Introduction: Navigating the Global Market for car starter cost

Navigating the global market for car starter costs presents a significant challenge for international B2B buyers. With diverse pricing structures and varying quality standards across regions, sourcing reliable starters can be daunting, particularly for businesses operating in Africa, South America, the Middle East, and Europe. This guide is designed to demystify the complexities of car starter costs, providing a comprehensive overview of types, applications, and the intricacies of supplier vetting.

In this guide, we will explore the different categories of car starters, including OEM and aftermarket options, and their respective applications across various vehicle types. Additionally, we will delve into critical factors influencing pricing, such as material quality, manufacturing standards, and regional supply chain dynamics. By presenting actionable insights and key considerations for evaluating suppliers, this resource empowers B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Ultimately, understanding the nuances of car starter costs is crucial for businesses looking to maintain vehicle performance and reliability. Whether you are a distributor, fleet manager, or automotive manufacturer, this guide will equip you with the knowledge needed to navigate the global marketplace effectively, ensuring you secure quality components at competitive prices.

Table Of Contents

- Top 5 Car Starter Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car starter cost

- Understanding car starter cost Types and Variations

- Key Industrial Applications of car starter cost

- 3 Common User Pain Points for ‘car starter cost’ & Their Solutions

- Strategic Material Selection Guide for car starter cost

- In-depth Look: Manufacturing Processes and Quality Assurance for car starter cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car starter cost’

- Comprehensive Cost and Pricing Analysis for car starter cost Sourcing

- Alternatives Analysis: Comparing car starter cost With Other Solutions

- Essential Technical Properties and Trade Terminology for car starter cost

- Navigating Market Dynamics and Sourcing Trends in the car starter cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car starter cost

- Strategic Sourcing Conclusion and Outlook for car starter cost

- Important Disclaimer & Terms of Use

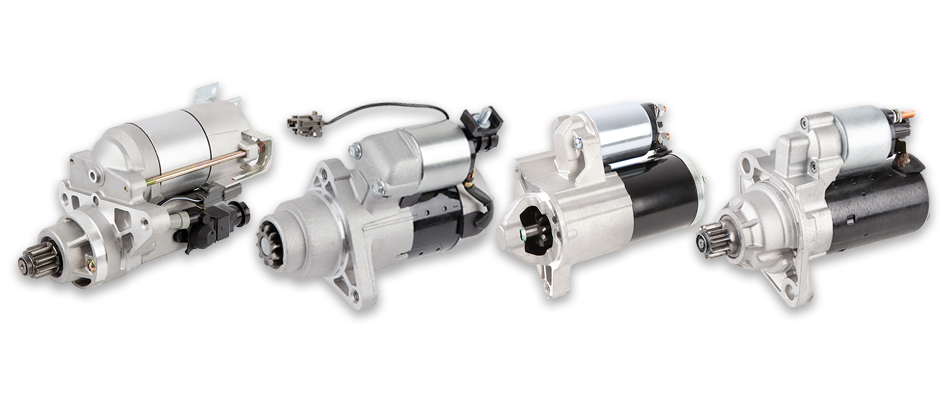

Understanding car starter cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Starters | Original equipment manufacturer parts; designed specifically for a vehicle model. | Dealerships, repair shops, fleet management. | Pros: Guaranteed fit and performance. Cons: Higher cost compared to aftermarket options. |

| Aftermarket Starters | Third-party manufactured parts; may vary in quality and price. | Independent auto shops, online retailers. | Pros: Generally lower cost; wider selection. Cons: Variable quality; potential compatibility issues. |

| Remanufactured Starters | Used starters that have been refurbished to meet OEM standards. | Budget-conscious repair shops, fleet services. | Pros: Cost-effective; environmentally friendly. Cons: May not have the same reliability as new parts. |

| High-Performance Starters | Designed for enhanced power and efficiency; often used in racing. | Performance shops, racing teams, specialty garages. | Pros: Improved starting power; suitable for high-demand applications. Cons: Higher price point; may require specific installation. |

| Remote Start Systems | Allow starting the vehicle from a distance; includes additional features like security. | Automotive electronics retailers, vehicle customization shops. | Pros: Convenience and added security. Cons: Installation complexity; potential compatibility issues with older vehicles. |

