Introduction: Navigating the Global Market for automotive alternator output

In the dynamic landscape of automotive manufacturing, understanding automotive alternator output is crucial for international B2B buyers looking to optimize their supply chains. A common challenge faced by businesses sourcing alternators is ensuring that they select products that not only meet technical specifications but also align with regional market demands and performance standards. This comprehensive guide delves into the intricacies of automotive alternator output, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

By exploring the nuances of alternator performance—including voltage output, efficiency metrics, and compatibility with various vehicle types—buyers can make informed decisions that enhance their product offerings. Additionally, we address key factors influencing alternator output, such as ambient conditions and engine specifications, which are vital for optimizing the operational lifespan of these components.

This guide is tailored specifically for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, who face unique challenges in sourcing automotive components. By leveraging the insights and actionable strategies presented here, businesses can navigate the complexities of the global market, ensuring they procure high-quality alternators that drive reliability and performance in their automotive applications. Ultimately, our aim is to empower buyers with the knowledge necessary to streamline their procurement processes and enhance their competitive edge in the automotive sector.

Table Of Contents

- Top 7 Automotive Alternator Output Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automotive alternator output

- Understanding automotive alternator output Types and Variations

- Key Industrial Applications of automotive alternator output

- 3 Common User Pain Points for ‘automotive alternator output’ & Their Solutions

- Strategic Material Selection Guide for automotive alternator output

- In-depth Look: Manufacturing Processes and Quality Assurance for automotive alternator output

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive alternator output’

- Comprehensive Cost and Pricing Analysis for automotive alternator output Sourcing

- Alternatives Analysis: Comparing automotive alternator output With Other Solutions

- Essential Technical Properties and Trade Terminology for automotive alternator output

- Navigating Market Dynamics and Sourcing Trends in the automotive alternator output Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automotive alternator output

- Strategic Sourcing Conclusion and Outlook for automotive alternator output

- Important Disclaimer & Terms of Use

Understanding automotive alternator output Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternators | Produces 13-14.5 volts, typically 3-phase output | General automotive applications | Pros: Cost-effective; widely available. Cons: Limited power for high-demand vehicles. |

| High-Output Alternators | Designed for high-demand applications, higher voltage output | Performance vehicles, aftermarket upgrades | Pros: Increased power for accessories. Cons: Higher cost; may require modifications. |

| Marine Alternators | Corrosion-resistant, designed for high humidity environments | Marine vessels and off-road vehicles | Pros: Durable and reliable in harsh conditions. Cons: More expensive; specific to marine needs. |

| Diesel Alternators | Higher voltage output at lower RPM, robust design | Heavy-duty trucks, commercial vehicles | Pros: Suitable for heavy loads; efficient. Cons: Heavier and bulkier; higher initial investment. |

| Smart Alternators | Incorporate advanced voltage regulation and monitoring | Electric vehicles, hybrid systems | Pros: Optimized performance and battery life. Cons: More complex; potentially higher repair costs. |

What Are the Key Characteristics of Standard Alternators?

Standard alternators are the most common type found in modern vehicles, producing a voltage range of 13 to 14.5 volts. They typically feature a three-phase output, which enhances efficiency by generating higher voltage more effectively. These units are ideal for general automotive applications, providing sufficient power for essential electrical components. B2B buyers should consider their widespread availability and cost-effectiveness, though they may not be suitable for vehicles with high electrical demands.

How Do High-Output Alternators Differ from Standard Models?

High-output alternators are specifically designed to meet the needs of performance vehicles and aftermarket upgrades, delivering increased voltage and current output. This makes them perfect for cars with numerous electrical accessories like high-powered audio systems or advanced lighting. Buyers in the automotive aftermarket should weigh the benefits of enhanced power against the higher cost and potential need for vehicle modifications to accommodate these systems.

What Makes Marine Alternators Unique?

Marine alternators are built to withstand harsh environmental conditions, including high humidity and saltwater exposure. They feature corrosion-resistant materials and robust designs, making them suitable for marine vessels and off-road vehicles. For B2B buyers in the marine industry, these alternators offer reliability and durability; however, the specialized construction comes at a premium price, which must be justified by the operational demands of marine applications.

Why Are Diesel Alternators Essential for Heavy-Duty Applications?

Diesel alternators are engineered to provide higher voltage output at lower RPMs, making them ideal for heavy-duty trucks and commercial vehicles that require substantial electrical power. Their robust design allows them to handle heavy loads efficiently. B2B purchasers should consider the balance between the initial investment and the long-term benefits of reliability and efficiency, especially in demanding operational environments.

What Advantages Do Smart Alternators Offer?

Smart alternators integrate advanced technology for voltage regulation and monitoring, optimizing the performance of electric and hybrid vehicles. They adapt to varying electrical demands, ensuring efficient battery charging and longevity. For B2B buyers focused on electric vehicle technology, smart alternators represent a forward-thinking investment. However, their complexity may lead to higher repair costs, which should be factored into purchasing decisions.

Key Industrial Applications of automotive alternator output

| Industry/Sector | Specific Application of Automotive Alternator Output | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Powering vehicle electrical systems | Ensures reliable operation of critical systems like lights and infotainment | Quality control standards, compatibility with vehicle models, and after-sales support |

| Commercial Transportation | Charging batteries in fleet vehicles | Maintains operational efficiency and reduces downtime due to battery failures | Voltage specifications, durability under heavy usage, and serviceability options |

| Agriculture | Supplying power for agricultural machinery | Supports essential equipment like GPS and monitoring systems, enhancing productivity | Environmental resilience, compatibility with various machinery, and ease of installation |

| Renewable Energy | Integration with hybrid and electric vehicles | Enhances energy efficiency and sustainability initiatives | Compliance with international standards, adaptability to different power systems, and availability of replacement parts |

| Mining | Powering vehicles and equipment in harsh conditions | Ensures continuous operation in remote areas, minimizing operational disruptions | Robustness against extreme temperatures, voltage stability, and maintenance accessibility |

How is Automotive Alternator Output Used in Automotive Manufacturing?

