Introduction: Navigating the Global Market for how much is a new starter

In today’s rapidly evolving automotive landscape, understanding the cost implications of sourcing a new starter is crucial for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. A new starter not only plays a pivotal role in ensuring vehicle reliability but also represents a significant investment for businesses managing fleets or automotive repair services. This guide aims to demystify the complexities surrounding starter costs, offering insights into various types, applications, and the factors that influence pricing.

From analyzing the differences between new, rebuilt, and aftermarket starters to exploring the intricacies of installation costs, this comprehensive resource equips international buyers with the knowledge necessary to make informed purchasing decisions. We delve into the nuances of supplier vetting, highlighting key criteria to consider when selecting a reliable vendor, thus ensuring that your investment meets quality and performance standards.

Furthermore, we address regional pricing variations and offer strategies for negotiating better deals, empowering B2B buyers to optimize their procurement processes. By understanding the complete landscape of starter costs, businesses can enhance their operational efficiency, reduce downtime, and ultimately drive profitability. As you navigate the global market for new starters, this guide will serve as your essential companion, unlocking the potential for smarter and more strategic purchasing decisions.

Table Of Contents

- Top 6 How Much Is A New Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much is a new starter

- Understanding how much is a new starter Types and Variations

- Key Industrial Applications of how much is a new starter

- 3 Common User Pain Points for ‘how much is a new starter’ & Their Solutions

- Strategic Material Selection Guide for how much is a new starter

- In-depth Look: Manufacturing Processes and Quality Assurance for how much is a new starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is a new starter’

- Comprehensive Cost and Pricing Analysis for how much is a new starter Sourcing

- Alternatives Analysis: Comparing how much is a new starter With Other Solutions

- Essential Technical Properties and Trade Terminology for how much is a new starter

- Navigating Market Dynamics and Sourcing Trends in the how much is a new starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much is a new starter

- Strategic Sourcing Conclusion and Outlook for how much is a new starter

- Important Disclaimer & Terms of Use

Understanding how much is a new starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| New Starter | Brand new, OEM parts, typically high quality | Fleet management, auto repair shops | Pros: Reliability, warranty, best performance. Cons: Higher initial cost. |

| Rebuilt Starter | Refurbished parts, generally lower cost | Small repair shops, independent mechanics | Pros: Cost-effective, good performance. Cons: Limited warranty, potential quality variability. |

| Aftermarket Starter | Non-OEM parts, varying quality and price | Auto parts retailers, online sellers | Pros: Wide range of prices, availability. Cons: Quality can be inconsistent, may not fit all vehicles. |

| High-Performance Starter | Designed for enhanced power and durability | Racing teams, performance vehicle builders | Pros: Superior performance, suitable for demanding conditions. Cons: Expensive, may require modifications. |

| Universal Starter | Generic design, adaptable to multiple vehicles | DIY mechanics, budget-conscious buyers | Pros: Versatile, lower cost. Cons: May lack specific fit and performance. |

What Are the Characteristics of a New Starter?

A new starter is an original equipment manufacturer (OEM) part, ensuring compatibility and reliability. Typically priced higher, it is ideal for businesses prioritizing performance and warranty. B2B buyers, such as fleet managers or auto repair shops, may prefer new starters for their dependability, especially in high-usage vehicles. The initial investment is often justified by the potential reduction in future repair costs.

Why Consider a Rebuilt Starter?

Rebuilt starters offer a cost-effective solution, utilizing refurbished components to provide similar performance to new starters. While they may not carry the same warranty as new parts, they are suitable for small repair shops and independent mechanics looking to minimize expenses. B2B buyers should consider the quality of the rebuild process and the reputation of the supplier to ensure satisfactory performance.

What Should You Know About Aftermarket Starters?

Aftermarket starters are non-OEM alternatives that vary widely in quality and pricing. They cater to a broad market, making them accessible for auto parts retailers and online sellers. B2B buyers should be cautious, as the quality can be inconsistent; therefore, thorough research and supplier vetting are essential. While they can offer savings, the risk of poor fit or performance issues should be weighed carefully.

When Are High-Performance Starters Necessary?

High-performance starters are specifically designed for vehicles requiring enhanced power and durability, such as racing cars or performance builds. They are more expensive but provide significant advantages in demanding conditions. B2B applications include racing teams and specialty vehicle manufacturers. Buyers should assess the specific requirements of their applications to determine if the investment aligns with their performance goals.

How Do Universal Starters Fit Into the Market?

Universal starters are generic options that can adapt to various vehicles, making them a versatile choice for DIY mechanics and budget-conscious buyers. While they are typically lower in cost, they may not provide the specific fit or performance required for all vehicles. B2B buyers should evaluate the trade-off between price and performance, especially for high-usage applications where reliability is critical.

Key Industrial Applications of how much is a new starter

| Industry/Sector | Specific Application of how much is a new starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Replacement of starters in vehicles | Reduces downtime and enhances customer satisfaction | Availability of parts, local regulations, warranty terms |

| Transportation & Logistics | Fleet management for commercial vehicles | Ensures operational efficiency and reliability | Bulk purchasing options, quality assurance, delivery times |

| Agriculture & Farming | Starting agricultural machinery | Minimizes equipment failure and increases productivity | Compatibility with various equipment, aftermarket support |

| Mining & Construction | Heavy machinery starter replacements | Enhances safety and productivity on site | Durability under extreme conditions, supplier reliability |

| Renewable Energy | Starter systems for wind turbines | Improves maintenance efficiency and energy output | Technical specifications, environmental compliance, local sourcing options |

How is ‘how much is a new starter’ relevant in the automotive repair industry?

