Introduction: Navigating the Global Market for bestest starter

In today’s competitive landscape, sourcing the bestest starter for your automotive or industrial needs can be a daunting task for international B2B buyers. The challenge lies not only in identifying quality products but also in navigating a myriad of suppliers and varying standards across different regions, especially in markets like Africa, South America, the Middle East, and Europe. This guide is designed to streamline that process, providing a comprehensive overview of the bestest starter, including its various types, applications, and critical factors for supplier vetting.

Understanding the nuances of remanufactured versus new starters, voltage requirements, and compatibility with specific vehicle models is essential for making informed decisions. This guide will delve into these aspects, equipping you with the knowledge to assess potential suppliers effectively and gauge the total cost of ownership, which includes not just the purchase price but also long-term performance and warranty considerations.

By leveraging this guide, you empower your purchasing strategy with data-driven insights and actionable information, ensuring you select the bestest starter that meets both operational demands and quality standards. Whether you are looking to enhance your fleet’s reliability or streamline your machinery operations, the insights provided here will help you navigate the complexities of the global market and make decisions that support your business objectives.

Table Of Contents

- Top 3 Bestest Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bestest starter

- Understanding bestest starter Types and Variations

- Key Industrial Applications of bestest starter

- 3 Common User Pain Points for ‘bestest starter’ & Their Solutions

- Strategic Material Selection Guide for bestest starter

- In-depth Look: Manufacturing Processes and Quality Assurance for bestest starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bestest starter’

- Comprehensive Cost and Pricing Analysis for bestest starter Sourcing

- Alternatives Analysis: Comparing bestest starter With Other Solutions

- Essential Technical Properties and Trade Terminology for bestest starter

- Navigating Market Dynamics and Sourcing Trends in the bestest starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bestest starter

- Strategic Sourcing Conclusion and Outlook for bestest starter

- Important Disclaimer & Terms of Use

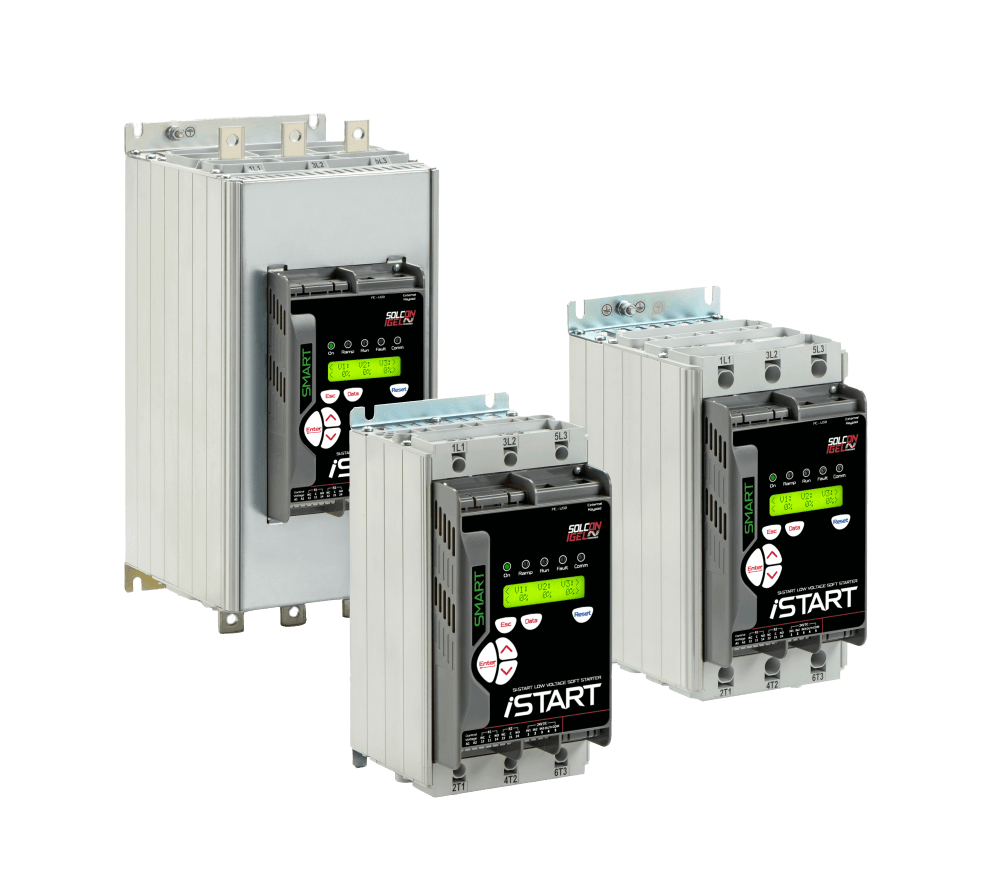

Understanding bestest starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Remanufactured Starters | Cost-effective, quality assurance through refurbishment | Automotive repair shops, fleet maintenance | Pros: Lower cost, reliable performance; Cons: Limited warranty compared to new units. |

| Direct Drive Starters | Simpler design, direct engagement with flywheel | Heavy-duty vehicles, industrial machinery | Pros: High torque, efficient operation; Cons: May require more frequent maintenance. |

| Gear Reduction Starters | Compact design, increased torque, reduced weight | Performance vehicles, racing applications | Pros: Improved efficiency, faster starts; Cons: Higher initial investment. |

| OEM Starters | Original Equipment Manufacturer parts, high reliability | Dealerships, high-end automotive repair | Pros: Guaranteed compatibility, superior quality; Cons: Premium pricing. |

| High-Performance Starters | Enhanced cranking power, designed for extreme conditions | Off-road vehicles, heavy-duty applications | Pros: Exceptional durability and reliability; Cons: Often more expensive and may require specialized installation. |

What are the characteristics of Remanufactured Starters?

Remanufactured starters are a popular choice for B2B buyers seeking cost-effective solutions without sacrificing quality. These starters undergo a rigorous refurbishment process, ensuring that they meet or exceed original specifications. They are commonly used in automotive repair shops and fleet maintenance operations, where budget constraints are a concern. Buyers should consider the warranty offered, as it typically may not match that of new starters, but the savings can be substantial.