In the automotive manufacturing sector, alternators play a crucial role in powering various electrical systems within vehicles, such as lighting, infotainment, and safety features. Reliable alternator output is essential to ensure these systems function optimally, contributing to overall vehicle performance. For international B2B buyers, especially in regions like Africa and the Middle East, sourcing high-quality alternators that meet specific vehicle model requirements is critical. Additionally, manufacturers must consider quality control standards and after-sales support to ensure long-term reliability.

What Role Does Alternator Output Play in Commercial Transportation?

In commercial transportation, alternators are vital for charging the batteries of fleet vehicles, which helps maintain operational efficiency. A dependable alternator output reduces the risk of battery failures that can lead to costly downtime. B2B buyers in South America and Europe should focus on sourcing alternators that meet voltage specifications and are durable enough to withstand heavy usage. Serviceability options are also important, as fleet operators require quick and efficient maintenance solutions to keep their vehicles on the road.

How is Automotive Alternator Output Utilized in Agriculture?

Agricultural machinery increasingly relies on automotive alternator output to supply power for essential equipment, including GPS systems and monitoring devices. This capability enhances productivity by ensuring that farmers can operate their machinery efficiently. Buyers from Africa and South America should prioritize sourcing alternators that demonstrate environmental resilience and compatibility with various types of agricultural machinery. Ease of installation is another critical consideration, as it can significantly affect operational readiness in the field.

How Does Automotive Alternator Output Support Renewable Energy Initiatives?

In the context of hybrid and electric vehicles, automotive alternator output is integral to enhancing energy efficiency and supporting sustainability initiatives. Alternators facilitate the conversion of mechanical energy into electrical energy, which is crucial for battery charging and overall vehicle performance. For international buyers, especially in Europe, compliance with international standards and adaptability to different power systems are key factors when sourcing alternators. The availability of replacement parts is also crucial for ensuring long-term operational success.

What Importance Does Alternator Output Hold in Mining Operations?

In the mining industry, automotive alternators are essential for powering vehicles and equipment that operate in harsh conditions. Reliable alternator output ensures continuous operation, minimizing disruptions in remote areas where access to power may be limited. B2B buyers in this sector should focus on sourcing robust alternators that can withstand extreme temperatures and provide voltage stability. Maintenance accessibility is also vital, as it enables quick repairs and reduces downtime, which can be costly in mining operations.

Illustrative image related to automotive alternator output

3 Common User Pain Points for ‘automotive alternator output’ & Their Solutions

Scenario 1: Inconsistent Alternator Performance Under High Demand

The Problem: B2B buyers in the automotive sector often face challenges when dealing with alternators that cannot meet the electrical demands of modern vehicles, especially those equipped with advanced electronic systems. As vehicles become more reliant on electrical components—such as infotainment systems, power windows, and advanced driver-assistance systems—buyers may encounter issues with alternators that fail to produce adequate output at critical moments. This can lead to frequent battery failures, dimming lights, and ultimately, a poor customer experience.

The Solution: To tackle this issue, buyers should prioritize sourcing alternators that provide consistent output across a range of RPMs. It is crucial to analyze the specifications of alternators thoroughly, focusing on their voltage output and the efficiency of the diodes used in the conversion from AC to DC. Additionally, engaging with suppliers who can provide detailed alternator output curves will allow buyers to select models that maintain performance under varying loads. Implementing regular performance checks and temperature monitoring can also ensure that the alternator operates within optimal parameters, ultimately reducing the risk of electrical failure.

Scenario 2: Voltage Regulation Issues Leading to Component Damage

The Problem: Voltage regulation is a common pain point for B2B buyers, particularly when alternators produce either too much or too little voltage. Inadequate voltage regulation can lead to battery damage, causing premature battery failures and creating additional costs for repairs and replacements. Buyers may also face the challenge of diagnosing these issues, as symptoms like flickering lights or engine stalls can be mistaken for other electrical problems.

Illustrative image related to automotive alternator output

The Solution: To mitigate voltage regulation issues, buyers should select alternators equipped with high-quality voltage regulators. It is essential to understand the two types of regulators—grounded and grounded field types—and how they function within different vehicle systems. Buyers should also ensure that the alternators they source have been tested under various operating conditions, as performance can vary with engine temperature and load. Conducting routine maintenance checks on the vehicle’s electrical system will help identify potential issues before they escalate, allowing for timely interventions that can save costs in the long run.

Scenario 3: Compatibility Challenges with Diverse Vehicle Models

The Problem: International B2B buyers often contend with the complexity of sourcing alternators that are compatible with a wide range of vehicle models, especially when dealing with different manufacturers and specifications. This can lead to significant inventory management challenges, as buyers may end up with parts that do not fit or function as required, resulting in increased downtime and lost revenue.

The Solution: To address compatibility challenges, buyers should invest in comprehensive databases or software solutions that track alternator specifications across various vehicle models. Partnering with suppliers who can provide detailed compatibility charts and part numbers will streamline the selection process. Additionally, considering modular alternator designs that can be easily adapted for multiple applications may also enhance inventory flexibility. Regular training sessions for procurement teams on the latest trends in alternator technologies and vehicle electrical systems will further empower them to make informed purchasing decisions, ensuring that they can meet the demands of their diverse clientele effectively.

Strategic Material Selection Guide for automotive alternator output

What Are the Key Materials Used in Automotive Alternator Output?

When selecting materials for automotive alternators, several options are commonly used, each with distinct properties, advantages, and limitations. Understanding these materials is crucial for B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe.

How Does Copper Impact Automotive Alternator Performance?

