Introduction: Navigating the Global Market for best car alternator brand

Navigating the global market for the best car alternator brand presents a significant challenge for international B2B buyers, particularly those sourcing components for diverse automotive applications across regions like Africa, South America, the Middle East, and Europe. With the rising demand for reliable electrical systems in vehicles, selecting the right alternator is critical not only for vehicle performance but also for customer satisfaction and operational efficiency. This comprehensive guide aims to equip B2B buyers with essential insights into various types of alternators, their applications, and factors influencing their performance.

In this guide, we delve into the different types of alternators available in the market, including high-output and standard models, and explore their compatibility with various vehicle makes and models. We also provide actionable advice on supplier vetting, cost considerations, and warranty evaluations to ensure that you make informed purchasing decisions. By understanding these elements, you can effectively navigate the complexities of the global automotive parts market and select the best alternator brand that meets your specific needs. Whether you are based in Saudi Arabia, Nigeria, or any other region, this guide empowers you to enhance your procurement strategy and ultimately improve the reliability and functionality of the vehicles you serve.

Table Of Contents

- Top 3 Best Car Alternator Brand Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best car alternator brand

- Understanding best car alternator brand Types and Variations

- Key Industrial Applications of best car alternator brand

- 3 Common User Pain Points for ‘best car alternator brand’ & Their Solutions

- Strategic Material Selection Guide for best car alternator brand

- In-depth Look: Manufacturing Processes and Quality Assurance for best car alternator brand

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best car alternator brand’

- Comprehensive Cost and Pricing Analysis for best car alternator brand Sourcing

- Alternatives Analysis: Comparing best car alternator brand With Other Solutions

- Essential Technical Properties and Trade Terminology for best car alternator brand

- Navigating Market Dynamics and Sourcing Trends in the best car alternator brand Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best car alternator brand

- Strategic Sourcing Conclusion and Outlook for best car alternator brand

- Important Disclaimer & Terms of Use

Understanding best car alternator brand Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Output Alternators | Produce 130-350 amps, designed for demanding electrical loads | Performance vehicles, heavy-duty trucks | Pros: High efficiency, supports advanced systems Cons: Higher cost, may require system modifications |

| Standard Alternators | Typically produce 60-130 amps, designed for standard vehicles | Everyday vehicles, light-duty applications | Pros: Cost-effective, widely available Cons: Limited power for upgrades, shorter lifespan |

| Remanufactured Alternators | Overhauled units with new components, meeting OEM standards | Fleet vehicles, budget-conscious buyers | Pros: Affordable, reliable performance Cons: Potentially variable quality, shorter warranty |

| Brushless Alternators | Use advanced technology to eliminate brushes, reducing wear | High-performance vehicles, racing | Pros: Longer lifespan, low maintenance Cons: Higher initial investment, specialized applications |

| OEM Alternators | Original equipment manufacturer parts, designed for specific models | Vehicle manufacturers, repair shops | Pros: Guaranteed compatibility, high reliability Cons: Higher price, limited availability for older models |

What Are High-Output Alternators and When Should B2B Buyers Consider Them?

High-output alternators are engineered to deliver significant amperage, ranging from 130 to 350 amps, making them ideal for vehicles with extensive electrical demands, such as performance cars and heavy-duty trucks. These alternators are crucial for powering advanced audio systems, additional lighting, and other high-draw electrical accessories. B2B buyers should assess the electrical load requirements of their vehicles and ensure that their systems can accommodate these powerful units, as installation may necessitate upgrading wiring and other components.

Why Choose Standard Alternators for Everyday Applications?

Standard alternators are the most common type found in everyday vehicles, typically generating between 60 and 130 amps. They are suitable for light-duty applications and provide sufficient power for essential electrical components. For B2B buyers managing fleets or regular maintenance services, standard alternators offer a cost-effective solution with broad availability. However, businesses should consider the potential limitations in power capacity for vehicles requiring additional electrical enhancements.

What Are the Advantages of Remanufactured Alternators for Cost-Conscious Buyers?

Remanufactured alternators are refurbished units that have undergone extensive testing and component replacement to meet OEM specifications. They present an economical option for B2B buyers, especially in fleet management or budget-sensitive operations. While remanufactured units offer reliable performance at a lower price point, buyers should be cautious about the quality variance and warranty terms, ensuring they source from reputable suppliers.

How Do Brushless Alternators Enhance Performance and Maintenance?

Brushless alternators utilize advanced technology that eliminates the need for traditional brushes, resulting in reduced wear and longer lifespans. These units are particularly beneficial for high-performance vehicles and racing applications, where reliability and efficiency are paramount. B2B buyers should weigh the higher upfront costs against the long-term savings in maintenance and replacement frequency, especially in competitive markets where performance is critical.

Why Are OEM Alternators Important for Specific Vehicle Models?

OEM alternators are designed and manufactured to meet the exact specifications of particular vehicle models, ensuring optimal compatibility and performance. For businesses involved in vehicle manufacturing or repairs, sourcing OEM parts can enhance customer satisfaction through reliable and consistent quality. However, the higher price and limited availability for older models may necessitate strategic planning and inventory management for B2B buyers.

Key Industrial Applications of best car alternator brand

| Industry/Sector | Specific Application of best car alternator brand | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicles requiring reliable power supply | Ensures efficient assembly line operations with minimal downtime | Compatibility with vehicle models and production standards |

| Heavy-Duty Vehicles | Powering electrical systems in trucks and buses | Enhances vehicle reliability and performance in demanding environments | High output specifications to handle increased loads |

| Agricultural Equipment | Supporting machinery like tractors and harvesters | Improves operational efficiency and reduces maintenance costs | Rugged design for harsh conditions and compatibility with specific machinery |

| Mining and Construction | Powering equipment used in remote locations | Increases productivity by ensuring equipment reliability in challenging environments | Durability and resistance to dust and moisture |

| Emergency Services | Ensuring power supply for ambulances and fire trucks | Critical for operational readiness and response times | Compliance with safety standards and robust performance under stress |

How is the Best Car Alternator Brand Used in Automotive Manufacturing?

In the automotive manufacturing sector, the best car alternator brands are essential for the production of vehicles. These alternators provide a reliable power supply to various components during the assembly process, ensuring that operations run smoothly and efficiently. For international buyers, particularly in regions like Africa and South America, sourcing alternators that meet specific compatibility and performance standards is crucial to avoid production delays and maintain quality control.