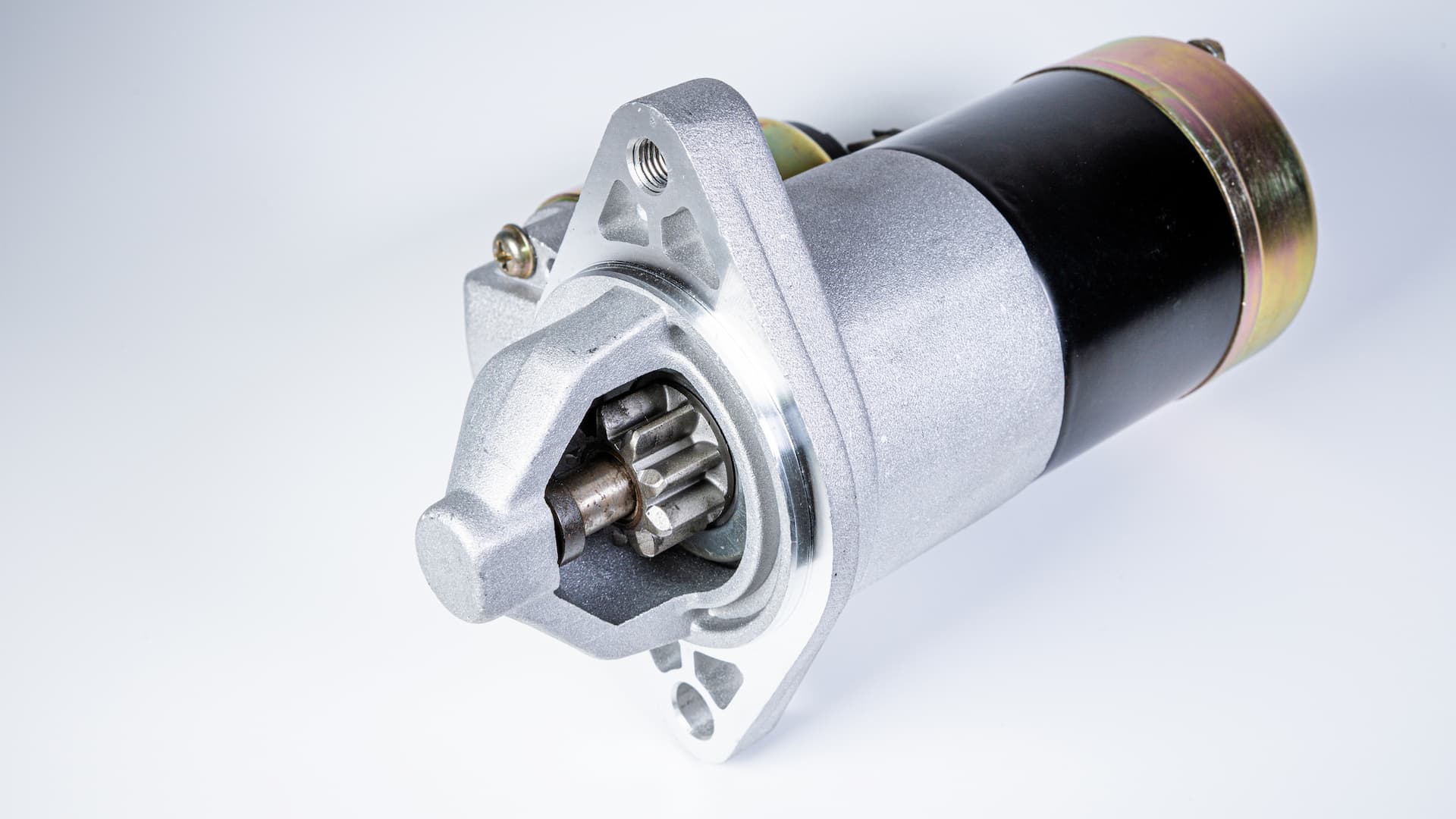

What Are OEM Starters and When Should They Be Purchased?

OEM starters are specifically designed to meet the standards of the vehicle manufacturer, ensuring optimal fit and performance. They are typically used by dealerships and authorized repair shops to maintain warranty compliance and vehicle integrity. B2B buyers should consider OEM starters for fleets or high-value vehicles where reliability is paramount, despite the higher costs associated with these parts.

How Do Aftermarket Starters Differ from OEM Options?

Aftermarket starters are produced by third-party manufacturers and offer a range of prices and quality levels. They are commonly utilized by independent auto shops and online retailers due to their lower cost and wider availability. While B2B buyers benefit from significant savings, they must carefully evaluate the quality and compatibility of these products to avoid potential issues in performance.

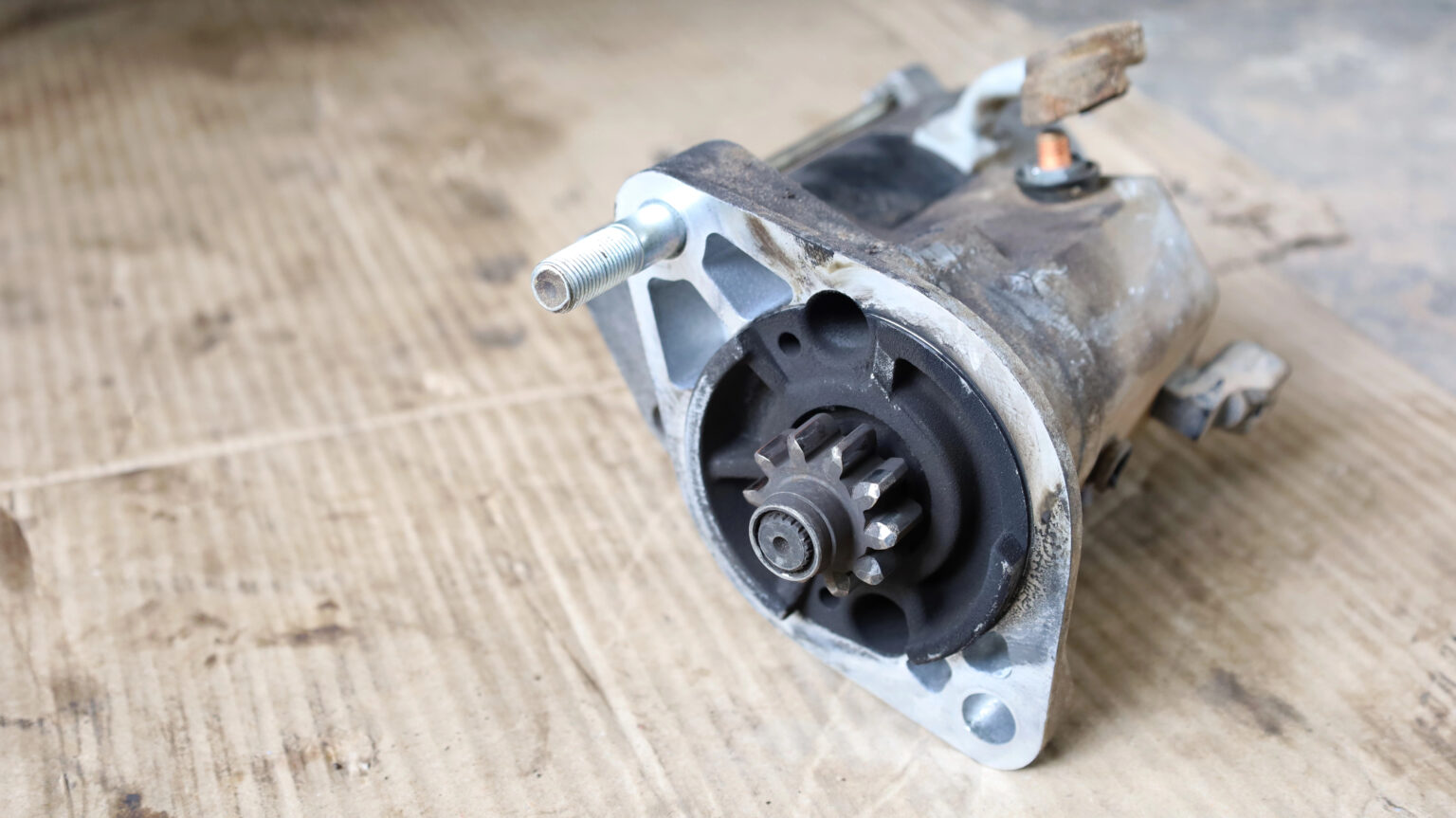

What Advantages Do Remanufactured Starters Offer for Budget-Conscious Buyers?

