you’re not overpaying and can provide a basis for negotiation.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better service, exclusive offers, and insights into upcoming pricing trends.

Conclusion

Navigating the complexities of alternator sourcing requires a thorough understanding of cost components and price influencers. By applying strategic negotiation techniques and focusing on total cost of ownership, B2B buyers can make informed decisions that lead to cost-effective purchasing solutions. Always keep in mind that prices can fluctuate, so maintaining flexibility and open communication with suppliers is key to achieving the best outcomes.

Alternatives Analysis: Comparing que hace el alternador de un carro With Other Solutions

Exploring Alternatives to ‘Que Hace El Alternador De Un Carro’

As the demand for efficient energy solutions in the automotive industry grows, understanding the role of the car alternator and its alternatives becomes increasingly critical for B2B buyers. The alternator is responsible for converting mechanical energy from the engine into electrical energy, which powers various vehicle systems. However, several alternative technologies and methods also serve similar purposes. This analysis compares the traditional car alternator with other viable solutions.

| Comparison Aspect | Que Hace El Alternador De Un Carro | Alternativa 1: Generador Eólico | Alternativa 2: Batería de Ion de Litio |

|---|---|---|---|

| Performance | Reliable and consistent power supply; operates when engine is running. | Variable output based on wind speed; suitable for stationary applications. | High energy density; can provide significant power but requires charging. |

| Cost | Moderate initial cost; long-term savings through vehicle efficiency. | High initial investment; ongoing maintenance costs can be substantial. | Higher upfront cost; lower operational costs due to less maintenance. |

| Ease of Implementation | Integrated into the vehicle’s design; requires minimal modifications. | Requires installation of wind turbines; not practical for mobile applications. | Requires integration into electric vehicles or hybrid systems; more complex than alternators. |

| Maintenance | Regular checks needed; generally low maintenance. | Requires regular inspections and potential repairs; higher maintenance. | Minimal maintenance; long lifespan but dependent on charging infrastructure. |

| Best Use Case | Ideal for conventional vehicles needing reliable electrical supply. | Best for stationary applications or hybrid systems in windy regions. | Optimal for electric or hybrid vehicles requiring efficient energy storage. |

Understanding the Pros and Cons of Each Alternative

Generador Eólico:

Wind generators harness wind energy to produce electricity. While they offer a renewable energy source, their performance can be inconsistent, depending on wind conditions. This makes them less suitable for mobile applications like vehicles but effective for stationary setups or hybrid systems. The high initial investment and ongoing maintenance requirements can be a deterrent for many businesses.

Batería de Ion de Litio:

Lithium-ion batteries are increasingly popular in electric vehicles due to their high energy density and efficiency. They can power vehicle systems effectively and are favored for their longevity and minimal maintenance needs. However, their higher upfront costs and the necessity for charging infrastructure can pose challenges, particularly in regions where access to charging stations is limited.

Conclusion: Choosing the Right Solution for Your Business

When selecting the appropriate solution for automotive electrical needs, B2B buyers should consider various factors such as performance, cost, ease of implementation, and maintenance. While the traditional car alternator remains a reliable choice for conventional vehicles, alternatives like wind generators and lithium-ion batteries offer unique benefits that may be better suited for specific applications, particularly in the growing electric vehicle market. Assessing the specific needs of your fleet or product line will guide you in making an informed decision that aligns with your operational goals and budget constraints.

Illustrative image related to que hace el alternador de un carro

Essential Technical Properties and Trade Terminology for que hace el alternador de un carro

What Are the Key Technical Properties of a Car Alternator?

When considering the procurement of alternators for automotive applications, several technical properties are critical to ensure optimal performance and reliability. Here are some key specifications that B2B buyers should understand:

1. Output Voltage and Current Rating

The output voltage of an alternator typically ranges from 12V to 14.5V, while current ratings can vary from 30A to over 200A depending on the vehicle’s electrical demands. This specification is vital as it determines the alternator’s ability to power various components, including lights, infotainment systems, and climate control. Ensuring that the alternator meets or exceeds the required ratings is essential for vehicle functionality and customer satisfaction.

2. Material Composition

Alternators are primarily made from materials such as aluminum for the casing and copper for the windings. The choice of materials impacts durability, weight, and thermal conductivity. High-grade materials can enhance the alternator’s lifespan and efficiency, which is particularly important in markets where vehicles may be subjected to extreme conditions.