How do Direct Drive Starters differ from other types?

Direct drive starters feature a straightforward design that directly engages the flywheel, providing high torque for reliable starting. They are well-suited for heavy-duty vehicles and industrial machinery, where robust performance is essential. While they are efficient, buyers should be aware that this type may require more frequent maintenance compared to more complex starter designs. Their simplicity, however, often results in lower repair costs over time.

What advantages do Gear Reduction Starters offer?

Gear reduction starters are designed to provide increased torque in a more compact form factor. This makes them ideal for performance vehicles and racing applications where weight and efficiency are critical. B2B buyers should weigh the benefits of improved efficiency and faster starts against the higher initial investment required for these starters. They are particularly valuable in applications where performance is a priority.

Illustrative image related to bestest starter

Why choose OEM Starters for B2B applications?

OEM starters are manufactured to the original specifications set by vehicle manufacturers, ensuring perfect compatibility and high reliability. They are favored by dealerships and high-end automotive repair shops that prioritize quality. While they come at a premium price, the assurance of performance and longevity can justify the investment, especially for businesses focused on customer satisfaction and vehicle reliability.

What should buyers know about High-Performance Starters?

High-performance starters are engineered for extreme conditions, providing enhanced cranking power for off-road and heavy-duty applications. They are built to withstand harsh environments and are often used in specialized vehicles. While they offer exceptional durability and reliability, buyers should be prepared for a higher price point and potentially specialized installation requirements. These starters are an excellent choice for businesses that need dependable performance under challenging conditions.

Key Industrial Applications of bestest starter

| Industry/Sector | Specific Application of bestest starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Integration in assembly lines for vehicle production | Enhances efficiency in vehicle assembly processes | Ensure compatibility with various vehicle models; OEM standards |

| Transportation & Logistics | Replacement for fleet vehicles | Reduces downtime and maintenance costs | Evaluate remanufactured options for cost-effectiveness; warranty terms |

| Agriculture | Starting agricultural machinery | Improves operational reliability during harvest | Verify voltage and design specifications for machinery compatibility |

| Construction | Powering heavy equipment like excavators and cranes | Increases productivity on construction sites | Assess durability and performance under heavy loads; local availability |

| Mining | Starting engines in mining equipment | Ensures consistent operation in harsh environments | Source starters that meet specific environmental conditions; consider remanufactured options for cost savings |

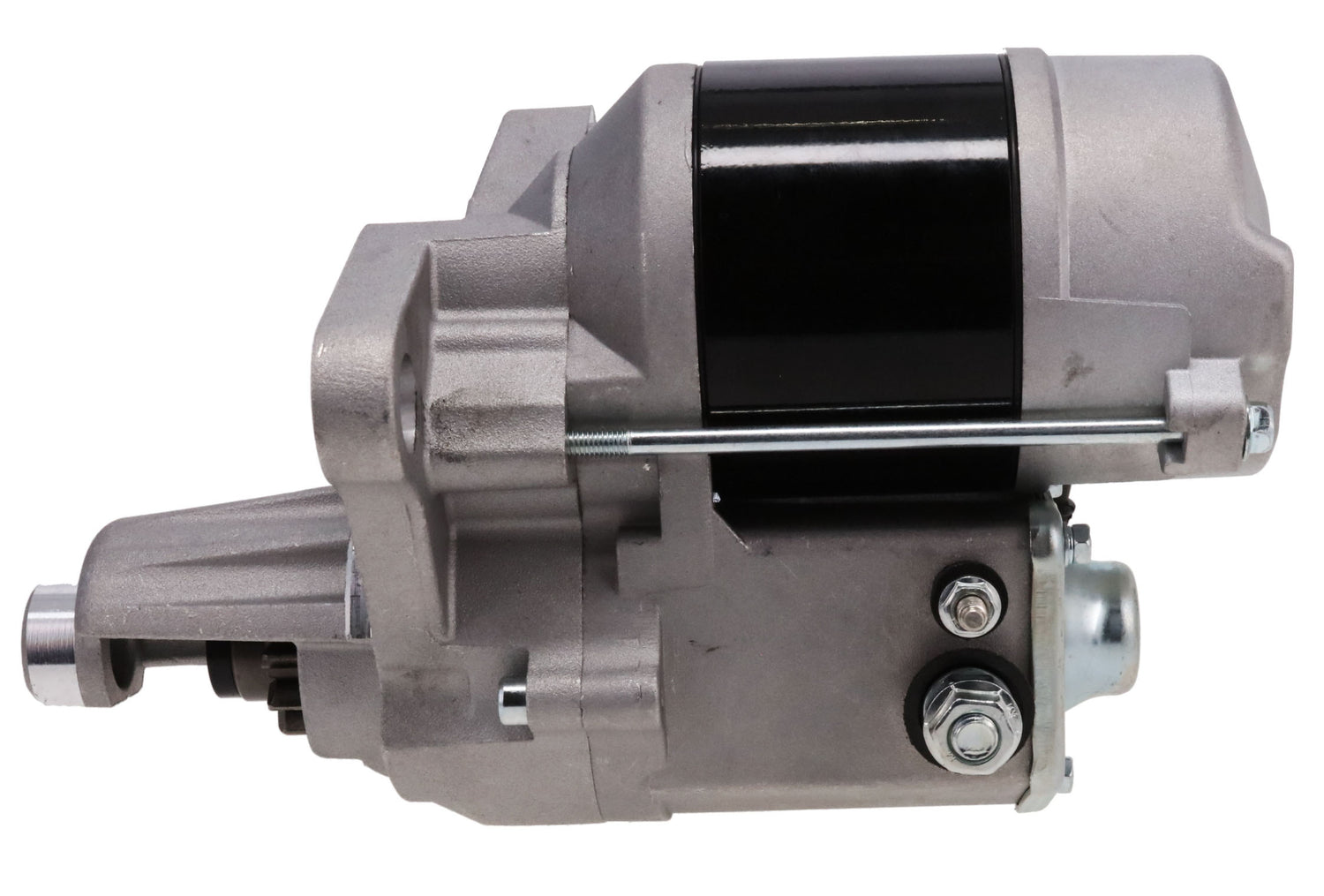

How is the ‘bestest starter’ Used in Automotive Manufacturing?