In the automotive repair sector, understanding the cost of a new starter is crucial for mechanics and garage owners. A starter is an essential component for vehicle functionality, and its failure can lead to significant downtime. By knowing the price range for different vehicle models, repair shops can provide accurate estimates to customers, enhancing trust and customer satisfaction. Buyers must consider factors such as part availability and warranty terms, especially in regions where specific vehicle models are prevalent.

Why is knowing the cost of a new starter important for transportation and logistics?

In the transportation and logistics industry, fleet managers must maintain their vehicles to ensure timely deliveries. The cost of new starters plays a vital role in budgeting for maintenance and repairs. By investing in reliable starters, companies can reduce the risk of breakdowns, leading to improved operational efficiency. When sourcing starters, fleet managers should prioritize bulk purchasing options and supplier reliability to minimize downtime and ensure quick repairs.

How does the cost of a new starter impact agriculture and farming operations?

Agricultural machinery relies heavily on starters to function efficiently. In the farming sector, knowing the cost of a new starter allows farmers to budget for repairs and replacements, which can significantly impact productivity during critical planting and harvesting seasons. Compatibility with various equipment is crucial, as farmers often use a mix of machinery. Buyers should also consider aftermarket support to ensure that they can quickly obtain parts when needed, minimizing equipment failure.

What are the implications of starter costs in mining and construction?

In the mining and construction industries, equipment reliability is paramount. The cost of replacing starters in heavy machinery can be substantial, but it is necessary to prevent safety hazards and operational delays. Understanding the pricing helps project managers allocate resources effectively. Buyers must focus on sourcing durable starters that can withstand harsh environments while ensuring that suppliers can meet demand consistently to avoid project delays.

How does the renewable energy sector benefit from understanding starter costs?

In renewable energy, particularly with wind turbines, starters play a critical role in system maintenance. Knowing the cost of new starters can help energy companies optimize their maintenance schedules and budget effectively. This understanding leads to improved energy output and operational efficiency. Buyers should pay attention to technical specifications and environmental compliance when sourcing starters, as these factors are crucial for maintaining sustainability and efficiency in their operations.

3 Common User Pain Points for ‘how much is a new starter’ & Their Solutions

Scenario 1: Navigating Cost Variability in Starter Replacement

The Problem:

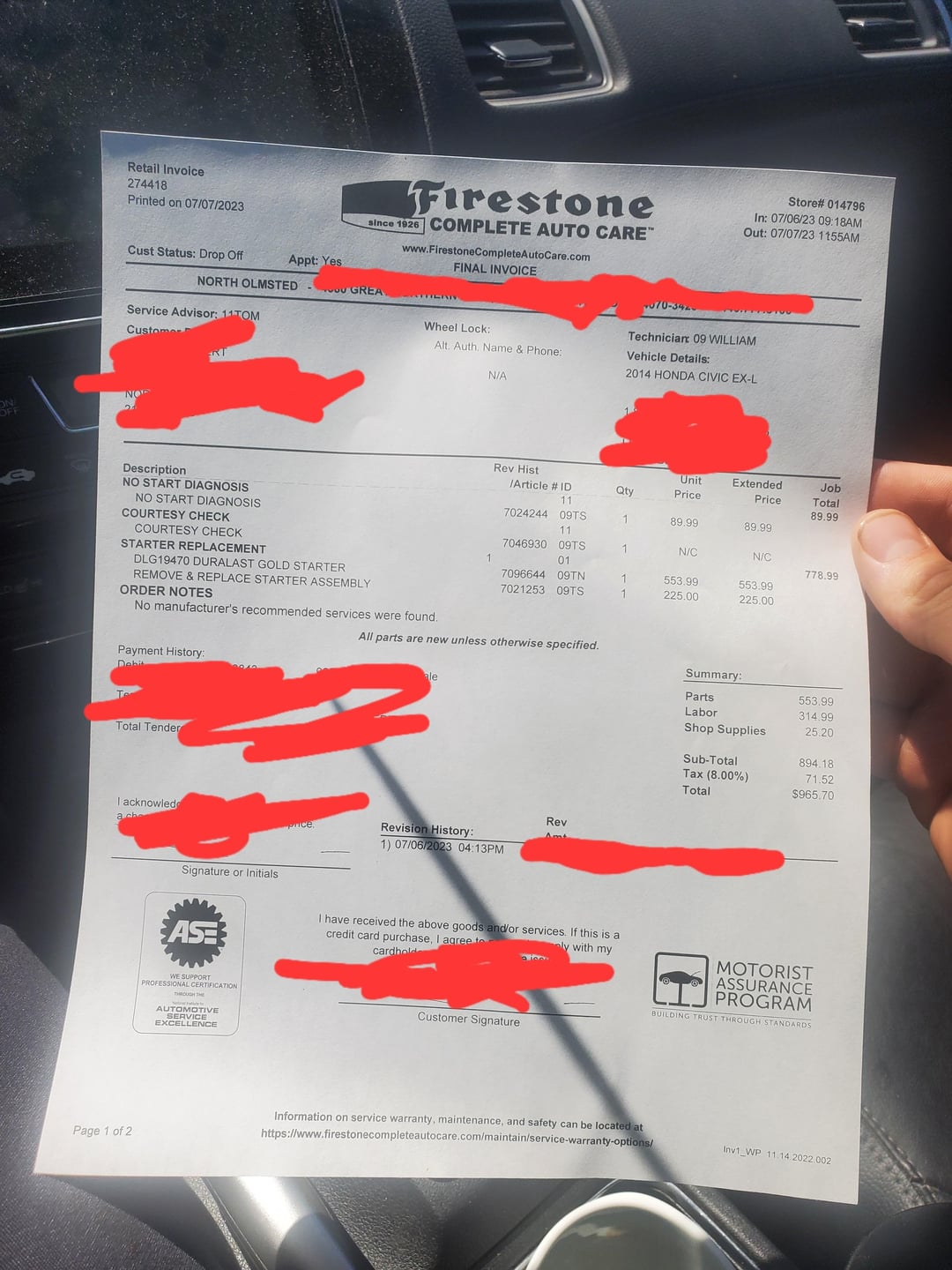

B2B buyers, particularly those managing fleets or automotive repair businesses, often struggle with the unpredictable costs associated with starter replacements. The price can vary dramatically based on vehicle make, model, and year, leading to challenges in budgeting and financial planning. A repair manager might receive quotes ranging from $150 to over $1,100 for different vehicles, creating confusion and uncertainty when trying to allocate funds for repairs. This lack of clarity can hinder operational efficiency and complicate the procurement process.

The Solution:

To effectively navigate this cost variability, B2B buyers should establish a comprehensive database of starter parts and their associated costs for the specific vehicles in their fleet or service range. This database can include factors such as average repair costs, common issues, and estimated labor times. Collaborating with reliable suppliers to obtain bulk purchase discounts can also mitigate costs. Additionally, investing in a diagnostic tool can help identify whether the starter is the actual issue, potentially saving time and money by addressing the correct problem. By creating a standardized approach to evaluating starter costs, buyers can enhance budgeting accuracy and streamline the repair process.

Scenario 2: Understanding the Impact of Vehicle Type on Starter Costs

The Problem:

International buyers often face difficulties when sourcing starters for a diverse range of vehicles, particularly if their fleet includes both standard sedans and luxury vehicles. The intricacies involved in luxury models, such as specialized parts or complex electrical systems, can lead to significantly higher replacement costs. This disparity may result in unexpected expenses that strain budgets and affect overall profitability.

The Solution:

To tackle this challenge, B2B buyers should categorize their fleet based on vehicle types and create tailored strategies for sourcing starters. For luxury vehicles, it is advisable to establish relationships with specialized suppliers who understand the unique requirements of high-end models. Buyers should also consider utilizing remanufactured starters for standard vehicles where applicable, as these can offer a cost-effective alternative without sacrificing quality. Conducting thorough market research to compare prices and terms from various suppliers will empower buyers to make informed decisions, ensuring they are not overpaying for parts. By implementing a segmented procurement strategy, buyers can better manage costs across their diverse vehicle types.

Scenario 3: Identifying the True Cause of Starting Issues

The Problem:

One common pain point for B2B buyers is misdiagnosing the root cause of starting problems, often attributing issues solely to the starter itself. This can lead to unnecessary replacements and inflated costs, as many factors such as battery health, wiring, or ignition systems can mimic starter failure symptoms. A fleet manager may replace starters multiple times, only to find that the real issue was an unrelated electrical component, wasting both time and money.

The Solution:

To mitigate this issue, B2B buyers should prioritize implementing a systematic diagnostic approach before proceeding with any starter replacements. This can involve training technicians to follow a checklist that includes checking battery voltage, inspecting wiring connections, and testing fuses and relays. Additionally, investing in diagnostic tools can provide accurate assessments of the starting system, ensuring that the right component is replaced. Establishing a protocol for thorough inspections will help buyers avoid unnecessary replacements and ultimately reduce costs associated with starter replacements. By fostering a culture of precise diagnostics, organizations can enhance operational efficiency and significantly lower repair expenses.

Strategic Material Selection Guide for how much is a new starter

When considering the materials used in the production of automotive starters, it is essential to analyze their properties, advantages, and limitations. This understanding can significantly influence procurement decisions for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to how much is a new starter

What Are the Key Properties of Common Starter Materials?

-

Steel

– Key Properties: Steel is known for its high tensile strength and durability. It can withstand significant mechanical stress and has a good resistance to wear and tear.

– Pros & Cons: Steel starters are relatively inexpensive and easy to manufacture. However, they can be prone to corrosion if not properly treated or coated. The manufacturing process can be complex due to the need for precise machining.

– Impact on Application: Steel starters are suitable for a wide range of vehicles but may require additional coatings for corrosion resistance, especially in humid or coastal environments.

– Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM in the U.S. or DIN in Germany, and consider the availability of corrosion-resistant coatings. -

Aluminum

– Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it ideal for automotive applications where weight savings are crucial.

– Pros & Cons: The primary advantage of aluminum starters is their reduced weight, which can enhance vehicle performance and fuel efficiency. However, they may not be as durable as steel under extreme conditions and can be more expensive to manufacture.

– Impact on Application: Aluminum starters are particularly beneficial for high-performance vehicles where weight is a critical factor. They are also suitable for environments with high humidity or corrosive elements.