Remanufactured starters are previously used parts that have been restored to meet OEM specifications. This option appeals to budget-conscious repair shops and fleet services looking to reduce costs without sacrificing quality. B2B buyers should consider remanufactured starters for general maintenance and repairs, keeping in mind that while they are cost-effective, they may not provide the same reliability as brand-new components.

Why Choose High-Performance Starters for Specialized Applications?

High-performance starters are engineered for enhanced efficiency and power, making them ideal for racing and high-demand automotive applications. They are primarily purchased by performance shops and racing teams. B2B buyers should opt for these starters when dealing with modified vehicles or applications that require superior starting power, understanding that the investment may be higher than standard options.

What Are the Benefits of Remote Start Systems in B2B Transactions?

Remote start systems allow users to start their vehicles from a distance, often incorporating additional security features. Automotive electronics retailers and vehicle customization shops frequently install these systems. B2B buyers should consider remote start systems for vehicles in harsh climates or for added convenience, but they must also be aware of installation complexities and potential compatibility issues with older models.

Key Industrial Applications of car starter cost

| Industry/Sector | Specific Application of car starter cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Replacement of faulty starters in vehicles | Reduces downtime and repair costs, ensuring customer satisfaction | OEM vs. aftermarket parts, warranty terms, delivery times |

| Fleet Management | Maintenance of fleet vehicles | Enhances fleet reliability and operational efficiency | Bulk purchasing options, compatibility with multiple vehicle types, pricing agreements |

| Vehicle Manufacturing | Production of vehicles with integrated starter systems | Lowers production costs and improves assembly efficiency | Supplier reliability, quality assurance, lead times |

| Export & Logistics | Shipping vehicles with compliant starter systems | Ensures vehicles meet international standards and regulations | Compliance with export regulations, documentation, shipping logistics |

| Agricultural Equipment | Starting systems for tractors and machinery | Increases productivity in agricultural operations | Compatibility with various machinery models, performance standards, cost-effectiveness |

How is Car Starter Cost Applied in the Automotive Repair Industry?

In the automotive repair industry, understanding car starter costs is crucial for mechanics and repair shops. A faulty starter can lead to vehicle breakdowns, impacting customer satisfaction and business reputation. By sourcing affordable yet reliable starters, repair shops can reduce their overhead costs and pass savings onto customers. International buyers should focus on OEM versus aftermarket parts, considering warranty terms and delivery times to ensure they maintain service quality while managing costs effectively.

What Role Does Car Starter Cost Play in Fleet Management?

For fleet management, the cost of car starters directly impacts operational efficiency. A well-maintained fleet requires reliable starting systems to minimize downtime. By purchasing starters in bulk, fleet managers can negotiate better pricing and ensure they have the right components for various vehicle models. Key considerations include compatibility with multiple vehicles and the establishment of pricing agreements to manage long-term costs effectively, especially in regions with fluctuating parts availability.

Why is Car Starter Cost Important in Vehicle Manufacturing?

In vehicle manufacturing, the integration of starter systems is essential for production efficiency. The cost of starters affects the overall manufacturing budget, and sourcing high-quality components can lead to lower assembly costs and improved product reliability. Manufacturers must evaluate supplier reliability, quality assurance processes, and lead times to ensure they can meet production schedules while keeping costs under control. This is particularly important for international manufacturers looking to maintain competitiveness in diverse markets.

How is Car Starter Cost Relevant in Export & Logistics?

For businesses involved in exporting vehicles, the cost of car starters is a critical factor in ensuring compliance with international standards. Vehicles must be equipped with reliable starting systems to meet regulatory requirements in different countries. Exporters should consider compliance with local regulations, proper documentation, and efficient shipping logistics to avoid delays. Understanding the total cost of ownership, including starter systems, can help exporters optimize their pricing strategies and enhance competitiveness in global markets.

What is the Impact of Car Starter Cost on Agricultural Equipment?

In agriculture, the cost of car starters is vital for the operation of tractors and other machinery. Reliable starting systems are essential for maintaining productivity during planting and harvesting seasons. Agricultural businesses must ensure that they source starters compatible with various machinery models to avoid operational delays. Cost-effectiveness and performance standards are critical for buyers, particularly in regions where agricultural machinery is a primary investment, ensuring that they can maximize their operational efficiency while managing expenses.

3 Common User Pain Points for ‘car starter cost’ & Their Solutions

Scenario 1: Navigating High Replacement Costs for Car Starters

The Problem: Many B2B buyers, particularly those managing fleets or automotive parts suppliers, often face the challenge of unexpectedly high replacement costs for car starters. When a vehicle fails to start, it can lead to costly downtime, affecting operational efficiency and customer satisfaction. Additionally, the market is filled with a wide variety of starter options, each with differing prices, making it difficult for buyers to ascertain which products offer the best value for their investment.

The Solution: To mitigate high replacement costs, B2B buyers should conduct thorough market research and build relationships with reputable suppliers. Start by comparing prices from multiple vendors and considering both OEM (Original Equipment Manufacturer) and aftermarket starters. Look for suppliers that offer bulk purchase discounts or loyalty programs. Moreover, implementing a regular maintenance schedule can help identify starter issues before they escalate, allowing for timely replacements at lower costs. Establishing a partnership with suppliers who provide warranties or guarantees can also add an extra layer of security, ensuring that any defective parts can be replaced without incurring additional expenses.

Scenario 2: Ensuring Compatibility with Diverse Vehicle Models

The Problem: B2B buyers often struggle with ensuring that the starters they procure are compatible with a wide range of vehicle models. This issue is particularly prevalent in regions with diverse vehicle populations, such as Africa and South America, where various makes and models are in use. Misordering the wrong starter can lead to delays, increased costs, and potential damage to the vehicle, frustrating both suppliers and customers.

The Solution: To overcome compatibility challenges, buyers should utilize comprehensive parts catalogs and databases that provide detailed specifications for each starter, including model compatibility and installation instructions. Implementing a systematic approach to inventory management—such as using inventory management software—can help track which starters are in stock and which are needed for upcoming repairs or replacements. Additionally, establishing communication with vehicle manufacturers or authorized dealers can provide valuable insights into the latest starter technologies and compatibility updates. Training staff on these systems ensures they are well-equipped to handle inquiries and orders efficiently.

