Introduction: Navigating the Global Market for best alternator

In the quest for the best alternator, international B2B buyers face the critical challenge of sourcing reliable electrical components that align with their specific vehicle requirements and market conditions. Whether you are in Nigeria, Saudi Arabia, or any other region, understanding the nuances of alternator selection is essential for maintaining operational efficiency and vehicle reliability. This comprehensive guide delves into various types of alternators, their applications across different vehicle models, and key factors to consider when making a purchase, including supplier vetting, cost analysis, and warranty evaluations.

As the global market for automotive parts expands, it becomes increasingly important for businesses to navigate through a myriad of options while ensuring quality and performance. Buyers will learn to assess alternatives between new and remanufactured units, evaluate amperage needs based on electrical loads, and understand the implications of total cost of ownership. By equipping yourself with this knowledge, you can make informed purchasing decisions that not only meet your immediate needs but also contribute to long-term operational success.

This guide empowers you to confidently engage with suppliers, ensuring that you source the best alternators tailored to your unique business requirements. With insights tailored for buyers across Africa, South America, the Middle East, and Europe, you will be well-prepared to tackle the complexities of the global alternator market and enhance your procurement strategy.

Table Of Contents

- Top 2 Best Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best alternator

- Understanding best alternator Types and Variations

- Key Industrial Applications of best alternator

- 3 Common User Pain Points for ‘best alternator’ & Their Solutions

- Strategic Material Selection Guide for best alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for best alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best alternator’

- Comprehensive Cost and Pricing Analysis for best alternator Sourcing

- Alternatives Analysis: Comparing best alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for best alternator

- Navigating Market Dynamics and Sourcing Trends in the best alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best alternator

- Strategic Sourcing Conclusion and Outlook for best alternator

- Important Disclaimer & Terms of Use

Understanding best alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| New Alternators | Brand new components, no core exchange required | OEM replacement, fleet vehicles | Pros: Reliability, warranty support; Cons: Higher initial cost. |

| Remanufactured Alternators | Refurbished units, often with core exchange | Cost-sensitive projects, older vehicles | Pros: Cost-effective, environmentally friendly; Cons: Potentially shorter lifespan than new. |

| High-Output Alternators | Increased amperage for heavy electrical loads | Performance vehicles, specialized equipment | Pros: Supports additional electronics; Cons: May require modifications for fitment. |

| Dual-Voltage Alternators | Offers both 12V and 24V outputs | Commercial trucks, construction equipment | Pros: Versatility for varied applications; Cons: Complexity in selection and installation. |

| Brushless Alternators | Reduced wear and longer lifespan due to design | Advanced vehicles, industrial machinery | Pros: Higher efficiency, less maintenance; Cons: Higher upfront cost, limited availability. |

What Are the Key Characteristics of New Alternators?

New alternators are manufactured from scratch, ensuring they meet or exceed original equipment specifications. They are ideal for businesses seeking reliable performance and longevity, particularly in fleet operations or when upgrading vehicle systems. Buyers should consider the warranty offered, as many new units come with robust support, reinforcing their reliability. Although the initial investment is higher, the absence of core returns simplifies the purchasing process.

How Do Remanufactured Alternators Benefit Cost-Sensitive Projects?

Remanufactured alternators are refurbished units that have been restored to meet OEM standards. They are an excellent choice for businesses looking to balance cost and quality, especially for older vehicles or cost-sensitive projects. While they are more affordable than new units, buyers should assess the warranty and reliability of the remanufactured parts, as the lifespan may not match that of brand-new alternators. These units often require a core exchange, which may complicate logistics.

When Should Businesses Consider High-Output Alternators?

High-output alternators are designed to provide increased amperage, making them suitable for performance vehicles or applications with heavy electrical demands, such as sound systems or additional lighting. B2B buyers in sectors like automotive racing or specialized equipment should prioritize these units to ensure they meet the electrical needs of their applications. While they offer significant advantages, potential fitment issues may necessitate modifications, so thorough compatibility checks are essential.

What Are the Advantages of Dual-Voltage Alternators?

Dual-voltage alternators can operate at both 12V and 24V, making them versatile for various applications, particularly in commercial trucks and construction equipment. These units are advantageous for businesses that operate mixed fleets or require flexibility in power supply. However, the complexity in selection and installation can be a drawback, necessitating specialized knowledge or additional resources to ensure proper integration into existing systems.

Why Choose Brushless Alternators for Advanced Applications?

Brushless alternators represent a cutting-edge design that minimizes wear and enhances efficiency, making them ideal for advanced vehicles and industrial machinery. Their longer lifespan and lower maintenance requirements appeal to B2B buyers focused on reducing downtime and maintenance costs. However, the higher upfront cost and potentially limited availability can be barriers for some businesses, necessitating a careful evaluation of long-term benefits versus initial investment.

Key Industrial Applications of best alternator

| Industry/Sector | Specific Application of best alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Replacement in passenger vehicles | Ensures reliable vehicle operation, reducing downtime | Compatibility with various vehicle makes and models |

| Agriculture | Powering farm machinery | Enhances productivity by maintaining equipment uptime | Durability against harsh conditions and load capacity |

| Construction | Used in heavy machinery like excavators | Increases operational efficiency and reduces failures | Ability to withstand vibrations and heavy loads |

| Renewable Energy | Supporting solar and wind energy systems | Provides consistent power supply for energy generation | Compatibility with energy storage systems and inverter specs |

| Marine | Powering boats and ships | Reliable electrical supply for navigation and safety | Resistance to corrosion and water exposure |

How is the Best Alternator Utilized in the Automotive Sector?

In the automotive industry, the best alternators are crucial for powering electrical systems in passenger vehicles. These components convert mechanical energy into electrical energy, ensuring that batteries remain charged and that all electrical systems function optimally. For international buyers, especially in regions like Africa and South America, sourcing alternators that fit specific vehicle models and amperage requirements is vital to avoid costly downtimes. Additionally, buyers should consider the availability of both new and remanufactured options to balance quality with cost-effectiveness.

What Role Does the Best Alternator Play in Agriculture?

In agriculture, the best alternators are essential for powering various types of farm machinery, such as tractors and harvesters. These machines often operate in challenging environments, where reliability is paramount. A high-quality alternator helps maintain equipment uptime, thereby enhancing productivity and operational efficiency. For B2B buyers in regions like the Middle East, where agricultural machinery is subject to extreme conditions, sourcing alternators with high durability ratings and load capacities is a key consideration to ensure long-term performance.

How Does the Best Alternator Benefit Construction Operations?

