Introduction: Navigating the Global Market for how long does a alternator last in a car

In the competitive landscape of automotive parts, understanding how long an alternator lasts in a car is crucial for international B2B buyers. With varying quality standards and market conditions across regions such as Africa, South America, the Middle East, and Europe, sourcing reliable alternators can present significant challenges. This guide delves into the lifespan of alternators, typically averaging around seven years or 150,000 miles, while highlighting critical factors that influence their durability, including vehicle usage, quality of parts, and maintenance practices.

Furthermore, we explore the types of alternators available, their applications across different vehicle models, and essential tips for supplier vetting. Buyers will gain insights into evaluating cost versus quality, ensuring that they make informed purchasing decisions that align with their operational needs. By addressing common issues such as identifying signs of alternator failure and understanding maintenance best practices, this guide equips B2B buyers with the knowledge to mitigate risks and enhance vehicle reliability.

Whether you’re a distributor looking to stock high-quality parts or a fleet manager seeking long-lasting solutions, this comprehensive resource empowers you to navigate the complexities of the global alternator market effectively. With actionable insights tailored for diverse regional contexts, you can optimize your procurement strategies and ultimately improve your bottom line.

Table Of Contents

- Top 3 How Long Does A Alternator Last In A Car Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long does a alternator last in a car

- Understanding how long does a alternator last in a car Types and Variations

- Key Industrial Applications of how long does a alternator last in a car

- 3 Common User Pain Points for ‘how long does a alternator last in a car’ & Their Solutions

- Strategic Material Selection Guide for how long does a alternator last in a car

- In-depth Look: Manufacturing Processes and Quality Assurance for how long does a alternator last in a car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does a alternator last in a car’

- Comprehensive Cost and Pricing Analysis for how long does a alternator last in a car Sourcing

- Alternatives Analysis: Comparing how long does a alternator last in a car With Other Solutions

- Essential Technical Properties and Trade Terminology for how long does a alternator last in a car

- Navigating Market Dynamics and Sourcing Trends in the how long does a alternator last in a car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long does a alternator last in a car

- Strategic Sourcing Conclusion and Outlook for how long does a alternator last in a car

- Important Disclaimer & Terms of Use

Understanding how long does a alternator last in a car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternator | Average lifespan of 5-7 years or 100,000-150,000 miles | General automotive repairs | Pros: Affordable, widely available. Cons: May require early replacement under heavy use. |

| High-Performance Alternator | Designed for increased power output and durability | Performance vehicles, racing | Pros: Enhanced performance, longer lifespan. Cons: Higher cost, may need specialized installation. |

| Remanufactured Alternator | Rebuilt from used parts, offering a cost-effective alternative | Budget-conscious repairs | Pros: Lower price, eco-friendly. Cons: Variable quality, shorter lifespan compared to new. |

| OEM Alternator | Original Equipment Manufacturer parts, matching factory specs | Fleet management, commercial vehicles | Pros: Guaranteed compatibility, reliability. Cons: Premium pricing, limited availability. |

| Heavy-Duty Alternator | Built to withstand extreme conditions and heavy loads | Trucks, construction vehicles | Pros: Robust design, longer lifespan in tough environments. Cons: Heavier, higher initial investment. |

What Are the Characteristics of Standard Alternators?

Standard alternators typically have a lifespan of 5-7 years or approximately 100,000-150,000 miles, making them suitable for everyday vehicles. They are commonly used in passenger cars and light-duty trucks. When purchasing standard alternators, B2B buyers should consider factors such as warranty terms and compatibility with various vehicle models. While they offer a cost-effective solution, their longevity can be compromised in vehicles with high electronic demands.

How Do High-Performance Alternators Differ?

High-performance alternators are engineered for enhanced power output and durability, making them ideal for performance vehicles and racing applications. These alternators can handle increased electrical loads, which is crucial for vehicles with numerous electronic components. B2B buyers should assess the specific power requirements of their vehicles when considering these alternators. Although they come at a higher price point, their longevity and reliability in demanding conditions can justify the investment.

What Should Buyers Know About Remanufactured Alternators?

Remanufactured alternators offer a budget-friendly option for businesses looking to minimize costs. These units are rebuilt from used parts, providing a more affordable alternative to new components. However, B2B buyers must be cautious about the quality of remanufactured parts, as they can vary significantly. It’s essential to source from reputable suppliers who guarantee performance and offer warranties. While they are eco-friendly, their lifespan may be shorter than that of new alternators.

Why Choose OEM Alternators for Fleet Management?

OEM alternators are manufactured to meet the exact specifications of vehicle manufacturers, ensuring compatibility and reliability. They are particularly advantageous for fleet management and commercial vehicles where uptime is critical. B2B buyers should consider the long-term benefits of investing in OEM parts, such as reduced maintenance costs and extended vehicle life. However, the premium price may be a deterrent for some businesses.

What Are the Advantages of Heavy-Duty Alternators?

Heavy-duty alternators are specifically designed to endure extreme conditions and heavy loads, making them perfect for trucks and construction vehicles. These units often feature enhanced cooling systems and robust construction to withstand demanding environments. When purchasing heavy-duty alternators, B2B buyers should evaluate the operational requirements of their vehicles and consider the higher initial investment as a long-term cost-saving measure due to reduced maintenance and replacement frequency.

Key Industrial Applications of how long does a alternator last in a car

| Industry/Sector | Specific Application of how long does a alternator last in a car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Quality control in alternator production | Ensures reliability and longevity of vehicles, reducing warranty claims | Sourcing high-quality materials and components for durability |

| Fleet Management | Scheduling maintenance based on alternator lifespan | Minimizes downtime and maximizes fleet efficiency | Understanding regional driving conditions and usage patterns |

| Automotive Repair Shops | Customer service through alternator diagnostics | Builds trust with customers by providing timely and accurate repairs | Access to diagnostic tools and replacement parts availability |

| Export and Trade | Importing alternators for local markets | Expands product offerings and meets local demand for reliable vehicles | Compliance with local regulations and standards for imports |

| Renewable Energy Vehicles | Integration of alternators in electric vehicle systems | Supports the transition to sustainable energy solutions | Evaluating compatibility with existing electric systems |

How is the Lifespan of an Alternator Relevant to Automotive Manufacturing?

In the automotive manufacturing sector, understanding the lifespan of an alternator is crucial for quality control. Manufacturers can ensure that their vehicles are equipped with reliable components, ultimately reducing warranty claims and enhancing customer satisfaction. For international buyers, particularly in regions like Africa and South America, the sourcing of high-quality materials and components is essential to meet the demands of local markets. This ensures that vehicles can withstand varying environmental conditions and usage patterns.