Copper is one of the most widely used materials in automotive alternators, particularly for windings and connectors due to its excellent electrical conductivity. Key properties include a high melting point (1,984°F or 1,085°C) and good corrosion resistance, particularly when coated.

Pros: Copper’s superior conductivity ensures efficient energy transfer, which is essential for optimal alternator performance. It is also relatively easy to work with, allowing for complex winding designs that enhance output.

Cons: However, copper can be more expensive than alternatives like aluminum. Its weight can also be a concern in applications where reducing overall vehicle weight is a priority.

Impact on Application: Copper’s conductivity makes it suitable for high-performance applications where reliability is critical. In regions with high humidity or corrosive environments, such as coastal areas in Africa or the Middle East, copper’s corrosion resistance becomes vital.

What Role Does Aluminum Play in Alternator Design?

Aluminum is increasingly being used in automotive alternators, particularly for the housing and some winding applications. It has a lower density than copper, making it a lightweight alternative.

Illustrative image related to automotive alternator output

Pros: Aluminum is cost-effective and offers good resistance to corrosion, especially when anodized. Its lightweight nature contributes to overall vehicle efficiency.

Cons: While aluminum has decent conductivity, it is not as effective as copper, which may lead to slightly reduced performance in high-demand applications. Additionally, manufacturing processes for aluminum can be more complex due to its properties.

Impact on Application: Aluminum is particularly favored in regions where weight savings are crucial, such as in electric vehicles. Compliance with local standards (e.g., DIN in Europe) is essential, as aluminum’s properties can vary based on alloy composition.

Why Is Steel Important for Structural Components?

Steel is often used for structural components of alternators, such as the frame and mounting brackets. It provides high strength and durability, making it suitable for demanding automotive environments.

Pros: Steel’s robustness ensures longevity and resistance to mechanical stress. It is also readily available and cost-effective.

Cons: However, steel is heavier than both copper and aluminum, which can affect overall vehicle weight and efficiency. Its susceptibility to rust requires protective coatings, which can add to manufacturing complexity.

Impact on Application: In regions with extreme temperatures, such as the deserts of Saudi Arabia, steel’s durability is advantageous. Buyers should consider the need for protective coatings to prevent corrosion in humid environments.

What About Composite Materials in Alternators?

Composite materials are becoming more common in automotive applications, including alternators. These materials can be engineered to provide specific properties, such as lightweight and high strength.

Pros: Composites can offer excellent resistance to temperature and corrosion, making them suitable for various environments. They can also be tailored for specific applications, enhancing performance.

Cons: The primary drawback is the higher manufacturing cost and complexity associated with composite materials. Additionally, their long-term durability under mechanical stress is still a topic of research.

Impact on Application: In markets focused on innovation, such as Europe, composites are appealing for high-performance vehicles. Buyers must ensure compliance with international standards and consider the environmental impact of composite disposal.

Summary Table of Material Selection for Automotive Alternators

| Material | Typical Use Case for automotive alternator output | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings and connectors | Excellent electrical conductivity | Higher cost and weight | High |

| Aluminum | Housing and some windings | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Steel | Structural components | High strength and durability | Heavier and rust-prone | Low |

| Composites | Specialized applications | Tailored properties and corrosion resistance | Higher manufacturing complexity | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials impacting automotive alternator output, enabling informed decisions tailored to specific market needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for automotive alternator output

What Are the Key Stages in the Manufacturing Process of Automotive Alternators?

The manufacturing process of automotive alternators involves several critical stages, each designed to ensure optimal performance and reliability. Here’s a breakdown of the main stages:

Illustrative image related to automotive alternator output

Material Preparation: What Materials Are Used in Automotive Alternator Manufacturing?

The first stage involves the selection and preparation of materials. Common materials include high-grade steel for the rotor and stator, copper wire for the windings, and various alloys for diodes and other electrical components. Quality assurance begins at this stage, with suppliers required to provide material certifications that meet international standards. Rigorous testing for material properties, such as tensile strength and conductivity, is conducted to ensure they can withstand operational stresses.

Forming: How Are Alternator Components Shaped?

The forming stage is where raw materials are shaped into the necessary components. This often includes processes such as stamping for metal parts, winding for coils, and machining for precision components. Advanced techniques like Computer Numerical Control (CNC) machining are frequently used to achieve high precision. The use of automated forming processes helps maintain consistency and reduces human error, which is crucial for maintaining quality standards.

Assembly: What Techniques Are Used in the Assembly of Alternators?

Assembly is a critical phase where all components come together. This stage often employs automated assembly lines, which streamline the process and enhance efficiency. Key components, such as the rotor, stator, and voltage regulator, are carefully assembled to ensure proper alignment and function. Workers typically follow strict assembly protocols, often informed by lean manufacturing principles, to minimize waste and optimize workflow. Each unit is assembled with attention to detail, focusing on ensuring all connections are secure and that the alternator meets design specifications.

Finishing: How Is the Final Product Prepared for Delivery?

Finishing involves several steps, including coating, testing, and packaging. Coatings are applied to prevent corrosion and enhance durability, which is especially important for automotive applications. After coating, each alternator undergoes rigorous testing to verify performance metrics, including voltage output and efficiency. This may involve simulating operating conditions to ensure reliability under various scenarios. Once testing is complete, the units are carefully packaged to prevent damage during transport.

Illustrative image related to automotive alternator output

What Quality Assurance Practices Are Commonly Implemented in Automotive Alternator Manufacturing?

Quality assurance (QA) in automotive alternator manufacturing is paramount, as it directly impacts product reliability and customer satisfaction. Here’s how manufacturers typically ensure quality:

Which International Standards Guide Quality Control in Alternator Production?