In the construction industry, the best alternators are integrated into heavy machinery such as excavators and bulldozers. These alternators are designed to handle high electrical loads and operate under severe conditions, contributing to increased operational efficiency. For buyers in Europe and Africa, sourcing alternators that can withstand heavy vibrations and extreme working conditions is critical. Additionally, ensuring compatibility with various machinery models can prevent delays and maintain project timelines.

Why is the Best Alternator Important for Renewable Energy Systems?

In renewable energy applications, the best alternators are utilized in systems like solar and wind energy setups to convert mechanical energy into electrical energy. This is crucial for maintaining a consistent power supply to energy storage systems. For international buyers, particularly in developing regions, selecting alternators that are compatible with specific inverter specifications and energy storage solutions is essential. This ensures that the systems operate efficiently, contributing to sustainable energy generation.

How is the Best Alternator Used in Marine Applications?

In the marine sector, the best alternators are vital for powering boats and ships, providing electrical supply for navigation, communication, and safety systems. Given the unique challenges posed by the marine environment, such as exposure to saltwater and vibrations, it is crucial for buyers to source alternators that are resistant to corrosion and designed for durability. For businesses in maritime operations, ensuring that the alternators meet specific performance criteria can significantly enhance safety and reliability at sea.

3 Common User Pain Points for ‘best alternator’ & Their Solutions

Scenario 1: Sourcing Reliable Alternators in Diverse Markets

The Problem: B2B buyers often face challenges in sourcing reliable alternators that meet the specific needs of their diverse markets, particularly in regions like Africa and South America. These markets may have varying vehicle types, electrical demands, and climatic conditions, leading to difficulties in finding alternators that perform consistently. Buyers may struggle with unreliable suppliers, leading to delays, increased costs, and potential customer dissatisfaction due to product failures.

