Introduction: Navigating the Global Market for alternator definition

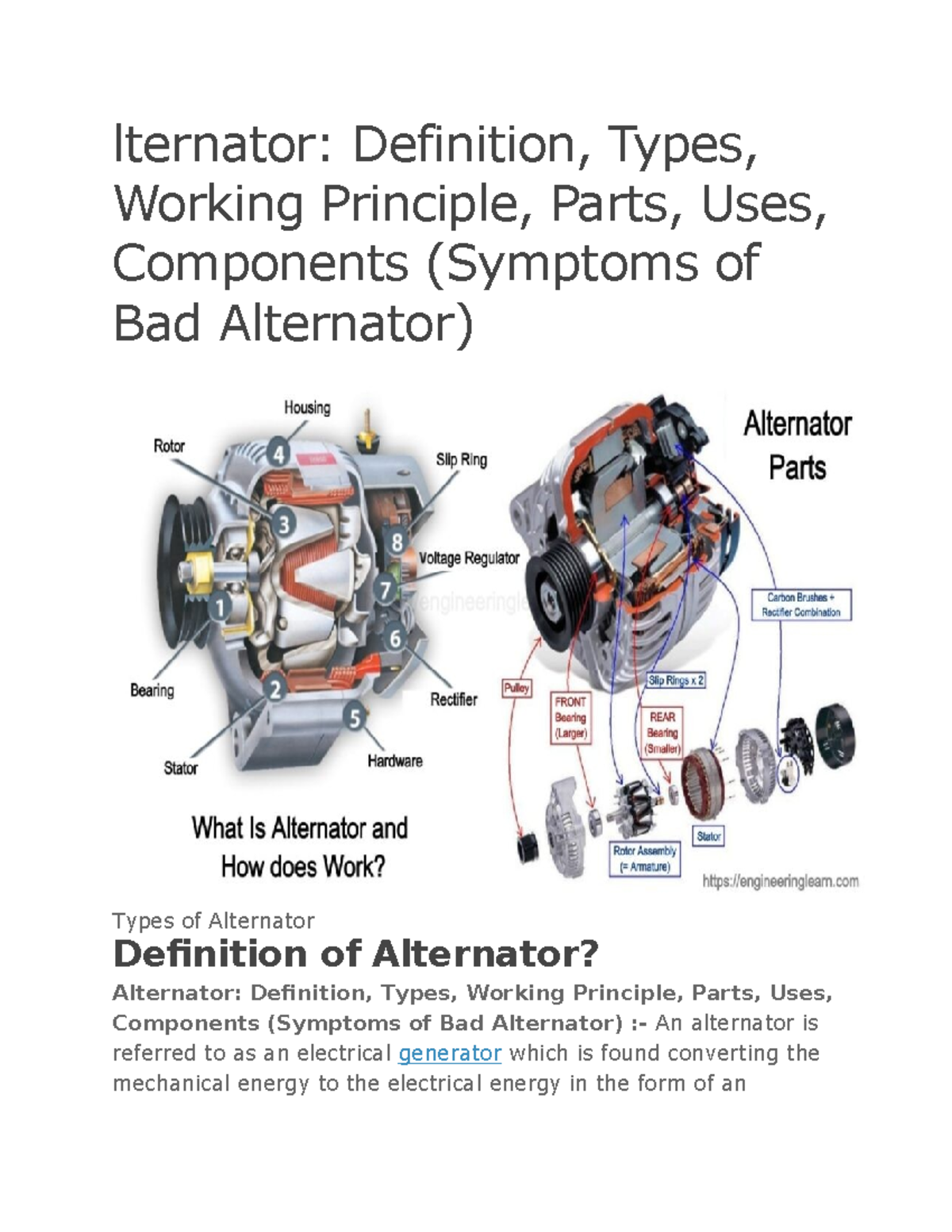

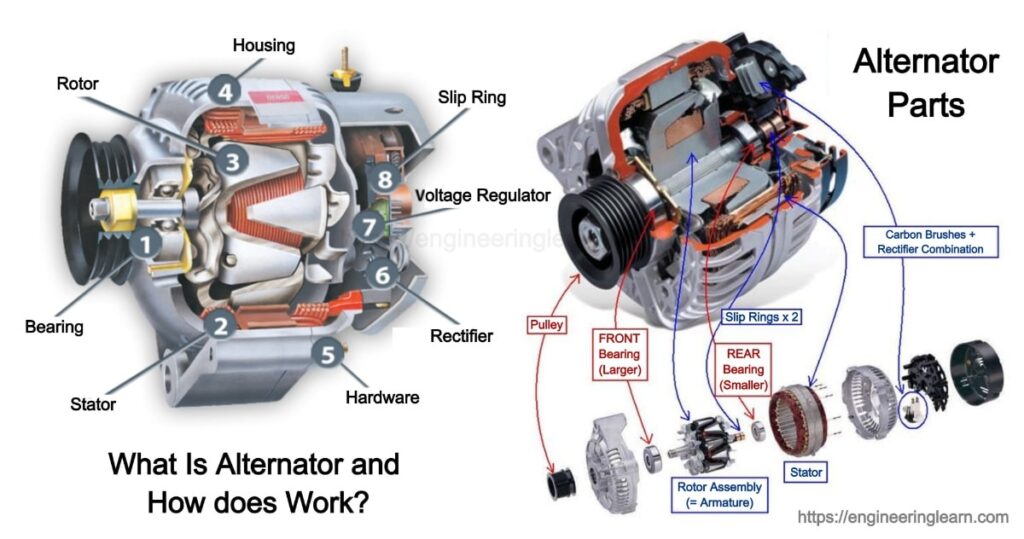

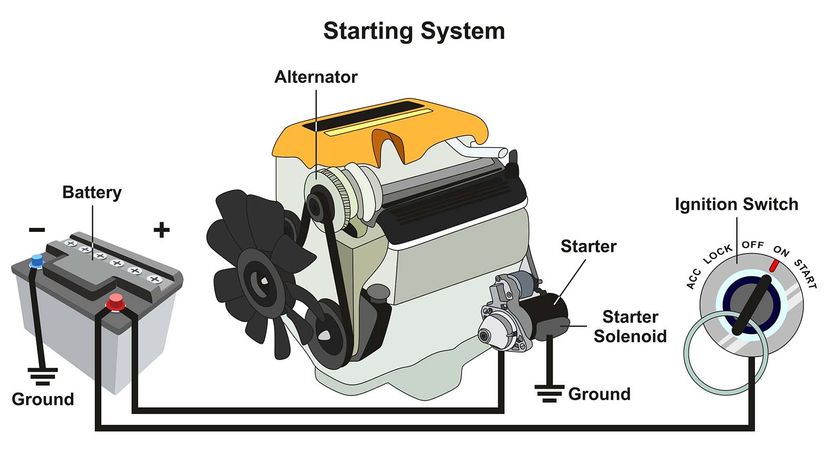

In the fast-paced world of international commerce, sourcing reliable components like alternators can pose significant challenges for B2B buyers. An alternator, defined as an electric generator that produces alternating current, is a critical component in various industries, from automotive to aviation and renewable energy. Understanding its specifications, applications, and the intricacies of different types can make a substantial difference in operational efficiency and cost-effectiveness.