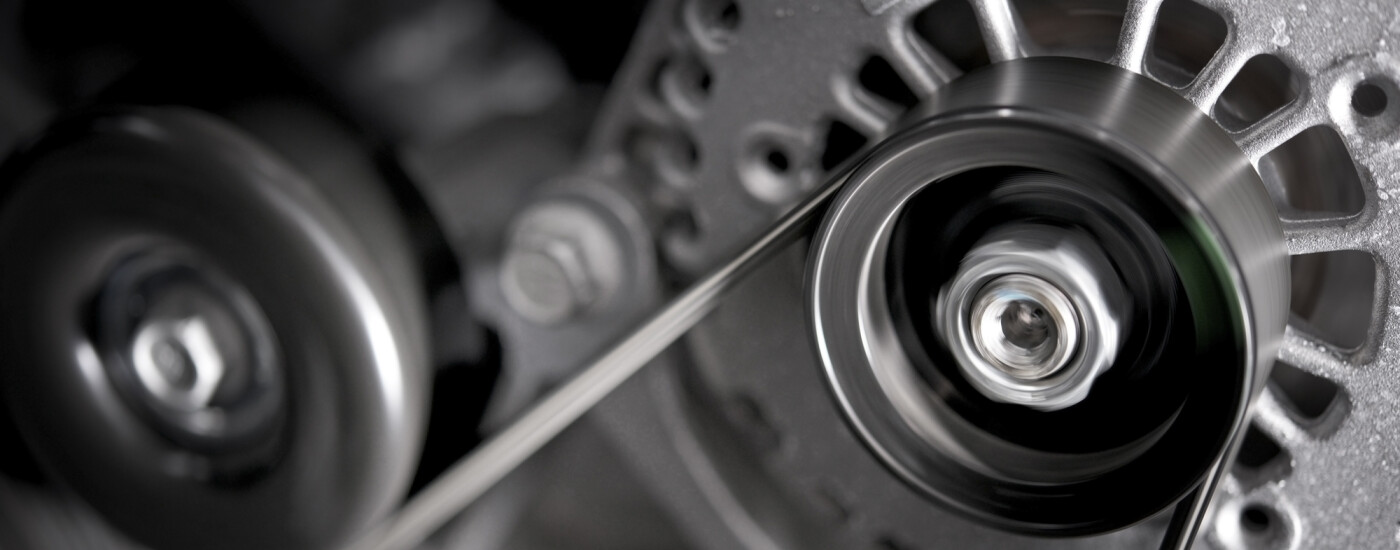

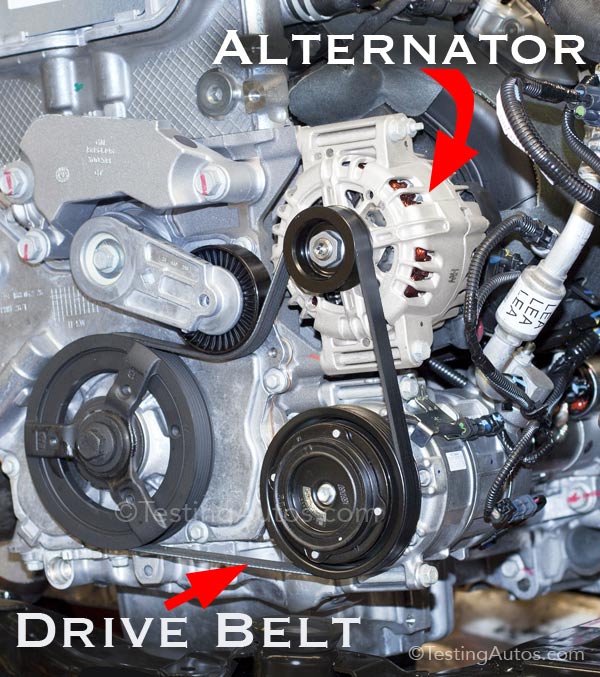

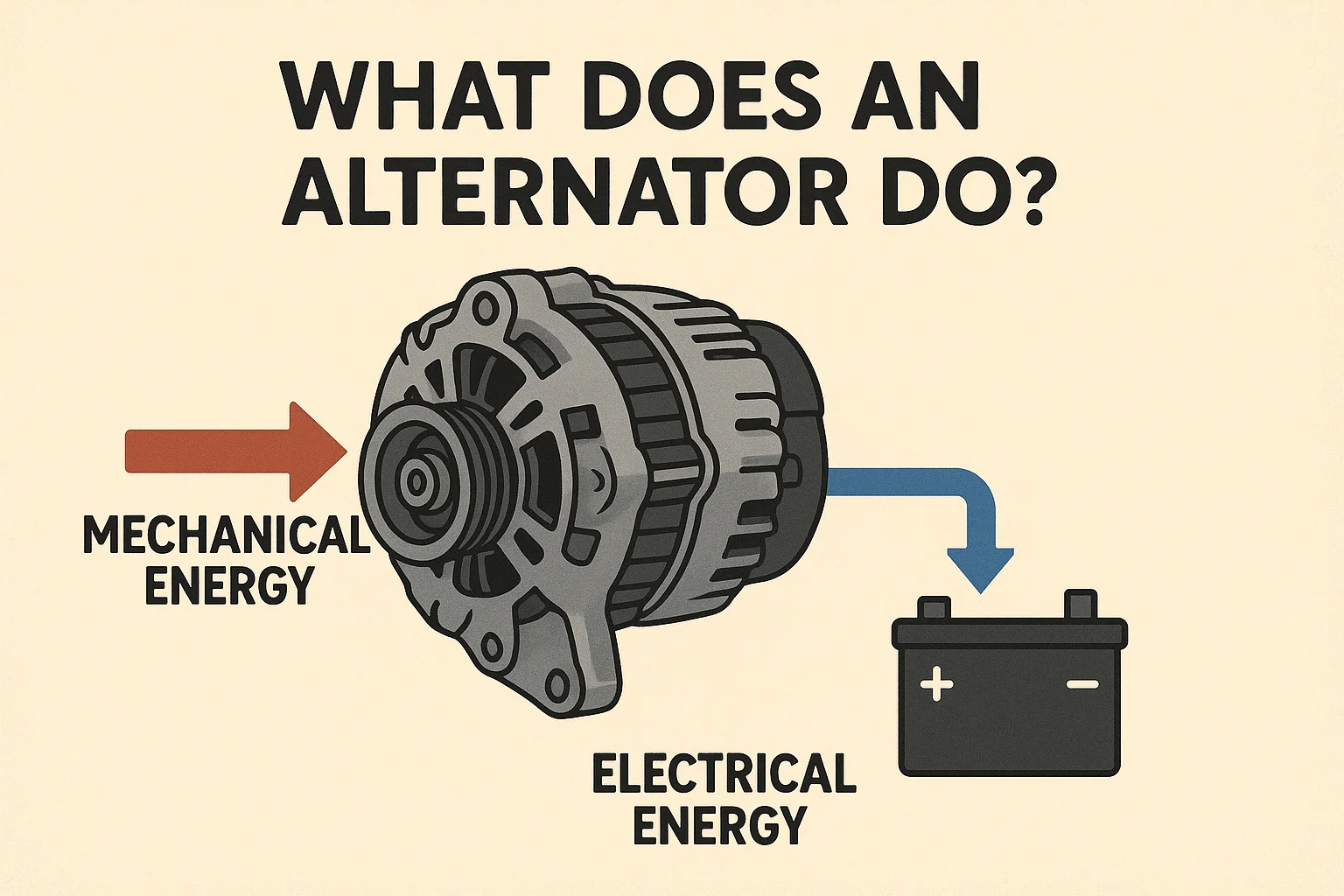

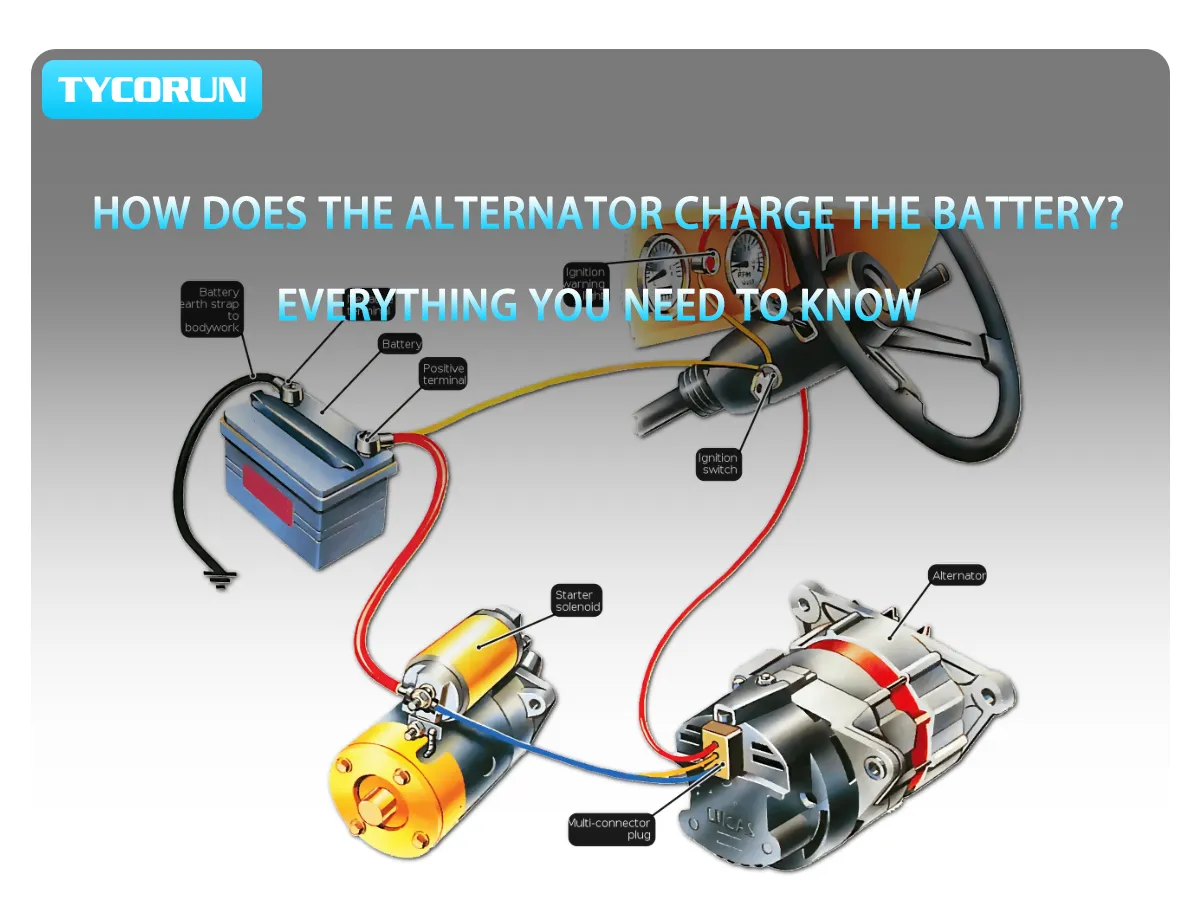

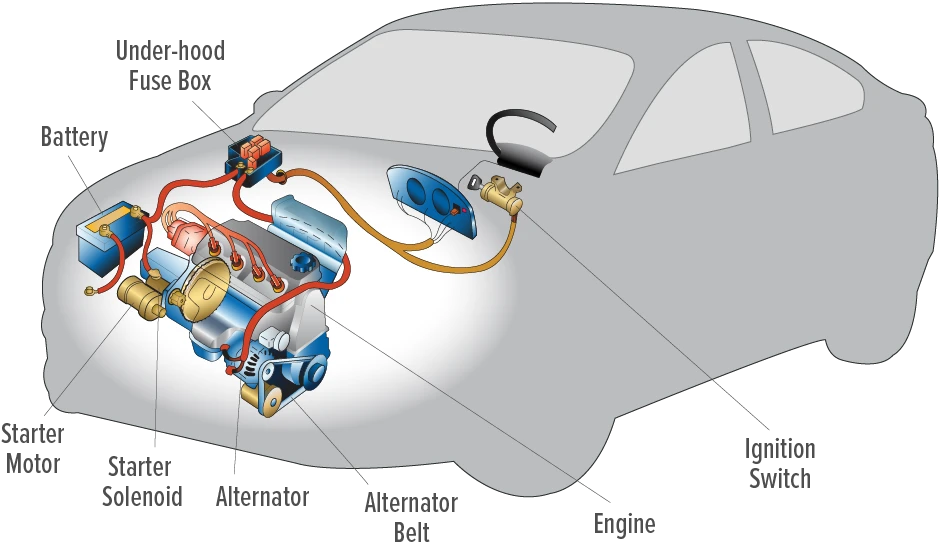

Illustrative image related to how long does a alternator last in a car

Why is Alternator Lifespan Critical for Fleet Management?

Fleet management companies can leverage knowledge of alternator lifespan to schedule proactive maintenance, thereby minimizing vehicle downtime and maximizing operational efficiency. By understanding the average lifespan of alternators, fleet managers can implement timely inspections and replacements, ensuring that their vehicles remain operational. For buyers in the Middle East and Europe, it’s vital to consider regional driving conditions, which can significantly affect the longevity of alternators. This insight aids in the selection of appropriate replacement parts and maintenance practices.

How Do Automotive Repair Shops Benefit from Alternator Diagnostics?

Automotive repair shops can enhance their customer service by offering thorough diagnostics related to alternator health. Recognizing the signs of alternator failure allows mechanics to provide timely and accurate repairs, fostering trust and repeat business. For B2B buyers in the automotive repair industry, access to advanced diagnostic tools and a steady supply of quality replacement parts are key considerations. This ensures that shops can effectively address alternator issues, ultimately improving customer satisfaction and retention.

What are the Challenges in Exporting Alternators for Local Markets?

For businesses involved in the export and trade of alternators, understanding local market demands is essential. By importing alternators that meet the expected lifespan and reliability, companies can expand their product offerings to cater to local consumers. Compliance with local regulations and standards is a critical factor for success in this arena, especially in diverse markets across Africa and Brazil. Buyers must be well-informed about these regulations to ensure smooth import processes and market acceptance.

How Does Knowledge of Alternator Lifespan Impact Renewable Energy Vehicles?

In the growing sector of renewable energy vehicles, integrating reliable alternators into electric systems is vital for performance and sustainability. Understanding how long alternators last helps manufacturers design systems that are both efficient and durable. International buyers focused on this market must evaluate the compatibility of alternators with existing electric systems to optimize performance. This consideration not only supports the transition to sustainable energy solutions but also aligns with global trends toward greener technologies.