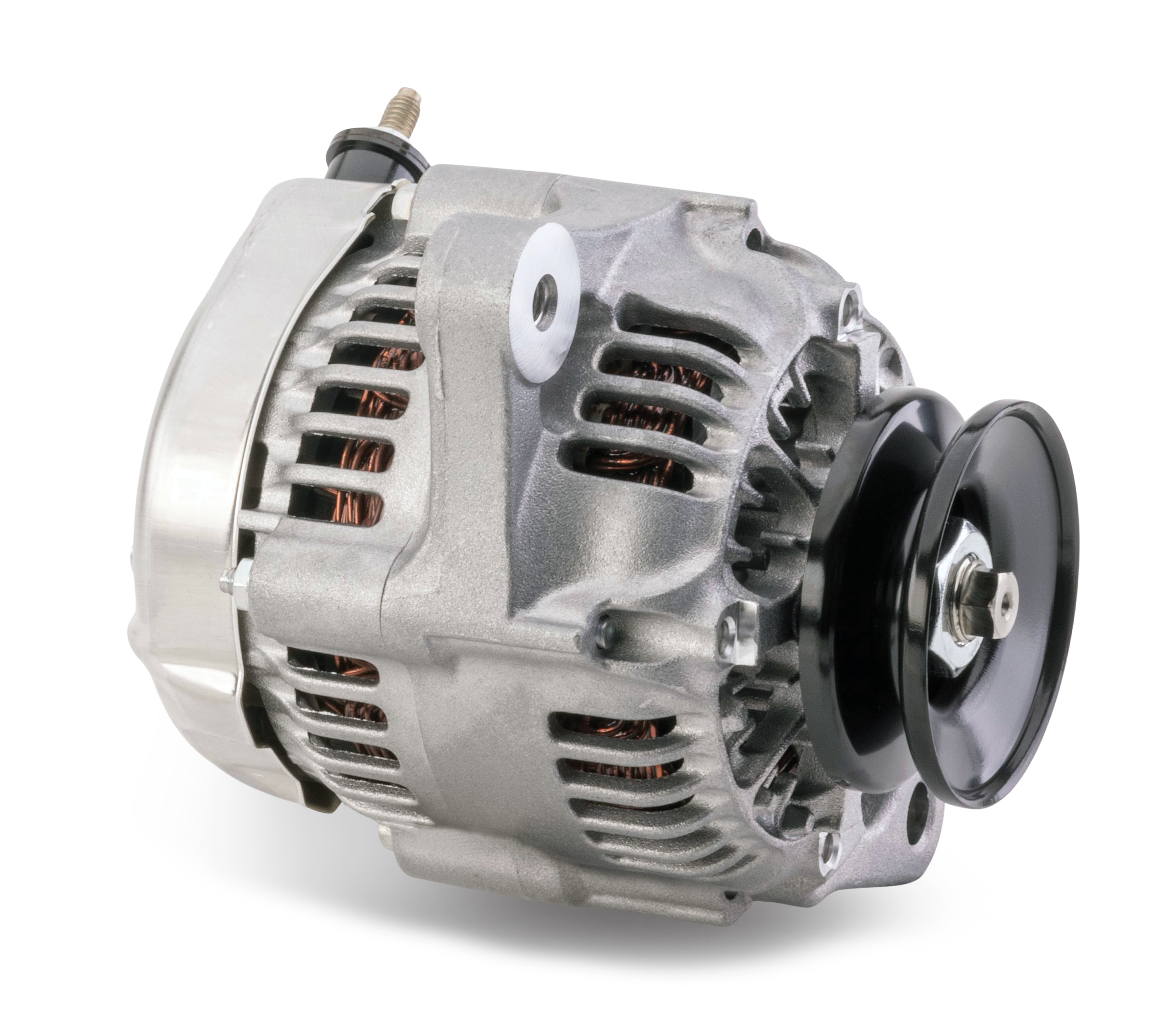

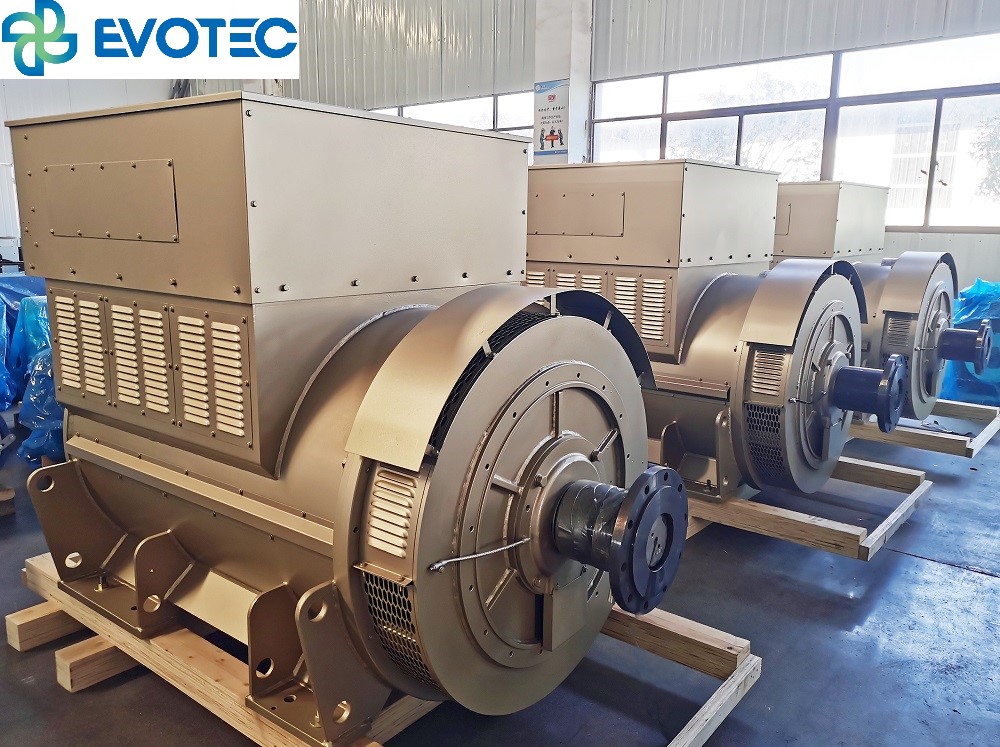

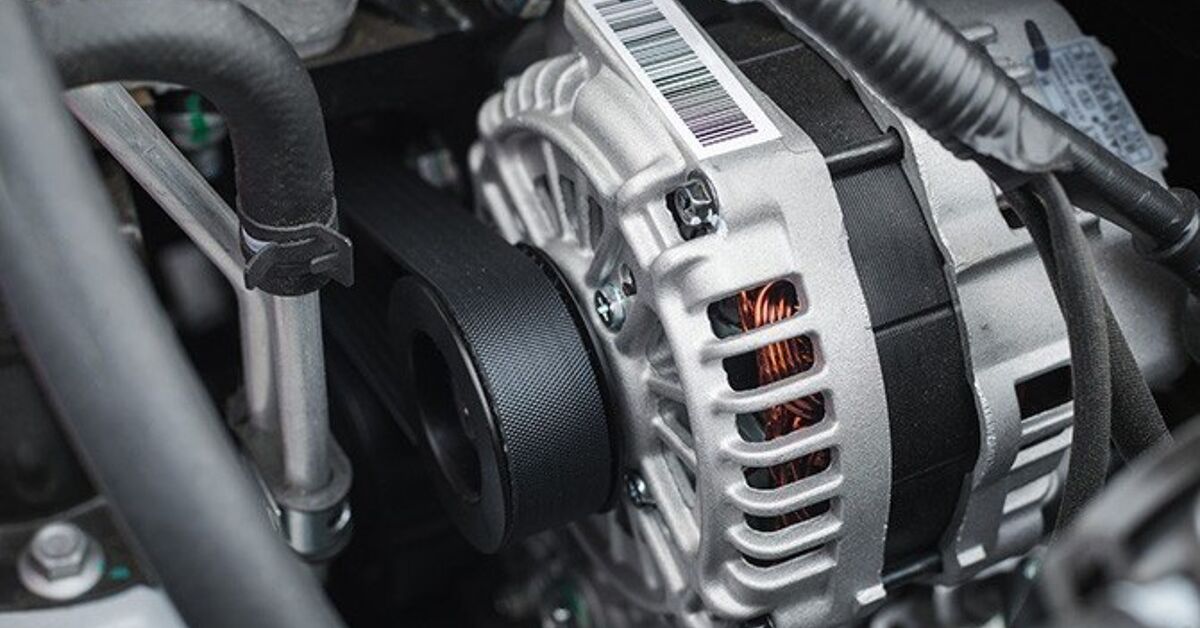

Illustrative image related to best alternator

The Solution: To overcome these sourcing challenges, B2B buyers should develop partnerships with reputable suppliers that have a proven track record in their respective regions. Conduct thorough research to identify manufacturers or distributors with a solid reputation for quality and reliability. It’s essential to prioritize suppliers who offer a range of alternators suitable for different vehicles, from light commercial vehicles to heavy-duty machinery. Buyers should also request product samples and conduct performance testing in local conditions before committing to bulk purchases. Establishing a reliable supply chain that includes local warehouses can significantly reduce lead times and ensure that the right alternators are available when needed.

Scenario 2: Understanding Technical Specifications for Optimal Performance

The Problem: Many B2B buyers lack the technical expertise to select the right alternators based on vehicle specifications, which can lead to mismatched products that do not meet performance expectations. This issue is particularly pronounced when dealing with aftermarket alternators, where variations in amperage, fitment, and electrical load can have significant implications for operational efficiency. Buyers may end up with alternators that either underperform or fail prematurely, resulting in wasted investments and potential operational downtime.

The Solution: To mitigate this issue, B2B buyers should invest in training for their procurement teams to enhance their understanding of alternator specifications and performance metrics. It’s crucial to analyze the electrical requirements of the vehicles in their fleet and align them with the specifications of potential alternators. Creating a standardized checklist that includes application and fitment criteria, amperage ratings, and warranty information can streamline the selection process. Furthermore, collaborating with technical experts or automotive engineers can provide insights into the best alternators for specific applications, ensuring that the selected products enhance vehicle performance and reliability.

Scenario 3: Navigating Warranty and Support Options

The Problem: B2B buyers often encounter confusion regarding warranty terms and customer support when purchasing alternators, especially when dealing with different manufacturers and aftermarket options. Inadequate warranty coverage can lead to significant costs if an alternator fails soon after purchase, and a lack of accessible customer support can exacerbate issues related to faulty products. This uncertainty can result in hesitance to invest in quality products, ultimately affecting the buyer’s bottom line.