This comprehensive guide is designed to empower international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany. We delve into the various types of alternators available, their specific applications, and critical factors for supplier vetting to ensure quality and reliability. Additionally, we address the cost implications associated with different models and the importance of maintenance and support services.

By equipping you with actionable insights and practical knowledge, this guide facilitates informed purchasing decisions, enabling your business to navigate the complexities of the global alternator market confidently. Whether you are looking to enhance your supply chain or ensure the longevity of your machinery, understanding the nuances of alternators will help you make strategic decisions that align with your operational goals.

Table Of Contents

- Top 5 Alternator Definition Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator definition

- Understanding alternator definition Types and Variations

- Key Industrial Applications of alternator definition

- 3 Common User Pain Points for ‘alternator definition’ & Their Solutions

- Strategic Material Selection Guide for alternator definition

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator definition

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator definition’

- Comprehensive Cost and Pricing Analysis for alternator definition Sourcing

- Alternatives Analysis: Comparing alternator definition With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator definition

- Navigating Market Dynamics and Sourcing Trends in the alternator definition Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator definition

- Strategic Sourcing Conclusion and Outlook for alternator definition

- Important Disclaimer & Terms of Use

Understanding alternator definition Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automotive Alternator | Designed for vehicles, converts mechanical energy to electrical | Automotive manufacturing, repair services | Pros: Compact, reliable power for vehicles; Cons: Limited to automotive use. |

| Industrial Alternator | High-capacity, robust design for heavy machinery | Manufacturing plants, construction equipment | Pros: Durable, can handle high loads; Cons: Higher initial investment. |

| Portable Alternator | Lightweight, often gas-powered for mobility | Outdoor events, emergency power supplies | Pros: Versatile, easy to transport; Cons: Limited power output compared to fixed units. |

| Marine Alternator | Specifically built to withstand marine environments | Marine vessels, fishing boats | Pros: Corrosion-resistant, reliable in harsh conditions; Cons: More expensive due to specialized materials. |

| Wind Turbine Alternator | Converts wind energy to electricity, often used in renewable energy | Renewable energy projects, off-grid solutions | Pros: Eco-friendly, potential for long-term savings; Cons: Requires significant upfront investment. |

What Are the Characteristics of Automotive Alternators?

Automotive alternators are specifically engineered to meet the electrical demands of vehicles. They typically produce between 12 to 14 volts of electricity and are designed to recharge the vehicle’s battery while powering electrical components such as lights and infotainment systems. For B2B buyers in the automotive sector, considerations include the alternator’s size, weight, and compatibility with various vehicle models. Reliability and durability are crucial, as automotive alternators must withstand vibrations and temperature fluctuations.

How Do Industrial Alternators Stand Out?

Industrial alternators are built for heavy-duty applications, often featuring higher output capacities and robust designs. They are commonly used in manufacturing plants and construction sites, providing power for large machinery and equipment. When purchasing industrial alternators, B2B buyers should assess the power requirements of their operations and consider factors like efficiency, maintenance needs, and the potential for future scalability. While they offer durability and performance, the higher initial costs may be a barrier for some businesses.

Why Choose Portable Alternators for Temporary Power Needs?

Portable alternators are favored for their lightweight and mobility, making them ideal for outdoor events and emergency power supplies. These units can be gas-powered or battery-operated, providing flexibility in various settings. B2B buyers should evaluate the power output needed for their applications and consider ease of transport and setup. While portable alternators offer convenience, they may not deliver the same power levels as fixed installations, which could be a limitation for larger operations.

What Makes Marine Alternators Unique?

Marine alternators are specifically designed to operate effectively in wet and corrosive environments, making them essential for boats and marine vessels. They typically feature enhanced sealing and corrosion-resistant materials to ensure longevity. B2B buyers in the marine industry should focus on the alternator’s capacity, durability, and compatibility with marine electrical systems. Although these units tend to be more expensive due to their specialized construction, their reliability in challenging conditions often justifies the investment.

How Do Wind Turbine Alternators Contribute to Renewable Energy?

Wind turbine alternators convert kinetic energy from wind into electrical energy, playing a pivotal role in renewable energy projects. These alternators are designed to operate efficiently in variable wind conditions and are often used in off-grid solutions. For B2B buyers interested in sustainability, the long-term savings and environmental benefits of wind turbine alternators are significant. However, the initial investment can be substantial, and buyers should consider the overall feasibility of integrating such systems into their energy strategy.

Key Industrial Applications of alternator definition

| Industry/Sector | Specific Application of alternator definition | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Vehicle Power Generation | Reliable power supply for electrical systems | Compatibility with vehicle models and energy efficiency |

| Aviation | Aircraft Electrical Systems | Lightweight and efficient power generation | Certification standards and weight restrictions |

| Renewable Energy | Wind and Solar Power Systems | Sustainable energy generation | Durability in harsh conditions and integration with existing systems |

| Marine | Shipboard Electrical Systems | Continuous operation of onboard equipment | Resistance to corrosion and compliance with maritime regulations |

| Industrial Manufacturing | Machinery and Equipment Power Supply | Enhanced productivity and operational reliability | Voltage requirements and maintenance support |

How is ‘alternator definition’ utilized in the automotive industry?

In the automotive sector, alternators are crucial for generating electrical power to recharge batteries and support various electrical systems, including lighting and infotainment. They ensure that vehicles operate efficiently, reducing the risk of battery failure. Buyers in this industry must consider factors such as the alternator’s compatibility with specific vehicle models, its energy efficiency, and its ability to handle varying load demands. This is particularly important for international buyers who may deal with diverse vehicle types and electrical standards.

What role do alternators play in aviation electrical systems?

In aviation, alternators provide a dependable source of electrical power for aircraft systems, including navigation and communication. Their lightweight design and ability to operate at lower speeds contribute to overall aircraft efficiency and reliability. B2B buyers in this sector should prioritize sourcing alternators that meet stringent aviation certification standards and can withstand the unique operational stresses of flight. Understanding weight restrictions and performance specifications is essential for ensuring safety and compliance.