– Considerations for International Buyers: Buyers should ensure that aluminum components meet international standards for strength and durability, particularly in regions with varying climate conditions. -

Copper

– Key Properties: Copper is an excellent conductor of electricity, which is vital for starter motors. It also has good thermal conductivity and resistance to corrosion.

– Pros & Cons: Copper starters provide superior electrical performance, which can lead to more reliable engine starts. However, copper is more expensive than steel or aluminum and may not be as mechanically robust.

– Impact on Application: Copper is often used in starter windings and connections, enhancing overall efficiency. Its use is particularly advantageous in environments where electrical performance is paramount.

– Considerations for International Buyers: Buyers should be aware of the fluctuating prices of copper and ensure compliance with electrical standards in their respective regions. -

Plastic Composites

– Key Properties: Plastic composites can offer good insulation properties and are lightweight. They can also be engineered to provide specific mechanical properties.

– Pros & Cons: These materials can reduce weight and manufacturing costs, but they may not withstand high temperatures or mechanical stress as well as metals. Their long-term durability can also be a concern.

– Impact on Application: Plastic composites are often used in non-structural components of starters, such as housings, where weight savings are beneficial.

– Considerations for International Buyers: Buyers should assess the thermal and mechanical properties of the composites to ensure they meet the demands of their specific applications and comply with local regulations.

Summary Table of Material Selection for Starters

| Material | Typical Use Case for how much is a new starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Common automotive starters for various vehicles | High strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | High-performance and lightweight starters | Excellent corrosion resistance | Less durable under extreme conditions | High |

| Copper | Electrical connections and windings in starters | Superior electrical conductivity | Higher cost and lower mechanical strength | High |

| Plastic Composites | Non-structural components in starters | Lightweight and cost-effective | Limited thermal and mechanical resistance | Low |

This analysis provides B2B buyers with essential insights into material selection for starters, enabling informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how much is a new starter

What Are the Key Stages in the Manufacturing Process of a Starter?

The manufacturing process of automotive starters involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages is essential for B2B buyers, as they directly influence the cost, reliability, and longevity of the starter.

Material Preparation: What Materials Are Used in Starter Production?

The first stage in starter manufacturing involves selecting high-quality materials. Common materials include:

Illustrative image related to how much is a new starter

- Steel: Utilized for the casing and internal components due to its strength and durability.

- Copper: Used for windings and electrical contacts, chosen for its excellent conductivity.

- Plastic: Employed in non-load-bearing components to reduce weight and cost.

These materials undergo rigorous quality checks to ensure they meet industry standards. For instance, steel is often tested for tensile strength and corrosion resistance.

Forming: How Are Starter Components Shaped and Formed?

The forming stage typically involves techniques such as stamping, forging, and machining.

- Stamping: Used to create the starter’s casing and other flat components. This process involves pressing sheets of metal into molds to achieve precise shapes.

- Machining: Critical for parts requiring tight tolerances, such as the armature and solenoid. CNC (Computer Numerical Control) machines are commonly employed for this purpose.

- Forging: Often applied to components like gears, where high strength is necessary. This process involves shaping metal using localized compressive forces.

Each technique is chosen based on the design specifications and performance requirements of the starter.

Assembly: How Are Starters Assembled for Optimal Performance?

The assembly process is crucial for ensuring that all components fit together correctly and function as intended. This typically involves:

- Sub-Assembly: Individual components like the solenoid and armature are first assembled separately.

- Main Assembly: The sub-assemblies are then brought together, with careful attention to alignment and torque specifications.

- Wiring: Electrical connections are made, ensuring proper insulation and securing against vibrations.

During this stage, automated systems and human operators work together to ensure precision and efficiency.

Finishing: What Final Treatments Are Applied to Starters?

Finishing processes enhance the starter’s durability and appearance. Common techniques include:

- Painting: Protective coatings are applied to prevent rust and corrosion.

- Electroplating: This process can enhance conductivity and reduce wear on contact surfaces.

- Quality Inspection: Each starter undergoes visual and functional testing to ensure it meets performance standards.

What Quality Assurance Practices Are Essential in Starter Manufacturing?

Quality assurance (QA) is vital in the manufacturing of starters, as it directly impacts their reliability and safety. B2B buyers should be aware of the standards and practices that govern this aspect.

What International Standards Should B2B Buyers Know About?

Manufacturers often adhere to internationally recognized standards to ensure product quality. Key standards include:

- ISO 9001: This standard focuses on quality management systems and helps organizations consistently meet customer and regulatory requirements.

- CE Marking: For products sold in the European Union, CE marking indicates compliance with safety and environmental protection standards.

- API Standards: Relevant for starters used in specific automotive applications, particularly concerning performance and safety.

These certifications provide buyers with confidence in the quality and safety of the products they purchase.

What Are the Key Quality Control Checkpoints in Starter Production?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process. These checkpoints typically include:

Illustrative image related to how much is a new starter

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing stages, including dimensional checks and functional tests.

- Final Quality Control (FQC): A comprehensive assessment of finished products before they are shipped. This may involve performance testing under simulated operating conditions.

By implementing these checkpoints, manufacturers can identify and rectify issues early in the production process, minimizing defects.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure they are sourcing from reliable manufacturers, B2B buyers should engage in thorough due diligence regarding quality control practices.

What Are Effective Methods for Assessing Supplier Quality?

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturer’s processes and adherence to quality standards firsthand.