3 Common User Pain Points for ‘how long does a alternator last in a car’ & Their Solutions

Scenario 1: Unexpected Vehicle Downtime and Its Cost Implications

The Problem:

B2B buyers, particularly fleet managers and automotive distributors, often face the unexpected challenge of vehicle downtime due to alternator failure. This situation not only results in immediate repair costs but can also lead to significant disruptions in operations, affecting deliveries and customer service. For instance, if a delivery vehicle suddenly fails because of a faulty alternator, it can delay shipments, frustrate clients, and ultimately damage the company’s reputation. Understanding how long an alternator typically lasts—around seven years or 150,000 miles—can help these buyers anticipate maintenance needs and budget accordingly.

The Solution:

To mitigate the risk of unexpected alternator failure, B2B buyers should implement a proactive maintenance schedule that includes regular inspections of the alternator’s condition. Establish partnerships with reliable automotive service providers who can perform routine checks and recommend replacements before failure occurs. Additionally, investing in quality alternators from reputable suppliers can improve longevity and performance. Keeping detailed maintenance records for each vehicle will allow fleet managers to track usage patterns and anticipate when an alternator is likely to need replacement, thereby minimizing operational disruptions.

Scenario 2: Difficulty in Sourcing Quality Alternators

The Problem:

B2B buyers, especially those in regions like Africa or South America, may struggle with sourcing high-quality alternators due to limited availability and the prevalence of counterfeit parts. This can lead to the purchase of substandard products that fail prematurely, causing further complications in the supply chain and increasing overall costs. Buyers may find it challenging to determine the lifespan of an alternator or the right specifications needed for various vehicle models, which can lead to poor purchasing decisions.

The Solution:

To address sourcing challenges, B2B buyers should establish relationships with certified manufacturers and distributors known for quality products. Utilize online platforms and industry networks to research and connect with reputable suppliers who provide warranties and after-sales support. Buyers should also familiarize themselves with the specifications and lifespan of alternators that fit their fleet’s vehicles. Conducting thorough market research and leveraging peer recommendations can significantly enhance sourcing efficiency and ensure the longevity of purchased alternators.

Scenario 3: Misdiagnosis of Electrical Issues

The Problem:

Another common pain point for B2B buyers is the misdiagnosis of electrical problems attributed to alternators. When vehicles exhibit symptoms such as dimming lights or difficulty starting, there is a tendency to jump to conclusions about the alternator’s condition. This can lead to unnecessary replacement costs and prolong downtime as vehicles may still have unresolved electrical issues. Misdiagnosis can arise from a lack of technical expertise or inadequate diagnostic tools, particularly in regions where access to advanced automotive technology is limited.

Illustrative image related to how long does a alternator last in a car

The Solution:

B2B buyers should invest in comprehensive training for their maintenance teams to accurately diagnose electrical issues. Providing access to diagnostic tools and software can help technicians determine whether the alternator or another component is at fault. Regular training sessions and workshops with automotive experts can empower staff with the knowledge necessary to make informed decisions. Additionally, establishing a protocol for comprehensive vehicle inspections before concluding that an alternator needs replacement can prevent unnecessary costs and ensure the reliability of the fleet.

Strategic Material Selection Guide for how long does a alternator last in a car

When considering the longevity of an alternator in a vehicle, the materials used in its construction play a critical role in determining performance, durability, and overall lifespan. Below is an analysis of common materials utilized in the manufacturing of alternators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

What Are the Common Materials Used in Alternators?

1. Aluminum

Key Properties:

Aluminum is lightweight, has excellent corrosion resistance, and can withstand moderate temperatures. Its thermal conductivity allows for efficient heat dissipation, which is crucial for alternator performance.

Pros & Cons:

The primary advantage of aluminum is its low weight, which contributes to better fuel efficiency in vehicles. It is also relatively easy to manufacture and form into complex shapes. However, aluminum can be less durable than other materials, particularly under high-stress conditions, and can be more expensive than steel.

Illustrative image related to how long does a alternator last in a car

Impact on Application:

Aluminum’s corrosion resistance makes it suitable for use in various environments, including coastal areas where saltwater exposure is a concern. However, it may not perform as well in extremely high-temperature applications.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and JIS for aluminum quality. In regions like Nigeria and Brazil, local sourcing may affect costs and availability.

2. Steel

Key Properties:

Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons:

The primary advantage of steel is its strength and longevity, which translates to a longer lifespan for the alternator. However, steel is heavier than aluminum, which may negatively impact vehicle efficiency. Additionally, it is more susceptible to corrosion unless treated or coated.

Impact on Application:

Steel is ideal for applications requiring high strength and durability, such as in commercial vehicles or in regions with rough terrain. Its weight can be a drawback in passenger vehicles where fuel efficiency is a priority.

Considerations for International Buyers:

Steel must comply with various international standards, and buyers should consider the availability of treated steel options to enhance corrosion resistance, especially in humid or coastal regions.

3. Copper

Key Properties:

Copper has excellent electrical conductivity and thermal properties, making it ideal for use in electrical components like alternators. It is also resistant to corrosion and has a high melting point.

Pros & Cons:

The main advantage of copper is its superior conductivity, which enhances the efficiency of the alternator. However, copper is more expensive than aluminum and steel, which can increase the overall cost of the alternator.

Impact on Application:

Copper’s conductivity is crucial for the effective charging of the vehicle’s battery and powering its electrical systems. However, its cost may limit its use in lower-end models.

Considerations for International Buyers:

Buyers should be aware of the fluctuating prices of copper in global markets, which can impact procurement strategies. Compliance with electrical standards is also essential.

4. Plastic Composites

Key Properties:

Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They can also provide thermal insulation.

Pros & Cons:

The primary advantage of plastic composites is their weight reduction, which can improve vehicle efficiency. However, they may not be as durable as metal alternatives and can be susceptible to damage from high temperatures.

Impact on Application:

Plastic composites are suitable for non-structural components of the alternator, such as housings or covers. Their use can reduce overall weight but may compromise durability in high-stress environments.

Considerations for International Buyers:

Buyers should ensure that plastic composites meet relevant standards for automotive applications, particularly in regions with varying climate conditions that may affect material performance.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for how long does a alternator last in a car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight alternator housings and components | Excellent corrosion resistance | Less durable under high stress | Medium |

| Steel | Heavy-duty alternators for commercial vehicles | High tensile strength | Heavier, prone to corrosion | Medium |

| Copper | Electrical windings and connectors | Superior electrical conductivity | Higher cost | High |

| Plastic Composites | Non-structural components like covers | Lightweight and corrosion-resistant | Less durable, temperature sensitive | Low |

This analysis provides a comprehensive overview of the materials involved in alternator production, offering valuable insights for B2B buyers in diverse international markets. Understanding these materials will aid in making informed purchasing decisions that align with performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how long does a alternator last in a car

What Are the Key Stages of the Manufacturing Process for Car Alternators?