How are alternators integrated into renewable energy systems?

In renewable energy applications, alternators are employed in wind turbines and solar power systems to convert mechanical energy into electrical energy. This conversion is vital for creating sustainable energy solutions that contribute to global energy goals. Buyers should focus on the durability and efficiency of alternators in harsh environmental conditions, as well as their compatibility with existing energy infrastructure. These factors are crucial for businesses in regions like Africa and South America, where renewable energy adoption is rapidly increasing.

What is the significance of alternators in marine applications?

Marine vessels rely on alternators to maintain continuous electrical power for navigation, communication, and operational systems. The specific requirements for marine alternators include resistance to corrosion and compliance with maritime safety regulations. B2B buyers in this sector must ensure that the alternators they source can perform reliably in harsh marine environments while providing adequate power output for various onboard systems. Understanding these needs is vital for maintaining operational efficiency and safety at sea.

How do alternators support industrial manufacturing operations?

In industrial manufacturing, alternators are essential for powering machinery and equipment. They ensure that production lines operate smoothly and efficiently, minimizing downtime caused by electrical failures. Buyers in this sector should consider the voltage requirements of their machinery, the alternator’s maintenance support, and its overall reliability. Sourcing high-quality alternators can significantly enhance productivity and operational reliability, making them a critical component for businesses looking to optimize their manufacturing processes.

3 Common User Pain Points for ‘alternator definition’ & Their Solutions

Scenario 1: Understanding Alternator Specifications for Diverse Applications

The Problem: B2B buyers often struggle with understanding the specific electrical requirements of alternators for various applications, such as automotive, aerospace, or industrial machinery. This lack of clarity can lead to purchasing the wrong type or size of alternator, resulting in operational inefficiencies or costly project delays. For instance, a company in the automotive sector might overlook the difference between alternators designed for standard vehicles versus those needed for high-performance engines, ultimately impacting performance and reliability.

The Solution: To navigate this challenge, buyers should conduct thorough research on the electrical specifications of alternators, focusing on factors such as voltage output, amperage, and compatibility with existing systems. Engaging with manufacturers or technical experts to obtain detailed product data sheets can provide insights into the best fit for specific applications. Additionally, participating in industry forums or attending trade shows can facilitate discussions with peers who have faced similar challenges. By gathering comprehensive information and understanding the nuances of alternator specifications, buyers can make informed decisions that align with their operational needs.

Scenario 2: Managing Supply Chain Issues with Alternator Procurement

The Problem: B2B buyers frequently encounter supply chain disruptions that affect the availability of alternators, especially in regions with limited access to reliable suppliers. This situation can delay projects, increase costs, and diminish trust in the supply chain. For example, a construction firm in Brazil might face delays in equipment operation due to a shortage of alternators, which can halt project timelines and incur additional expenses.

The Solution: To mitigate supply chain risks, buyers should diversify their supplier base and establish relationships with multiple manufacturers, both locally and internationally. This strategy can enhance resilience against shortages. Additionally, implementing just-in-time inventory practices can help maintain adequate stock levels without overcommitting resources. Utilizing digital procurement platforms can also streamline sourcing processes and improve visibility into inventory status. By proactively managing supplier relationships and inventory, companies can better navigate supply chain challenges and ensure timely access to essential components like alternators.

Scenario 3: Ensuring Compliance with Regional Standards for Alternators

The Problem: Different regions, such as Europe, Africa, and South America, have varying regulatory standards for electrical components, including alternators. B2B buyers may find it challenging to ensure compliance with these standards, which can result in legal issues, increased costs, and reputational damage. For instance, an electronics manufacturer in Germany might inadvertently purchase non-compliant alternators, leading to costly recalls and penalties.

The Solution: Buyers should invest time in understanding the regulatory landscape relevant to their target markets. This includes familiarizing themselves with compliance standards such as CE marking in Europe or IEC standards globally. Collaborating with local regulatory experts or consultants can provide valuable insights into the specific requirements for alternators in different regions. Additionally, buyers should prioritize sourcing from manufacturers who are transparent about their compliance certifications and testing processes. By prioritizing compliance from the outset, companies can avoid potential pitfalls and ensure that their products meet the necessary legal and industry standards.

Strategic Material Selection Guide for alternator definition

What Are the Common Materials Used in Alternator Manufacturing?

When selecting materials for alternators, several factors influence performance, cost, and suitability for specific applications. Here, we analyze four common materials used in alternator construction: aluminum, copper, steel, and plastic composites. Each material presents unique properties and considerations that can significantly impact the performance and longevity of alternators.

How Does Aluminum Contribute to Alternator Efficiency?

Aluminum is widely used in alternator housings and components due to its lightweight and excellent corrosion resistance. Key properties include a high strength-to-weight ratio and good thermal conductivity, which aids in heat dissipation during operation.

Pros: Aluminum’s lightweight nature reduces the overall weight of the alternator, enhancing fuel efficiency in automotive applications. It is also relatively inexpensive and easy to manufacture, allowing for cost-effective production.

Cons: While aluminum is durable, it may not withstand extreme temperatures as well as some other metals. Additionally, it can be more susceptible to wear over time in high-stress environments.

Impact on Application: Aluminum is compatible with various media and environments, making it suitable for automotive and light aircraft applications.

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with standards such as ASTM and DIN, particularly regarding corrosion resistance and mechanical properties.

Why Is Copper Essential for Electrical Conductivity in Alternators?

Copper is a critical material for windings and electrical connections within alternators due to its superior electrical conductivity. It has a high melting point and excellent thermal properties, making it ideal for high-performance applications.

Pros: The high conductivity of copper ensures efficient energy transfer, which is essential for the performance of alternators. Its durability contributes to a longer lifespan of electrical components.

Cons: Copper is more expensive than aluminum and can be heavy, which may not be ideal for all applications. It is also prone to corrosion if not properly insulated or protected.

Impact on Application: Copper’s properties make it suitable for high-load applications, such as in heavy machinery or commercial vehicles.

Considerations for International Buyers: Buyers should be aware of the fluctuating copper prices and consider sourcing from regions with stable supply chains. Compliance with electrical standards is also crucial.

How Does Steel Enhance Structural Integrity in Alternators?

Steel is often used in the structural components of alternators, such as frames and mounting brackets, due to its high tensile strength and durability.

Pros: Steel provides excellent structural integrity, making it suitable for heavy-duty applications. It is also cost-effective and widely available.