In the automotive manufacturing sector, the ‘bestest starter’ is crucial for integrating into assembly lines where vehicles are produced. It ensures efficient engine start-up, which is vital for maintaining the pace of production. Manufacturers benefit from reduced assembly time, leading to increased output and profitability. Buyers should consider compatibility with various vehicle models and adhere to OEM standards to ensure optimal performance.

What Role Does the ‘bestest starter’ Play in Transportation and Logistics?

In transportation and logistics, the ‘bestest starter’ is often used as a replacement for fleet vehicles, ensuring reliability and performance. By minimizing downtime caused by starter failures, companies can significantly reduce maintenance costs and enhance operational efficiency. When sourcing, businesses should evaluate remanufactured options for cost-effectiveness and pay attention to warranty terms to safeguard their investment.

How is the ‘bestest starter’ Essential for Agricultural Machinery?

The ‘bestest starter’ is integral to starting agricultural machinery, such as tractors and harvesters. Reliable starting systems are essential during critical harvest periods, where time is of the essence. Buyers in this sector must verify voltage and design specifications to ensure compatibility with specific machinery types. A dependable starter can greatly improve operational reliability, leading to better productivity and yield.

Why is the ‘bestest starter’ Important for Construction Equipment?

In the construction industry, the ‘bestest starter’ powers heavy equipment like excavators and cranes. Its role is vital in ensuring that these machines operate smoothly, thereby increasing productivity on construction sites. Buyers should assess the durability and performance of starters under heavy loads, ensuring they can withstand the rigors of construction work. Local availability is also a key consideration to minimize downtime.

How Does the ‘bestest starter’ Benefit Mining Operations?

The ‘bestest starter’ is crucial for starting engines in mining equipment, where reliable performance is essential in harsh environments. Consistent operation is necessary to avoid costly delays and ensure safety on mining sites. Buyers should source starters that meet specific environmental conditions, such as resistance to dust and moisture. Considering remanufactured options can provide significant cost savings while maintaining performance standards.

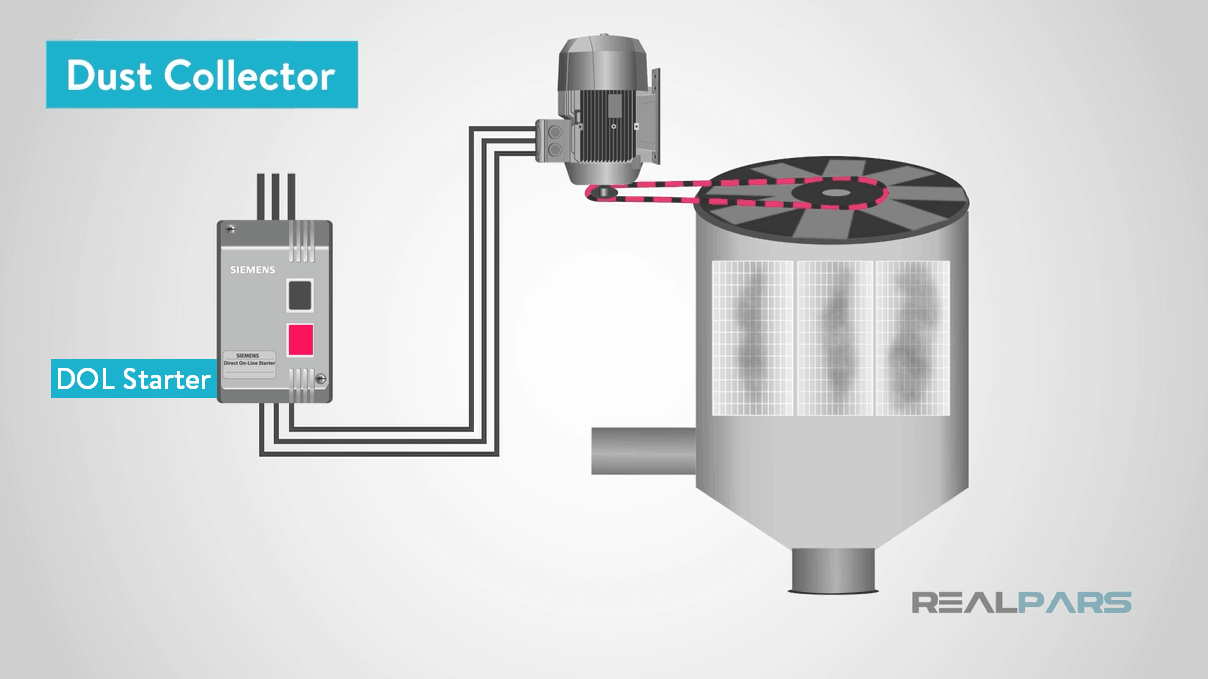

3 Common User Pain Points for ‘bestest starter’ & Their Solutions

Scenario 1: Sourcing Reliable Remanufactured Bestest Starters

The Problem:

B2B buyers often struggle with sourcing reliable remanufactured bestest starters that meet the specifications for their fleet of vehicles. Given the diversity of models and the varying quality of remanufactured parts on the market, buyers can easily end up with subpar products that lead to frequent failures. This not only increases operational downtime but also escalates repair costs, creating a ripple effect on overall productivity and customer satisfaction.

The Solution:

To address this challenge, it’s essential for buyers to develop a robust supplier relationship and conduct thorough research on potential vendors. Start by verifying the vendor’s reputation through reviews and testimonials, particularly focusing on their remanufacturing processes and quality control measures. Request detailed product specifications, including voltage, pinion teeth, and compatibility with your vehicle models. Also, inquire about the warranty and return policies to safeguard against defects. By selecting suppliers that provide transparent information and demonstrate a commitment to quality, buyers can ensure they are investing in reliable starters that will perform well over time.