Understanding the manufacturing process of alternators is essential for B2B buyers, as it directly impacts product quality, longevity, and performance. The production of alternators typically involves several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to how long does a alternator last in a car

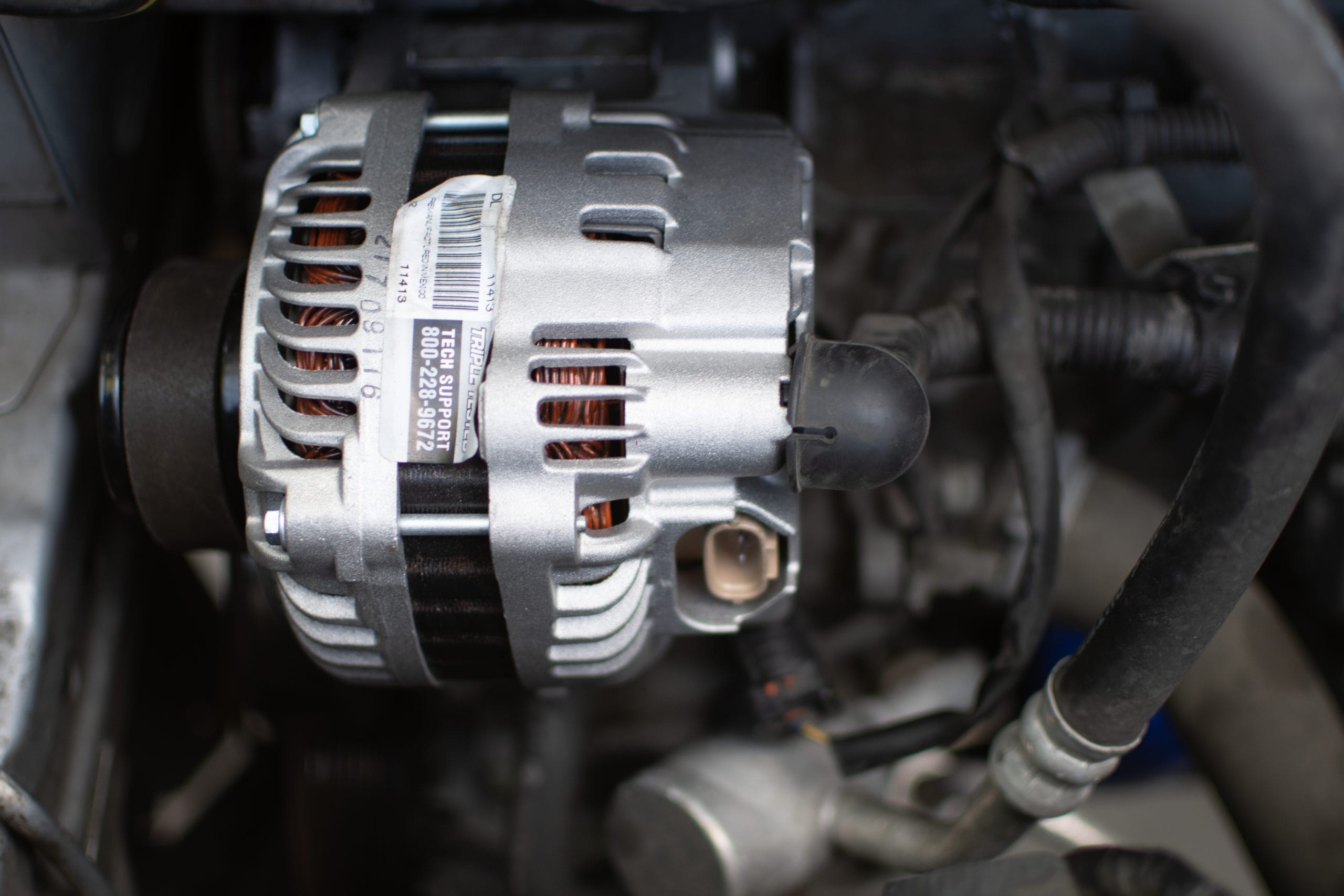

How Is Material Prepared for Car Alternators?

The first stage in the manufacturing process involves selecting and preparing high-quality materials. Common materials include aluminum for the housing, copper for the windings, and various types of steel for internal components. These materials must meet specific standards for durability and conductivity to ensure optimal performance.

Material preparation includes processes such as cutting, machining, and treating the metals to enhance their properties. For example, aluminum parts may undergo anodizing to improve corrosion resistance, while copper windings are often insulated with high-temperature enamel.

What Forming Techniques Are Used in Alternator Production?

After material preparation, the forming stage shapes these materials into the necessary components. Techniques such as die casting, stamping, and machining are commonly employed.

Illustrative image related to how long does a alternator last in a car

- Die Casting: This method is often used for the aluminum housing, allowing for precise dimensions and a smooth finish, which is crucial for effective heat dissipation.

- Stamping: Steel components are stamped from sheets, ensuring uniformity and reducing waste.

- Machining: CNC machines are frequently utilized to achieve high precision in critical parts like the rotor and stator, where even minor discrepancies can affect performance.

How Is the Assembly Process Conducted for Alternators?

Once the components are formed, they move to the assembly stage. This stage is critical as it combines individual parts into a fully functional alternator.

During assembly, components such as the rotor, stator, voltage regulator, and rectifier are meticulously fitted together. Automated assembly lines are often employed to ensure consistency and efficiency, but skilled technicians also play a vital role in quality control during this stage. Proper alignment and secure fastening are paramount to prevent issues like vibration and mechanical failure during operation.

What Finishing Techniques Are Applied to Enhance Alternator Quality?

The finishing stage involves processes that enhance the alternator’s performance and durability. This may include:

- Coating: Protective coatings are applied to various components to prevent corrosion and wear.

- Balancing: Rotors are dynamically balanced to minimize vibrations, which can lead to premature wear and noise.

- Final Inspection: Each alternator undergoes a comprehensive visual and functional inspection to ensure it meets all specifications before packaging.

How Is Quality Assurance Integrated into the Manufacturing of Alternators?

Quality assurance (QA) is a critical component of alternator manufacturing, ensuring that products meet both international standards and customer expectations.

What Are the Relevant International Standards for Alternator Manufacturing?

For B2B buyers, understanding the applicable international quality standards is crucial. ISO 9001 is one of the most recognized standards, focusing on quality management systems. Compliance with ISO 9001 ensures that manufacturers maintain consistent quality across their processes.

Illustrative image related to how long does a alternator last in a car

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for oil and gas applications may also be relevant. These certifications demonstrate compliance with safety and performance requirements specific to the automotive industry.

What Quality Control Checkpoints Are Common in Alternator Production?

Quality control in alternator manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Ensuring that materials meet specifications prevents defects later in the process.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular checks are performed to monitor critical parameters, such as dimensions and assembly integrity. This proactive approach helps catch defects early.

-

Final Quality Control (FQC): Before the alternators are shipped, a comprehensive inspection is conducted. This includes functional testing to ensure the alternators perform correctly under load, as well as checking for visual defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to ensure the quality of alternators should take several steps to verify supplier quality control practices:

-

Supplier Audits: Conducting regular audits of potential suppliers can help assess their adherence to quality standards. This includes reviewing their QA processes, equipment, and staff qualifications.