Scenario 3: Managing Supply Chain Disruptions Affecting Starter Availability

The Problem: Global supply chain disruptions, exacerbated by factors such as geopolitical tensions and the COVID-19 pandemic, have made it increasingly difficult for B2B buyers to secure car starters in a timely manner. Delays in shipment can lead to extended vehicle downtime, impacting service delivery and customer trust. Buyers may find themselves facing fluctuating prices and uncertain availability, complicating budget forecasts and inventory management.

The Solution: To navigate supply chain disruptions, B2B buyers should diversify their sourcing strategies. Establish relationships with multiple suppliers across different regions to reduce dependency on a single source. Implementing a just-in-time inventory system can help manage stock levels effectively, ensuring that essential starters are on hand without overstocking. Additionally, keeping abreast of market trends and potential disruptions allows buyers to proactively adjust their procurement strategies. Regularly communicating with suppliers about lead times and potential shortages can also foster transparency, enabling buyers to plan accordingly and maintain operational continuity.

Strategic Material Selection Guide for car starter cost

What Are the Key Materials Used in Car Starters and Their Implications for Cost?

When selecting materials for car starters, understanding their properties and implications on performance and cost is crucial for B2B buyers. Here, we analyze four common materials used in car starter construction: steel, aluminum, copper, and plastic composites.

How Does Steel Affect Car Starter Performance and Cost?

Steel is a primary material used in the manufacturing of car starter housings and components due to its high strength and durability. Key properties include excellent resistance to wear and high-temperature performance, making it suitable for the extreme conditions that starters face during operation.

Pros: Steel’s strength ensures longevity and reliability, which is critical for automotive applications. It is also relatively low in cost compared to other metals, making it an economical choice for manufacturers.

Cons: However, steel is prone to corrosion if not properly treated or coated, which can affect performance and lifespan. Additionally, the weight of steel can lead to increased fuel consumption in vehicles.

For international buyers, particularly from regions like Africa and South America, compliance with corrosion resistance standards is essential, especially in humid or coastal environments. Buyers should consider ASTM standards for steel quality.

What Role Does Aluminum Play in Car Starter Design?

Aluminum is increasingly used in car starters due to its lightweight properties and good thermal conductivity. It is often utilized in components where weight reduction is a priority.

Illustrative image related to car starter cost

Pros: The lightweight nature of aluminum contributes to improved fuel efficiency and overall vehicle performance. Additionally, aluminum has good resistance to corrosion, especially when anodized.

Cons: The main drawback is that aluminum is generally more expensive than steel and can be less durable under high-stress conditions. Its manufacturing complexity can also lead to higher production costs.

International buyers should ensure that aluminum components meet relevant standards, such as DIN or JIS, to guarantee quality and performance.

Illustrative image related to car starter cost

Why Is Copper Essential for Electrical Connections in Starters?

Copper is a critical material for electrical connections in car starters due to its excellent electrical conductivity. This property ensures efficient power transfer, which is vital for quick engine starts.

Pros: Copper’s conductivity enhances performance and reduces energy loss, making it ideal for high-performance starters. It is also relatively easy to work with in terms of manufacturing.

Cons: The primary limitation of copper is its susceptibility to corrosion, which can lead to electrical failures over time. Additionally, copper prices can be volatile, impacting overall costs.

For buyers in Europe and the Middle East, adhering to electrical standards and ensuring that copper components are treated for corrosion resistance is vital for long-term reliability.

How Do Plastic Composites Enhance Starter Applications?

Plastic composites are often used in non-structural components of car starters, such as covers and insulators. They provide a lightweight alternative to metals.

Illustrative image related to car starter cost

Pros: These materials are resistant to corrosion and can be molded into complex shapes, allowing for innovative designs. They are also generally lower in cost compared to metals.

Cons: However, plastic composites may not withstand high temperatures and mechanical stresses as well as metals, which can limit their application in critical areas.

International buyers should consider the specific temperature and pressure ratings of plastic composites and ensure compliance with relevant standards to avoid performance issues in extreme conditions.

Illustrative image related to car starter cost

Summary Table of Material Selection for Car Starters

| Material | Typical Use Case for car starter cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Housings and structural components | High strength and durability | Prone to corrosion | Low |

| Aluminum | Lightweight components | Lightweight, good corrosion resistance | More expensive, less durable | Med |

| Copper | Electrical connections | Excellent conductivity | Susceptible to corrosion | Med |

| Plastic Composites | Covers and insulators | Corrosion resistant, moldable | Limited high-temperature performance | Low |

In summary, understanding the properties, advantages, and limitations of these materials can guide B2B buyers in making informed decisions that align with their operational needs and compliance requirements in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for car starter cost

What Are the Key Stages in the Manufacturing Process of Car Starters?

The manufacturing of car starters involves several critical stages that ensure the final product is reliable and efficient. Understanding these stages can help B2B buyers make informed decisions when sourcing starters for their automotive needs.

1. Material Preparation: What Materials Are Used and How Are They Processed?

The first step in the manufacturing process is the preparation of raw materials. Car starters primarily consist of metals such as steel, copper, and aluminum, along with various plastics for insulation and housing.

-

Metal Processing: The metals undergo processes like forging, casting, or machining to achieve the desired shape and dimensions. For instance, copper is often used for windings due to its excellent conductivity.

-

Plastic Components: Plastics are molded into specific shapes to create housings and insulators that protect the electrical components from damage and environmental factors.

2. Forming: How Are Car Starters Shaped?

After material preparation, the next stage is forming. This involves shaping the components into their final forms using various techniques.

Illustrative image related to car starter cost

-

Stamping and Die-Cutting: These methods are commonly used to create metal components like the starter’s housing and brackets. Precision in these processes is critical to ensure that parts fit together seamlessly.

-

Winding: The armature, an essential part of the starter, is created by winding copper wire around a core. This step requires precision to ensure optimal electrical performance.

3. Assembly: What Are the Steps Involved in Assembling Car Starters?

Once the components are formed, they are assembled into the final product. This stage includes:

-

Mechanical Assembly: Parts such as the motor, solenoid, and pinion gear are assembled. Each component must be aligned correctly to ensure functionality.

-

Electrical Connections: Wiring and connections are made to ensure that the starter operates effectively when the vehicle is started. Quality checks during assembly can prevent common issues like short circuits.

4. Finishing: What Final Steps Ensure Quality and Durability?

The final stage of the manufacturing process involves finishing touches that enhance the product’s durability and performance.