Many manufacturers adhere to international standards such as ISO 9001, which provides a framework for quality management systems. Compliance with these standards ensures that processes are consistent, and products meet customer and regulatory requirements. In addition to ISO certifications, industry-specific standards such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the intended market and application of the alternators.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. Key checkpoints include:

Illustrative image related to automotive alternator output

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor processes and identify issues before they escalate.

- Final Quality Control (FQC): Once assembly is complete, each alternator undergoes comprehensive testing to verify output specifications, including voltage and efficiency, ensuring they meet the required standards.

Which Common Testing Methods Are Used to Validate Alternator Performance?

Common testing methods for automotive alternators include:

- Load Testing: This evaluates how well the alternator performs under various load conditions.

- Voltage Regulation Testing: Ensures the alternator maintains proper voltage output across different RPMs.

- Thermal Testing: Assesses the alternator’s performance under high-temperature conditions to prevent overheating.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies:

What Types of Audits Can Buyers Conduct to Assess Supplier Quality?

Conducting supplier audits is a proactive way to assess quality control practices. Buyers can request on-site audits or third-party assessments to evaluate the manufacturing processes and quality systems in place. This not only helps ensure compliance with international standards but also builds trust between the buyer and supplier.

How Can Buyers Review Quality Reports and Certifications?

Buyers should request access to quality reports, including details on testing outcomes and certifications. Suppliers should be able to provide documentation that demonstrates compliance with relevant standards, including ISO certifications and any industry-specific approvals.

Illustrative image related to automotive alternator output

What Are the QC and Certification Nuances for Different Regions?

B2B buyers need to be aware of regional regulations and certification nuances. For instance, automotive parts sold in Europe may need to meet stringent CE marking requirements, while products destined for the Middle East might require compliance with local standards. Understanding these differences helps buyers make informed decisions and mitigate risks associated with non-compliance.

Conclusion

In summary, the manufacturing processes and quality assurance practices for automotive alternators are complex and critical to ensuring reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to more successful partnerships and superior product offerings in the competitive automotive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive alternator output’

Introduction

In the competitive landscape of automotive components, understanding and sourcing the right alternator output is essential for ensuring reliability and performance. This checklist provides a structured approach for B2B buyers to effectively evaluate, procure, and integrate automotive alternators, particularly focusing on their output specifications. By following these steps, you can make informed decisions that align with your operational needs and enhance your supply chain efficiency.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the alternators you intend to source. This includes voltage output ranges, current ratings, and compatibility with specific vehicle models.

- Voltage Output: Ensure the alternator can produce between 13 to 14.5 volts to meet automotive standards.

- Current Ratings: Determine the amperage needed based on the vehicle’s electrical demands.

Step 2: Assess Supplier Capabilities

Evaluate potential suppliers based on their production capabilities and technological advancements. This step is crucial to ensure that the supplier can meet your specifications and quality standards.

- Manufacturing Standards: Look for suppliers that comply with international automotive standards such as ISO/TS 16949.

- Production Capacity: Verify that the supplier can scale production to meet your order volumes without compromising quality.

Step 3: Evaluate Product Performance

Investigate the performance characteristics of the alternators offered by potential suppliers. This includes understanding how their output varies under different conditions, such as temperature and RPM.

- Output Curves: Request output curves to see how the alternators perform at various engine speeds and temperatures.

- Real-World Testing: Ask for data from real-world applications to validate performance claims.

Step 4: Verify Supplier Certifications

Before finalizing any agreements, ensure that the supplier holds relevant certifications and adheres to quality control processes. Certifications can be a strong indicator of a supplier’s commitment to quality.

- Quality Assurance: Check for certifications like ISO 9001 and any specific automotive-related certifications.

- Testing Protocols: Inquire about the testing methods used to ensure product reliability and safety.

Step 5: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples allows you to evaluate the alternators firsthand and ensures they meet your specifications.

- Functionality Tests: Conduct tests for voltage output, durability, and compatibility with your vehicles.

- Feedback Loop: Use feedback from your technical team to assess performance and make necessary adjustments before full-scale procurement.

Step 6: Review Warranty and Support Options

Understand the warranty terms and after-sales support provided by the supplier. A solid warranty can protect your investment and enhance long-term partnership stability.

- Warranty Period: Look for suppliers that offer a warranty period that reflects confidence in their product quality.

- Technical Support: Ensure that the supplier provides adequate technical support for installation and troubleshooting.

Step 7: Negotiate Terms and Finalize Agreements

Finally, negotiate pricing, payment terms, and delivery schedules to ensure that they align with your budget and operational timelines. Clear agreements help prevent misunderstandings later on.

- Flexible Payment Options: Discuss payment terms that accommodate your cash flow needs.

- Delivery Timelines: Set realistic delivery expectations to align with your production schedules.

By following this checklist, B2B buyers can streamline the sourcing process for automotive alternator outputs, ensuring they procure high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for automotive alternator output Sourcing

What Are the Key Cost Components for Sourcing Automotive Alternator Output?

Understanding the cost structure of automotive alternators is essential for international B2B buyers. The primary components influencing the total cost include:

-

Materials: The choice of materials significantly impacts the cost. High-quality copper wire, robust housing, and durable diodes are essential for performance and longevity. Prices can fluctuate based on global supply chain dynamics, with copper being particularly sensitive to market variations.

-

Labor: Labor costs can vary significantly by region. Countries with lower labor costs may offer competitive pricing, but it’s crucial to assess the skill level and expertise of the workforce involved in production.

-

Manufacturing Overhead: This includes costs related to utilities, facilities, and equipment. Efficient manufacturing processes can reduce overhead, contributing to lower overall costs.

-

Tooling: Initial tooling costs for specific designs can be significant, especially for custom alternators. Buyers should consider these costs when evaluating pricing.

-

Quality Control (QC): Ensuring that alternators meet industry standards requires investment in quality control processes. This can add to the overall cost but is essential for preventing defects and ensuring reliability.