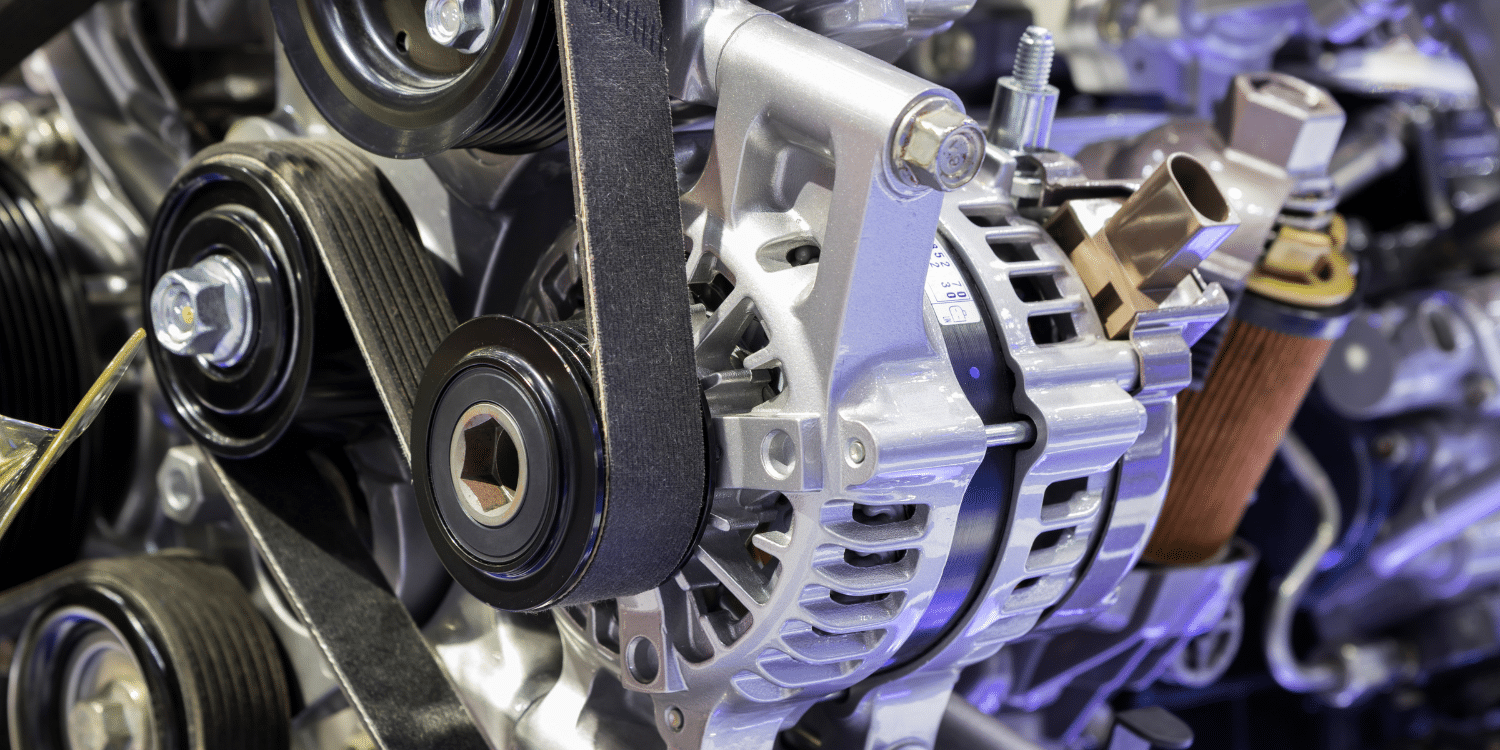

Illustrative image related to best alternator

The Solution: To address warranty and support concerns, B2B buyers should prioritize suppliers that offer clear, comprehensive warranty policies and responsive customer service. Before making a purchase, buyers should thoroughly review warranty terms to understand what is covered and the process for claims. Establishing a relationship with suppliers that provide robust after-sales support, including technical assistance and easy return processes, can enhance buyer confidence. Additionally, buyers should consider keeping a record of warranty claims and customer interactions to evaluate supplier performance over time, which can inform future purchasing decisions and help in negotiating better terms. By focusing on suppliers that prioritize customer satisfaction and support, B2B buyers can safeguard their investments in alternators.

Strategic Material Selection Guide for best alternator

What Materials Are Commonly Used in the Best Alternators?

When selecting the best alternators for various applications, understanding the materials used in their construction is crucial. This analysis will cover four common materials: aluminum, copper, steel, and plastic, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Contribute to Alternator Performance?

Aluminum is a widely used material in alternator housings and components due to its lightweight and excellent thermal conductivity. It typically has a temperature rating of around 150°C and offers good corrosion resistance, making it suitable for various environments.

Pros: Aluminum’s lightweight nature contributes to overall vehicle efficiency, while its corrosion resistance ensures longevity. Additionally, it is relatively easy to manufacture and can be formed into complex shapes.

Cons: While aluminum is durable, it is not as strong as steel, which can be a limitation in high-stress applications. The cost can also be moderate, which may affect budget-conscious buyers.

Impact on Application: Aluminum’s compatibility with a range of media and environments makes it ideal for automotive applications. However, in regions with extreme temperatures, additional protective coatings may be necessary.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should consider compliance with local standards such as ASTM or DIN for aluminum specifications. They should also be aware of the availability of aluminum alloys that meet their specific needs.

Illustrative image related to best alternator

What Role Does Copper Play in Alternator Efficiency?

Copper is primarily used in the windings of alternators due to its superior electrical conductivity. It has a high-temperature rating of about 200°C and excellent resistance to corrosion.

Pros: The high conductivity of copper allows for efficient energy transfer, which is critical for alternator performance. Its durability and resistance to wear also make it a reliable choice for long-term use.

Cons: The primary drawback of copper is its cost, which is significantly higher than aluminum or steel. Additionally, copper is heavier, which can impact vehicle efficiency.

Impact on Application: Copper’s excellent conductivity ensures stable voltage output, making it suitable for high-performance applications. However, the weight may be a concern in lightweight vehicle designs.

Considerations for International Buyers: Buyers should ensure that the copper used meets international standards such as JIS or ASTM. Additionally, fluctuations in copper prices can impact total costs, so buyers should consider market trends.

How Does Steel Enhance Alternator Durability?

Steel is often used in the construction of alternator frames and internal components due to its strength and durability. It typically has a temperature rating of around 300°C and is known for its excellent resistance to mechanical stress.

Pros: The robustness of steel contributes to the overall durability of the alternator, making it suitable for heavy-duty applications. Steel is also relatively cost-effective compared to aluminum and copper.

Cons: Steel is prone to corrosion if not properly coated, which can lead to premature failure. Its weight can also negatively impact fuel efficiency in vehicles.

Impact on Application: Steel’s strength makes it ideal for rugged environments, particularly in heavy machinery or commercial vehicles. However, additional protective measures may be necessary in humid or corrosive environments.

Illustrative image related to best alternator

Considerations for International Buyers: Buyers should verify that the steel used complies with relevant standards such as DIN or ASTM. In regions with high humidity, selecting stainless steel or additional coatings may be advisable.

What Is the Role of Plastic in Modern Alternators?