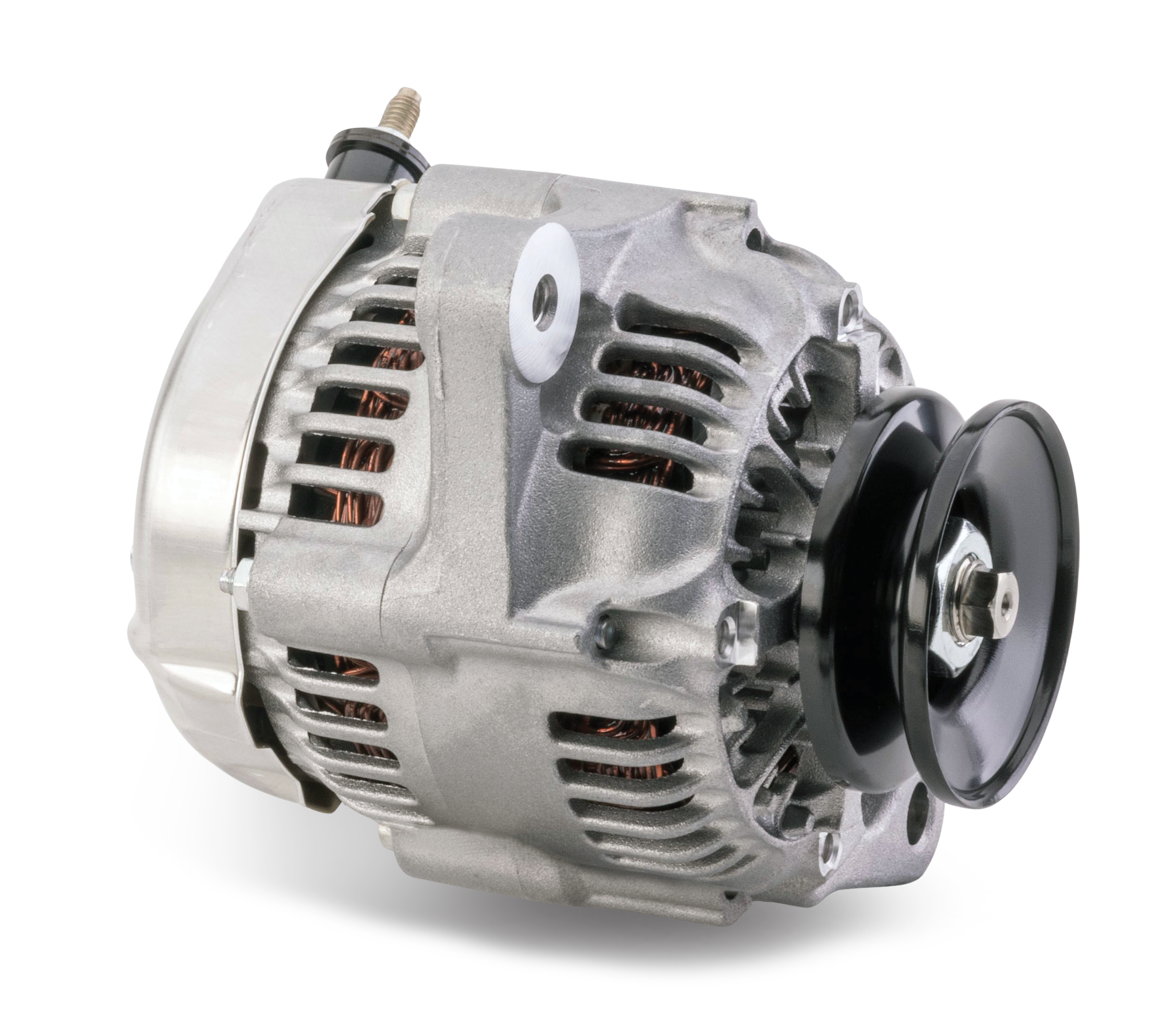

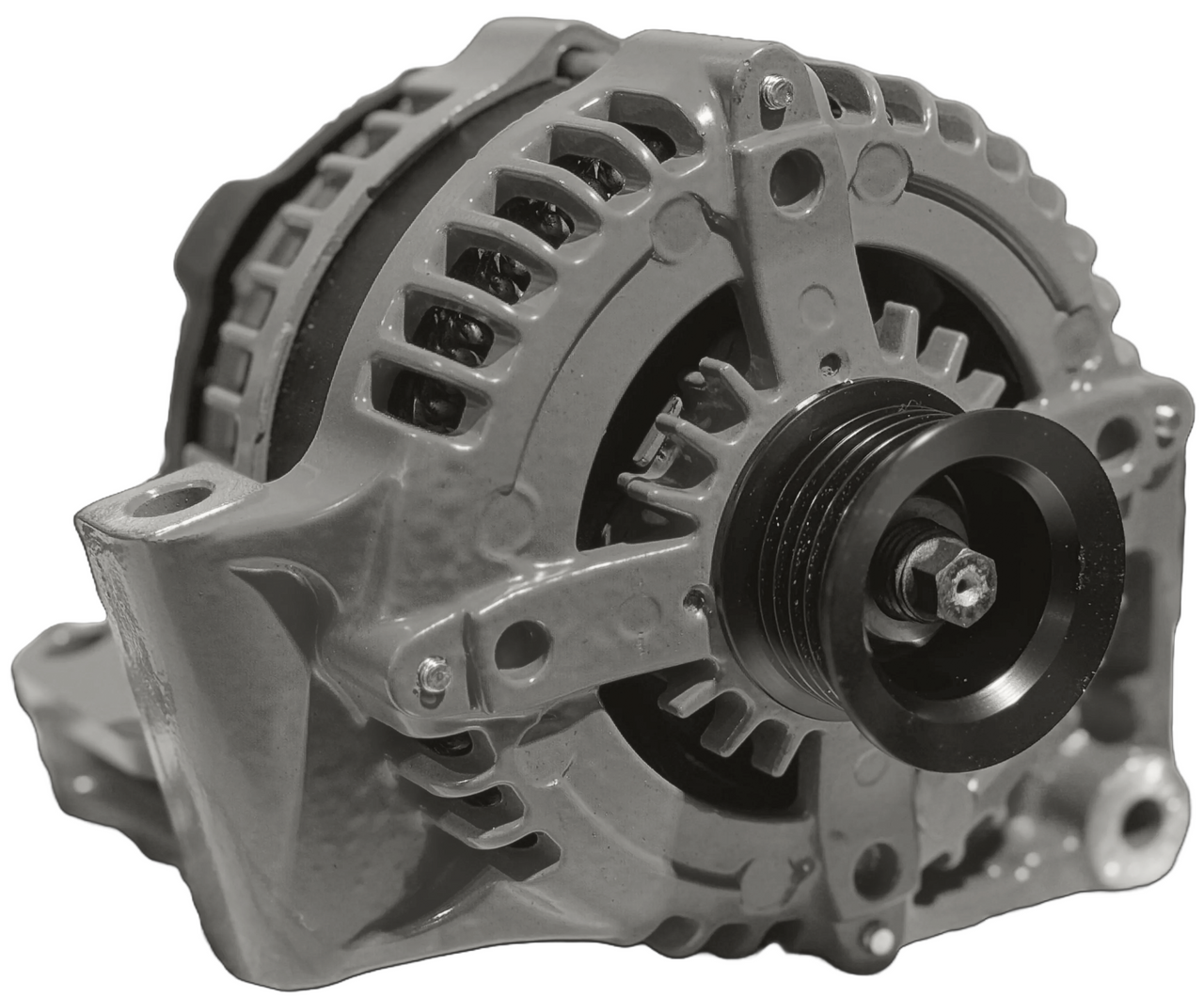

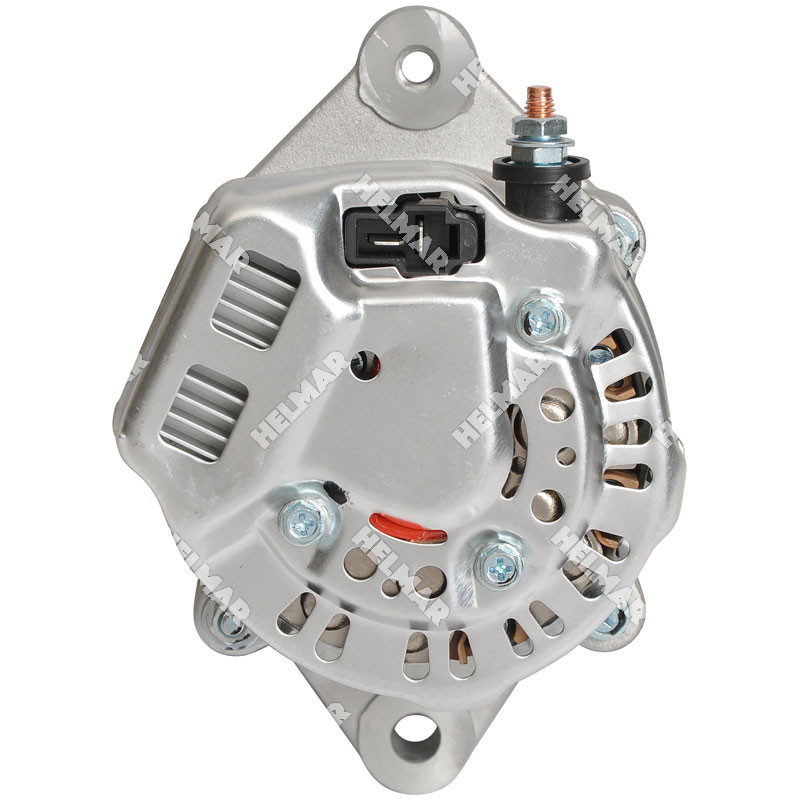

Illustrative image related to best car alternator brand

What Role Do High-Performance Alternators Play in Heavy-Duty Vehicles?

Heavy-duty vehicles, such as trucks and buses, rely on high-performance alternators to power extensive electrical systems. These alternators must handle increased loads from advanced technologies like GPS, communication systems, and onboard diagnostics. Businesses in the Middle East and Europe should prioritize sourcing alternators that can deliver consistent performance under demanding conditions, ensuring vehicle reliability and minimizing maintenance costs.

How Are Alternators Beneficial for Agricultural Equipment?

In agriculture, the best car alternator brands support the operation of machinery like tractors and harvesters. These alternators are designed to withstand harsh working environments while providing a steady power supply to essential systems. For B2B buyers in regions like Nigeria, where agricultural productivity is vital, sourcing rugged and reliable alternators can lead to improved operational efficiency and lower maintenance expenses.

What Importance Do Alternators Hold in Mining and Construction?

Mining and construction industries often operate in remote and challenging environments, making the reliability of equipment crucial. High-quality alternators ensure that heavy machinery remains operational, thus enhancing productivity. For international buyers, especially in regions with extreme weather conditions, sourcing alternators that are durable and resistant to dust and moisture is key to maintaining equipment performance and reducing downtime.