-

Logistics: Shipping costs, including freight and handling, can vary widely based on the distance and mode of transport. International buyers must factor in these logistics costs when assessing total expenses.

-

Margin: Supplier margins can vary based on market conditions and competition. Understanding this aspect can help buyers negotiate better terms.

How Do Price Influencers Affect Automotive Alternator Output Costs?

Several factors can influence the pricing of automotive alternators beyond the basic cost structure:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to reduced per-unit costs. Buyers should evaluate their needs and consider bulk purchasing to leverage better pricing.

-

Specifications and Customization: Custom alternators tailored to specific vehicle models may incur higher costs. Buyers must weigh the benefits of customization against the additional expenses.

-

Materials Quality and Certifications: Alternators with higher-grade materials and recognized quality certifications (e.g., ISO standards) often command higher prices. Buyers should ensure that the quality meets their operational requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with proven track records may charge a premium, but they often provide better service and reliability.

-

Incoterms: Understanding Incoterms is critical for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping costs and risks, which can significantly affect overall pricing.

What Are the Best Negotiation Tips for B2B Buyers in Sourcing Automotive Alternators?

Negotiating favorable terms is crucial for optimizing costs. Here are some actionable tips for international B2B buyers:

-

Research Market Prices: Familiarize yourself with average market prices for automotive alternators to provide a solid foundation for negotiations.

-

Leverage Volume Discounts: If possible, commit to larger orders to negotiate lower prices. Suppliers are often more willing to provide discounts for bulk purchases.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs such as maintenance, warranty, and potential downtime. This holistic view can justify higher initial costs if they lead to greater savings.

-

Understand Regional Variances: Prices can vary significantly between regions. Buyers from Africa, South America, the Middle East, and Europe should consider local market conditions when negotiating.

-

Be Aware of Pricing Nuances: Factors like exchange rates, tariffs, and local regulations can impact pricing for international buyers. Staying informed can provide leverage in discussions.

Conclusion

In summary, a comprehensive understanding of the cost components and pricing influencers is essential for B2B buyers in the automotive alternator market. By leveraging insights into cost structures, negotiating effectively, and considering total costs, buyers can make informed decisions that enhance their sourcing strategies. Always remember that prices can fluctuate based on market conditions and regional factors, so maintaining flexibility and awareness is key.

Alternatives Analysis: Comparing automotive alternator output With Other Solutions

Understanding Alternatives to Automotive Alternator Output

In the automotive sector, the alternator plays a crucial role by generating electrical power to charge the battery and supply the vehicle’s electrical system. However, as technology evolves, various alternative solutions emerge that can achieve similar objectives. This section examines automotive alternator output in comparison with other viable alternatives, helping B2B buyers make informed decisions based on performance, cost, and practical implementation.

Illustrative image related to automotive alternator output

| Comparison Aspect | Automotive Alternator Output | Lithium-Ion Battery Systems | Fuel Cell Technology |

|---|---|---|---|

| Performance | Typically produces 13-14.5V, adequate for most vehicles. | High energy density, can provide stable power for extended periods. | Offers continuous power generation with water as a byproduct. |

| Cost | Generally affordable, costing between $100 – $300 per unit. | Higher initial investment, typically $500 – $1,500 depending on capacity. | Very high upfront costs, often exceeding $5,000 per unit. |

| Ease of Implementation | Widely used and easy to install in most vehicles. | Requires specialized installation and management systems. | Complex installation requiring additional infrastructure for hydrogen storage and delivery. |

| Maintenance | Low maintenance; lasts around 100,000 miles with minimal service. | Requires periodic checks and potential replacement every 5-10 years. | High maintenance due to the complexity of components and hydrogen management. |

| Best Use Case | Ideal for traditional internal combustion engine vehicles. | Suitable for electric and hybrid vehicles needing reliable power. | Best for applications requiring continuous power, such as public transportation or industrial use. |

What Are the Benefits and Drawbacks of Lithium-Ion Battery Systems?

Lithium-ion battery systems represent a prominent alternative to automotive alternators, especially in electric and hybrid vehicles. These systems are known for their high energy density, allowing them to store significant amounts of energy in a compact form. This capability makes them ideal for applications where space and weight are critical. However, the initial costs can be a barrier, as they often require a substantial investment upfront. Additionally, while they provide stable power over extended periods, they necessitate careful management and periodic maintenance to ensure longevity and optimal performance.

How Does Fuel Cell Technology Compare to Traditional Alternators?

Fuel cell technology is another emerging alternative that generates electricity through a chemical reaction, typically using hydrogen. This technology offers the advantage of continuous power generation, making it suitable for long-range applications such as public transportation and heavy-duty vehicles. Fuel cells produce only water as a byproduct, making them environmentally friendly. However, they come with significant challenges, including high initial costs and the need for a specialized infrastructure for hydrogen storage and distribution. Moreover, the complexity of fuel cells can result in increased maintenance requirements compared to traditional alternators.

Conclusion: How Should B2B Buyers Choose the Right Power Solution?

When selecting the appropriate power solution for automotive applications, B2B buyers must consider several factors, including performance requirements, budget constraints, and implementation capabilities. Automotive alternators remain a reliable choice for traditional vehicles due to their affordability and ease of installation. In contrast, lithium-ion batteries are more suitable for electric vehicles that prioritize energy efficiency and performance. Fuel cell technology, while promising, is best reserved for specialized applications where continuous power is essential. By carefully evaluating these alternatives, buyers can align their choice with their operational needs and long-term strategic goals.

Essential Technical Properties and Trade Terminology for automotive alternator output

What Are the Key Technical Properties of Automotive Alternator Output?