Plastic is increasingly used in alternators for non-structural components, such as covers and insulators. It typically has a temperature rating of around 120°C and offers good resistance to chemicals and moisture.

Pros: Plastic is lightweight and cost-effective, making it an attractive option for reducing overall alternator weight and cost. It also provides excellent insulation properties.

Cons: The primary limitation of plastic is its lower strength compared to metals, which can affect durability in high-stress applications. It may also degrade over time when exposed to UV light.

Impact on Application: Plastic components can help reduce weight and improve efficiency, but they may not be suitable for all applications, particularly those requiring high strength.

Considerations for International Buyers: Buyers should ensure that the plastics used are compliant with local regulations and standards. They should also consider the environmental impact of plastic materials in their regions.

Summary Table of Material Properties for Best Alternators

| Material | Typical Use Case for best alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Less strong than steel | Medium |

| Copper | Windings and electrical connections | Superior electrical conductivity | High cost and weight | High |

| Steel | Frames and internal components | High strength and durability | Prone to corrosion | Low |

| Plastic | Covers and insulators | Lightweight and cost-effective | Lower strength and UV degradation | Low |

This analysis provides a comprehensive understanding of the materials commonly used in alternators, helping international B2B buyers make informed decisions tailored to their specific needs and regional considerations.

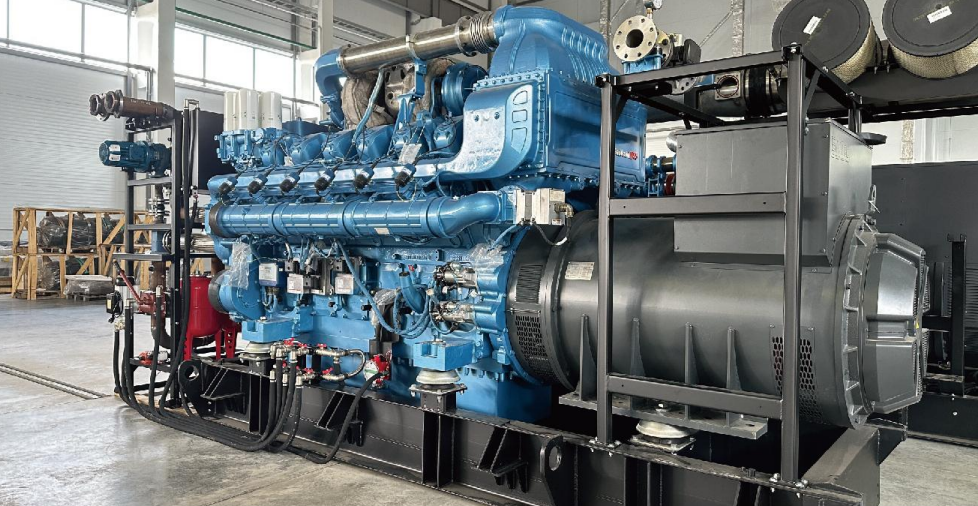

Illustrative image related to best alternator

In-depth Look: Manufacturing Processes and Quality Assurance for best alternator

What Are the Key Stages in the Manufacturing Process of High-Quality Alternators?

The manufacturing of alternators involves several critical stages that ensure both performance and durability. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: How Are Components Selected and Processed?

The first step in alternator manufacturing is material preparation. Manufacturers typically use high-grade materials such as copper for windings, aluminum or steel for housings, and durable plastics for insulation. This phase often involves sourcing materials from certified suppliers who meet international standards.

Once materials are procured, they undergo various treatments, such as annealing for copper, to enhance conductivity and reduce brittleness. This ensures that the components can withstand the stresses of operation, particularly in demanding environments found in regions like Africa and the Middle East.

What Techniques Are Used in the Forming Stage of Alternator Production?

After material preparation, the forming stage begins. This includes processes like stamping, die-casting, and machining. For example, the rotor and stator are often produced using die-casting techniques, which allow for precise shaping and improved strength.

At this stage, manufacturers may also employ advanced technologies such as CNC machining to ensure accuracy in component dimensions. This precision is crucial, as even minor discrepancies can lead to performance issues, particularly in high-load applications common in agricultural or industrial settings.

How Is Assembly Performed in the Manufacturing of Alternators?

The assembly process is where all the prepared components come together. Skilled technicians or automated systems assemble the rotor, stator, voltage regulator, and other electrical components. Each unit typically goes through a series of standardized assembly procedures to maintain consistency.

During assembly, critical connections, such as those for the electrical wiring, are meticulously checked to ensure reliability. This is particularly vital for B2B buyers in regions where equipment downtime can lead to significant financial losses.

Illustrative image related to best alternator

What Finishing Techniques Are Applied to Ensure Quality?

The finishing stage involves several processes, including painting, coating, and final inspection. Manufacturers often use corrosion-resistant coatings to enhance durability, especially for alternators intended for harsh environments.

Final inspections are performed to verify that the alternators meet the required specifications. This includes checking for physical defects, ensuring proper alignment of components, and confirming that the electrical connections are secure.

What Quality Assurance Standards Are Relevant for Alternator Manufacturing?

Quality assurance is a critical aspect of alternator manufacturing. Many manufacturers adhere to international standards like ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to maintaining high-quality processes and products.

In addition to ISO certification, industry-specific standards such as CE marking for European markets or API specifications for automotive parts are often required. These certifications assure B2B buyers that the alternators meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Alternator Production?

Quality control (QC) checkpoints play a vital role in ensuring the reliability of alternators. Common checkpoints include:

Illustrative image related to best alternator

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival. It ensures that only high-quality materials enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to monitor the assembly process. This includes checking dimensions, electrical performance, and other critical parameters.

-

Final Quality Control (FQC): Before shipping, each alternator undergoes a final inspection. This includes testing electrical output, verifying physical integrity, and ensuring compliance with specifications.

What Testing Methods Are Commonly Used to Ensure Alternator Performance?

Testing is an integral part of the quality assurance process for alternators. Common methods include:

-

Electrical Testing: This involves checking the voltage output and current capacity to ensure that the alternator meets its rated specifications.

-

Thermal Testing: Assessing how the alternator performs under heat conditions is crucial, especially in hotter climates. Manufacturers simulate high temperatures to evaluate performance and reliability.

-

Vibration Testing: Alternators must withstand vibrations from the engine. Vibration tests ensure that components are secure and will not fail during operation.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control measures is essential. Here are some actionable steps:

-

Request Certifications: Ask for copies of ISO certifications, CE markings, and other relevant documents to confirm compliance with international standards.

-

Review Quality Control Reports: Suppliers should provide reports detailing their QC processes, including results from IQC, IPQC, and FQC stages.