-

Coating and Painting: Starters are often coated to prevent corrosion and wear. This step is crucial for starters that will be used in harsh environments.

-

Final Assembly Inspection: Before the starters are packaged, they undergo a thorough inspection to ensure all components are correctly installed and functioning.

How Is Quality Assurance Implemented in Car Starter Manufacturing?

Quality assurance (QA) is vital in the production of car starters, as it directly impacts the product’s reliability and safety.

What International Standards Guide Quality Assurance in Car Starter Production?

B2B buyers should be aware of various international standards that govern the manufacturing and quality assurance of automotive components.

-

ISO 9001: This standard focuses on quality management systems. Manufacturers that comply with ISO 9001 demonstrate their commitment to quality processes and customer satisfaction.

-

CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API Standards: The American Petroleum Institute (API) sets standards that can apply to automotive parts, particularly those that interact with fuel systems.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early and ensure high standards.

-

Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specifications before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify issues in real-time, preventing defective parts from being assembled into the final product.

-

Final Quality Control (FQC): The completed starters undergo rigorous testing, including electrical and mechanical performance tests, to confirm they meet all specifications and safety standards.

What Testing Methods Are Commonly Used to Ensure Product Reliability?

Testing is a critical aspect of quality assurance for car starters. Common methods include:

-

Functional Testing: Each starter is tested to ensure it can engage and disengage properly under various conditions, simulating real-world usage.

-

Durability Testing: Starters may be subjected to extreme conditions, such as high temperatures or humidity, to ensure they can withstand environmental stressors.

-

Vibration Testing: This assesses how well the starter can endure vibrations that occur during vehicle operation, ensuring it remains functional over time.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, verifying a supplier’s quality assurance practices is essential to ensure reliability and compliance.

What Steps Can Buyers Take to Ensure Supplier Compliance with Quality Standards?

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess adherence to quality standards and manufacturing processes. This can include reviewing documentation, visiting facilities, and observing production practices.

-

Requesting Quality Reports: Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC tests. These documents can help buyers evaluate product reliability before making purchasing decisions.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices, ensuring compliance with international standards.

What Are the Unique Quality Control Considerations for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must consider unique factors that can affect quality assurance.

-

Regulatory Compliance: Different countries have varying regulations regarding automotive parts. Buyers must ensure that their suppliers comply with local regulations to avoid penalties or product recalls.

-

Supply Chain Transparency: Ensuring transparency in the supply chain can help buyers assess risks related to quality control. This includes understanding where materials are sourced and how they are processed.

-

Cultural and Environmental Factors: Buyers should be aware of how local conditions might affect manufacturing quality, such as variations in temperature or humidity that could impact materials and processes.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing car starters, ensuring they receive reliable and compliant products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car starter cost’

In the competitive landscape of automotive parts procurement, understanding the costs associated with car starters is essential for B2B buyers. This guide outlines the necessary steps to ensure you make informed purchasing decisions that align with your business’s operational needs and budget.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical requirements for the car starters you need. This includes understanding the specific make and model of vehicles you are servicing, as well as any performance specifications necessary for your applications.

– Key Considerations: Voltage ratings, starter type (gear reduction vs. direct drive), and compatibility with existing systems are critical factors that can affect performance and reliability.

Step 2: Research Market Prices

Conduct thorough market research to gain insights into current pricing trends for car starters. This step is vital to avoid overpaying and to understand the price range for different types of starters, including OEM and aftermarket options.

– Action Items: Utilize online platforms, industry reports, and competitor pricing to establish a baseline for what you should expect to pay.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a comprehensive evaluation. This involves reviewing their company profile, product quality, and customer service reputation.

– What to Look For: Request references from similar businesses and check for customer reviews on platforms like Trustpilot or industry-specific forums. A supplier with a proven track record can significantly reduce risks associated with procurement.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and compliance with international standards. This step is particularly important for maintaining quality and safety in automotive parts.

– Certification Examples: Look for ISO certifications, compliance with local regulations, and any specific certifications that pertain to automotive parts. Verified suppliers are more likely to provide reliable products.

Step 5: Assess Shipping and Delivery Options

Investigate the shipping and delivery capabilities of potential suppliers. Timely delivery is crucial in the automotive sector, where delays can lead to significant operational disruptions.

– Considerations: Evaluate shipping times, costs, and the reliability of delivery services. Additionally, inquire about options for expedited shipping if urgent needs arise.

Step 6: Negotiate Terms and Pricing

Once you have narrowed down your options, engage in negotiations with suppliers regarding pricing and terms of service. Effective negotiation can lead to better pricing, payment terms, and warranty conditions.

– Tactics to Employ: Don’t hesitate to leverage competitive quotes from other suppliers to negotiate better terms. Establish clear expectations for after-sales service and support.

Step 7: Review Purchase Agreements Carefully

Before finalizing any agreements, review all purchase contracts meticulously. Ensure that all terms, including payment schedules, delivery timelines, and warranty conditions, are clearly outlined to avoid potential disputes.

– Final Checks: Look for hidden fees, return policies, and conditions for warranty claims. A well-defined agreement protects both parties and fosters a long-term business relationship.

By following these steps, B2B buyers can navigate the complexities of sourcing car starters effectively, ensuring that they procure high-quality products at competitive prices while building strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for car starter cost Sourcing

What Are the Key Cost Components of Car Starter Manufacturing?

When sourcing car starters, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of raw materials, such as steel, copper, and plastic, can significantly impact the final price. The choice of materials affects durability and performance, which can vary based on the vehicle specifications.

-

Labor: Labor costs encompass wages, benefits, and training for skilled workers involved in the production process. In regions like Africa and South America, labor costs may be lower, but the availability of skilled labor can vary.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs for creating molds and production equipment can be substantial. These costs are typically amortized over the production volume, impacting the per-unit price.

-

Quality Control: Implementing rigorous QC processes ensures that the products meet industry standards and customer expectations. However, this adds to the overall cost, particularly if certifications (like ISO) are required.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, mode of transportation, and shipping terms can influence logistics costs.

-

Margin: Suppliers add a profit margin to their costs, which can vary based on market demand, competition, and negotiation dynamics.

How Do Price Influencers Affect Car Starter Costs?

Several price influencers can significantly impact the cost of car starters, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Buyers should negotiate MOQ terms to optimize cost savings while ensuring they meet their inventory needs.