When evaluating automotive alternators, understanding their technical specifications is crucial for B2B buyers. Here are several critical specs that should be considered:

-

Voltage Output

The standard voltage output of an automotive alternator typically ranges from 13.0 to 14.5 volts. This specification is essential for ensuring compatibility with the vehicle’s electrical system. A voltage that is too high can damage components, while too low can lead to inadequate battery charging. For international buyers, understanding voltage requirements helps in selecting alternators suitable for diverse automotive applications. -

Current Rating (Amperage)

The amperage rating indicates the maximum electrical current the alternator can supply to the battery and electrical systems. Common ratings range from 40 to 200 amps. For businesses, knowing the current rating is vital for determining whether an alternator can support additional electrical accessories, such as high-powered audio systems or advanced lighting, which are becoming increasingly popular in various markets. -

Temperature Rating

Automotive alternators are designed to operate efficiently within specific temperature ranges, typically from -40°C to 85°C. The performance of an alternator can degrade if these temperatures are exceeded. For buyers in regions with extreme climates, understanding temperature ratings ensures they choose alternators that maintain optimal performance under local conditions. -

RPM Range

The revolutions per minute (RPM) rating indicates the engine speed at which the alternator operates effectively. Most automotive alternators perform best between 1,500 and 3,000 RPM. This specification is crucial for compatibility with the vehicle’s engine specifications, impacting overall efficiency and longevity. -

Winding Type

Alternators utilize either delta or wye winding configurations. Delta windings allow for higher current flow at lower RPMs, while wye windings are better for producing higher voltage at low speeds. Understanding the differences helps buyers select alternators based on the specific requirements of the vehicles they are servicing.

What Are Common Trade Terms in the Automotive Alternator Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B automotive sector. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in the assembly of vehicles. For buyers, sourcing OEM alternators can ensure compatibility and quality, as these components are designed to meet the original specifications of the vehicle manufacturer. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for buyers to manage inventory and costs effectively. It often affects purchasing decisions, especially for small to medium-sized businesses. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. It typically includes detailed specifications of the desired products. For B2B buyers, issuing an RFQ can help compare prices and services among multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms helps buyers understand shipping obligations, costs, and risks associated with international purchases. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. This term is critical for supply chain management, as longer lead times can affect production schedules and inventory levels. Buyers must consider lead times when planning their purchases to avoid potential delays.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing automotive alternators, ensuring compatibility and performance that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the automotive alternator output Sector

What Are the Current Market Dynamics in the Automotive Alternator Output Sector?

The automotive alternator output sector is experiencing significant shifts driven by technological advancements and changing consumer demands. Key trends include the growing adoption of electric and hybrid vehicles, which require high-efficiency alternators capable of supporting more complex electrical systems. As these vehicles proliferate in markets across Africa, South America, the Middle East, and Europe, there is an increasing demand for alternators that not only meet stringent voltage requirements but also offer improved durability and performance under varying conditions.

International B2B buyers should also be aware of the impact of global supply chain disruptions. Factors such as geopolitical tensions, trade tariffs, and the ongoing effects of the COVID-19 pandemic have led to fluctuating material costs and longer lead times. Buyers are advised to diversify their supplier base and consider local sourcing options to mitigate risks associated with global supply chains. Additionally, the rise of Industry 4.0 technologies, including IoT and AI, is enhancing manufacturing processes, allowing for real-time monitoring and predictive maintenance, which can significantly reduce downtime and enhance product reliability.

Another emerging trend is the focus on customizability and modular designs in alternators, allowing manufacturers to cater to specific market needs and vehicle types. For buyers, this translates to more options and the potential for tailored solutions that optimize performance for diverse applications. Staying informed about these dynamics will be crucial for making strategic sourcing decisions in the automotive alternator output sector.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Automotive Alternator Sector?

Sustainability and ethical sourcing are becoming increasingly important considerations for B2B buyers in the automotive alternator output sector. The environmental impact of manufacturing processes, particularly concerning energy consumption and waste generation, necessitates a shift towards greener practices. Buyers should prioritize suppliers who employ sustainable production methods and materials, as this not only aligns with global sustainability goals but also enhances brand reputation and appeal to environmentally-conscious consumers.

Illustrative image related to automotive alternator output

The demand for ‘green’ certifications, such as ISO 14001 for environmental management systems or the use of recycled materials, is on the rise. Suppliers who can demonstrate these certifications provide buyers with assurances of compliance with environmental regulations and standards. This is particularly relevant in regions like Europe, where stringent environmental laws are in place, but the trend is gaining traction globally, including in emerging markets like Africa and South America.

Moreover, ethical sourcing of materials is crucial to ensure that supply chains are free from human rights violations and exploitative labor practices. Buyers should engage with suppliers who are transparent about their sourcing practices and who can provide traceability for the materials used in alternator production. This commitment not only fosters a positive corporate image but also builds trust with end consumers, ultimately influencing purchasing decisions in a competitive market.

What Historical Developments Have Shaped the Automotive Alternator Output Sector?

The evolution of the automotive alternator output sector can be traced back to the transition from generators to alternators in the early 20th century. Initially, cars relied on direct current (DC) generators, which were less efficient and unable to meet the increasing power demands of modern vehicles. The introduction of the alternating current (AC) alternator revolutionized automotive electrical systems by providing a more efficient and reliable power source.

As automotive technology advanced, the need for higher power outputs became evident, leading to the development of three-phase alternators. This design not only improved efficiency but also enabled vehicles to support more electrical accessories and systems. Over the decades, innovations such as voltage regulation and improved materials have further enhanced alternator performance and longevity.

Illustrative image related to automotive alternator output

Today, the sector continues to evolve, driven by the emergence of electric and hybrid vehicles, which require advanced alternator technologies that can handle higher loads and integrate seamlessly with battery management systems. Understanding this historical context is essential for B2B buyers to appreciate the advancements in alternator technology and the factors influencing current market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive alternator output

-

How do I solve issues with low alternator output?