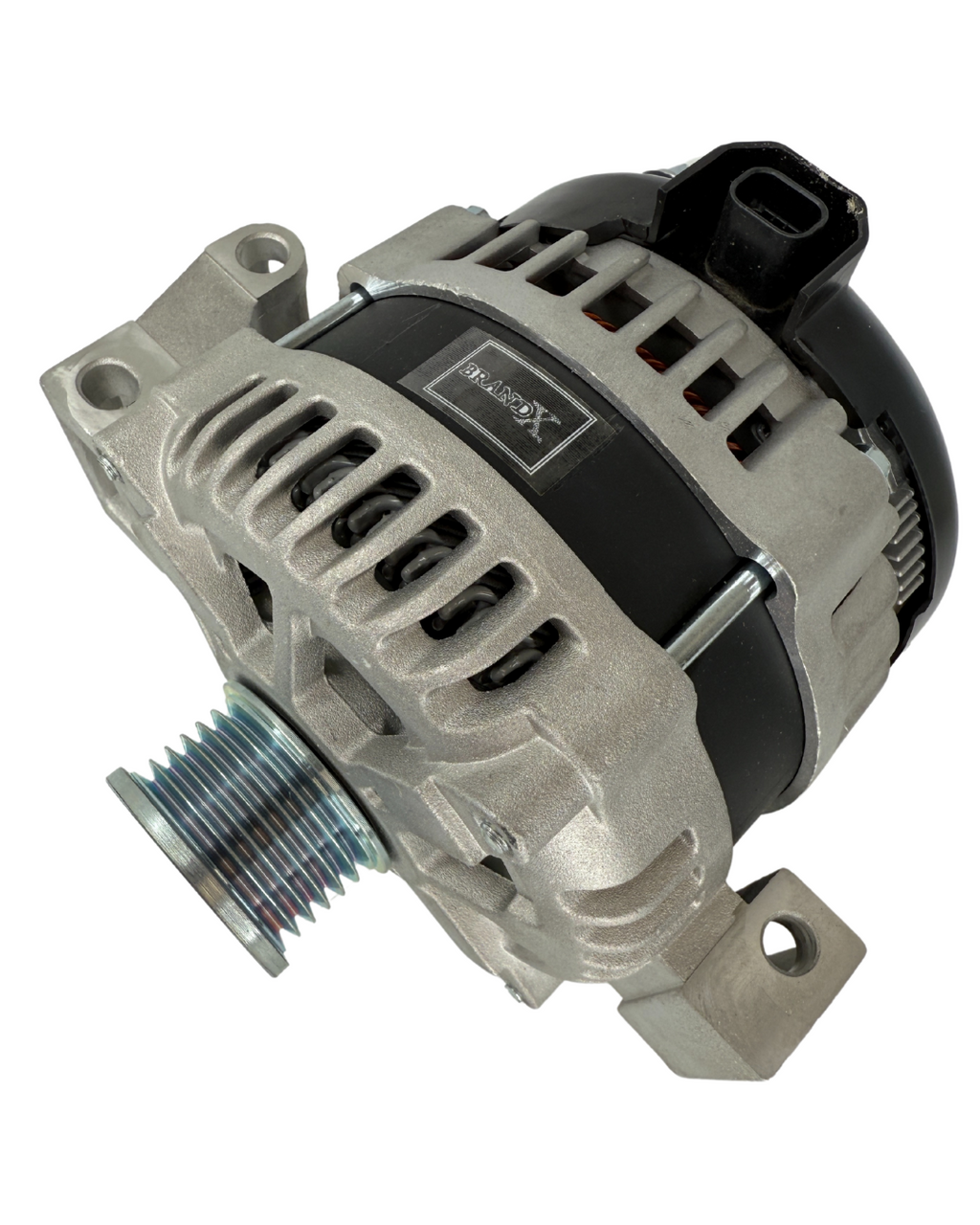

Illustrative image related to best car alternator brand

Why Are Alternators Critical for Emergency Services?

In emergency services, such as ambulances and fire trucks, the best car alternator brands ensure that all electrical systems function correctly, which is vital for operational readiness. These alternators must meet stringent safety standards and deliver robust performance under pressure. Buyers from regions like Saudi Arabia and Europe should focus on sourcing alternators that guarantee reliability and efficiency, ensuring that emergency responders can perform their duties without interruption.

3 Common User Pain Points for ‘best car alternator brand’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Alternator Specifications

The Problem: B2B buyers often face the challenge of selecting the correct alternator specifications that align with their vehicle’s requirements. This is particularly difficult for companies operating a fleet of diverse vehicles, where compatibility issues can lead to significant downtime and increased operational costs. Misjudgments in amperage requirements, size, or mounting configurations can result in purchasing alternators that are either underpowered or incompatible, causing disruptions in service and repair workflows.

The Solution: To effectively address this issue, B2B buyers should develop a detailed inventory management system that tracks the specifications of each vehicle in their fleet. This system should include the make, model, year, and specific electrical demands of the vehicle. Additionally, when sourcing alternators, buyers should engage directly with manufacturers or reputable distributors who can provide detailed product specifications and compatibility charts. Utilizing these resources ensures that the selected alternator meets or exceeds the electrical load requirements of the vehicle, thus minimizing the risk of operational interruptions.

Scenario 2: Concerns Over Quality and Reliability of Alternators

The Problem: A common pain point for B2B buyers is the variability in quality and reliability among different alternator brands. In regions such as Africa and South America, where infrastructure may be less robust, the consequences of using subpar alternators can be severe, leading to frequent breakdowns and increased maintenance costs. Buyers often struggle to distinguish between reputable brands and those that may compromise on quality, which can affect their business operations and customer satisfaction.

The Solution: To mitigate this risk, B2B buyers should prioritize sourcing from well-established brands with a proven track record in the automotive industry. Conducting thorough research, including reviewing customer testimonials and industry certifications, can help identify reliable manufacturers. Additionally, buyers should consider implementing a quality assurance process that includes testing alternators upon receipt before they are deployed in the field. Establishing long-term partnerships with trusted suppliers can also ensure consistent quality and supply chain reliability, thus enhancing operational efficiency.

Scenario 3: Balancing Cost with Performance Needs

The Problem: B2B buyers often grapple with the dilemma of balancing cost against the performance needs of their vehicles. While opting for cheaper alternators may seem financially prudent, it can lead to higher costs in the long run due to frequent replacements and repairs. In regions with harsh driving conditions or extensive electrical demands, this trade-off can significantly impact a company’s bottom line. Buyers may find themselves unsure of how to assess the long-term value of an alternator relative to its initial purchase price.

The Solution: To navigate this challenge, B2B buyers should conduct a total cost of ownership analysis that considers not just the purchase price but also potential maintenance costs, longevity, and performance capabilities. It is advisable to invest in high-quality alternators, particularly those designed for high-demand applications, as they tend to offer better durability and efficiency. Engaging with technical experts or consultants can provide valuable insights into the best alternators for specific applications, ensuring that buyers make informed decisions that align with their operational needs and budget constraints.

Strategic Material Selection Guide for best car alternator brand

What Are the Key Materials Used in High-Performance Car Alternators?

When selecting the best car alternator brand, understanding the materials used in their construction is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials used in alternator manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to best car alternator brand

1. Aluminum: The Lightweight Champion

Key Properties:

Aluminum is known for its excellent strength-to-weight ratio, high corrosion resistance, and good thermal conductivity. It typically withstands temperatures up to 150°C (302°F) and is effective in dissipating heat, which is vital for alternator performance.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which contributes to fuel efficiency and ease of installation. However, it can be more expensive than other metals and may not be as durable under extreme conditions, leading to potential wear over time.

Impact on Application:

Aluminum’s corrosion resistance makes it suitable for vehicles operating in humid or coastal environments, where salt and moisture can accelerate corrosion.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure compliance with local standards regarding aluminum grades, such as ASTM or JIS specifications, to guarantee quality and performance.

2. Copper: The Electrical Conductor

Key Properties:

Copper is renowned for its exceptional electrical conductivity, with a conductivity rating of 100% IACS (International Annealed Copper Standard). It also has a high melting point of around 1,984°F (1,085°C), making it suitable for high-temperature applications.

Pros & Cons:

The primary advantage of copper is its superior conductivity, which enhances the efficiency of the alternator. However, copper is heavier and more expensive than aluminum, which can increase the overall cost of the alternator.

Impact on Application:

Copper’s high conductivity ensures effective energy transfer, making it ideal for high-performance vehicles with demanding electrical loads.

Considerations for International Buyers:

B2B buyers should be aware of potential fluctuations in copper prices and consider sourcing from regions with stable supply chains. Compliance with international standards for electrical components is also crucial.

Illustrative image related to best car alternator brand

3. Steel: The Durable Option

Key Properties:

Steel is characterized by its high tensile strength and durability, with a temperature rating that can exceed 1,000°F (538°C). It is less prone to deformation under stress compared to aluminum or copper.