-

Specifications and Customization: Custom starters designed for specific vehicle models or performance enhancements can lead to higher prices. Buyers should assess the necessity of customization against their budget constraints.

-

Material Quality and Certifications: Higher-quality materials and certifications can increase costs but may also enhance product lifespan and reliability. It’s essential to evaluate whether these investments align with the total cost of ownership.

-

Supplier Factors: Supplier reputation, reliability, and history of quality can affect pricing. Established suppliers may charge a premium for their products due to perceived value and trustworthiness.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk transfer, impacting the overall pricing strategy.

What Are the Best Negotiation and Cost-Efficiency Strategies for Buyers?

For international B2B buyers, particularly in emerging markets, implementing strategic negotiation and cost-efficiency tactics can yield significant savings.

Illustrative image related to car starter cost

-

Leverage Total Cost of Ownership (TCO): Focus on the TCO rather than just the initial purchase price. Consider factors like durability, warranty, and maintenance costs to assess the long-term value of the starter.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, priority service, and more favorable terms. Suppliers may be more willing to negotiate with trustworthy partners.

-

Consider Regional Suppliers: Sourcing from local manufacturers can reduce logistics costs and lead times. Additionally, regional suppliers may offer more competitive pricing due to lower overhead costs.

-

Be Transparent About Needs: Clearly communicate your specifications and expectations with suppliers. This transparency can facilitate better pricing and reduce misunderstandings that may lead to costly errors.

-

Stay Informed on Market Trends: Keeping abreast of industry trends and fluctuations in material costs can provide leverage during negotiations and help in making informed purchasing decisions.

Disclaimer on Indicative Prices

It’s important to note that prices for car starters can vary widely based on the factors discussed above. Indicative prices should be viewed as a starting point for negotiation and not as fixed costs. Always conduct thorough market research and consider obtaining multiple quotes to ensure competitive pricing.

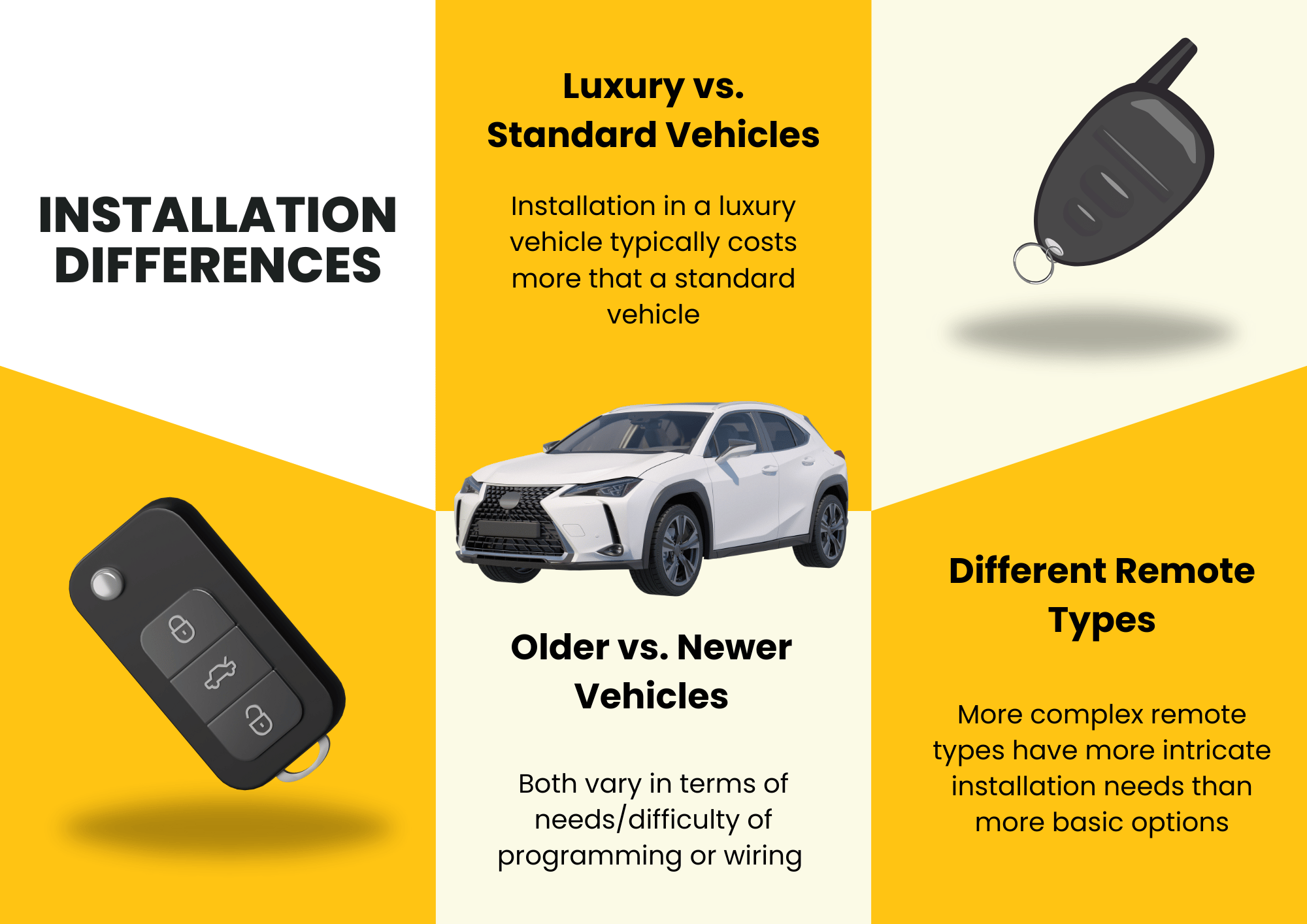

Alternatives Analysis: Comparing car starter cost With Other Solutions

Exploring Alternative Solutions to Car Starter Costs

In the automotive industry, understanding the cost dynamics of car starters is crucial for B2B buyers. While traditional car starters are a reliable solution, alternative technologies and methods can provide varying benefits that may better align with specific business needs. This section compares the cost of traditional car starters with two viable alternatives: remote car starters and battery jump starters.