- Quality Reports: Requesting documentation of QC processes, including inspection reports and compliance certificates, provides insight into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent inspection agencies to assess the manufacturer’s processes can provide an unbiased view of their quality control measures.

These methods are particularly important for international buyers who may face additional challenges in verifying supplier capabilities and compliance.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should consider specific nuances in quality control:

- Regulatory Compliance: Different countries have varying regulations that may affect product specifications and certifications. Buyers should be aware of local requirements.

- Cultural Differences: Understanding the manufacturing culture and practices of different regions can aid in assessing supplier reliability and quality.

- Logistics and Supply Chain: Quality control should extend to the entire supply chain, as delays or issues in transportation can impact product integrity.

By addressing these nuances, international buyers can better navigate the complexities of sourcing automotive starters and ensure they are investing in high-quality products.

Conclusion: How Do Manufacturing Processes and Quality Assurance Affect the Cost of Starters?

The manufacturing processes and quality assurance practices employed in the production of starters significantly influence their cost. By understanding these elements, B2B buyers can make informed decisions, ensuring they receive reliable products that meet their operational needs while maintaining budgetary constraints. As the automotive market continues to evolve, prioritizing quality in procurement will be crucial for maintaining competitive advantage.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is a new starter’

Introduction

This sourcing guide serves as a practical checklist for B2B buyers seeking to procure new starters for vehicles. Understanding the costs and specifications associated with starter replacements is crucial for making informed purchasing decisions, especially in diverse international markets such as Africa, South America, the Middle East, and Europe. This guide will help you navigate the complexities of sourcing a starter, ensuring you get the best value for your investment.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the starter you need. This includes the make, model, and year of the vehicle, as well as any specific performance characteristics required.

– Why it matters: Different vehicles have unique starter specifications, and knowing these details helps in sourcing the correct part.

– What to look for: Consult your vehicle’s manual for specifications and ensure that any potential starter matches these requirements.

Step 2: Research Market Prices

Conduct thorough research to understand the price range for starters in your target market. Prices can vary significantly based on brand, quality, and local demand.

– Why it matters: Understanding the market helps you set a realistic budget and avoid overpaying.

– What to look for: Compare prices from multiple suppliers and include shipping costs to assess the total expenditure accurately.

Step 3: Evaluate Supplier Certifications

Assess the certifications and standards of potential suppliers. Look for ISO certifications or compliance with local automotive standards.

– Why it matters: Certifications indicate a supplier’s commitment to quality and reliability, which is essential for automotive parts.

– What to look for: Request documentation of certifications and check if the supplier has a history of compliance with industry regulations.

Step 4: Check for Warranty and Return Policies

Inquire about warranty terms and return policies for the starters. A solid warranty can protect your investment in case of defects or performance issues.

– Why it matters: A good warranty reflects the supplier’s confidence in their product and provides peace of mind.

– What to look for: Ensure the warranty covers a reasonable period and check the conditions under which returns are accepted.

Step 5: Request Samples or Test Products

If possible, request samples or trial units of the starter to evaluate their performance. This is especially important for bulk orders.

– Why it matters: Testing a starter can help you assess quality and compatibility before making a significant investment.

– What to look for: Observe the starter’s functionality and fitment during testing, and consider feedback from your technical team.

Step 6: Negotiate Terms and Conditions

Engage in negotiations with suppliers regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better deals and stronger partnerships.

– Why it matters: Securing favorable terms can enhance your overall procurement strategy and reduce costs.

– What to look for: Be clear about your needs and expectations, and don’t hesitate to push for concessions that benefit your organization.

Step 7: Establish a Long-Term Relationship

Consider building a long-term relationship with reliable suppliers. A consistent partnership can lead to better pricing, priority service, and access to new products.

– Why it matters: Long-term relationships can provide stability and ensure a consistent supply of high-quality parts.

– What to look for: Evaluate the supplier’s reliability over time and communicate openly to foster a mutually beneficial partnership.

By following this checklist, B2B buyers can effectively navigate the procurement process for new starters, ensuring they make informed and strategic purchasing decisions.

Comprehensive Cost and Pricing Analysis for how much is a new starter Sourcing

What Are the Key Cost Components of Sourcing a New Starter?

When evaluating the cost of sourcing a new starter, several cost components come into play. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to how much is a new starter

-

Materials: The core components of a starter include electrical coils, solenoids, armatures, and housing materials. Prices for these materials can fluctuate based on availability and market demand. For instance, copper prices have a direct impact on the cost of electrical components.

-

Labor: Labor costs vary significantly depending on the region. In countries with higher wage standards, such as Germany, labor costs for assembly and quality control can be substantial. Conversely, in regions like Nigeria, labor costs may be lower, but this could affect quality.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Manufacturers often distribute these costs across their product range, influencing the pricing of starters.

-

Tooling: The initial investment in machinery and tools needed to produce starters can be significant. This cost is typically amortized over production runs, affecting pricing for smaller orders.

-

Quality Control: Implementing rigorous QC processes ensures that each starter meets safety and performance standards. While this adds to the cost, it is essential for maintaining a reputable product.

-

Logistics: Transportation and warehousing costs can vary greatly, especially for international shipments. Factors such as shipping method, distance, and customs duties must be considered.

-

Margin: Suppliers will factor in their desired profit margins, which can differ based on market competition and business strategy.

How Do Price Influencers Affect the Cost of Starters?