3. Efficiency Rating

The efficiency of an alternator, which typically ranges from 60% to 80%, indicates how well it converts mechanical energy into electrical energy. Higher efficiency ratings lead to reduced fuel consumption and lower emissions, aligning with global sustainability trends. B2B buyers should prioritize suppliers that provide high-efficiency models to meet environmental regulations and customer expectations.

4. Cooling Mechanism

Alternators often incorporate cooling fans or are designed with ventilation systems to dissipate heat generated during operation. Effective cooling is crucial to prevent overheating, which can lead to premature failure. Understanding the cooling design can help buyers choose alternators that perform reliably in hot climates or heavy-duty applications.

Illustrative image related to que hace el alternador de un carro

5. Mounting Configuration

Different vehicles require specific mounting configurations for alternators. Common types include side-mounted and front-mounted setups, which can affect installation time and cost. Buyers should consider compatibility with various vehicle models to minimize aftermarket modifications.

6. Regulator Type

Alternators feature either internal or external voltage regulators, which manage the output voltage. Internal regulators are more common in modern vehicles due to their compact design and ease of integration. Understanding the type of regulator can influence maintenance practices and the overall efficiency of the electrical system.

What Are the Common Trade Terms Related to Car Alternators?

Familiarity with industry terminology can facilitate smoother transactions and negotiations in the B2B automotive market. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of alternators, purchasing OEM parts ensures compatibility and quality assurance, as these components are designed to meet specific vehicle standards.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to assess inventory needs and negotiate purchase agreements that align with their operational capacity.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing, availability, and terms for specific products. This process is essential for B2B buyers to gather competitive offers and make informed purchasing decisions.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, ensuring smoother logistics in global trade.

5. Aftermarket

The aftermarket encompasses all parts and accessories sold after the original sale of the vehicle. Understanding the aftermarket landscape for alternators can provide insights into potential sales opportunities and customer preferences.

6. Warranty Terms

Warranty terms specify the conditions under which a manufacturer will repair or replace faulty products. Knowledge of warranty provisions is vital for B2B buyers to assess the long-term reliability and support associated with their purchases.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their product offerings and operational efficiency in the automotive sector.

Navigating Market Dynamics and Sourcing Trends in the que hace el alternador de un carro Sector

The automotive alternator sector is witnessing significant transformation driven by advancements in technology and shifting market demands. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate these changes, understanding the market dynamics becomes crucial for strategic sourcing decisions.

Illustrative image related to que hace el alternador de un carro

What Are the Key Trends Influencing the Alternator Market?

One of the primary drivers of growth in the alternator market is the increasing demand for electric and hybrid vehicles. As manufacturers shift towards electrification, the need for efficient alternators that can support advanced electrical systems and battery management becomes paramount. This trend is particularly pronounced in emerging markets where electric vehicle adoption is gaining momentum, driven by government incentives and environmental concerns.

Additionally, advancements in manufacturing technology, such as automation and the use of advanced materials, are reshaping how alternators are produced. These innovations not only enhance product performance but also reduce production costs, enabling suppliers to offer competitive pricing. Furthermore, the rise of digital platforms for procurement and supply chain management is streamlining sourcing processes, allowing buyers to access a broader range of suppliers and negotiate better terms.

How Are Sustainability and Ethical Sourcing Shaping the Automotive Alternator Industry?

The importance of sustainability in the alternator supply chain cannot be overstated. Environmental impact assessments are becoming standard practice, with many companies seeking to minimize their carbon footprint. Buyers are increasingly looking for manufacturers who utilize environmentally friendly materials and production processes. This includes the use of recycled metals and non-toxic components, which are critical for reducing waste and promoting a circular economy.

Moreover, ethical sourcing practices are gaining traction. Buyers are now more aware of the social implications of their supply chains, demanding transparency and adherence to labor standards. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility are becoming essential benchmarks for suppliers aiming to establish credibility in the market.

Illustrative image related to que hace el alternador de un carro

What Is the Brief Evolution of the Alternator in the Automotive Sector?