-

Conduct Audits: Periodically auditing suppliers can provide insights into their manufacturing processes and quality control systems. This can be done through on-site visits or third-party inspections.

-

Seek References: Engage with other businesses that have previously worked with the supplier to understand their experiences regarding quality and reliability.

-

Evaluate Warranty Policies: A robust warranty can indicate the supplier’s confidence in their products. Look for warranties that cover a reasonable duration and outline the terms clearly.

What Are the QC and Certification Nuances for International Buyers?

International buyers need to be aware of the specific certification requirements in their regions. For instance, alternators sold in Europe must comply with CE standards, while those in the United States may require compliance with SAE standards.

Illustrative image related to best alternator

Additionally, buyers should consider the logistics of sourcing products from different regions. Import duties, taxes, and shipping logistics can significantly affect total costs. Understanding these nuances can help in making informed purchasing decisions and in negotiating better terms with suppliers.

By comprehensively understanding the manufacturing processes and quality assurance practices, B2B buyers can confidently select alternators that meet their operational needs while ensuring reliability and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best alternator’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring the best alternators for their specific needs. With a focus on quality, reliability, and cost-effectiveness, this checklist will help you navigate the complexities of selecting the right alternator to ensure optimal performance in your vehicles.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is essential to clearly outline the technical specifications for the alternators you require. This includes determining the vehicle types, engine sizes, and electrical loads they will support.

– Key considerations: Amperage ratings, mounting configurations, and compatibility with existing electrical systems are crucial to prevent installation issues.

Step 2: Research Leading Brands and Manufacturers

Identifying reputable brands and manufacturers is vital for ensuring quality and performance. Look for established names such as Denso, Bosch, and AC Delco, which are known for their durability and efficiency.

– Investigate: Read reviews, compare product specifications, and check for any industry certifications to gauge reliability.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that potential suppliers meet relevant industry certifications. This could include ISO certifications or compliance with regional automotive standards.

– Why it matters: Certified suppliers are more likely to provide high-quality products and adhere to best manufacturing practices, reducing the risk of defects or failures.

Step 4: Request Detailed Product Information

Once you have shortlisted potential suppliers, request detailed product specifications and testing reports. This should include information on performance metrics, warranty details, and any testing methodologies used.

– Look for: Evidence of independent testing, such as thermal and vibration assessments, which can provide insights into the alternator’s reliability under real-world conditions.

Step 5: Compare Pricing and Total Cost of Ownership

When evaluating quotes, consider not only the initial purchase price but also the total cost of ownership. This includes shipping costs, potential core charges for remanufactured units, and any additional fees.

– Consider: A slightly higher upfront cost may be justified if it leads to lower maintenance expenses and reduced downtime in the long term.

Step 6: Assess Warranty and After-Sales Support

A strong warranty and reliable after-sales support are indicators of a manufacturer’s confidence in their products. Ensure that the alternators come with a warranty that covers both parts and labor.

– What to check: Warranty duration, terms, and the availability of technical support can significantly affect your overall satisfaction and operational efficiency.

Step 7: Finalize Supplier Selection and Place Orders

After thorough evaluation, finalize your supplier selection based on your research, product evaluations, and pricing comparisons. Ensure that all terms are clearly outlined in the purchase agreement before placing your order.

– Best practices: Maintain clear communication with the supplier to confirm lead times and delivery schedules, ensuring that your supply chain remains uninterrupted.

By following this checklist, B2B buyers can make informed decisions when sourcing alternators, ultimately enhancing the reliability and performance of their vehicles.

Comprehensive Cost and Pricing Analysis for best alternator Sourcing

When sourcing alternators in the B2B market, it is vital to understand the comprehensive cost structure that influences pricing. This not only helps in making informed purchasing decisions but also allows for effective negotiation and long-term cost management.

What Are the Key Cost Components in Alternator Manufacturing?

The cost structure for alternators comprises several critical components:

-

Materials: The choice of raw materials, such as copper for windings and high-grade aluminum for casings, significantly impacts the final price. Higher-quality materials may increase initial costs but can enhance durability and performance.

-

Labor: Labor costs vary based on geographic location and the complexity of the assembly process. Skilled labor is essential for quality assurance and assembly, particularly for high-performance or specialized alternators.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead costs, which can be reflected in the pricing of the final product.

-

Tooling: The costs associated with creating molds and tooling for production can be substantial, particularly for custom or specialized alternators. These costs are often amortized over production runs, affecting pricing based on order volume.

-

Quality Control (QC): Implementing rigorous QC processes ensures that each alternator meets specific performance standards. This may increase production costs but is crucial for minimizing returns and enhancing brand reputation.

-

Logistics: Shipping costs can vary widely based on the destination and mode of transport. For international buyers, understanding logistics, including customs duties and taxes, is essential for calculating total costs.

-

Margin: Manufacturers typically build a profit margin into the price to cover operational risks and ensure sustainability. Understanding the standard margins in the industry can aid in negotiation.

How Do Price Influencers Affect Alternator Sourcing?

Several factors influence the final pricing of alternators:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can lead to significant cost reductions. Suppliers often provide better pricing structures for larger orders, making it advantageous for businesses to forecast demand accurately.

-

Specifications and Customization: Custom alternators tailored for specific vehicles or applications may incur additional costs due to unique design and manufacturing processes. Clear specifications can help suppliers provide accurate quotes.

-

Materials and Quality Certifications: Alternators that meet specific industry standards or certifications may be priced higher. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers with a track record of quality may charge more but offer better warranties and support.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, Freight) can significantly affect the total cost of ownership by determining who is responsible for shipping costs and risks at various points in the supply chain.

What Are the Best Buyer Tips for Sourcing Alternators?

-

Negotiate Wisely: Leverage your knowledge of cost components and market trends to negotiate better terms. Establishing long-term relationships with suppliers can also lead to more favorable pricing.

-

Focus on Cost-Efficiency: Consider the total cost of ownership, which includes not just the purchase price but also shipping, potential downtime, and maintenance costs. Investing in higher-quality alternators can reduce long-term expenses associated with repairs and replacements.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and local market conditions that can affect pricing. Engage with suppliers who understand the local market dynamics in your region, whether it’s Africa, South America, the Middle East, or Europe.

-

Request Indicative Prices: While engaging with suppliers, ask for indicative pricing based on various volume scenarios to understand potential cost savings. However, always clarify that prices are subject to change based on market conditions and final specifications.

In summary, a comprehensive understanding of the cost structure, price influencers, and strategic negotiation tactics can empower B2B buyers in sourcing the best alternators effectively, ensuring both quality and cost-efficiency.