Several price influencers can significantly impact the overall cost of sourcing a new starter.

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs due to economies of scale. Many suppliers offer tiered pricing based on Minimum Order Quantities (MOQ), making it essential to assess how many units you plan to purchase.

-

Specifications/Customization: Custom starters that meet specific performance requirements or fit unique vehicle models will generally cost more. Clear communication of your specifications can help avoid unexpected costs.

-

Materials: The choice of materials directly influences price. High-performance starters made from advanced materials will be more expensive than standard versions.

-

Quality/Certifications: Compliance with industry standards and certifications can raise costs. However, sourcing certified products often leads to better reliability, which can reduce long-term expenses.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of trade, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial. These terms determine who bears the cost and risk at various stages of shipping, impacting your total landed cost.

What Are the Best Buyer Tips for Sourcing Starters Internationally?

When sourcing starters, particularly for international markets in Africa, South America, the Middle East, and Europe, consider the following tips to enhance cost efficiency:

-

Negotiate: Don’t hesitate to negotiate prices and terms with suppliers. Many are open to discussion, especially for larger orders.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, performance, and potential downtime costs. A more expensive starter may offer better longevity, saving money in the long run.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, logistics and tariffs can vary significantly between Europe and Africa, affecting your overall costs.

-

Research and Select Reputable Suppliers: Look for suppliers with positive reviews and a strong track record in your region. This can help mitigate risks associated with quality and delivery.

-

Request Samples: Before committing to large orders, request samples to assess quality and compatibility with your requirements.

Disclaimer on Pricing

Please note that the prices for starters can vary widely based on numerous factors, including market fluctuations, supplier pricing strategies, and regional economic conditions. The figures mentioned in this analysis are indicative and should be verified with suppliers for accurate quotations tailored to your specific needs.

Alternatives Analysis: Comparing how much is a new starter With Other Solutions

Exploring Alternatives to a New Starter: What Are Your Options?

When considering the purchase of a new starter for a vehicle, it’s essential to evaluate alternatives that may provide similar functionality or benefits. Different solutions can vary in performance, cost, and suitability depending on the specific needs of the vehicle and the buyer’s circumstances. This analysis compares the cost and effectiveness of a new starter against two alternative solutions: starter repair and using a high-quality battery.

Comparison Table

| Comparison Aspect | How Much Is A New Starter | Starter Repair | High-Quality Battery |

|---|---|---|---|

| Performance | Reliable, new component | Restores functionality, but may not guarantee longevity | Enhances overall starting system performance |

| Cost | $80 – $350 (parts) + labor | $50 – $200 (parts) + labor | $100 – $250 (depending on capacity) |

| Ease of Implementation | Moderate (requires professional installation) | Moderate (can be DIY or professional) | Easy (can be self-installed) |

| Maintenance | Low (new part) | Moderate (may require future repairs) | Low to moderate (battery maintenance needed) |

| Best Use Case | When starter is beyond repair | When minor issues are present | When battery issues are suspected |

What Are the Pros and Cons of Starter Repair?

Starter repair can be a cost-effective alternative to purchasing a new starter, particularly for minor issues such as worn brushes or faulty solenoids. The cost of repair typically ranges from $50 to $200, depending on the specific parts needed and labor costs. One of the primary advantages of this approach is the potential for savings compared to a full replacement. However, repairs may not always guarantee long-term functionality, especially if the starter has underlying issues. Therefore, if the starter has been in use for many years or shows multiple signs of wear, opting for a new starter might be more prudent.

How Does a High-Quality Battery Compare?

Investing in a high-quality battery can improve the overall starting system’s performance, potentially resolving starting issues attributed to insufficient power. While the cost of a quality battery ranges from $100 to $250, the ease of installation makes this option appealing for those who prefer a DIY approach. A new battery can enhance the reliability of the starting system and prolong the life of other components. However, if the starter itself is faulty, merely upgrading the battery may not resolve the underlying problem, leading to repeated issues.

Making the Right Choice: What Should B2B Buyers Consider?

For B2B buyers evaluating how much a new starter costs against alternative solutions, several factors should guide the decision. Consider the specific symptoms of the vehicle: if starting issues persist even after battery upgrades, a new starter may be necessary. On the other hand, if the starter shows signs of wear but is not entirely non-functional, repair could be a viable option. Additionally, evaluating the total cost of ownership—including maintenance and potential future failures—will help in making a more informed decision. Ultimately, the best solution will depend on the specific needs of the vehicle, the budget, and the buyer’s willingness to engage in repairs or replacements.

Essential Technical Properties and Trade Terminology for how much is a new starter

What Are the Key Technical Properties of a New Starter?

When considering the purchase of a new starter for automotive applications, several technical properties are crucial for ensuring compatibility, performance, and longevity. Here are the key specifications to evaluate:

-

Material Grade

– Definition: The quality of materials used in the starter, often including steel, copper, and aluminum.

– B2B Importance: Higher material grades typically enhance durability and performance, leading to a longer lifespan. Understanding material quality helps buyers avoid low-cost options that may compromise vehicle reliability. -

Torque Rating

– Definition: The amount of torque generated by the starter to turn the engine over, usually measured in Newton-meters (Nm).

– B2B Importance: A starter must produce adequate torque to start the engine efficiently, especially in larger or high-performance vehicles. Insufficient torque can lead to starting failures, impacting operational uptime and maintenance costs. -

Electrical Specifications

– Definition: Includes voltage rating, current draw, and resistance of the starter motor.