Pros & Cons:

Steel’s durability makes it an excellent choice for heavy-duty applications, but it is heavier and more prone to corrosion unless treated with protective coatings. This can lead to increased maintenance costs over time.

Impact on Application:

Steel is particularly suitable for alternators used in commercial vehicles or environments where durability is paramount, such as construction sites.

Considerations for International Buyers:

Buyers should ensure that the steel used meets local and international standards for automotive applications, such as ASTM A36 or equivalent. Corrosion resistance treatments may also be necessary in humid climates.

4. Plastic Composites: The Modern Alternative

Key Properties:

Plastic composites are lightweight materials that offer good electrical insulation properties and resistance to corrosion. They can typically withstand temperatures up to 200°F (93°C) and are often used in non-structural components.

Illustrative image related to best car alternator brand

Pros & Cons:

The main advantage of plastic composites is their low weight and resistance to corrosion, which can enhance the longevity of the alternator. However, they may not provide the same level of structural integrity as metals, which could be a concern in high-stress applications.

Impact on Application:

Plastic composites are ideal for components like housings or covers, where weight reduction is beneficial, but they may not be suitable for load-bearing parts.

Considerations for International Buyers:

When sourcing plastic components, buyers should verify compliance with international standards for automotive plastics, such as ISO 9001, to ensure quality and safety.

Summary Table of Material Selection for Car Alternators

| Material | Typical Use Case for best car alternator brand | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight alternator housings | Excellent corrosion resistance | Higher cost and less durability | Medium |

| Copper | Electrical windings in high-performance alternators | Superior electrical conductivity | Heavy and expensive | High |

| Steel | Heavy-duty alternators for commercial vehicles | High durability and tensile strength | Heavier and prone to corrosion | Medium |

| Plastic Composites | Non-structural components like covers | Lightweight and corrosion-resistant | Lower structural integrity | Low |

This analysis provides B2B buyers with critical insights into material selection for car alternators, facilitating informed purchasing decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for best car alternator brand

What Are the Main Stages in the Manufacturing Process of High-Quality Car Alternators?

The manufacturing process of car alternators involves several crucial stages, each designed to ensure the reliability and efficiency of the final product.

Material Preparation: What Materials Are Used in Car Alternator Manufacturing?

The first stage in manufacturing alternators is material preparation. High-quality alternators are typically constructed using premium-grade materials such as aluminum for the housing, copper for the windings, and various durable plastics for components like insulators and covers. The choice of materials is vital, as they significantly influence the alternator’s performance, weight, and longevity.

Before production, these materials undergo rigorous quality checks to ensure they meet specific standards. Suppliers often provide certificates of compliance to validate the material quality, which is especially critical for international buyers concerned about sourcing integrity.

Forming: How Are Alternator Components Shaped?

Following material preparation, the forming stage involves shaping the components of the alternator. This includes processes like die-casting for the housing and stamping for internal parts. Advanced techniques such as CNC (Computer Numerical Control) machining are employed to achieve precise tolerances, ensuring that each part fits seamlessly during assembly.

The forming process is critical for maintaining the structural integrity of the alternator. High-quality manufacturers may also employ methods such as heat treatment to enhance the strength and durability of metal parts, particularly the rotor and stator, which are subject to significant operational stress.

Assembly: What Techniques Are Used to Assemble Car Alternators?

Once the components are prepared, they move to the assembly stage. This process often involves automated assembly lines where components are put together using robotic arms and skilled labor. Key techniques include:

- Soldering and Welding: These methods are used to connect electrical components securely, ensuring reliable conductivity.

- Mechanical Fastening: Bolts and screws are used to secure the assembly, providing stability and ease of maintenance.

- Quality Control Inspections: Each assembled alternator undergoes preliminary checks to confirm that all components are correctly installed.

This assembly stage is crucial, as it directly affects the alternator’s functionality and lifespan.

Finishing: What Final Touches Are Applied to Car Alternators?

The finishing stage includes painting, coating, and other treatments to enhance the alternator’s resistance to corrosion and wear. Manufacturers often apply a protective coating, such as powder coating or anodizing, to metal parts to prevent oxidation, especially in regions with harsh climates.

Additionally, final inspections are performed to ensure that the alternator meets aesthetic and operational standards. This may include visual inspections and tests to check for any defects or irregularities.

What Quality Assurance Measures Are Implemented in Car Alternator Manufacturing?

Quality assurance (QA) is a critical aspect of alternator manufacturing, ensuring that each unit meets international standards and customer expectations.

Illustrative image related to best car alternator brand

Which International Standards Are Relevant for Car Alternator Quality Assurance?

Leading manufacturers adhere to international quality standards, such as ISO 9001, which focuses on effective quality management systems. Compliance with ISO standards demonstrates a commitment to continuous improvement and customer satisfaction.

Additionally, industry-specific certifications like CE marking (for European markets) and API (American Petroleum Institute) certifications may also apply, especially for alternators designed for specific applications.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integral to the manufacturing process and typically include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility to ensure they meet specified criteria.

-

In-Process Quality Control (IPQC): Throughout the assembly process, quality checks are performed at various stages to identify defects early. This can include measuring electrical outputs and physical dimensions of parts.

-

Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is conducted to assess the overall performance and aesthetics of the finished alternator. This stage may involve testing electrical output and functionality under simulated operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks associated with product quality.

Illustrative image related to best car alternator brand

What Audit and Report Options Should Buyers Consider?

Buyers can request documentation such as:

-

Quality Management System (QMS) Certifications: Proof of compliance with ISO standards or other relevant certifications.

-

Quality Control Reports: Detailed reports outlining the results of quality checks conducted during the manufacturing process.

-

Supplier Audits: Conducting or requesting third-party audits of the manufacturing facility can provide insights into the supplier’s quality assurance practices.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can significantly enhance buyer confidence. These independent entities assess the manufacturing processes and quality control measures, providing an unbiased evaluation of the supplier’s capabilities.

For buyers in emerging markets, this step is particularly crucial as it can help identify potential issues before placing large orders, thereby reducing the risk of receiving subpar products.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control is vital for international buyers. Factors such as import regulations, local standards, and logistical challenges can impact the overall quality assurance process. Buyers should familiarize themselves with the specific requirements of their home country, as these can affect product acceptance and warranty claims.

Additionally, establishing strong communication channels with suppliers can facilitate better understanding and adherence to quality standards, ensuring that both parties are aligned on expectations.