Comparison Table

| Comparison Aspect | Car Starter Cost | Remote Car Starter | Battery Jump Starter |

|---|---|---|---|

| Performance | Reliable but limited to starting the engine | Enhances convenience and vehicle security | Provides a temporary solution for dead batteries |

| Cost | Typically $150-$300 for new starters | Ranges from $50-$200 depending on features | Costs between $50-$150 for decent models |

| Ease of Implementation | Requires professional installation for some models | Generally easy installation; some models are DIY-friendly | Plug-and-play; very easy to use |

| Maintenance | May require occasional replacement | Minimal; typically just battery upkeep | Requires recharging; may need replacement after extensive use |

| Best Use Case | Essential for engine start | Ideal for convenience and security in colder climates | Useful for emergency situations or in case of battery failure |

Detailed Breakdown of Alternatives

Remote Car Starter

Remote car starters offer a blend of convenience and security, allowing users to start their vehicle from a distance, which is particularly beneficial in colder climates. These systems can also integrate security features, such as alarm systems, providing added value. However, the initial cost can vary significantly based on features and the complexity of installation. While remote starters do not replace the function of a traditional starter, they enhance the user experience by allowing pre-heating of the engine and cabin, making them an attractive option for businesses with a fleet operating in harsh weather.

Illustrative image related to car starter cost

Battery Jump Starter

Battery jump starters are portable devices that can jump-start a vehicle’s engine without needing another vehicle. They are particularly advantageous in emergency situations where traditional starter issues arise. Their affordability and ease of use make them a popular choice for businesses that require mobility and quick solutions. However, the downside is that they only provide a temporary fix for a dead battery and are not a substitute for a fully functioning starter. This solution is ideal for companies that want to equip their fleet with emergency tools to minimize downtime.

Making the Right Choice for Your Business Needs

When deciding between car starter costs and alternative solutions, B2B buyers should assess their specific operational requirements. Companies operating in regions with extreme weather might prioritize remote car starters for convenience and security, while those focused on emergency readiness may find battery jump starters more beneficial. Ultimately, the right choice will depend on a combination of performance needs, budget constraints, and the specific challenges faced by the fleet or individual vehicles. Analyzing these factors will help businesses make informed decisions that align with their operational strategies and enhance overall efficiency.

Essential Technical Properties and Trade Terminology for car starter cost

What Are the Key Technical Properties Influencing Car Starter Costs?

When evaluating the cost of car starters, several technical specifications play a crucial role in determining both pricing and performance. Understanding these properties can empower B2B buyers to make informed purchasing decisions.

-

Material Grade

– The material used in manufacturing car starters significantly affects durability and performance. Common materials include high-grade steel and composites, which provide strength and resistance to environmental factors. Buyers should prioritize starters made from corrosion-resistant materials for longevity, especially in regions with harsh weather conditions. -

Torque Rating

– Torque rating, measured in Newton-meters (Nm), indicates the rotational force the starter can provide. A higher torque rating often translates to better performance, especially in larger vehicles with higher engine displacements. For B2B buyers, selecting starters with appropriate torque ratings is critical to ensure compatibility with specific vehicle models. -

Electrical Specifications

– This includes voltage (typically 12V for most vehicles) and amp draw. Understanding the electrical requirements is vital for ensuring that the starter operates efficiently within the vehicle’s electrical system. B2B buyers should verify these specifications to avoid issues like battery drain or inadequate starting power. -

Weight

– The weight of the starter can influence installation and performance. Lighter starters may offer easier installation and can positively impact the vehicle’s overall performance, particularly in high-performance applications. Buyers should consider weight when sourcing starters for specific vehicle types. -

Fitment and Compatibility

– Each starter is designed to fit specific vehicle makes and models. Detailed fitment notes ensure that the starter will work seamlessly within the intended vehicle. B2B purchasers must verify compatibility to prevent costly returns and installation delays.

What Are Common Trade Terms Related to Car Starter Costs?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B marketplace. Here are some essential terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– OEM parts are produced by the vehicle’s original manufacturer. They typically guarantee compatibility and quality, which can justify a higher price. Buyers looking for reliability often prefer OEM starters due to their proven performance. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to ensure they meet the supplier’s requirements while also managing inventory costs effectively. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing for specific products. B2B buyers utilize RFQs to compare costs and terms from different suppliers, which aids in securing the best deal. -

Incoterms (International Commercial Terms)

– These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps in understanding shipping responsibilities, risk management, and cost allocation. -

Aftermarket

– Aftermarket parts are replacements made by companies other than the original manufacturer. They may be less expensive than OEM options but vary in quality. B2B buyers should evaluate aftermarket starters carefully to ensure they meet performance standards. -

Warranty

– A warranty is a promise by the manufacturer to repair or replace a defective product within a specified time frame. Understanding warranty terms is vital for buyers, as it can influence long-term costs and service quality.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of the car starter market more effectively, ensuring they make informed purchasing decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the car starter cost Sector

What Are the Key Market Dynamics and Sourcing Trends in the Car Starter Cost Sector?

The global car starter market is undergoing significant transformation driven by technological advancements, economic shifts, and evolving consumer expectations. A surge in vehicle production, particularly in developing regions like Africa and South America, is boosting demand for both OEM and aftermarket starters. Furthermore, the rising trend toward electric vehicles (EVs) is reshaping the starter market, as traditional starters are being replaced by advanced start-stop systems that enhance fuel efficiency. This shift necessitates B2B buyers to adapt their sourcing strategies to include suppliers who offer innovative solutions for both conventional and electric vehicles.

Emerging technologies such as AI and IoT are also influencing sourcing trends. Companies are increasingly leveraging data analytics for demand forecasting and inventory management, allowing for more efficient supply chain operations. Additionally, international buyers are gravitating towards suppliers that can offer competitive pricing without compromising on quality, as evidenced by the price variations observed in different markets. For instance, while the average starter price may hover around $150 in local parts stores, alternatives are available at significantly lower costs, such as $35 from online retailers, prompting buyers to explore diverse sourcing options.

How Is Sustainability Influencing B2B Sourcing Decisions in the Car Starter Sector?

Sustainability has become a pivotal factor in the decision-making processes of B2B buyers in the car starter market. With increasing awareness of environmental impacts, companies are prioritizing ethical sourcing practices and sustainability in their supply chains. This shift is not only driven by regulatory pressures but also by consumer demand for environmentally responsible products. Buyers are now more inclined to partner with manufacturers who utilize eco-friendly materials and sustainable production methods.