Cons: Steel is heavier than aluminum and can be prone to rust without proper treatment. Its weight may impact fuel efficiency in automotive applications.

Impact on Application: Steel is commonly used in industrial alternators where strength and durability are paramount.

Considerations for International Buyers: Buyers should ensure compliance with international standards for structural components, such as JIS and ASTM, particularly regarding strength and corrosion resistance.

What Role Do Plastic Composites Play in Alternator Design?

Plastic composites are increasingly used in non-structural components of alternators, such as covers and insulators, due to their lightweight and corrosion-resistant properties.

Pros: They are lightweight and can be molded into complex shapes, allowing for innovative designs. Plastic composites also resist corrosion, which can enhance the longevity of the alternator.

Cons: While they are cost-effective, plastic composites may not provide the same level of strength as metals, potentially limiting their use in high-stress applications.

Impact on Application: Plastic composites are suitable for lightweight and corrosion-resistant applications, particularly in automotive and consumer electronics.

Considerations for International Buyers: Buyers should consider the environmental impact of plastics and ensure compliance with regulations regarding material safety and recycling.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for alternator definition | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and lightweight components | Lightweight and corrosion-resistant | Less effective at high temperatures | Medium |

| Copper | Windings and electrical connections | Excellent electrical conductivity | High cost and weight | High |

| Steel | Structural components | High tensile strength | Heavy and prone to rust | Low |

| Plastic Composites | Covers and insulators | Lightweight and corrosion-resistant | Lower strength compared to metals | Low |

This strategic material selection guide provides critical insights for international B2B buyers in selecting the most suitable materials for alternators, ensuring compliance with regional standards and optimizing performance across various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator definition

What Are the Main Stages of Manufacturing an Alternator?

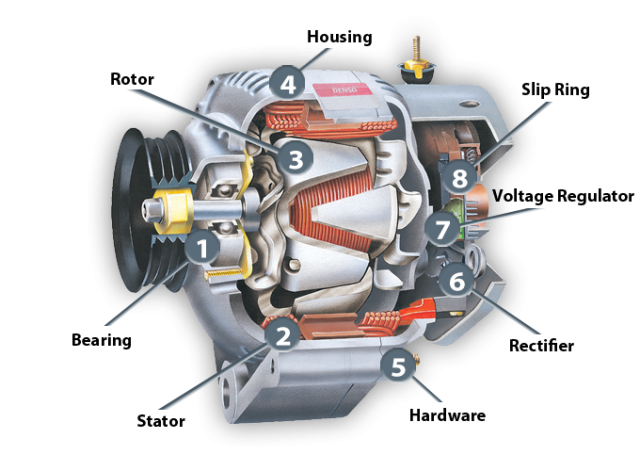

The manufacturing process of an alternator involves several critical stages that ensure the final product meets quality standards and performance specifications. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Alternator Production?

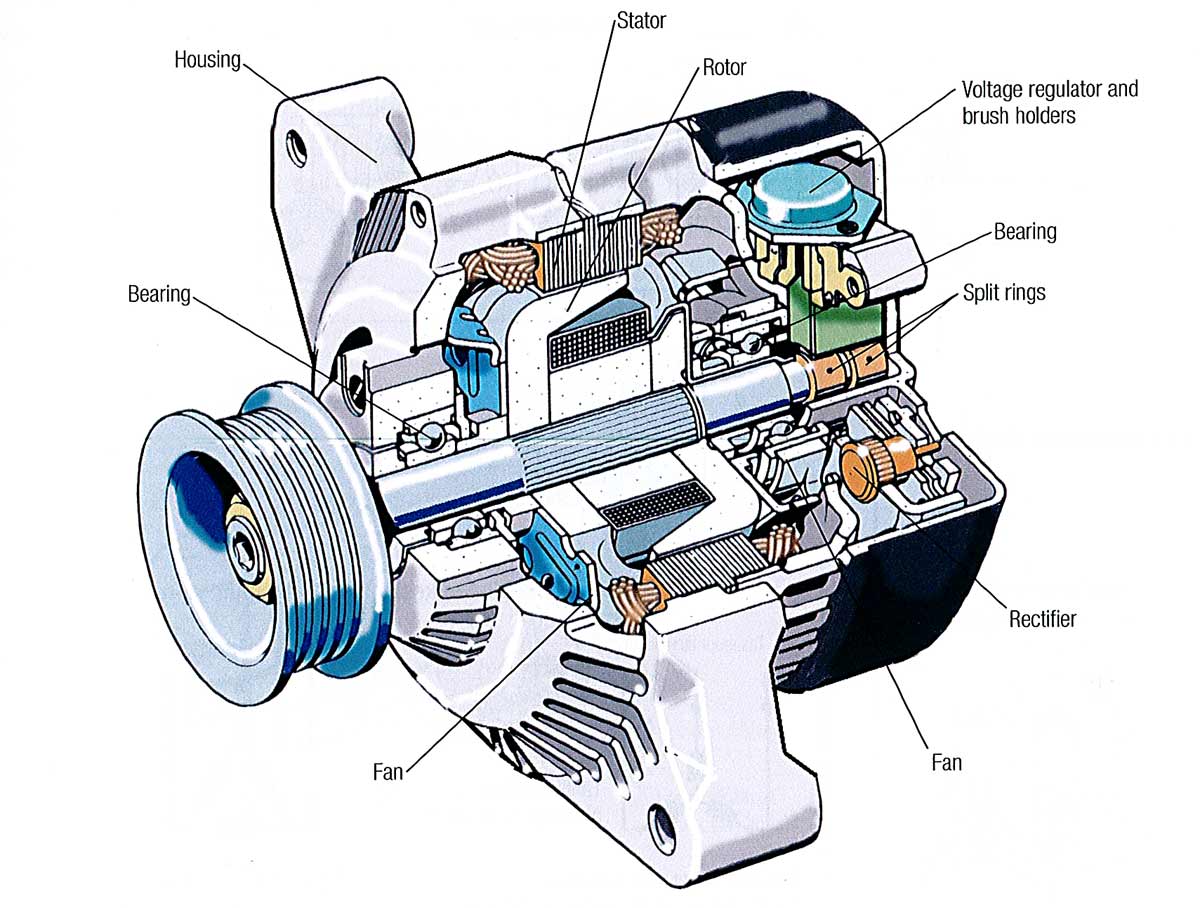

Material preparation is the first step in the alternator manufacturing process. Key components such as the rotor, stator, diodes, and housing must be sourced from reliable suppliers. Typically, high-grade materials like silicon steel for the stator and copper wire for the windings are used to enhance conductivity and efficiency. Suppliers must provide material certifications to confirm compliance with international standards, ensuring that only high-quality materials are utilized.