Illustrative image related to best car alternator brand

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures in car alternator production is essential for B2B buyers. By focusing on these areas, buyers can ensure they partner with reputable suppliers who deliver high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best car alternator brand’

Introduction

When sourcing the best car alternator brands, B2B buyers must navigate a complex landscape of suppliers, product specifications, and regional requirements. This guide provides a structured checklist to help you make informed decisions and secure high-quality alternators that meet your business needs.

Step 1: Define Your Technical Specifications

Understanding your vehicle’s requirements is the first step in sourcing the right alternator. Determine the electrical load, voltage requirements, and compatibility with existing systems. This specificity ensures that you select an alternator capable of delivering optimal performance without overloading your vehicle’s electrical system.

Step 2: Research and Identify Reputable Brands

Take the time to research established alternator brands known for reliability and quality. Look for companies with a solid reputation in the automotive sector, such as Wilson, Denso, or Remy. Brand reputation often reflects the quality of materials and manufacturing processes, which can significantly impact the longevity and performance of the alternators.

Step 3: Evaluate Supplier Certifications

Before engaging with potential suppliers, verify their certifications and compliance with international standards. Check for ISO certifications and adherence to industry-specific quality management systems. Such certifications indicate a commitment to quality and can mitigate the risks associated with subpar products.

Step 4: Assess Product Range and Customization Options

A supplier’s product range should align with your specific needs, including options for both new and remanufactured alternators. Assess whether the supplier offers customization options that can accommodate unique vehicle specifications or electrical demands. This flexibility can be crucial for businesses operating diverse fleets or specialized vehicles.

Step 5: Request Detailed Product Information

Once you have shortlisted potential suppliers, request comprehensive product data sheets. Look for information on amperage ratings, dimensions, and warranty terms. Detailed specifications will help you evaluate whether the alternator can meet your operational demands and provide peace of mind regarding its performance.

Step 6: Check for After-Sales Support and Warranty Policies

Evaluate the after-sales support provided by potential suppliers, including warranty coverage and return policies. A robust warranty indicates the supplier’s confidence in their product quality and can protect your investment. Ensure that you understand the terms and conditions associated with warranties, including coverage duration and claims processes.

Step 7: Negotiate Pricing and Terms

Finally, engage in negotiations with your chosen suppliers. Consider the total cost of ownership, including shipping and handling fees, and any potential discounts for bulk purchases. Establish clear payment terms and delivery timelines to ensure a smooth procurement process that aligns with your operational schedule.

By following this checklist, B2B buyers can confidently navigate the sourcing of high-quality car alternators, ensuring optimal performance and reliability in their automotive operations.

Comprehensive Cost and Pricing Analysis for best car alternator brand Sourcing

What Are the Key Cost Components in Sourcing Car Alternators?

When assessing the total cost of sourcing car alternators, several key components contribute to the overall price structure. These include:

-

Materials: The quality and type of materials used, such as copper for windings and aluminum for housings, significantly impact the price. Higher-grade materials enhance performance and longevity but may increase costs.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Skilled labor in regions with higher wage standards can lead to increased production costs, while automated processes may reduce labor expenses.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing practices can minimize overhead, thereby reducing the overall cost.

-

Tooling: Initial tooling costs for molds and equipment can be substantial, especially for custom designs. This is often amortized over larger production volumes, affecting unit pricing.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability and safety, but it also adds to the overall cost. Certifications and compliance with international standards can further increase expenses.

-

Logistics: Transportation and warehousing costs are critical, particularly for international shipments. Factors like shipping routes, customs duties, and tariffs must be considered, especially when sourcing from or to regions such as Africa, South America, the Middle East, and Europe.

-

Margin: Suppliers typically add a margin to cover risks and profit. This margin can fluctuate based on market demand, competition, and the buyer’s negotiation leverage.

What Price Influencers Should B2B Buyers Consider?

Several factors can influence the pricing of car alternators:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally lead to lower unit prices due to economies of scale. Understanding the supplier’s MOQ can aid in planning procurement strategies.

-

Specifications and Customization: Custom alternators tailored to specific vehicle requirements or performance standards often come at a premium. Buyers should weigh the benefits of customization against the additional costs.

-

Material Quality and Certifications: Alternators made from high-quality materials or those that meet specific certifications (e.g., ISO, CE) may command higher prices. However, these often ensure better performance and durability.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established brands may charge more due to their proven track record, while lesser-known suppliers might offer lower prices but with potential quality risks.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect the total landed cost. Buyers should understand who bears the risk and cost at each stage of the shipping process to avoid unexpected expenses.

What Buyer Tips Can Help in Negotiating Costs Effectively?

For international B2B buyers, particularly from diverse regions, effective negotiation and cost management are crucial:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and pricing based on your purchasing power and volume. Suppliers may be willing to offer discounts for early payments or bulk orders.

-

Consider Total Cost of Ownership (TCO): Rather than focusing solely on the initial purchase price, evaluate the TCO, which includes installation, maintenance, and potential downtime costs. A higher-quality alternator might save money in the long run.

-

Understand Pricing Nuances: Pricing can vary significantly based on regional market dynamics. Research local market conditions and historical price trends to gain leverage during negotiations.

-

Establish Long-term Relationships: Building a solid relationship with suppliers can lead to better pricing and terms over time. Loyalty can yield benefits like priority service and favorable pricing adjustments.

Disclaimer on Indicative Prices

Prices for car alternators can fluctuate based on market conditions, availability, and regional economic factors. Always conduct thorough market research and consult multiple suppliers to obtain the most accurate and competitive pricing for your specific needs.

Alternatives Analysis: Comparing best car alternator brand With Other Solutions

Introduction to Alternatives for Car Alternators

When evaluating the best car alternator brands, it is crucial for B2B buyers to consider viable alternatives that can meet the specific needs of their automotive applications. Different brands and technologies offer varied performance characteristics, cost structures, and maintenance requirements. Understanding these alternatives can help businesses make informed decisions that align with their operational goals and customer expectations.

Comparison Table

| Comparison Aspect | Best Car Alternator Brand | Alternative 1: Remanufactured Alternators | Alternative 2: High-Output Alternators |

|---|---|---|---|

| Performance | Reliable and consistent output, tailored to OEM specifications. | Comparable performance to new units, often with a lower price point. | Enhanced output, ideal for vehicles with high electrical demands. |

| Cost | Premium pricing reflecting quality and warranty support. | Lower cost, typically 30-50% less than new units. | Higher upfront cost due to advanced technology and materials. |

| Ease of Implementation | Direct fit for most vehicles, minimal installation complexity. | Installation similar to new units; however, may require additional checks for compatibility. | Requires modifications to wiring and possibly other components. |

| Maintenance | Low maintenance with long lifespan; backed by warranties. | Similar maintenance to new units, but longevity may vary based on component quality. | Potentially higher maintenance due to increased electrical load and heat generation. |

| Best Use Case | Standard vehicles requiring dependable performance. | Budget-conscious buyers looking for quality alternatives. | High-performance and modified vehicles with significant electrical demands. |

Detailed Breakdown of Alternatives

Remanufactured Alternators

Remanufactured alternators are refurbished units that have been inspected and rebuilt to meet original equipment (OE) specifications. They provide a cost-effective solution for buyers who need reliable performance without the premium price tag of new units. The main advantage is the significant cost savings, often 30-50% less than new alternatives. However, the longevity of remanufactured units can vary based on the quality of the components used during the refurbishment process, which may pose a risk for buyers seeking long-term reliability.