– B2B Importance: Ensuring that the starter’s electrical specifications match the vehicle’s requirements is critical. Mismatched specifications can lead to electrical failures, damage to the starter or battery, and increased operational costs. -

Dimensions and Weight

– Definition: Physical size and weight of the starter unit.

– B2B Importance: Accurate dimensions ensure proper fitment in the engine bay, while weight considerations can affect vehicle performance and handling. Buyers must confirm compatibility with their specific vehicle models. -

Lifecycle and Warranty

– Definition: Expected operational lifespan and warranty period provided by the manufacturer.

– B2B Importance: A longer lifecycle and robust warranty indicate a manufacturer’s confidence in their product. This information aids buyers in making informed decisions and can reduce future replacement costs. -

Compliance Standards

– Definition: Certifications and standards met by the starter, such as ISO or SAE standards.

– B2B Importance: Compliance with recognized standards ensures that the starter meets safety and performance benchmarks. This can be a deciding factor for buyers looking for reliability and assurance in their purchases.

What Are Common Trade Terms Related to Starter Purchases?

Understanding industry jargon can streamline communication and negotiation processes when purchasing starters. Here are essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to parts made by the original manufacturer of the vehicle.

– Importance: OEM parts are generally preferred for their guaranteed compatibility and reliability, making them a common choice for businesses seeking quality replacements. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their inventory and manage cash flow. Understanding this can prevent over-ordering or stock shortages. -

RFQ (Request for Quotation)

– Definition: A formal process for soliciting price quotes from suppliers for specific products.

– Importance: Submitting an RFQ allows businesses to compare pricing, terms, and conditions from multiple suppliers, facilitating better decision-making. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is essential for B2B transactions, as they clarify shipping responsibilities, risks, and costs, which can significantly impact pricing. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Importance: Understanding lead times helps businesses plan their operations and inventory management effectively, minimizing disruptions caused by delays. -

Aftermarket

– Definition: Refers to parts and accessories not made by the OEM but available for sale.

– Importance: The aftermarket can offer cost-effective alternatives to OEM parts, and understanding this can help buyers find suitable options that meet their budgetary constraints without sacrificing quality.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing new starters, ensuring they meet their operational needs while optimizing costs.

Navigating Market Dynamics and Sourcing Trends in the how much is a new starter Sector

What Are the Current Market Dynamics for New Starters?

The market for automotive starters is undergoing significant transformation, driven by several global factors. Increasing vehicle ownership in emerging markets such as Nigeria and Brazil is propelling demand for reliable starter systems. Additionally, the rise in electric vehicles (EVs) is reshaping traditional starter requirements, as EVs utilize different starting mechanisms compared to internal combustion engines. International B2B buyers must navigate this evolving landscape by understanding both the traditional and emerging technologies related to starters.

Key trends include the digitalization of the sourcing process, where B2B platforms enable buyers to compare prices and specifications from various suppliers quickly. This trend is particularly relevant for buyers in Europe and the Middle East, who seek efficiency and transparency in procurement. Moreover, the integration of artificial intelligence in inventory management is allowing suppliers to predict demand more accurately, reducing lead times and optimizing stock levels. For instance, sourcing starters for popular vehicle models can now be done through automated systems that provide real-time data, ensuring that buyers have access to the most current pricing and availability.

How Does Sustainability Impact the Sourcing of Starters?

The shift toward sustainability is increasingly influencing the sourcing of automotive components, including starters. Environmental concerns regarding waste management and resource depletion are prompting manufacturers to adopt eco-friendly practices. B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable sourcing, which may include the use of recyclable materials and energy-efficient manufacturing processes.

Illustrative image related to how much is a new starter

Ethical supply chains are becoming a critical criterion for international buyers. Companies that can provide certifications such as ISO 14001 for environmental management or other green credentials are more likely to gain trust from buyers focused on sustainability. Furthermore, transparency in sourcing practices, including the traceability of materials used in starter production, is becoming essential. By aligning with suppliers that adhere to these principles, businesses can enhance their brand reputation and meet the growing consumer demand for environmentally responsible products.

What Is the Historical Context of Starter Systems?

The evolution of starter systems has been marked by significant technological advancements. Early vehicles relied on manual cranking, which was labor-intensive and impractical. The introduction of the electric starter motor in the early 20th century revolutionized vehicle operation, making it more accessible and efficient. Over the decades, advancements in materials and engineering have led to the development of more reliable and compact starter systems.

Today, the focus is shifting towards integrating smart technologies within starters, such as sensors that communicate with the vehicle’s diagnostic systems. This evolution reflects broader trends in the automotive industry, where connectivity and automation are becoming increasingly important. For B2B buyers, understanding this historical context is vital for making informed sourcing decisions that align with current and future market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of how much is a new starter

-

How do I determine the cost of a new starter for my vehicle?

The cost of a new starter can vary significantly based on factors such as the vehicle’s make, model, and year. Typically, you can expect to pay between $80 to $350 for a new starter itself. Additional costs arise from labor if you choose to have a professional install it, which can range from $150 to over $1,100 depending on accessibility and complexity. It’s advisable to consult local suppliers or online platforms for specific pricing based on your vehicle’s specifications. -

What factors influence the price of a starter motor?