Illustrative image related to best alternator

Alternatives Analysis: Comparing best alternator With Other Solutions

Understanding Alternative Solutions in Alternator Selection

When sourcing alternators for commercial vehicles or machinery, B2B buyers often consider various options beyond the traditional best alternators. While high-quality aftermarket alternators are a reliable choice, it’s essential to explore alternative solutions that may better suit specific operational needs or budget constraints. This analysis provides a comparison of the best alternator against two viable alternatives: solar power systems and generator sets.

Comparison Table

| Comparison Aspect | Best Alternator | Solar Power Systems | Generator Sets |

|---|---|---|---|

| Performance | Reliable voltage output, high efficiency | Variable output, dependent on sunlight | Consistent power output, versatile |

| Cost | Moderate initial cost, lower long-term maintenance | High upfront cost, low operating costs | High initial and operational costs |

| Ease of Implementation | Direct fit for specific vehicles, straightforward installation | Requires site assessment, installation expertise | Requires space, fuel source, and setup |

| Maintenance | Low maintenance, occasional checks | Minimal, but requires cleaning and inspection | Regular maintenance needed, fuel management |

| Best Use Case | Standard vehicles needing electrical reliability | Remote areas with no grid access | Backup power for critical operations or events |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of Solar Power Systems?

Solar power systems harness energy from the sun to generate electricity, making them an eco-friendly alternative to traditional power sources. The primary advantages of solar systems include their low operational costs and sustainability, ideal for remote locations where conventional power sources are unavailable. However, their performance is heavily dependent on weather conditions and geographical location, which can lead to inconsistent power supply. Additionally, the initial investment for solar panels and installation can be significant, making it less appealing for businesses focused on immediate cost savings.

Why Consider Generator Sets as an Alternative?

Generator sets provide a reliable power source, especially in emergency situations or for temporary projects. They can generate electricity consistently, regardless of external conditions, which is advantageous for businesses requiring uninterrupted power for operations. However, the cost of fuel and regular maintenance can add up, making them a more expensive long-term solution. Moreover, the noise and emissions produced by generators can be a drawback in certain environments, particularly in urban areas or near sensitive ecosystems.

Illustrative image related to best alternator

Conclusion: How to Choose the Right Solution for Your Needs

When selecting an alternator or alternative power solution, B2B buyers should evaluate their specific operational requirements, budget constraints, and environmental considerations. The best alternator offers a reliable and cost-effective solution for standard vehicle applications, while solar power systems may be ideal for businesses looking to invest in sustainable energy for remote areas. Generator sets serve as a practical backup power solution but come with higher operational costs and maintenance needs. Ultimately, the choice hinges on balancing performance, cost, and the intended use case to ensure optimal operational efficiency.

Essential Technical Properties and Trade Terminology for best alternator

What Are the Essential Technical Properties of the Best Alternators?

When selecting the best alternator for your automotive needs, understanding its technical properties is crucial. These specifications not only determine the performance and compatibility of the alternator but also ensure reliability and efficiency in your vehicle’s electrical system. Here are some critical technical properties to consider:

-

Amperage Rating

The amperage rating indicates the amount of electrical current an alternator can produce. Typically measured in amps, this rating is vital for ensuring that the alternator can meet the electrical demands of your vehicle. A higher amperage rating is essential if the vehicle is equipped with additional accessories like high-powered audio systems or multiple electronic devices. Selecting an alternator with an appropriate amperage rating can prevent electrical failures and ensure optimal performance. -

Material Grade

The materials used in alternator construction significantly impact durability and efficiency. High-grade materials such as aluminum or high-strength plastics are often preferred due to their resistance to corrosion and heat. In B2B contexts, sourcing alternators made from quality materials reduces maintenance costs and enhances the longevity of the product, making them more appealing to buyers focused on total cost of ownership. -

Voltage Output

Alternators typically produce a voltage output of 12V to 14.5V, which is crucial for charging the vehicle’s battery and powering electrical systems. Understanding the voltage output helps in selecting an alternator that aligns with the vehicle’s requirements. A mismatch can lead to battery overcharging or undercharging, resulting in increased wear and tear on electrical components. -

Core Type: New vs. Remanufactured

Alternators are available as either new or remanufactured units. New alternators are produced from brand-new components, while remanufactured units are refurbished from used alternators. While new units often come at a premium price, remanufactured options can provide significant savings without sacrificing quality, especially if they come with warranties and performance guarantees. Businesses should weigh the benefits of each type based on their budget and performance needs. -

Warranty Period

A robust warranty can indicate the manufacturer’s confidence in their product. Warranties typically range from one to three years and can cover parts and labor. For B2B buyers, a longer warranty can be a decisive factor, offering peace of mind and protection against potential defects or failures that could disrupt operations.

What Are Common Trade Terms Used in Alternator Transactions?

Familiarizing yourself with industry-specific jargon can streamline the purchasing process and enhance communication with suppliers. Here are several important trade terms relevant to alternators:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These components are often preferred for their guaranteed compatibility and quality. In B2B transactions, OEM parts can command higher prices but are often seen as a reliable choice for maintaining vehicle integrity. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers looking to manage inventory costs. A higher MOQ may lead to better pricing per unit but can also result in excess stock if demand is overestimated. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This term is common in B2B transactions, as it allows companies to compare offers and negotiate terms based on their requirements. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. They clarify who pays for shipping, insurance, and tariffs, which is crucial for B2B transactions that involve cross-border trade. Understanding these terms can prevent costly misunderstandings and streamline logistics. -

Aftermarket

The aftermarket refers to parts and accessories made by companies other than the original manufacturer. Aftermarket alternators can offer cost-effective alternatives without compromising quality, making them an attractive option for businesses looking to reduce expenses while maintaining vehicle performance.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they select the best products for their needs while optimizing their purchasing processes.

Illustrative image related to best alternator

Navigating Market Dynamics and Sourcing Trends in the best alternator Sector

What Are the Current Market Dynamics and Key Trends in the Alternator Sector for International B2B Buyers?

The global alternator market is experiencing significant growth driven by several factors. Increased vehicle production, particularly in emerging markets like Nigeria and Saudi Arabia, is a major contributor. The rise in demand for electric and hybrid vehicles is also reshaping the landscape, prompting manufacturers to innovate and adapt their product lines to meet new performance standards. Furthermore, advancements in automotive technology are leading to higher electrical loads within vehicles, necessitating more efficient and reliable alternators.