Illustrative image related to best car alternator brand

High-Output Alternators

High-output alternators are designed for vehicles with increased electrical demands, such as those equipped with advanced audio systems or additional electrical accessories. These units can deliver significantly more amperage, ensuring that all electrical components function optimally even under heavy load. While they provide enhanced performance, the upfront cost is typically higher, and installation may require modifications to the vehicle’s wiring and electrical systems. Additionally, they can generate more heat, leading to potential maintenance challenges over time.

Conclusion: How to Choose the Right Solution for Your Needs

For B2B buyers, selecting the appropriate alternator solution requires a careful assessment of their specific operational needs, budget constraints, and vehicle requirements. While the best car alternator brands provide reliable performance and warranty support, alternatives like remanufactured and high-output units can offer significant advantages depending on the application. Buyers should consider factors such as cost-effectiveness, installation complexity, and maintenance requirements to ensure they choose the right solution that aligns with their business objectives and the expectations of their customers.

Essential Technical Properties and Trade Terminology for best car alternator brand

What Are the Key Technical Properties of High-Quality Car Alternators?

Understanding the essential technical properties of car alternators is crucial for B2B buyers looking to invest in reliable and efficient automotive electrical components. Here are some of the critical specifications to consider:

Illustrative image related to best car alternator brand

-

Output Voltage and Amperage

The output voltage of a typical automotive alternator is between 13 to 14.8 volts, while the amperage can range from 50 to over 300 amps, depending on the vehicle’s electrical demands. Higher output amperage is essential for vehicles with extensive electrical systems or aftermarket upgrades, such as high-performance audio systems. Selecting the right amperage ensures that the alternator can meet the vehicle’s power requirements without overloading or damaging the electrical system. -

Material Grade

The materials used in the construction of an alternator, such as copper for windings and high-grade aluminum for housings, significantly affect performance and durability. High-quality materials enhance conductivity, reduce heat generation, and extend the lifespan of the alternator. For B2B buyers, understanding material specifications can inform decisions about product longevity and reliability in different operating conditions. -

Cooling System

Alternators may feature built-in cooling systems, such as fans or heat sinks, to dissipate heat generated during operation. Effective cooling is essential for maintaining performance, particularly in high-output alternators that operate under heavy loads. Buyers should consider cooling features, especially for vehicles in hot climates or with demanding electrical systems. -

Regulator Type

Alternators can be equipped with internal or external voltage regulators. Internal regulators are more common and simplify installation, while external regulators can offer better performance in specific applications. Understanding the regulator type helps buyers determine compatibility and ease of integration into various vehicle types. -

Weight and Size

The physical dimensions and weight of an alternator can impact installation and vehicle performance. Lightweight and compact designs are often preferred in high-performance applications, as they reduce strain on the engine and improve fuel efficiency. Buyers should assess the space available in the vehicle’s engine compartment to ensure proper fitment. -

Durability Ratings

Many alternators come with durability ratings or certifications, such as ISO standards. These ratings indicate the alternator’s ability to withstand extreme conditions, including temperature fluctuations, vibrations, and moisture exposure. For B2B buyers, certifications can serve as a benchmark for quality assurance and reliability.

What Common Trade Terms Should B2B Buyers Know When Purchasing Alternators?

Navigating the automotive parts market requires familiarity with specific industry jargon. Here are some common trade terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM parts are components manufactured by the original vehicle manufacturer or their authorized suppliers. They are designed to meet the specific standards and specifications of the vehicle. B2B buyers often prefer OEM parts for their guaranteed compatibility and reliability. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier requires for a purchase order. Understanding MOQ is vital for buyers to manage inventory and cost-effectiveness, especially when dealing with manufacturers or wholesalers. -

RFQ (Request for Quotation)

An RFQ is a formal request from a buyer to suppliers to provide price quotes for specific products. This process helps buyers compare pricing and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized shipping terms that define the responsibilities of buyers and sellers in international trade, including shipping costs and risk management. Familiarity with Incoterms helps buyers understand their obligations and rights during the shipping process. -

Aftermarket

The aftermarket refers to the secondary market of automotive parts and accessories that are not sourced from the OEM. Aftermarket alternators can offer competitive pricing and varied options, but buyers should ensure quality and compatibility. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and durability of the alternator over a specified period. Understanding warranty terms is crucial for B2B buyers to assess the risk and potential return on investment in alternator purchases.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their offerings in the automotive sector.

Navigating Market Dynamics and Sourcing Trends in the best car alternator brand Sector

Market Overview & Key Trends in the Best Car Alternator Brand Sector

The global automotive alternator market is witnessing significant growth, driven by the increasing demand for electrical power in vehicles. As automotive technology evolves, vehicles are equipped with advanced electrical systems requiring robust alternators to maintain battery performance and power essential components. This shift is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where the automotive industry is expanding rapidly.

Emerging trends include the rise of high-output alternators, which cater to the growing need for power in vehicles outfitted with advanced audio systems and other electronic accessories. B2B buyers are increasingly looking for suppliers who offer both new and remanufactured options, as remanufactured alternators provide a cost-effective solution without compromising on quality. Moreover, the integration of digital technologies in sourcing processes, such as AI-driven analytics for demand forecasting and inventory management, is enhancing procurement efficiency for international buyers.

Market dynamics are also influenced by regional automotive regulations aimed at reducing emissions and improving fuel efficiency. Buyers must stay informed about these regulations as they can impact alternator specifications and sourcing strategies. Additionally, the competitive landscape is shifting, with manufacturers focusing on innovation and product differentiation to meet the demands of diverse markets. This presents an opportunity for international buyers to partner with brands that not only meet quality standards but also demonstrate adaptability to market changes.

Illustrative image related to best car alternator brand

How is Sustainability and Ethical Sourcing Important in the Best Car Alternator Brand Sector?