Scenario 2: Understanding Compatibility and Fitment Issues

The Problem:

Another common pain point for B2B buyers is ensuring that the bestest starter they purchase is compatible with their specific vehicle models. With various designs and configurations available, there can be significant confusion regarding which starter fits which vehicle. Incorrect fitment can lead to operational disruptions, as well as unnecessary returns and exchanges, further complicating logistics and inventory management.

The Solution:

To mitigate fitment issues, buyers should implement a systematic approach to compatibility checks. Start by compiling a comprehensive list of all vehicles in your fleet, including make, model, and year. Use this information to cross-reference with the starter specifications provided by suppliers. Most reputable manufacturers offer fitment guides or compatibility charts, which can be a valuable resource. Additionally, consider investing in a dedicated parts management system that allows for easy tracking of vehicle specifications and corresponding parts. This proactive approach minimizes the risk of purchasing incorrect starters and ensures a smoother operational workflow.

Scenario 3: Dealing with Warranty and Return Complications

The Problem:

Warranty and return complications often create headaches for B2B buyers when dealing with bestest starters. Many suppliers have restrictive return policies or fail to honor warranties, leaving businesses stuck with defective products. This situation not only incurs additional costs but also can lead to prolonged downtime as companies scramble to replace faulty components.

The Solution:

To navigate warranty and return issues effectively, buyers should prioritize suppliers with clear, customer-friendly policies. Before making a purchase, carefully review the warranty terms and conditions. Look for suppliers that offer comprehensive warranties covering both parts and labor. Additionally, maintain detailed records of all purchases, including receipts and correspondence with suppliers, to streamline the return process should it become necessary. Establishing a good line of communication with suppliers can also facilitate quicker resolutions in case of defects. By taking these steps, businesses can protect themselves from the financial implications of faulty starters and ensure they have reliable components on hand.

Strategic Material Selection Guide for bestest starter

What Are the Key Materials Used in Bestest Starters?

When selecting materials for the ‘bestest starter,’ it is crucial to consider their properties, advantages, and limitations. This analysis will focus on four common materials: steel, aluminum, copper, and plastic composites. Each material plays a significant role in the performance and reliability of starters, particularly in diverse international markets.

How Does Steel Impact Bestest Starter Performance?

Steel is a widely used material in starter construction due to its strength and durability. It typically exhibits excellent temperature and pressure ratings, making it suitable for high-performance applications. Steel’s corrosion resistance can vary based on the specific alloy used, with stainless steel offering superior protection.

Pros: Steel’s high tensile strength ensures longevity and reliability. It is also relatively cost-effective compared to other materials, making it a preferred choice for many manufacturers.

Illustrative image related to bestest starter

Cons: The weight of steel can be a disadvantage, especially in applications where weight reduction is critical. Additionally, certain steel grades may require additional treatments to enhance corrosion resistance.

Impact on Application: Steel is compatible with various media, including oil and fuel, making it versatile for automotive applications. However, international buyers should be aware of specific standards, such as ASTM A36 or DIN 17100, that may apply.

What Role Does Aluminum Play in Bestest Starters?

Aluminum is increasingly popular in starter design due to its lightweight properties and good thermal conductivity. It typically offers a lower density than steel, which can improve the overall efficiency of the starter.

Pros: The primary advantage of aluminum is its weight, which can enhance fuel efficiency in vehicles. Aluminum also has decent corrosion resistance, particularly when anodized.

Cons: While aluminum is strong, it is not as durable as steel and can be prone to deformation under excessive stress. It is generally more expensive than steel, which can impact manufacturing costs.

Impact on Application: Aluminum starters are particularly advantageous in high-performance vehicles where weight savings are critical. International buyers should consider compliance with standards like ASTM B221 for aluminum extrusions.

How Does Copper Enhance Electrical Conductivity in Starters?

Copper is a key material used in the electrical components of starters due to its excellent conductivity. It is often used for wiring and connections within the starter assembly.

Pros: The high electrical conductivity of copper ensures efficient power transfer, which is essential for quick engine starts. Copper is also relatively easy to work with during manufacturing.

Illustrative image related to bestest starter

Cons: Copper is susceptible to corrosion, especially in harsh environments, which can lead to performance issues over time. It is also more expensive than aluminum and steel.

Impact on Application: In regions with high humidity or salt exposure, the corrosion resistance of copper must be considered. International buyers should ensure that copper components comply with relevant standards like ASTM B170.

What Are the Benefits of Plastic Composites in Bestest Starters?

Plastic composites are increasingly used in non-structural components of starters, such as housings and covers. They offer a unique combination of lightweight and durability.

Pros: Plastic composites are resistant to corrosion and can be molded into complex shapes, allowing for design flexibility. They are typically less expensive than metals.

Cons: The main limitation of plastic composites is their lower strength compared to metals, which may not be suitable for all applications. They can also degrade under high temperatures.

Illustrative image related to bestest starter

Impact on Application: Plastic composites are ideal for applications where weight savings and corrosion resistance are prioritized. International buyers should ensure compliance with standards like ISO 9001 for quality management.

Summary Table of Material Selection for Bestest Starters

| Material | Typical Use Case for bestest starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and durability | Heavier than alternatives | Medium |

| Aluminum | Lightweight applications | Reduces overall weight | Less durable than steel | High |

| Copper | Electrical connections | Excellent electrical conductivity | Prone to corrosion | High |

| Plastic Composites | Non-structural components | Lightweight and corrosion-resistant | Lower strength than metals | Low |

This analysis provides a comprehensive overview of material options for bestest starters, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bestest starter

What Are the Key Stages in the Manufacturing Process of a Bestest Starter?

The manufacturing process of a bestest starter involves several critical stages, each designed to ensure the product meets high-performance standards required by automotive applications. Understanding these stages can help B2B buyers assess the reliability and quality of the starters they are sourcing.