-

Quality Reports: Requesting detailed quality reports can provide insight into a supplier’s performance history and any past issues they may have encountered.

-

Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased evaluation of the manufacturing process and the final product quality.

What Are the Unique Quality Control Challenges for International B2B Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, there are several nuances in quality control that should be considered:

-

Regulatory Compliance: Different regions may have varying regulatory requirements for automotive components. B2B buyers must ensure that their suppliers are compliant with local regulations to avoid legal issues.

-

Cultural Differences: Understanding cultural practices in manufacturing and quality assurance can be beneficial. Communication styles and business practices vary by region, impacting how quality is prioritized and managed.

-

Logistical Considerations: The transportation of alternators across borders can introduce risks of damage. Proper packaging and handling procedures are vital to maintain product integrity during transit.

Conclusion: Ensuring Longevity and Reliability in Alternators

In summary, understanding the manufacturing processes and quality assurance measures in the production of alternators is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and robust quality control practices, businesses can ensure they source reliable and long-lasting alternators. Engaging in thorough supplier evaluations, audits, and inspections will further enhance the likelihood of successful partnerships and high-quality products that meet the demanding needs of the automotive industry.

Illustrative image related to how long does a alternator last in a car

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does a alternator last in a car’

Introduction

This practical sourcing guide is designed to assist B2B buyers in understanding the lifespan of automotive alternators and the key considerations when procuring them. Knowing how long an alternator lasts and the factors affecting its longevity is crucial for making informed purchasing decisions. This checklist will help you evaluate suppliers, assess product quality, and ensure optimal performance for your automotive needs.

Step 1: Understand the Average Lifespan of Alternators

Before sourcing alternators, familiarize yourself with their average lifespan, which is typically around seven years or 150,000 miles. This knowledge will help you set realistic expectations for your procurement strategy. Consider the operating conditions in your region, as extreme temperatures and driving habits can significantly influence the longevity of alternators.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications required for your alternators. This includes factors such as voltage output, amperage, and compatibility with specific vehicle models. Precise specifications will help streamline the sourcing process and ensure that you receive products that meet your operational needs.

- Voltage Requirements: Identify the voltage required for your applications to avoid compatibility issues.

- Amperage Needs: Determine the amperage based on the electrical load of the vehicles you operate.

Step 3: Evaluate Supplier Certifications

When sourcing alternators, it’s essential to verify supplier certifications. Look for suppliers that comply with international quality standards, such as ISO 9001. Certification ensures that the supplier adheres to stringent quality control processes, which is critical for reliable product performance.

Illustrative image related to how long does a alternator last in a car

- Quality Assurance: Certified suppliers often have better quality assurance practices in place.

- Regulatory Compliance: Ensure that the products meet local regulations, especially in regions with strict automotive standards.

Step 4: Assess Product Quality and Warranty Options

Investigate the quality of the alternators offered by potential suppliers. High-quality alternators will have robust construction and reliable performance. Additionally, inquire about warranty options, as a solid warranty can provide peace of mind and protect your investment.

- Material Durability: Look for alternators made from high-quality materials to enhance longevity.

- Warranty Coverage: A longer warranty period indicates the manufacturer’s confidence in their product.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the alternators to evaluate their performance. Testing samples allows you to assess compatibility, reliability, and overall quality in real-world conditions. This step is crucial to avoid costly mistakes in procurement.

- Performance Testing: Check for consistent voltage output and durability under load.

- Fitment Check: Ensure that the alternator fits the intended vehicle models without modifications.

Step 6: Review Customer Feedback and Case Studies

Examine customer feedback and case studies from previous buyers who have sourced from your potential suppliers. This information can provide valuable insights into the reliability and performance of the alternators, as well as the supplier’s responsiveness and service quality.

- User Reviews: Look for patterns in feedback to gauge overall satisfaction.

- Success Stories: Case studies can illustrate how the alternators performed in similar applications.

Step 7: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms and conditions to ensure a mutually beneficial agreement. Discuss pricing, delivery timelines, and after-sales support. Clear agreements can prevent misunderstandings and ensure a smooth procurement process.

Illustrative image related to how long does a alternator last in a car

- Payment Terms: Clarify payment schedules to align with your cash flow.

- Delivery Expectations: Set realistic timelines for delivery to avoid operational disruptions.

By following this checklist, B2B buyers can effectively source high-quality alternators that meet their operational needs while ensuring longevity and reliability in vehicle performance.

Comprehensive Cost and Pricing Analysis for how long does a alternator last in a car Sourcing

What Are the Key Cost Components in Sourcing Alternators for Cars?

When sourcing alternators, several cost components contribute to the overall price structure. The primary elements include:

-

Materials: The raw materials used, such as copper, aluminum, and various plastics, significantly influence costs. High-quality materials enhance durability and efficiency but may increase the base price.

-

Labor: Labor costs vary by region and manufacturing complexity. Skilled technicians are required for assembly and quality checks, impacting overall labor expenses.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead and lower prices.

-

Tooling: Initial costs for tooling and machinery can be high, especially for custom alternators. These costs are amortized over production runs, affecting the unit price.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but adds to costs. International standards and certifications can further influence pricing.

-

Logistics: Shipping and handling costs vary based on the distance from manufacturing facilities to buyers. The choice of transportation method (air, sea, or land) also affects logistics expenses.

-

Margin: Suppliers typically add a margin for profit, which varies based on market demand, competition, and economic conditions.

How Do Price Influencers Affect Alternator Costs?

Several factors can influence the pricing of alternators:

-

Volume/MOQ: Purchasing in bulk can significantly reduce the per-unit cost. Many suppliers offer tiered pricing based on minimum order quantities (MOQs).

-

Specifications and Customization: Custom alternators designed for specific vehicles or applications may incur additional costs. Standardized models usually provide better pricing.

-

Materials Quality and Certifications: Alternators built with high-grade materials or those that meet specific industry certifications may command higher prices. Buyers should assess their needs for quality versus cost.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers might offer premium pricing due to their proven quality, while newer entrants may provide competitive rates.

-

Incoterms: The agreed-upon delivery terms can affect the total cost. Understanding Incoterms helps buyers anticipate additional charges related to shipping and customs.

What Buyer Tips Can Help in Sourcing Alternators Cost-Effectively?

International B2B buyers should consider several strategies to enhance cost-efficiency when sourcing alternators:

Illustrative image related to how long does a alternator last in a car

-

Negotiate Effectively: Understanding market trends and competitor pricing can empower buyers during negotiations. Leverage volume purchasing to secure better deals.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, consider maintenance, replacement frequency, and warranty terms. A slightly higher upfront cost might lead to lower long-term expenses.

-

Understand Pricing Nuances for International Markets: Different regions have varying pricing structures due to labor, regulations, and market demand. For instance, prices in Europe may differ significantly from those in Africa or South America.

-

Assess Currency Fluctuations: When dealing with international suppliers, be aware of currency exchange rates, as they can impact the final cost of alternators.