Sustainability is becoming a crucial consideration in the automotive industry, particularly in the sourcing of alternators. The environmental impact of manufacturing processes, including resource extraction and waste generation, necessitates a shift towards more sustainable practices. For B2B buyers, partnering with manufacturers who prioritize eco-friendly production methods is essential. This includes the use of recycled materials and minimizing carbon footprints throughout the supply chain.

Ethical sourcing plays a vital role in ensuring that the materials used in alternators are obtained responsibly. Buyers should look for suppliers who adhere to ethical standards and possess certifications that reflect their commitment to sustainable practices. For instance, certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) indicate a manufacturer’s dedication to maintaining high environmental and quality standards. Additionally, the growing consumer demand for ‘green’ products is pushing manufacturers to innovate, leading to the development of alternators that utilize sustainable materials and processes.

Incorporating sustainability into sourcing strategies not only enhances brand reputation but also aligns with global trends towards corporate responsibility. For B2B buyers, this means selecting partners who are not only cost-effective but also contribute to a more sustainable future.

What is the Brief Evolution/History of the Best Car Alternator Brands?

The evolution of car alternators can be traced back to the early 20th century, when generators were the primary source of electrical power in vehicles. As automotive technology advanced, the need for a more efficient power generation system led to the development of the alternator in the 1960s. This innovation allowed for higher output at lower engine speeds, making it an essential component in modern vehicles.

Over the decades, brands such as Denso, Remy, and Wilson have established themselves as leaders in the alternator market, continuously innovating to meet the increasing demands of the automotive industry. The transition from traditional manufacturing to advanced techniques, including the use of high-performance materials and computer-aided design, has significantly improved the efficiency and durability of alternators.

Today, the best car alternator brands not only focus on performance but also prioritize sustainability and ethical sourcing, reflecting the changing expectations of B2B buyers in a globalized market. As the industry continues to evolve, these brands remain pivotal in shaping the future of automotive electrical systems.

Frequently Asked Questions (FAQs) for B2B Buyers of best car alternator brand

-

How do I determine the right alternator for my vehicle?

To find the right alternator, consider your vehicle’s electrical load and specifications. Check the amperage requirements, which should ideally be 50% greater than your vehicle’s total electrical demand. Ensure compatibility with your vehicle’s model, year, and engine layout. It’s also vital to assess whether you need a new or remanufactured alternator based on your budget and performance needs. Consulting with your supplier for detailed specifications and compatibility checks can further ensure a proper fit. -

What are the best brands of alternators available for B2B buyers?

Top alternator brands recognized for quality and performance include Wilson, Remy, Denso, and Armature DNS. These brands are known for their reliability and adherence to OEM specifications, making them ideal for various vehicle types. When sourcing, consider factors such as warranty, availability, and supplier reputation. Engaging with established manufacturers ensures you receive high-quality products that meet international standards. -

What factors should I consider when sourcing alternators from international suppliers?

When sourcing alternators internationally, evaluate the supplier’s credibility, production capacity, and quality assurance processes. Assess their compliance with international standards and certifications, as well as their history of reliability and customer service. Additionally, consider the logistics and shipping options available, including lead times and costs. Communication is key; ensure the supplier is responsive and transparent about their processes. -

What are the typical minimum order quantities (MOQs) for alternators?

Minimum order quantities can vary significantly by supplier and product type. Generally, MOQs for alternators range from 50 to 200 units, depending on the brand and specifications. It’s advisable to discuss MOQs with potential suppliers during negotiations, as some may offer flexibility for new partnerships or bulk orders. Understanding your market demand will help you negotiate favorable terms. -

What payment terms should I expect when purchasing alternators internationally?

Payment terms can vary by supplier but typically include options like upfront payment, partial payment upon order confirmation, and balance upon delivery. Common methods include wire transfers, letters of credit, and payment through secure platforms. It’s crucial to clarify payment terms early in negotiations to avoid misunderstandings and ensure smooth transactions. Consider establishing a mutually agreeable payment plan that aligns with your cash flow. -

How can I ensure the quality of alternators I am sourcing?

To ensure quality, request certifications and test reports from suppliers to verify that their products meet industry standards. Conduct factory visits or arrange for third-party inspections if feasible. Additionally, consider trial orders to evaluate performance and durability before committing to larger quantities. Establishing a robust quality assurance protocol can help mitigate risks associated with product defects. -

What logistics considerations should I keep in mind when importing alternators?

Logistics play a critical role in international sourcing. Assess shipping options, including air freight and sea freight, based on cost, speed, and reliability. Ensure that you understand customs regulations and import duties in your country to avoid delays. Collaborating with a logistics partner familiar with automotive parts can streamline the process and ensure compliance with all necessary documentation. -

Can I customize alternators to meet specific vehicle requirements?

Yes, many manufacturers offer customization options for alternators to suit specific vehicle needs. Customizations can include variations in amperage, size, and design features. When discussing with suppliers, provide detailed specifications and volume requirements to facilitate the customization process. Be prepared for potential lead times and additional costs associated with tailored products.

Top 3 Best Car Alternator Brand Manufacturers & Suppliers List

1. Denso – Quality Automotive Parts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Denso – Quality Automotive Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. AC Delco – Alternators

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Alternator brands mentioned: AC Delco, Duralast

3. Mechman – High Output Alternators

Domain: mechman.com

Registered: 1996 (29 years)

Introduction: Mechman Alternators are U.S.A made high output alternators with options ranging from 150a to 370a. They offer 1-year, 2-year, and lifetime extended warranty options. The product line includes 24 Volt and 48 Volt alternators, as well as various accessories such as engine stands, bracket kits, pulleys, plugs and harnesses, and voltage control. Notable products include the 48-Volt Elite Alternator fo…

Strategic Sourcing Conclusion and Outlook for best car alternator brand

In the competitive landscape of automotive components, strategic sourcing of high-quality alternators is crucial for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the differences between new and remanufactured alternators, as well as the electrical demands of various vehicles, empowers businesses to make informed purchasing decisions. Opting for reputable brands, such as Wilson, Remy, and Denso, not only ensures reliability but also enhances vehicle performance and longevity.

As the automotive industry continues to evolve with increasing electrical demands, the need for superior alternators will only grow. Buyers should prioritize partnerships with manufacturers that adhere to stringent quality standards and offer comprehensive warranties, ensuring they receive value and support post-purchase.

Illustrative image related to best car alternator brand

Moving forward, B2B buyers are encouraged to conduct thorough market research and leverage supplier relationships to optimize their sourcing strategies. By aligning with trusted brands and understanding the specific needs of their markets, businesses can secure a competitive edge and foster sustainable growth. Embrace the opportunity to enhance your supply chain today and drive your operations towards a more efficient future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to best car alternator brand