-

Material Preparation: The first stage involves selecting high-quality raw materials, primarily metals such as steel and aluminum, for the starter’s housing and internal components. Suppliers often source materials from reputable vendors who comply with international quality standards to ensure durability and performance. Material testing is conducted to verify that they meet specifications, including tensile strength and corrosion resistance.

-

Forming Processes: The next stage includes forming techniques such as stamping, casting, or machining. Components like the starter housing, pinion gear, and armature are created through these processes. Advanced techniques such as CNC machining may be employed for precision components, ensuring they fit together perfectly and operate efficiently.

-

Assembly: During the assembly phase, the various components are brought together. Skilled technicians or automated systems assemble the starters, ensuring that each part is correctly aligned and secured. This stage often incorporates the use of torque specifications and assembly jigs to maintain consistency across units.

-

Finishing: The final stage involves surface treatments such as painting, plating, or coating to protect against environmental factors. Quality control checks are performed at this stage to ensure that aesthetic and functional standards are met. This might include verifying finishes for uniformity and adherence to specifications.

What International Standards Guide Quality Assurance in Starter Manufacturing?

Quality assurance is paramount in the manufacturing of bestest starters, especially when targeting international markets. Various standards guide manufacturers in maintaining quality throughout the production process.

-

ISO 9001 Certification: This internationally recognized standard focuses on quality management systems. Manufacturers with ISO 9001 certification demonstrate their commitment to quality, customer satisfaction, and continuous improvement. B2B buyers should prioritize suppliers with this certification as it indicates a structured approach to quality management.

-

CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with EU safety, health, and environmental protection standards. This is crucial for starters intended for vehicles operating in European markets, as it assures buyers of the product’s safety and regulatory compliance.

-

API Standards: The American Petroleum Institute (API) sets standards for products in the automotive and petroleum industries. While not directly applicable to starters, adherence to API standards can reflect a manufacturer’s overall commitment to quality and performance in related components.

What Are the Quality Control Checkpoints in Starter Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each starter meets the required specifications before it reaches the market.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Tests may include dimensional checks, material composition analyses, and visual inspections to ensure that incoming materials are free from defects.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is essential. This includes regular checks on machinery calibration, assembly precision, and adherence to process specifications. Techniques such as statistical process control (SPC) may be employed to analyze data and control variability.

-

Final Quality Control (FQC): Before products are packaged and shipped, a thorough final inspection is conducted. This includes functional testing of starters to verify performance under simulated conditions, dimensional checks, and a review of compliance with applicable standards. Documentation of these tests is crucial for traceability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure they are investing in reliable products. Here are some strategies to consider:

-

Supplier Audits: Conducting audits allows buyers to assess the manufacturing processes and quality assurance practices of potential suppliers directly. This can include reviewing documentation, observing manufacturing processes, and interviewing staff about their quality assurance protocols.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their quality control measures. These reports should outline testing methods, results, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of supplier quality. These services can conduct inspections at various stages of production and provide comprehensive reports that detail compliance with international standards.

What Are the Unique Quality Control Nuances for International Buyers?

When sourcing starters for international markets, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should consider specific nuances related to quality control:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers must ensure that suppliers comply with local regulations, which may include specific certifications or testing protocols.

-

Cultural and Language Barriers: Effective communication is essential for ensuring quality expectations are understood. Buyers may need to consider hiring local representatives or translators to facilitate clear communication with suppliers.

-

Logistics and Supply Chain Considerations: Quality control does not end at the factory. Buyers should ensure that logistics providers also adhere to quality standards during transportation and storage, as improper handling can affect product integrity.

In summary, understanding the manufacturing processes and quality assurance practices of bestest starters is vital for B2B buyers. By evaluating suppliers based on their adherence to international standards, quality control checkpoints, and verification methods, buyers can make informed decisions that ensure the reliability and performance of the starters they procure.

Illustrative image related to bestest starter

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bestest starter’

Introduction

This practical sourcing guide serves as a step-by-step checklist for international B2B buyers looking to procure the best ‘bestest starter’ for their vehicles or machinery. With a diverse range of suppliers and products available globally, it’s essential to establish a clear and structured approach to ensure you make informed purchasing decisions that meet your operational needs.

Step 1: Define Your Technical Specifications

Before you start sourcing, clearly outline the technical specifications of the bestest starter you require. This includes voltage, design type (e.g., direct drive), and compatibility with specific vehicle models. Understanding these details helps in narrowing down your options and prevents costly mismatches during procurement.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Look for companies with a strong reputation in the market, ideally those that specialize in remanufactured starters, as these often offer a balance of quality and cost-efficiency. Utilize industry forums, supplier directories, and trade shows to gather information about various suppliers and their offerings.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that your potential suppliers have the necessary certifications and compliance with international standards. Look for ISO certifications and any specific automotive industry standards that apply to starters. Certifications indicate that the supplier adheres to quality control processes, which can significantly affect product reliability.

Step 4: Request Detailed Product Information

Engage with suppliers to request detailed product specifications, including warranty information and return policies. Ask for data sheets that outline performance metrics, installation guidelines, and maintenance recommendations. This information is vital for ensuring the product meets your operational requirements and helps in making an informed decision.

Step 5: Assess Pricing Structures

Compare pricing across different suppliers while considering factors such as shipping costs, import duties, and potential discounts for bulk purchases. Evaluate whether the price reflects the quality and reliability of the product. Remember that the cheapest option may not always be the best choice in terms of longevity and performance.

Step 6: Check Customer Reviews and References

Before finalizing a supplier, check customer reviews and request references from other businesses that have purchased the bestest starter. This feedback can provide valuable insights into the supplier’s reliability, customer service, and product performance in real-world applications.

Step 7: Negotiate Terms and Finalize Purchase

Once you’ve selected a supplier, negotiate the terms of purchase, including payment methods, delivery timelines, and after-sales support. Ensure that all terms are documented to avoid misunderstandings later. Finalizing these details helps build a strong foundation for your business relationship and ensures a smooth procurement process.

Illustrative image related to bestest starter

By following this checklist, B2B buyers can streamline their procurement process for the bestest starter, ensuring they select the right product from a reputable supplier while maximizing value for their investment.