-

Leverage Local Suppliers: In regions like Nigeria or Brazil, sourcing from local manufacturers can reduce logistics costs and enhance supply chain reliability.

Disclaimer on Pricing Variability

Prices for alternators can fluctuate based on market dynamics, economic conditions, and supply chain factors. This analysis serves as a guideline and should not be considered as fixed pricing. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they achieve the best value for their specific needs.

Alternatives Analysis: Comparing how long does a alternator last in a car With Other Solutions

Exploring Alternatives to Traditional Alternators in Automotive Applications

As automotive technology evolves, various solutions have emerged to power vehicle electrical systems. While traditional alternators have a lifespan of about seven years or 150,000 miles, businesses looking to optimize vehicle performance may explore alternative technologies that serve similar purposes. Understanding the differences between these options can help B2B buyers make informed decisions tailored to their operational needs.

| Comparison Aspect | How Long Does An Alternator Last In A Car | Lithium-Ion Battery Systems | Solar-Powered Charging Systems |

|---|---|---|---|

| Performance | Reliable for standard vehicle needs | High energy density, fast charging | Limited by sunlight availability |

| Cost | Moderate initial cost, replacement needed | Higher upfront cost, longer life | Variable costs, depends on installation |

| Ease of Implementation | Standard installation in most vehicles | Requires compatible system integration | Requires solar panel installation and battery management |

| Maintenance | Regular checks needed, typically low | Low maintenance, but monitoring is essential | Requires panel cleaning and battery checks |

| Best Use Case | General automotive applications | Electric vehicles, hybrid systems | Eco-friendly options, off-grid vehicles |

In-Depth Analysis of Alternative Solutions

Lithium-Ion Battery Systems

Lithium-ion battery systems have gained popularity in electric and hybrid vehicles due to their high energy density and efficient power management. These systems offer fast charging capabilities and a lifespan that can exceed a decade with proper maintenance. However, the initial investment can be significantly higher than traditional alternators. Additionally, compatibility with existing vehicle systems can pose challenges during installation. Businesses looking to invest in electric fleets may find lithium-ion systems beneficial in the long run, as they reduce reliance on fossil fuels and lower overall operational costs.

Solar-Powered Charging Systems

Solar-powered charging systems represent a sustainable alternative, especially for vehicles used in remote or off-grid locations. These systems harness solar energy to charge the vehicle’s batteries, reducing dependence on conventional power sources. However, their performance is heavily dependent on sunlight availability, making them less reliable in regions with limited sunlight. While the installation costs can vary, the long-term savings on energy consumption can be substantial. Companies focused on eco-friendly solutions and sustainability may find solar charging systems align well with their corporate values.

Making the Right Choice for Your Business Needs

When evaluating options for vehicle electrical systems, B2B buyers should consider multiple factors, including performance, cost, ease of implementation, and maintenance requirements. While traditional alternators are reliable and cost-effective for standard applications, alternatives like lithium-ion battery systems and solar-powered charging may offer enhanced performance and sustainability for specific use cases. Ultimately, the right choice will depend on the operational goals, budget constraints, and environmental considerations of the business. By carefully assessing these factors, companies can optimize their vehicle performance and align with their strategic objectives.

Essential Technical Properties and Trade Terminology for how long does a alternator last in a car

What Are the Key Technical Properties of an Alternator’s Lifespan?

Understanding the technical properties of alternators is crucial for B2B buyers in the automotive sector. Here are several key specifications that impact an alternator’s lifespan and performance:

-

Material Grade:

– Alternators are typically constructed from high-quality metals such as aluminum and copper. The grade of these materials affects durability and heat resistance. High-grade materials can withstand higher temperatures and resist corrosion, ultimately extending the lifespan of the alternator. For B2B buyers, sourcing alternators made from superior materials can lead to lower failure rates and reduced warranty claims. -

Tolerance Levels:

– Tolerance refers to the allowable deviation in dimensions and performance characteristics. Precise tolerances in alternator components, such as bearings and windings, are essential for optimal performance. Poor tolerance can lead to inefficiencies and increased wear, impacting the longevity of the unit. Buyers should prioritize manufacturers who adhere to strict tolerance standards to ensure reliability and performance. -

Output Voltage:

– The standard output voltage for most automotive alternators is typically between 12 to 14 volts. Understanding the output voltage is essential for compatibility with various vehicle electrical systems. Buyers must ensure that the alternators they procure match the voltage requirements of the intended applications to avoid electrical issues and ensure efficient battery charging. -

Cooling System Efficiency:

– An effective cooling system within the alternator helps to manage heat generated during operation. Features such as ventilation and heat sinks can significantly enhance an alternator’s lifespan. B2B buyers should evaluate the cooling mechanisms used in the alternators they are considering to ensure they can handle the demands of prolonged use in various environmental conditions. -

Bearing Quality:

– The type of bearings used in alternators can significantly impact performance and durability. High-quality bearings reduce friction and wear, leading to a longer lifespan. Buyers should assess the bearing specifications and materials to ensure they are investing in reliable products that will withstand daily usage.

What Are Common Trade Terms Related to Alternators?

Familiarity with industry jargon is vital for effective communication and procurement processes in the automotive sector. Below are some common terms associated with alternators:

-

OEM (Original Equipment Manufacturer):

– Refers to parts made by the manufacturer that originally supplied the car. OEM alternators are often preferred for their guaranteed compatibility and performance. B2B buyers should consider OEM products for reliability and quality assurance. -

MOQ (Minimum Order Quantity):

– This term indicates the smallest quantity that a supplier is willing to sell. Understanding MOQ is crucial for B2B negotiations, as it can impact inventory levels and cash flow. Buyers should clarify MOQ with suppliers to align with their purchasing strategies. -

RFQ (Request for Quotation):

– An RFQ is a document sent to suppliers requesting pricing and availability for specific products. B2B buyers should utilize RFQs to obtain competitive pricing and assess multiple suppliers before making procurement decisions. -

Incoterms (International Commercial Terms):

– These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms can help buyers manage shipping costs and risks associated with purchasing alternators from international suppliers. -

Lifecycle Cost:

– This term refers to the total cost of owning an alternator over its entire lifespan, including purchase price, maintenance, and replacement costs. B2B buyers should evaluate lifecycle costs when making purchasing decisions to ensure they are investing in products that offer long-term value.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators for their automotive needs, ensuring quality, reliability, and value in their investments.

Navigating Market Dynamics and Sourcing Trends in the how long does a alternator last in a car Sector

What Are the Key Trends Influencing the Lifespan of Car Alternators?

The automotive sector is experiencing a notable transformation driven by several global factors. The average lifespan of an alternator, typically around seven years or 150,000 miles, is influenced by advancements in vehicle technology and consumer preferences. As electric and hybrid vehicles gain traction, the demand for high-performance alternators that can support complex electrical systems is surging. This trend is particularly relevant for international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where the market for electric vehicles is expanding.

Emerging technologies, such as smart sensors and IoT-enabled diagnostics, are becoming essential tools for maintenance and sourcing strategies. These technologies allow for real-time monitoring of alternator performance, enabling proactive maintenance that can extend lifespan and reduce downtime. Additionally, the shift towards e-commerce platforms is simplifying the sourcing process, allowing buyers to quickly compare prices and specifications from various suppliers globally.