The alternator has evolved significantly since its inception in the early 20th century. Initially, vehicles relied on simple DC generators, which were less efficient and required more maintenance. The transition to the alternator in the 1960s marked a crucial advancement, as these components offered higher efficiency and better performance for the growing electrical demands of vehicles. Over the decades, the design and technology of alternators have continued to improve, incorporating features such as smart charging systems and lightweight materials. This evolution not only enhances vehicle performance but also aligns with modern sustainability goals, reflecting the industry’s commitment to innovation and environmental responsibility.

In conclusion, as international B2B buyers navigate the alternator market, understanding these dynamics—ranging from technological advancements to sustainability practices—will be critical for making informed sourcing decisions that align with both market needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of que hace el alternador de un carro

-

How does an alternator work in a vehicle?

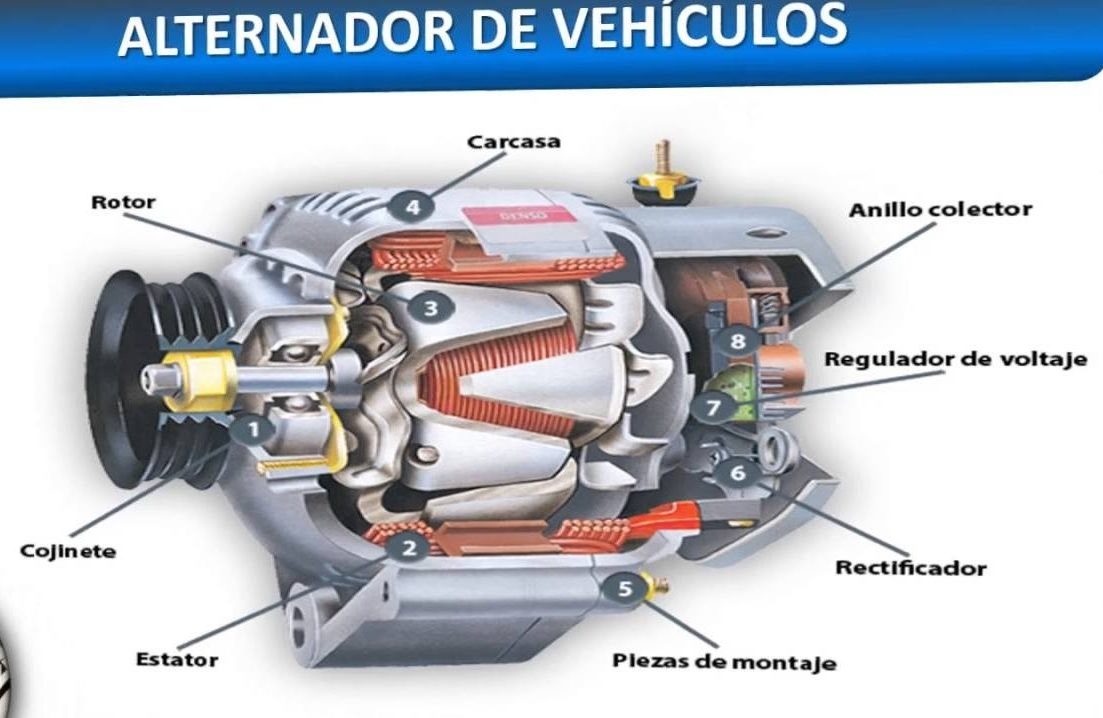

An alternator converts mechanical energy from the engine into electrical energy. When the engine runs, the alternator’s rotor spins within a magnetic field created by the stator, generating alternating current (AC). This AC is then converted into direct current (DC) by a rectifier, which powers the vehicle’s electrical systems and charges the battery. Understanding this process is crucial for B2B buyers when assessing alternator performance and reliability for their vehicle fleets. -

What are the key components of an alternator?

An alternator comprises several critical parts: the rotor, stator, rectifier, voltage regulator, and bearings. The rotor generates a magnetic field, while the stator contains coils of wire that convert this magnetic energy into electrical energy. The rectifier changes AC to DC, and the voltage regulator ensures a consistent output voltage. Familiarity with these components helps buyers evaluate product quality and durability, vital for long-term investment. -

How can I identify a failing alternator?

Signs of a failing alternator include dimming headlights, flickering dashboard lights, strange noises (like grinding or whining), and difficulty starting the vehicle. Additionally, a battery warning light on the dashboard may indicate issues. For B2B buyers, ensuring reliable performance is essential; thus, sourcing alternators with a proven track record of durability and reliability can mitigate maintenance costs. -

What should I consider when sourcing alternators for my fleet?