Comprehensive Cost and Pricing Analysis for bestest starter Sourcing

What Are the Key Cost Components for Sourcing Bestest Starters?

When evaluating the cost structure for sourcing bestest starters, several critical components come into play. Materials represent a significant portion of the total cost, including high-quality metals, magnets, and electrical components. Labor costs are also essential, reflecting the skill level required for assembly and quality assurance processes. Manufacturing overhead encompasses expenses related to facility operations, utilities, and indirect labor, while tooling costs involve the expense of molds and dies required for production. Quality Control (QC) is another crucial component, ensuring that each starter meets industry standards and performance specifications.

Logistics costs should not be overlooked, particularly for international transactions. These include shipping, insurance, and customs duties, which can vary widely based on the destination. Finally, the margin is the profit markup applied by suppliers, which can fluctuate based on market competition and demand.

How Do Price Influencers Affect Bestest Starter Costs?

Several factors can influence the pricing of bestest starters. Volume and Minimum Order Quantity (MOQ) play a vital role; higher order quantities typically lead to lower per-unit prices. Specifications and customization requirements can increase costs, particularly if unique features or modifications are requested. The choice of materials and the overall quality of the product also significantly impact pricing. For instance, starters made with premium materials or those that meet specific certifications may command higher prices.

Illustrative image related to bestest starter

Supplier factors such as reputation, reliability, and geographical location can also influence costs. Companies with a proven track record may charge a premium for their products. Additionally, understanding Incoterms is crucial, as they define the responsibilities of buyers and sellers in international shipping, which can affect overall costs.

What Are the Best Negotiation Strategies for B2B Buyers?

Effective negotiation is essential for achieving cost efficiencies when sourcing bestest starters. Start by conducting thorough market research to understand pricing benchmarks and competitor offerings. Leverage your purchasing power by consolidating orders to meet or exceed MOQs, allowing for better pricing agreements.

Establish long-term relationships with suppliers, as this can lead to discounts and favorable terms over time. When negotiating, be transparent about your needs and constraints, which can facilitate a collaborative approach to pricing. Furthermore, consider discussing flexible payment terms or volume discounts, which can significantly reduce the overall cost.

What Is the Total Cost of Ownership for Bestest Starters?

When assessing the cost of bestest starters, it’s vital to consider the Total Cost of Ownership (TCO). This concept goes beyond the initial purchase price to include maintenance, operational efficiency, and potential downtime costs. A higher-quality starter may have a higher upfront cost but could lead to lower maintenance expenses and increased reliability over time, making it a more economical choice in the long run.

Illustrative image related to bestest starter

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should factor in additional costs such as tariffs, customs fees, and potential delays in logistics. Understanding these nuances can help buyers make informed decisions that align with their budget and operational needs.

What Pricing Nuances Should International B2B Buyers Be Aware Of?

International buyers must be aware of several pricing nuances when sourcing bestest starters. Currency fluctuations can impact costs, especially in regions with volatile exchange rates. Additionally, varying local regulations and standards can affect the acceptance and pricing of imported products.

Buyers should also be mindful of different payment methods and their associated costs, such as wire transfer fees or credit card surcharges. Lastly, building a strong rapport with suppliers can lead to better pricing and terms, making it easier to navigate the complexities of international sourcing.

Disclaimer on Indicative Prices

It is important to note that the prices for bestest starters can vary widely based on the factors discussed above. The information provided serves as a general guideline, and prospective buyers should conduct their own research and obtain quotes from multiple suppliers to determine accurate pricing for their specific needs.

Alternatives Analysis: Comparing bestest starter With Other Solutions

Exploring Alternatives to Bestest Starter: A Comparative Analysis

In the competitive landscape of automotive starter solutions, various options are available to meet the diverse needs of businesses. Choosing the right starter can significantly impact operational efficiency, cost-effectiveness, and overall performance. This analysis compares the Bestest Starter with two viable alternatives: OEM Starters and Aftermarket Starters, offering insights into their respective advantages and limitations.

Illustrative image related to bestest starter

| Comparison Aspect | Bestest Starter | OEM Starter | Aftermarket Starter |

|---|---|---|---|

| Performance | Reliable with good torque; suitable for many models | High reliability; designed specifically for original vehicle specs | Variable quality; performance can vary widely by brand |

| Cost | Moderate price point; often lower than OEM | Higher upfront cost; premium pricing justified by reliability | Lower cost options available; can be budget-friendly |

| Ease of Implementation | Direct fit for many models; installation is straightforward | OEM fit ensures easy installation; may require specific tools | Installation can vary; some may require modifications |

| Maintenance | Low maintenance; built for durability | Minimal maintenance; designed to last long | Maintenance needs vary; some may require frequent checks |

| Best Use Case | Ideal for budget-conscious businesses with diverse vehicle fleets | Best for businesses prioritizing reliability and performance | Suitable for businesses with specific budget constraints or older vehicles |

In-Depth Look at Alternatives

What are the Advantages and Disadvantages of OEM Starters?

OEM (Original Equipment Manufacturer) Starters are known for their exceptional reliability and performance tailored to the specifications of the vehicle. They are often the preferred choice for businesses that prioritize durability and longevity. However, the cost can be significantly higher than alternatives, which may deter budget-conscious buyers. Moreover, sourcing OEM parts can be time-consuming, especially in regions with limited availability.

How Do Aftermarket Starters Compare?

Aftermarket Starters provide a cost-effective solution, often at a lower price point than both Bestest and OEM options. They can be suitable for businesses that require a quick replacement or are operating older models where OEM parts are no longer available. However, the quality of aftermarket starters can vary widely. Some brands may offer excellent performance, while others may not meet the reliability standards expected by businesses, potentially leading to increased maintenance costs and downtimes.

Choosing the Right Starter: Factors to Consider

When selecting the appropriate starter for your business needs, it is crucial to assess several factors: performance requirements, budget constraints, installation capabilities, and maintenance expectations. For businesses operating a fleet of vehicles, the Bestest Starter presents a balanced option, offering reliable performance at a moderate cost. In contrast, if your business values long-term reliability and is willing to invest upfront, an OEM Starter may be the best fit. Alternatively, for businesses with tighter budgets or specific vehicle requirements, an Aftermarket Starter could provide a viable solution, albeit with due diligence on quality assurance.