International B2B buyers are increasingly leaning towards aftermarket products as they offer a cost-effective alternative to OEM parts without compromising on quality. Brands such as Denso and Bosch are gaining traction due to their reputation for durability and performance. Additionally, the trend towards remanufactured alternators is on the rise, as these products provide a sustainable option that appeals to environmentally conscious buyers. With the integration of e-commerce platforms, sourcing has become more streamlined, allowing buyers from diverse regions to access a broader range of products and suppliers with ease.

How Are Sustainability and Ethical Sourcing Influencing the Alternator Market?

Sustainability has become a critical focus within the alternator sector, reflecting a broader shift in global supply chains. Environmental impacts, such as the carbon footprint associated with manufacturing processes and material sourcing, are under scrutiny. As a result, companies are prioritizing ethical supply chains that promote responsible sourcing and waste reduction.

B2B buyers are increasingly seeking suppliers who demonstrate commitment to sustainability through certifications like ISO 14001 or adherence to green manufacturing practices. The use of recycled materials in the production of alternators, along with energy-efficient manufacturing processes, is becoming a standard expectation. This not only helps reduce environmental impact but also enhances brand reputation in an increasingly eco-conscious market.

What Is the Evolution of the Alternator Market Relevant to B2B Buyers?

The alternator has evolved significantly since its inception in the early 20th century, transitioning from simple mechanical devices to complex electronic systems that are integral to modern vehicles. Initially designed to charge batteries and power electrical systems, today’s alternators are equipped with advanced technology that optimizes performance and efficiency.

In the past decade, the shift towards electric and hybrid vehicles has spurred innovation, with manufacturers developing alternators that can handle higher electrical loads while maintaining reliability. This evolution presents B2B buyers with a unique opportunity to invest in cutting-edge products that not only meet current standards but also anticipate future demands in the automotive sector. Understanding this historical context can help international buyers make informed decisions when sourcing alternators that align with evolving market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of best alternator

-

How do I determine the right alternator for my vehicle?

To find the correct alternator, start by identifying your vehicle’s year, make, model, and engine type. This information is crucial as alternators are designed for specific applications, and even minor differences can lead to installation issues. Additionally, consider the electrical load requirements; if you’ve upgraded components like sound systems or lighting, select an alternator with a higher amperage to prevent performance issues. Always refer to the manufacturer’s specifications or consult with a knowledgeable supplier to ensure compatibility. -

What is the best brand of alternator for commercial vehicles?

For commercial vehicles, brands like Bosch, Denso, and AC Delco are highly recommended due to their reliability and performance. Bosch is known for its durability and extensive range, making it suitable for various applications. Denso alternators are often original equipment for many manufacturers, ensuring high quality. AC Delco offers excellent options for GM vehicles, providing a solid balance of cost and performance. When selecting a brand, consider the specific needs of your fleet and the warranty support offered. -

What should I consider when vetting suppliers for alternators?

When vetting suppliers, prioritize their reputation, experience, and product quality. Check for certifications such as ISO or IATF, which indicate adherence to quality management standards. Request samples to assess the alternators’ performance and reliability. Additionally, inquire about their supply chain capabilities, lead times, and after-sales support. Engaging with other businesses in your region can provide insights into supplier reliability, helping you make an informed decision. -

What are the typical payment terms for purchasing alternators in bulk?

Payment terms can vary significantly depending on the supplier and the order size. Common arrangements include upfront payments, net 30, or net 60 terms, allowing you some time to manage cash flow after receiving the goods. For larger orders, suppliers may offer discounts or flexible payment plans. Always clarify payment terms upfront and ensure they are documented in the purchase agreement to avoid any misunderstandings later. -

How can I ensure quality assurance for the alternators I purchase?

To ensure quality assurance, request detailed documentation, including testing reports and warranties from the supplier. Many reputable manufacturers perform rigorous testing on their products, so ask for specifics on quality control processes. Establish a quality assurance protocol that includes inspecting received shipments for damage and verifying specifications against your order. Additionally, consider establishing a return policy for defective units to protect your investment. -

What is the minimum order quantity (MOQ) for alternators?

Minimum order quantities can vary widely among suppliers, often depending on the alternator model and the supplier’s production capabilities. Some suppliers may have MOQs as low as 10 units, while others may require orders of 100 or more for bulk pricing. When negotiating, discuss your needs openly to find a mutually beneficial arrangement, especially if you’re testing a new product line or are a smaller business. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider shipping costs, customs duties, and import regulations specific to your country. Ensure your supplier can handle logistics and provide shipping documentation, including bills of lading and customs declarations. Choose a reliable freight forwarder familiar with automotive parts to streamline the process. Additionally, factor in lead times for production and shipping to avoid delays in your operations. -

Can I customize alternators to meet specific requirements?

Yes, many suppliers offer customization options for alternators, such as specific voltage outputs, colors, or connector types. Discuss your requirements during the initial negotiations to see if the supplier can accommodate them. Customization may affect the MOQ and lead time, so be prepared for these variables. Ensure that any modifications do not compromise the alternator’s performance or warranty coverage.

Top 2 Best Alternator Manufacturers & Suppliers List

1. Cadillac – AC Delco Alternator

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Cadillac Dhs-Dts-Deville, AC Delco alternator, Duralast alternator

2. Mechman – High Output Alternators

Domain: mechman.com

Registered: 1996 (29 years)

Introduction: Mechman Alternators are U.S.A made high output alternators with options for 1-year, 2-year, and lifetime extended warranties. They offer various categories including 24 Volt and 48 Volt alternators, engine stands, bracket kits, pulleys, plugs and harnesses, voltage control, and cable accessories. The alternators have outputs ranging from 150a to 370a, specializing in bolt-in high output charging s…

Strategic Sourcing Conclusion and Outlook for best alternator

In the competitive landscape of automotive components, strategic sourcing of the best alternators is essential for businesses looking to enhance their operational efficiency and reliability. Key takeaways from this guide emphasize the importance of choosing trusted brands such as Denso, Bosch, and AC Delco, which offer a balance of quality, performance, and affordability. Understanding the nuances of new versus remanufactured alternators, fitment, and warranty options can significantly impact your total cost of ownership and operational uptime.

Illustrative image related to best alternator

As you navigate the diverse marketplace, especially in regions like Africa, South America, the Middle East, and Europe, it is crucial to leverage strategic partnerships with suppliers who can deliver not just products, but also support and expertise tailored to your specific needs. The future of automotive sourcing is poised for innovation, with advancements in technology and logistics enhancing accessibility and reliability.

Take proactive steps today by assessing your sourcing strategy and aligning with reputable suppliers who can provide the best alternators for your fleet. Investing in high-quality components will not only minimize downtime but also ensure your operations run smoothly and efficiently. Embrace this opportunity to strengthen your supply chain and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.