Several factors affect starter motor pricing, including the brand, quality, and whether it’s new or rebuilt. Specialty vehicles or luxury models often have higher costs due to the need for specialized parts and labor. Additionally, geographical location can influence prices due to shipping costs and local market conditions. Always consider the total cost of ownership, including potential installation fees and warranty options. -

Where can I source high-quality starters for international shipping?

To source quality starters for international shipping, consider reputable auto parts distributors or manufacturers with a strong global presence. Websites of established suppliers often feature detailed product specifications and customer reviews. Engaging with local distributors who have access to international markets can also be beneficial. Ensure they adhere to quality standards and offer warranties to safeguard your investment. -

What is the minimum order quantity (MOQ) for purchasing starters in bulk?

Minimum order quantities for starters can vary widely based on the supplier and the type of starter. Generally, MOQs may range from 10 to 100 units for bulk purchases. It’s essential to communicate with potential suppliers to negotiate terms that suit your purchasing needs while ensuring you meet their MOQ requirements. Some suppliers may offer flexibility for first-time buyers or for ongoing partnerships. -

What payment terms should I expect when sourcing starters internationally?

Payment terms for international orders can vary by supplier, but common arrangements include upfront payment, 30% deposit with the balance upon delivery, or net 30/60 days after invoice. It’s crucial to establish clear payment terms before finalizing your order to avoid misunderstandings. Always inquire about accepted payment methods, including wire transfers, letters of credit, or online payment systems, to ensure secure transactions. -

How do I vet suppliers for automotive starters?

Vetting suppliers involves reviewing their credentials, customer reviews, and industry reputation. Request certifications that demonstrate adherence to international quality standards, such as ISO certifications. Engaging in direct communication can also reveal their responsiveness and willingness to provide support. If possible, ask for references or case studies from other international buyers to assess their reliability and product quality. -

What quality assurance measures should I look for in starter motors?

When sourcing starter motors, ensure that suppliers implement stringent quality assurance measures. Look for details on testing protocols, warranty coverage, and compliance with international standards. Certifications such as ISO 9001 can indicate a commitment to quality management. Additionally, inquire about return policies and guarantees to safeguard against defective products. -

What logistics considerations should I keep in mind when ordering starters?

Logistics is crucial when ordering starters internationally. Consider shipping methods, lead times, and costs associated with customs duties and taxes. Ensure the supplier has experience in handling international shipments to mitigate delays. It’s also beneficial to discuss packaging to prevent damage during transit. Establishing a clear logistics plan will help streamline the ordering process and ensure timely delivery.

Top 6 How Much Is A New Starter Manufacturers & Suppliers List

1. Starter Replacement – Cost Breakdown

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Starter replacement, labor charges, diagnostics fees, OEM starter pricing, price variations by location, and potential markup on parts.

2. Starter Replacement – Cost Breakdown

Domain: lastchanceautorepairs.com

Registered: 2009 (16 years)

Introduction: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Average total cost ranges from $250 – $1,000+. Factors affecting cost include vehicle type, new vs remanufactured starters, and additional repairs. DIY costs: Parts only: $100 –…

3. Facebook – Auto Repair Costs

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: cost to get car to the shop and replace starter

4. CarParts.com – Quality Starters

Domain: carparts.com

Registered: 1999 (26 years)

Introduction: Car Starters – Standard, Reverse Rotation from $72 | CarParts.com. Wide selection of high-quality replacement starters, both new and remanufactured. Guaranteed to fit. Fast shipping and hassle-free returns. Ideal for replacing a bad starter that may cause engine issues.

5. Car Talk – Starter Replacement Costs

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: The cost to replace a starter typically ranges from $600 to $900 for common vehicles, and $900 to $1,400 for luxury models. The price varies based on the vehicle model and the accessibility of the starter. Symptoms of a failing starter include a clicking sound when attempting to start, a screeching noise, or intermittent functionality. Starters can be new, remanufactured, or repaired, with remanuf…

6. CarBuzz – Starter Motor Replacement Cost

Domain: carbuzz.com

Registered: 2003 (22 years)

Introduction: Starter motor replacement cost ranges from $450 to $600 on average, with specific models like the Toyota Tundra (2000-2005) costing between $650 and $900 due to complex installation. The Honda Civic’s replacement cost is estimated at $490 to $760. Factors affecting costs include labor time (1.5 to 2.5 hours for most starters, up to 4 hours for valley-mounted starters) and the type of starter (afte…

Strategic Sourcing Conclusion and Outlook for how much is a new starter

In summary, understanding the costs associated with a new starter is crucial for B2B buyers across diverse markets. The price range for starter replacements can vary significantly based on vehicle type, brand, and labor costs. A strategic sourcing approach allows businesses to evaluate the most cost-effective solutions while ensuring quality and reliability. By considering factors such as the vehicle’s make and model, accessibility of the starter, and potential need for specialized parts, buyers can make informed decisions that align with their operational budgets.

Illustrative image related to how much is a new starter

As you navigate the complexities of sourcing automotive components, it is essential to build relationships with reputable suppliers who can offer not only competitive pricing but also valuable insights into trends and best practices in the industry. Looking ahead, the automotive sector is poised for innovation, and staying ahead of these changes will be vital. We encourage international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to leverage strategic sourcing to enhance their procurement processes and drive efficiency. Embrace the opportunity to connect with trusted partners who can support your business’s growth and sustainability in a dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.