To address low alternator output, first, check the alternator’s voltage using a multimeter; it should typically read between 13.5 to 14.5 volts. If the output is lower, inspect the connections and wiring for corrosion or damage. Additionally, assess the alternator’s temperature; overheating can reduce efficiency. If the alternator is functioning improperly, it may need repair or replacement. Regular maintenance checks can also prevent such issues, ensuring optimal performance of your electrical system. -

What is the best alternator output for heavy-duty vehicles?

Heavy-duty vehicles generally require alternators that produce higher outputs, typically in the range of 150 to 300 amps, depending on the electrical load. When sourcing, consider alternators with three-phase systems as they offer better efficiency and power management. Custom options may also be available to meet specific vehicle demands, such as those equipped with advanced electrical systems or additional accessories. Always consult with manufacturers to determine the best fit for your vehicle’s requirements. -

How can I verify the reliability of an alternator supplier?

To verify a supplier’s reliability, start by checking their industry reputation through reviews and testimonials from other B2B buyers. Request references and examine their track record in fulfilling orders on time and maintaining quality standards. Additionally, assess their certifications and compliance with international quality standards, such as ISO 9001. Engaging in a small trial order can also help you gauge their responsiveness and product quality before committing to larger purchases. -

What are the minimum order quantities (MOQs) for automotive alternators?

Minimum order quantities for automotive alternators can vary significantly based on the supplier and product specifications. Generally, MOQs may range from 50 to 500 units. It’s essential to discuss your requirements with potential suppliers to understand their policies. Some suppliers may offer flexibility in MOQs for first-time buyers or during promotional periods, allowing you to test the market without a significant upfront investment. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms can differ widely among suppliers, but common arrangements include payment in advance, a letter of credit, or net 30/60/90 days after delivery. It’s advisable to negotiate terms that provide security for both parties. Consider using escrow services for large transactions to protect your investment. Always review the payment terms in the context of shipping and customs clearance timelines to avoid unexpected delays. -

How can I ensure the quality of automotive alternators I purchase?

To ensure quality, request detailed product specifications and compliance certifications from the supplier. Ask for samples or conduct quality assurance tests before placing large orders. Implementing a quality control process, such as third-party inspections, can also safeguard against defects. Establish clear communication with your supplier about your quality expectations, and consider engaging with suppliers who offer warranties or guarantees on their products. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider shipping methods, customs clearance, and import tariffs that may apply in your region. Work with a logistics partner experienced in automotive parts to navigate these complexities efficiently. Ensure that all necessary documentation, such as bills of lading and customs declarations, is prepared in advance to avoid delays. Additionally, factor in lead times for production and shipping to align with your inventory needs. -

How does climate affect alternator performance in different regions?

Climate can significantly impact alternator performance, particularly in extreme temperatures. In hotter climates, alternators may overheat, affecting their output and lifespan. Conversely, colder temperatures can lead to thicker oil, increasing resistance and reducing efficiency. When sourcing alternators, consider models designed for specific climatic conditions, and inquire about temperature ratings and durability features. This ensures reliable performance regardless of environmental challenges.

Top 7 Automotive Alternator Output Manufacturers & Suppliers List

1. Oxford Automotive – Alternator Solutions

Domain: oxfordautomotivepa.com

Registered: 2021 (4 years)

Introduction: The alternator in an automobile produces a minimum of 13 volts and a maximum of 14.5 volts. It generally lasts about 100,000 miles. Signs of a malfunctioning alternator include burning wires, dead battery, dim headlights, frequent stalls, slow accessories, and a warning light on the dashboard.

2. HowStuffWorks – Automotive Alternator

Domain: auto.howstuffworks.com

Registered: 1998 (27 years)