What Forming Techniques Are Employed in Alternator Manufacturing?

Once materials are prepared, forming techniques are applied to create the necessary components. Stamping and machining are commonly used for the rotor and stator. Stamping involves using dies to cut and shape metal sheets into the desired forms, while machining processes, such as CNC (Computer Numerical Control) milling, are used to achieve precise dimensions. These techniques ensure that components fit together seamlessly, which is crucial for optimal performance.

Illustrative image related to alternator definition

How Are Alternators Assembled?

The assembly phase involves integrating the various components of the alternator. Skilled technicians typically carry out this process, which includes winding the copper wire around the stator, installing the rotor, and connecting diodes to convert alternating current (AC) into direct current (DC). Each assembly line may incorporate automated systems to improve efficiency and reduce human error. It is vital that each connection is secure, as improper assembly can lead to electrical failures.

What Finishing Processes Are Necessary for Alternators?

Finishing processes involve both aesthetic and functional enhancements. The alternator may undergo surface treatments, such as anodizing or powder coating, to prevent corrosion and enhance durability. Additionally, electrical testing is conducted at this stage to ensure that the alternator meets its specified output and performance standards. Proper finishing not only improves the lifespan of the alternator but also its overall reliability.

What International Standards Govern Quality Assurance for Alternators?

Quality assurance is paramount in alternator manufacturing, with several international standards guiding the process. ISO 9001 is one of the most recognized standards, focusing on quality management systems. Adhering to ISO 9001 ensures that manufacturers maintain consistent quality in their production processes, which is essential for B2B buyers looking for reliable suppliers.

Which Industry-Specific Certifications Are Important for Alternator Manufacturers?

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are crucial. CE certification indicates compliance with European safety and environmental regulations, which is particularly important for buyers in Europe. API certification is relevant for alternators used in the oil and gas industry, ensuring that products meet stringent performance standards.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) is integrated into the manufacturing process through various checkpoints. These include:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process. This includes visual inspections and measurements to detect any deviations from standards early on.

- Final Quality Control (FQC): The final product undergoes thorough testing to verify its performance and safety before it is shipped to customers.

By implementing these QC checkpoints, manufacturers can identify and rectify issues at different stages of production, thus maintaining high-quality standards.

Illustrative image related to alternator definition

What Common Testing Methods Are Used to Ensure Alternator Quality?

Various testing methods are employed to ensure the reliability and performance of alternators. Common methods include:

- Electrical Testing: This involves measuring the output voltage, current, and frequency to ensure the alternator operates within specified parameters.

- Thermal Testing: Alternators are subjected to thermal cycling tests to assess their performance under varying temperature conditions.

- Vibration Testing: This method evaluates the mechanical stability of the alternator, ensuring it can withstand operational stresses without failure.

These testing methods help manufacturers deliver products that meet or exceed customer expectations, which is crucial for maintaining strong B2B relationships.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can verify a supplier’s quality control processes through several methods:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place. This hands-on approach provides insights into the supplier’s commitment to quality.

- Quality Reports: Requesting documentation related to quality control, including test results and compliance certificates, can help buyers make informed decisions.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the manufacturer’s processes and products. This is particularly important for buyers from regions with varying quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. Different countries may have unique regulatory requirements and standards that affect product acceptance. For instance, European buyers may prioritize CE certification, while those in Africa might focus more on local compliance standards.

Illustrative image related to alternator definition

Understanding these nuances is vital for buyers to ensure that the alternators they procure not only meet their specific needs but also comply with local regulations. Establishing clear communication with suppliers regarding quality standards and certifications can mitigate risks associated with international procurement.

In conclusion, the manufacturing processes and quality assurance measures surrounding alternators are intricate and vital for ensuring product reliability. By understanding these processes, B2B buyers can make informed decisions and establish strong partnerships with manufacturers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator definition’

In the rapidly evolving landscape of electrical components, understanding the definition and functionality of an alternator is crucial for B2B buyers, particularly in industries reliant on robust electrical systems. This guide provides a structured checklist to assist in sourcing the right alternator for your specific needs, ensuring you make informed decisions that align with your operational requirements.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes determining the voltage and current ratings needed for your application, as well as any specific operational conditions (e.g., temperature, humidity) that the alternator must withstand. Understanding these specifications will help narrow down your options and ensure compatibility with existing systems.

Step 2: Research Market Trends and Innovations

Stay updated on the latest advancements in alternator technology. Newer models may offer improved efficiency, reduced weight, and enhanced durability. By understanding current market trends, you can identify potential suppliers who are leading in innovation and may offer better products suited to your needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Assess their reputation in the market, as well as their experience with alternators specifically, to ensure they can meet your quality and service expectations.

Step 4: Check Compliance and Certifications

Ensure that the alternators meet relevant industry standards and regulations. This could include certifications such as ISO 9001 for quality management or specific electrical safety standards applicable in your region. Compliance not only guarantees product quality but also protects your business from potential liabilities.

Step 5: Request Samples or Prototypes

Where possible, request samples or prototypes of the alternators you are considering. Testing these units in real-world conditions can provide valuable insights into their performance and reliability. It also allows you to assess the supplier’s responsiveness and support during the evaluation phase.

Illustrative image related to alternator definition

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, delivery times, and payment terms. Ensure that you have a clear understanding of the total cost of ownership, including potential maintenance and warranty provisions. A well-negotiated agreement can lead to long-term savings and better supplier relationships.

Step 7: Establish a Long-Term Relationship

After procurement, focus on building a strong partnership with your supplier. Regular communication can facilitate better service and support, ensuring that you receive timely updates on product innovations and availability. A collaborative approach will help both parties adapt to future needs and market changes.

By following this checklist, B2B buyers can systematically approach the sourcing of alternators, ensuring they secure high-quality products that align with their operational goals.

Comprehensive Cost and Pricing Analysis for alternator definition Sourcing

What Are the Key Cost Components in Sourcing Alternators?

When analyzing the cost structure for sourcing alternators, several components contribute to the overall expense. These include:

Illustrative image related to alternator definition

-

Materials: The primary materials involved in manufacturing alternators are copper, aluminum, and various types of steel, which are essential for creating the rotor and stator. The cost of these raw materials fluctuates based on market conditions, impacting the final pricing.

-

Labor: Labor costs encompass wages for skilled workers involved in assembly and quality control. As labor rates vary by region, international buyers should consider the implications of sourcing from countries with different wage standards.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. High overhead costs can drive up the price of alternators, particularly in regions with stringent regulations or high operational costs.