By thoroughly evaluating these alternatives, B2B buyers can make informed decisions that align with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for bestest starter

What Are the Key Technical Properties of Bestest Starters?

When selecting a bestest starter for various applications, understanding its technical specifications is crucial for ensuring compatibility and performance. Here are some essential properties to consider:

-

Voltage Rating

The voltage rating, typically 12V for many automotive starters, indicates the electrical supply required for operation. Understanding the voltage specification is vital for ensuring that the starter matches the vehicle’s electrical system, preventing damage or inadequate performance. -

Design Type

Bestest starters often feature either a direct drive or gear reduction design. A direct drive starter is simpler and generally more robust, suitable for most standard applications, while gear reduction starters provide higher torque at lower speeds, ideal for heavy-duty or high-performance vehicles. Buyers should choose based on the specific demands of their applications. -

Pinion Teeth Count

The number of pinion teeth (commonly 9 for many models) impacts the starter’s engagement with the flywheel. This specification is crucial for compatibility with the engine’s design and can affect the starter’s efficiency and longevity. -

Kw Rating

The kilowatt (Kw) rating, such as 1.4 Kw, indicates the power output of the starter. A higher Kw rating generally means better performance, particularly in cold starts or under heavy load conditions. Selecting a starter with an appropriate Kw rating is essential for ensuring reliable engine starting, especially in challenging environments. -

Rotation Direction

Bestest starters are designed to rotate in a specific direction, usually clockwise. Ensuring the starter’s rotation direction aligns with the engine’s requirements is critical for proper installation and operation. -

Nose Cone Type

The nose cone type (e.g., closed) affects the starter’s structural integrity and fitment. A closed nose cone provides better protection against debris and environmental factors, enhancing durability. Buyers should consider this feature based on the operating conditions of their vehicles.

What Are Common Trade Terms Associated with Bestest Starters?

Familiarity with industry terminology can facilitate smoother transactions and improve communication with suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are designed to meet specific standards and can offer better reliability and performance compared to aftermarket alternatives. B2B buyers should prioritize OEM parts for critical applications to ensure compatibility and longevity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers negotiate better pricing and manage inventory effectively. For startups or small businesses, being aware of MOQ can prevent overstocking and unnecessary costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a standard practice in B2B transactions that allows buyers to compare offers and negotiate terms. Crafting a precise RFQ can streamline the procurement process and secure favorable conditions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for international trade, ensuring clarity in logistics and reducing potential disputes. -

Core Charge

A core charge is a fee applied when purchasing remanufactured starters, which is refunded upon returning the old starter. This practice encourages recycling and helps maintain a sustainable supply chain. Buyers should factor in core charges when budgeting for new parts. -

Warranty Terms

Warranty terms outline the conditions under which a product can be returned or repaired. Familiarity with warranty policies is essential for B2B buyers, as it provides assurance regarding product quality and performance, impacting purchasing decisions.

By comprehensively understanding the technical specifications and trade terminology associated with bestest starters, B2B buyers can make informed decisions that enhance operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the bestest starter Sector

What Are the Key Trends Influencing the Bestest Starter Market?

The global market for bestest starters is witnessing a transformative shift driven by several key factors. Increased demand for reliable automotive components in emerging markets, particularly in Africa and South America, is creating a robust growth trajectory. Technological advancements in manufacturing processes, such as automation and precision engineering, are enhancing product quality and reducing lead times. Additionally, the trend towards remanufactured parts is gaining traction, appealing to cost-conscious buyers while promoting sustainability.

International B2B buyers are also increasingly focused on digital sourcing solutions. Platforms that facilitate direct connections between manufacturers and buyers are streamlining procurement processes, making it easier to access high-quality products. Moreover, as businesses seek to mitigate risks associated with supply chain disruptions, diversifying suppliers and sourcing regions has become a prevalent strategy. This trend is particularly relevant for buyers in Europe and the Middle East, who are looking to ensure consistent availability and competitive pricing.

Another emerging trend is the integration of data analytics into procurement strategies. Buyers are leveraging analytics to better understand market dynamics, predict demand fluctuations, and optimize inventory levels. This data-driven approach allows companies to make informed sourcing decisions, ultimately enhancing their operational efficiency and profitability.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing for Bestest Starters?

Sustainability is increasingly becoming a pivotal consideration for B2B buyers in the automotive parts sector, including bestest starters. The environmental impact of manufacturing processes and the disposal of automotive components can be significant, prompting a shift towards more sustainable practices. Buyers are encouraged to look for suppliers who prioritize eco-friendly materials and sustainable manufacturing methods, which can significantly reduce the carbon footprint associated with production.

The importance of ethical supply chains cannot be overstated. Buyers should seek out manufacturers that comply with fair labor practices and uphold ethical sourcing standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By partnering with certified suppliers, businesses not only enhance their corporate social responsibility (CSR) profile but also gain a competitive advantage in a market that increasingly values sustainability.

Furthermore, the demand for remanufactured bestest starters aligns with sustainability goals. These products offer a way to extend the lifecycle of automotive components, reducing waste and resource consumption. Buyers should prioritize suppliers that offer remanufactured options as part of their product lines, thereby contributing to a circular economy.

What Is the Historical Context of Bestest Starters in B2B Sourcing?

The history of bestest starters can be traced back to the evolution of automotive technology and the increasing need for reliable ignition systems. Early automotive starters were often simple and mechanical, but as vehicles became more sophisticated, so did the components that powered them. The introduction of electrical starters revolutionized vehicle operation, leading to the development of more efficient and powerful bestest starters.

In the B2B context, the sourcing of automotive parts has evolved significantly over the decades. Initially dominated by local suppliers, the market has expanded to include international manufacturers, enabling buyers to access a wider range of products at competitive prices. The rise of remanufactured starters reflects a growing trend towards sustainability and cost-effectiveness, allowing companies to meet the dual demands of performance and environmental responsibility.