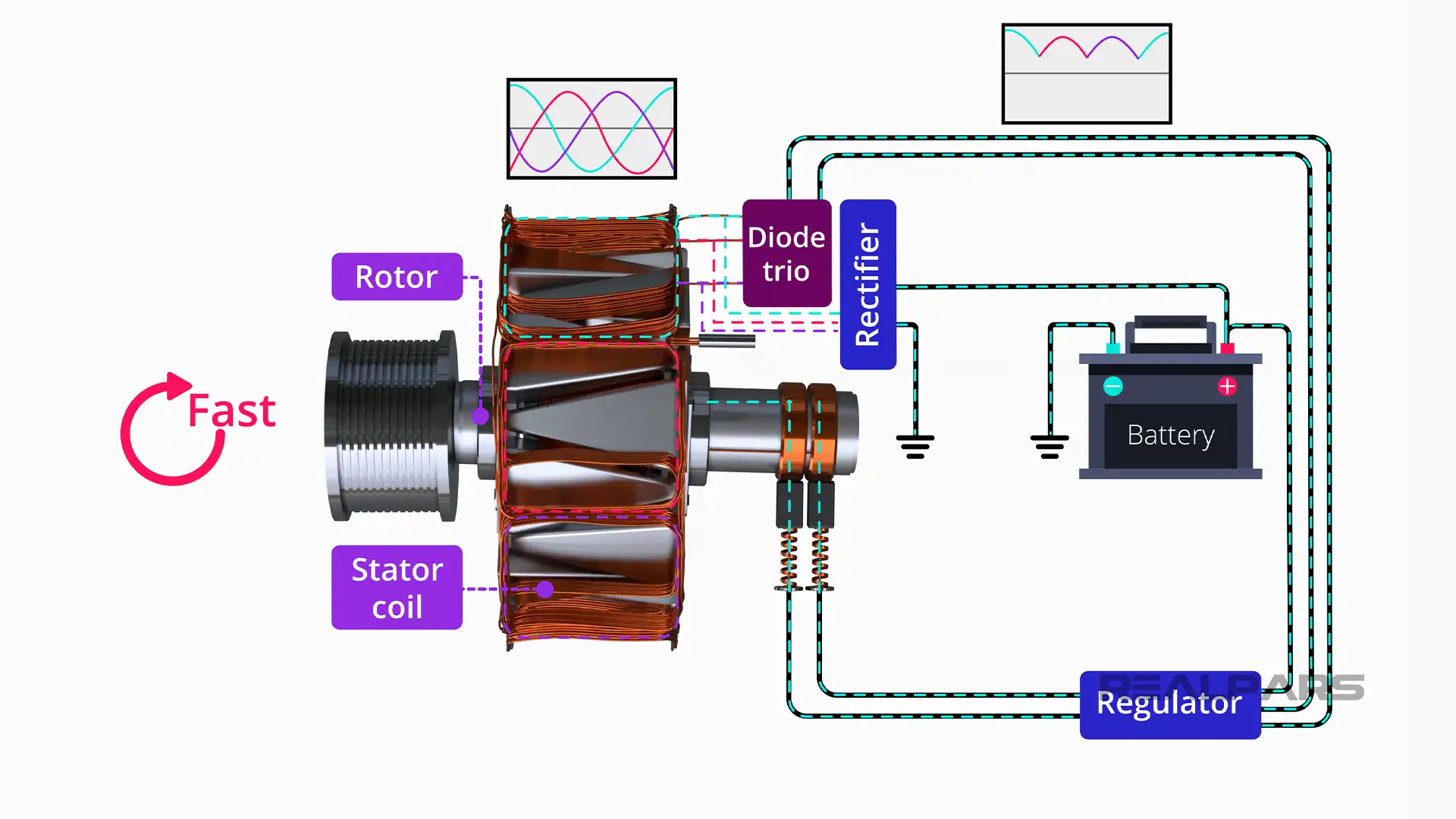

Introduction: Alternator converts AC power to DC power for automotive use; consists of rotor and stator; generates three-phase current; uses diodes to regulate current; two basic stator winding designs: delta wound (high current flow at lower RPM) and wye style (higher voltage at lower RPM); voltage regulator ensures correct voltage for battery; two types of regulators: grounded regulator and grounded field typ…

3. Alternator – Key Specifications

Domain: forum.allaboutcircuits.com

Registered: 2003 (22 years)

Introduction: This company, Alternator – Key Specifications, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

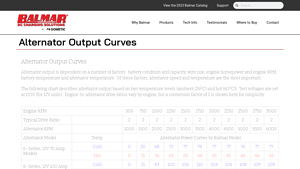

4. Balmar – Alternator Output Curves

Domain: balmar.net

Registered: 1999 (26 years)

Introduction: Alternator Output Curves provide information on the performance of Balmar alternators based on various factors such as battery condition, wire size, engine horsepower, engine RPM, battery temperature, and alternator temperature. Key models include: 6-Series (12V 70A, 100A, 120A), XT-Series (12V 170A, 250A; 24V 90A), 94/94LY-Series (12V 210A; 24V 140A), 95-Series (12V 210A; 24V 140A), 96-Series (48…

5. Tire Depot – Alternator Power Output

Domain: tiredepotmechanical.com

Registered: 2022 (3 years)

Introduction: The power output of an alternator in a vehicle typically ranges from 500 watts to 3,000 watts (or 0.5 kW to 3 kW). Specific wattage depends on the alternator’s capacity and the vehicle’s electrical demands. For standard passenger cars, the output is 500 to 1,500 watts, while high-performance or larger vehicles (e.g., SUVs, trucks) range from 1,500 to 3,000 watts. The current output of a car altern…

6. Alternator – 100A/13.5V Performance

Domain: electronics.stackexchange.com

Registered: 2009 (16 years)

Introduction: Alternator rated at 100A/13.5V, outputting 1350 Watts. Capable of outputting 28A/48V with modifications. Designed to supply at least 14 volts to charge a 12V battery at idle RPM (600-900 RPM). Maximum RPM can reach 6000-9000 RPM. Output voltage can reach 120-140 VAC (three phase) and rectified output can be as high as 200 VDC. Potential for modification to bypass diodes for higher voltage at high …

7. HotRod – Essential Alternators for Street Rods

Domain: hotrod.com

Registered: 1998 (27 years)

Introduction: Alternators convert mechanical energy from the engine into alternating current (AC) and then into direct current (DC). They are essential for handling electrical loads in street rods, especially with the addition of modern electronics. Key performance factors include:

– Alternators lose about 10% of output capability when moving from room temperature to operating temperature.

– Most alternators …

Strategic Sourcing Conclusion and Outlook for automotive alternator output

What Are the Key Takeaways for B2B Buyers in Automotive Alternator Sourcing?

As the automotive industry continues to evolve, understanding the nuances of alternator output is crucial for international B2B buyers. Key takeaways include the importance of selecting high-quality alternators that meet specific voltage requirements—typically between 13 to 14.5 volts—to ensure optimal performance and longevity. Additionally, factors such as engine RPM, temperature, and battery condition significantly influence alternator output, making it essential to consider these variables in sourcing decisions.

Strategic sourcing plays a pivotal role in enhancing supply chain efficiency. By partnering with reliable manufacturers and suppliers, businesses can secure alternators that not only meet rigorous quality standards but also align with their unique operational needs. This proactive approach minimizes downtime and enhances customer satisfaction, particularly in regions like Africa, South America, the Middle East, and Europe, where demand for reliable automotive components is on the rise.

How Can International Buyers Prepare for Future Trends in Automotive Alternator Technology?

Looking ahead, the automotive sector is poised for transformation with advancements in technology, including electric vehicles and hybrid systems that may require specialized alternators. International buyers should stay informed and adaptable to these trends, ensuring their sourcing strategies are aligned with future market demands. Engaging with industry experts and participating in trade shows can provide valuable insights into emerging technologies and best practices. Now is the time to refine your sourcing strategies to remain competitive in this dynamic landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.