When sourcing alternators, consider factors like compatibility with your vehicle models, supplier reputation, warranty terms, and after-sales support. It’s also essential to evaluate the manufacturer’s production capabilities, quality control processes, and adherence to international standards. These considerations will help ensure you select a reliable supplier that meets your operational needs. -

What are the typical minimum order quantities (MOQs) for alternators?

MOQs for alternators can vary significantly based on the supplier and the type of alternator. Generally, they range from 50 to several hundred units. It’s advisable to discuss your specific needs with suppliers to negotiate favorable terms, especially if you require custom specifications or have a smaller fleet. Understanding MOQs helps manage inventory effectively and optimize purchasing costs. -

What payment terms are common for B2B purchases of alternators?

Common payment terms for B2B transactions include net 30, net 60, or payment upon delivery. Some suppliers may offer discounts for early payment or require a deposit before manufacturing. It’s crucial to negotiate terms that align with your cash flow and operational budget. Being clear about payment terms upfront can foster better relationships with suppliers and reduce financial risks. -

How can I ensure quality assurance (QA) for the alternators I purchase?

To ensure quality assurance, request documentation of the manufacturer’s quality control processes, including certifications like ISO 9001. It’s beneficial to ask for samples or conduct on-site inspections before bulk purchases. Additionally, establishing clear specifications and performance standards in your contracts can help ensure that the alternators meet your expectations and reduce the likelihood of defects. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider shipping costs, customs duties, and import regulations specific to your country. It’s essential to work with logistics providers experienced in automotive parts to navigate these challenges effectively. Additionally, ensure that your supplier can provide necessary shipping documents and track shipments to avoid delays in receiving your orders, which can impact your operations.

Top 3 Que Hace El Alternador De Un Carro Manufacturers & Suppliers List

1. Kia – Alternador Esencial

Domain: kia.com

Registered: 1996 (29 years)

Introduction: Un alternador es un componente esencial en vehículos con motor de combustión, encargado de convertir energía química en energía eléctrica para cargar la batería y alimentar otros componentes eléctricos. Funciona mediante un sistema de carga que incluye la batería, el regulador de voltaje y el alternador, que transforma energía mecánica en corriente alterna (CA) y luego en corriente continua (CC) p…

2. Race.es – Alternador de Coche

Domain: race.es

Introduction: El alternador es un componente del coche que produce electricidad mediante el giro rotativo del motor. Convierte electricidad alterna en continua de 12 voltios para acumularla en la batería. Funciona con un regulador que mantiene el voltaje entre 13,5 V y 14,5 V. En coches antiguos, el alternador era una pieza independiente, mientras que en coches modernos incluye un gestor de carga que regula su …

3. Infinity Auto – Alternadores

Domain: infinityauto.com

Registered: 2002 (23 years)

Introduction: El alternador es un generador que distribuye electricidad al auto y recarga la batería. Funciona convirtiendo energía mecánica en energía eléctrica, impulsado por el cigüeñal del motor a través de una correa serpentina. Sus componentes incluyen: 1. Rotor: pieza cilíndrica rodeada de imanes que gira dentro del estator. 2. Estator: parte fija que contiene cables de cobre y trabaja con el rotor para …

Strategic Sourcing Conclusion and Outlook for que hace el alternador de un carro

In summary, the alternator plays a critical role in the functionality of vehicles, converting mechanical energy into electrical energy to power various systems. For B2B buyers, understanding the components and workings of alternators is essential for making informed purchasing decisions, whether sourcing parts for manufacturing or maintaining vehicle fleets. Strategic sourcing not only ensures the procurement of high-quality alternators but also optimizes costs and enhances supply chain efficiency.

As the automotive industry continues to evolve, particularly with advancements in technology and increasing demands for electric vehicles, the importance of reliable alternators cannot be overstated. International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with reputable suppliers who offer quality assurance and competitive pricing.

Looking ahead, the focus on sustainability and innovation in automotive components will shape the market landscape. Engaging with suppliers who are committed to these values can provide a competitive edge. Take proactive steps now to secure your supply chain and ensure your business thrives in this dynamic market.

Illustrative image related to que hace el alternador de un carro

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to que hace el alternador de un carro