Overall, understanding the historical context of bestest starters provides valuable insights into current market dynamics and helps B2B buyers navigate the complexities of sourcing in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of bestest starter

-

How do I solve issues with sourcing reliable bestest starters?

To address sourcing issues with bestest starters, start by identifying reputable suppliers through industry directories and trade platforms. Verify their credentials, including certifications and customer reviews, to ensure reliability. Engage in direct communication to discuss your specific requirements, such as quality standards and lead times. Additionally, consider visiting suppliers’ facilities if feasible, or request product samples to assess quality firsthand. Establishing a clear contract that outlines quality assurance measures will further mitigate risks associated with sourcing. -

What is the best starter for high-performance applications?

For high-performance applications, the best starter is one that offers high torque and durability under extreme conditions. Look for starters specifically designed for performance vehicles, such as those with enhanced gear reduction technology and robust materials. Brands that have garnered positive reviews in performance circles, such as OEM options, are often recommended. Ensure that the starter is compatible with your vehicle’s specifications and provides the necessary voltage and torque ratings for optimal performance. -

How can I vet potential suppliers for bestest starters?

To vet potential suppliers, begin by conducting thorough research online. Check for industry certifications, customer testimonials, and case studies that showcase their reliability and quality of products. Engage in direct conversations with suppliers to assess their customer service and responsiveness. Request references from other B2B clients who have sourced bestest starters from them. Finally, consider starting with a small order to evaluate product quality and service before committing to larger purchases. -

What are the minimum order quantities (MOQ) for bestest starters?

Minimum order quantities (MOQ) for bestest starters can vary significantly based on the supplier and your specific needs. Many suppliers offer flexible MOQs, especially for new customers or bulk orders. Generally, MOQs can range from as low as 10 units to several hundred. It’s advisable to discuss your requirements directly with suppliers to negotiate an MOQ that aligns with your business needs while considering cost-effectiveness. -

What payment terms should I expect when sourcing internationally?

When sourcing bestest starters internationally, payment terms can differ widely among suppliers. Common arrangements include upfront payments, partial payments upon order confirmation, and the balance upon delivery. Letters of credit and escrow services are also popular for larger transactions, providing security for both parties. Always clarify payment terms before finalizing orders to avoid misunderstandings and ensure alignment with your cash flow management. -

How can I ensure quality assurance for my bestest starters?

To ensure quality assurance for bestest starters, establish clear specifications and quality standards with your supplier before placing an order. Request detailed product documentation, including certificates of compliance and test reports. Implement a quality control process that includes inspections upon receipt of goods. Consider third-party inspection services if purchasing large quantities or from unfamiliar suppliers. Maintaining open communication with your supplier regarding quality expectations is also essential for fostering a partnership focused on excellence. -

What logistics considerations should I keep in mind when importing starters?

When importing bestest starters, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling automotive parts. Ensure that the packaging meets international shipping standards to prevent damage during transit. Familiarize yourself with the customs clearance process in your country to avoid delays and additional costs. Planning for contingencies, such as unexpected shipping delays or customs inspections, will also help streamline the process. -

Can I customize bestest starters for specific applications?

Yes, many suppliers offer customization options for bestest starters to meet specific application requirements. Customizations may include modifications to voltage, size, torque ratings, and specific mounting configurations. Discuss your needs with potential suppliers, providing detailed specifications and use cases. Be prepared for possible minimum order requirements for customized products, and allow adequate lead time for manufacturing and testing to ensure that the final product meets your expectations.

Top 3 Bestest Starter Manufacturers & Suppliers List

1. REMAN – REMAN BesTest Starter

Domain: trucklinerparts.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “REMAN BesTest Starter”, “Part Number”: “V713217B”, “Price”: “$69.30”, “Voltage”: “12 V”, “Design”: “Direct Drive”, “Nose Cone Type”: “Closed”, “Overcrank Protection”: “No”, “Number Of Pinion Teeth”: “9”, “Kw Rating”: “1.4”, “Mounting Shims Included”: “Yes”, “Rotation Direction”: “Clockwise”, “Starter Drive Included”: “Yes”, “OE Manufacturer”: “Delco, Delphi”, “Series”: “10MT”, “C…

2. Facebook – Power Master 9612

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Power Master 9612, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Motorcraft – OEM Starter

Domain: ford-trucks.com

Registered: 1997 (28 years)

Introduction: 1. OEM Motorcraft Starter: Recommended for reliability and longevity. One user mentioned having a spare Motorcraft starter for emergencies. 2. NAPA Starter: A user reported issues with the quality of NAPA rebuilds, specifically the Mitsubishi 17578 model, which led to multiple failures. 3. Denso Starter: Another user expressed satisfaction with a Denso starter purchased from a vendor, indicating g…

Strategic Sourcing Conclusion and Outlook for bestest starter

What Are the Key Benefits of Strategic Sourcing for Bestest Starters?

In conclusion, the strategic sourcing of bestest starters represents a critical avenue for international B2B buyers seeking reliability, cost-effectiveness, and quality assurance. By engaging with reputable suppliers and understanding product specifications, such as the voltage, design, and manufacturer details, buyers can mitigate risks associated with subpar products. The remanufactured options available not only present a sustainable choice but also enhance the procurement process by ensuring faster delivery and reduced lead times.

Illustrative image related to bestest starter

How Can International Buyers Leverage Market Trends?

As markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential for buyers to stay informed about emerging trends in automotive components. Leveraging platforms that offer comprehensive product insights and customer reviews can facilitate informed decision-making, ultimately leading to enhanced operational efficiency.

What Steps Should Buyers Take Moving Forward?

Looking ahead, buyers are encouraged to prioritize strategic partnerships with trusted suppliers. By fostering these relationships, businesses can unlock better pricing models and exclusive access to innovative products. Embrace the opportunity to streamline your sourcing strategy today—invest in quality bestest starters to ensure your operations run smoothly and efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.