International buyers must also consider regional variations in automotive standards and the availability of quality parts. Understanding local market dynamics, including economic factors and regulatory requirements, can provide a competitive edge when sourcing alternators. As sustainability becomes a priority, buyers are increasingly looking for suppliers that align with eco-friendly practices and can offer certifications that validate their commitment to sustainability.

How Does Sustainability Affect the Sourcing of Car Alternators?

Sustainability and ethical sourcing are increasingly critical factors in the automotive parts industry, particularly for alternators. The production and disposal of automotive components can have significant environmental impacts, from the extraction of raw materials to energy consumption during manufacturing. B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as using recycled materials and reducing waste in their manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers should seek out suppliers who adhere to fair labor practices and comply with international standards for worker safety and environmental protection. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the demand for “green” materials is on the rise. Suppliers who can provide alternators made from eco-friendly components or those that have undergone sustainable manufacturing processes will likely have a competitive advantage. By aligning sourcing strategies with sustainability goals, B2B buyers can not only enhance their brand reputation but also contribute positively to the global push for environmental responsibility.

Illustrative image related to how long does a alternator last in a car

What Has Been the Evolution of Alternators in the Automotive Industry?

The alternator has evolved significantly since its inception in the early 20th century. Originally designed as a simple generator, it has transformed into a complex electrical component essential for modern vehicles. The introduction of electronic systems in cars necessitated a shift from traditional mechanical systems to more sophisticated alternators capable of handling increased electrical loads.

In recent years, the rise of electric and hybrid vehicles has prompted manufacturers to innovate further, leading to the development of high-efficiency alternators that optimize energy use and reduce emissions. This evolution not only reflects advancements in technology but also responds to consumer demand for more efficient and environmentally friendly vehicles. As the automotive landscape continues to change, understanding the historical context of alternators can provide valuable insights for B2B buyers looking to source reliable and innovative products.

Frequently Asked Questions (FAQs) for B2B Buyers of how long does a alternator last in a car

-

How do I determine the lifespan of an alternator in different vehicle models?

The lifespan of an alternator can vary significantly based on the vehicle model, usage, and environmental conditions. On average, alternators last between 7 to 10 years or approximately 150,000 miles. However, luxury or high-performance vehicles might require more frequent replacements due to higher electrical demands. When sourcing alternators for different models, consider the manufacturer’s specifications and customer reviews to gauge reliability and performance across various conditions. -

What are the key signs indicating a failing alternator?

A failing alternator may exhibit several symptoms, including dimming headlights, difficulty starting the engine, and warning lights on the dashboard. Other indicators can include unusual noises, intermittent electrical issues, or a burning smell. For B2B buyers, understanding these signs is crucial for ensuring timely replacement and maintaining customer satisfaction, particularly in regions with limited access to repair services. -

What factors influence the cost of an alternator for bulk purchases?

The cost of an alternator can be influenced by several factors, including the manufacturer, quality of materials, and any additional features such as integrated technology or warranties. For bulk purchases, consider negotiating payment terms, shipping costs, and discounts based on order volume. Suppliers in different regions may offer varying prices, so it’s beneficial to compare quotes from multiple sources before making a decision. -

How can I ensure the quality of alternators from international suppliers?

To ensure quality, it’s vital to conduct thorough supplier vetting. Check for certifications such as ISO 9001, which indicates quality management standards. Request samples or product specifications to assess the alternator’s performance and durability. Additionally, consider suppliers who provide detailed warranty information and customer testimonials, especially for markets in Africa, South America, and the Middle East where quality assurance may vary. -

What is the minimum order quantity (MOQ) for alternators from suppliers?

Minimum order quantities (MOQ) can vary widely among suppliers, often ranging from 50 to 500 units, depending on the manufacturer and product type. It’s advisable to communicate directly with potential suppliers to understand their MOQ policies. For smaller businesses or those just entering the market, some suppliers may offer flexibility on MOQ, especially if they value building a long-term relationship. -

What payment terms should I negotiate when sourcing alternators?

Payment terms can greatly impact cash flow and profitability. Common terms include net 30, 60, or 90 days, but it’s crucial to negotiate terms that align with your business’s financial capacity. Consider discussing options for partial payments upon order confirmation and the remainder upon delivery. Additionally, inquire about payment methods accepted, as some suppliers may offer discounts for upfront payments or specific payment platforms. -

How can I manage logistics effectively when importing alternators?

Effective logistics management involves understanding shipping options, customs regulations, and potential tariffs. Work with logistics partners experienced in automotive parts to streamline the process. Ensure that your supplier provides all necessary documentation for customs clearance, and consider using freight forwarders who can manage the complexities of international shipping, particularly when dealing with suppliers from different continents. -

What are the best practices for maintaining alternators to maximize their lifespan?

To maximize the lifespan of alternators, it’s essential to implement routine maintenance practices. Encourage customers to regularly inspect belts and connections, keep the alternator clean, and avoid overloading the electrical system with aftermarket components. Providing educational resources on proper maintenance can enhance customer satisfaction and reduce the likelihood of premature failures, ultimately benefiting your business reputation in the market.

Top 3 How Long Does A Alternator Last In A Car Manufacturers & Suppliers List

1. Robert Basil – Alternators

Domain: robertbasilcars.com

Registered: 2005 (20 years)

Introduction: The alternator sends power to the car’s electrical system when the vehicle is running. It works like a generator using the gas engine as an energy source. Common signs of a failing alternator include: battery warning light on the dashboard, dim headlights or interior lights, burning rubber smell, devices not charging, whining or screeching sounds, and inability to start the vehicle. The average li…

2. Honda – 8th Generation Accord (08-12)

3. Savannah Toyota – Alternator Services

Domain: savannahtoyota.com

Registered: 1996 (29 years)

Introduction: The alternator powers all electronics in a vehicle while the engine is running, functioning as a generator using the gas engine as its energy source. Signs of a failing alternator include a battery warning light, dim headlights, burning rubber smell, devices not charging, whining sounds, and inability to start the vehicle. Most alternators last between 80,000 and 150,000 miles or about seven years…

Strategic Sourcing Conclusion and Outlook for how long does a alternator last in a car

In conclusion, understanding the lifespan and maintenance of alternators is crucial for international B2B buyers in the automotive sector. On average, alternators last between seven years or 150,000 miles, depending on various factors including vehicle condition and electrical demands. Recognizing early warning signs of alternator failure—such as dimming headlights, electrical issues, or unusual noises—can prevent costly breakdowns and ensure smooth operations.

Strategic sourcing of high-quality alternators not only enhances vehicle performance but also fosters customer satisfaction and loyalty. By investing in reliable parts and maintenance practices, businesses can minimize downtime and reduce operational costs.

As the automotive market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, now is the time for B2B buyers to prioritize partnerships with reputable suppliers. Embrace the opportunity to enhance your procurement strategies to secure quality alternators that align with your operational needs. By doing so, you can position your business for success in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how long does a alternator last in a car

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.