The significance of certifications such as ISO 14001 and the use of recycled materials is growing, as they indicate a commitment to environmental stewardship. B2B buyers are advised to seek out suppliers who can provide transparency in their sourcing and production processes, ensuring compliance with global sustainability standards. Additionally, the integration of circular economy principles—where materials are reused and recycled—can lead to cost savings and improved brand reputation, making it a vital consideration in sourcing strategies.

What Is the Historical Context of the Car Starter Cost Market?

The car starter market has evolved significantly since the introduction of the electric starter motor in the early 20th century. Initially, starters were bulky and costly, primarily used in luxury vehicles. However, advancements in technology and manufacturing processes have led to the development of compact, cost-effective starter motors, making them accessible for a broader range of vehicles. Over the decades, the emergence of global supply chains has facilitated the distribution of starter components, allowing for competitive pricing and diversified sourcing options.

As the automotive landscape continues to change—especially with the rise of electric vehicles—the car starter market is poised for further innovation. B2B buyers must stay informed about these historical trends and current dynamics to effectively navigate the complexities of sourcing in this evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of car starter cost

-

How do I determine the cost of a car starter for my specific vehicle?

To accurately determine the cost of a car starter, begin by identifying the make, model, and year of the vehicle. This information is crucial as starter prices can vary significantly based on these factors. Utilize online parts catalogs or contact suppliers directly for quotes. Additionally, consider whether you need an OEM (Original Equipment Manufacturer) part, which may be more expensive, or an aftermarket option, which could offer savings. Don’t forget to account for shipping and potential customs fees if sourcing internationally. -

What factors influence the price of car starters in the international market?

The price of car starters can be influenced by several factors, including the brand, type (OEM vs. aftermarket), and the materials used in production. Additionally, market demand, currency fluctuations, and shipping costs can impact pricing, especially for international buyers. Local tariffs and import duties may also add to the overall cost. It’s advisable to compare prices from multiple suppliers and consider the total landed cost when sourcing from overseas. -

What is the best way to vet suppliers for car starters?

To vet suppliers effectively, start by checking their industry reputation and customer reviews. Request references from previous clients to gauge reliability and service quality. Ensure they comply with international standards and certifications relevant to automotive parts. Additionally, conduct a site visit if feasible or request a virtual tour to assess their manufacturing capabilities. Utilizing platforms like Alibaba or Global Sources can also help identify credible suppliers based on ratings and transaction history. -

What are the minimum order quantities (MOQ) for car starters?

Minimum order quantities for car starters can vary widely depending on the supplier and the specific product. Some manufacturers may offer MOQs as low as 10-50 units, while others might require orders of 100 or more. It’s important to clarify this upfront during negotiations, especially if you’re a smaller business. Discussing flexibility in MOQs can also lead to better pricing or terms, particularly if you plan to establish a long-term relationship with the supplier. -

Can I customize car starters for my business needs?

Yes, many manufacturers offer customization options for car starters, such as branding, performance specifications, or specific features to meet unique market demands. When inquiring about customization, be clear about your requirements, including any design elements or performance enhancements you need. Keep in mind that custom orders may involve higher costs and longer lead times, so factor this into your planning and budget. -

What payment terms should I expect when sourcing car starters internationally?

Payment terms can vary significantly among suppliers. Common options include upfront payment, partial payment with the balance due upon delivery, or payment against documents. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Consider utilizing secure payment methods like letters of credit or escrow services to protect your investment. Always review the supplier’s payment policies and be cautious of those requiring full payment upfront without established trust. -

What quality assurance measures should I implement when sourcing car starters?

Implementing quality assurance measures is essential to ensure you receive reliable products. Request certifications from suppliers that demonstrate compliance with quality standards, such as ISO 9001. Establish a clear inspection process, including pre-shipment inspections, to verify product quality before acceptance. Additionally, consider setting up a return policy for defective items and maintain open communication with suppliers to address any quality issues promptly. -

What logistics considerations should I keep in mind when importing car starters?

When importing car starters, logistics plays a critical role in ensuring timely and cost-effective delivery. Research the best shipping options based on your location, considering air freight for speed and sea freight for cost savings. Be aware of customs regulations and documentation required for importing auto parts into your country. Collaborating with a freight forwarder can simplify the process, helping you navigate duties, taxes, and compliance requirements efficiently.

Top 5 Car Starter Cost Manufacturers & Suppliers List

1. Reddit – Starter Replacement Costs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Starter replacement, labor charges, diagnostic fees, OEM starter pricing, markup on parts.

2. Best Buy – Remote Car Starter

Domain: bestbuy.com

Registered: 1994 (31 years)

Introduction: This company, Best Buy – Remote Car Starter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Facebook – Starter Replacement Cost

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: cost to get car to shop and replace starter

4. Last Chance Auto Repairs – Starter Replacement Costs

Domain: lastchanceautorepairs.com

Registered: 2009 (16 years)

Introduction: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Common symptoms of a failing starter include: car won’t start, clicking noise, slow engine cranking, burning smell, intermittent starting issues. Factors affecting cost: Vehicle…

5. Car Parts – Starters

Domain: carparts.com

Registered: 1999 (26 years)

Introduction: Car Starters – Standard, Reverse Rotation from $75 | High-quality replacement starters, new and remanufactured options available. Guaranteed to fit. Fast shipping and hassle-free returns. Signs of a bad starter include engine not cranking, oil-drenched starter, and smoke from the vehicle.

Strategic Sourcing Conclusion and Outlook for car starter cost

In the competitive landscape of automotive parts, particularly car starters, strategic sourcing emerges as a crucial element for B2B buyers looking to optimize costs and ensure quality. Understanding the pricing dynamics—where replacement starters can range from as low as $35 to upwards of $150—enables buyers to make informed decisions. Engaging with reputable suppliers that offer a vast selection of OEM and aftermarket options can yield significant savings and enhance supply chain resilience.

Moreover, international buyers from regions such as Africa, South America, the Middle East, and Europe must consider factors like shipping logistics, local market conditions, and potential tariffs that could impact overall costs. Establishing strong relationships with multiple suppliers not only mitigates risks associated with supply shortages but also fosters competitive pricing.

As the automotive market continues to evolve, staying ahead of trends in technology and consumer preferences will be vital. We encourage you to leverage strategic sourcing initiatives to enhance your procurement processes. By doing so, you can better position your business for success in an increasingly globalized market, ensuring that you secure the best value for your car starter investments. Engage with suppliers today to explore tailored solutions that meet your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.