-

Tooling: Custom tooling may be required for specific alternator designs. The initial investment in tooling can be significant but is often amortized over large production runs, affecting the unit cost.

-

Quality Control (QC): Rigorous quality assurance processes ensure that alternators meet safety and performance standards. The associated costs can vary significantly based on the complexity of the QC processes and certifications required.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and local customs duties can greatly influence overall logistics expenses.

-

Margin: Supplier margins can vary based on brand reputation, market demand, and competition. Understanding these margins can help buyers negotiate better prices.

How Do Price Influencers Affect Alternator Costs?

Several factors influence the pricing of alternators, which buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Higher purchase volumes generally lead to lower unit prices due to economies of scale. Buyers should evaluate their needs against supplier MOQs to optimize costs.

-

Specifications and Customization: Customized alternators with specific features or performance metrics may incur additional costs. Buyers need to balance their requirements with budget constraints when requesting customization.

-

Material Quality and Certifications: The quality of materials used and any necessary certifications (e.g., ISO, CE) can affect pricing. Higher-quality components generally lead to higher prices but can result in better performance and longevity.

-

Supplier Factors: Supplier reliability, reputation, and production capabilities can significantly impact pricing. Engaging with reputable suppliers can lead to better quality and service, albeit sometimes at a premium.

-

Incoterms: The terms of sale (Incoterms) dictate the responsibilities of buyers and sellers regarding shipping and delivery costs. Understanding these terms is crucial for accurate cost assessments and avoiding unexpected fees.

What Buyer Tips Can Enhance Cost-Efficiency in Alternator Sourcing?

To maximize cost-efficiency when sourcing alternators, consider the following strategies:

-

Negotiation: Engage in proactive negotiations with suppliers to secure better pricing, especially for bulk purchases. Leverage market research to strengthen your position.

-

Understanding Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, warranties, and potential downtime. A lower upfront cost may not always translate to savings over time.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and regional economic conditions that may affect pricing. Establishing relationships with local distributors can also provide insights into market trends.

-

Research and Supplier Evaluation: Conduct thorough research on potential suppliers, including their production capabilities, delivery times, and customer service. This diligence can help mitigate risks and ensure a smooth procurement process.

Disclaimer

The prices and cost components outlined above are indicative and may vary based on numerous factors, including market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct their own market research and consult with suppliers for precise pricing.

Alternatives Analysis: Comparing alternator definition With Other Solutions

Exploring Alternatives to Alternators: A Comparative Analysis

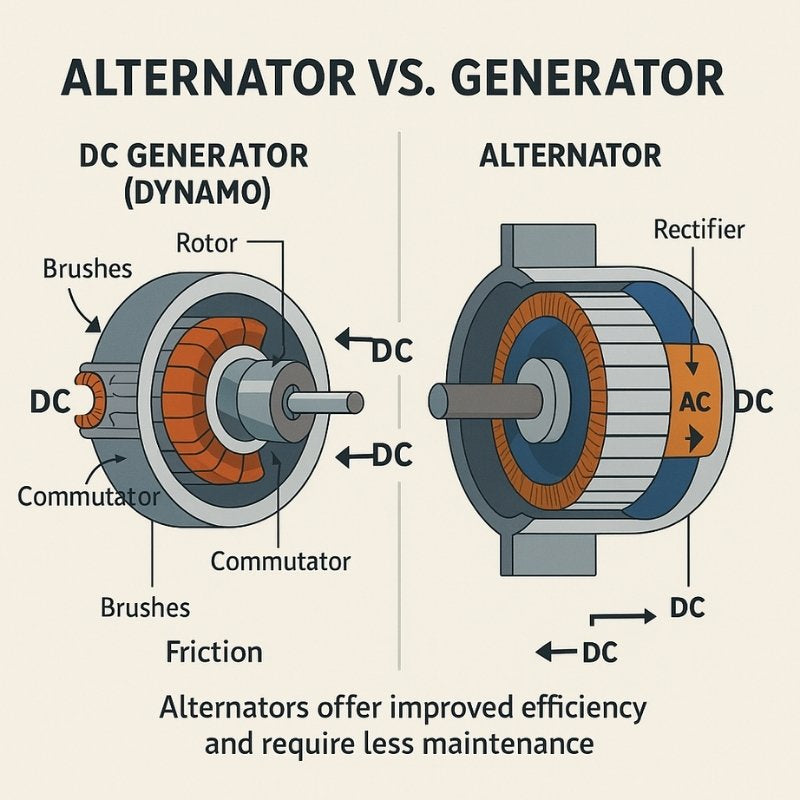

In the realm of electrical generation, particularly within automotive and aviation industries, the alternator serves as a critical component for converting mechanical energy into electrical energy. However, there are alternative technologies and methods that can also fulfill similar functions. This section will compare the traditional alternator with two viable alternatives: DC generators and solar power systems.

Comparison Table

| Comparison Aspect | Alternator Definition | DC Generator | Solar Power System |

|---|---|---|---|

| Performance | High efficiency in converting energy, lightweight, and compact. | Good for lower-speed applications, but less efficient overall. | Dependent on sunlight; can be variable. |

| Cost | Moderate initial cost, low operational cost. | Generally lower initial cost, but higher maintenance needs. | High initial investment, but low operational costs. |

| Ease of Implementation | Straightforward integration in vehicles and aircraft. | Requires careful sizing and installation; more complex. | Requires extensive planning for installation and placement. |

| Maintenance | Low maintenance, durable with minimal wear. | Requires regular maintenance and attention to brushes and commutators. | Minimal maintenance after installation; periodic cleaning required. |

| Best Use Case | Ideal for vehicles, aircraft, and portable generators. | Suitable for older vehicles and specific industrial applications. | Excellent for off-grid applications and renewable energy setups. |

Analyzing the Alternatives

1. DC Generators

DC generators are older technology that converts mechanical energy into direct current (DC) electricity. They are often employed in applications where a steady DC supply is crucial, such as in certain industrial settings. While they can be more affordable upfront, their efficiency is typically lower compared to alternators, especially at higher speeds. Additionally, DC generators require more frequent maintenance due to wear on brushes and commutators. This can lead to increased operational costs over time, making them less attractive for modern applications where efficiency and reliability are paramount.

2. Solar Power Systems

Solar power systems harness energy from the sun to generate electricity, making them a renewable and environmentally friendly alternative. These systems can be particularly advantageous in remote areas where grid access is limited. However, the initial investment for solar panels and necessary infrastructure can be substantial. Additionally, their performance is contingent upon sunlight availability, leading to variability in energy production. Despite these challenges, once installed, solar systems offer low operational costs and minimal maintenance, positioning them as a long-term solution for sustainable energy needs.

Conclusion: Making the Right Choice for Your Needs

When considering alternatives to the alternator, B2B buyers must evaluate their specific requirements, including performance needs, budget constraints, and maintenance capabilities. The alternator excels in efficiency and reliability for automotive and aviation applications, while DC generators may serve niche markets that require steady DC power. Solar power systems present an innovative solution for those seeking renewable energy, albeit with higher initial costs and variable performance. By carefully weighing these factors, businesses can make informed decisions that align with their operational goals and sustainability initiatives.

Essential Technical Properties and Trade Terminology for alternator definition

What Are the Essential Technical Properties of an Alternator?

Understanding the technical properties of an alternator is crucial for B2B buyers looking to invest in reliable electrical systems. Here are some key specifications that influence performance and durability:

1. Output Voltage

The output voltage of an alternator is typically rated between 12V and 24V for automotive applications. This specification is vital because it determines the compatibility of the alternator with various electrical systems. B2B buyers must ensure that the alternator’s voltage rating aligns with their equipment to prevent potential electrical failures.

2. Amperage Rating

The amperage rating indicates the maximum current the alternator can produce, often ranging from 30 to 200 amps. This property is essential for applications requiring significant electrical load, such as heavy machinery or commercial vehicles. Understanding the amperage rating helps buyers assess whether the alternator can meet their power needs without overloading.

Illustrative image related to alternator definition

3. Efficiency

Efficiency refers to how effectively the alternator converts mechanical energy into electrical energy, typically expressed as a percentage. Higher efficiency means less energy waste and can lead to cost savings in fuel consumption and operational costs. For businesses looking to optimize their equipment’s performance, selecting a highly efficient alternator can significantly impact the bottom line.

4. Cooling System

Alternators may feature built-in cooling systems, such as fans or liquid cooling, to dissipate heat generated during operation. A robust cooling system is critical in preventing overheating, which can lead to premature failure. B2B buyers should consider cooling options, especially in high-demand environments or regions with extreme temperatures.

5. Material Composition

The materials used in an alternator’s construction, such as copper windings and aluminum housings, affect its durability and performance. High-quality materials can enhance resistance to corrosion and wear, which is especially important for equipment operating in harsh conditions. Buyers should inquire about material specifications to ensure longevity and reliability.

6. Regulatory Compliance

Alternators must often meet specific industry standards and regulations, such as ISO certifications or emissions standards. Compliance with these regulations is crucial for international trade, as it can affect market access and operational legality. B2B buyers should verify that the alternators they consider are certified to avoid potential legal and financial repercussions.

What Are Common Trade Terminology and Jargon in the Alternator Industry?

Familiarity with industry jargon can facilitate smoother negotiations and purchasing processes. Here are some essential terms for B2B buyers:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another company’s brand. For alternators, working with OEMs ensures that the parts meet specific quality standards and compatibility requirements. Buyers should prioritize OEM parts for reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for businesses that may not need large quantities at once. Buyers should negotiate MOQ terms to align with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Crafting a comprehensive RFQ helps buyers obtain competitive pricing and ensures that suppliers understand their requirements. This process is vital for making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms is essential for international transactions, as they clarify who bears the risk and cost during transport. B2B buyers should ensure they understand these terms to mitigate risks associated with shipping.

Illustrative image related to alternator definition

5. Warranty Terms

Warranty terms outline the conditions under which a supplier will repair or replace defective products. Understanding warranty coverage is vital for managing risk and ensuring product longevity. Buyers should always clarify warranty terms to protect their investments.

6. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Knowing the lead time is crucial for planning and scheduling in production processes. Buyers should discuss lead times with suppliers to align delivery with project timelines.

By grasping these essential properties and terminologies, B2B buyers can make informed decisions when purchasing alternators, ensuring they select the right components for their operational needs.

Illustrative image related to alternator definition

Navigating Market Dynamics and Sourcing Trends in the alternator definition Sector

What Are the Current Market Dynamics and Key Trends in the Alternator Sector?

The global alternator market is witnessing significant growth, driven by the increasing demand for reliable and efficient power generation solutions across various sectors, including automotive, aviation, and renewable energy. As industries seek to enhance energy efficiency and reduce operational costs, the trend is shifting towards advanced alternator technologies that offer higher performance and lower maintenance needs. For international B2B buyers, particularly in emerging markets such as Africa and South America, this presents an opportunity to source innovative products that meet evolving energy demands.

Key trends impacting the alternator market include the integration of smart technologies and IoT capabilities. Modern alternators are now being designed with embedded sensors that provide real-time monitoring of performance metrics, enabling predictive maintenance and reducing downtime. Buyers from Europe and the Middle East are increasingly seeking suppliers who can provide alternators that are compatible with renewable energy sources, such as solar and wind, as these markets push for sustainable energy solutions.

Moreover, the rise of electric vehicles (EVs) is reshaping the demand for alternators. As traditional combustion engines give way to electric drivetrains, the focus is shifting towards alternators that support hybrid systems and energy recovery processes. This transition is particularly relevant for B2B buyers in regions like Germany, where the automotive industry is rapidly evolving. Understanding these market dynamics is crucial for buyers aiming to align their sourcing strategies with technological advancements and customer expectations.

How Important Is Sustainability and Ethical Sourcing in the Alternator Market?

The environmental impact of manufacturing processes and product lifecycle is becoming increasingly critical in the alternator market. B2B buyers are recognizing the importance of sourcing from manufacturers that prioritize sustainability. This includes using eco-friendly materials, reducing waste in production, and ensuring that the entire supply chain adheres to stringent environmental standards.

Ethical sourcing has gained prominence as companies strive to enhance their corporate social responsibility (CSR) profiles. Buyers are now more inclined to partner with suppliers who can demonstrate compliance with recognized sustainability certifications, such as ISO 14001 or the Global Reporting Initiative (GRI). These certifications not only signify a commitment to environmental stewardship but also assure buyers of a transparent supply chain.

In addition, the demand for “green” alternators, which utilize sustainable materials and energy-efficient technologies, is on the rise. This trend is particularly relevant for international buyers in regions like Africa and South America, where sustainable development is a key focus. By prioritizing sustainability and ethical sourcing, B2B buyers can not only reduce their environmental footprint but also enhance their market competitiveness and appeal to eco-conscious consumers.

What Is the Brief Evolution and History of the Alternator?

The alternator, as a critical component in electrical systems, has evolved significantly since its inception in the late 19th century. Originally developed as an “alternating current generator,” the first alternators were cumbersome and less efficient compared to modern designs. Over the years, advancements in materials and engineering have led to the creation of lighter and more reliable alternators that are capable of generating higher outputs with lower energy consumption.

By the mid-20th century, the automotive industry began to adopt alternators as a standard component, replacing older generator systems that had limitations in efficiency and durability. This shift was driven by the need for more reliable electrical systems in vehicles, paving the way for the integration of advanced electronics and features that we see in today’s automobiles.

As industries continue to innovate and demand more efficient power generation solutions, the alternator’s role is expected to expand further, with ongoing research focusing on enhancing performance, reducing costs, and improving sustainability. Understanding this evolution provides B2B buyers with context on the technological advancements and market demands that shape their sourcing decisions today.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator definition

-

How do I determine the right alternator specifications for my needs?

To select the appropriate alternator, begin by assessing the electrical load requirements of your application. Calculate the total wattage needed for all electrical components, and ensure the alternator’s output exceeds this demand. Additionally, consider the operating environment and whether you need a specific voltage rating. Always consult with manufacturers or suppliers for detailed specifications and compatibility with your existing systems. -

What are the key differences between alternators and generators?

Alternators and generators both produce electricity, but they do so differently. Alternators generate alternating current (AC) and convert it to direct current (DC) using diodes, making them more efficient and reliable. They operate at lower speeds and are lighter than traditional generators, which produce DC directly but require more maintenance. For most modern applications, especially in vehicles and aircraft, alternators are preferred due to their durability and efficiency. -

What factors should I consider when sourcing alternators internationally?

When sourcing alternators, evaluate the supplier’s experience in international trade, certifications, and compliance with local regulations. Investigate their manufacturing processes, quality assurance measures, and whether they offer customization options. Additionally, consider logistical aspects, including shipping times, customs duties, and local distribution channels, to ensure a smooth procurement process. -

What is the typical minimum order quantity (MOQ) for alternators?

Minimum order quantities for alternators can vary significantly based on the supplier and the specific model. Generally, MOQs range from 50 to 100 units for standard products. However, many manufacturers may offer flexibility for bulk orders or first-time buyers. Always discuss your requirements with suppliers to negotiate favorable terms that align with your business needs. -

How can I vet potential alternator suppliers effectively?

To vet alternator suppliers, start by reviewing their online presence, including company websites and customer testimonials. Request product samples to assess quality firsthand. Additionally, check for certifications such as ISO or industry-specific standards. Engage in direct communication to evaluate their responsiveness and willingness to address your specific needs, which can indicate their commitment to customer service. -

What payment terms are commonly offered in international alternator transactions?

Payment terms for international transactions can vary widely but often include options such as letter of credit, advance payment, or payment upon delivery. Many suppliers may also accept payment via escrow services to ensure security for both parties. It is crucial to discuss and agree upon payment terms upfront to avoid misunderstandings and ensure smooth financial transactions. -

What quality assurance processes should I expect from alternator manufacturers?

Reputable alternator manufacturers typically implement rigorous quality assurance processes, including raw material inspections, in-process testing, and final product evaluations. Look for suppliers who provide certifications or documentation that demonstrate compliance with industry standards. Additionally, inquire about warranty policies and after-sales support, as these can reflect the manufacturer’s confidence in their product quality. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider shipping methods, lead times, and customs clearance procedures. Evaluate whether your supplier can handle logistics or if you need to engage a freight forwarder. Be aware of import tariffs, taxes, and compliance with local regulations to avoid unexpected costs. Effective communication with your supplier about shipping terms can help streamline the process and ensure timely delivery.

Top 5 Alternator Definition Manufacturers & Suppliers List

1. Merriam-Webster – Alternator

Domain: merriam-webster.com

Registered: 1999 (26 years)

Introduction: Alternator: an electric generator for producing alternating current. First known use: 1883.

2. Study – Alternator Essentials

Domain: study.com

Registered: 1995 (30 years)

Introduction: An alternator is a crucial component of a vehicle’s electrical system that generates power for all electrical devices. Its primary function is to provide a steady stream of electrical energy to power components such as the motor, lights, power steering, power brakes, and electric locks. The alternator recharges the car battery while the vehicle is running, as the battery alone cannot sustain power…

3. Byju’s – Alternator

Domain: byjus.com

Registered: 2013 (12 years)

Introduction: Alternator: A device that converts mechanical energy into AC electrical energy. It induces alternating current, is highly efficient, has a higher output, conserves energy by using only the required amount, does not require polarization after installation, has a rotating magnetic field inside the stator, has a stationary armature, takes input from the stator, has a wide RPM range, produces voltage …

4. Dictionary.com – Alternator

Domain: dictionary.com

Registered: 1995 (30 years)

Introduction: An alternator is an electrical machine that generates an alternating current. It is commonly used in vehicles to charge the battery and power the electrical system when the engine is running. The term ‘alternator’ was first recorded between 1890 and 1895, derived from the word ‘alternate’ with the suffix ‘-or’.

5. Britannica – Alternator

Domain: britannica.com

Registered: 1995 (30 years)

Introduction: The alternator is a source of direct electric current in modern vehicles, providing power for ignition, lights, fans, and other electrical systems. It is mechanically coupled to the engine, featuring a rotor field coil supplied with current through slip rings and a stator with a three-phase winding. A rectifier converts the generated alternating current to direct current, while a voltage regulator…

Strategic Sourcing Conclusion and Outlook for alternator definition

As the global demand for reliable electrical systems continues to grow, understanding the intricacies of alternators is essential for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Alternators, as electric generators producing alternating current, play a critical role in various applications, from automotive to aviation. Their lightweight design, efficiency, and reliability make them superior to traditional generators, ensuring that businesses can optimize energy use and reduce operational costs.

Strategic sourcing of alternators involves not only identifying quality suppliers but also understanding the specific needs of your market. This approach can lead to better pricing, enhanced product quality, and improved supply chain resilience. Buyers should prioritize partnerships with manufacturers who demonstrate innovation and adaptability, especially in regions where energy solutions are evolving rapidly.

Looking ahead, the integration of advanced technologies in alternator design will likely enhance performance and sustainability. International B2B buyers are encouraged to stay informed about these advancements and engage with suppliers who prioritize eco-friendly practices. Embrace strategic sourcing today to secure a competitive edge and foster long-term growth in your business ventures.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to alternator definition

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.